Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181 results about "Three dimensional microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

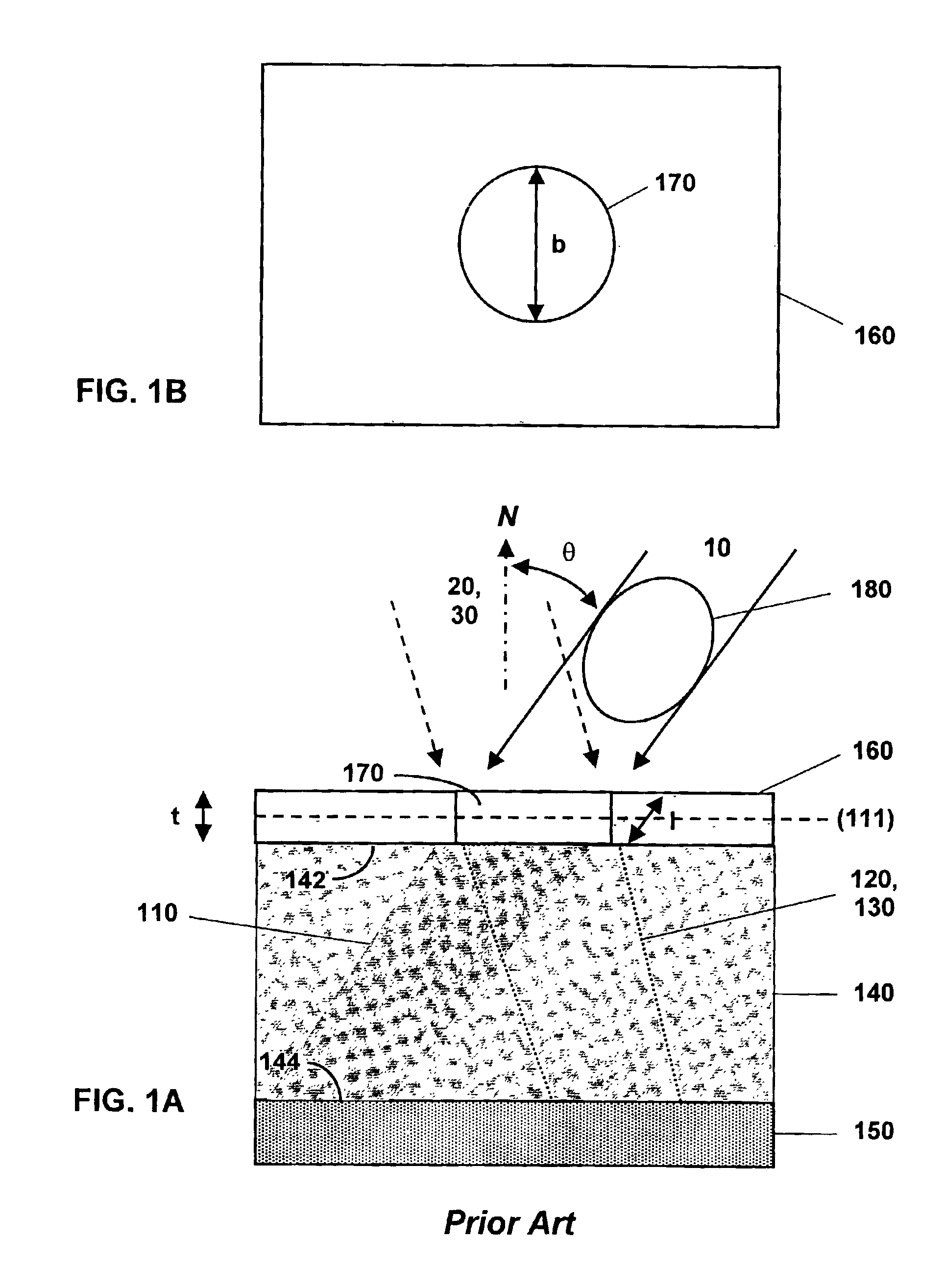

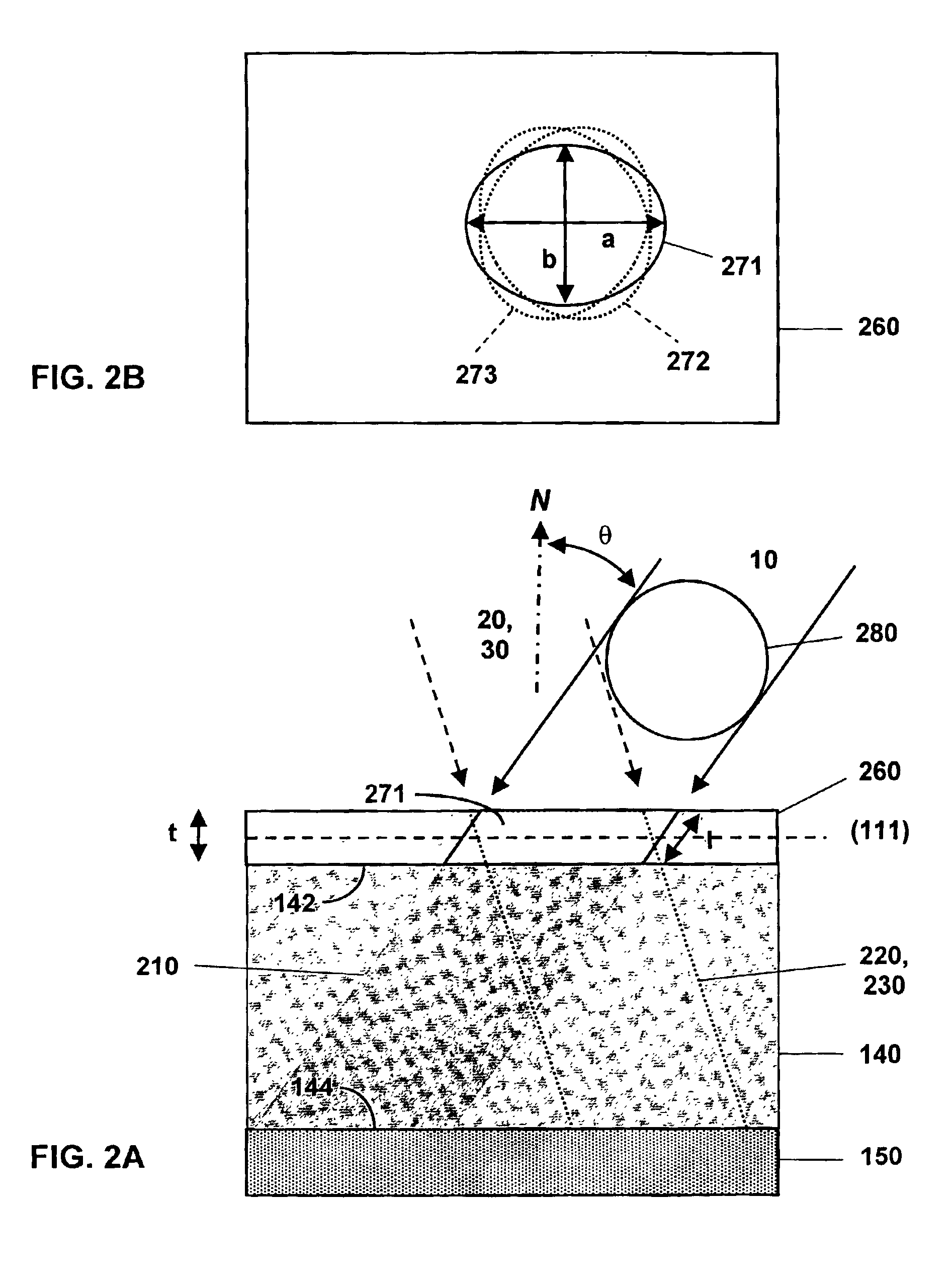

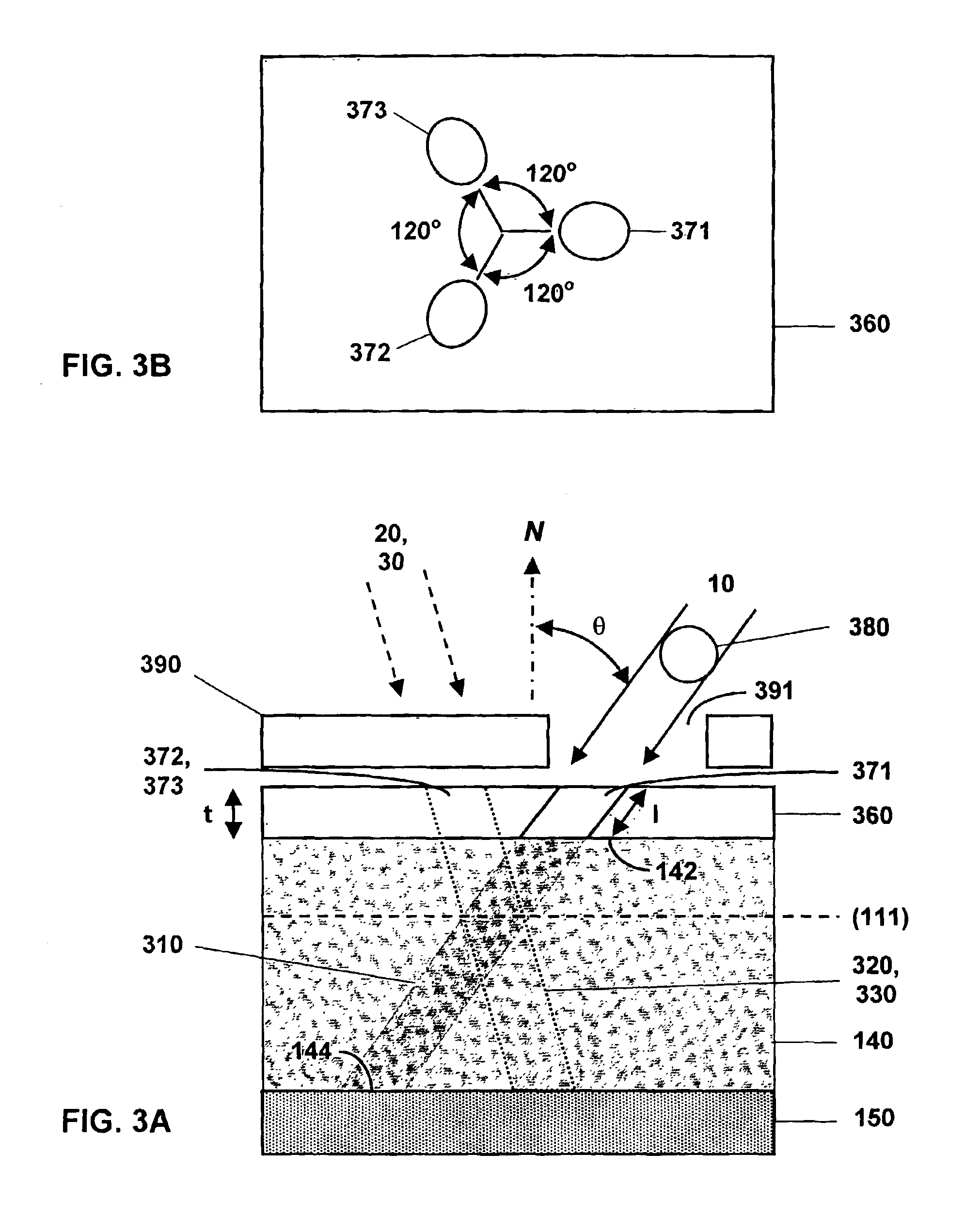

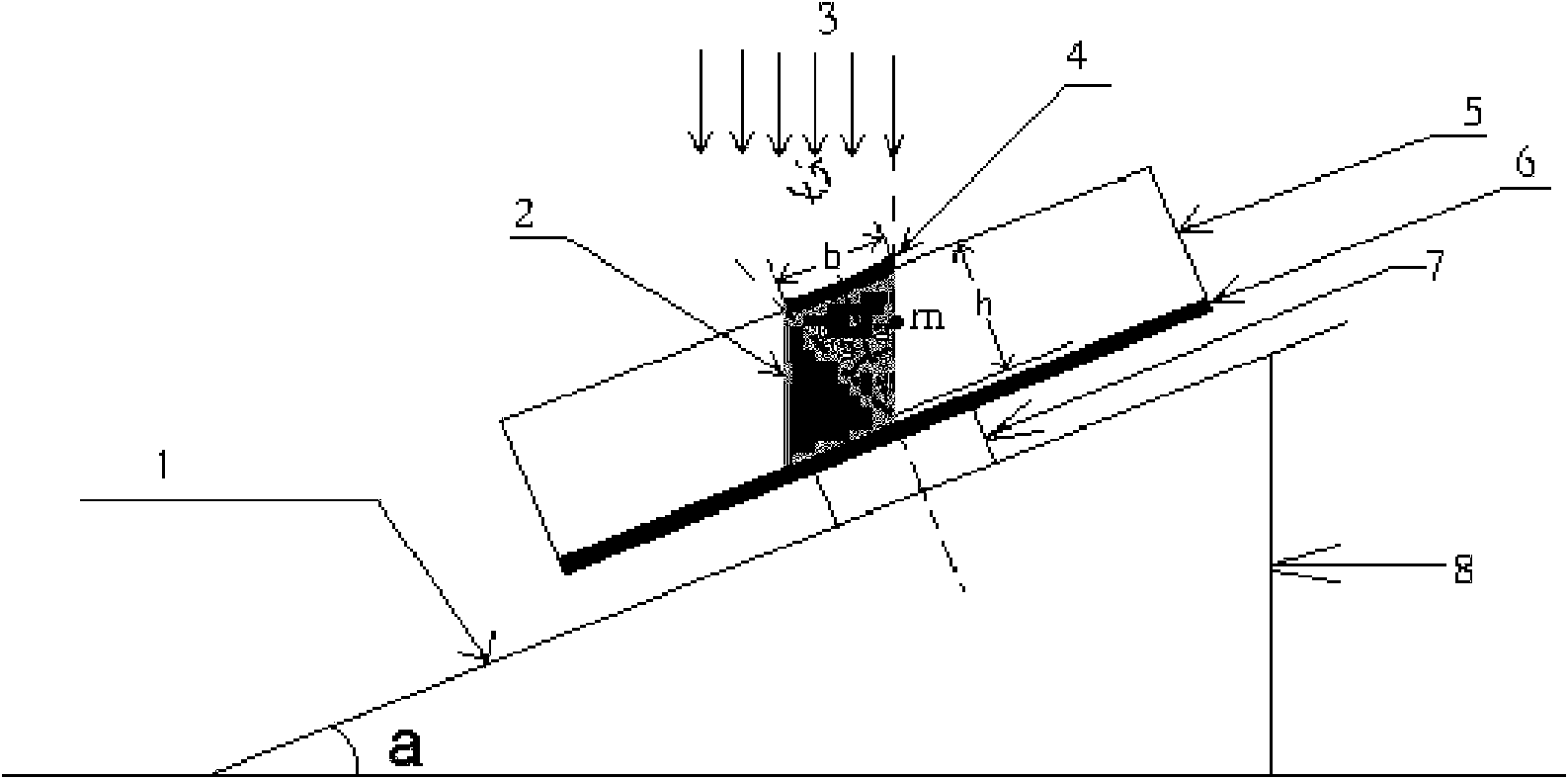

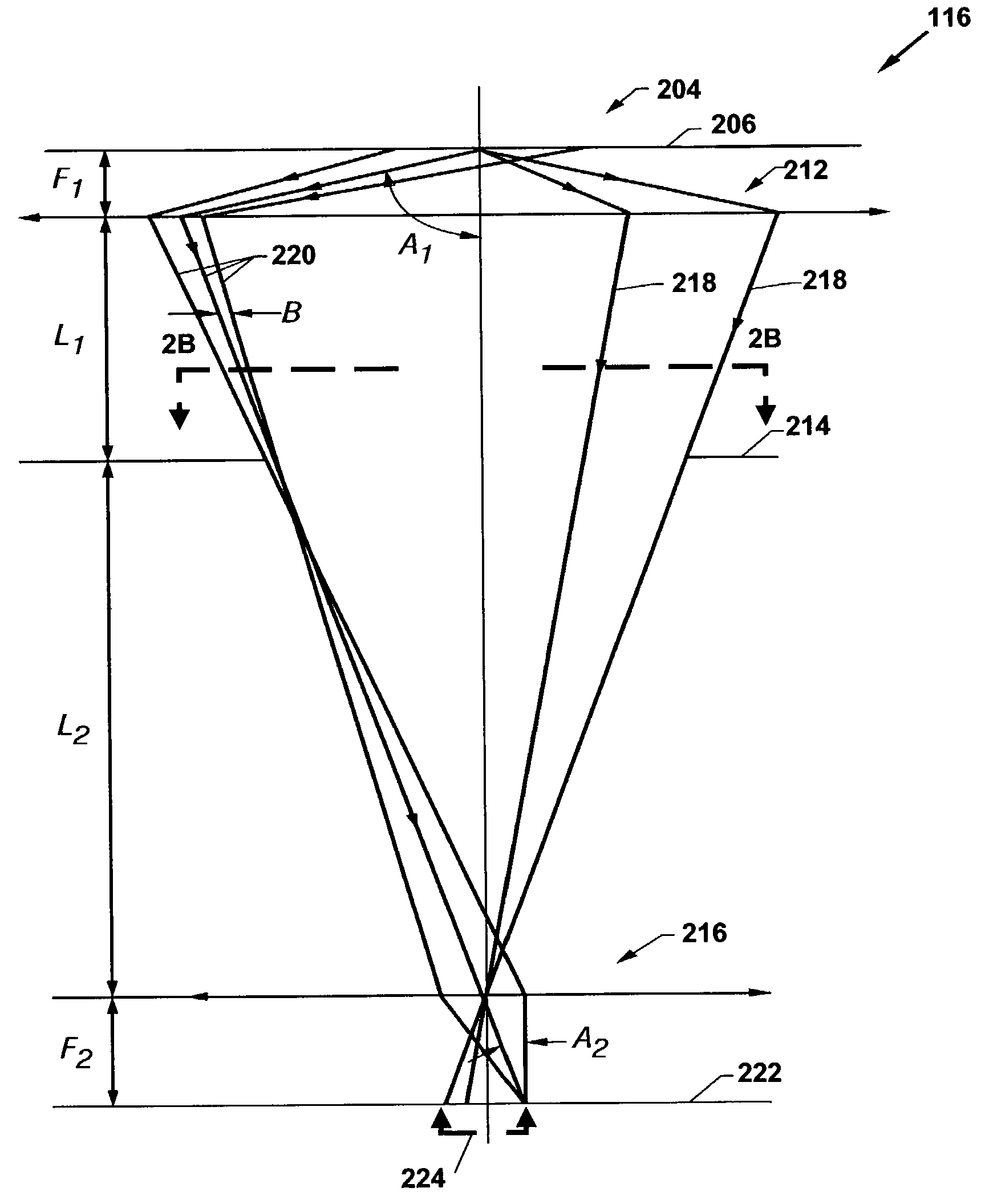

Method for the fabrication of three-dimensional microstructures by deep X-ray lithography

InactiveUS6875544B1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusThree dimensional microstructureX-ray

A method for the fabrication of three-dimensional microstructures by deep X-ray lithography (DXRL) comprises a masking process that uses a patterned mask with inclined mask holes and off-normal exposures with a DXRL beam aligned with the inclined mask holes. Microstructural features that are oriented in different directions can be obtained by using multiple off-normal exposures through additional mask holes having different orientations. Various methods can be used to block the non-aligned mask holes from the beam when using multiple exposures. A method for fabricating a precision 3D X-ray mask comprises forming an intermediate mask and a master mask on a common support membrane.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

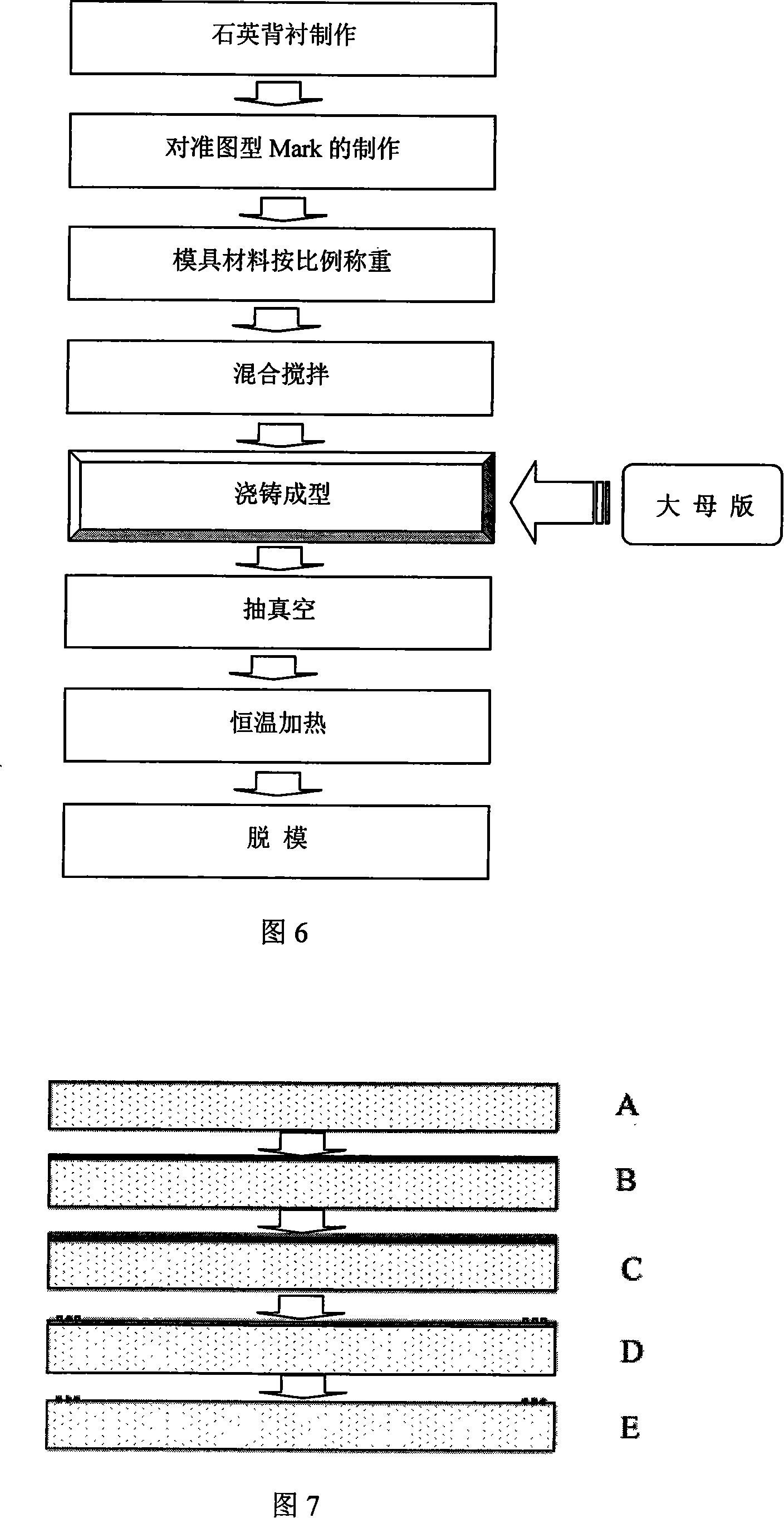

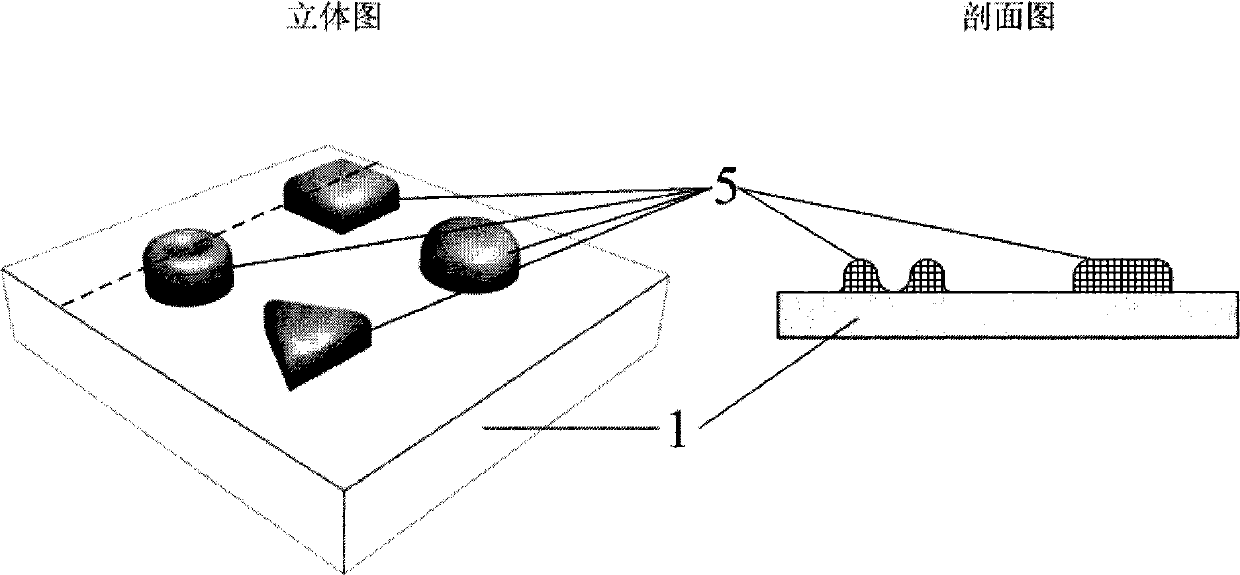

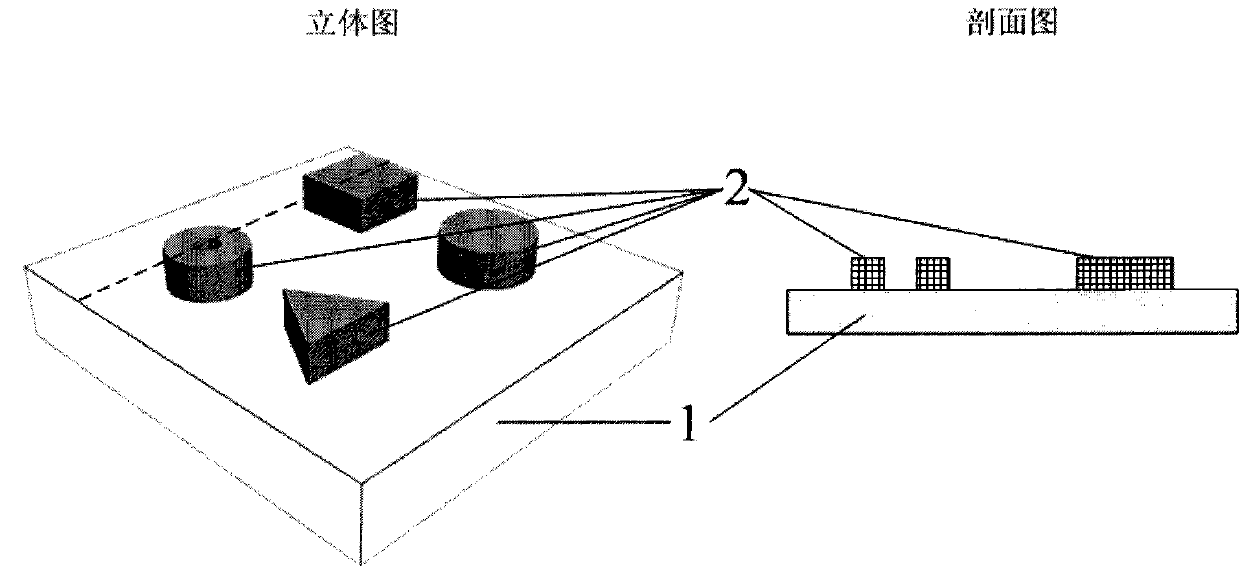

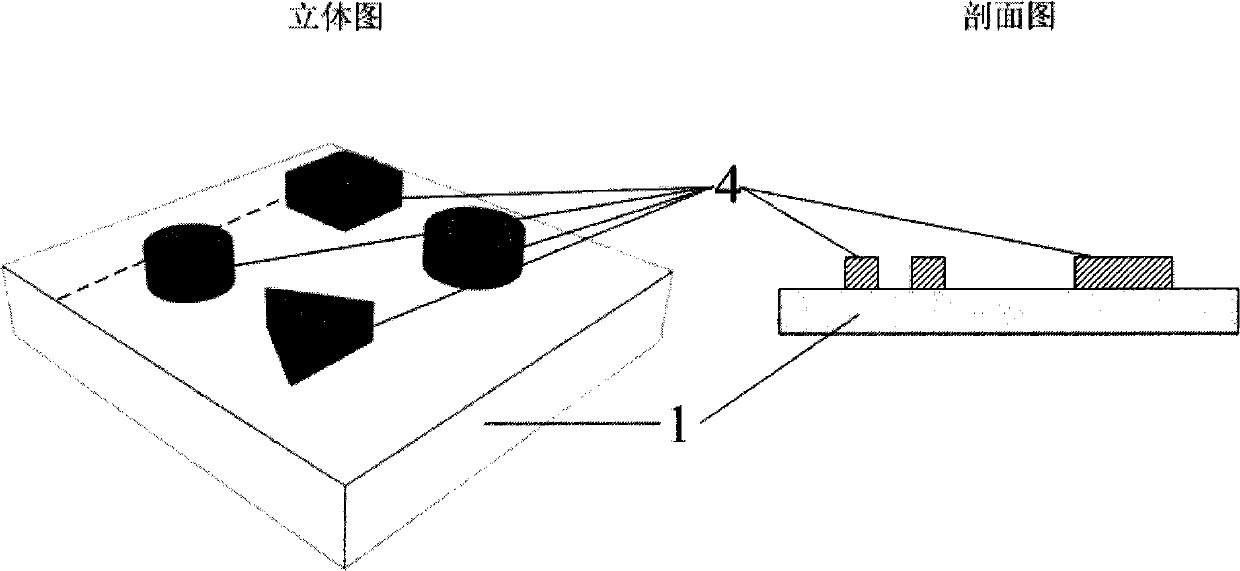

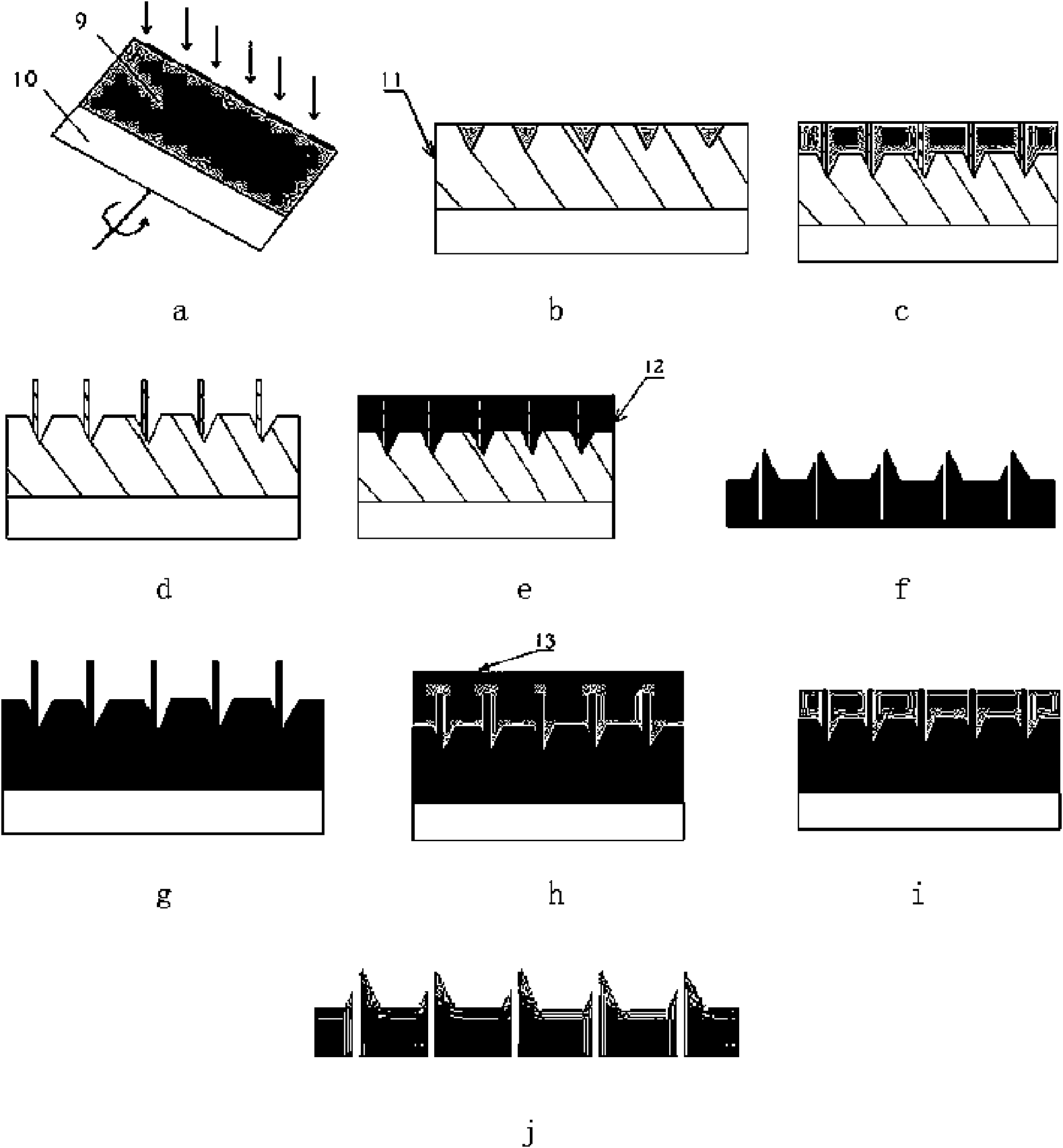

Large area periodic array three-dimensional microstructure preparation method

InactiveCN101101441ASimple preparation processReduce manufacturing costSemi-permeable membranesDecorative surface effectsThree dimensional microstructureSilicon rubber

The invention discloses a large-area periodical array 3D microstructure preparing method, based on UV nano press printing technique, adopting soft mould and inverse pressure printing to implement low-cost preparation of large-area periodical array 3D microstructure and its basic process flow includes: 1. making small master by electron beam direct write photoetching and dry etching; 2. making large master by small master step-pressure printing and accurate micro-electroforming; 3. pouring liquid PDMS material to large master by vacuum assistance to make silicon rubber soft mould; 4. using quartz glass as substrate and making anti-adhesion surface preprocessing on the substrate; 5. using the ready-made silicon rubber soft mould, and combining with the inversing pressure printing to prepare large area periodical array 3D microstructure on the substrate. And the method has advantages of low cost, process simple, suitable to large batch production, and low cost preparation.

Owner:SHANDONG UNIV

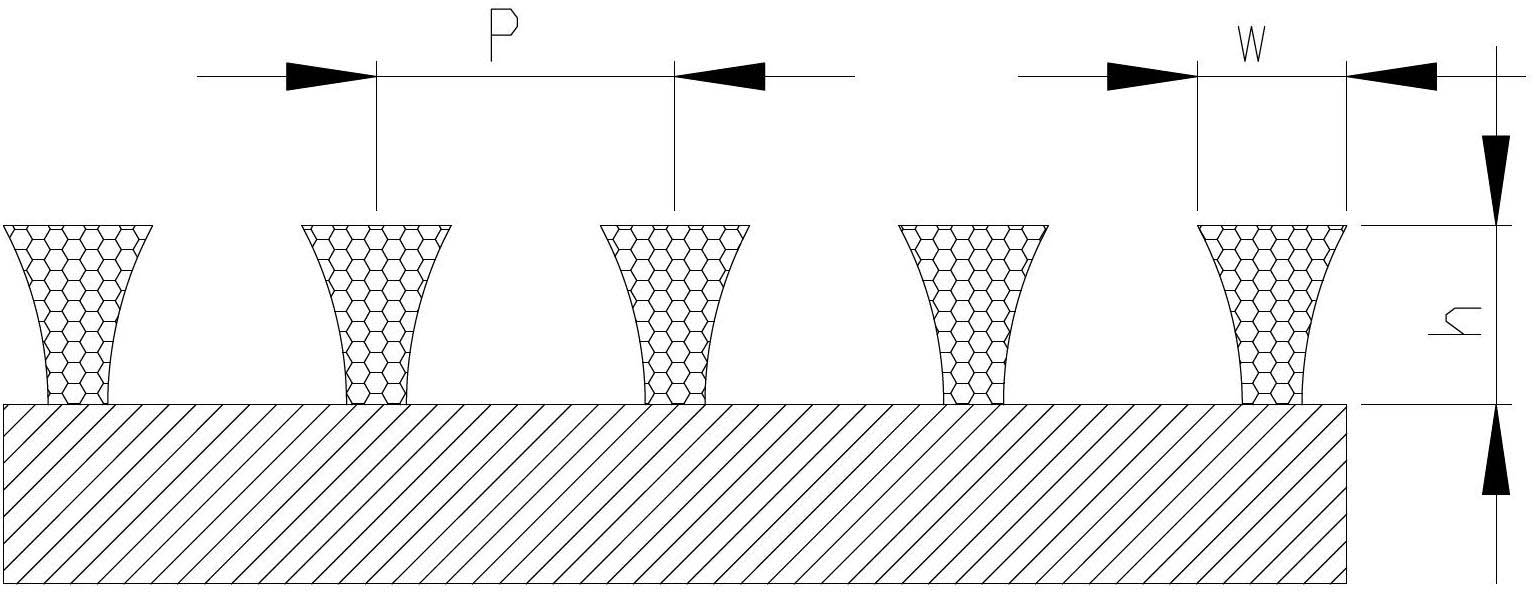

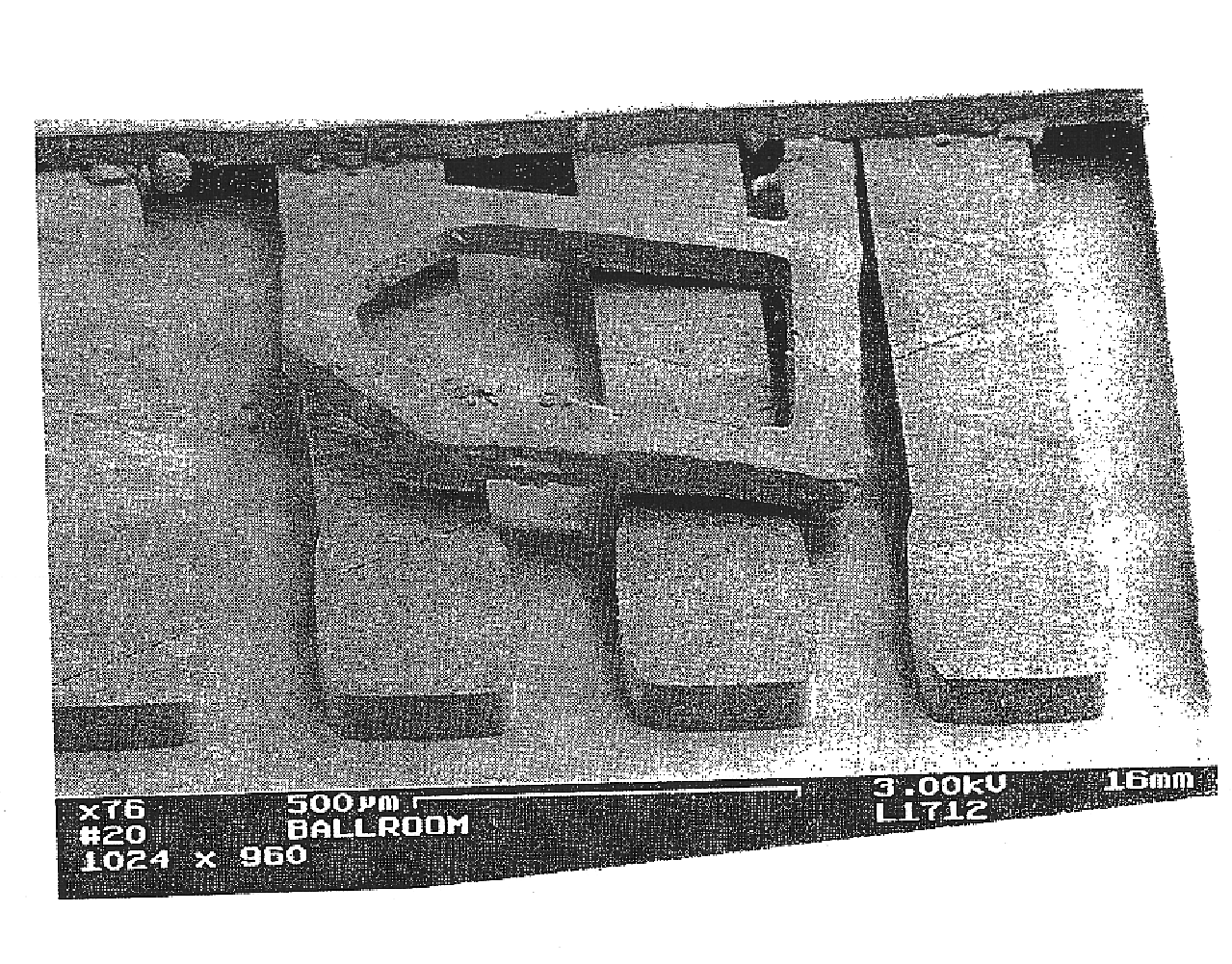

Chip reinforced boiling heat transfer structure of multi-pore microcolumn variable camber molded surfaces

InactiveCN102683305AIncrease the number ofImprove nucleate boiling heat transferSemiconductor/solid-state device detailsSolid-state devicesHeat flowThree dimensional microstructure

The invention relates to an ultra-high heat-flow density reinforced boiling heat transfer technology, in particular to a chip reinforced boiling heat transfer structure of multi-pore microcolumn variable camber molded surfaces, which is suitable for an ultra-high heat-flow density micro-electronic chip efficiently-cooling technology. The chip reinforced boiling heat transfer structure comprises a heat radiating plate on the surface of a chip, and a plurality of multi-pore variable camber molded surface three-dimensional microstructures formed on the heat radiating plate by using foam metal, wherein the multi-pore variable camber molded surface three-dimensional microstructures are arranged in an array form and are of a six-faced shape, the upper surfaces and the lower surfaces of the multi-pore variable camber molded surface three-dimensional microstructures are squares with different sizes, and four side surfaces of the multi-pore variable camber molded surface three-dimensional microstructures are arc surfaces with same shapes. According to the chip reinforced boiling heat transfer structure, enough steam bubble nucleuses of boiling and large specific surface area as well as high heat transfer efficiency are provided, the problem of interaction of a suction function of a capillary pump and synchronous increasing or synchronous reducing of a fluid flow resistance is effectively solved, therefore, ultra-high heat-flow density nucleate boiling heat transfer is remarkably improved, thus effective heat transfer of an ultra-high critical heat-flow density micro-electronic device is ensured.

Owner:XI AN JIAOTONG UNIV

Three dimensional microstructures and method of making

InactiveUS6861205B2Additive manufacturing apparatusDecorative surface effectsThree dimensional microstructureEngineering

A method of forming complex three-dimensional microstructures wherein an external stimulus is applied to a first layer of a photosensitive material, thereby creating voids in the first layer, and any material present in those voids is removed. A sacrificial material is then provided within at least a portion of the voids. This sacrificial layer fills the voids, either in whole or in part, and enables a second layer of photosensitive material to be stacked upon the first, while still preserving the pattern formed in the first layer. Once the sacrificial layer has been applied, a second layer of photosensitive material may then be stacked onto the first. Successive layers of photosensitive material and sacrificial material may be added until a final, complex three-dimensional structure is created. The sacrificial material may then be removed with a solvent such as carbon dioxide.

Owner:BATTELLE MEMORIAL INST

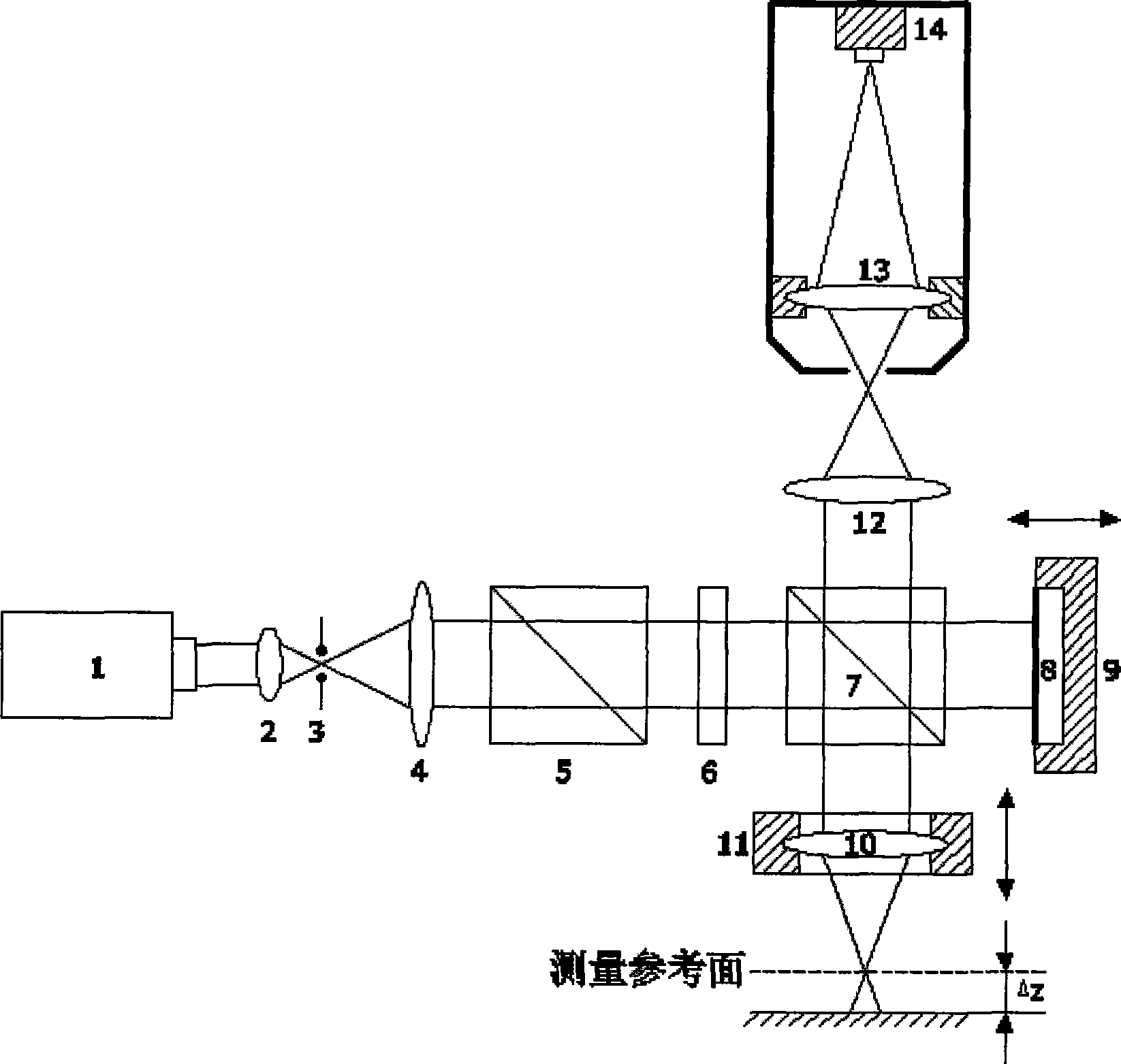

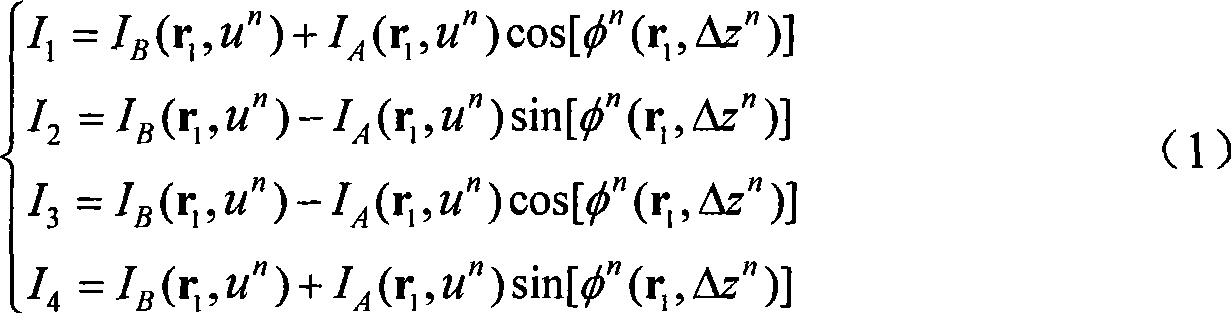

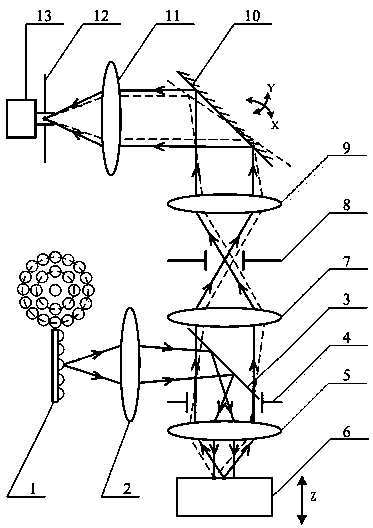

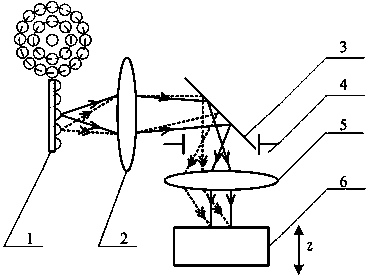

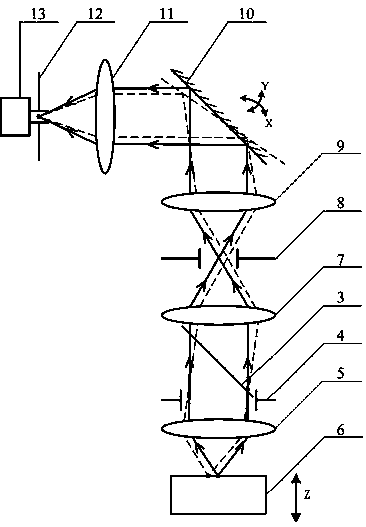

Phase-shifting secondary interference confocal soft-pinhole detection device and method

InactiveCN101520304AFlexible equivalent pinhole sizeReduce the difficulty of assembly and adjustmentUsing optical meansPhase shiftedThree dimensional microstructure

The invention relates to a phase-shifting secondary interference confocal soft-pinhole detection device and a method, belonging to the field of measurement of ultra-precise three-dimensional microstructure surface topography. The soft-pinhole detection device comprises a microobjective and a CCD camera. The method comprises the steps: removing a measuring surface, moving the microobjective and the CCD camera to determine the position for collecting a microobjective benchmark focal plane, positioning an Airy spot center on a CCD image surface, intercepting and locking a fixed pixel area with different microscopic magnification times on the CCD image surface as a soft-pinhole, adjusting the microobjective and the CCD camera to display a clear amplified image of a horizontal spot on the position for collecting the microobjective benchmark focal plane, adding the measured surface, and completing the specific micro-displacement measurement by phase-shifting secondary interference confocal measurement. The invention can provide the flexible equivalent pinhole style, effectively reduce alignment errors of the actual confocal pinhole and improve the detection precision of phase-shifting secondary interference confocal spots.

Owner:HARBIN INST OF TECH

Roll-to-roll method and system for micro-replication of a pattern of large relief three-dimensional microstructures

ActiveUS20080156421A1High viscosityMechanical working/deformationPaper/cardboard wound articlesPolyesterEpoxy

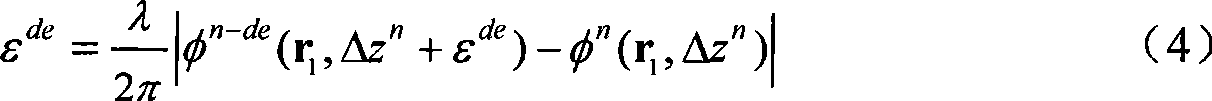

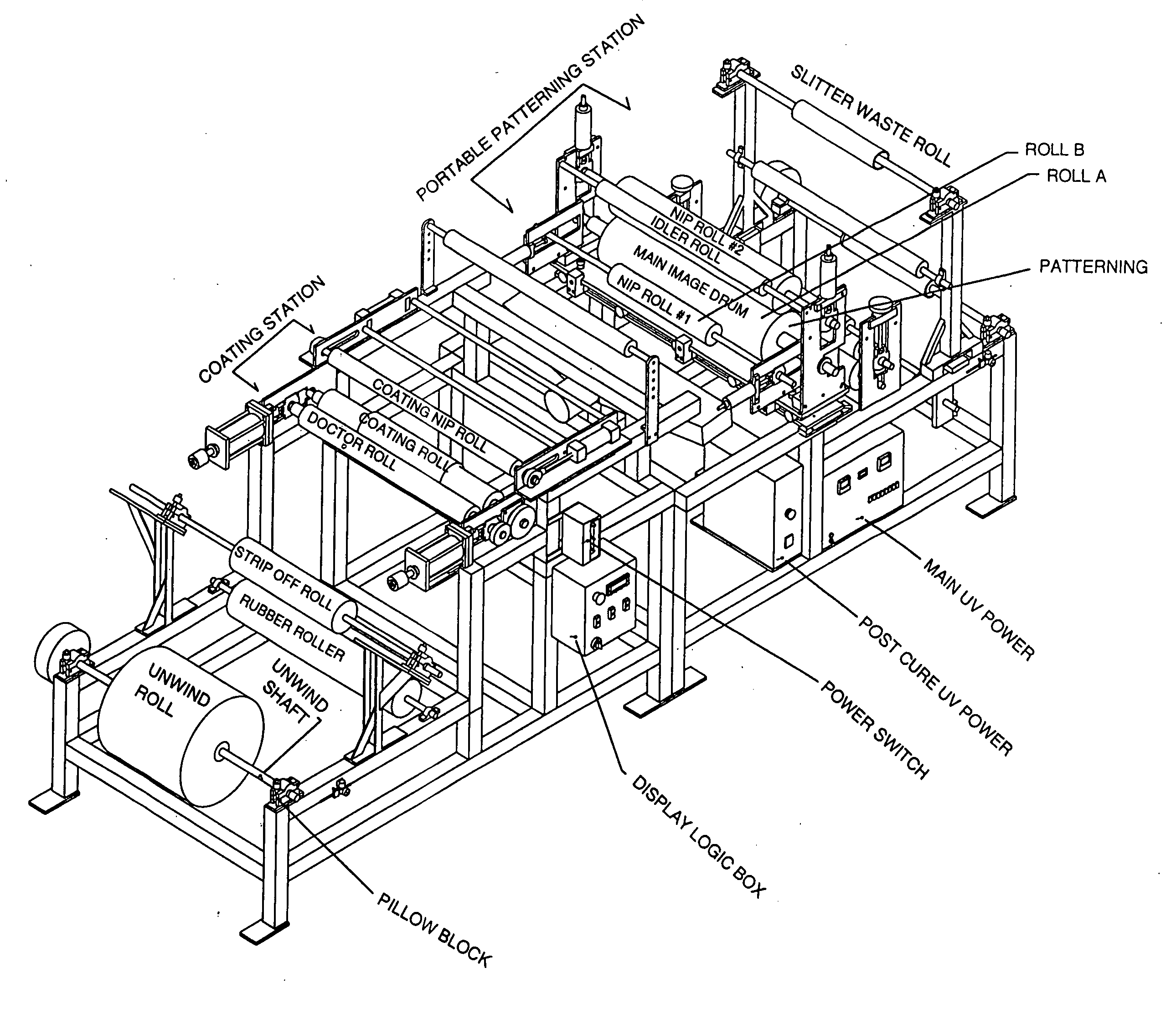

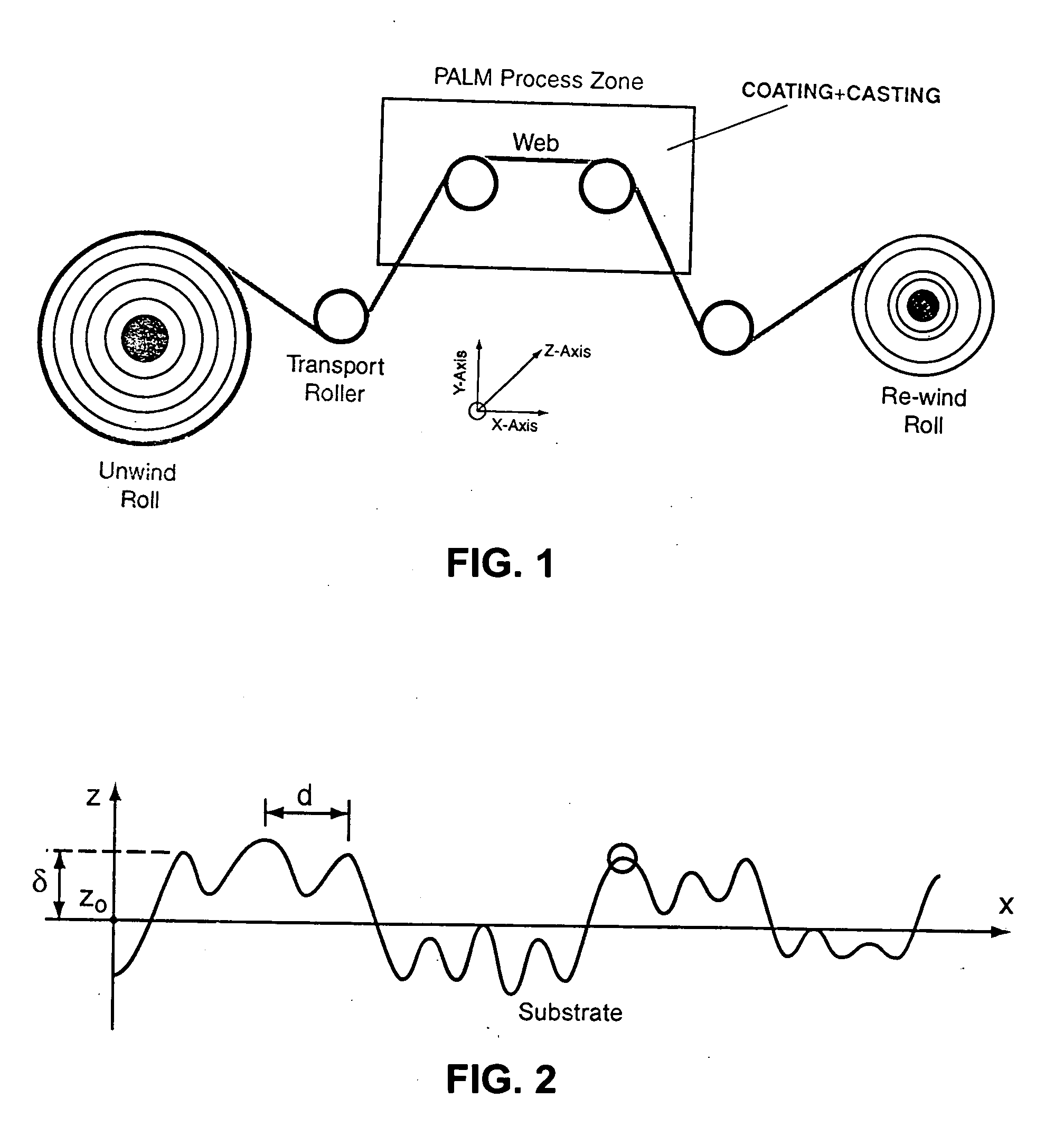

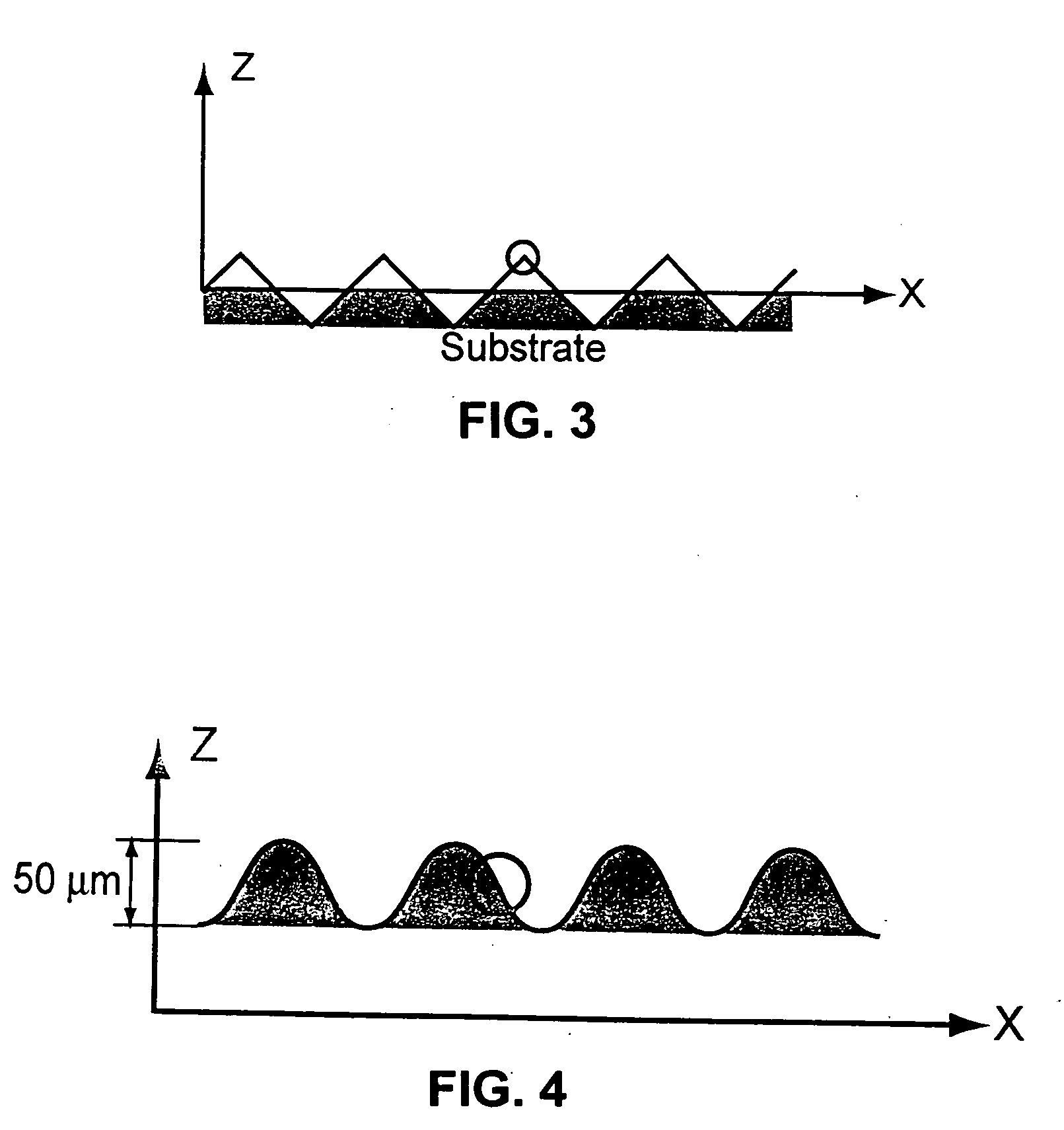

A method and system referred to as PALM (Patterning by Adhesive of Large Relief Three-Dimensional Microstructures) with large reliefs exceeding 1 μm and being as large as 100 μm. The microstructures can be either deterministic (such as microprisms), or random (such as diffusers), the first obtained by copying an original supermaster, and latter obtained by copying a laser speckle pattern. The master process entails copying a supermaster into the form of the microstructure constituting a pattern on the patterning cylinder (called a drum), to be then continuously multiplied in the PALM system, in a continuous roll-to-roll web process. The latter method, together with the related system, is the subject of this invention. The rolls continuously repeat the master pattern, copying by adhesive with large viscosity on acrylic (hybrid) as well as by a monolithic process. The monolithic process can be accomplished using temperature and pressure, or by UV-cured polymerization. Therefore, the invention comprises three alternative processes: one, hybrid (adhesive on acrylic), and two monolithic ones. In the PALM (hybrid) process, an epoxy is wet-coated on film substrates such as polycarbonate (PC), polyester (PET), (PE), or other flexible material. The adhesive, in liquid form, is applied to the substrate by a self-metered coating sub-process. In the present invention, the adhesive is used for forming the microstructure pattern. The microstructure pattern is replicated from a master roll or image drum onto a coating roll.

Owner:LUMINIT

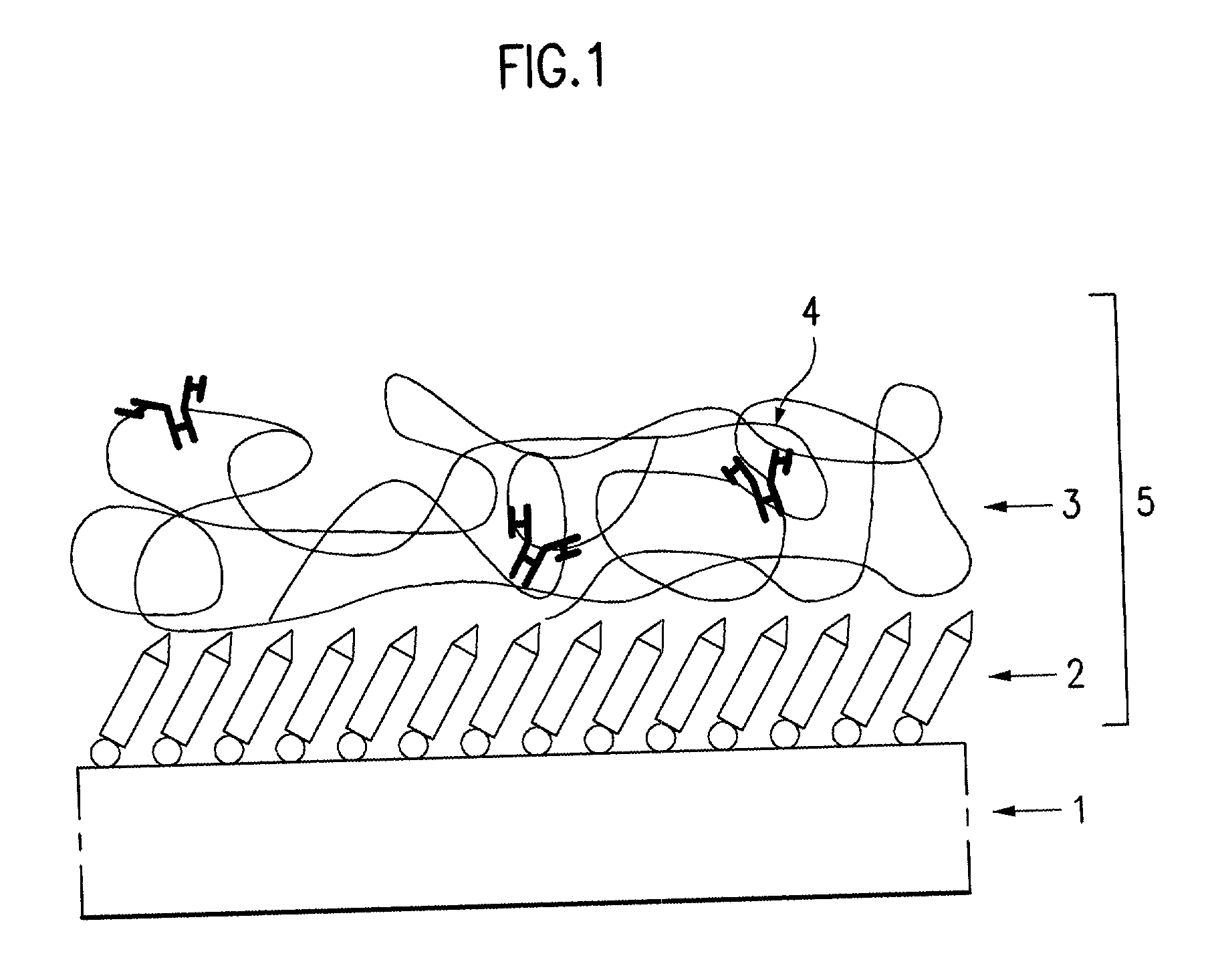

Interface sensing membrane in bioelectronic device and method for forming the same

InactiveUS20010009774A1Microbiological testing/measurementMaterial analysisThree dimensional microstructureAdhesive

Interface sensing membrane in a bioelectronic device and a method for forming the same, the device including a molecular adhesive layer chemically adsorbed to a surface of a solid state element, a three dimensional microstructured layer of a hydrophilic polymer connected to the molecular adhesive layer in a covalent bond, and a bioelement immobilized in the three dimensional microstructured layer by covalent adhesive, whereby causing a stable biomolecular interaction.

Owner:LG ELECTRONICS INC

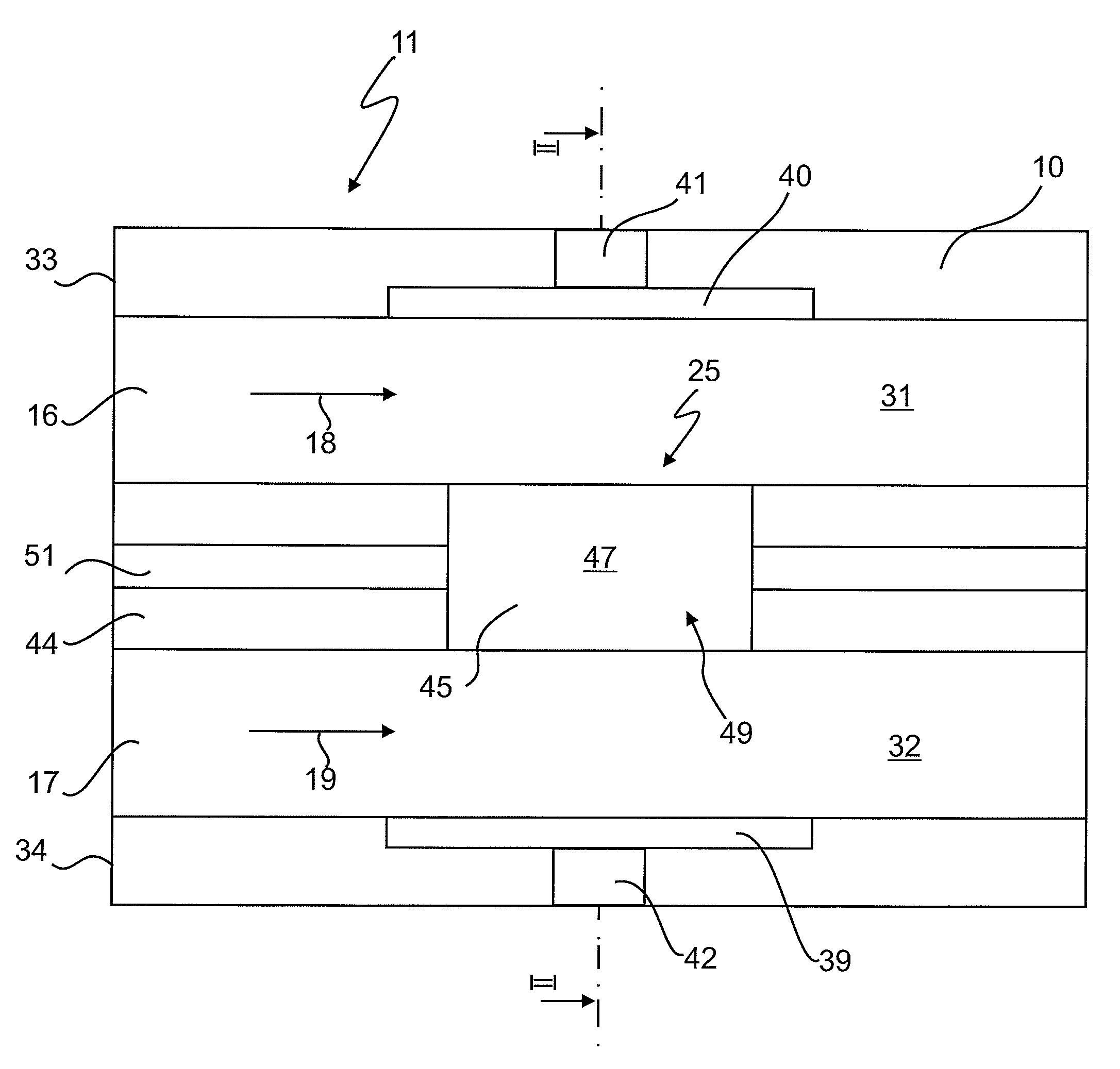

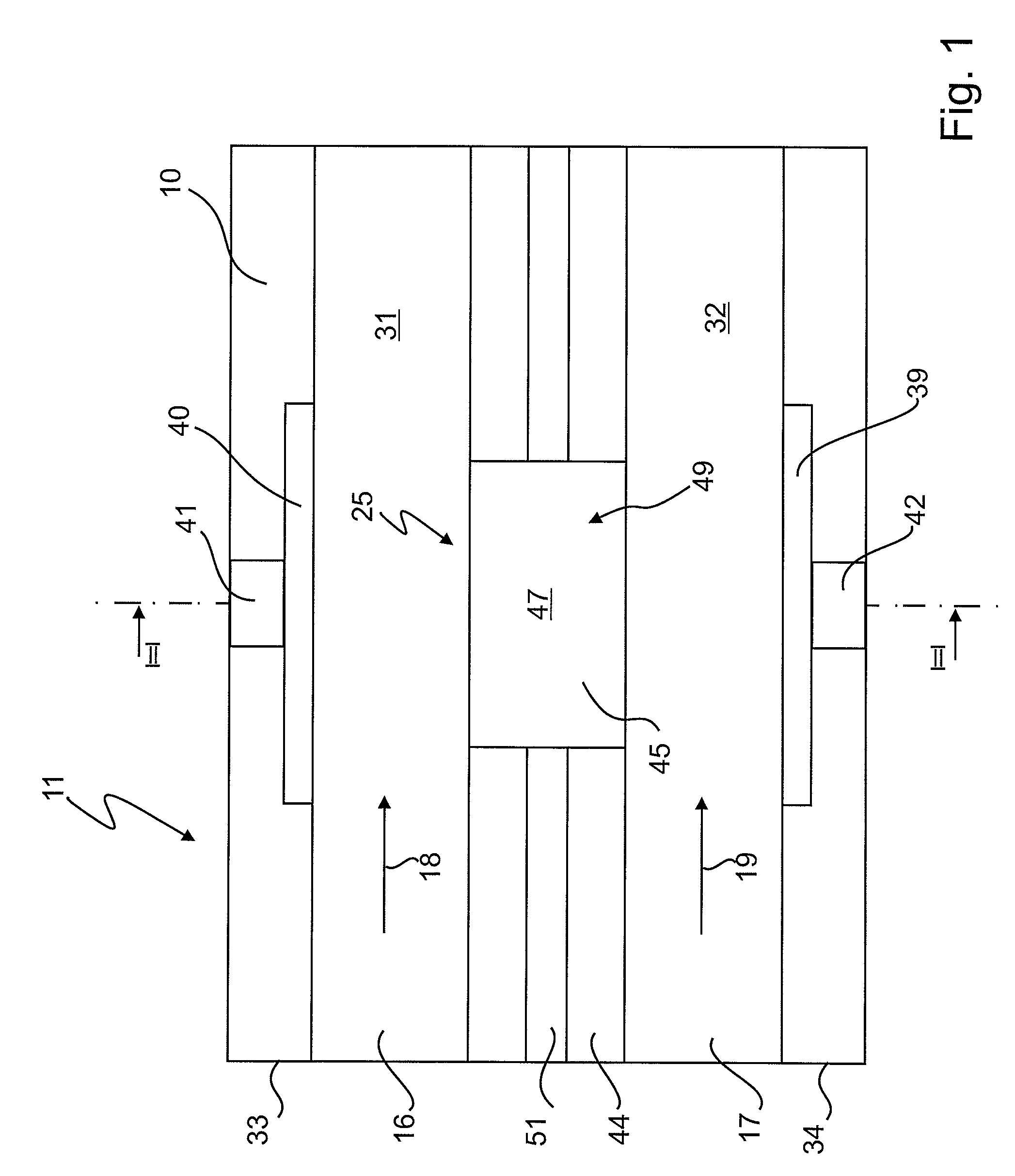

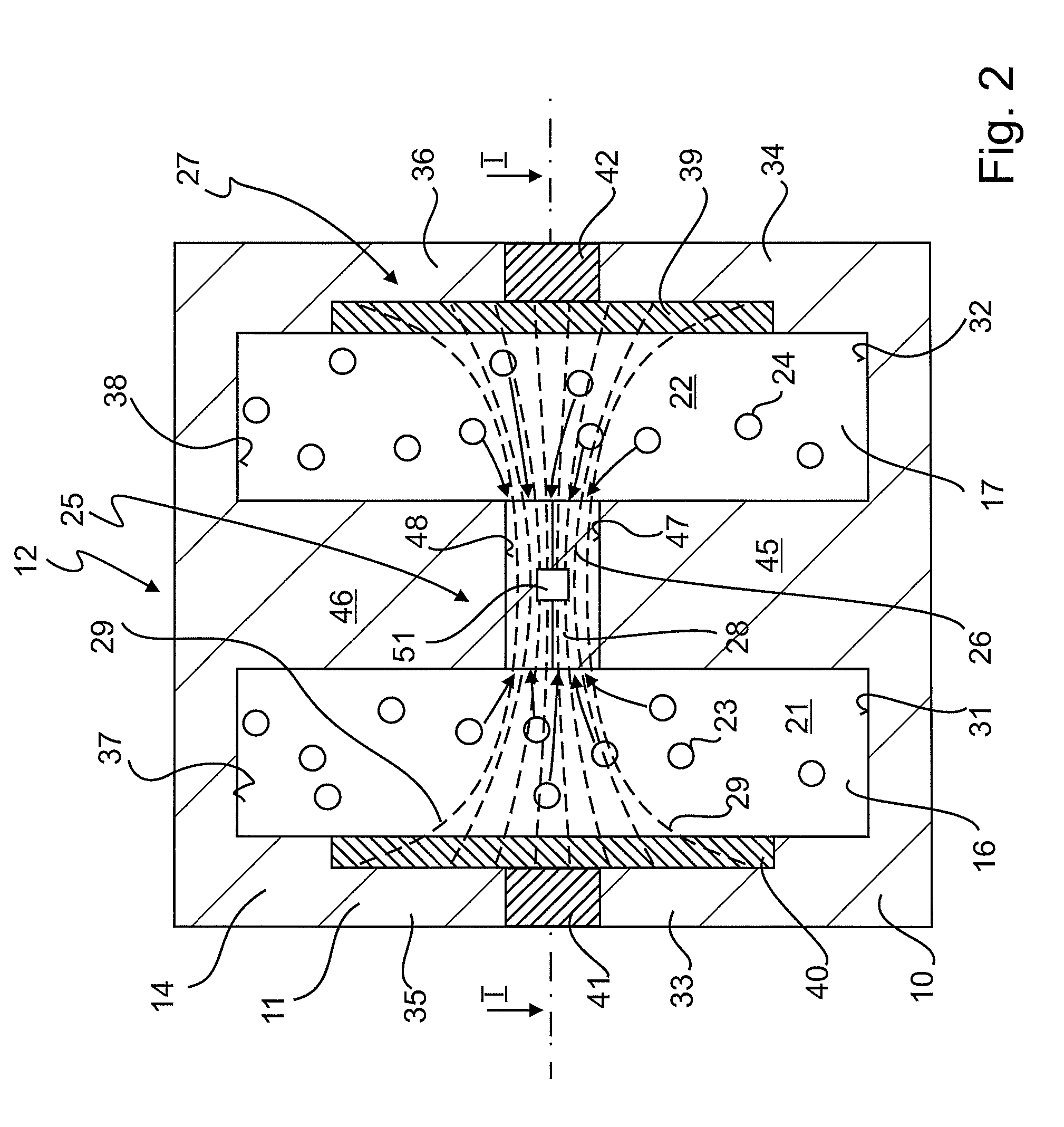

Microfluidic system and method for assembling and for subsequently cultivating, and subsequent analysis of complex cell arrangements

ActiveUS20110079513A1Electrostatic separatorsSludge treatmentThree dimensional microstructureElectric field

A microfluidic system (12) for assembling and subsequently investigating complex cell arrangements has a three-dimensional microstructure (11) in which the cell culture is assembled, cultivated and investigated. At least two microchannel segments (16, 17) through which the microstructure (11) can be perfused from outside with a medium (21, 22) run in the microstructure (11), whereby the microchannel segments (16, 17) run at least in sections approximately parallel or equidistant to one another. The two microchannel segments (16, 17) are separated from one another by a wall structure (25) in which at least one aperture (26) connecting the two microchannel segments (16, 17) is provided. An electrode arrangement (27) is provided in or on the microstructure (11) in order to generate an inhomogeneous electric field (28) in the region of the at least one aperture (26). A cell arrangement is assembled in this microstructure (11) by supplying medium (21, 22) with cells (23, 24) for assembling the cell culture in the microstructure (11), with the inhomogeneous electric field (28) determined by the microstructure (11) bringing about the assembling of the cell arrangement from the supplied cells (23, 24).

Owner:NMI NATURWISSENSCHAFTLICHES & MEDIZINISCHES INST AN DER UNIV TUBINGEN

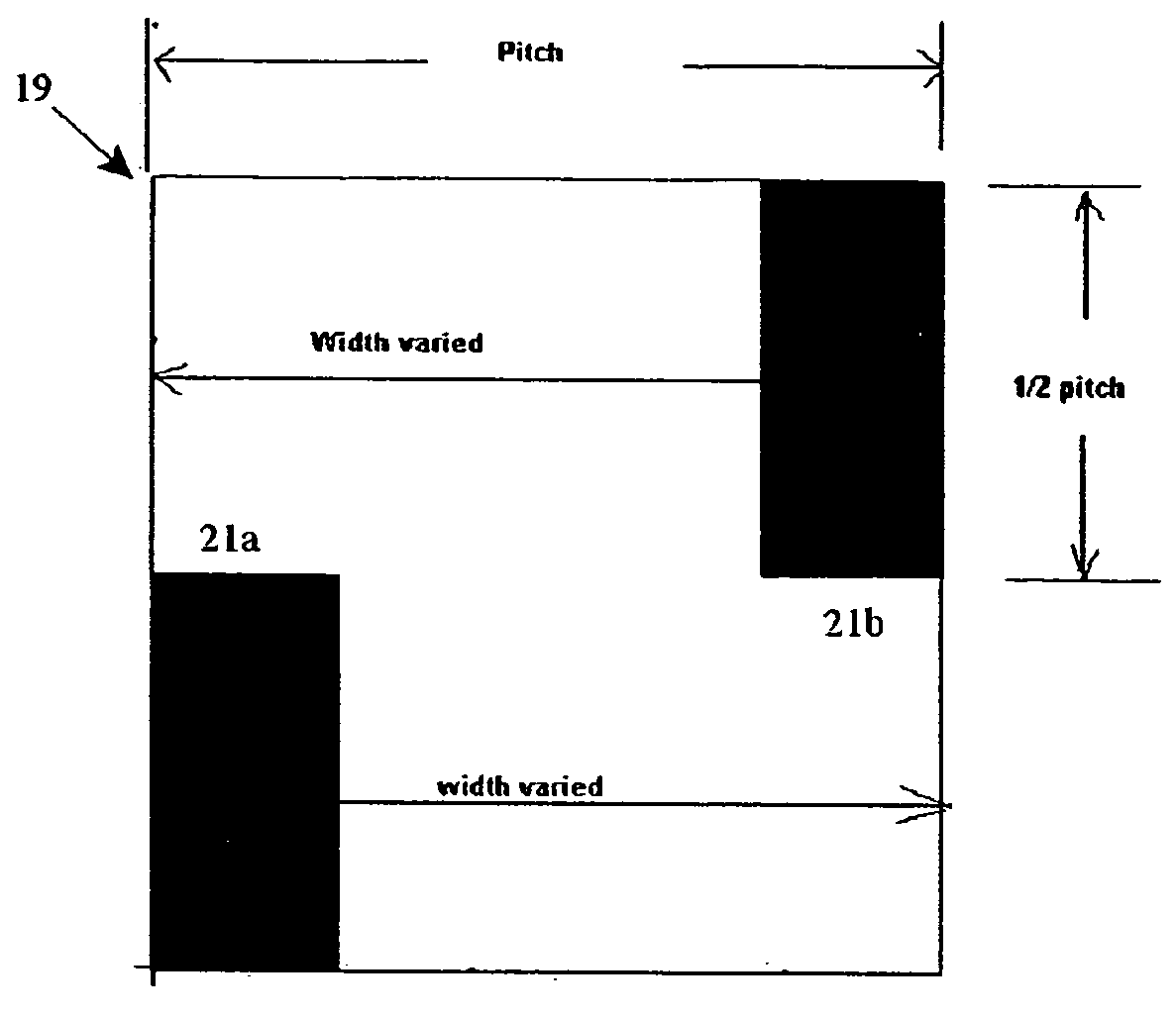

Binary half tone photomasks and microscopic three-dimensional devices and method of fabricating the same

InactiveUS20050118515A1Reduce areaNanoinformaticsPhotomechanical apparatusMicro structureThree dimensional microstructure

The present invention generally relates to improved binary half tone (“BHT”) photomasks and microscopic three-dimensional structures (e.g., MEMS, micro-optics, photonics, micro-structures and other three-dimensional, microscopic devices) made from such BHT photomasks. More particularly, the present invention provides a method for designing a BHT photomask layout, transferring the layout to a BHT photomask and fabricating three-dimensional microscopic structures using the BHT photomask designed by the method of the present invention. In this regard, the method of designing a BHT photomask layout comprises the steps of generating at least two pixels, dividing each of the pixels into sub-pixels having a variable length in a first axis and fixed length in a second axis, and arraying the pixels to form a pattern for transmitting light through the pixels so as to form a continuous tone, aerial light image. The sub-pixels' area should be smaller than the minimum resolution of an optical system of an exposure tool with which the binary half tone photomask is intended to be used. By using this method, it is possible to design a BHT photomask to have continuous gray levels such that the change in light intensity between each gray level is both finite and linear. As a result, when this BHT photomask is used to make a three-dimensional microscopic structure, it is possible to produce a smoother and more linear profile on the object being made.

Owner:PHOTRONICS INC

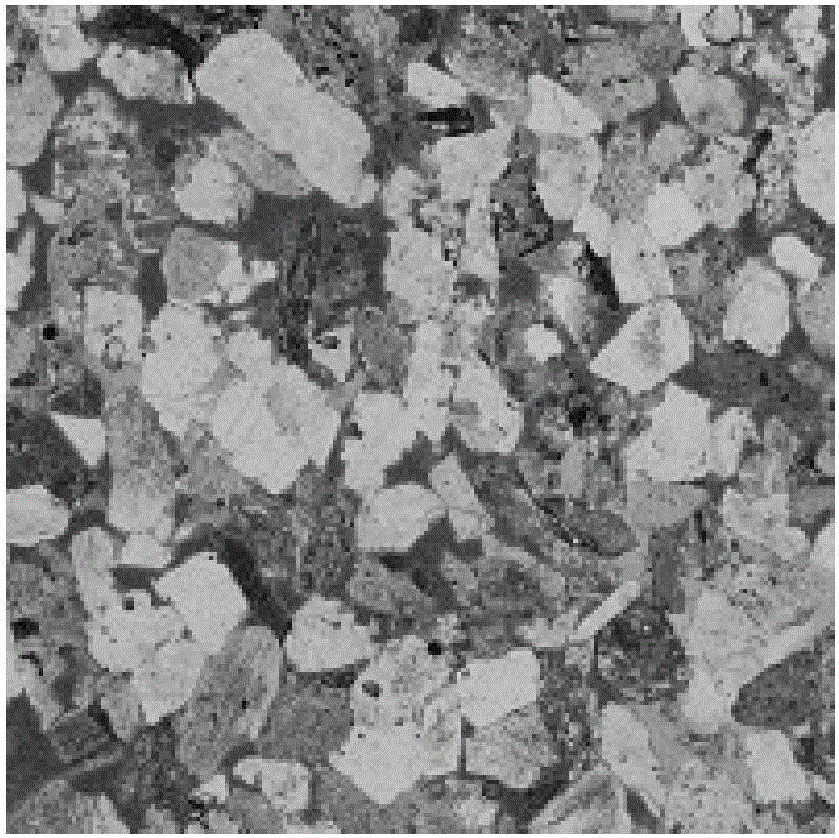

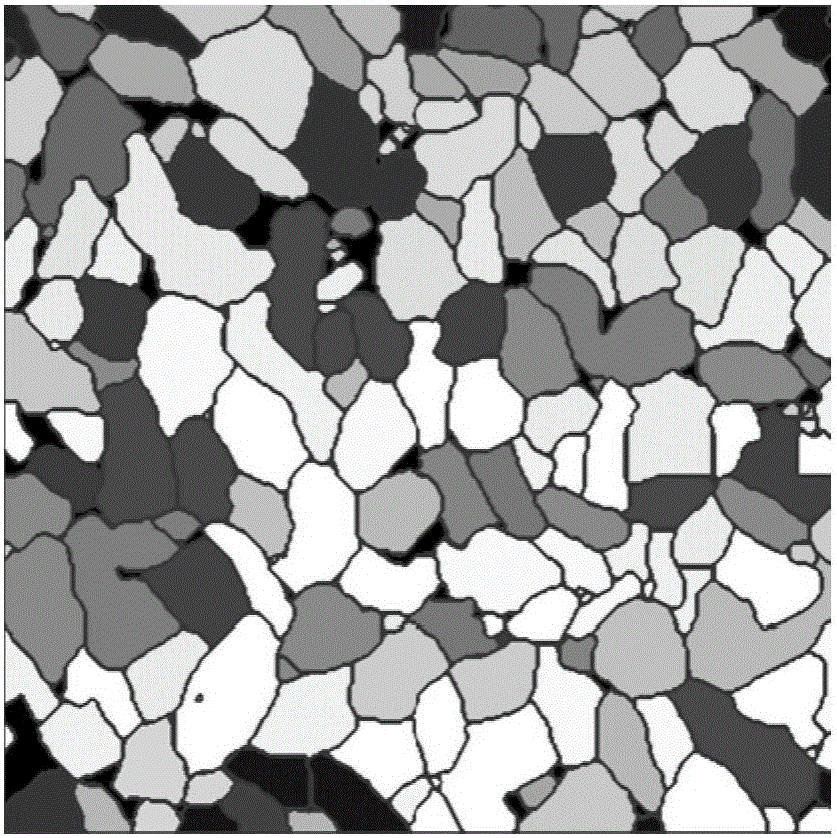

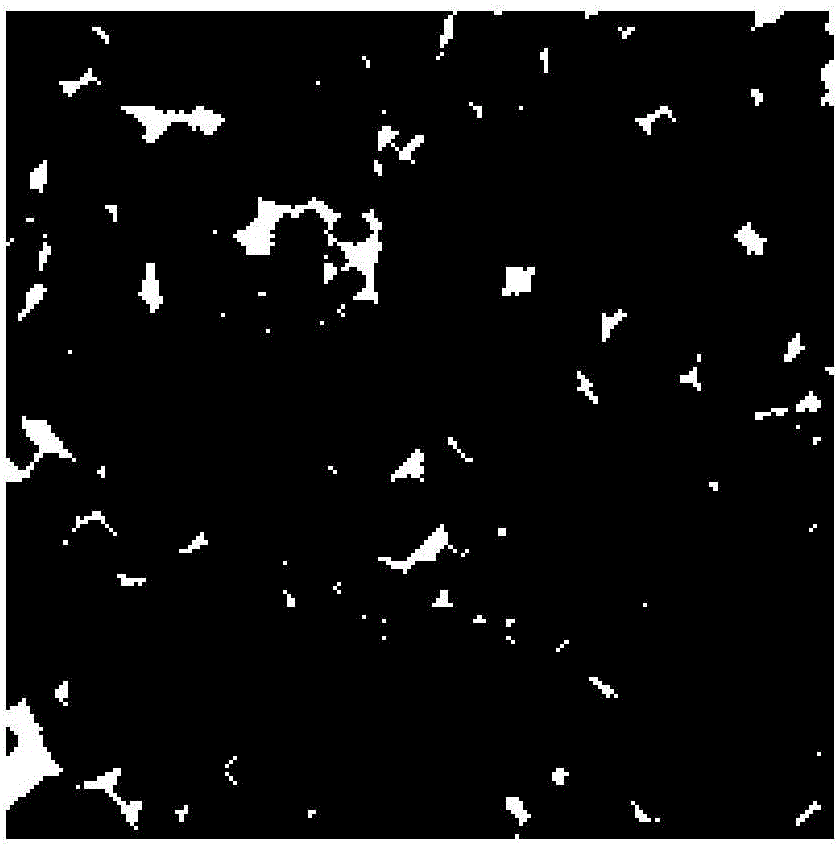

Three-dimensional particle structure reconstruction method based on rock-core two-dimensional particle image

ActiveCN105139444ABeneficial technical effectEasy to explain3D modellingThree dimensional microstructureRock core

The invention relates to a three-dimensional particle structure reconstruction method based on a rock-core two-dimensional particle image. Aiming at a three-dimensional modeling problem based on the rock-core two-dimensional image, the mineral particle information contained in the two-dimensional image is utilized to deduce three-dimensional particle structure information corresponding to a two-dimensional particle structure. Particularly, a rock-core particle microstructure reconstruction algorithm is proposed based on the combination of a simulated annealing algorithm and a particle growth algorithm, so that the reference images of the reconstructed three-dimensional particle structure and the two-dimensional particle structure have similar morphologic distribution, and the rock-core particle structure characteristics can be captured better; the three-dimensional distribution of mineral particles in the microstructure represents the spatial distribution of the mineral particles, and the influence of different mineral constituents on the structural performance of the three-dimensional particle structure is quantized based on the three-dimensional particle structure; the reconstructed three-dimensional microstructure provides a better explanation for the real rock-core microstructure; and the three-dimensional particle structure reconstruction method can be applicable for research on the electrical characteristics and seepage characteristics of the rock-core microstructure, and has practical values.

Owner:SICHUAN UNIV

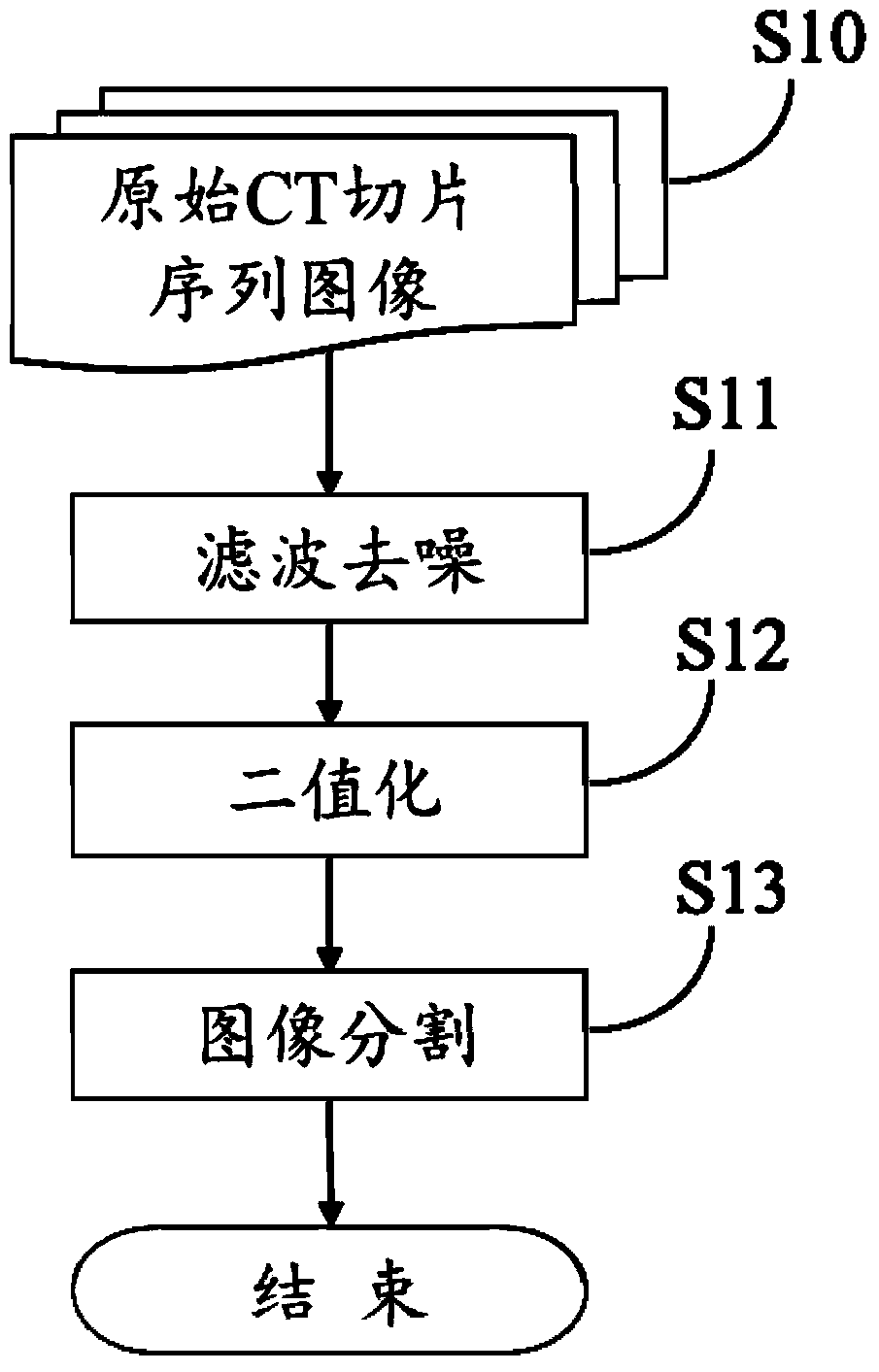

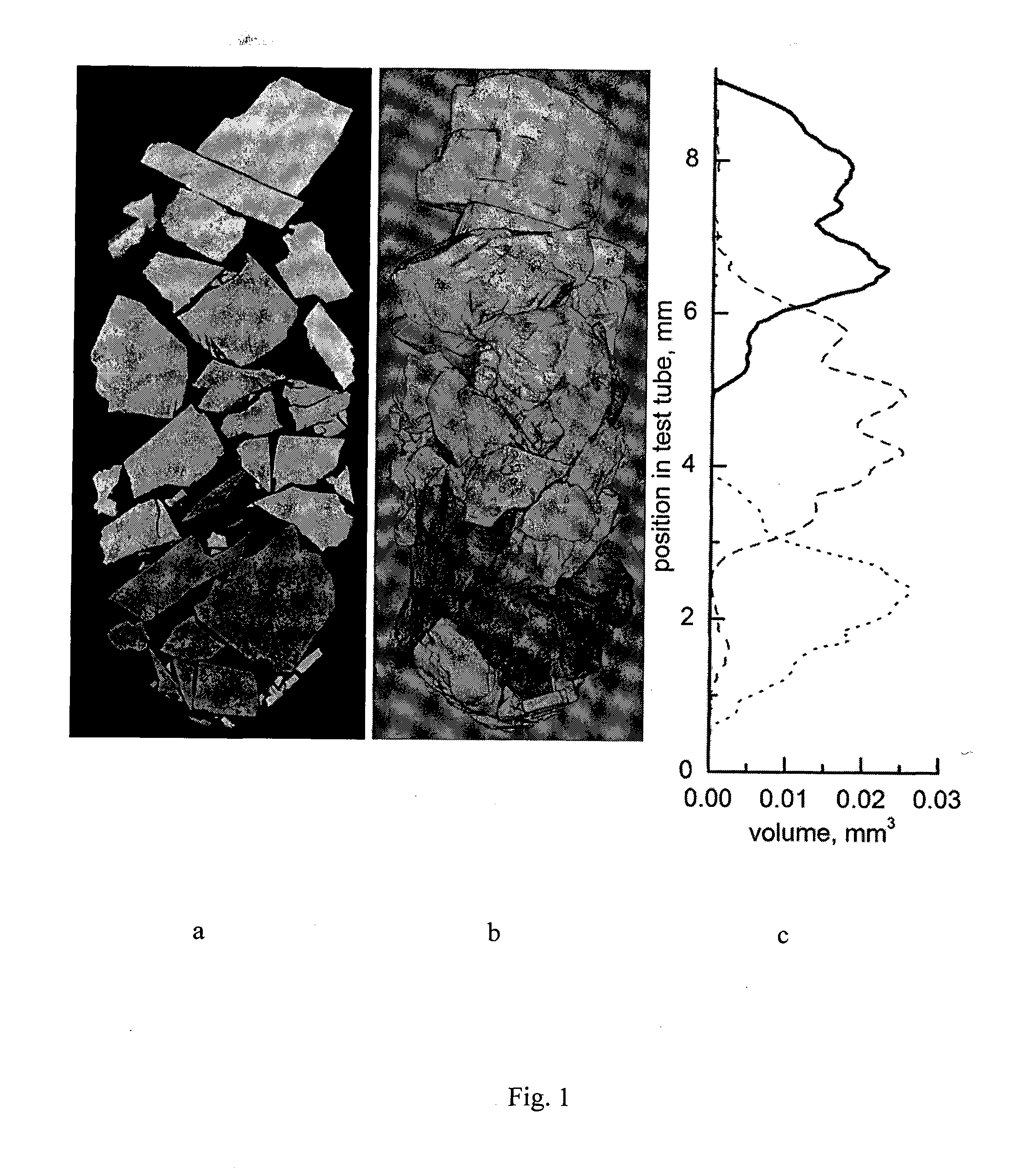

Method and system for reconstruction and analysis of earth-rock aggregate three-dimensional microstructure

InactiveCN104036538AEasy to set upRealize 3D visualization displayImage analysis3D-image renderingThree dimensional microstructureComputing tomography

The invention provides a method and a system for reconstruction and analysis of an earth-rock aggregate three-dimensional microstructure. The method includes preparing an earth-rock aggregate sample, subjecting the earth-rock aggregate sample to computed tomography (CT) scanning to acquire a CT cross-section image sequence of the earth-rock aggregate sample, acquiring rubble cross-section area of each CT cross-section image of the CT cross-sectional image sequence and dividing the rubble cross-section area into multiple independent rubble cross sections, registering the independent rubble cross sections in each CT cross-section image to generate a three-dimensional microstructure model of rubbles according to a registration result, analyzing the three-dimensional microstructure model to determine rock percentage, grain distribution, rubble spatial distribution, rubble geometrical features and rubble morphological characteristics of the earth-rock aggregate sample. The three-dimensional microstructure model is easy to generate by the method and the system. The method and the system have the advantage of accurate and reliable analysis result of the earth-rock aggregate and can be applied to numerical calculation and analysis directly.

Owner:TSINGHUA UNIV

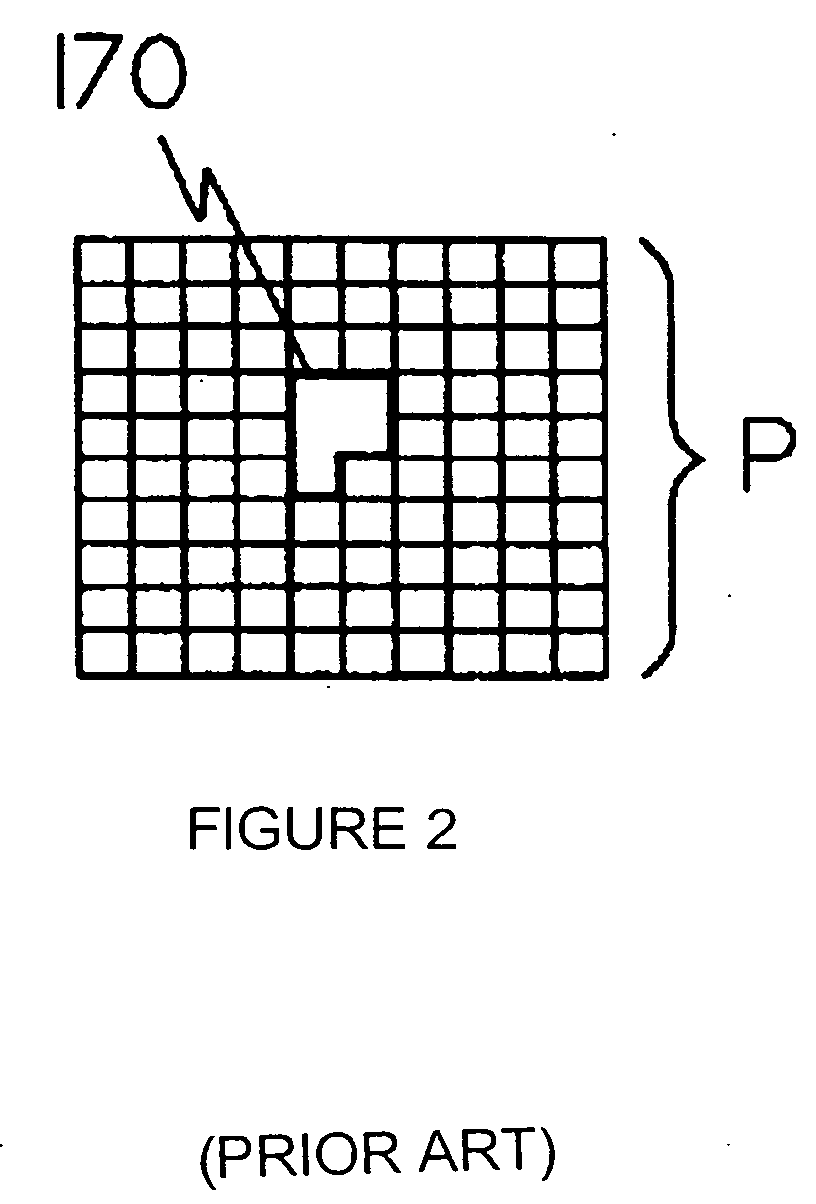

Gray scale all-glass photomasks

InactiveUS20050053844A1Facilitates new designLow costElectric discharge tubesPhotomechanical exposure apparatusThree dimensional microstructureEffect light

A narrowly defined range of zinc silicate glass compositions is found to produce High Energy Beam Sensitive-glass (HEBS-glass) that possesses the essential properties of a true gray level mask which is necessary for the fabrication of general three dimensional microstructures with one optical exposure in a conventional photolithographic process. The essential properties are (1) A mask pattern or image is grainiless even when observed under optical microscope at 1000× or at higher magnifications. (2) The HEBS-glass is insensitive and / or inert to photons in the spectral ranges employed in photolithographic processes, and is also insensitive and / or inert to visible spectral range of light so that a HEBS-glass mask blank and a HEBS-glass mask are permanently stable under room lighting conditions. (3) The HEBS-glass is sufficiently sensitive to electron beam exposure, so that the cost of making a mask using an e-beam writer is affordable for at least certain applications. (4) The e-beam induced optical density is a unique function of, and is a very reproducible function of electron dosages for one or more combinations of the parameters of an e-beam writer. The parameters of e-beam writers include beam acceleration voltage, beam current, beam spot size, addressing grid size and number of retraces. A method of fabricating three-dimensional microstructures using HEBS-glass gray scale photomask for three dimensional profiling of photoresist and reproducing the photoresist replica in the substrate with the existing microfabrication methods normally used for the production of microelectronics is described.

Owner:CANYON MATERIALS

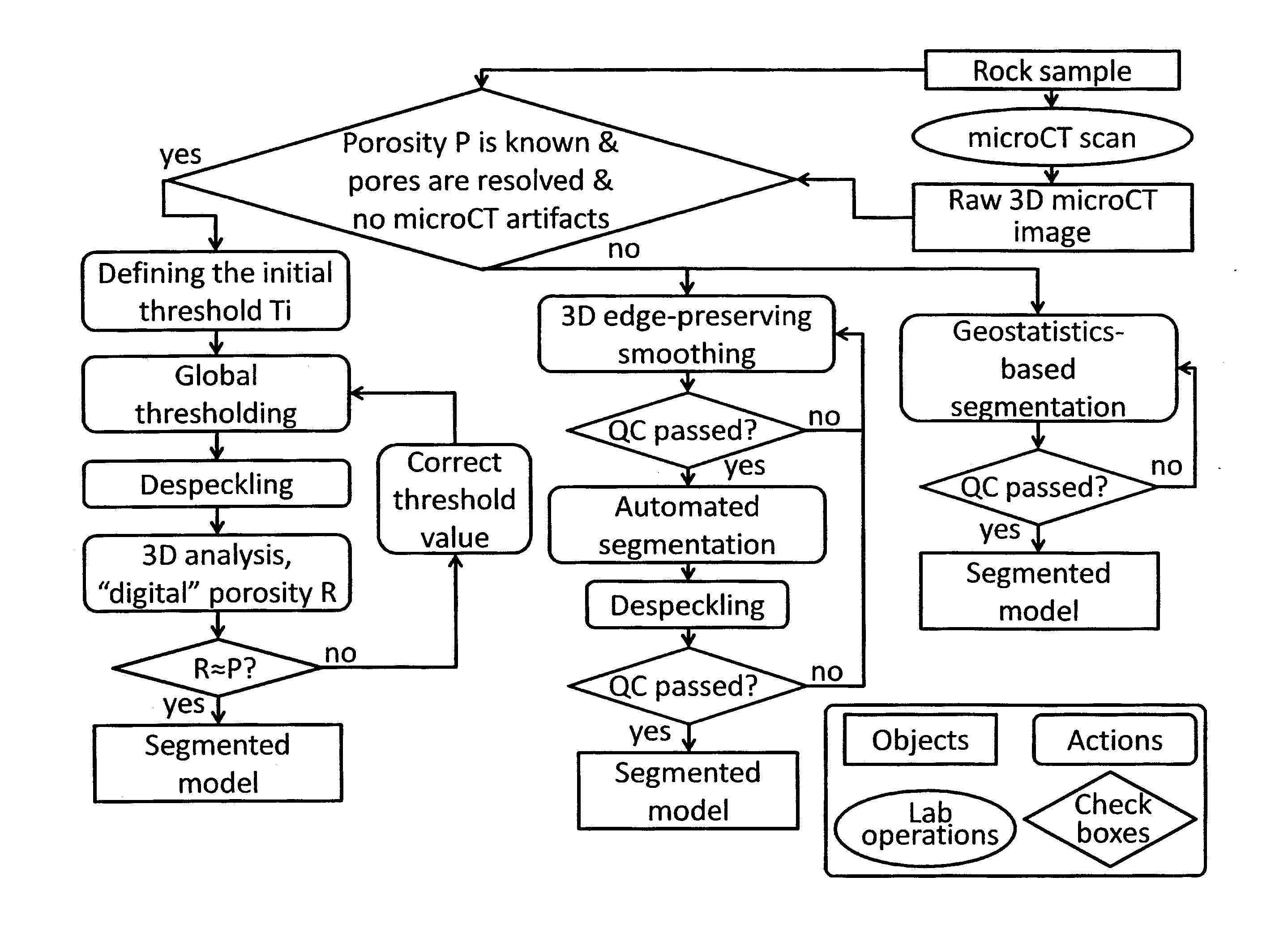

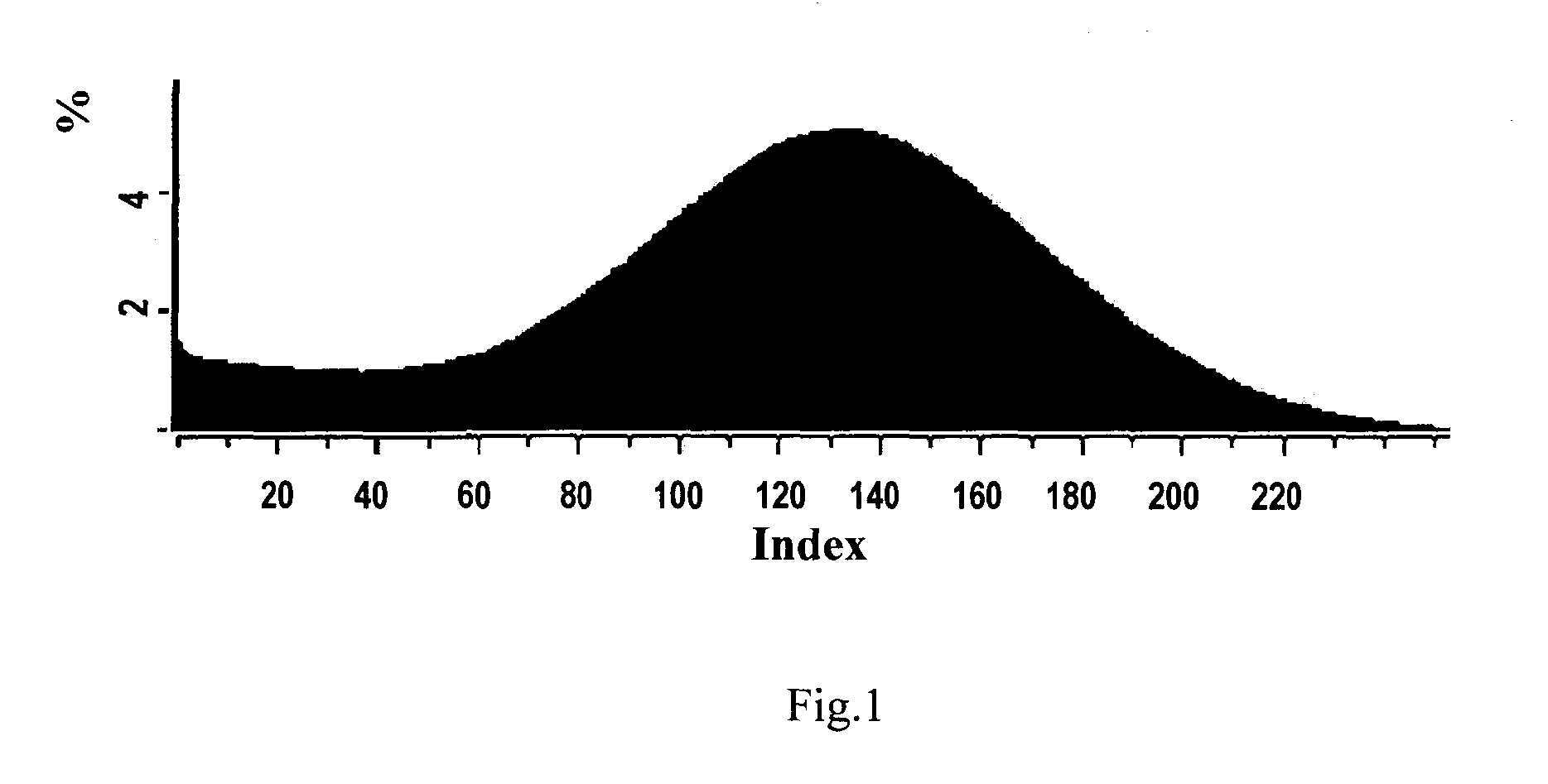

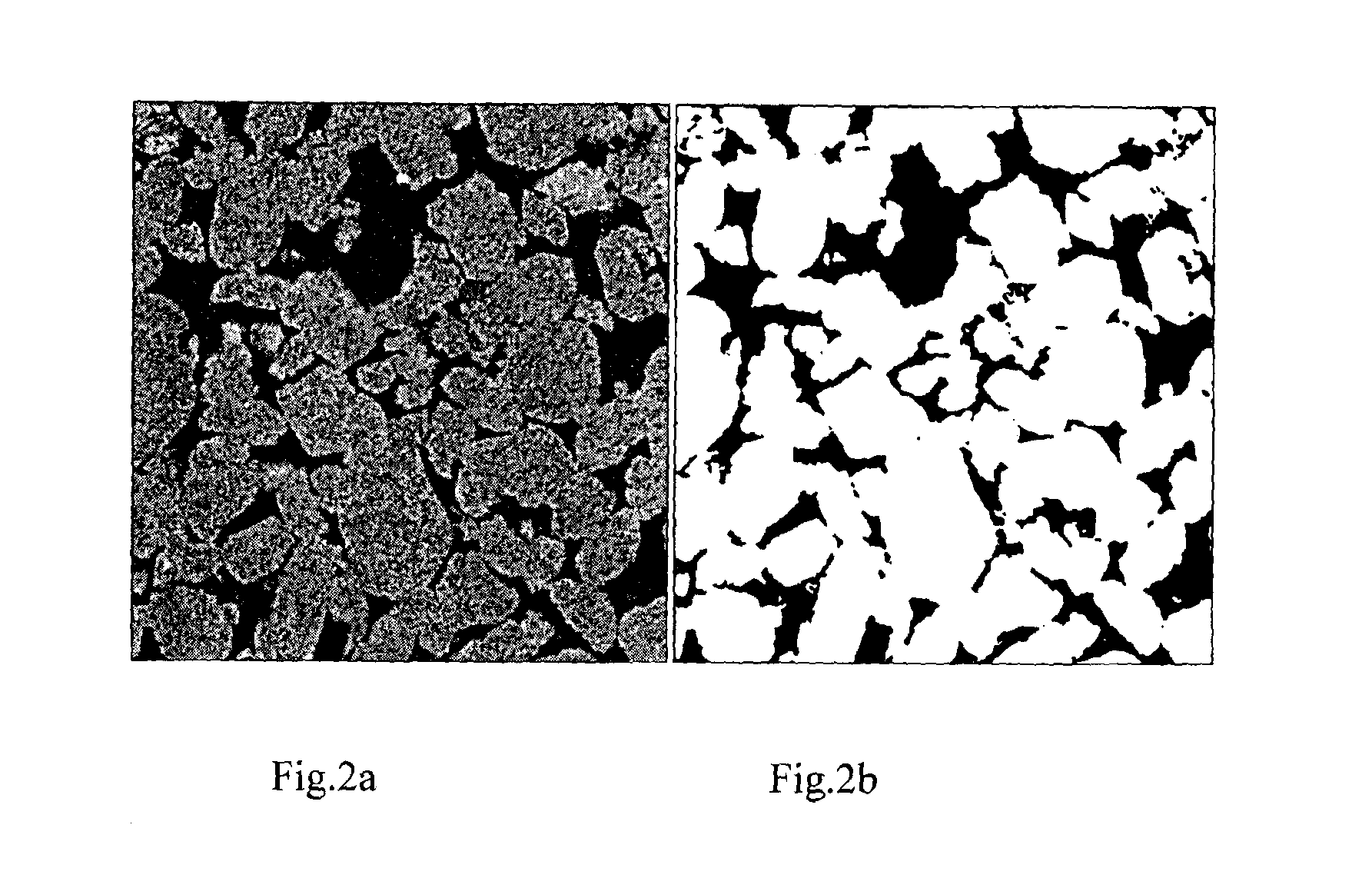

Method for building a 3D model of a rock sample

ActiveUS20150262417A1Image enhancementMaterial analysis using wave/particle radiationThree dimensional microstructureComputed tomography

A method for building a 3D model of a rock sample comprises performing X-ray micro / nanoCT scanning of a rock sample and obtaining its initial three-dimensional microstructure image in a gray scale. Then, an analysis of the obtained three-dimensional image of the rock sample is performed and a binarization method is selected in dependence of the image quality and properties of the rock sample. The selected binarization method is at least once applied to the obtained initial three-dimensional image of the sample. Obtained 3D binarized image represents a 3D model of the rock sample.

Owner:SCHLUMBERGER TECH CORP

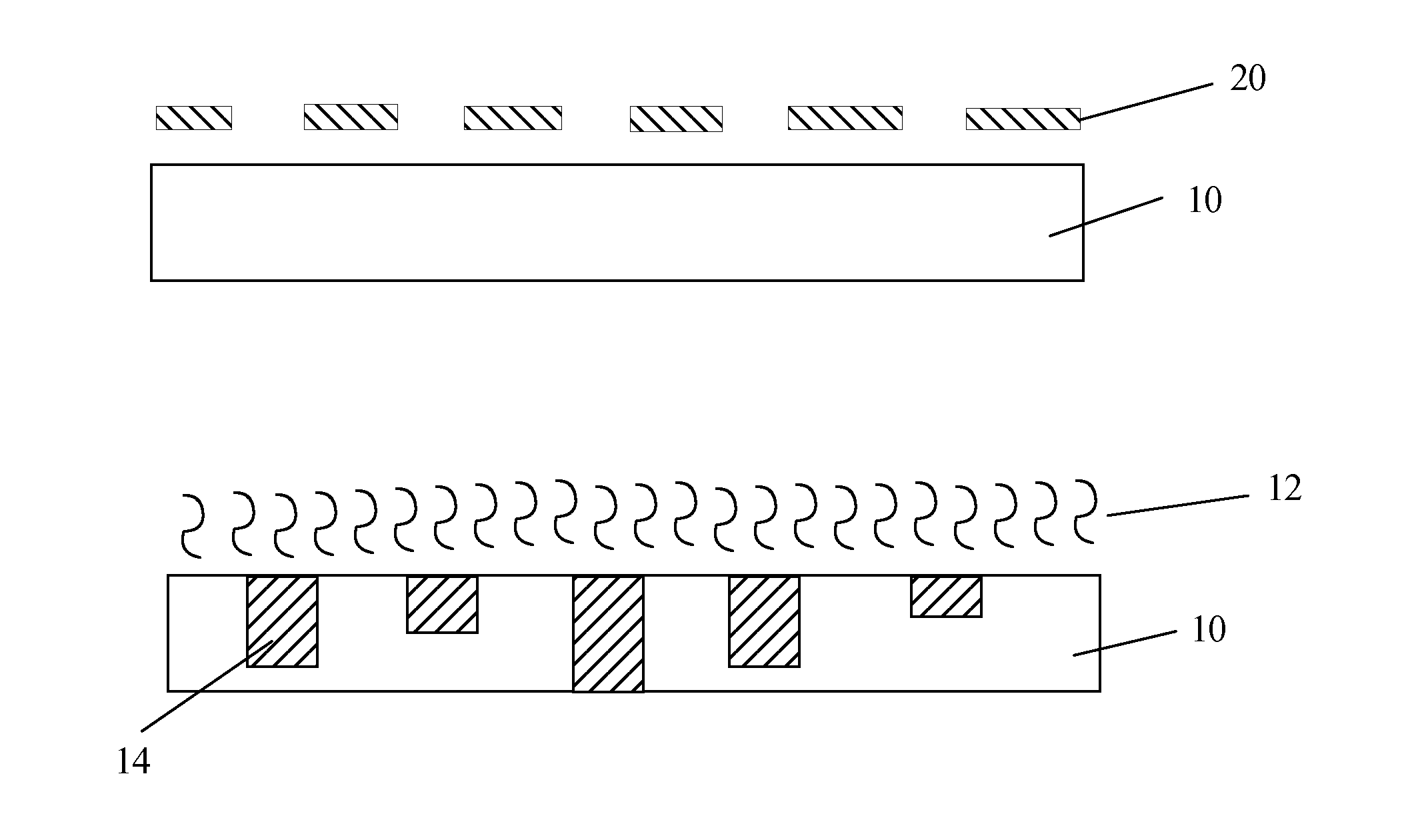

Method for manufacturing three-dimensional smooth curved surface microstructure based on SU-8 thick photo-resist

ActiveCN101950126AGood chemistryExcellent thermalDecorative surface effectsPhotomechanical apparatusResistCross-link

The invention discloses a method for manufacturing a three-dimensional smooth curved surface microstructure based on SU-8 thick photo-resist. The method is characterized in that the microstructure with smooth curved surface characteristic is manufactured by combining stamping technology of polydimethyl siloxane (PDMS) and the refluxing characteristic of non-crosslinked SU-8 photo-resist. The method comprises the following steps of: manufacturing an SU-8 master die by photo-etching technology; pouring PDMS to form a female die by using the master die; converting the PDMS female die into an SU-8 male die by using the stamping technology; stripping the PDMS die; and refluxing the SU-8 male die which is not subjected to exposure and cross-linking reaction under the environment of high temperature of between 55 and 120 DEG C to form the three-dimensional microstructure with smooth curved surface characteristic. Compared with the conventional gray scale mask technology, diverging light exposure technology and positive photo-resist refluxing method, the smooth curved surface microstructure provided by the invention has the characteristics of simple and convenient machining, low cost, stable structure, large structure curvature range and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

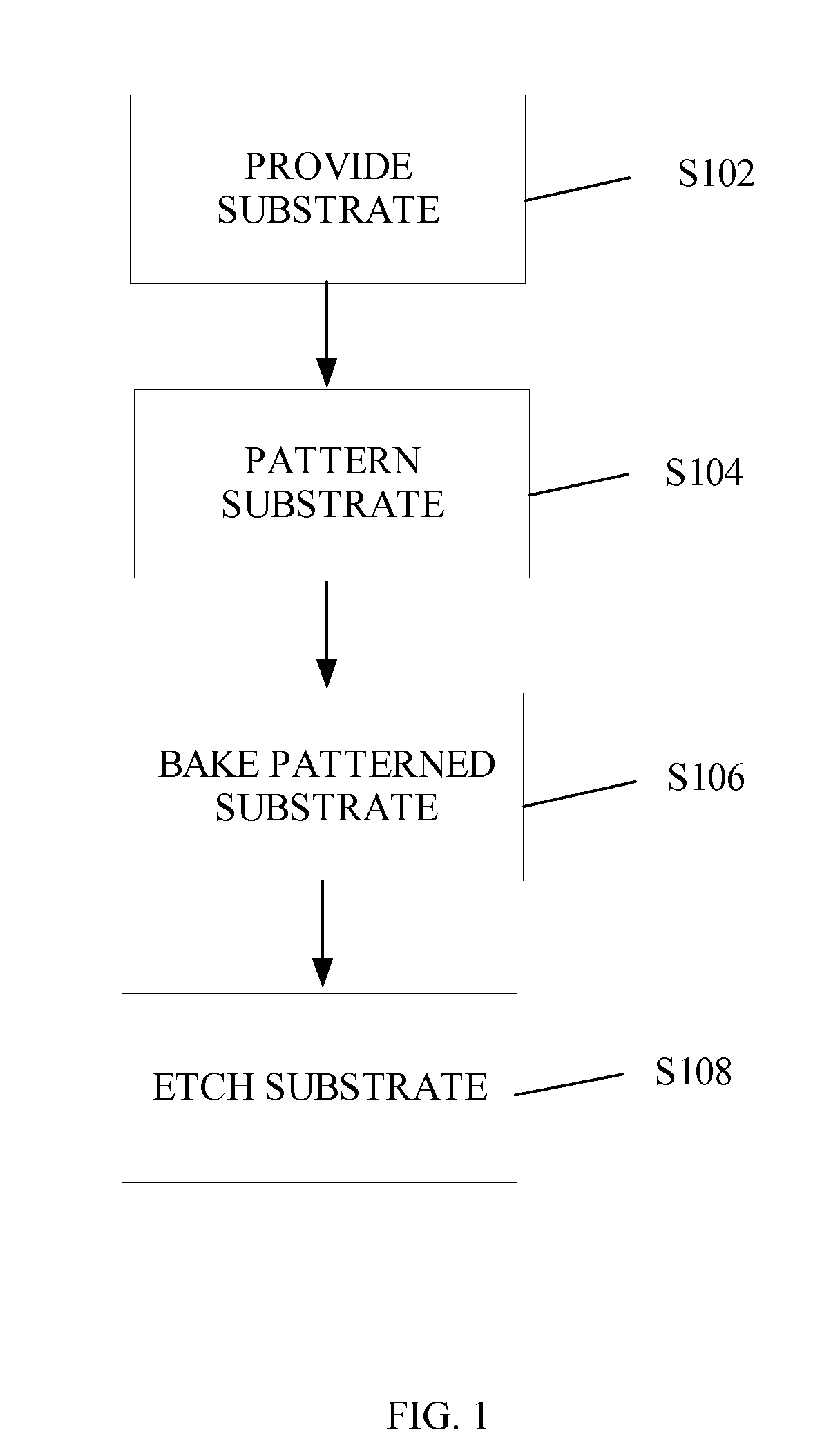

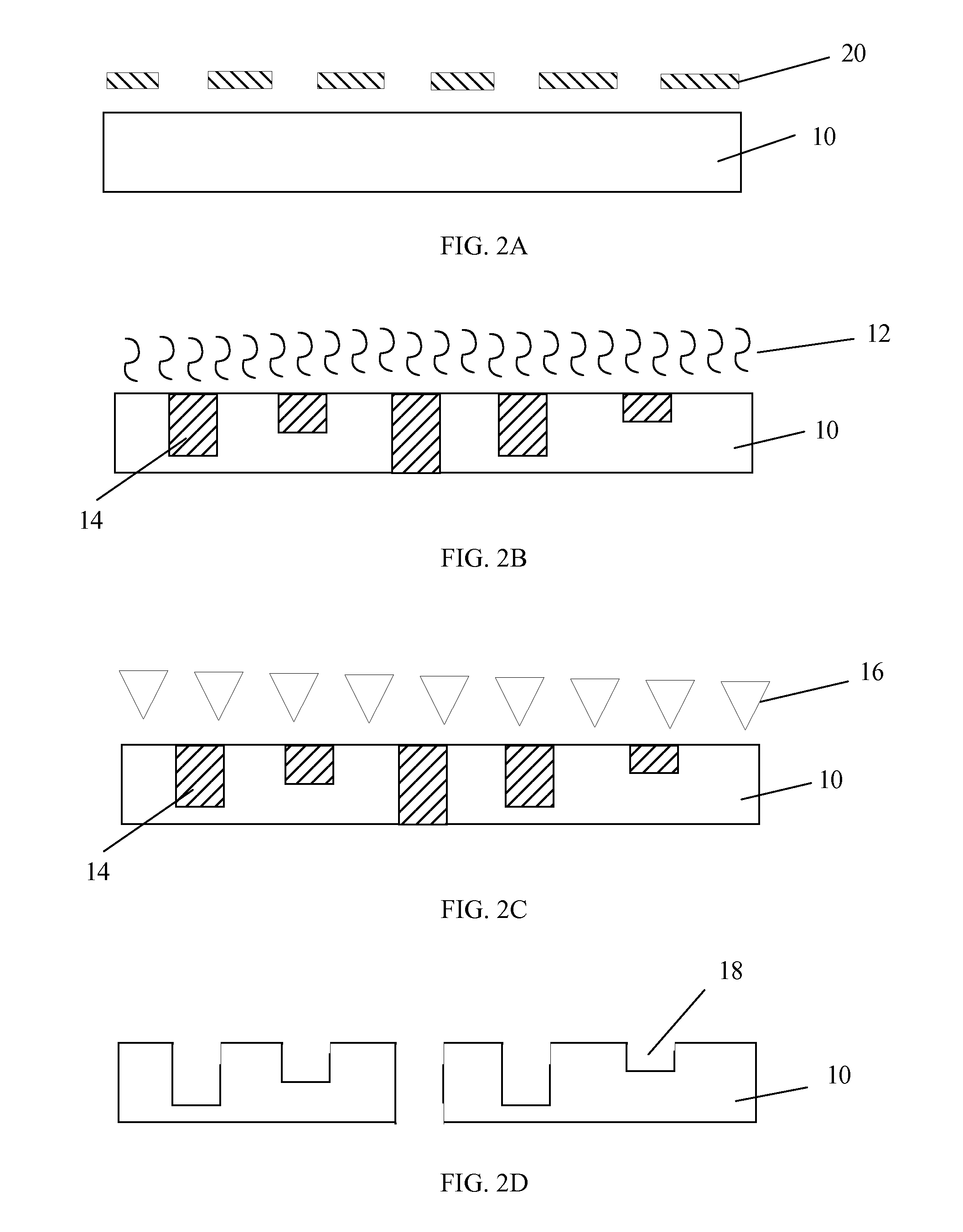

Grayscale lithography of photo definable glass

InactiveUS20140272688A1Increased autofluorescenceBiofuelsPhotomechanical exposure apparatusThree dimensional microstructureContinuous tone

A method for forming a three-dimensional microstructure includes providing a photosensitive glass substrate; exposing the photosensitive glass substrate to energy through a continuous tone, variable transmission photomask so as to form opaque portions in the photosensitive glass substrate, each of the opaque portions having one of a variety of depths extending through the entire thickness of the photosensitive glass substrate; and removing the opaque portions so as to form three-dimensional features in the photosensitive glass substrate.

Owner:PHOTRONICS INC

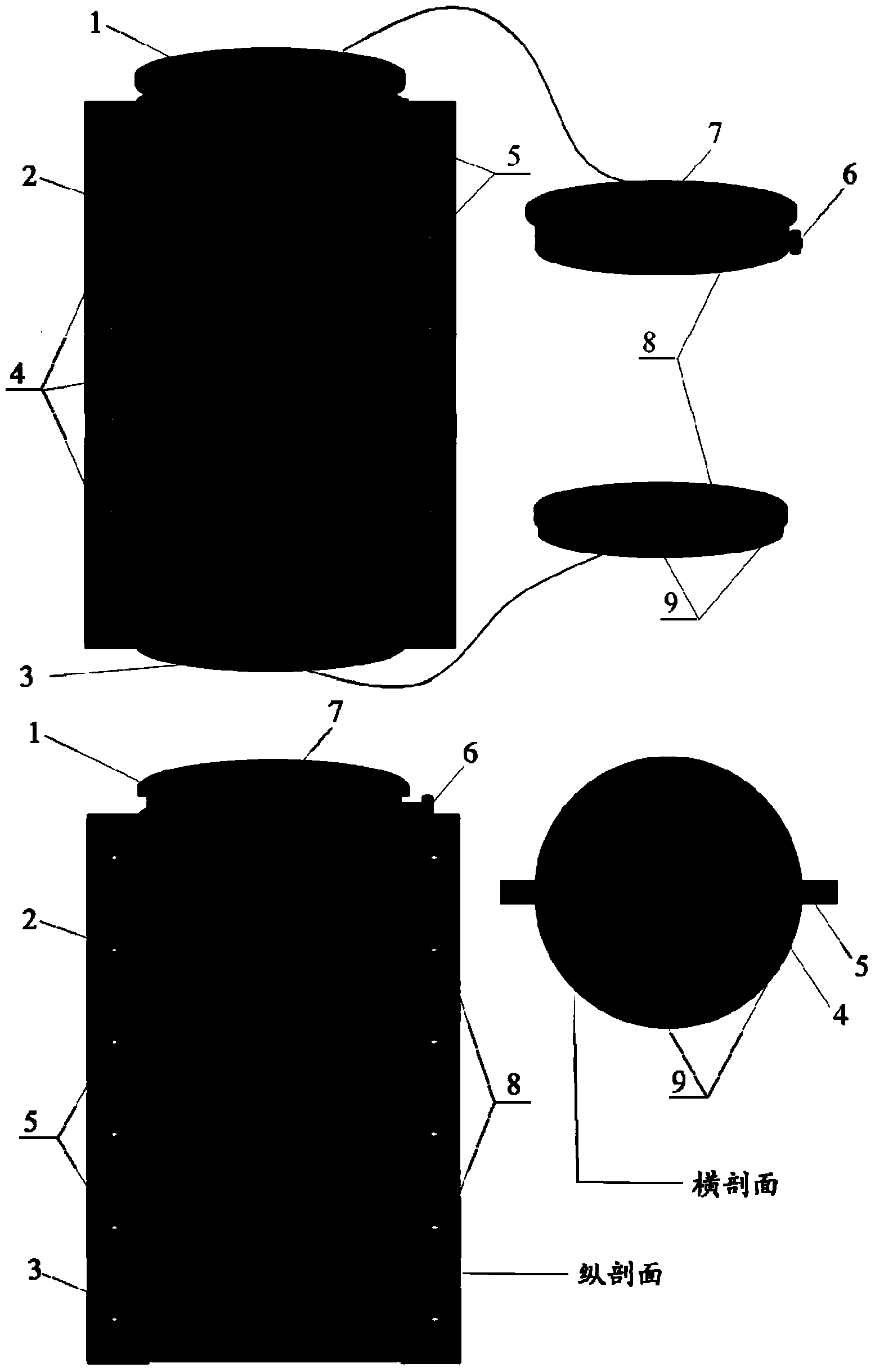

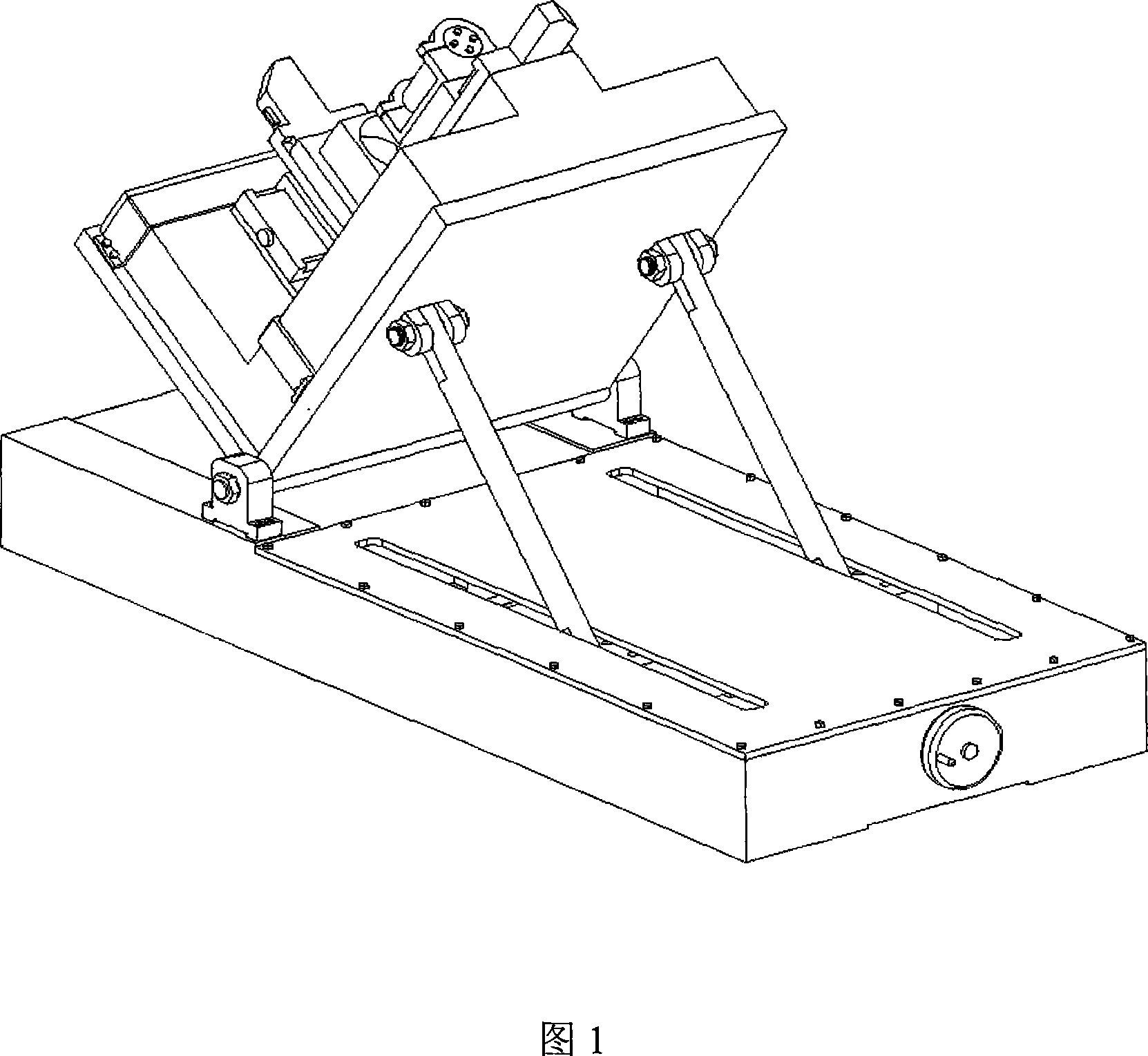

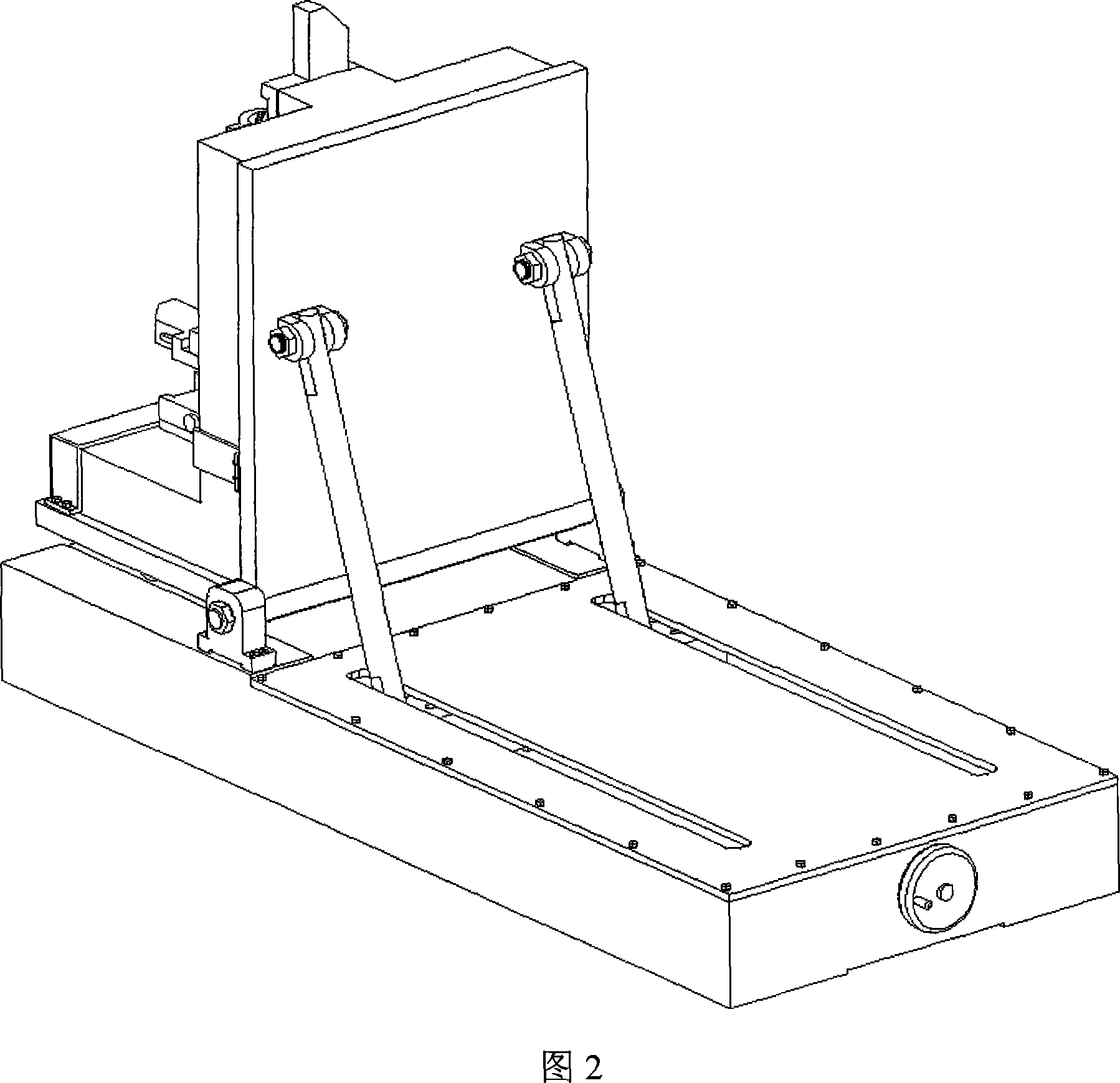

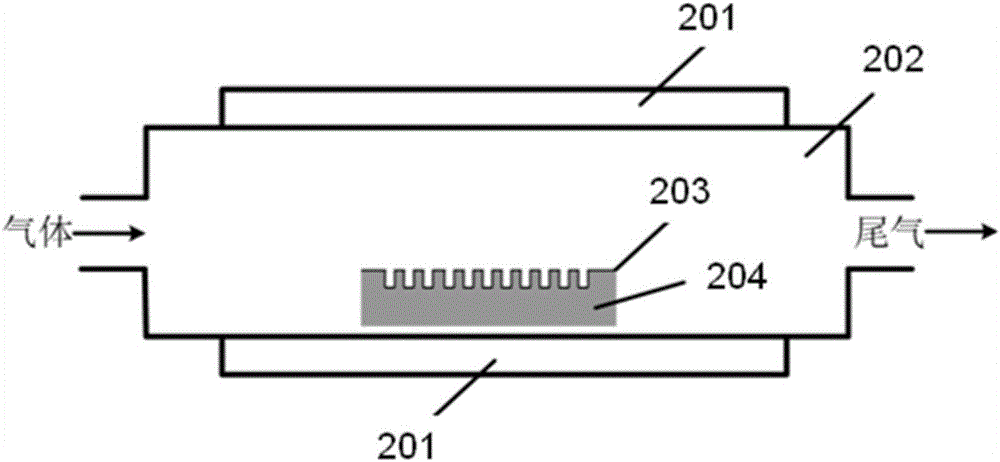

Random working angle precision electrolytic machining method and machine tool

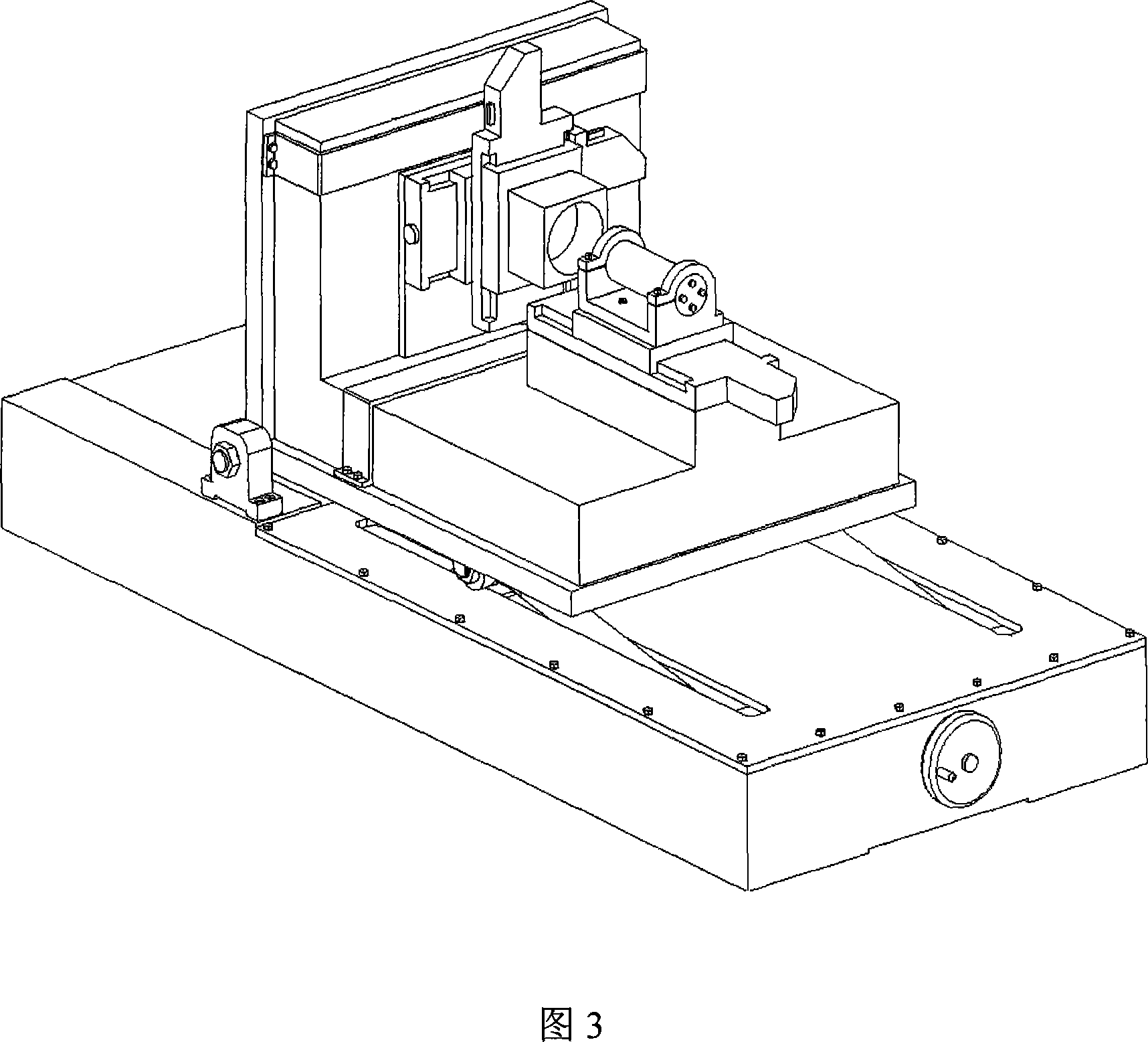

InactiveCN101185985AReduce volumeReduce weightLarge fixed membersElectrochemical machining apparatusElectricityThree dimensional microstructure

The invention relates to an arbitrary work-angle accurate ECM method and a machine tool, belonging to the technical field of ECM machining. The method makes use of an angle-regulating device to lead the main shaft of the machine tool to realize a vertical style, a horizontal style or any angle between the vertical and horizontal styles machining positions and to synthetically solve the draining of ECM outcome and the venting of gases generated in the ECM process. The machine tool comprises a machine tool base, a machine tool body (6), a work table which consists of an X work table (1), a Y work table (2) and a Z work table (5) and is arranged on the machine tool body (6), a work box (3) and a main shaft (13) provided with an electricity conducting device. The invention is characterized in that an angle regulating device (7) is arranged between the machine tool body (6) and the machine tool base. The design of the invention is modularized and miniaturized and foreign work tables are adopted. The whole machine tool has light weight and small volume and can carry out an angle regulation and an ECM for a three-dimensional microstructure with excellent operation space.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

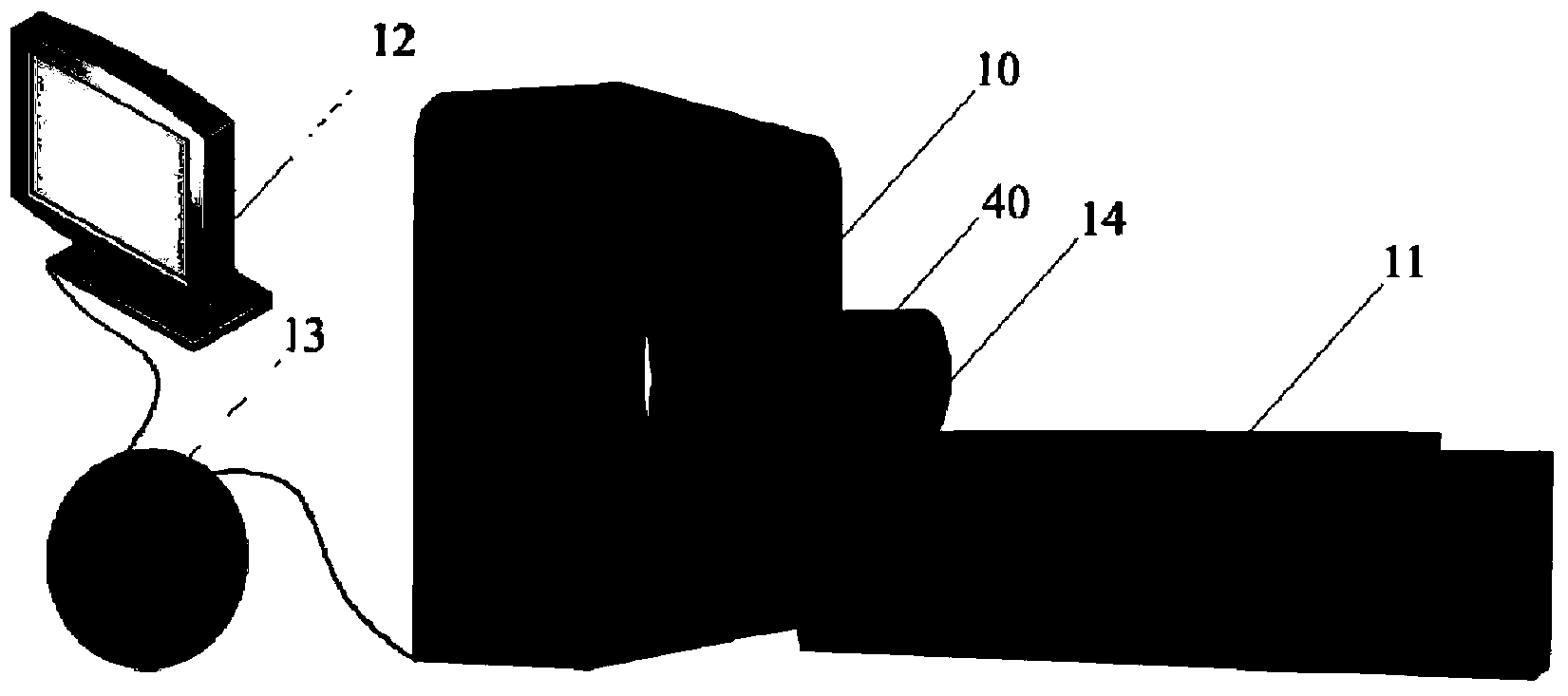

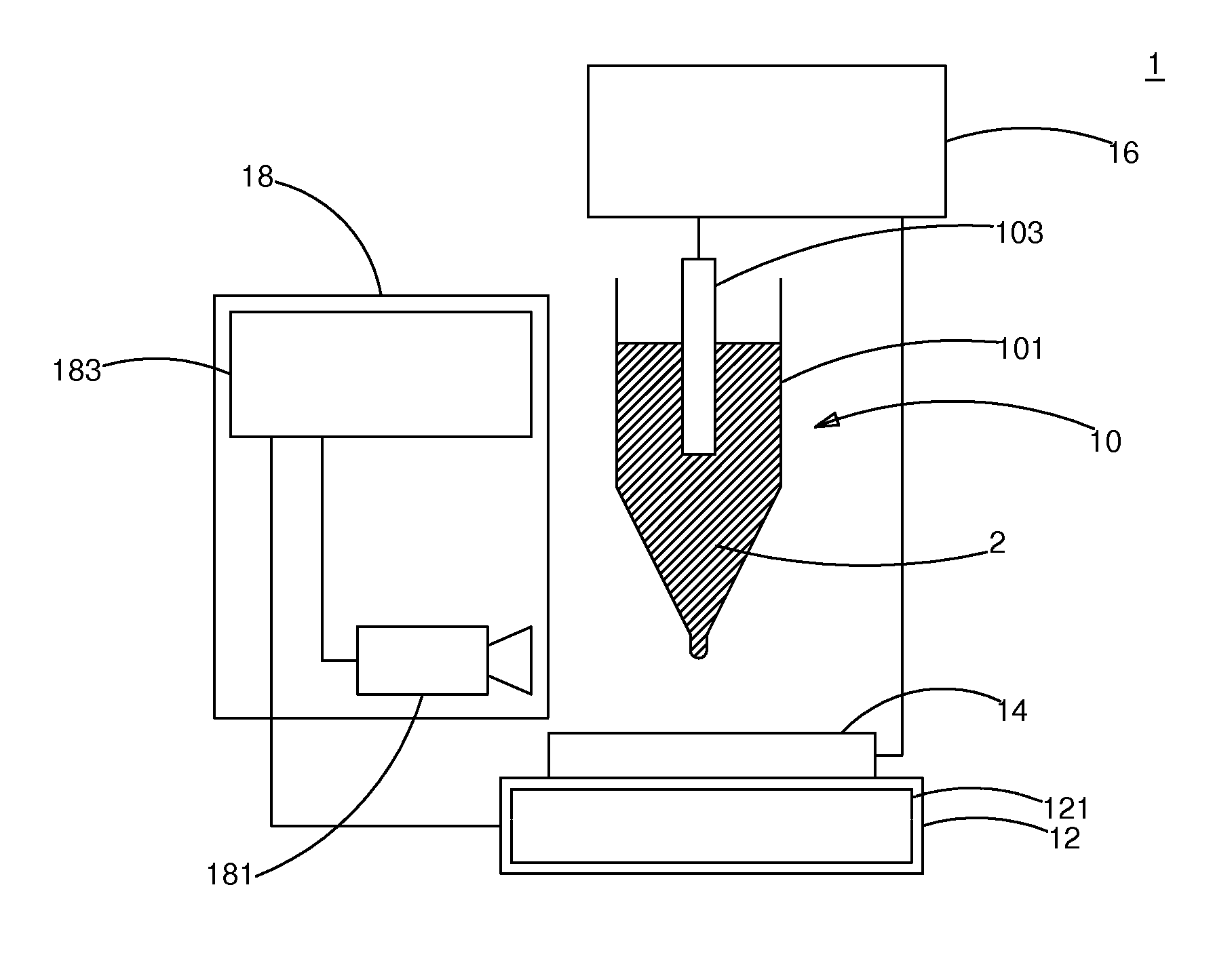

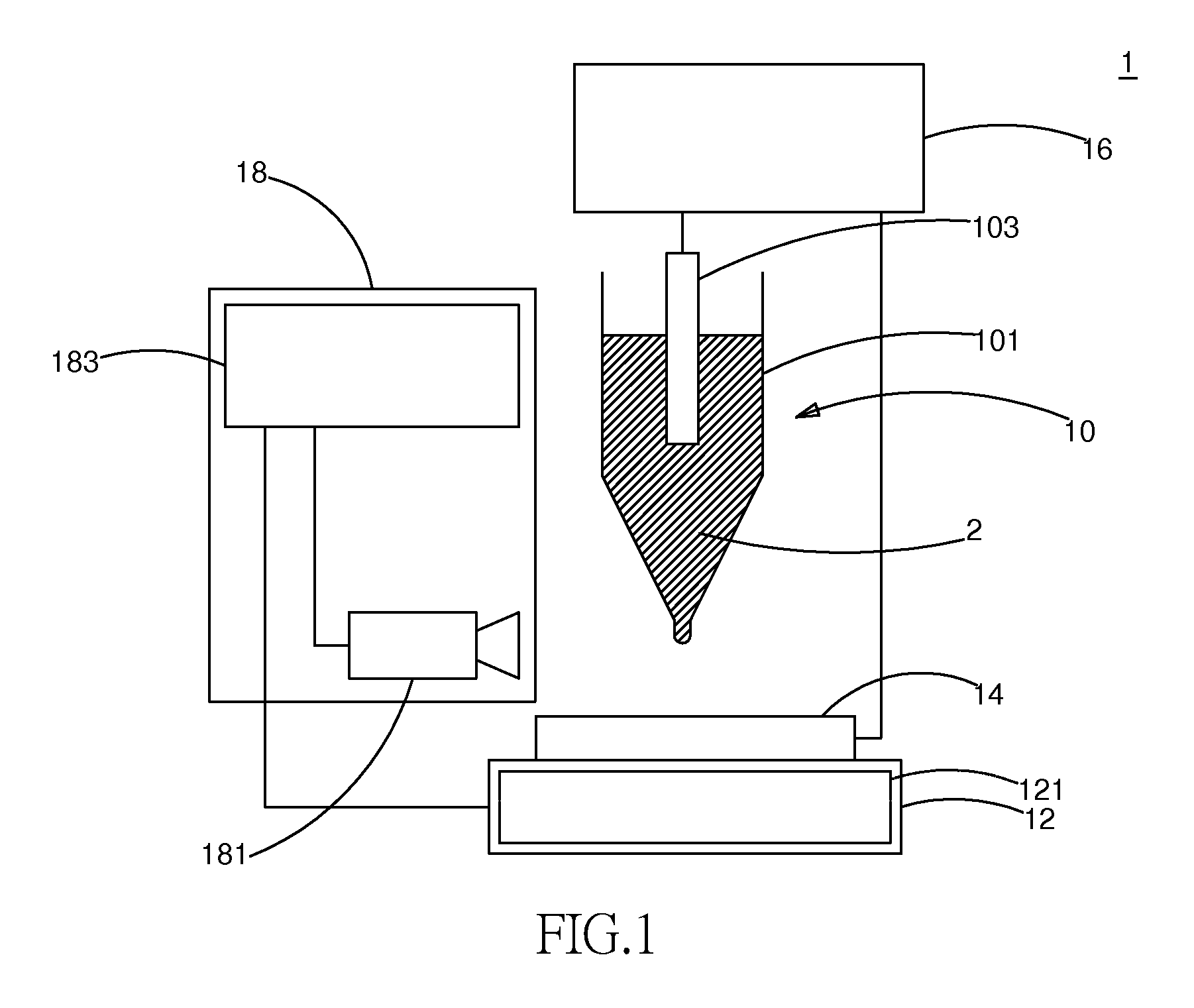

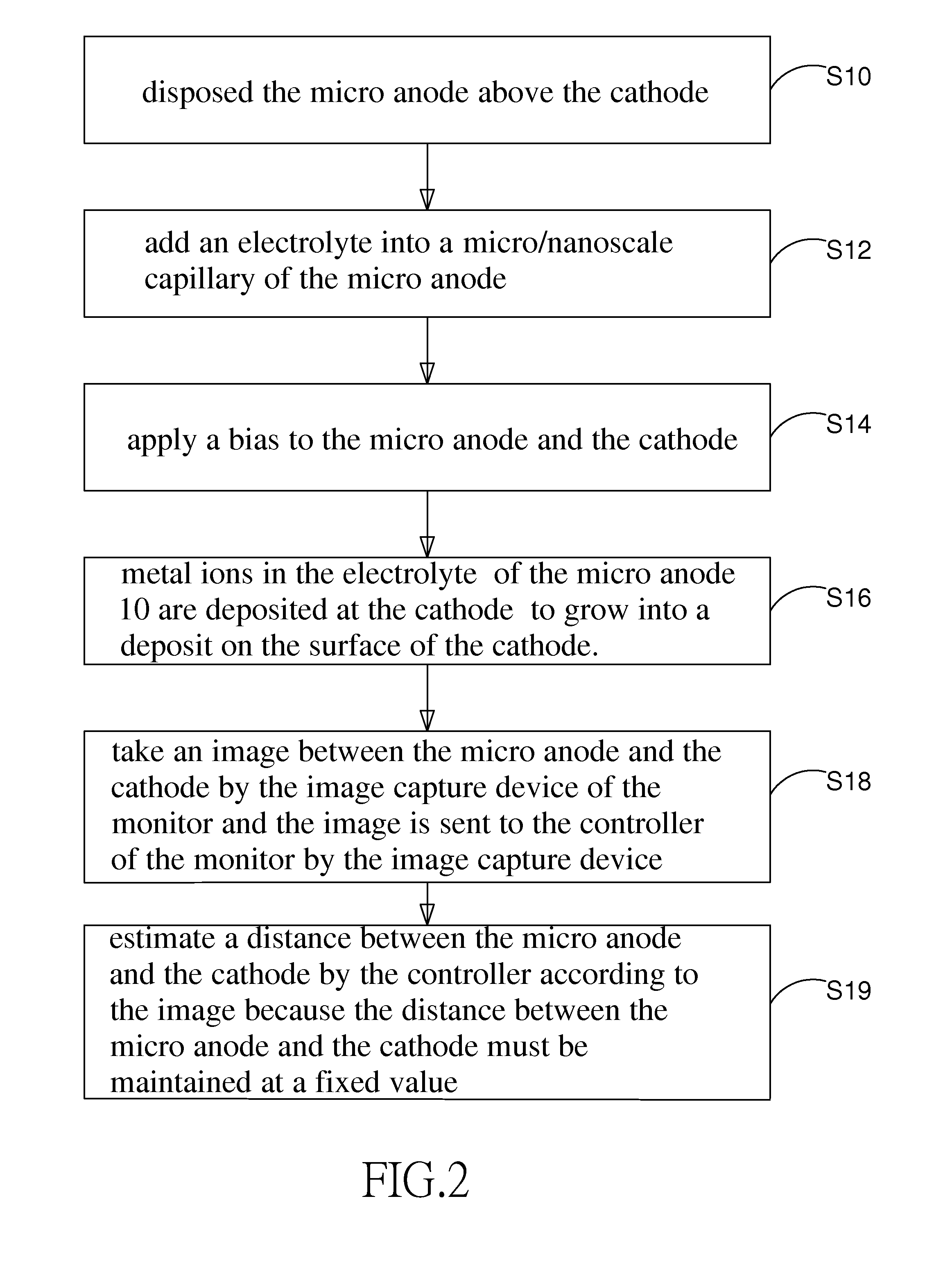

Continuous micro anode guided electroplating device and method thereof

InactiveUS20100300886A1Reduce pollutionUniform growthCellsElectrodesThree dimensional microstructureCapillary action

A continuous micro anode guided electroplating device and a method thereof are revealed. By real-time image monitoring and capillary action of the micro / nanoscale tube, a three-dimensional microstructure is deposited on a workpiece at the cathode. The deposit is growing smoothly under the real-time image monitoring. Moreover, the workpiece is not immersed in an electrolyte so that contaminations of the workpiece caused by electrolyte are reduced.

Owner:NAT CENT UNIV

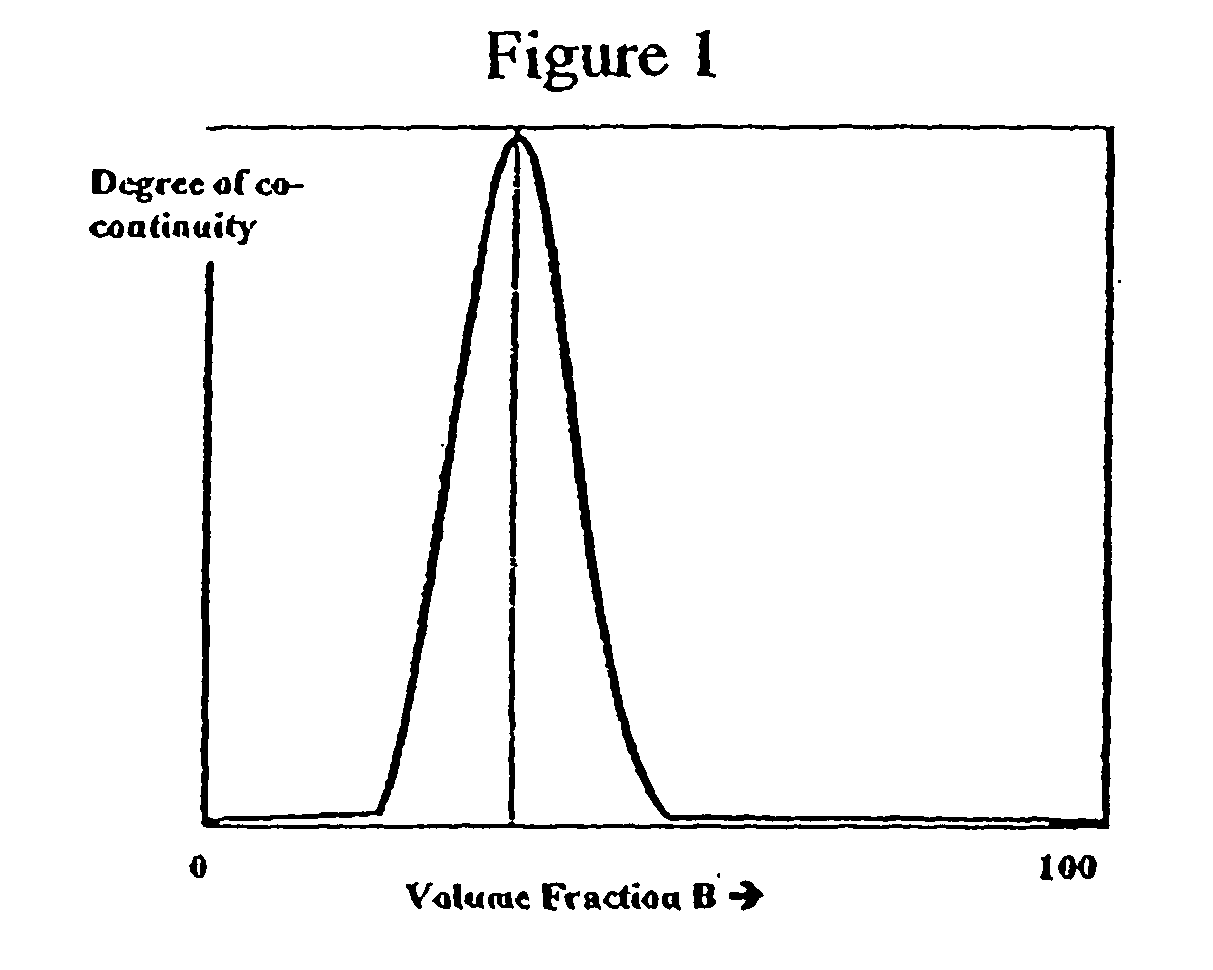

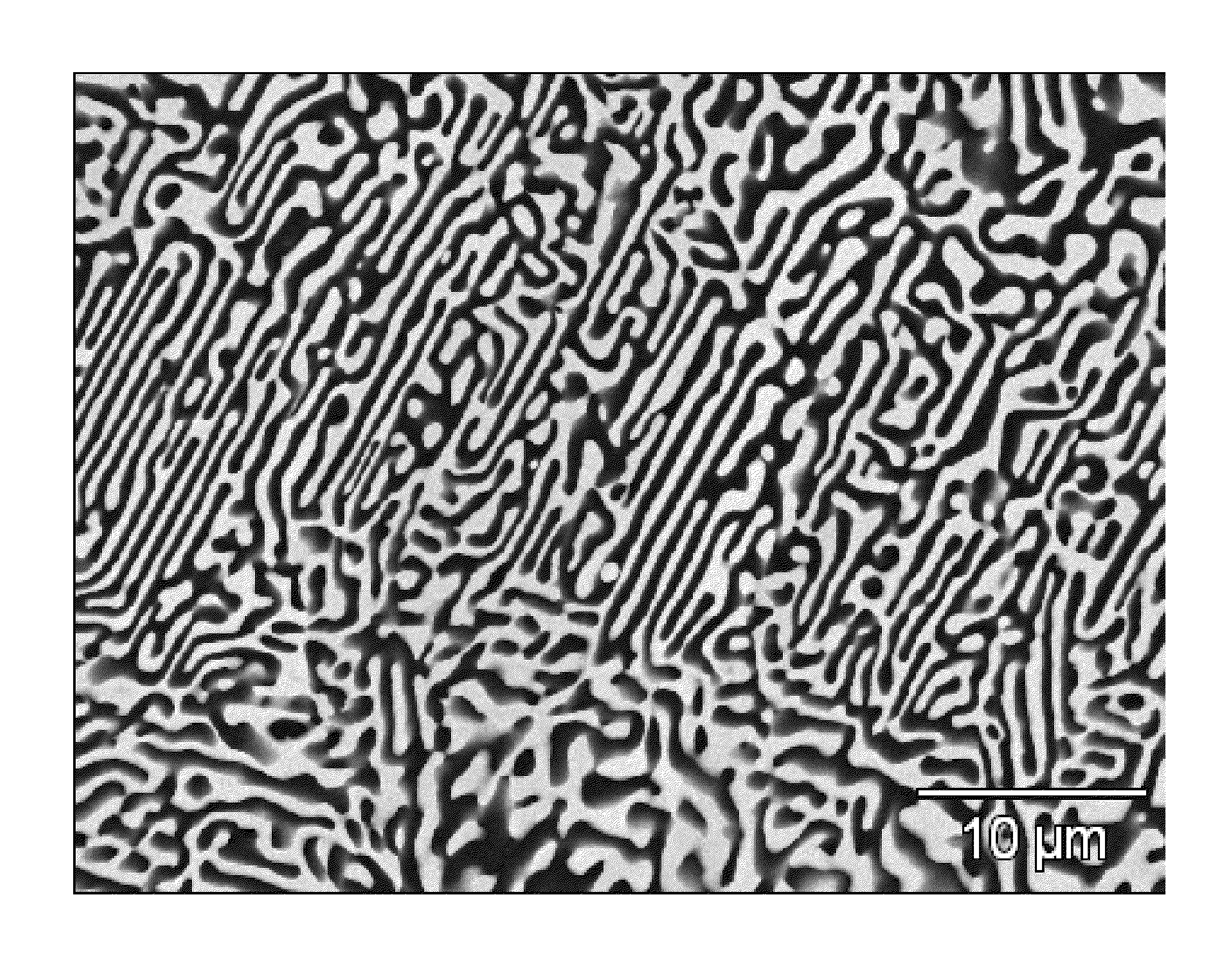

Co-continuous phase composite polymer blends for in-vivo and in-vitro biomedical applications

InactiveUS20060134157A1Promote tissue ingrowthPromote ingrowthLayered productsThin material handlingPolymer scienceThree dimensional microstructure

Tissue-compatible polymer composites characterized by a co-continuous, integrated multi-phase, three-dimensional microstructured network of two or more immiscible biocompatible polymers.

Owner:RUTGERS THE STATE UNIV

Microfluidic system and method for assembling and for subsequently cultivating, and subsequent analysis of complex cell arrangements

ActiveUS8268152B2Electrostatic separatorsSludge treatmentThree dimensional microstructureElectric field

A microfluidic system (12) for assembling and subsequently investigating complex cell arrangements has a three-dimensional microstructure (11) in which the cell culture is assembled, cultivated and investigated. At least two microchannel segments (16, 17) through which the microstructure (11) can be perfused from outside with a medium (21, 22) run in the microstructure (11), whereby the microchannel segments (16, 17) run at least in sections approximately parallel or equidistant to one another. The two microchannel segments (16, 17) are separated from one another by a wall structure (25) in which at least one aperture (26) connecting the two microchannel segments (16, 17) is provided. An electrode arrangement (27) is provided in or on the microstructure (11) in order to generate an inhomogeneous electric field (28) in the region of the at least one aperture (26). A cell arrangement is assembled in this microstructure (11) by supplying medium (21, 22) with cells (23, 24) for assembling the cell culture in the microstructure (11), with the inhomogeneous electric field (28) determined by the microstructure (11) bringing about the assembling of the cell arrangement from the supplied cells (23, 24).

Owner:NMI NATURWISSENSCHAFTLICHES & MEDIZINISCHES INST AN DER UNIV TUBINGEN

Preparation method of epoxy resin hollow micropin array

The invention relates to a preparation method of an epoxy resin hollow micropin array, belonging to the technical field of a microelectronic mechanical system. The preparation method adopts the methodof organically combining inclined rotation and the traditional photoetching to prepare an SU-8 three-dimensional microstructure, obtains a bracket inclined angle of 0 to 90 degrees by adjusting the height of the bracket, then places a motor on a horizontal base plate, drives a substrate adhered thereon to rotate freely by the motor, controls rotating speed by externally applying direct current voltage on the motor, fills polydimethylsiloxane into a mold with the SU-8 three-dimensional microstructure, obtains a hollow micropin array mold after demolding, refills polydimethylsiloxane after sputtering metallic chromium-copper on the hollow micropin array for compounding, obtains a hollow micropin array mold after demolding, fills epoxy resin on the mold, demolds after grinding the bottom part into polydimethylsiloxane, and obtains the epoxy resin hollow micropin array. The prepared micropin has smooth taper shape, has better tip end and has little injury to the skin when in work.

Owner:SHANGHAI JIAO TONG UNIV

Method for 3D mineral mapping of a rock sample

InactiveUS20140376685A1Saving informationRadiation/particle handlingEarth material testingThree dimensional microstructureGray level

The method for 3D mineral mapping of a rock sample comprises the steps of defining a total mineral content of a sample and calculating X-ray attenuation coefficients for the defined minerals. X-ray micro / nanoCT scanning of the sample is performed and its three-dimensional microstructure image in gray scale is obtained. Characteristic grayscale levels in the image corresponding to calculated X-ray attenuation coefficients and accordingly to the minerals are allocated and the 3D mineral map of the interior of the sample is provided.

Owner:SCHLUMBERGER TECH CORP

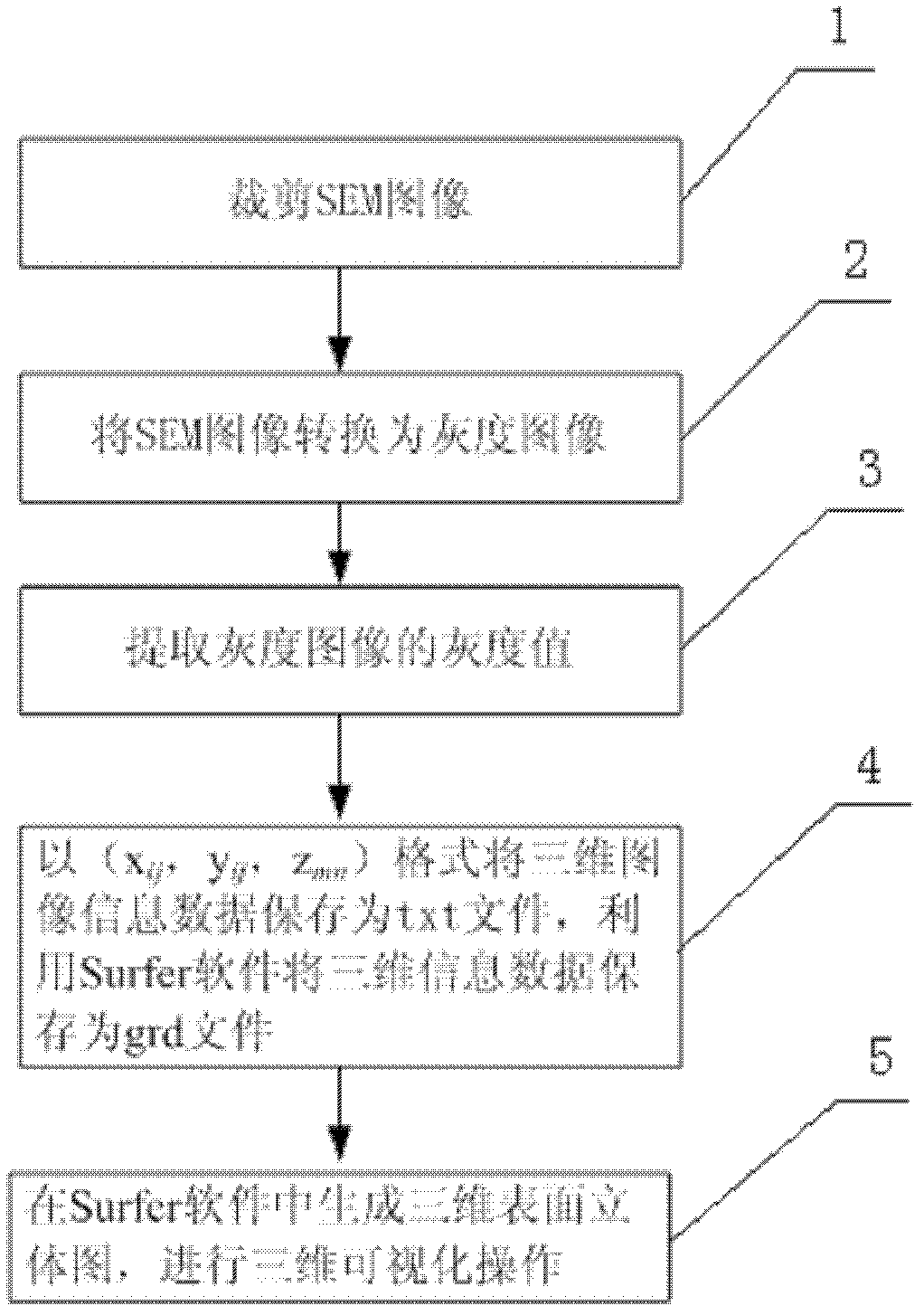

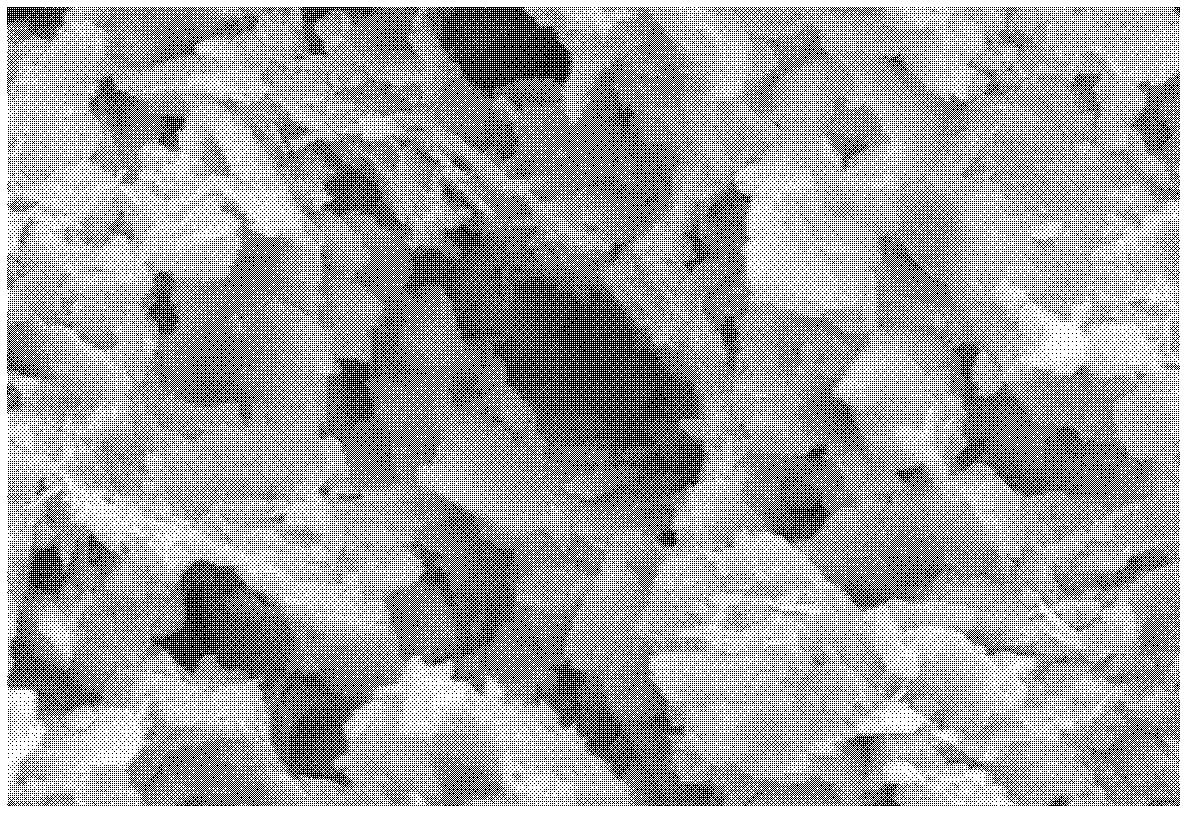

Method for implementing microstructure surface morphology three-dimensional visualization of soil

InactiveCN102254354AEasy to operateGood effect3D modellingThree dimensional microstructureScanning electron microscope

The invention discloses a method for implementing microstructure surface morphology three-dimensional visualization of soil. The method comprises the following steps of: (1) cutting an SEM (scanning electron microscope) image: removing SEM image attribute information by a cutting function of image processing software Photoshop; (2) converting the SEM image into a gray level image: obtaining the gray level image of the SEM image through mathematical software MATLAB; (3) extracting a gray value: obtaining corresponding gray value of each pixel of the SEM image through the MATLAB; (4) obtaining three-dimensional information data of the SEM image: sorting the three-dimensional image information according to certain format, and storing the three-dimensional image information as a txt file; and (5) implementing the three-dimensional visualization, specifically, importing the three-dimensional image information, generating a three-dimensional surface space pattern by graphics software Surfer, and performing visualized operations. The method is easy to perform and simple and convenient to operate, and sets the gray level to be the distance between a microstructure surface to an imaging surface so as to obtain the three-dimensional microstructure information of the soil and implement the establishment and the visualization of a three-dimensional model of the microstructure surface morphology of the soil.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

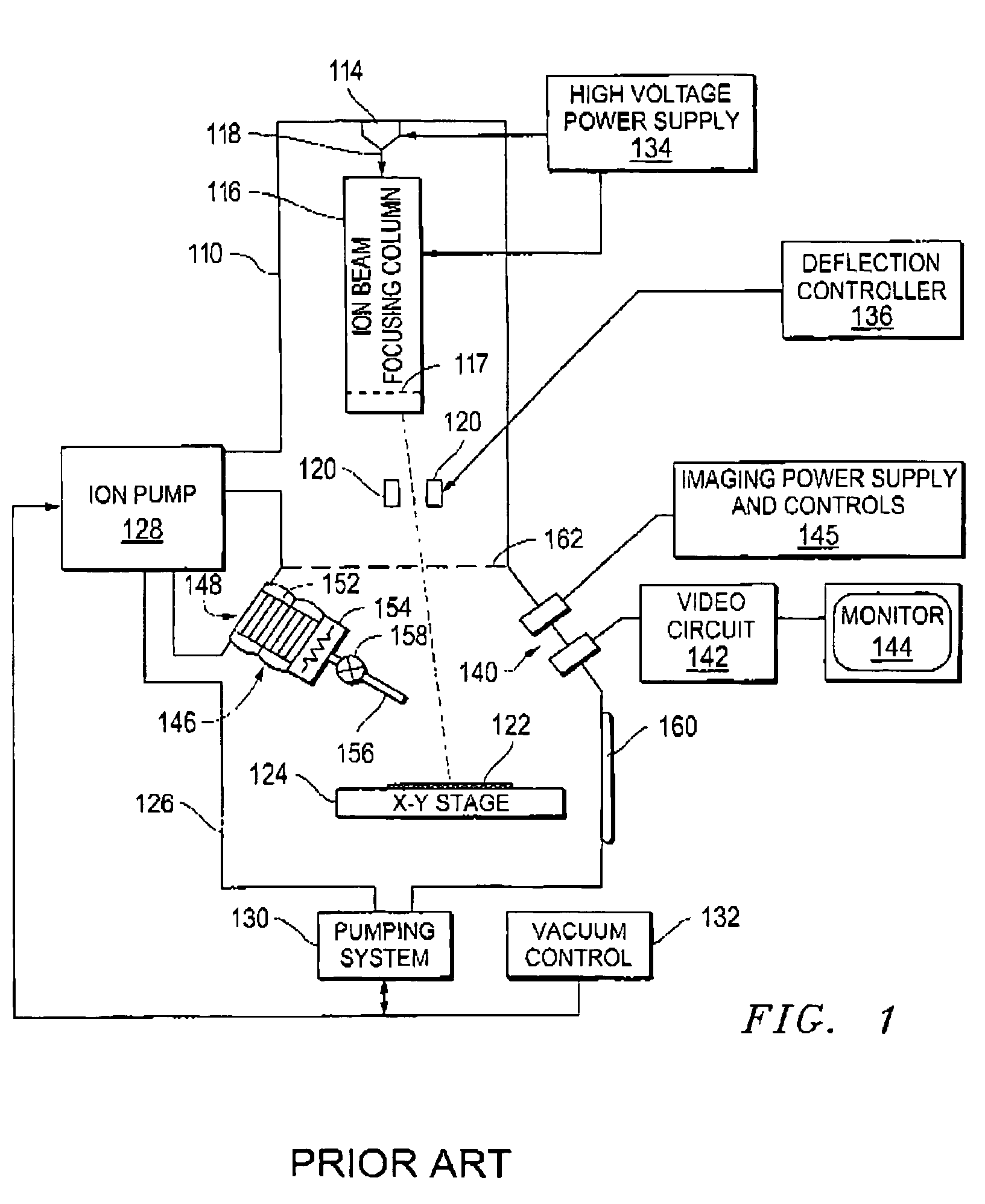

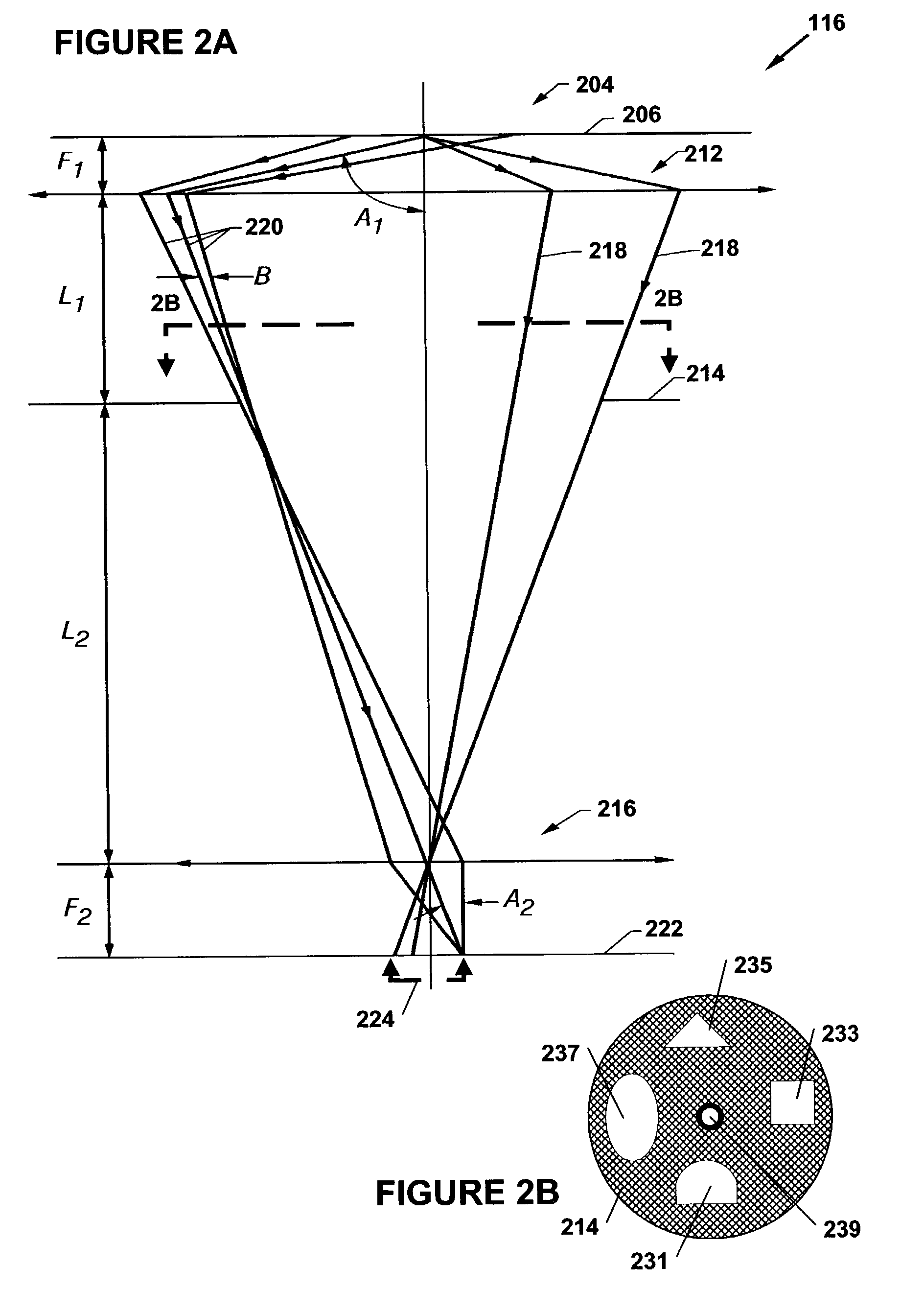

Fabrication of three dimensional structures

InactiveUS7160475B2NanoinformaticsVacuum evaporation coatingThree dimensional microstructureShaped beam

The present disclosure relates to a method for generating a three-dimensional microstructure in an object. In one embodiment, a method for fabricating a microscopic three-dimensional structure is provided. A work piece is provided that includes a target area at which the three-dimensional structure is to be fabricated. The target area has a plurality of virtual dwell points. A shaped beam is provided to project onto the work piece. The intersection of the shaped beam with the work piece defines a beam incidence region that has a desired shape. The beam incidence region is sufficiently large to encompass multiple ones of the virtual dwell points. The shaped beam is moved across the work piece such that different ones of the virtual dwell points come into it and leave it as the beam moves across the work piece thereby providing different doses to different ones of the virtual dwell points as the different dwell points remain in the beam incidence region for different lengths of time during the beam scan. In this way, a desired dose array of beam particles is applied onto the target area to form the three dimensional microstructure.

Owner:FEI CO

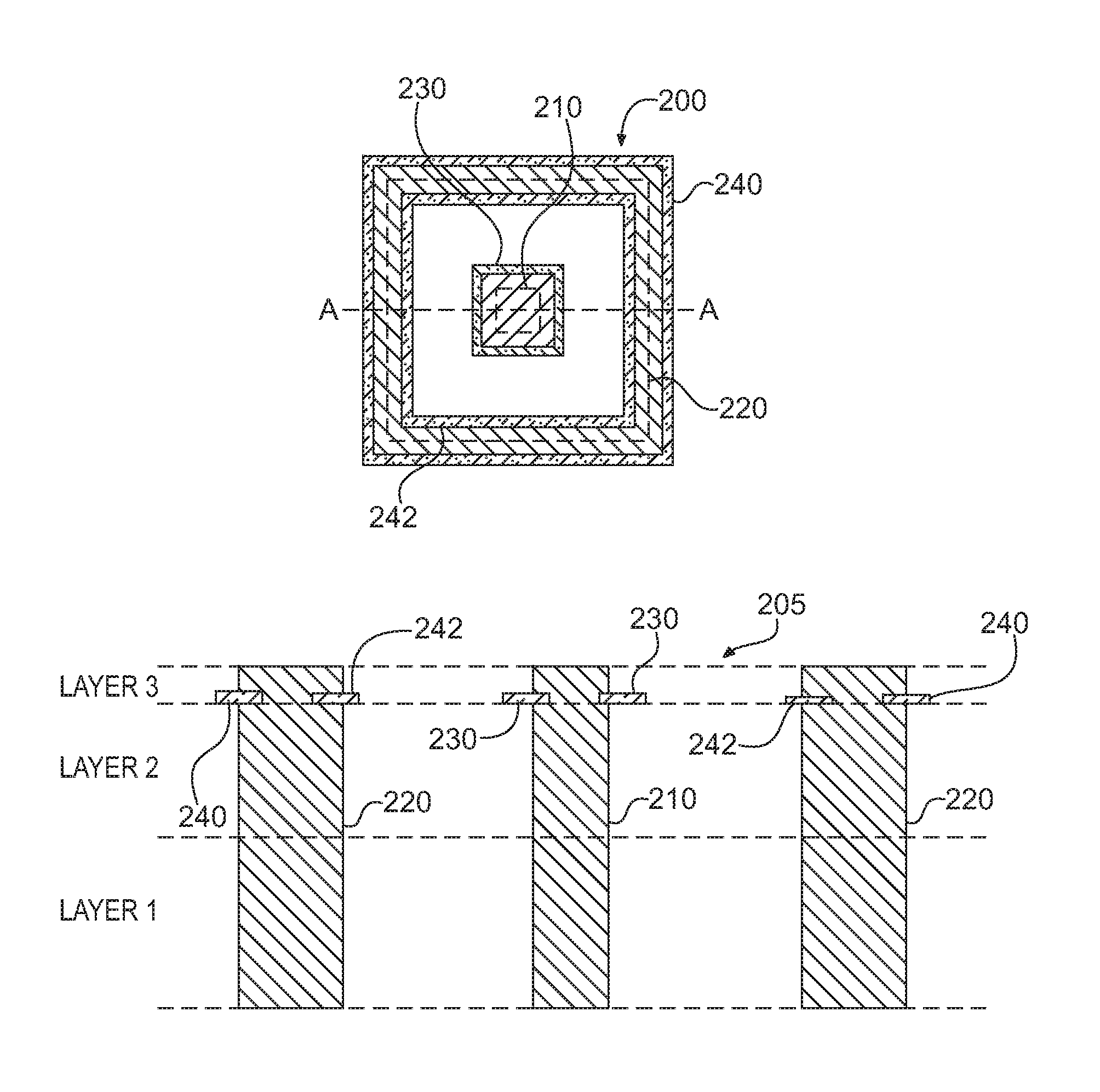

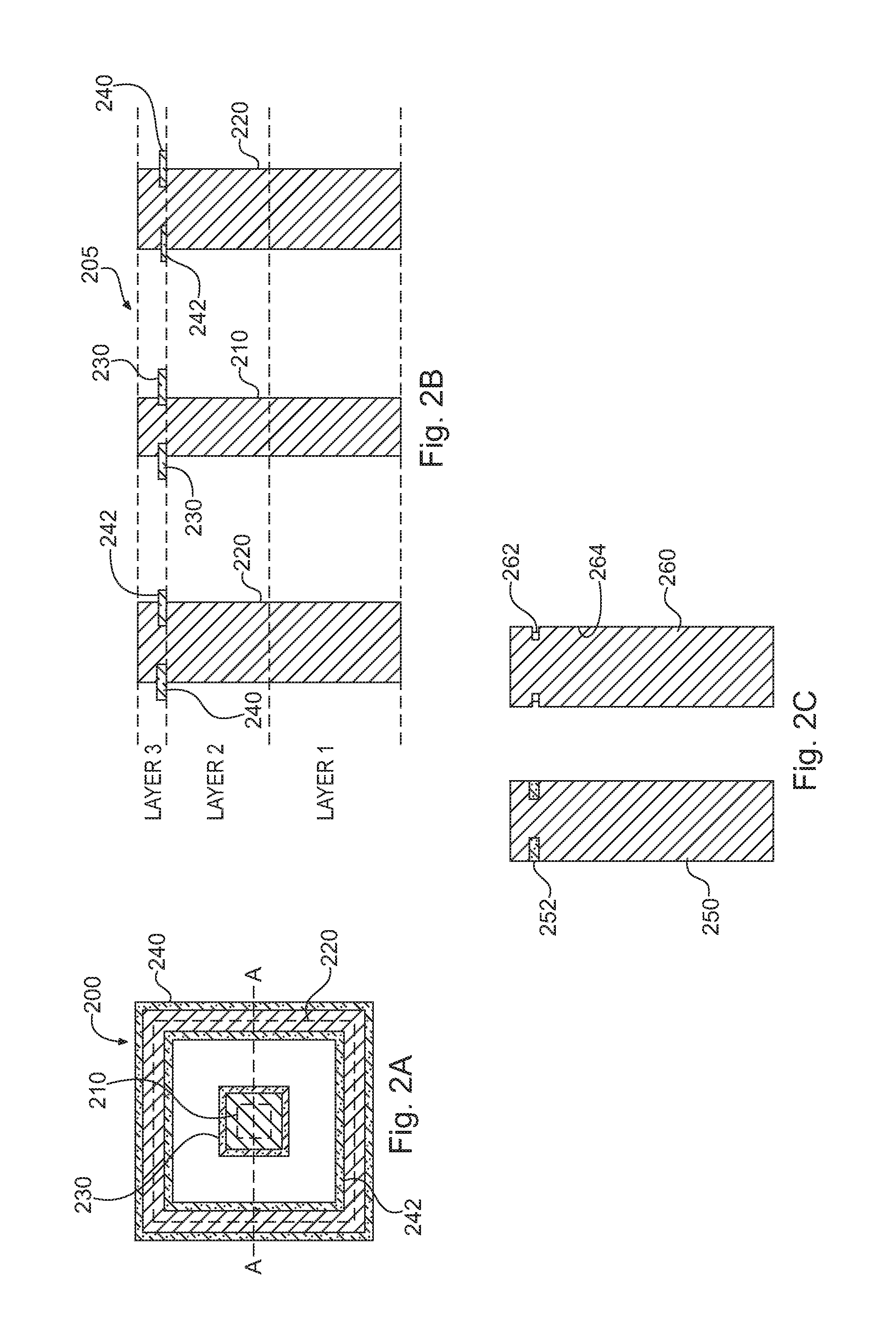

Devices and methods for solder flow control in three-dimensional microstructures

InactiveUS8866300B1Provide stabilityPrinted circuit assemblingElectrically conductive connectionsThree dimensional microstructureMetallurgy

Structures, materials, and methods to control the spread of a solder material or other flowable conductive material in electronic and / or electromagnetic devices are provided.

Owner:CUBIC CORPORATION

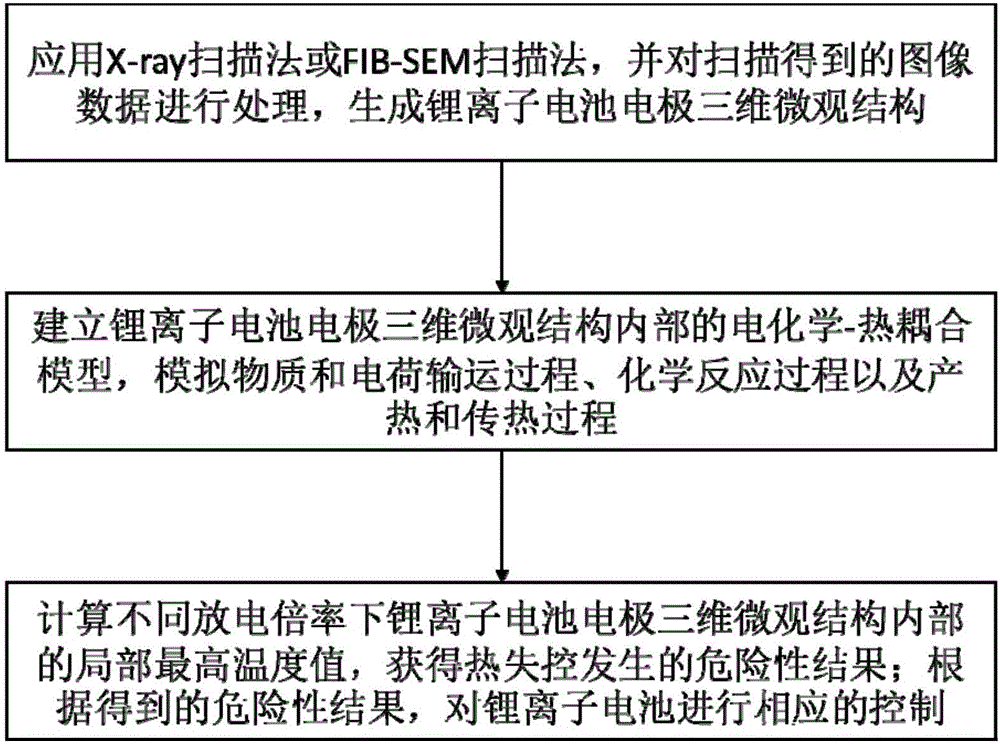

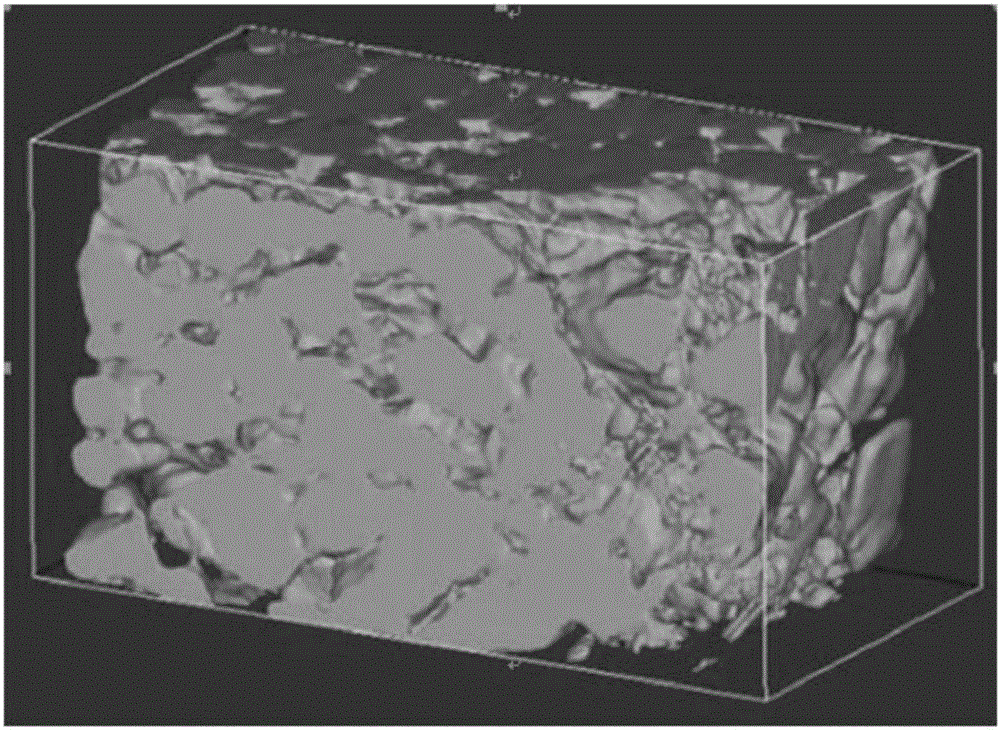

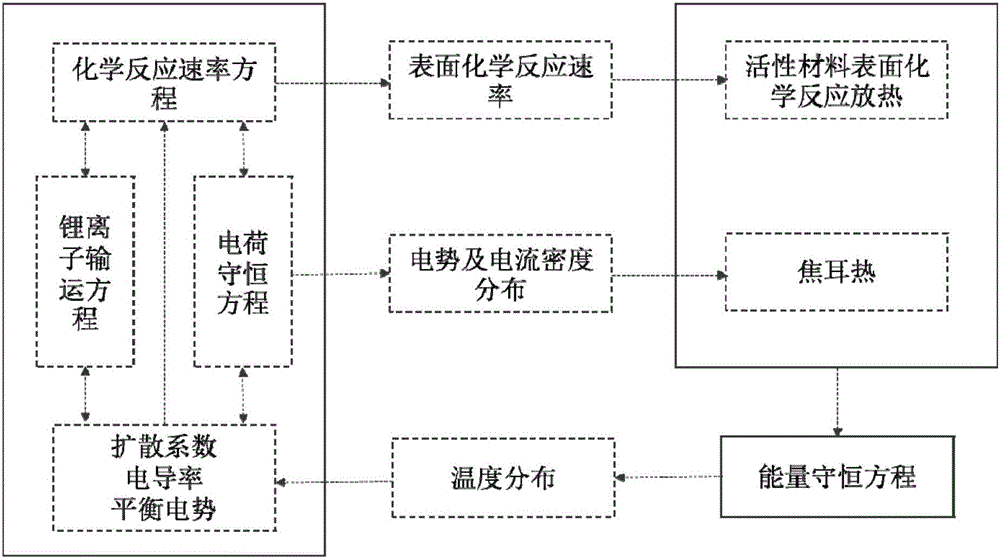

Method for controlling risks of lithium-ion battery thermal runaway

ActiveCN106816655AAnalyze, compare and control the danger of thermal runawayCells structural combinationVehicular energy storageThree dimensional microstructureChemical reaction

The invention relates to the technical field of batteries and discloses a method for controlling risks of lithium-ion battery thermal runaway. The method for controlling the risks of the lithium-ion battery thermal runaway includes the steps of firstly, using an X-ray scanning method or FIB-SEM scanning method, and processing image date obtained by scanning to generate a three-dimensional microstructure of an electrode of a lithium-ion battery; secondly, constructing an electrochemical-thermal coupling model in the microstructure for simulating a matter and charge transport process, a chemical reaction process and a thermal generation and transfer process; lastly, using the electrochemical-thermal coupling model to compute the highest local temperature in the microstructure under different discharging rates so as to obtain a risk result leading to the thermal runaway so as to control a lithium-ion battery correspondingly. The method for controlling the risks of the lithium-ion battery thermal runaway has the advantages that impacts of an electrode microstucture on matter transport, thermal generation and thermal transfer are taken into account, the risks of thermal runaway of lithium-ion batteries with different microstructures can be analyzed, compared and controlled, and the method plays an important guiding role in design of preventing the thermal runaway of the lithium-ion batteries.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

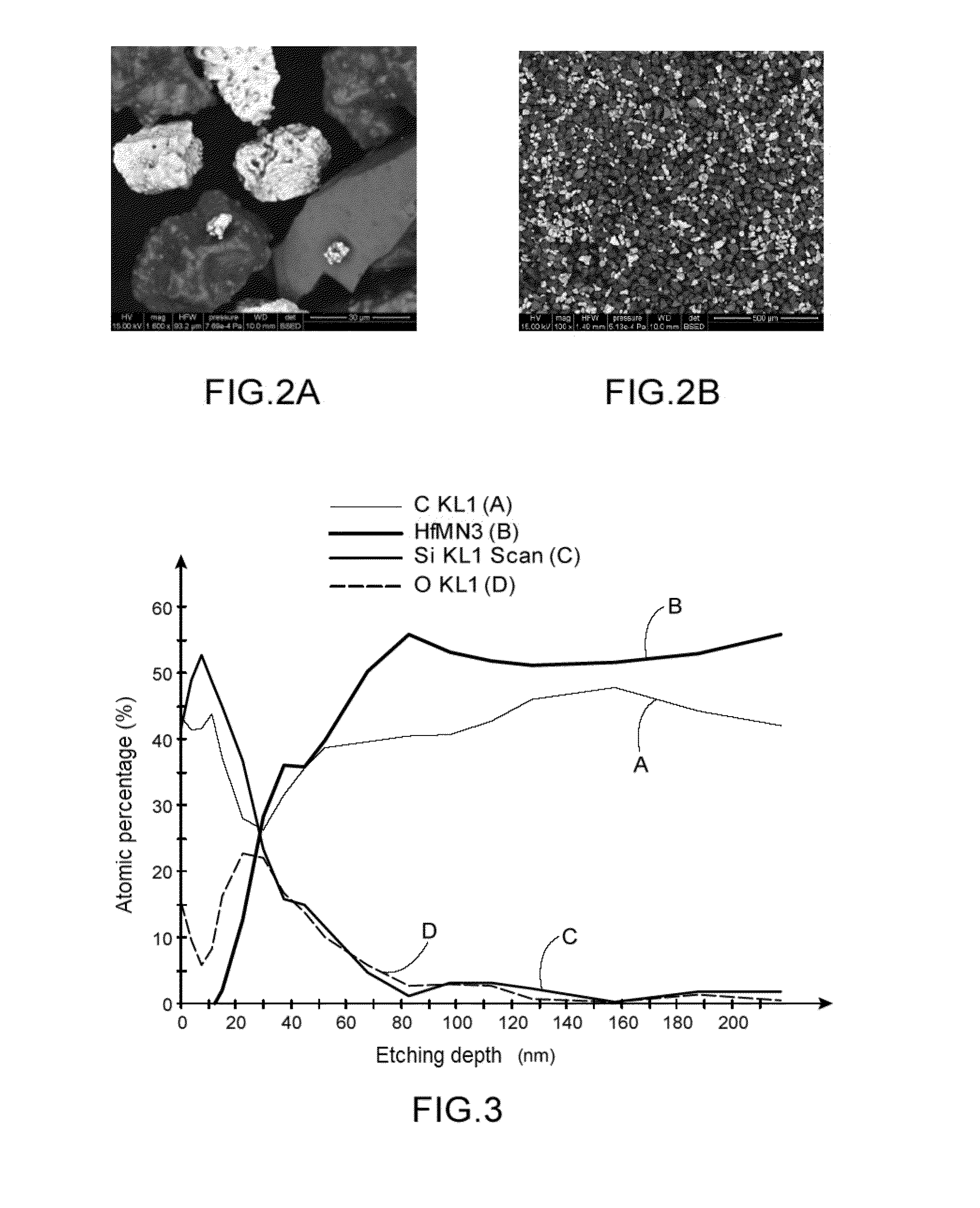

Process for coating a part with an oxidation-protective coating

ActiveUS20140004271A1Efficient oxidationEfficient use ofMolten spray coatingSpecial surfacesThree dimensional microstructureOxidation resistant

A method for preparing a protective coating against oxidation on at least one surface of at least one part made of at least one material capable of being oxidized, wherein the following successive steps are carried out:a) each of the particles of a powder made of a first ceramic selected from refractory ceramics and ceramics which resist oxidation, is coated with at least one layer selected from layers made of a refractory ceramic, layers made of a ceramic which resist oxidation, and layers made of a refractory metal, provided that the coating comprises at least one ceramic which resists oxidation, and at least one refractory ceramic or metal;b) the powder is deposited onto the surface to be coated of the part;c) sintering of the powder is achieved on the surface of the part by a Spark Plasma Sintering (SPS) Method;d) the part is cooled;e) the cooled part, coated on at least one of its surfaces with a protective refractory monolayer coating against oxidation, with a three-dimensional microstructure, is recovered.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Microfluidic system and method for assembling and for subsequently cultivating, and subsequent analysis of complex cell arrangements

The present invention provides an apparatus and a method to assemble organotypical tissues which can then be perfused and investigated under preferably physiological conditions. This is achieved by a microfluidic system for assembling and subsequently cultivating complex cell arrangements, comprising: a three-dimensional microstructure in which the cell arrangement is assembled and cultivated, at least two microchannel segments running in the microstructure and defining a flow direction, through which microchannel segments the microstructure can be perfused from outside with a medium, whereby the microchannel segments run approximately parallel or equidistant to one another at least in sections, a wall structure which separates the at least two microchannel segments and in which at least one aperture connecting the at least two microchannel segments is provided, and an electrode arrangement provided in or on the microstructure in order to generate an inhomogeneous electric field in the region of the at least one aperture.

Owner:NMI NATURWISSENSCHAFTLICHES & MEDIZINISCHES INST AN DER UNIV TUBINGEN

Multiphase eutectic ceramic coatings

Owner:LOCKHEED MARTIN CORP

Angular spectrum scanning quasi-confocal annular microstructure measuring device and method of array illumination

InactiveCN103411557AConvenient lighting angleAvoid lightUsing optical meansMicroscopesThree dimensional microstructureBeam splitter

The invention discloses an angular spectrum scanning quasi-confocal annular microstructure measuring device and method of array illumination, and belongs to the field of ultra-precision three-dimensional microstructure surface morphology measurement. The device is designed to be provided with an angular spectrum scanning illumination light path; after sequentially passing through an imaging lens, a beam splitter prism and a microscope objective, beams emitted from a concentric annulus light source are shone onto the surface of a circularly-symmetrical microstructure sample to be measured in parallel, and different annular rings of the concentric annulus light source correspond to different angular spectra for illumination. According to the method, tomographic images of all the pixels under scanning illumination of different angular spectra are acquired first, then, on the basis of the confocal three-dimensional measurement principle, the axial coordinate of each pixel is judged, and finally the three-dimensional morphology of the microstructure sample to be measured is obtained in a fitting mode. Due to the design, an optimum illumination angle can be found for every part of the circularly-symmetrical microstructure sample to be measured, and the device and method avoid the problem that some areas can not be illuminated or complex reflection occurs to the areas, wherein the problem is caused by bumps of the surface profile of the circularly-symmetrical microstructure sample to be measured. Detection signal strength is promoted, background noise is lowered, and measurement precision is improved.

Owner:HARBIN INST OF TECH

Conformal graphene-based capacitive pressure sensor and preparation method thereof

InactiveCN106370324ASimple structureIncrease contactForce measurementFluid pressure measurement using capacitance variationElastomerCapacitive pressure sensor

The present invention discloses a conformal graphene-based capacitive pressure sensor and a preparation method thereof. The sensor is of a flat plate structure and comprises three main layers, namely, a graphene electrode layer, a dielectric layer and a graphene electrode layer which are sequentially distributed from top to bottom, wherein one or both of the upper graphene electrode layer and the low graphene electrode layer are conformal graphene transparent conductive films. The conformal graphene transparent conductive films are obtained by transferring conformal graphene on a metal surface with three-dimensional microstructures to the surface of a polymer elastomer through using a conformal transfer method. The conformal graphene can be both an electrode layer and a pressure sensing layer; and the three-dimensional microstructures on the surface of the conformal graphene are used to sense local deformation caused by touch pressure. With the microstructures adopted, the contacts of the capacitive pressure sensor can be increased, and the pressure sensitivity of the capacitive pressure sensor can be improved. A lot of pores exist between the three-dimensional microstructures, and therefore, the extrusion space of the elastomer can be increased, and a pressure test range can be extended. The conformal graphene-based capacitive pressure sensor has the advantages of simple structure, low cost, transparency, flexibility and easiness in processing.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com