Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "X-ray lithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

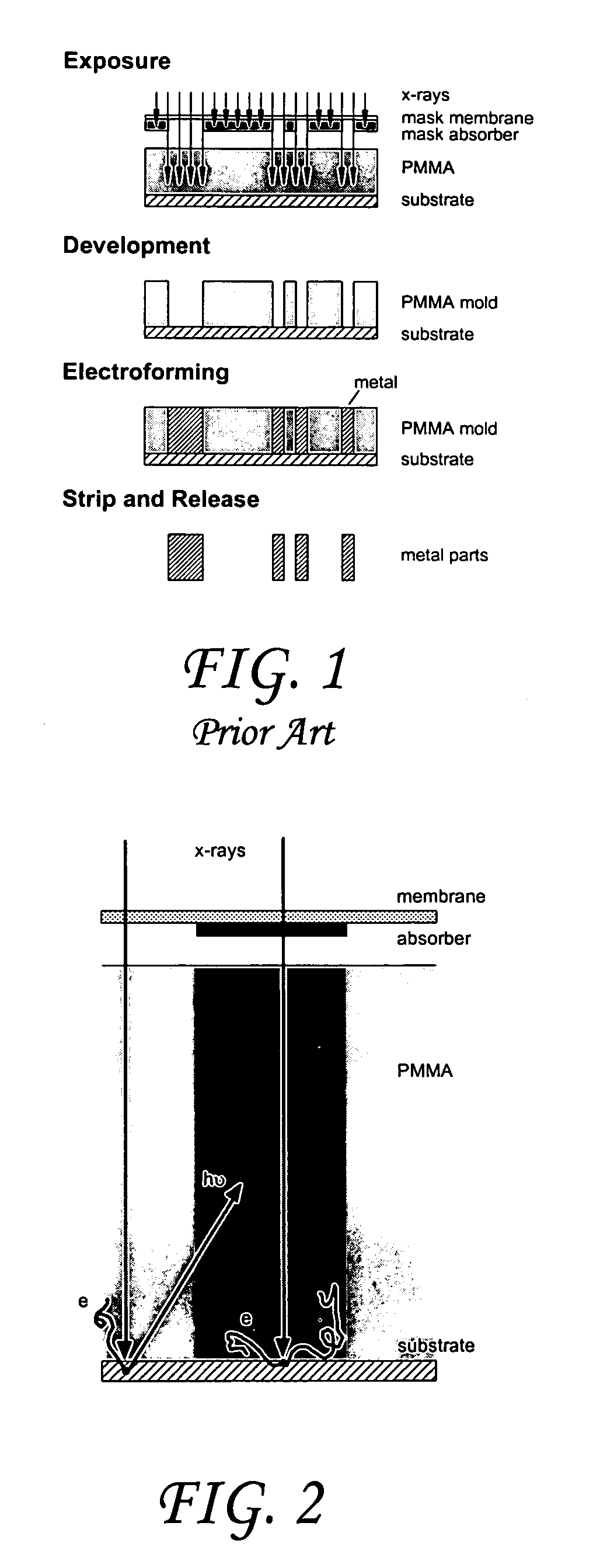

X-ray lithography, is a process used in electronic industry to selectively remove parts of a thin film. It uses X-rays to transfer a geometric pattern from a mask to a light-sensitive chemical photoresist, or simply "resist," on the substrate. A series of chemical treatments then engraves the produced pattern into the material underneath the photoresist.

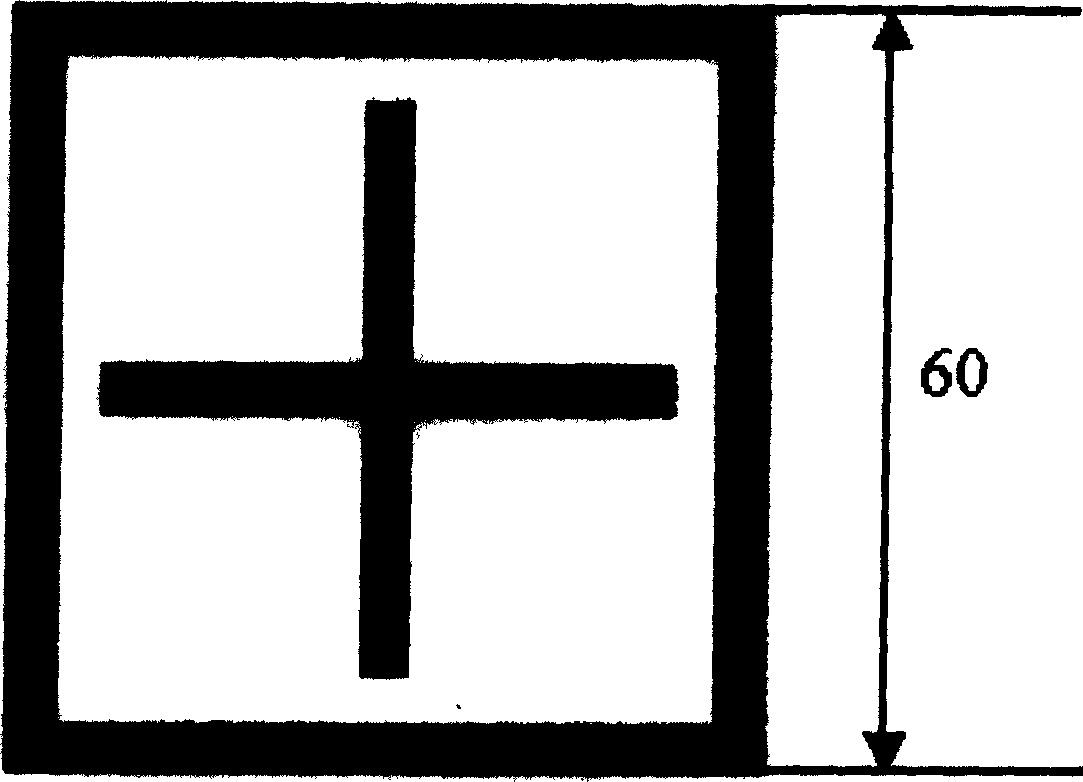

Method for the fabrication of three-dimensional microstructures by deep X-ray lithography

InactiveUS6875544B1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusThree dimensional microstructureX-ray

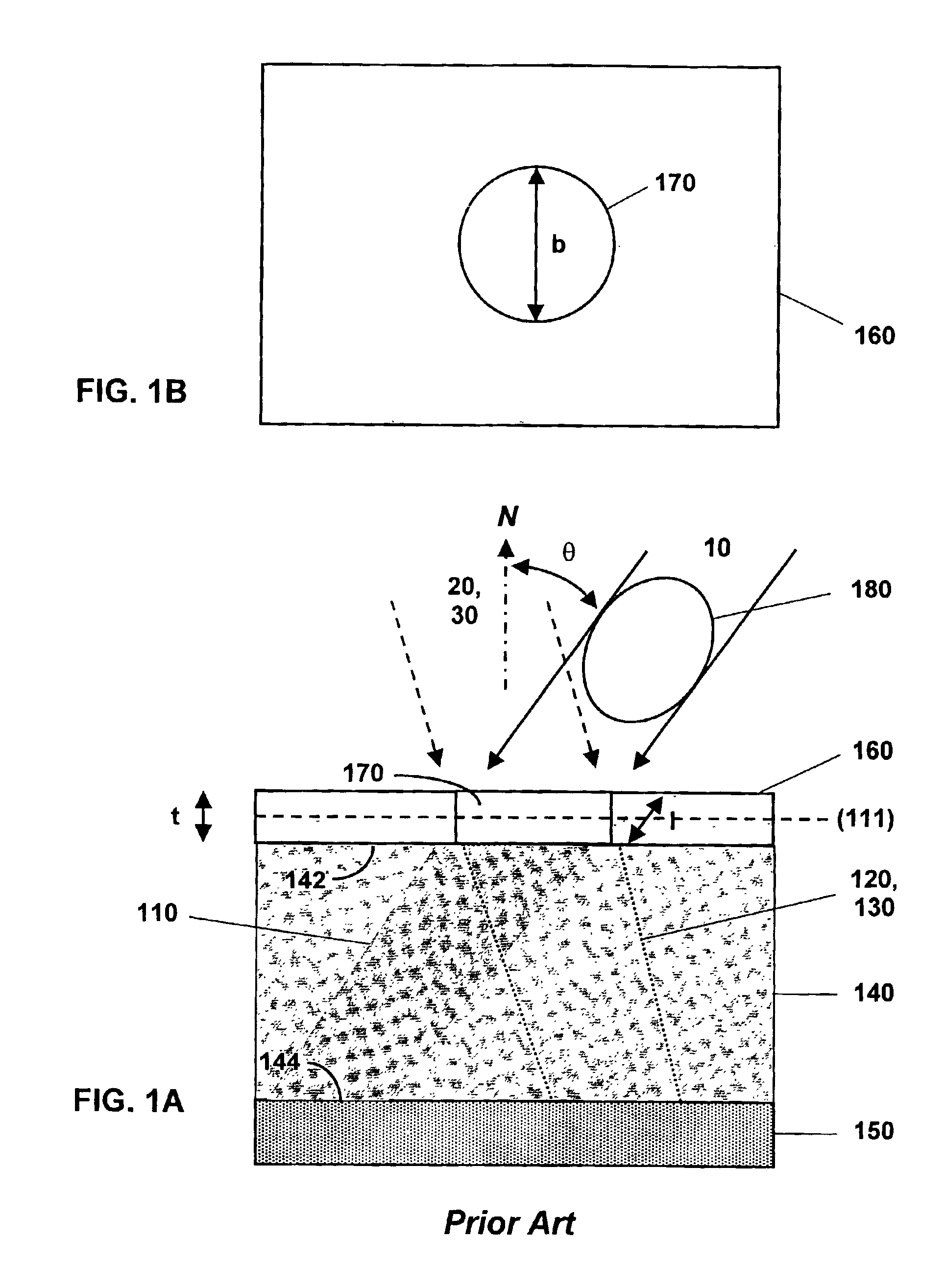

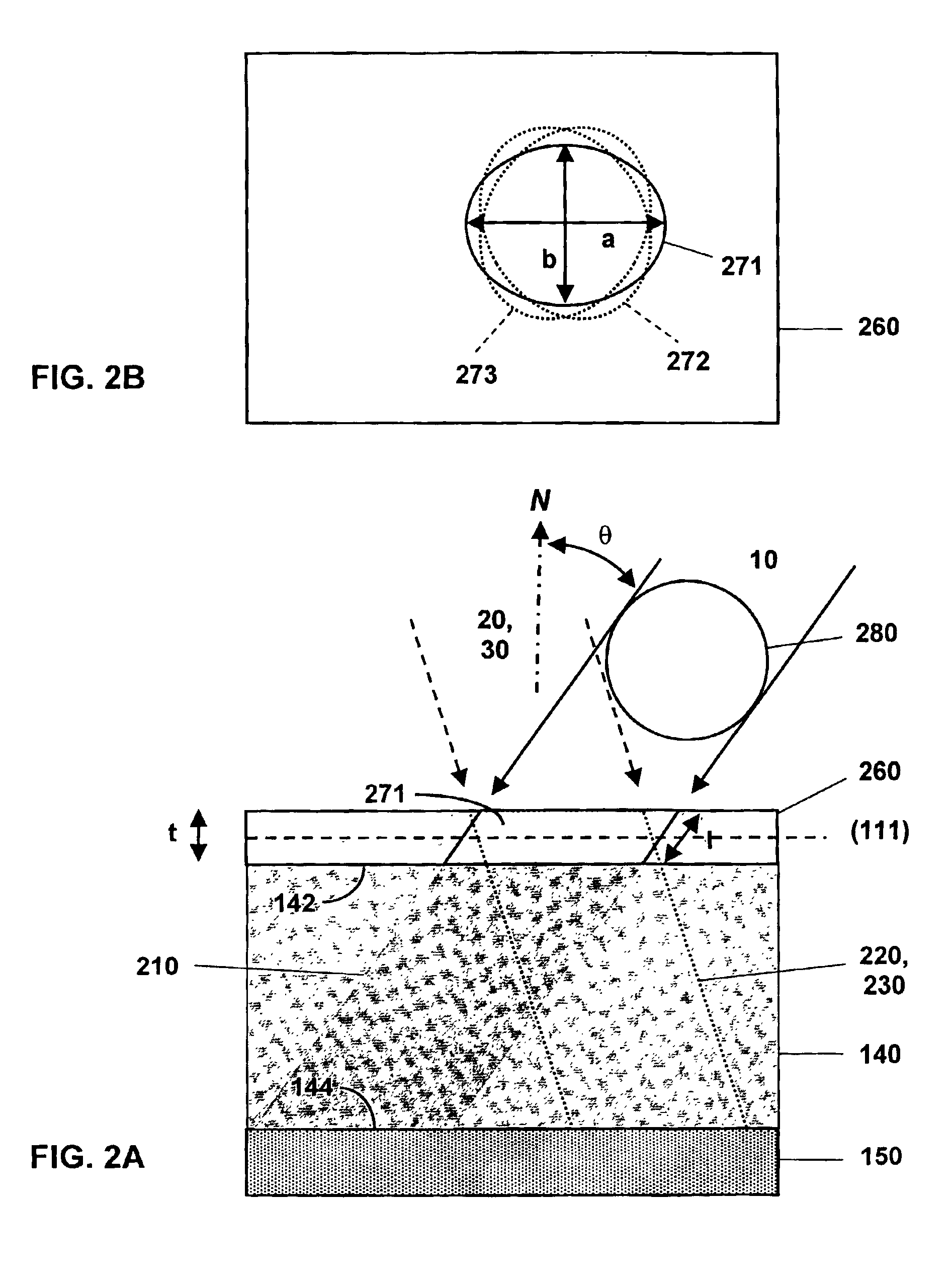

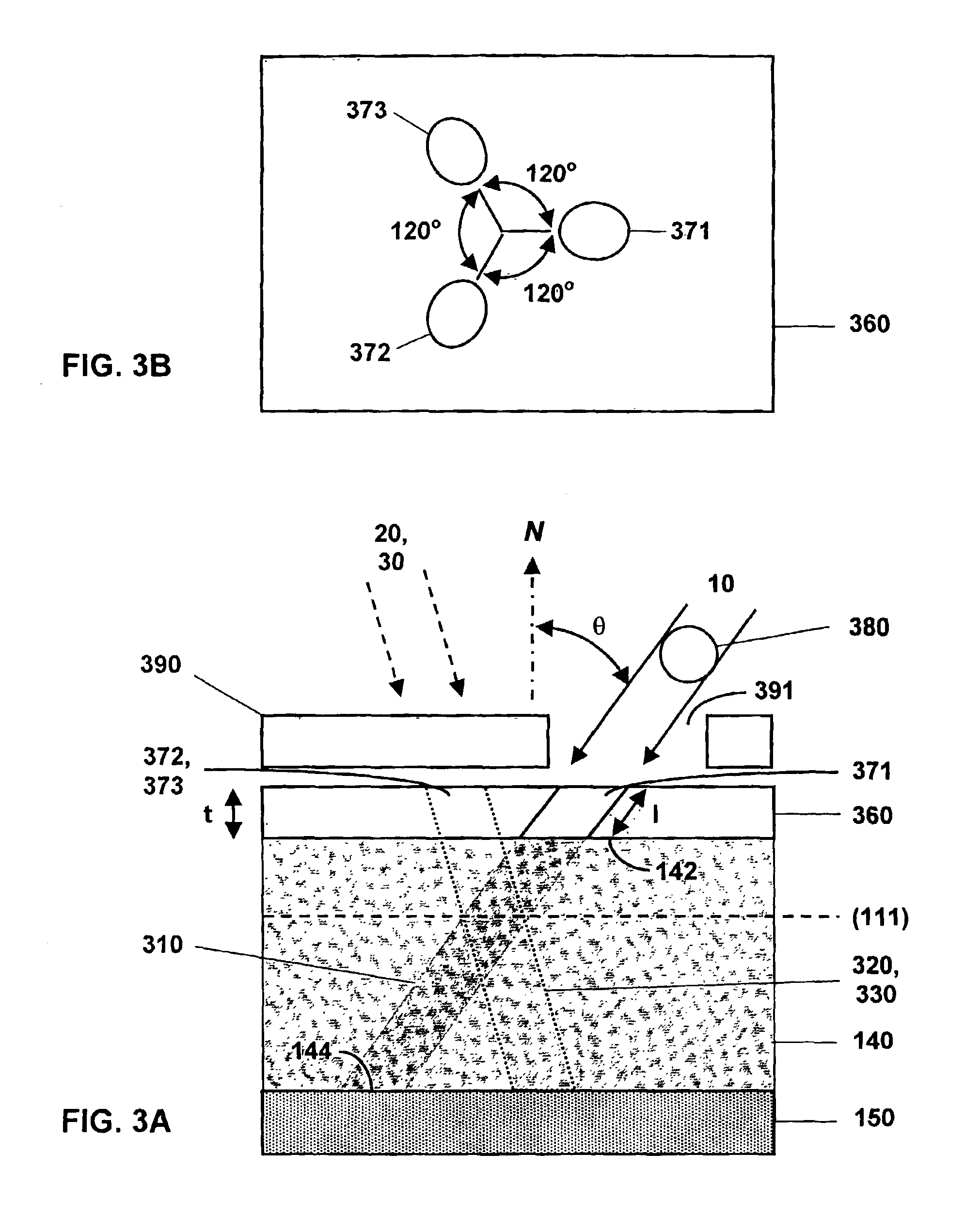

A method for the fabrication of three-dimensional microstructures by deep X-ray lithography (DXRL) comprises a masking process that uses a patterned mask with inclined mask holes and off-normal exposures with a DXRL beam aligned with the inclined mask holes. Microstructural features that are oriented in different directions can be obtained by using multiple off-normal exposures through additional mask holes having different orientations. Various methods can be used to block the non-aligned mask holes from the beam when using multiple exposures. A method for fabricating a precision 3D X-ray mask comprises forming an intermediate mask and a master mask on a common support membrane.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

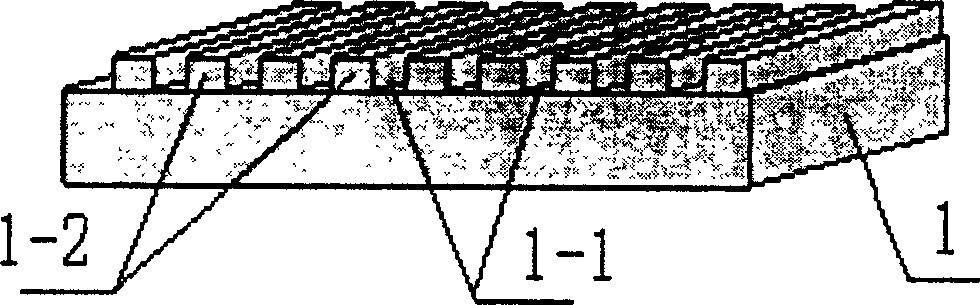

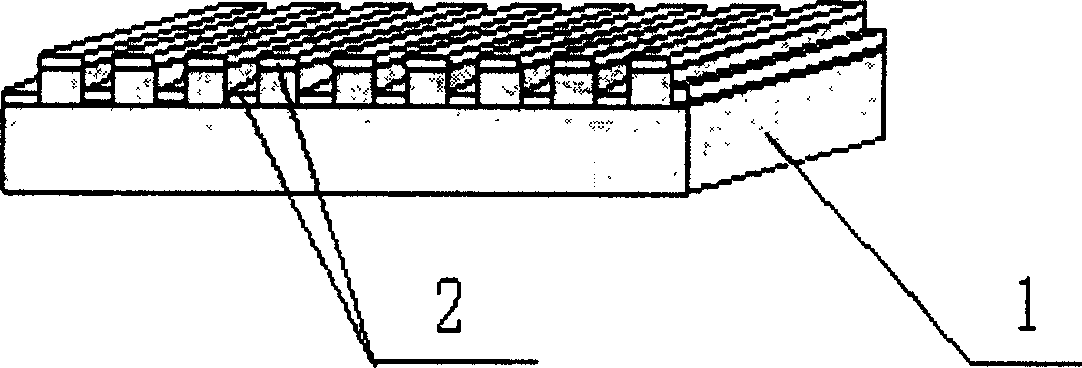

Nano level grating for polarization beam division / combination and method for making same

InactiveCN1567002AIdeal solid surfaceOvercoming the problem of very fragile surfacesPolarising elementsDiffraction gratingsEtchingRadiation x

This invention provides a nanometer grating used in polarized splitting and combination beam and its process method. The metal grating bar is located in the ditch bottom of the nanometer grating and it deposit a layer of protective film with same quality with upper layer of the grating structure. The process method are the following: 1, first to make nanometer grating by use of synchronization radiation X-ray light etching method; 2, to unromantically coat a metal film with high reflection on the surface of nanometer grating; 3, to remove the metal film on the back of the optical grating by use of ion beam inclined etching method; 4, to cover material with same quality with underlay on the grating surface. The metal grating surface can have an ideal solid surface and reliable protective cover.

Owner:GUANGXUN SCI & TECH WUHAN

Method for varying x-ray hybrid resist space dimensions

InactiveUS6014422ASpace width can be variedIncrease spaceRadiation applicationsPhotomechanical exposure apparatusResistX-ray

The present invention provides combining the advantages of hybrid resist with the unique properties of x-ray lithography to form high tolerance devices with x-ray pitch and to provide a means for varying the space width and fine tuning to account for process variations. Accordingly, a space width in the hybrid resist can be selectively printed by varying the mask-wafer gap distance, allowing more versatile structures to be formed and adjustments to be made for process changes such as resist composition and ion implant levels.

Owner:IBM CORP

Manufacture method of high resolution self-supporting totally hollowed-out transmission grating

ActiveCN101017214AHigh resolutionIncrease productivitySemiconductor/solid-state device manufacturingDiffraction gratingsGratingX-ray

This invention relates to one X ray infraction optical element high resolution rate self-supportive cast transparent grating, which comprises the following: a, depositing film gold layer to support X ray mask underlay; b, in surface layer etching electron glue to get etch pattern; c, the slice is put to coating liquid for X ray mode absorptive gold pattern; d, the said slice removes electron beam glue; e, then removing electron beam for film of chromium layer; f, coating medlin on glass for fixing; g, depositing gold on its surface; h, coating X ray etch glue on gold surface; I, removing medlin; j, removing etch glue; k, back surface erosion of glass to fulfill the process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Liquid metal flexible shielding material and preparation method thereof

ActiveCN107901534AGood radiation absorption performanceThe overall thickness is thinProtective equipmentFibre treatmentLiquid metalRadiation shield

The invention provides a liquid metal flexible shielding material and a preparation method thereof. The liquid metal flexible shielding material includes a substrate layer, a liquid metal layer and ananti-aging layer which are sequentially arranged from bottom to top. The liquid metal flexible shielding material has an excellent shielding performance and a thin thickness, is nontoxic, has a far better yield limit than traditional lead-containing particle radiation shielding materials, can achieve extremely excellent stretchable radiation shielding materials, and has excellent values in the fields of flexible shielding gloves, shielding clothes and even X-ray lithography.

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

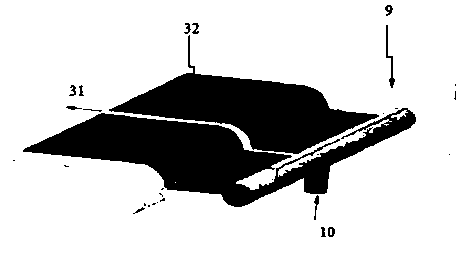

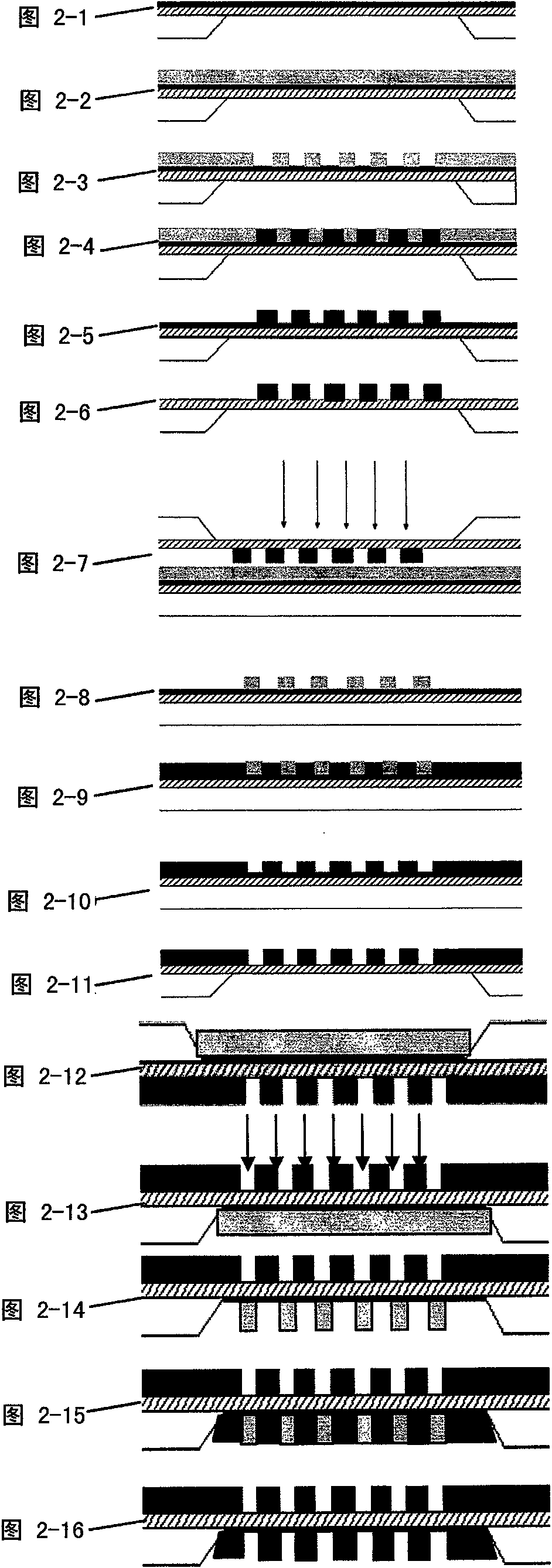

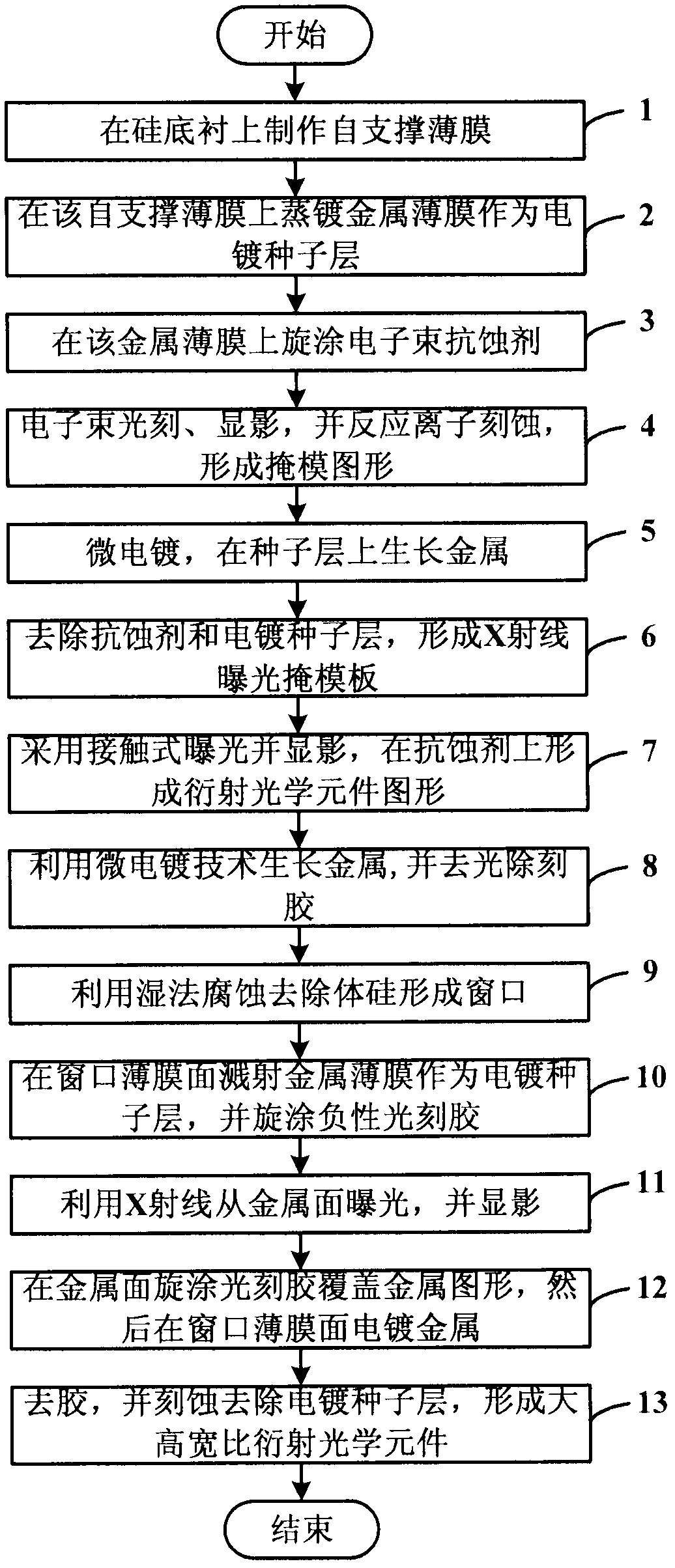

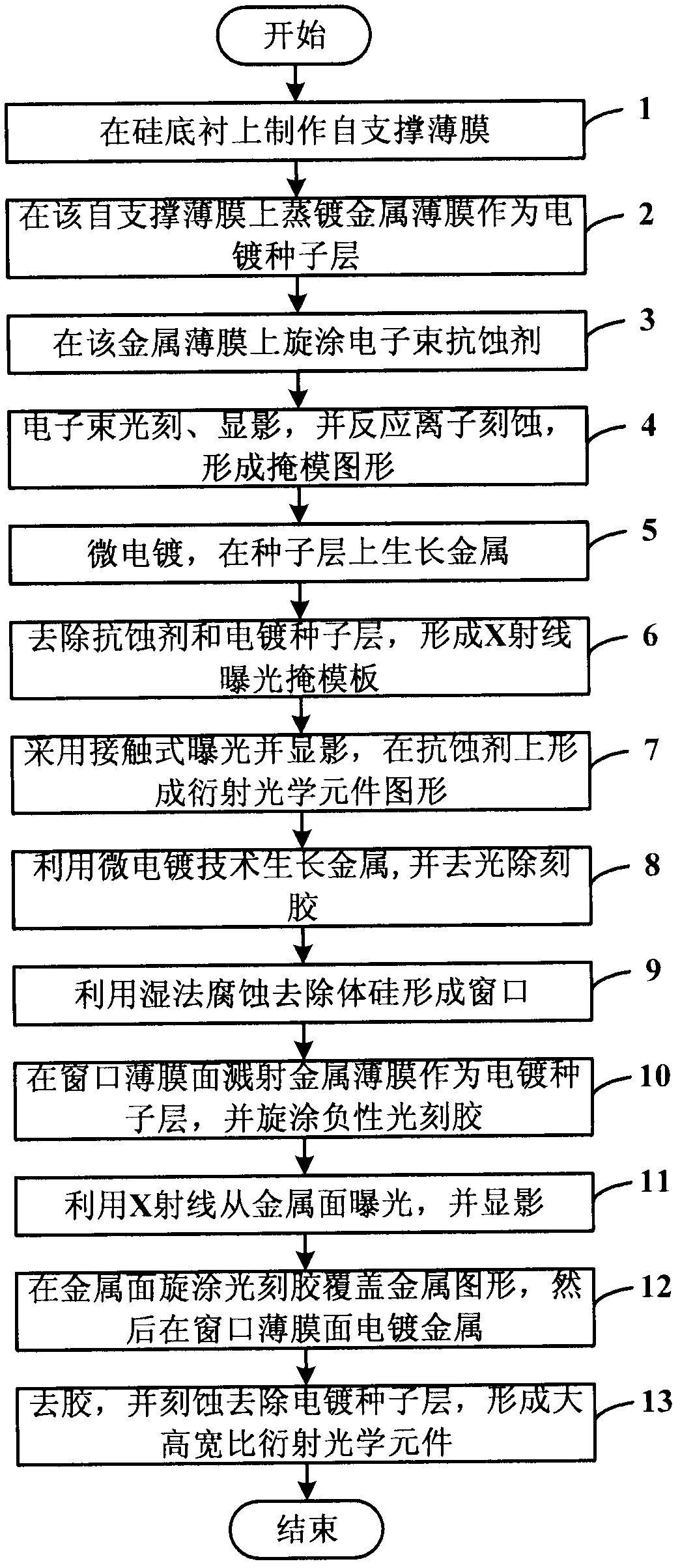

Manufacture method of diffractive optical element with large aspect ratio

ActiveCN102466967AEasy to mass manufactureDiffraction gratingsPhotomechanical exposure apparatusSoft x rayX-ray

The invention discloses a manufacture method of a diffractive optical element with large aspect ratio. In the method, an X ray exposure mask is manufactured through electron beam direct writing, a transmission diffractive optical element is manufactured through contact exposure, an electrofacing seed layer is sputtered on a transmission thin film substrate surface, then negative photoresist is coated in a rotating way, X ray is utilized for exposure again, the electroplated and etched electrofacing seed layer is developed, and the diffractive optical element with the large aspect ratio is formed. According to the manufacture method disclosed by the invention, the X ray photoetching mask is prepared through the electron beam direct writing, double exposure utilizing the X ray is carried out, and the diffractive optical element with the large aspect ratio being 10:1 is prepared. The method has the advantages of stability and reliability, easiness in batch preparation, and compatible performance with the traditional photoetching craft.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

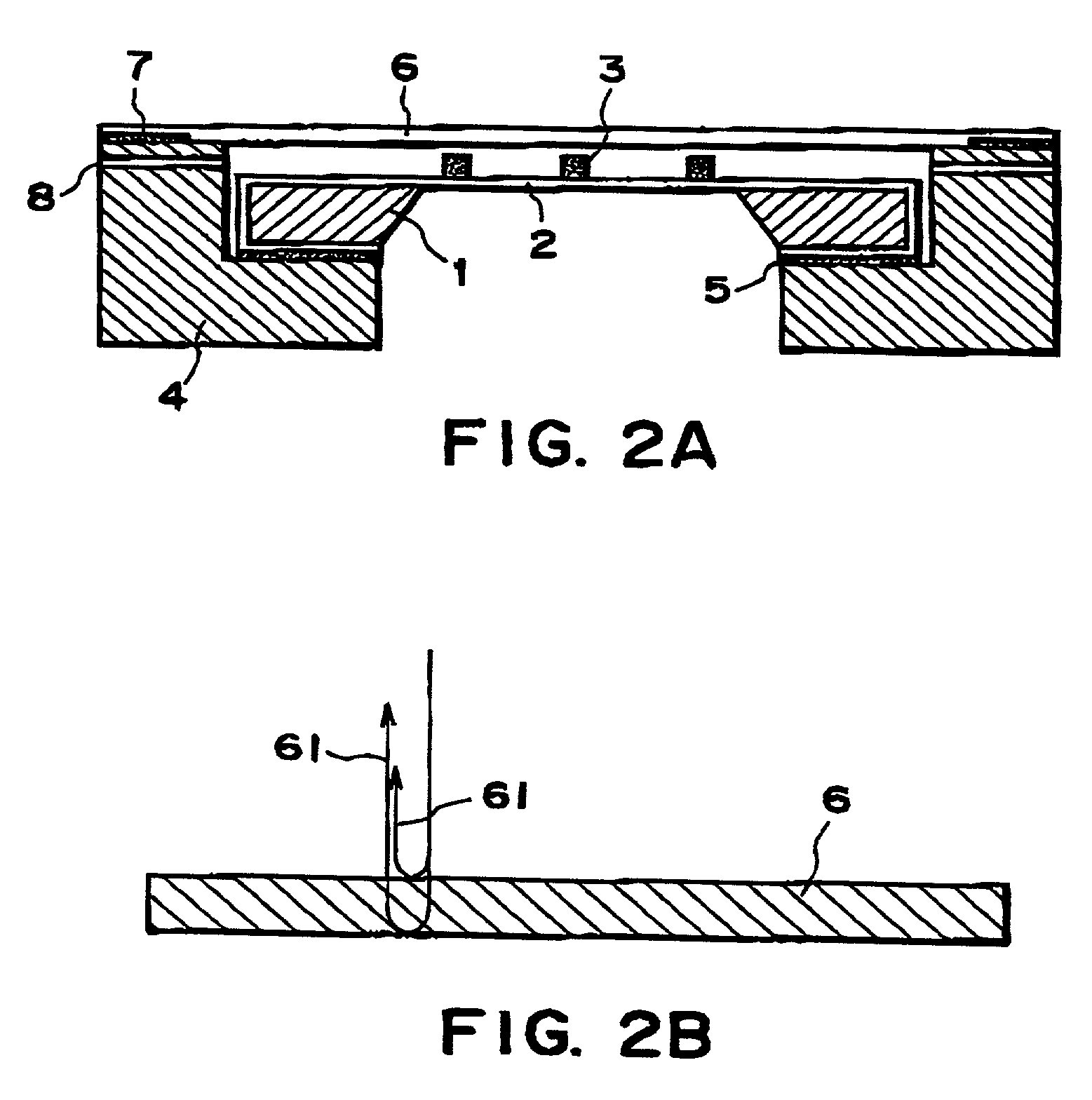

X-ray mask structure, and x-ray exposure method and apparatus using the same

InactiveUS20020018941A1Picture framesSemiconductor/solid-state device manufacturingX-rayOptoelectronics

An X-ray mask structure for use in X-ray lithography includes an X-ray transmission film to be disposed opposed to a workpiece in X-ray exposure, the X-ray transmission film having an X-ray absorptive material corresponding to a pattern to be printed on the workpiece, and a thin film covering at least a portion of the X-ray transmission film, the thin film having an anti-reflection function with respect to alignment light to be projected to the thin film for direct or indirect detection of relative positional deviation between the mask structure and the workpiece.

Owner:CANON KK

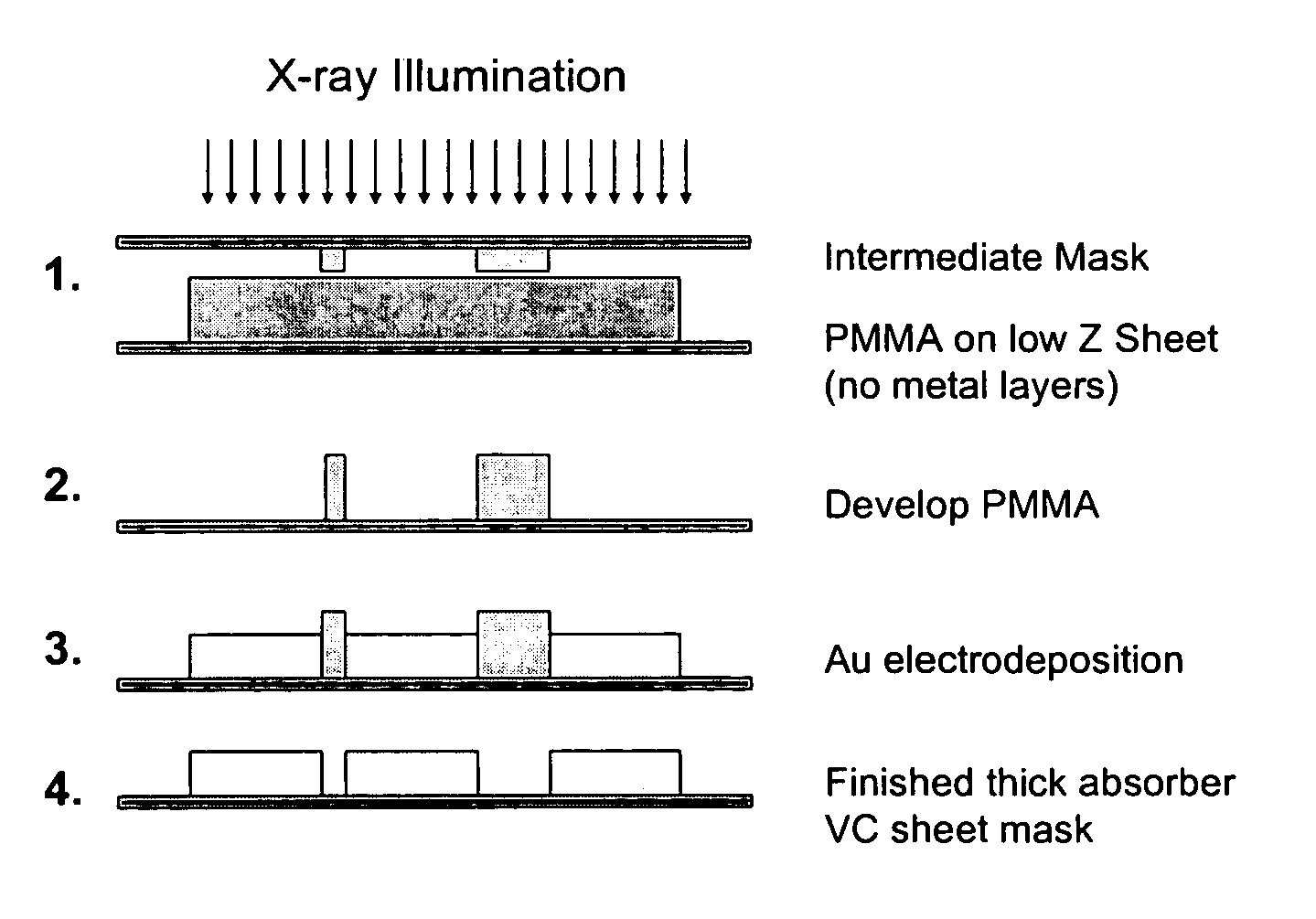

Vitreous carbon mask substrate for X-ray lithography

InactiveUS7608367B1Improve imaging resolutionIncrease contrastOriginals for photomechanical treatmentIrradiation devicesResistX-ray

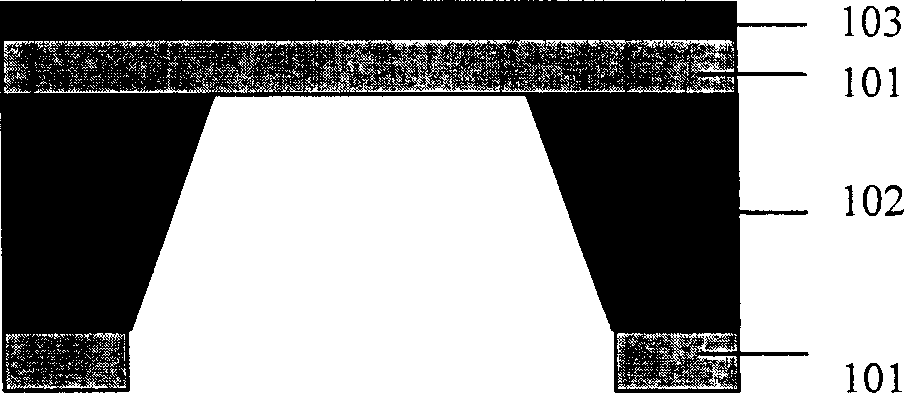

The present invention is directed to the use of vitreous carbon as a substrate material for providing masks for X-ray lithography. The new substrate also enables a small thickness of the mask absorber used to pattern the resist, and this enables improved mask accuracy. An alternative embodiment comprised the use of vitreous carbon as a LIGA substrate wherein the VC wafer blank is etched in a reactive ion plasma after which an X-ray resist is bonded. This surface treatment provides a surface enabling good adhesion of the X-ray photoresist and subsequent nucleation and adhesion of the electrodeposited metal for LIGA mold-making while the VC substrate practically eliminates secondary radiation effects that lead to delamination of the X-ray resist form the substrate, the loss of isolated resist features, and the formation of a resist layer adjacent to the substrate that is insoluble in the developer.

Owner:SANDIA NAT LAB

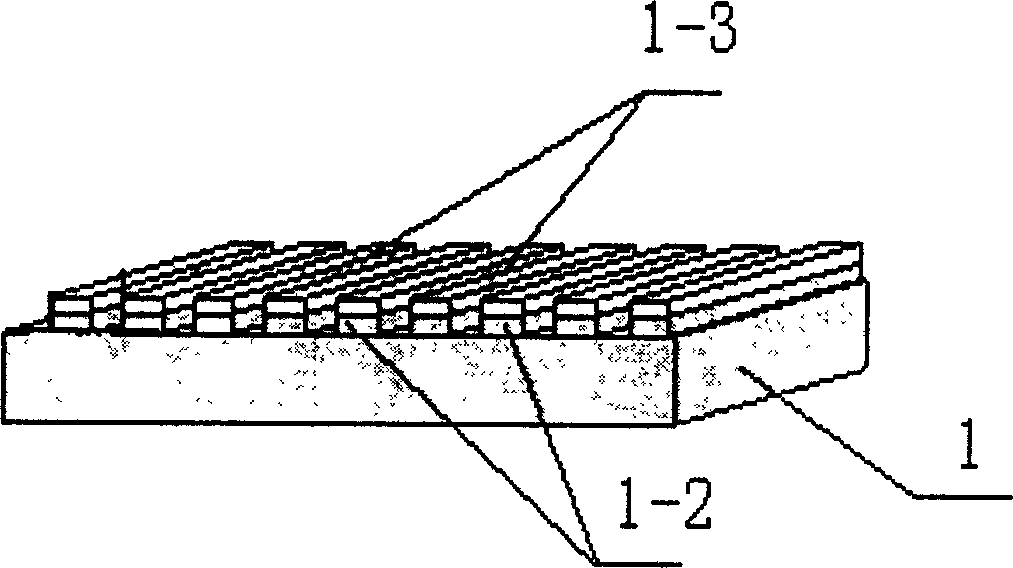

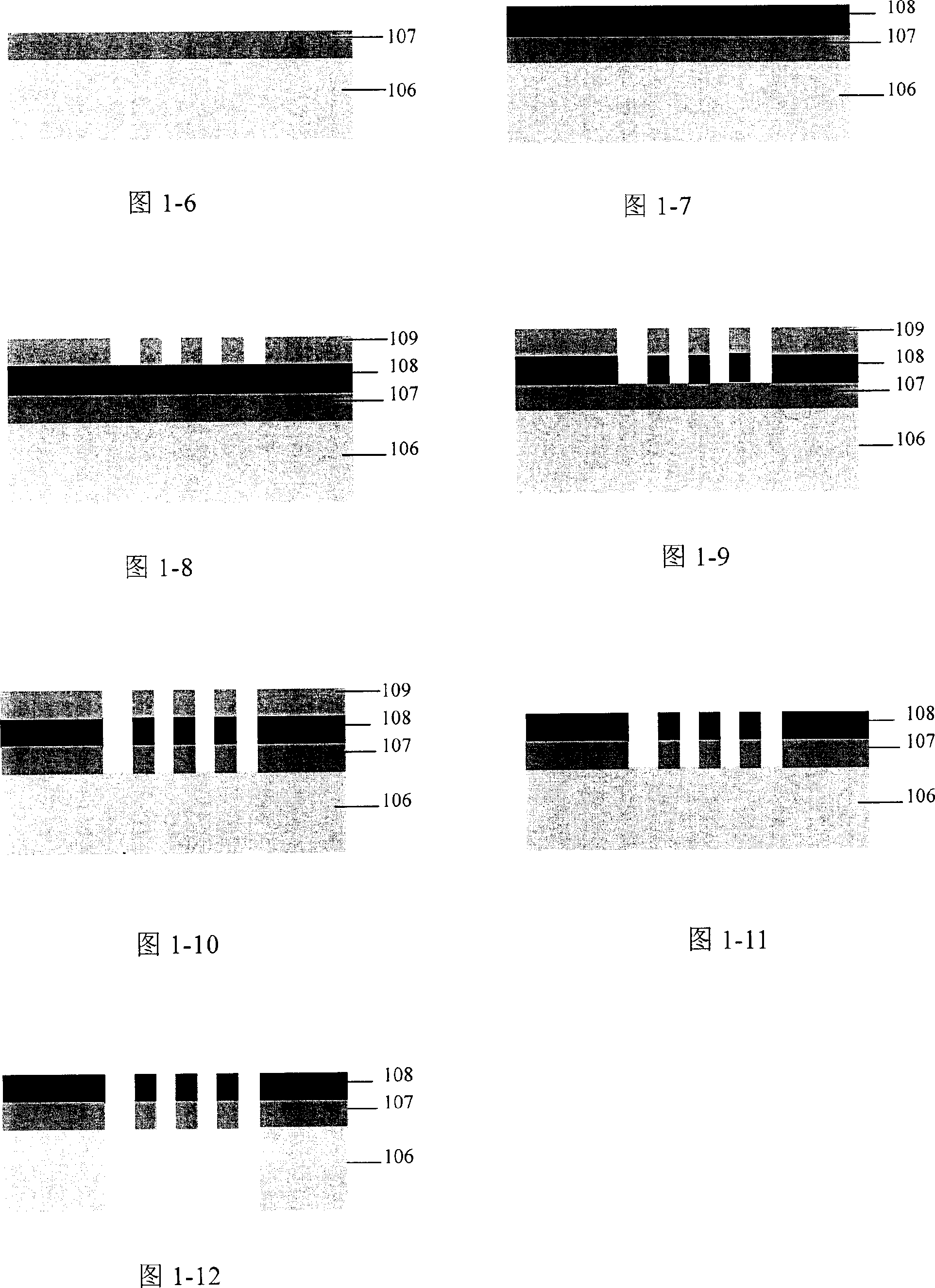

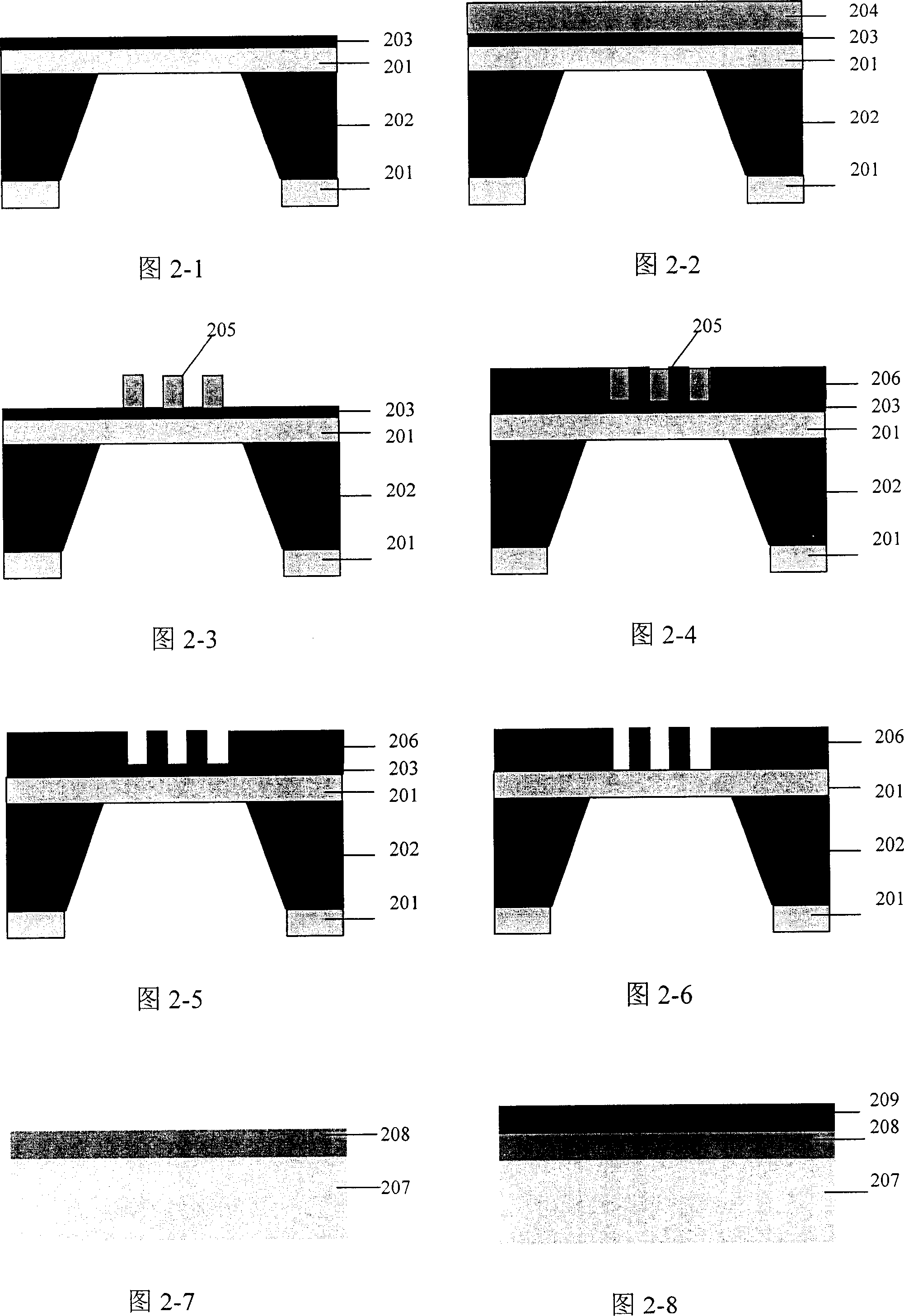

High depth-width ratio deep sub-micrometer, nanometer metal structure making process based on self-supporting thin film

ActiveCN1801458AStrong practical valueSuitable for mass productionNanostructure manufacturePhotomechanical apparatusManufacturing technologyX-ray

The invention bases on metal structure manufacture technology of deep sub-micron and nanometer for high aspect ratio of self-support film comprises: 1. depositing thin Cr and Au on front face of self-support film; 2. whirling electron micelle on thin Cr / Au surface to exposure and develop the electron beam; 3. putting the slice into electroplate liquid to electroplate metal firstly; 4. whirling X-ray resist on front face of slice; 5. taking X-ray exposure and develop from the film back surface; 6. electroplating secondly; 7. removing glue and Cr / Au, and completing the manufacture. This invention has strong applied value and fit to large-scale production.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

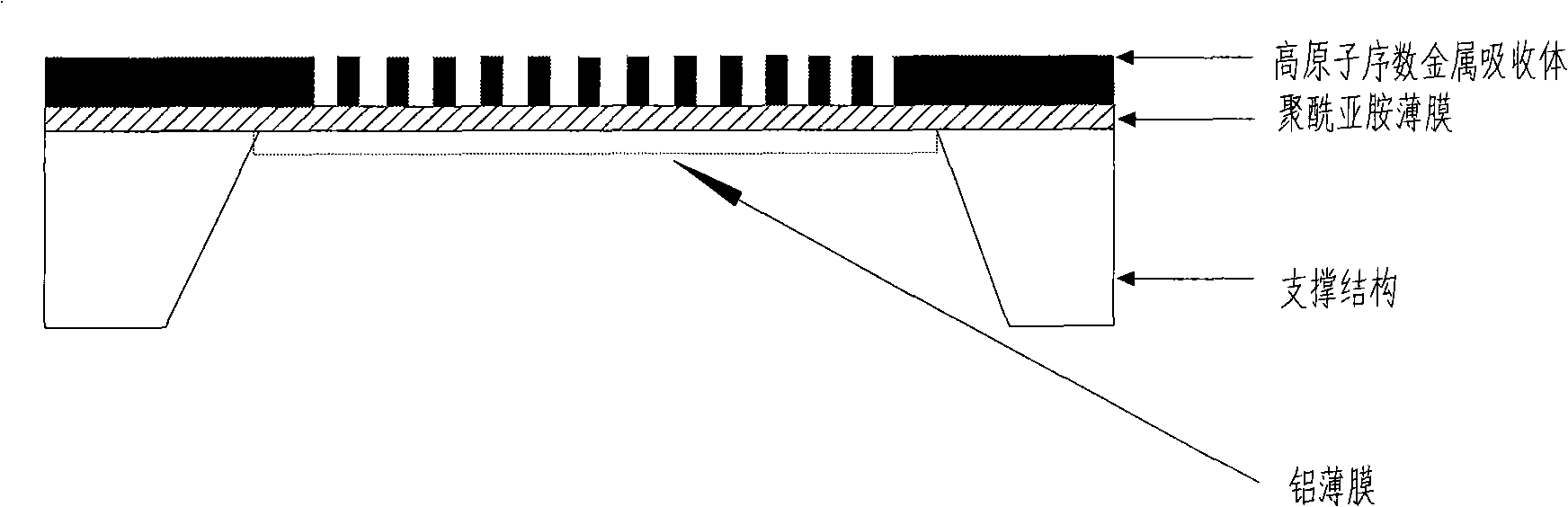

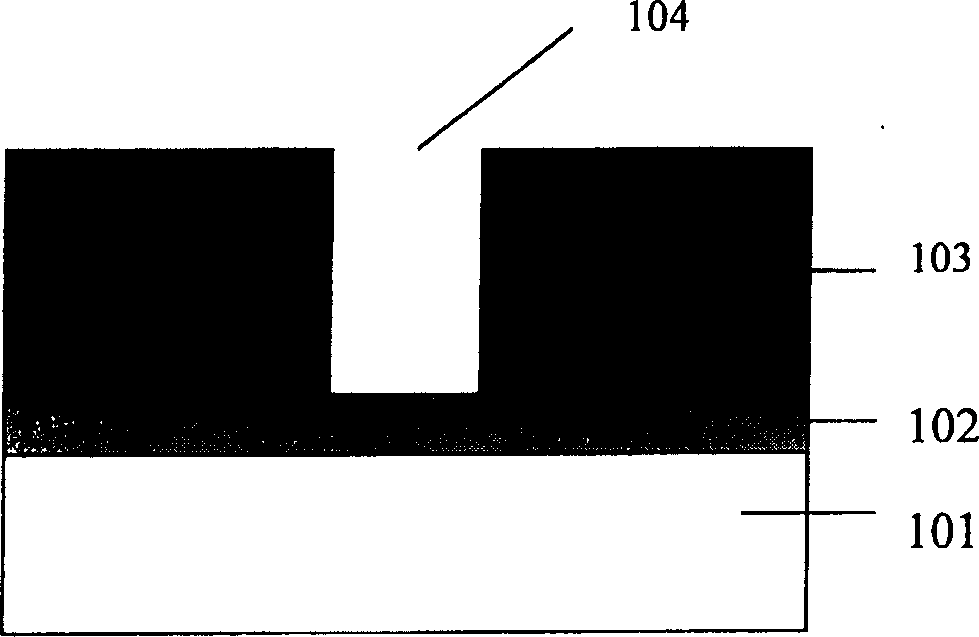

Photoetching mask structure for aeration of X-ray and method for preparing same

InactiveCN101515110ALow costSimple processPhotomechanical exposure apparatusMicrolithography exposure apparatusOrganic filmHeat conducting

The invention discloses a photoetching mask structure for the aeration of X-ray. The structure, from the bottom to top, sequentially consists of a metallic film in low atomic number, a polyimide film and a metallic absorber figure in high atomic number. The invention simultaneously discloses a method for preparing the photoetching mask structure. By utilizing the method, because of the adoption of the multi-layer film structure formed by metal aluminum in low atomic number, the polyimide and the metallic absorber in high atomic number, the photoetching mask structure can be used for the X-ray photoetching on the level of micron, deep submicron and nanometer. Compared with the inorganic film based mask, the photoetching mask structure has the advantages of low cost, simple process flow and difficult cracking; and compared with the organic film based mask, the photoetching mask structure has the advantages of high mechanical strength, hard deformation and good heat conducting performance.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

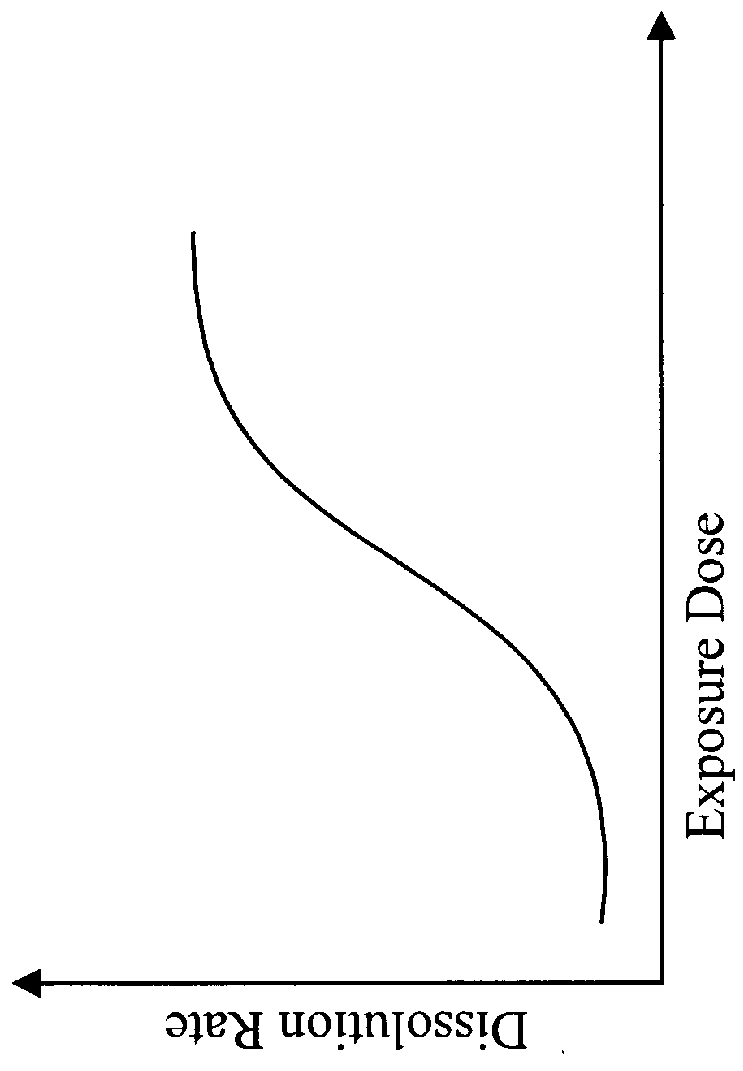

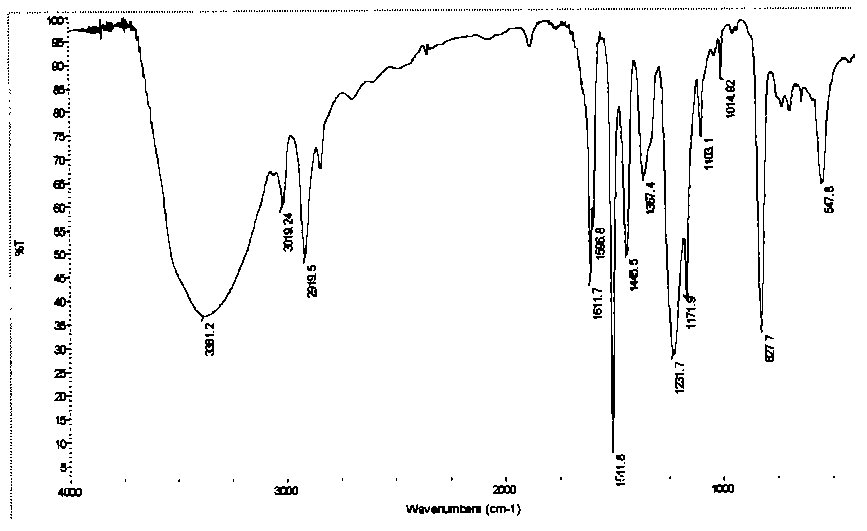

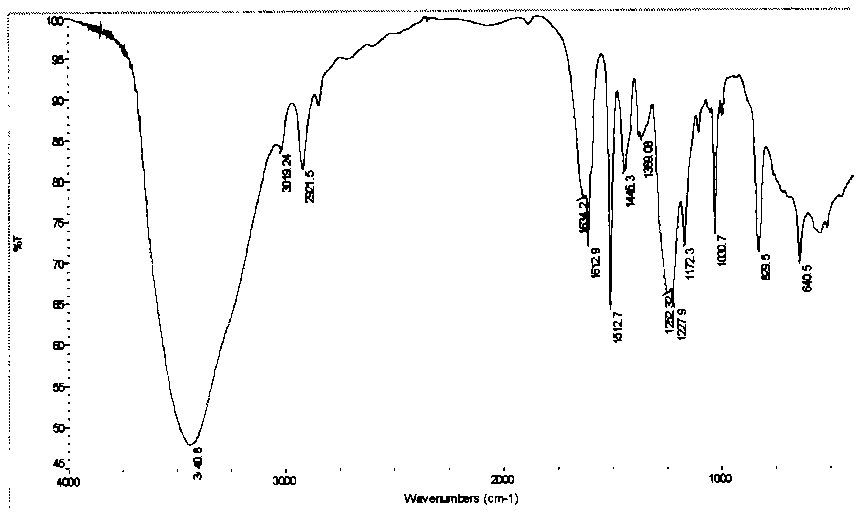

Poly p-hydroxystyrene based chemically amplified one-component photoresist material, and synthetic method and application thereof

The present invention relates to a novel poly p-hydroxystyrene (PHS) based chemically amplified one-component photoresist material and a synthetic method thereof. The derivative of the PHS contains illumination acid generating group on portion of benzene rings, and part of the phenolic hydroxyl groups are protected by acid decomposable protecting groups. During exposure, acid producing groups produce a strong acid, which catalyzes decomposition of the protecting groups under postbaking conditions to release phenolic hydroxyl group; therefore, alkaline solubility of the exposure section is increased, and developing and imaging can be realized in dilute alkaline solution. The derivative of the PHS can be used as a novel chemically amplified one-component photoresist material and be used as a chemically amplified photoresist in deep ultraviolet lithography, electron beam lithography and other next generation super-large-scale integration processing technology, such as extreme ultraviolet lithography and X-ray lithography, etc.

Owner:BEIJING NORMAL UNIVERSITY

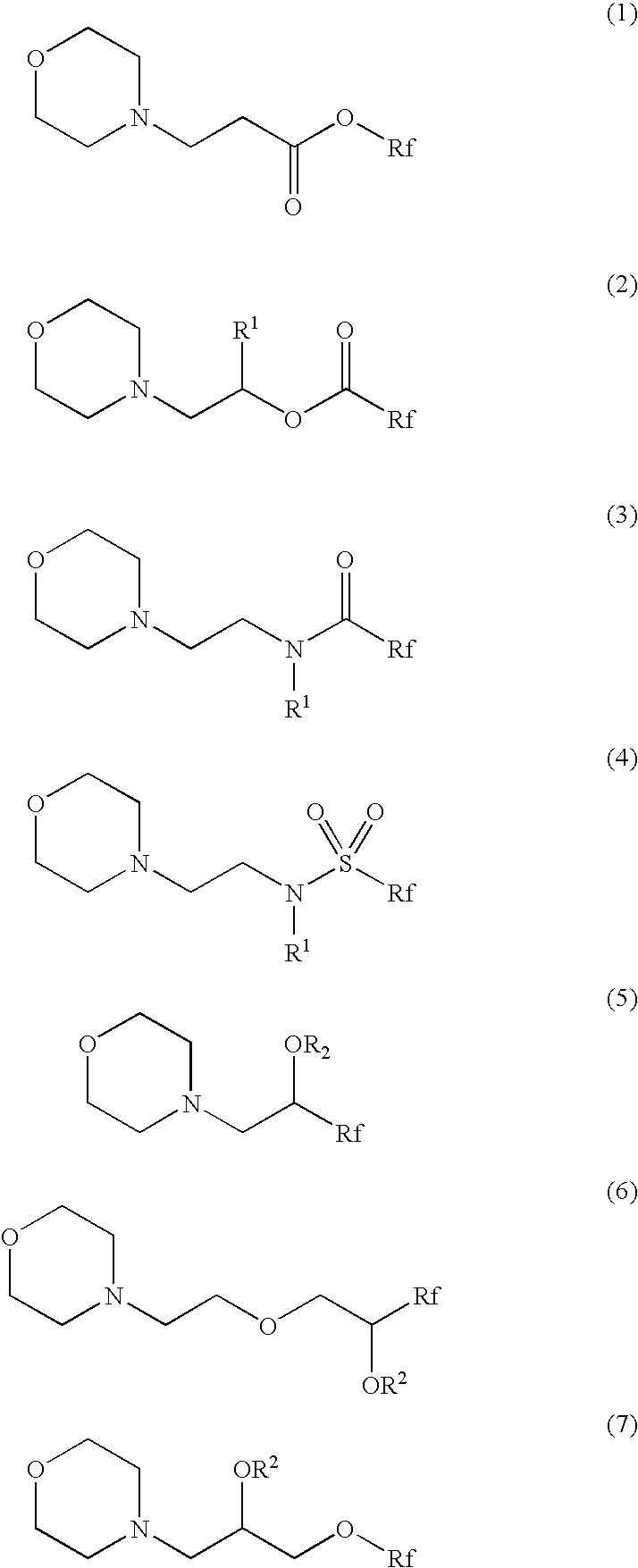

Amine compound, chemically amplified resist composition and patterning process

ActiveUS20070087287A1High resolutionEnhance the imageOrganic chemistryPhotosensitive materialsImage resolutionPhotochemistry

Chemically amplified resist compositions comprising amine compounds having a fluorinated alkyl group offer an excellent resolution and a precise pattern profile and are useful in microfabrication by KrF, ArF, F2, EUV, EB or X-ray lithography. They are also effective in the immersion lithography.

Owner:SHIN ETSU CHEM IND CO LTD

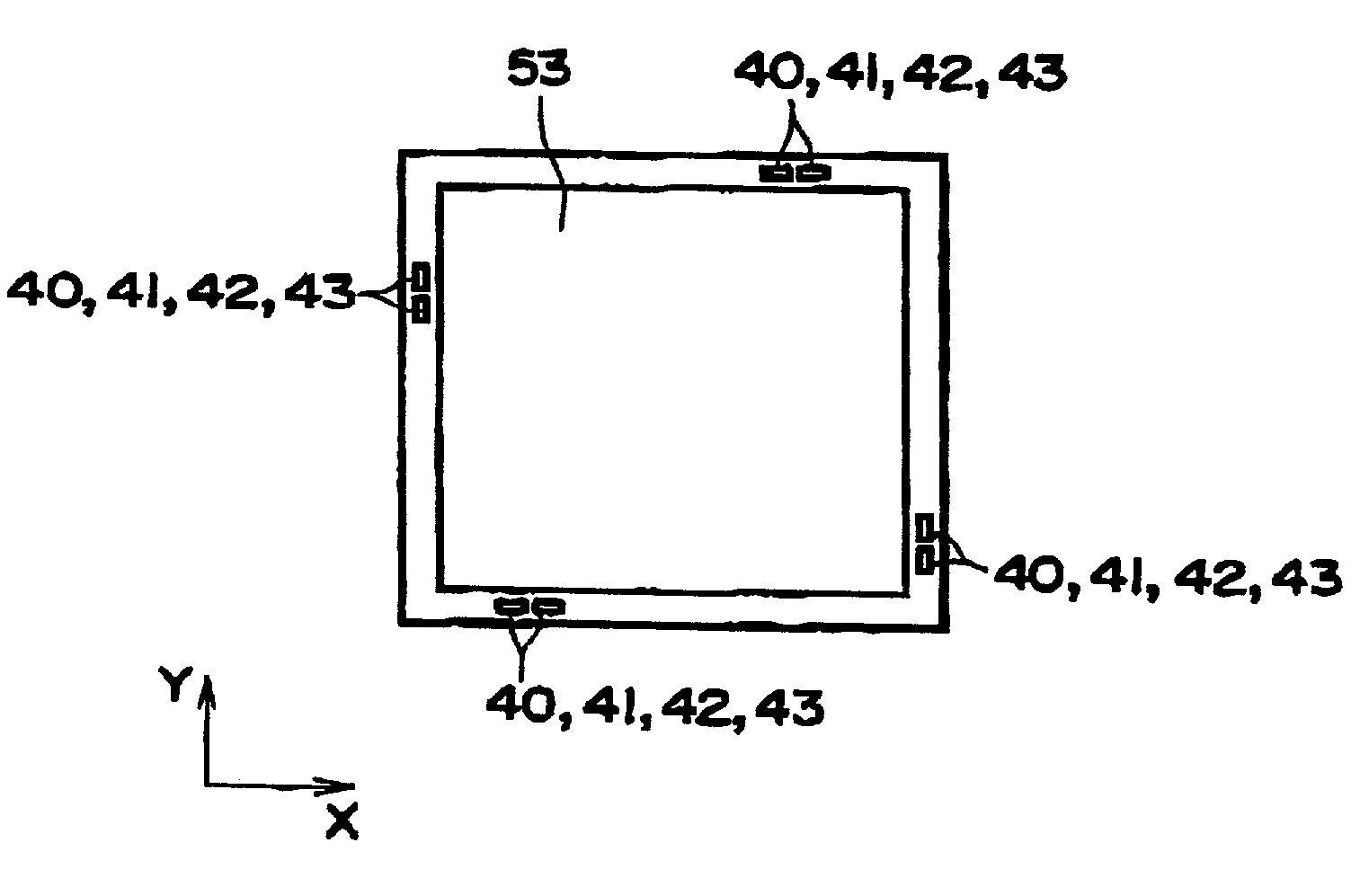

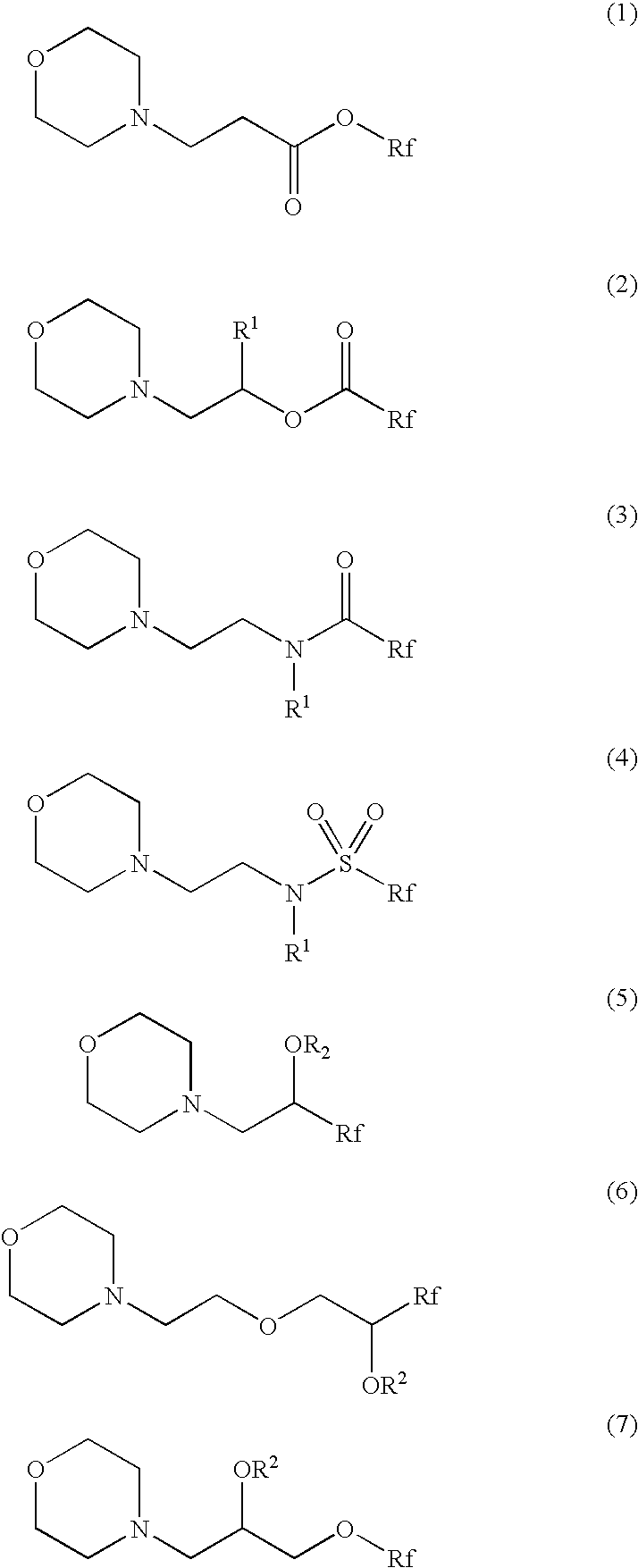

Photo etching alignment mark in use for X-ray

InactiveCN1627190AAccurately obtainedImprove alignment accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusX-raySilicon chip

This invention relates to labels used in the alignment of x-ray photoetching. The labels are composed of two labels on the mask and silicon chip, which are composed of three square blocks on the mask and six cross-lines on the silicon chip, among which, the three square blocks are sleeved orderly from small to big and share one central point, the label is set on SiNx film. Among the six cross lines, three are arrayed horizontally in equal distance the other three are arrayed vertically in equal distance, the label is set on the silicon chip substrate. This invented alignment label has a redundancy to the deformation of the mask and silicon chip, its uniform value can make alignment system to get more accurate position information of the label, to increase the alignment accuracy of photoetching.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

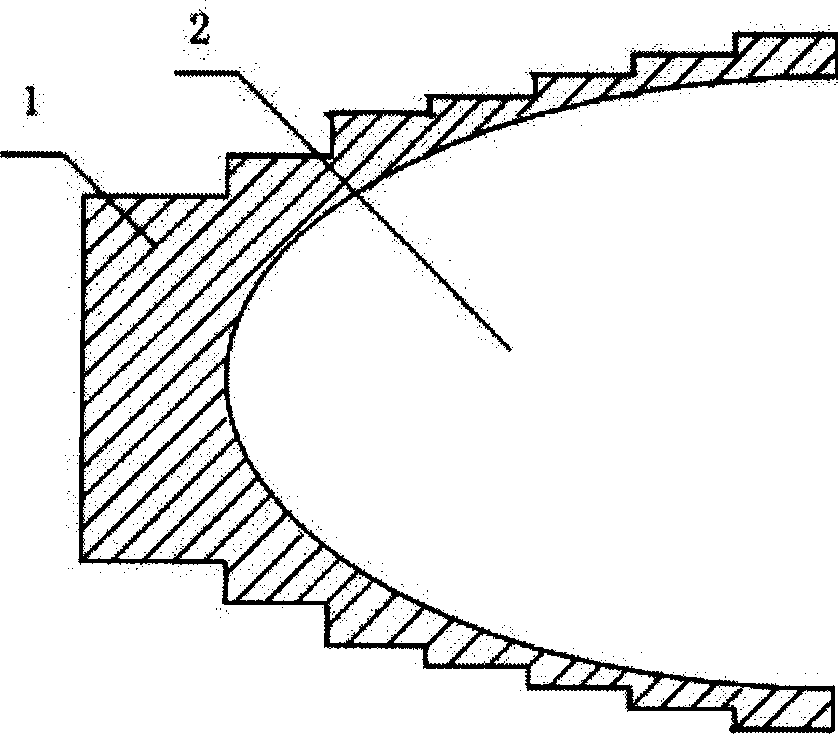

Variable focal length X-ray compound lens and manufacturing method thereof

InactiveCN101118290AImprove machining accuracyFocusRadiation/particle handlingPhotomechanical apparatusResistX-ray

The present invention belongs to the field of the optical technology and relates to a varifocal X-ray combination lens and its manufacture method. This combination lens consists of a lens main body and air cavities arranged on the lens main body at intervals; the material of the lens main body is PMMA. The manufacture method of the present invention is firstly making in turn the required lays of polyimide, metal film, optical resist, etc. on the surface of the monocrystal line silicon chip which plays the role of support; secondly performing the processes of photoetching, electroforming, removing of photoresist, windowing, and so on, then completing the preparation of the photomask used in photoetching the lens main body and the photomask used in photoetching the air cavities; Finally, performing two times of the X-ray photoetching using the prepared photomasks, thus finishing the manufacture of the varifocal X-ray combination lens. The present invention has the advantages of good focusing effect, slight scattering, high transmission of the X-ray radiation, simple technics, and so on.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Process for mfg. unidimensional X ray refracted diffraction micro structural component of aluminium material

InactiveCN1786742AReduce absorptionIncreased depth dimensionMaterial analysis using wave/particle radiationPhotomechanical exposure apparatusUltraviolet lightsX-ray

The invention relates to aluminum material one dimension X ray diffraction refraction microstructure device manufacturing method. It includes the following steps: making ultraviolet light photolithography mask and its edition; preparing X ray photolithography base body; and forming aluminum material one dimension X ray diffraction refraction microstructure device. The invention optimizes one dimension X ray diffraction refraction microstructure device face form shape. Its aberration is almost zero. And the quality of the focal spot is good. It offers manufacturing technique pointed to aluminum material one dimension X ray diffraction refraction microstructure device and increase device depth size for scores times. Thus this can greatly improve depth direction light gathering caliber, and improve X ray radiation transmissibility.

Owner:乐孜纯

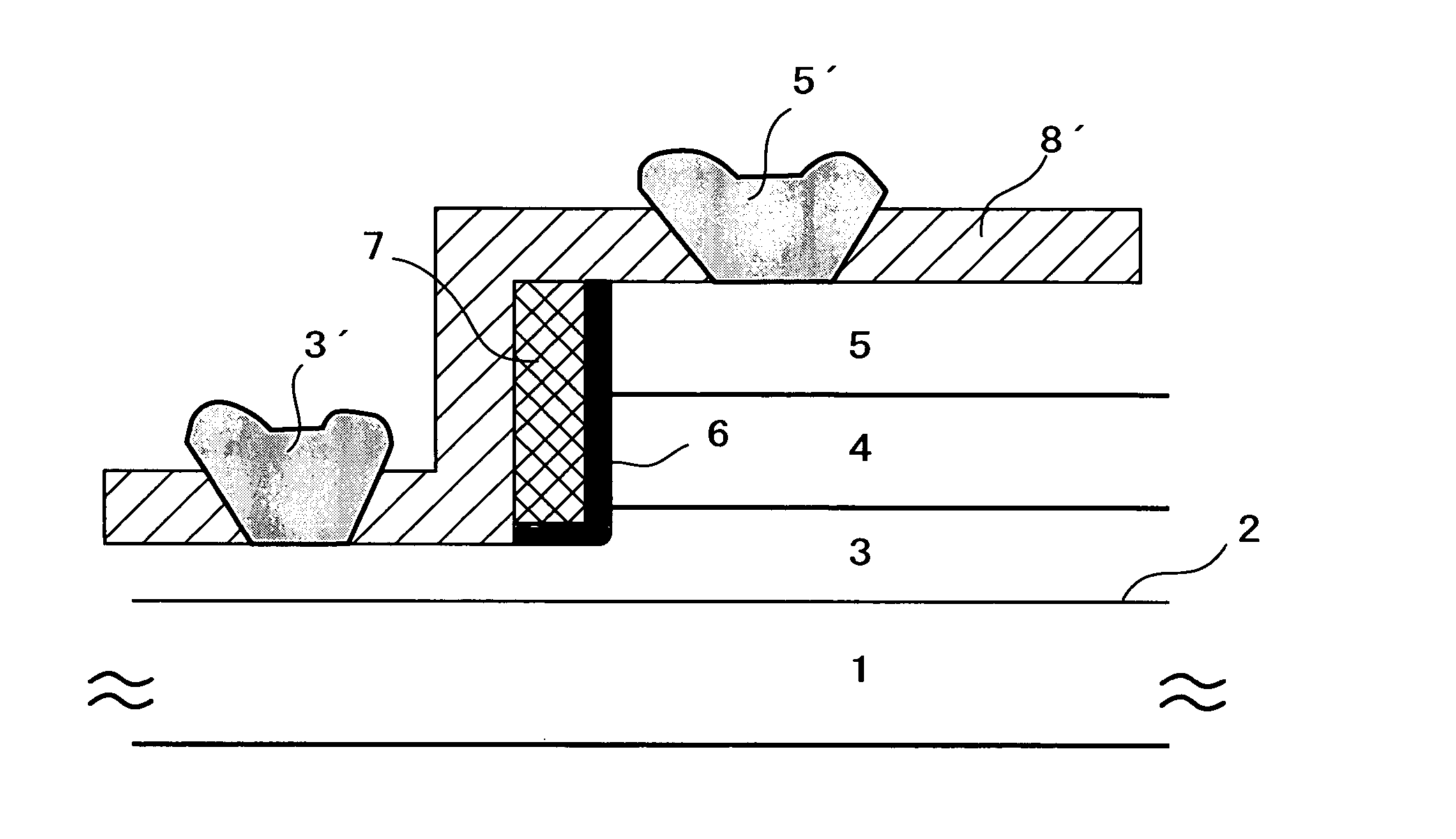

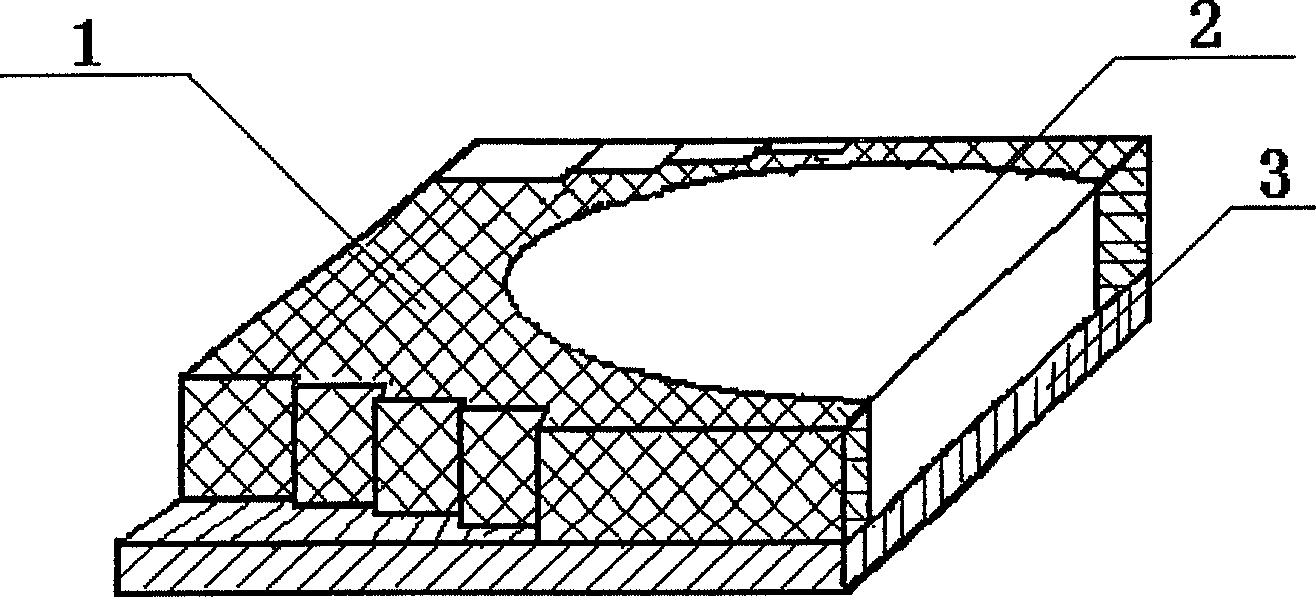

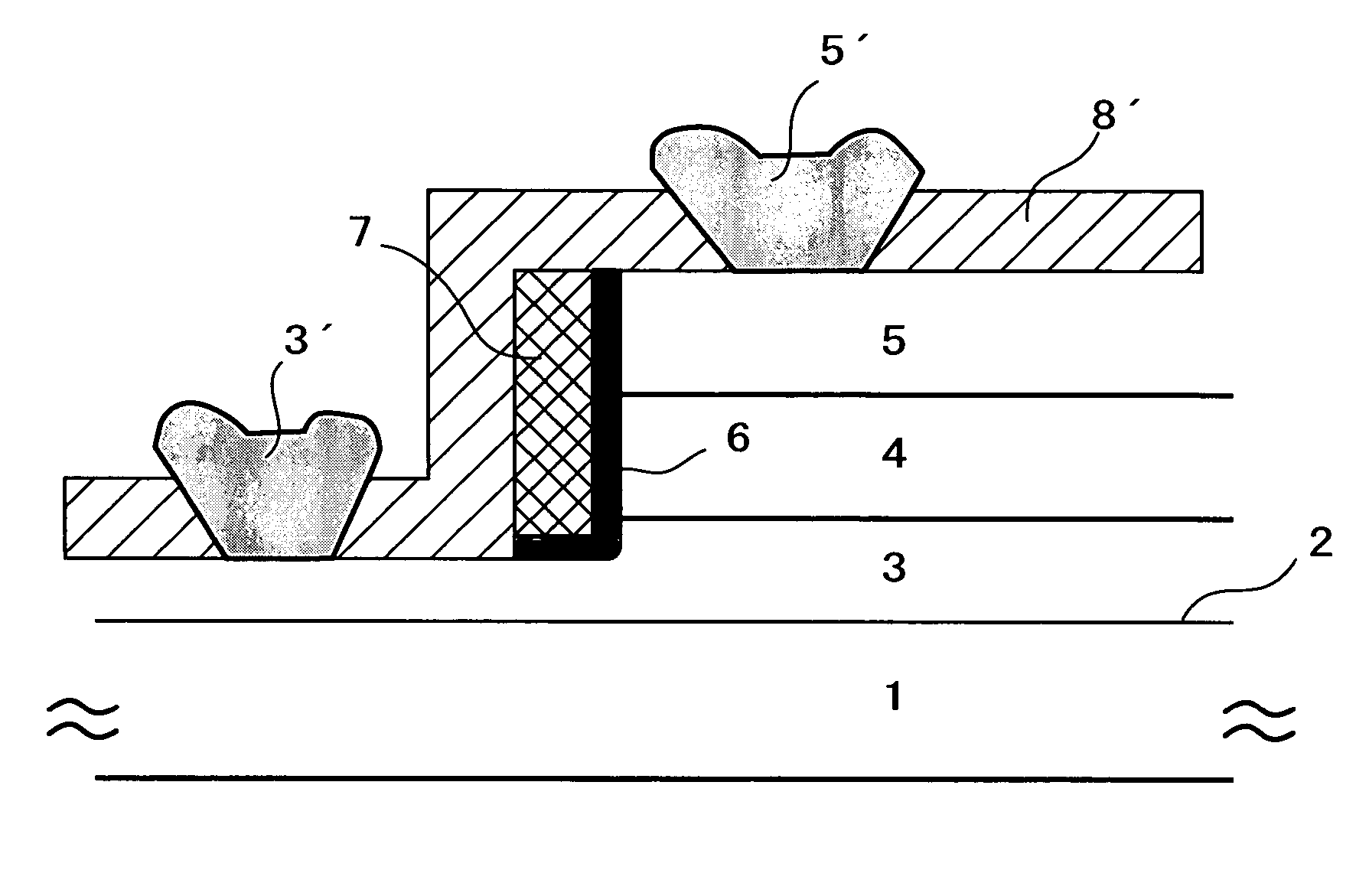

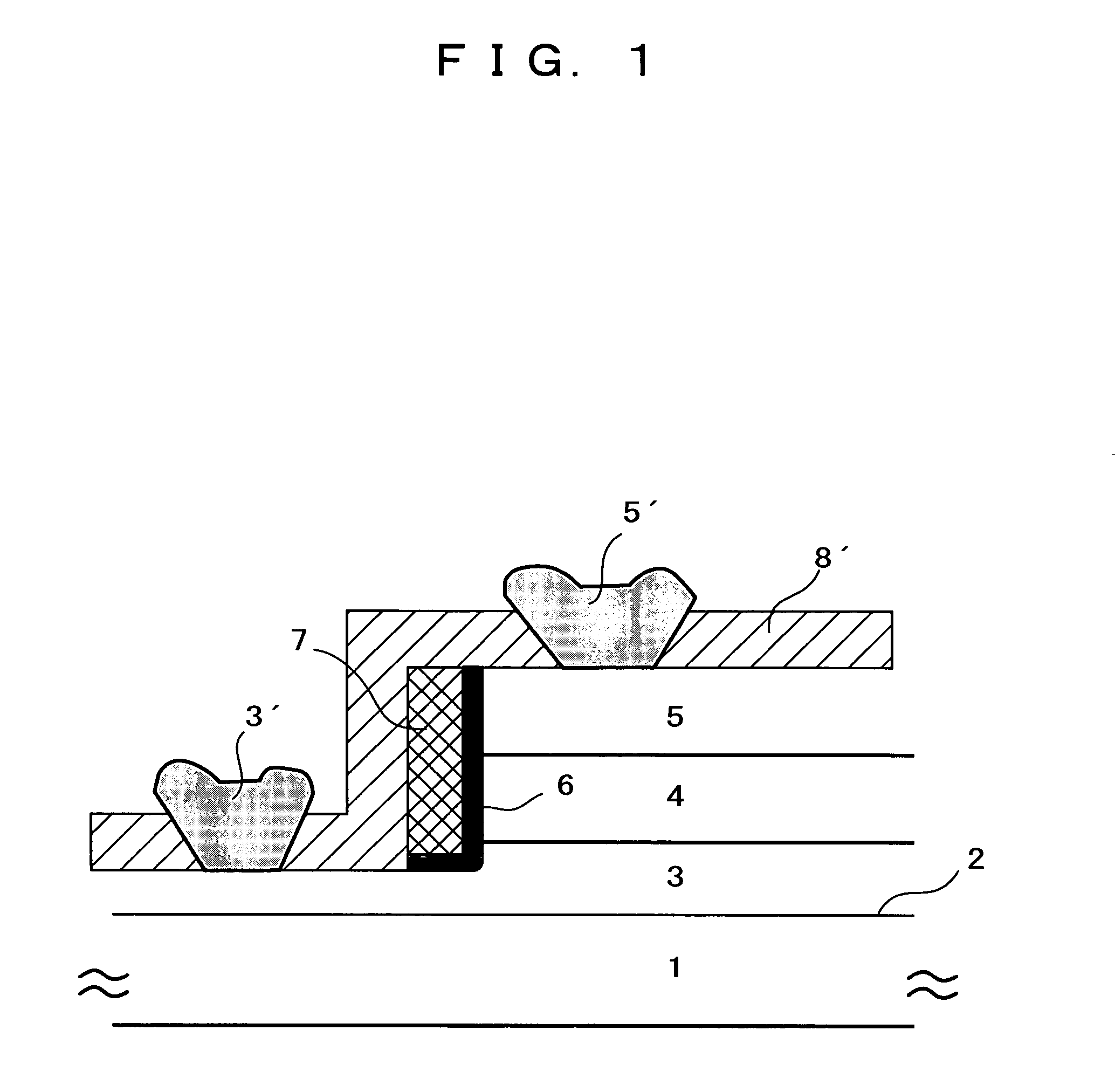

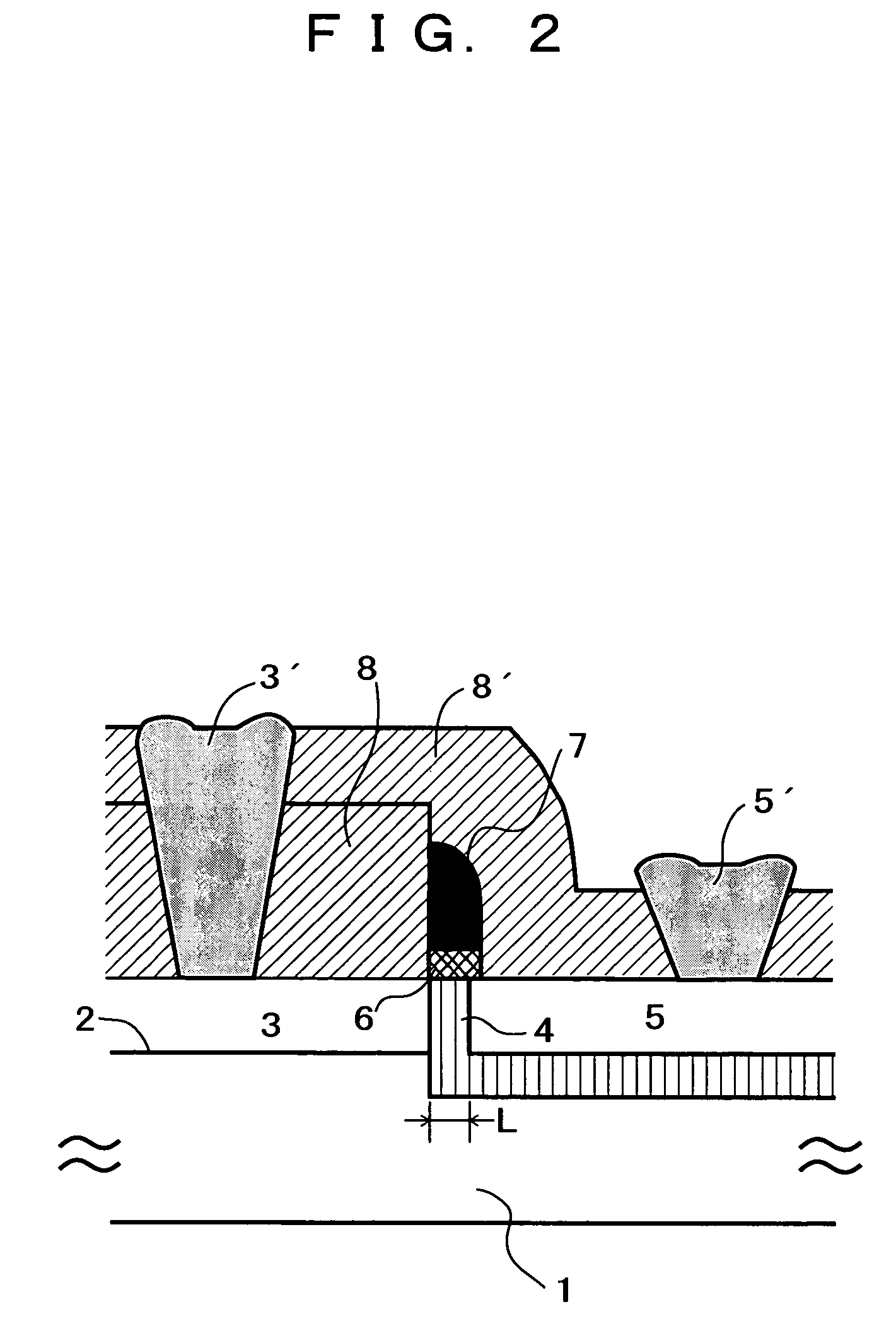

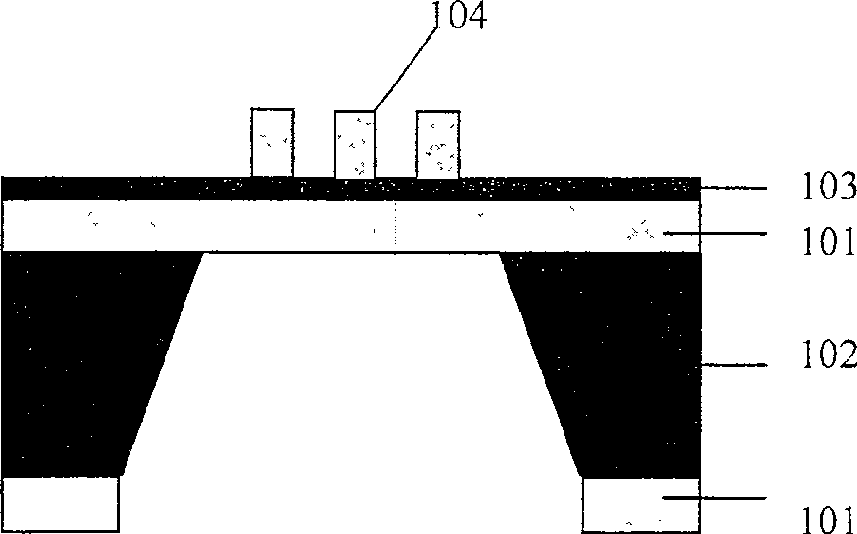

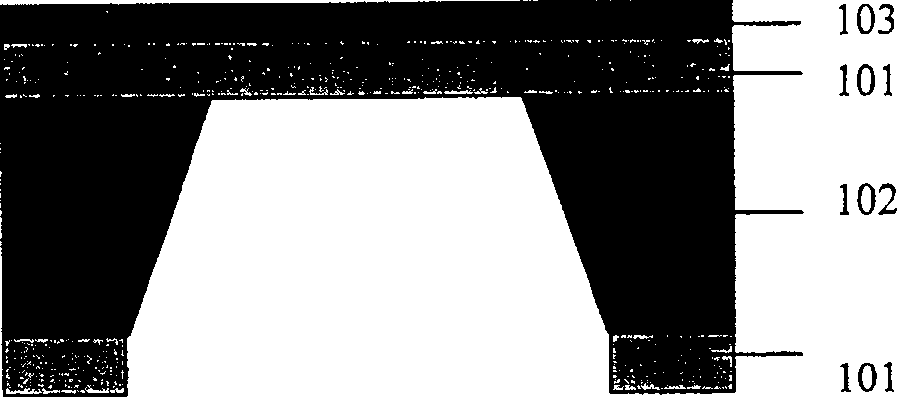

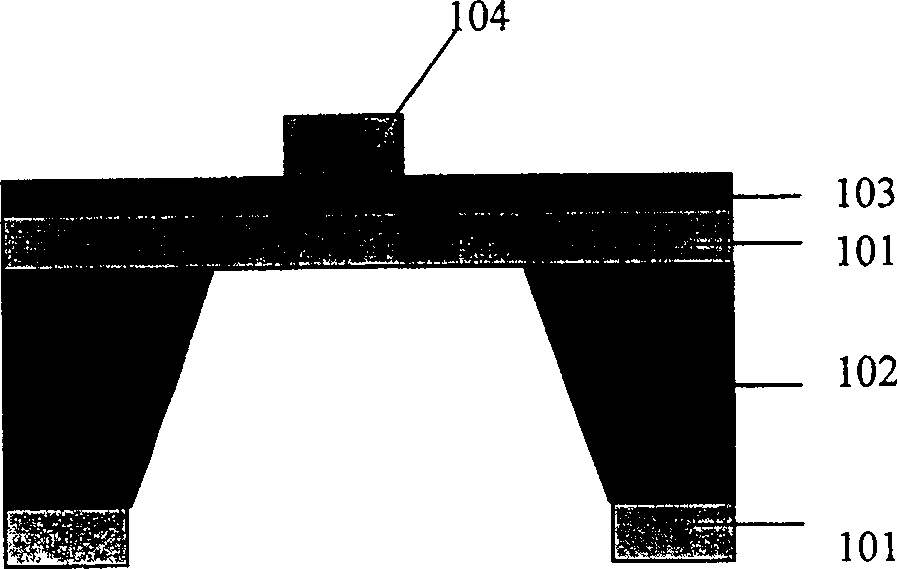

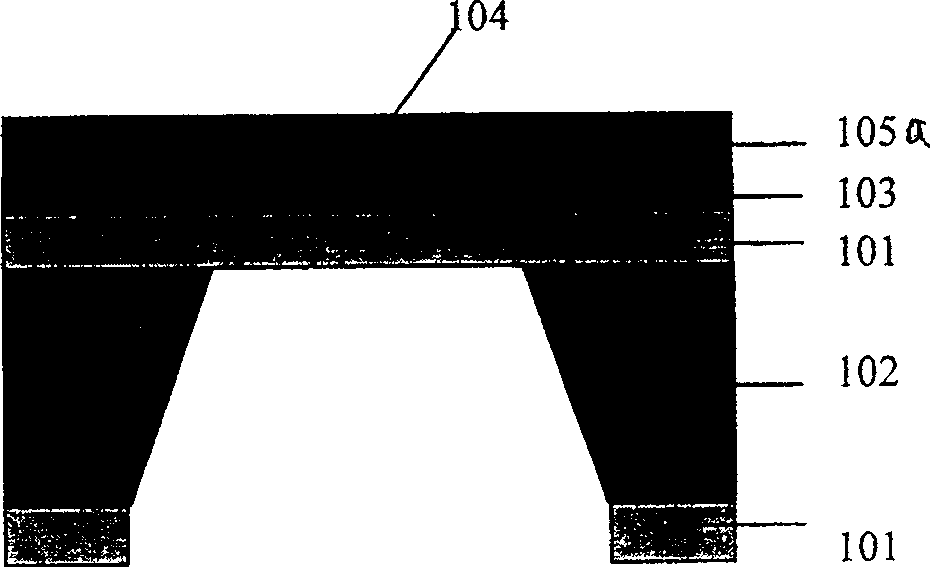

Short channel insulated-gate static induction transistor and method om manufacturing the same

InactiveUS20040178442A1Improve accuracyUnified operationTransistorSolid-state devicesUltra high speedX-ray

The ultra high-speed vertical short channel insulated-gate static induction transistor with uniform operating characteristic which has the drain layer 3 consisting of an epitaxial single crystal layer on the main surface 2 of substrate 1, the channel layer 4 with thickness 1000 Å or less on the drain layer, the source layer 5 consisting of an epitaxial single crystal layer on the channel layer 4, and the insulated-gates 6 and 7 on the sidewalls of the drain, the channel, and the source layers. Since the thickness of 1000 Å or less is accurately controlled using the molecular layer epitaxial method and the channel layer 4 is grown up, the X-ray photolithography is not needed. Since the gate oxide film is formed by low temperature CVD using active oxygen, impurity re-distribution does not occur.

Owner:TELECOMM ADVANCEMENT ORG OF JAPAN +1

A X-lay assembling lens and producing technology thereof

InactiveCN1811491AReduce spherical aberrationImprove machining accuracyRadiation/particle handlingLensMulti materialX-ray

The present invention belongs to a X-ray microstructure optical device, in particular, it relates to a X-ray composite lens and its making process. Said invention includes supporting body, lens main body and air cavity, and its making process includes the following steps: firstly, on single crystal silicon wafer surface successively making polyimide film and metal film, photoetching, electroforming, stripping, opening window and making X-ray photomask; then on the titanium wafer surface preparing X-ray photoresist, using prepared mask to make X-ray photoetching operation to form photoresist structure with double-paraboloidal type lens form and gap with air cavity form; finally, electroforming, moulding and making X-ray composite lens.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Production for aluminium-material X-ray assembled lens

InactiveCN1614448AIncrease thickness dimensionIncrease light collecting apertureRadiation/particle handlingPhotomechanical exposure apparatusX-rayPhotoresist

A method for preparing integrated lens includes forming windows on substrate and using it as mask, preparing titanium plate being used as X ray optical etching substrate, using NaOH / H2O2 to carry out surface treatment and forming X ray optical etching substrate; filling silicon rubber into sample structure for curing process filling aluminium material into rubber mould being taken off, separating out mould after curing; including scaled bottom plate, lens main body and air gap on the retained structure.

Owner:ZHEJIANG UNIV OF TECH

Amine compound, chemically amplified resist composition and patterning process

ActiveUS7468236B2High resolutionAccurate configurationOrganic chemistryPhotosensitive materialsImage resolutionPhotochemistry

Chemically amplified resist compositions comprising amine compounds having a fluorinated alkyl group offer an excellent resolution and a precise pattern profile and are useful in microfabrication by KrF, ArF, F2, EUV, EB or X-ray lithography. They are also effective in the immersion lithography.

Owner:SHIN ETSU CHEM IND CO LTD

High sensitivity X-ray photoresist

InactiveUS6872504B2Improve absorption rateHigh sensitivityPhoto-taking processesPhotosensitive materialsSoft x rayLithographic artist

The present invention provides methods for lithography utilizing X-ray radiation. More particularly, the methods of the invention can be employed for lithography at wavelengths in a range between about 0.8 nm and 30 nm, and more particularly, at wavelengths in a range between 0.8 and 1.2 nm. The methods of the invention employ photoresist compositions having fluorinated polymers with a fluorine content of at least about 10% by weight to provide enhanced sensitivity for X-ray lithography.

Owner:MASSACHUSETTS INST OF TECH

Process for mfg. one-dimensional X ray refracted diffraction micro structural component of polymethyl methyl acrylate material

InactiveCN1786741AReduce absorptionIncrease thickness dimensionMaterial analysis using wave/particle radiationPhotomechanical exposure apparatusPhotoengravingX-ray

The invention relates to poly methyl methacrylate material one dimension X ray diffraction refraction microstructure device manufacturing method. It includes the following steps: making photolithography mask edition; processing silicon substrate; coating polyimide and baking and solidifying; producing metallic film to use as electro forming cathode; coating thick photoresist; exposing, developing, and hardening; producing metallic film to use as X ray photolithography mask absorbent; removing the photoresist an electro forming cathode; back photoengraving and silicon corroding; making titanium slice as supporting; coating poly methyl methacrylate, backing, and solidifying; X ray photoengraving and developing.

Owner:乐孜纯

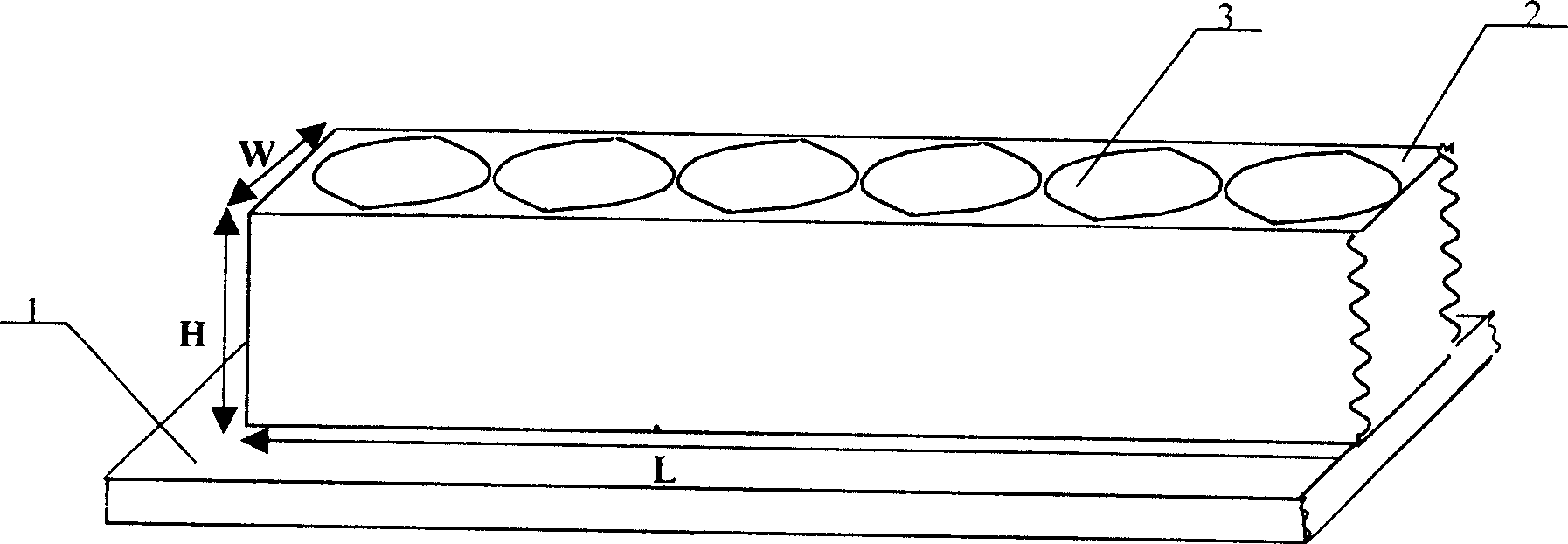

Device for x-ray lithography

A lithography device including a soft X-ray source 1 transforming to a quasi-parallel radiation apparatus for placing a mask 3 and a plate-substrate 4 coated with a resist 5, and an absorbing filter 6 for smoothing of intensity decreasing as from the center to the periphery of a beam. The filter 6 is placed between the source 1 and the input face of the half-lens 2. The half-lens has an enlarged capture angle. This angle is chosen depending on radiation energy (0.6-6 keV) of the source 1. As a result, there is an opportunity to increase the size of the plate-substrate.

Owner:KUMAKHOV MURADIN ABUBEKIROVICH

Short channel insulated-gate static induction transistor and method of manufacturing the same

InactiveUS6977406B2Improve accuracyUnified operationTransistorSolid-state devicesUltra high speedX-ray

The ultra high-speed vertical short channel insulated-gate static induction transistor with uniform operating characteristic which has the drain layer 3 consisting of an epitaxial single crystal layer on the main surface 2 of substrate 1, the channel layer 4 with thickness 1000 Å or less on the drain layer, the source layer 5 consisting of an epitaxial single crystal layer on the channel layer 4, and the insulated-gates 6 and 7 on the sidewalls of the drain, the channel, and the source layers. Since the thickness of 1000 Å or less is accurately controlled using the molecular layer epitaxial method and the channel layer 4 is grown up, the X-ray photolithography is not needed. Since the gate oxide film is formed by low temperature CVD using active oxygen, impurity re-distribution does not occur.

Owner:TELECOMM ADVANCEMENT ORG OF JAPAN +1

Manufacture method of high resolution self-supporting totally hollowed-out transmission grating

ActiveCN100501461CHigh resolutionIncrease productivitySemiconductor/solid-state device manufacturingDiffraction gratingsGratingX-ray

This invention relates to one X ray infraction optical element high resolution rate self-supportive cast transparent grating, which comprises the following: a, depositing film gold layer to support X ray mask underlay; b, in surface layer etching electron glue to get etch pattern; c, the slice is put to coating liquid for X ray mode absorptive gold pattern; d, the said slice removes electron beam glue; e, then removing electron beam for film of chromium layer; f, coating medlin on glass for fixing; g, depositing gold on its surface; h, coating X ray etch glue on gold surface; I, removing medlin; j, removing etch glue; k, back surface erosion of glass to fulfill the process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

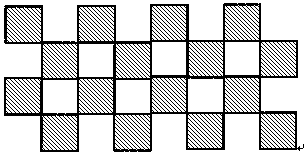

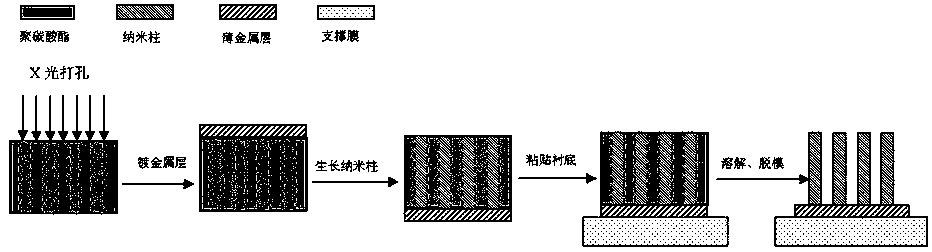

X-ray broadband energy selection device and method for manufacturing same

ActiveCN108877961AReduce the difficulty of cooperationImprove efficiencyMaterial nanotechnologyNuclear energy generationHigh energyX-ray

The invention provides an X-ray broadband energy selection device. The X-ray broadband energy selection device comprises a nano-rod array, a thin metal layer and a supporting film, wherein the nano-rod array is manufactured on the upper surface of the thin metal layer and the supporting film is pasted to the lower surface of the thin metal layer. The energy selection device has the advantages of small infinitesimal element size and high energy selection precision and can be applied to imaging diagnosis apparatuses with a space resolution of a few microns to realize band spectrum imaging diagnosis. The invention also provides a method for manufacturing the X-ray broadband energy selection device. The method comprises the steps of punching a polycarbonate material by using the X-ray lithography technology, and growing nano-rods in the holes by using the electrochemical deposition method to form nano-rods with great rod body perpendicularity and side wall roughness. Square nano-rod arrayswith any high aspect ratio can be manufactured according to the characteristics of to-be-selected energy sections. Band-pass energy selection in any energy section range in a soft X-ray range can berealized by flexibly design the height of the nano-rods, the material and the thickness of the thin metal layer and the grazing incident angle of X-rays.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

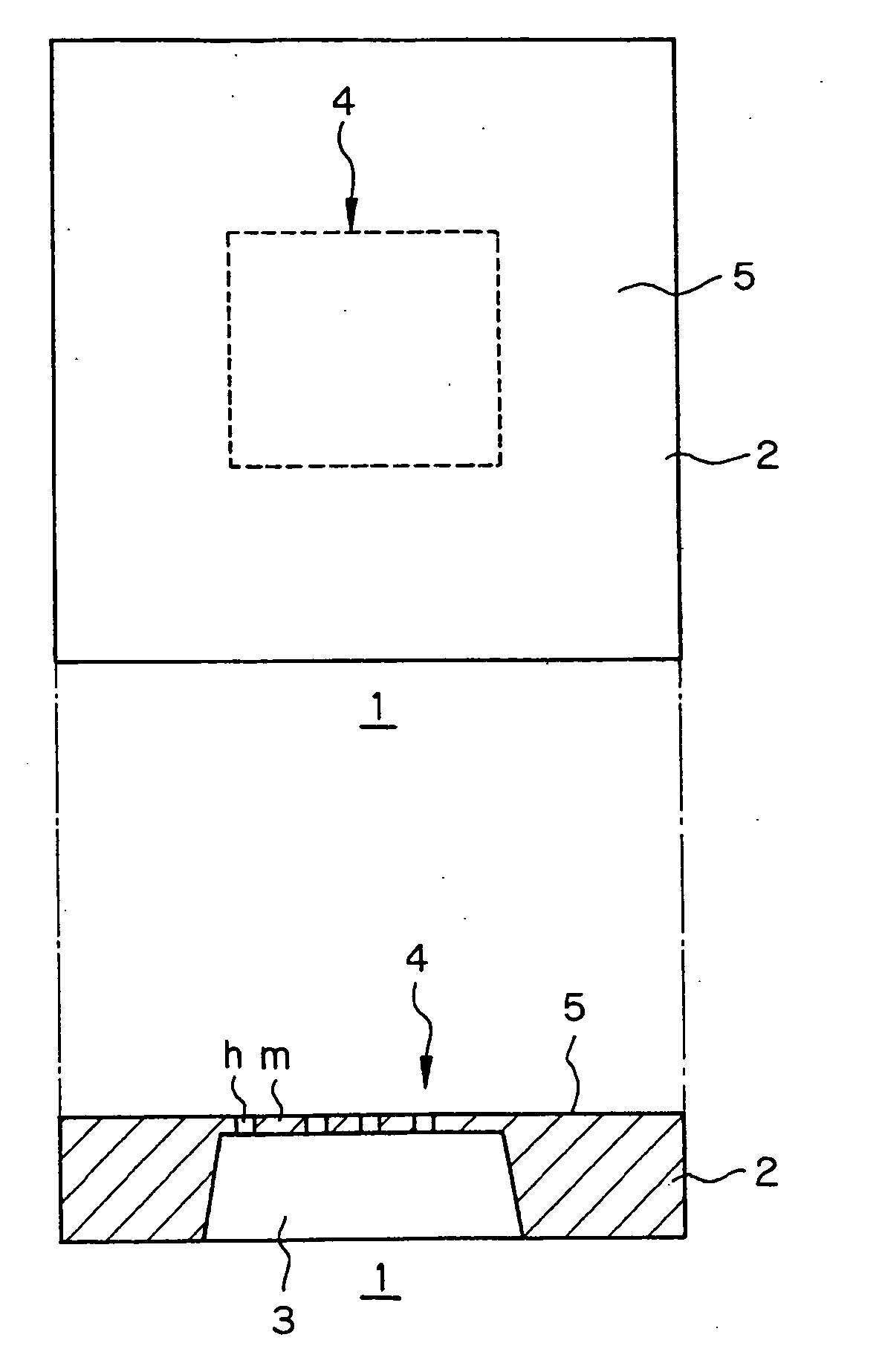

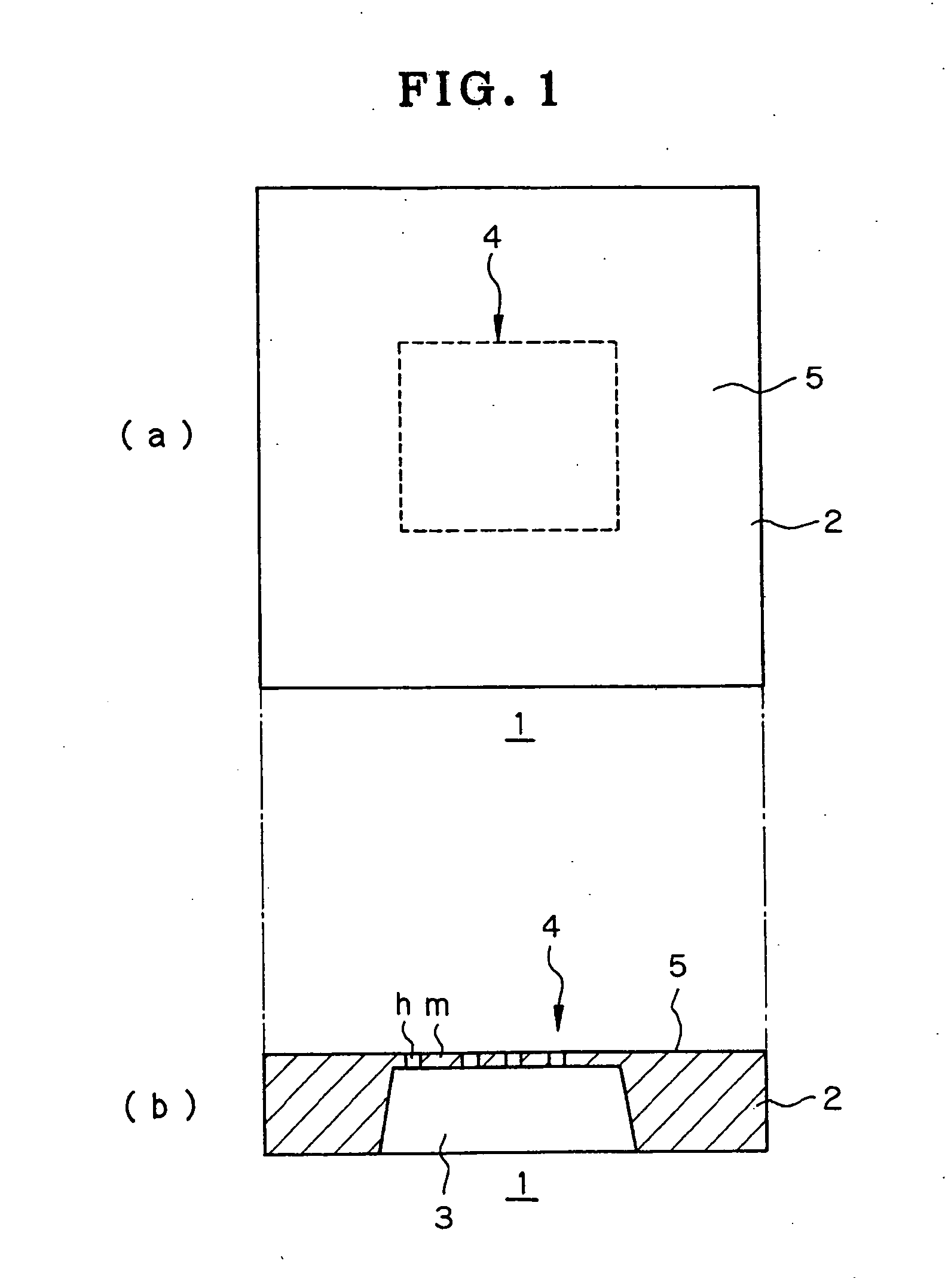

Transfer mask blank, transfer mask, and transfer method using the transfer mask

InactiveUS20060068298A1Improve machining accuracyEfficient preparationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLithographic artistExtreme ultraviolet

It is an object of the present invention to effectively manufacture a charged-particle beam lithography mask, an X-ray lithography mask, or an extreme ultraviolet beam lithography mask by using, for example, an existing writer such as an electron beam writer for photomasks, while achieving improvement in processing accuracy of a mask pattern. A lithography mask (1) comprises a substrate (2) which has a lower surface provided substantially at the center thereof with an opening (3) and a self-supporting membrane (m) having a pattern region (4) substantially at the center of an upper surface of the substrate (2) corresponding to the opening (3). The self-supporting membrane (m) is provided with through-holes (h) of a mask pattern in it or an absorber or scatterer of a mask pattern on it, and the pattern region (4) and a peripheral region around the pattern region (5) are in one plane.

Owner:DAI NIPPON PRINTING CO LTD

High depth-width ratio deep sub-micrometer, nanometer metal structure making process based on self-supporting thin film

ActiveCN100466171CStrong practical valueSuitable for mass productionNanostructure manufacturePhotomechanical apparatusManufacturing technologyX-ray

The invention bases on metal structure manufacture technology of deep sub-micron and nanometer for high aspect ratio of self-support film comprises: 1. depositing thin Cr and Au on front face of self-support film; 2. whirling electron micelle on thin Cr / Au surface to exposure and develop the electron beam; 3. putting the slice into electroplate liquid to electroplate metal firstly; 4. whirling X-ray resist on front face of slice; 5. taking X-ray exposure and develop from the film back surface; 6. electroplating secondly; 7. removing glue and Cr / Au, and completing the manufacture. This invention has strong applied value and fit to large-scale production.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

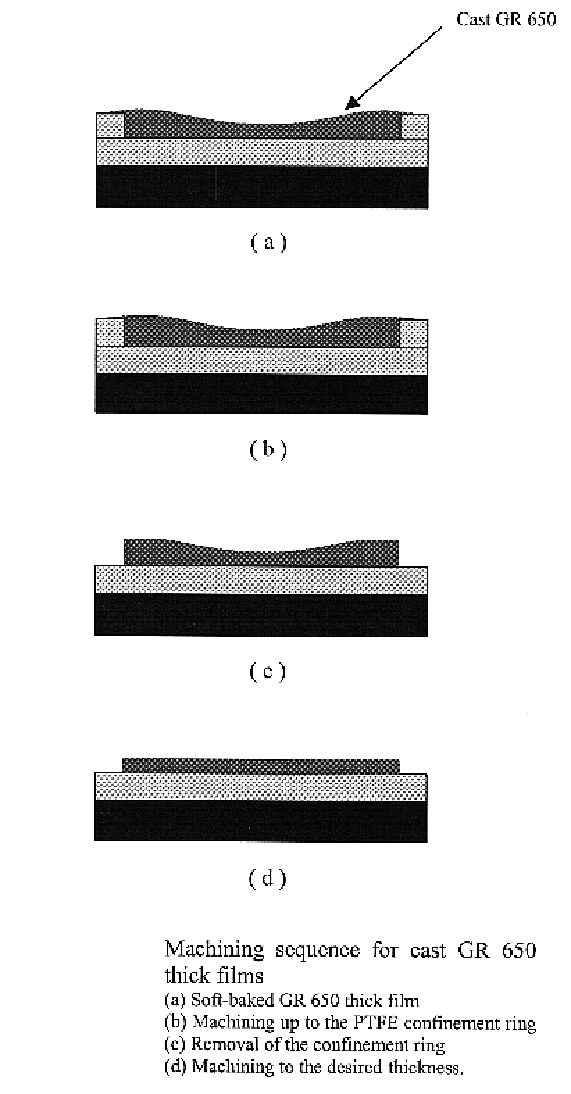

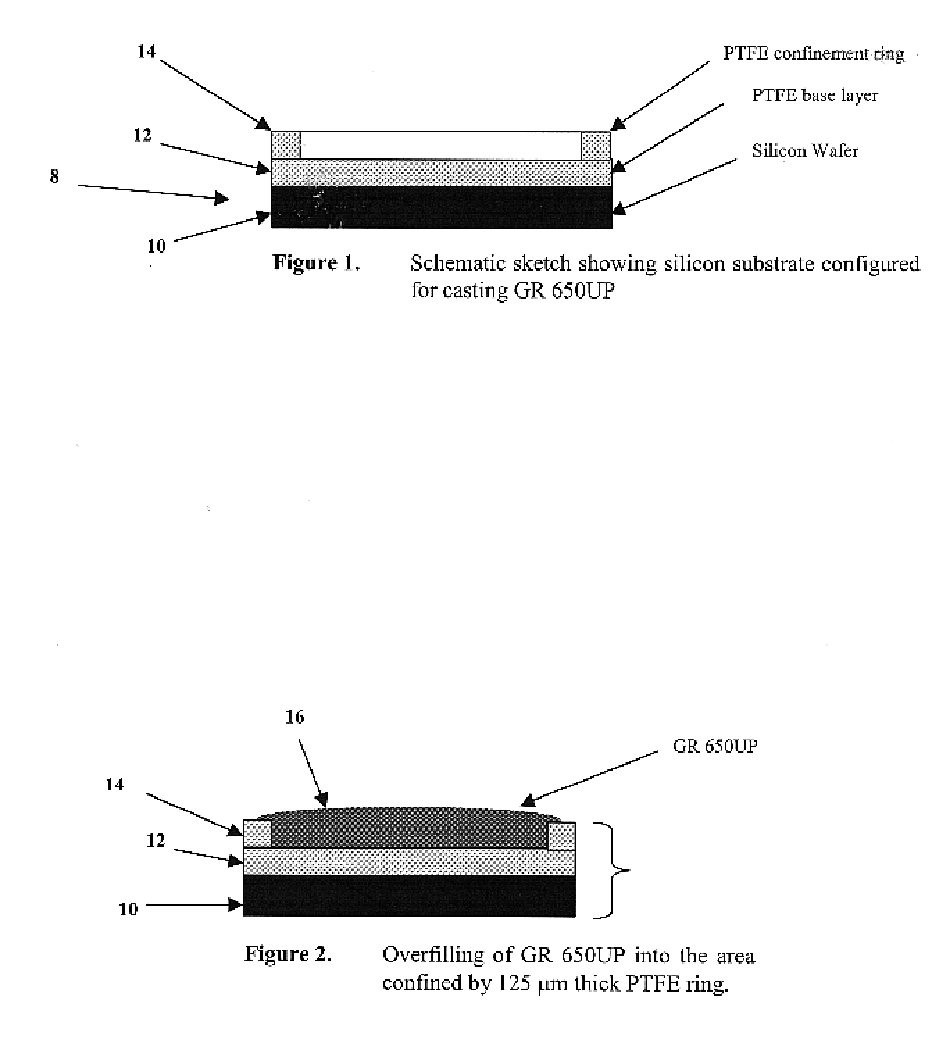

Method of producing silica micro-structures from x-ray lithography of SOG materials

InactiveUS6713408B1High aspect ratioRadiation applicationsSemiconductor/solid-state device manufacturingX-ray lithographyAspect ratio

A lithographic method for producing high aspect ratio silica micro-structures having the steps of: providing a carrier substrate with a confinement boundary placed on the carrier substrate; placing the SOG material within the confinement boundary and soft baking at a temperature above its glass transition temperature; forming a pattern of interest on the soft baked SOG material by x-ray lithography; and heating the SOG material until it is substantially converted to a silica-like oxide.

Owner:LOUISIANA TECH UNIV RES FOUND A DIV OF LOUISIANA TECH UNIV FOUND

X-ray photolithographic mask with through hole

InactiveCN101846874AImprove performanceAvoid deformationOriginals for photomechanical treatmentX-rayOptoelectronics

The invention discloses an X-ray photolithographic mask with a through hole, which comprises a support frame, a layer of thin film with a through hole and a group of absorbers, wherein the support frame is provided with a smooth upper surface and used for fixing and supporting the thin film with the through hole; the thin film with the through hole is positioned on the smooth upper surface of the support frame; and the absorbers are adhered to the thin film with a through hole. By utilizing the invention, residual gas between a mask and a substrate can be effectively discharged by one or a plurality of through holes during vacuumization, thereby a smaller clearance between the mask and the substrate is maintained. Accordingly, on one hand, the mask breakage caused by gas expansion is prevented, and on the other hand, the reduction of an exposure clearance is beneficial to obtaining a more favorable exposure effect.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for making T type grating through combination of X-ray etching and optical etching

InactiveCN1567087ASuitable for mass productionPhotomechanical apparatusSemiconductor/solid-state device manufacturingGratingEtching

It is process method for T-shaped grating by X-ray etching and optics etching and its process steps are the following:1,to coat a base X-ray etching glue on the semi-conductive base slice; 2, to expose the base X-ray etching glue by X-ray etching method ; 3, to coat top optics etching glue; 4, to expose the top optics etching glue by optics etching method; 5, to develop the top optics etching glue to get wide-grating graph ; 6, to develop the base X-ray etching glue to get grating trough graph; 7, to vaporize and stripe the grating metal and accomplish the process of T-shaped grating.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com