A X-lay assembling lens and producing technology thereof

A technology of combining lenses and X-rays, applied in the fields of lenses, nuclear engineering, radiation/particle processing, etc., can solve the problems of affecting X-ray radiation transmittance, large spherical aberration affecting focusing effect, thin structure height and size, etc. The effect of X-ray radiation transmittance, high machining accuracy, high structure height and aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

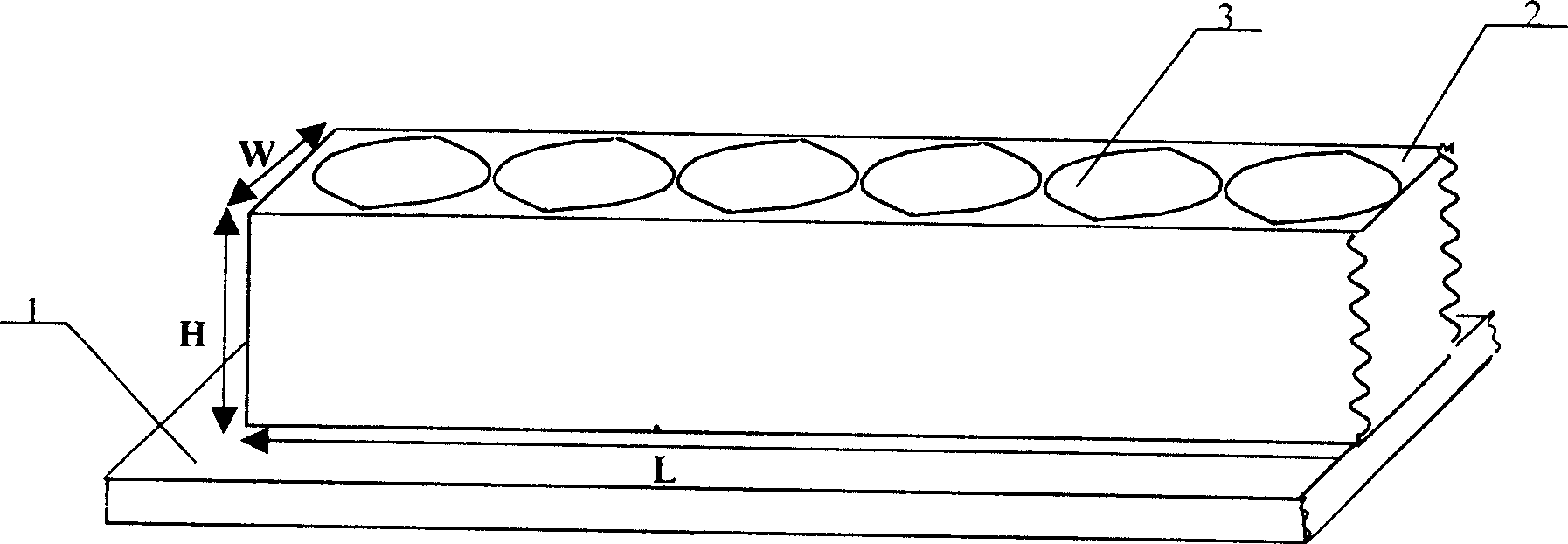

[0011] Such as figure 1 As shown, the X-ray focusing combination lens of the present invention includes a support body 1 , a lens body 2 and an air cavity 3 . The support body 1 and the lens main body 2 can be made of organic materials such as trimethacrylate, polyimide, polycarbonate, and epoxy resin. The air cavity 3 is air. The focal length of the lens body 2 is greater than the length of the lens body 2 and can be selected to be 0.5 meters or 1 meter or 2 meters or 3 meters or 5 meters or other sizes.

[0012] Manufacturing process of the present invention is specifically as follows:

[0013] 1. The silicon substrate can be a single crystal silicon wafer with (100) or (110) or (111) crystal plane, and the substrate cleaning steps are as follows:

[0014] 1). Remove oil and other organic matter with toluene, acetone, ethanol, etc.,

[0015] 2). Boil with aqua regia to remove metal ions,

[0016] 3). Ultrasonic cleaning with deionized water, dehydration with absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com