Liquid nitrogen spay frozen granulation vacuum drying device and working method

A vacuum drying device and spray freezing technology, which is applied in the direction of liquid droplet granulation, etc., can solve the problems of limited ice particle uniformity, uneven size distribution, and low-temperature spray granulation technology has not been industrialized. The effect of large sublimation surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

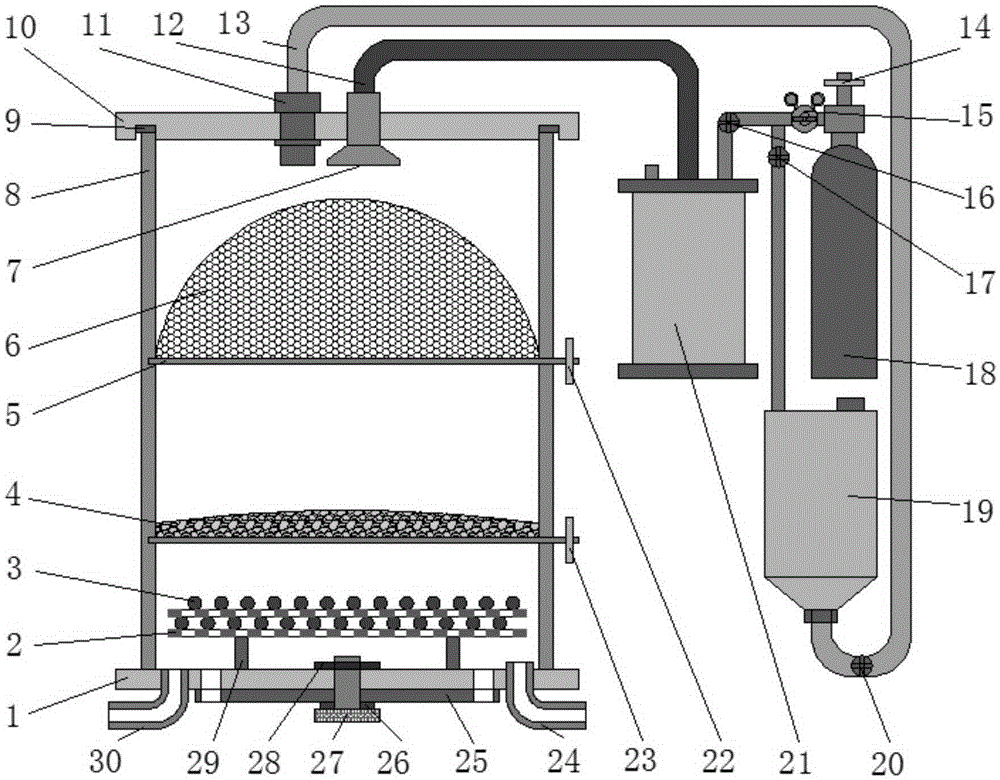

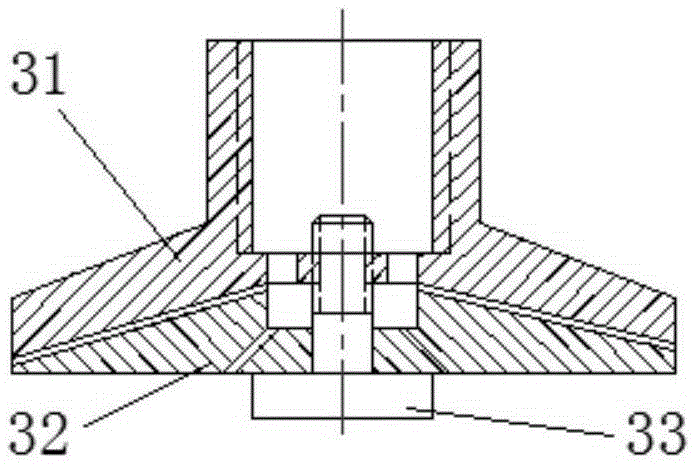

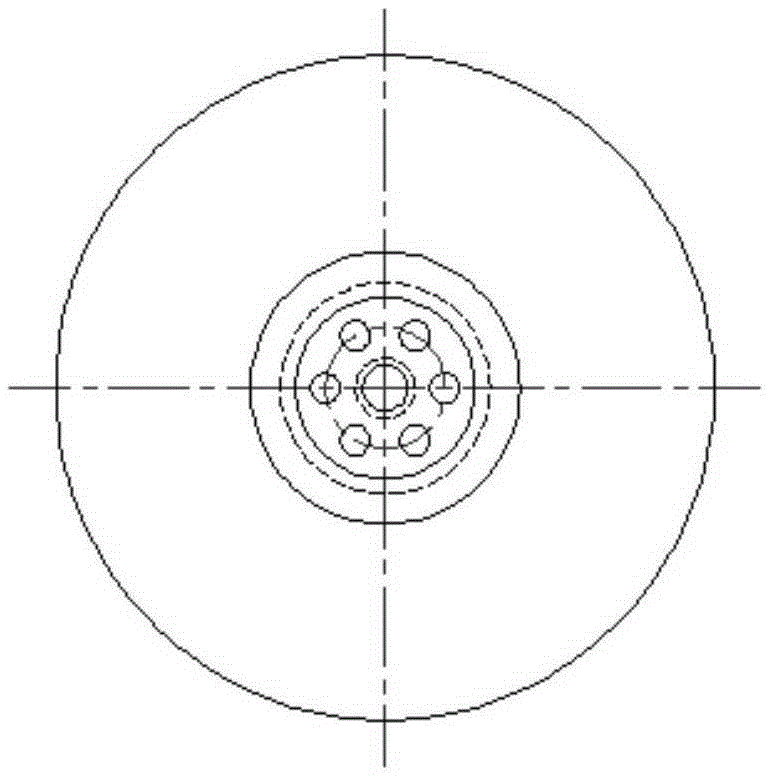

[0025] Such as figure 1 with figure 2 As shown, the present invention provides a liquid nitrogen spray freeze granulation vacuum drying device, which comprises a bottom plate 1, a porous backing plate 2, a condensation pipe 3, a material 4, a rotating shaft 5, a screen 6, a liquid nitrogen nozzle 7, a drying Barrel 8, sealing gasket 9, upper cover 10, spray head 11, liquid nitrogen tube 12, infusion tube 13, handwheel 14, pressure reducing valve 15, first one-way valve 16, second one-way valve 17, high pressure Nitrogen gas bottle 18, liquid storage bottle 19, third one-way valve 20, liquid nitrogen tank 21, second handle 22, first handle 23, vacuum nozzle 24, exhaust baffle 25, sealing ring 26, handle 27, lock Ring 28, bracket 29, drain port 30, liquid nitrogen nozzle seat 31, liquid nitrogen nozzle nozzle 32, positioning bolt 33 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com