Barrier film and vacuum insulating board adopting same

A barrier film and vacuum aluminum plating technology, applied in vacuum evaporation plating, ion implantation plating, coating, etc., can solve the problems of harsh barrier properties and adverse effects of barrier films, and achieve improved gas barrier performance and heat sealing conditions Reduced, excellent oxygen resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

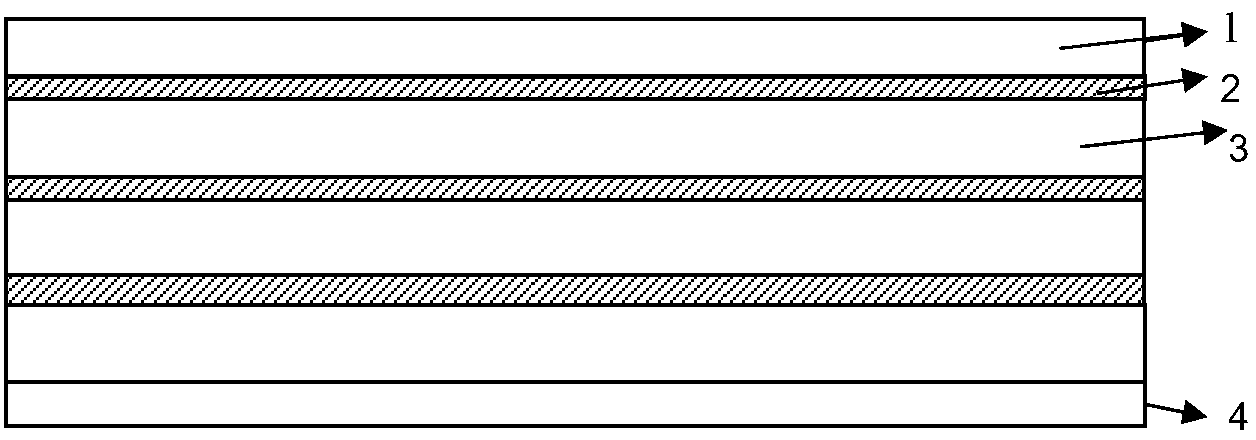

[0039] Barrier film described in this embodiment such as figure 1 As shown, its thickness is 110 μm, and it is composed of a surface layer, a gas barrier layer and a heat-sealing layer, wherein the surface layer is a PET film layer, and the heat-sealing layer is a low-density PE film layer with a thickness of 70 μm. The gas-barrier layer is located between the surface layer and the heat-sealing layer; the gas-barrier layer is composed of 3 layers of the aluminized PET film layer, and the aluminum-coated layer and the aluminum-coated PET film layer of each layer are The thickness ratio of described aluminized PET film layer is 1:350, and wherein, the preparation technology of described aluminized PET film comprises the steps:

[0040] (1) Place the PET base film in the aluminum plating chamber for vacuum aluminum plating. During the vacuum aluminum plating process, the temperature in the aluminum plating chamber is 1300°C, and the vacuum degree is 2×10 -2 Pa, the unwinding spe...

Embodiment 2

[0044] Barrier film described in this embodiment such as figure 1 As shown, its thickness is 110 μm, and it is composed of a surface layer, a gas barrier layer and a heat-sealing layer, wherein the surface layer is a PET film layer, and the heat-sealing layer is a low-density PE film layer with a thickness of 70 μm. The gas-barrier layer is located between the surface layer and the heat-sealing layer; the gas-barrier layer is composed of 3 layers of the aluminized PET film layer, and the aluminum-coated layer and the aluminum-coated PET film layer of each layer are The thickness ratio of described aluminized PET film layer is 1:400, and wherein, the preparation technology of described aluminized PET film comprises the steps:

[0045] (1) Use 10000V / m 2 The high-frequency AC voltage is used to corona-treat the PET film to obtain a PET base film;

[0046] (2) Place the PET base film in the aluminum plating chamber for vacuum aluminum plating. During the vacuum aluminum plating...

Embodiment 3

[0050] The barrier film described in this embodiment has a thickness of 105 μm and is composed of a surface layer, a gas barrier layer and a heat-sealing layer bonded together, wherein the surface layer is a PET film layer, and the heat-sealing layer is a low-density PE film with a thickness of 40 μm. film layer, the gas barrier layer is located between the surface layer and the heat-sealing layer; the gas barrier layer is composed of 2 layers of the aluminized PET film layer, each layer of the aluminized PET film layer The thickness ratio of aluminized layer and described aluminized PET film layer is 1:450, and wherein, the preparation technology of described aluminized PET film comprises the steps:

[0051] (1) Use 5000V / m 2 The high-frequency AC voltage is used to corona-treat the PET film to obtain a PET base film;

[0052] (2) Place the PET base film in the aluminum plating chamber for vacuum aluminum plating. During the vacuum aluminum plating process, the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com