Graphene-coated glass fiber reinforced resin-based composite material and preparation method thereof

A technology for reinforcing resin base and glass fiber, which is applied in the field of graphene-coated glass fiber reinforced resin-based composite material and its preparation, can solve the problems that have not been disclosed before, and achieves the effect of solving the dispersion problem, simple process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

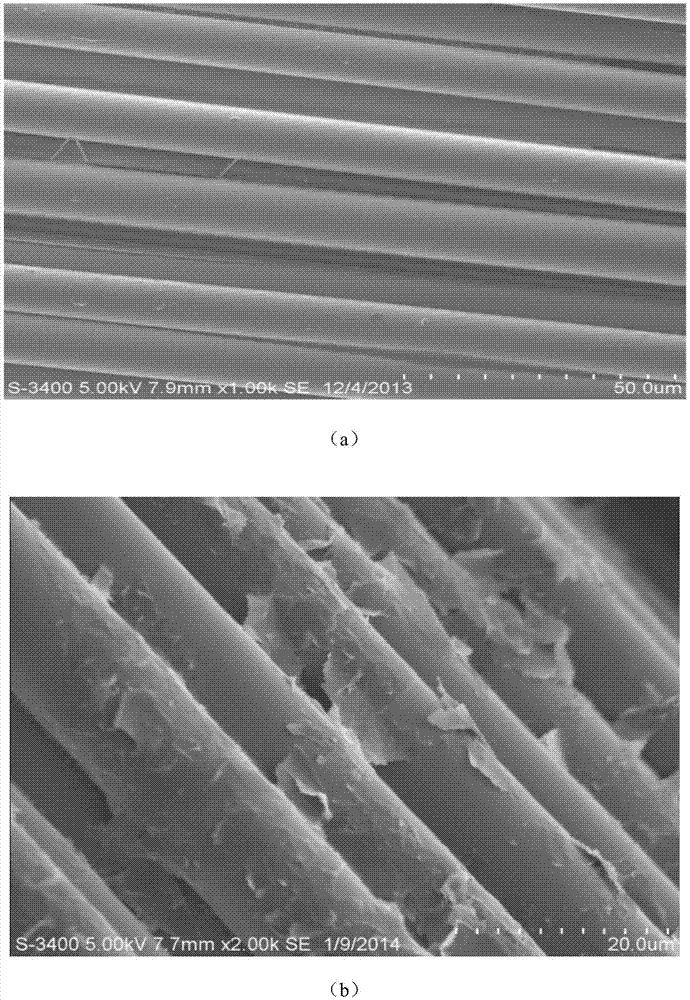

[0031] ① Silane coupling agent modified graphene: Dissolve 2g graphene powder in a mixed solvent of 200mL distilled water and 150mL absolute ethanol, and form a uniform dispersion after ultrasonication for 1h; then 50mL containing 15g aminopropyltriethoxysilane (A1100) of absolute ethanol was slowly added to the above-mentioned dispersion liquid under stirring, and reacted at 60°C for 24 hours after the addition was completed, and the obtained pasty product was first washed with absolute ethanol three times to remove excess A1100, and then Wash 3 times with distilled water, and finally centrifuge at 8000r / min for 15min to obtain 1.5g of A1100 modified graphene.

[0032]② water dispersion of glass fiber impregnated with silane coupling agent-modified graphene: take 1 g of silane coupling agent-modified graphene obtained in step ① and disperse it in 1000 mL of distilled water to obtain the mass fraction of silane coupling agent-modified graphene It is a 0.1% aqueous dispersion, ...

Embodiment 2

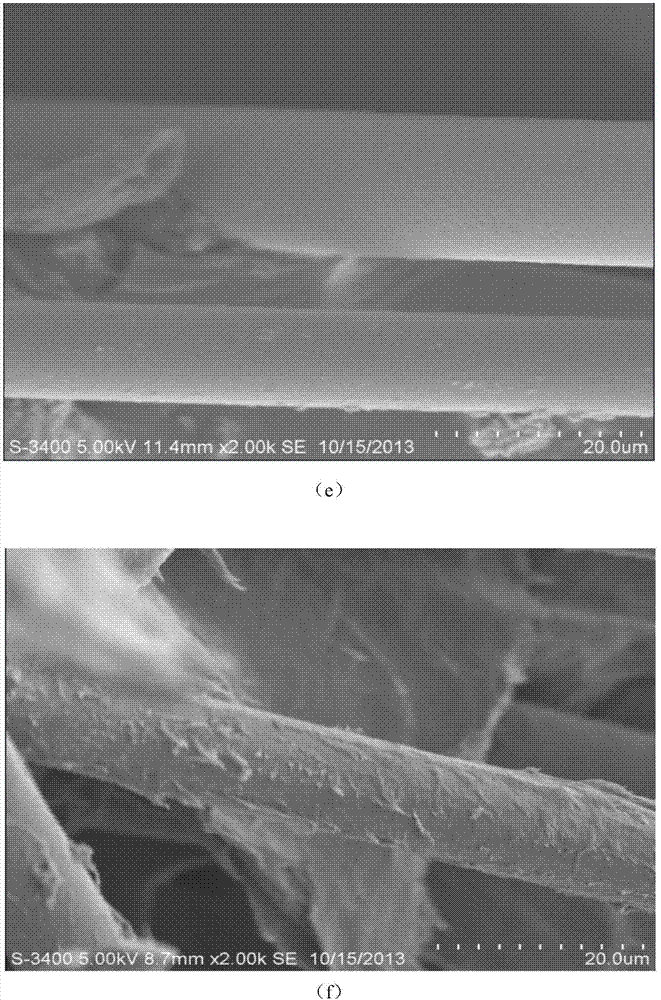

[0039] ① Silane coupling agent modified graphene: Dissolve 2g graphene powder in a mixed solvent of 200mL distilled water and 150mL absolute ethanol, and form a uniform dispersion after ultrasonication for 1h; then 50mL containing 15g aminopropyltriethoxysilane (A187) dehydrated alcohol was slowly added to the above-mentioned dispersion liquid under stirring, and reacted at 60°C for 24 hours after the addition, and the obtained pasty product was first washed 3 times with dehydrated ethanol to remove excess A187, and then Wash 3 times with distilled water, and finally centrifuge at 8000r / min for 15min to obtain 1.5g of A187 modified graphene.

[0040] ② water dispersion of glass fiber impregnated with silane coupling agent-modified graphene: take 1 g of silane coupling agent-modified graphene obtained in step ① and disperse it in 1000 mL of distilled water to obtain the mass fraction of silane coupling agent-modified graphene It is a 0.1% aqueous dispersion, and a uniform dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com