Supporting anti-corrosive coating modified by graphene, preparation and application thereof

A graphene modified and anti-corrosion coating technology, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problem that the graphene modified coating is not used in conjunction with the topcoat, and achieve excellent anti-corrosion effects. The effect of strong protection ability and good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 modified graphene

[0034] Add 2.0g of graphene to 10g of deionized water; add 4.0g of sodium hexametaphosphate dispersant, stir well to fully disperse the powder particles; slowly add hydrochloric acid in the slurry to adjust the pH value of the slurry to 3-5; Add 2.72g of sodium dodecylbenzenesulfonate as a modifier, stir slowly for 30min, move it to an ultrasonic cleaner, continue constant temperature ultrasonication for 30min, to make it fully react; after repeated filtration and washing with deionized water, take the filter residue in the Dry at 110-135°C, dry and cool, then grind to obtain modified graphene; perform XRD characterization on the surface-modified graphene. figure 1 It is the XRD pattern of graphene before and after modification. It can be seen from the figure that the crystal structure of graphene does not change before and after modification.

Embodiment 2

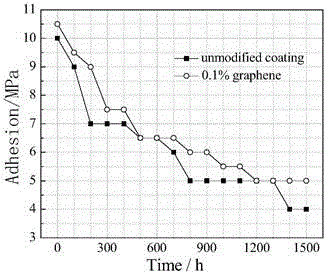

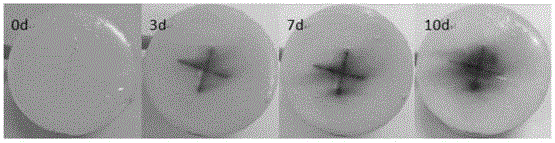

[0035] Embodiment 2 Preparation of graphene modified epoxy supporting coating system

[0036] Get 0.1g of above-mentioned obtained modified graphene, add it in excess ethanol, ultrasonic 1 hour, stir fully then, make it disperse evenly; Resin Chemical Company), then add 0.6g leveling agent (BYK371), 0.9g defoamer (BYK085), 1.1g silane coupling agent (KH550), and stir well; 48.5g curing agent (purchased from Feicheng De Yuan Chemical Co., Ltd.) was added to the prepared organic resin dispersion, stirred evenly, scraped on the surface of the metal test plate, and then placed in a 60 ° C oven to completely remove the organic solvent to obtain the primer. Place the prepared coating test panel in an oven at 60°C for drying, and then apply another coat of paint after the first coat of paint dries for 24 hours as an intermediate paint. Then apply the polyurethane topcoat (purchased from Ningbo Feilun Paint Co., Ltd.) according to the method of coating the intermediate paint, and the...

Embodiment 3

[0037] Embodiment 3 Preparation of graphene modified polyurethane supporting coating system

[0038] Take 0.1 g of modified graphene, add it to excess ethanol, ultrasonicate for 1 hour, and then fully stir to make it evenly dispersed. The prepared dispersion containing graphene was added to 80g of polyurethane resin (purchased from Ningbo Feilun Paint Co., Ltd.), followed by adding 0.6g leveling agent (BYK371), 0.9g defoamer (BYK085), 1.1g silane Combine agent (KH560) and 13.6g of polyurethane curing agent, stir evenly, scrape coat on the surface of the metal test plate, and then place it in a 60°C oven to completely remove the organic solvent to obtain the primer. Place the prepared coating test panel in an oven at 60°C for drying, and then apply another coat of paint after the first coat of paint dries for 24 hours as an intermediate paint. Then apply the polyurethane topcoat (purchased from Ningbo Feilun Paint Co., Ltd.) according to the method of coating the intermediate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com