Biodegradable drain board, and preparation method thereof

A technology of biodegradation and preparation process, applied in the field of drainage board processing, can solve the problems of poor chemical stability of polystyrene, not easy to biodegrade, and pollution caused by the environment, so as to improve the surface hydrophobicity, improve the water resistance effect, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

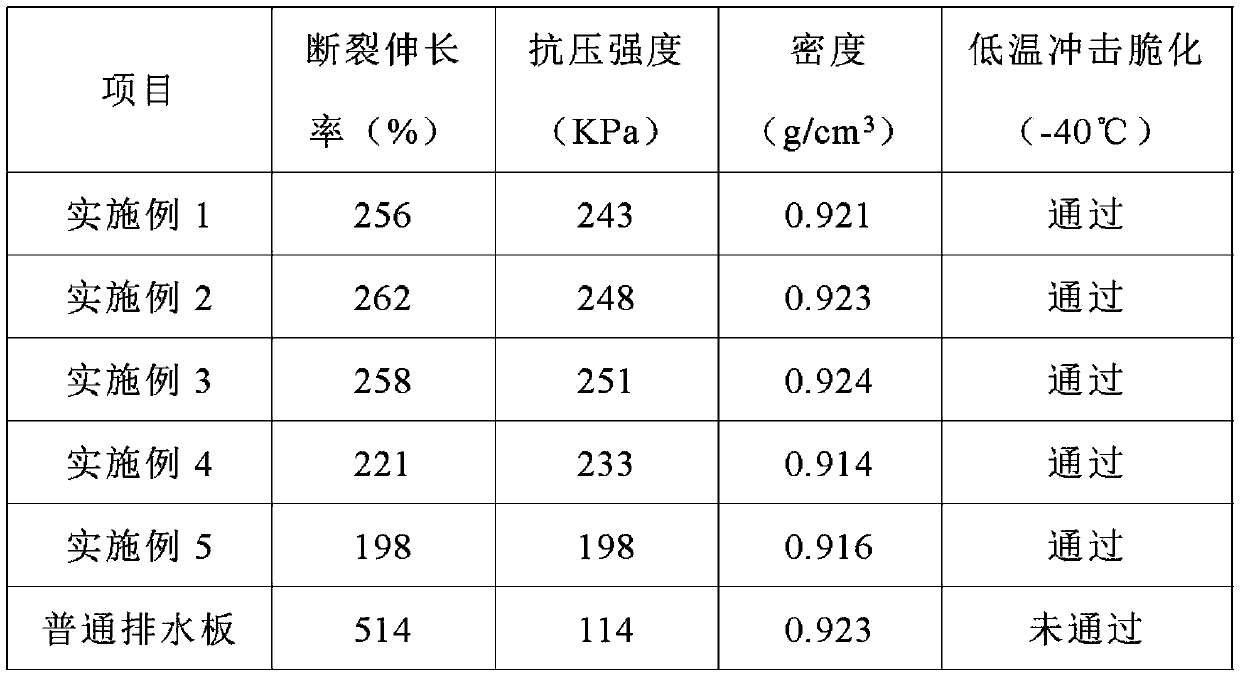

Examples

Embodiment 1

[0050] First prepare the raw materials, weigh photosensitizer, heat sensitizer, emulsifier, styrene, azobisisobutyronitrile, polylactic acid, maleic anhydride, benzoyl peroxide, coupling agent, silicon dioxide gas condensation Glue and wood fiber, spare; preparation of polystyrene emulsion: take the emulsifier and put it in a three-necked beaker, dissolve it in ethanol under the assistance of ultrasound, start stirring, raise the temperature to 70°C, put in azobisisobutyronitrile, react for 30min, and then add benzene Ethylene, continue to react for 3h, cool to normal temperature, obtain polystyrene emulsion;

[0051] Then the surface modification of the wood fiber, take the wood fiber, place it in a sodium hydroxide solution, stir at a constant temperature of 40°C for 50 minutes, filter and wash twice with water; then put it into the coupling agent and soak it at 30°C for 3 minutes to obtain the material A: Take silica airgel, dissolve and disperse at room temperature to obta...

Embodiment 2

[0057] First prepare the raw materials, weigh photosensitizer, heat sensitizer, emulsifier, styrene, azobisisobutyronitrile, polylactic acid, maleic anhydride, benzoyl peroxide, coupling agent, silicon dioxide gas condensation Glue and wood fiber, spare; preparation of polystyrene emulsion: take the emulsifier and put it in a three-necked beaker, dissolve it in ethanol under the assistance of ultrasound, start stirring, raise the temperature to 75°C, put in azobisisobutyronitrile, react for 35min, and then add benzene Ethylene, continue to react for 3.5h, cool to normal temperature, obtain polystyrene emulsion;

[0058] Then the surface modification of the wood fiber, take the wood fiber, place it in a sodium hydroxide solution, stir at a constant temperature of 40-50°C for 55min, filter it, and wash it with water for 3 times; then put it into the coupling agent, soak it at 35°C for 4min, Obtain material A; take silica airgel, dissolve and disperse at room temperature to obtai...

Embodiment 3

[0064] First prepare the raw materials, weigh photosensitizer, heat sensitizer, emulsifier, styrene, azobisisobutyronitrile, polylactic acid, maleic anhydride, benzoyl peroxide, coupling agent, silicon dioxide gas condensation Glue and wood fiber, spare; preparation of polystyrene emulsion: take the emulsifier and put it in a three-necked beaker, dissolve it in ethanol under the assistance of ultrasound, start stirring, raise the temperature to 80°C, put in azobisisobutyronitrile, react for 40min, and then add benzene Ethylene, continue to react for 4h, cool to normal temperature, obtain polystyrene emulsion;

[0065] Then the surface modification of the wood fiber, take the wood fiber, place it in a sodium hydroxide solution, stir at a constant temperature of 50°C for 60 minutes, filter and wash 3 times with water; then put it into the coupling agent, and soak it at 40°C for 5 minutes to obtain the material A: Take the silica airgel, dissolve and disperse at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com