Ultra-high performance cement-based composite material for sensor, sensor and preparation method thereof

A composite material, ultra-high performance technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, etc., can solve the problems of poor toughness, low tensile strength, easy cracking, etc., to achieve stable performance, stable agility, promotion The effect of cement hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

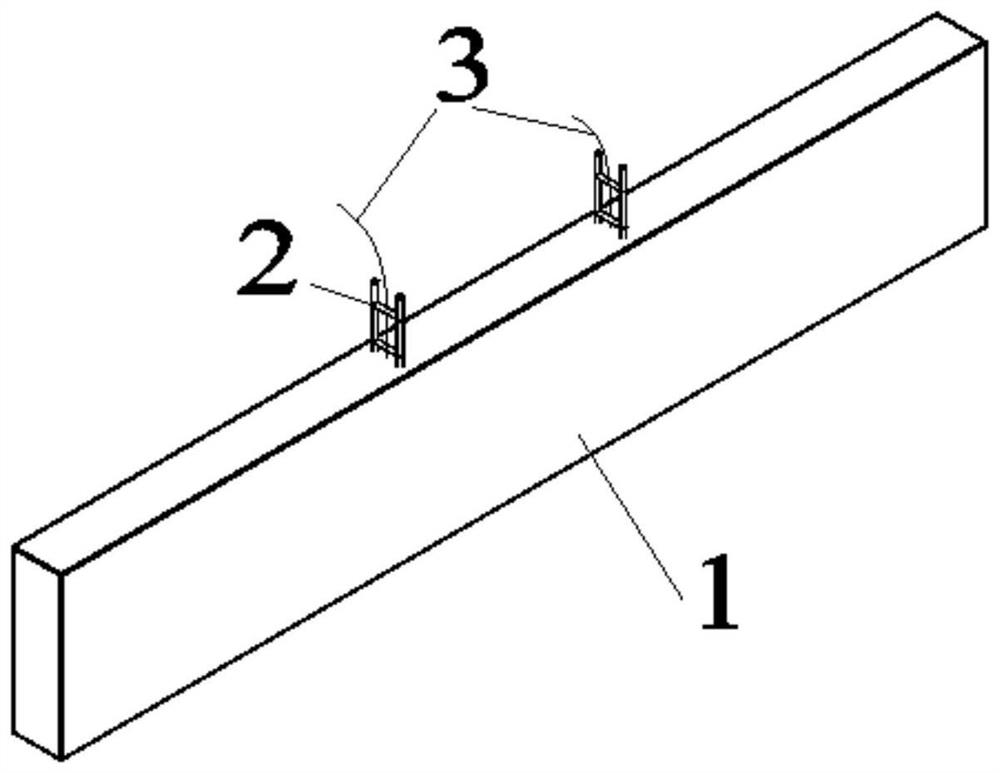

[0054] An ultra-high-performance cement-based composite material for sensors, including cement, fly ash, quartz sand, fibers, water reducer, starch gel, water, carbon nanotubes (CNTs), graphite powder, and surfactants;

[0055] The mass ratio of cement to fly ash is 1:1.1, and the percentages of other ingredients relative to the total mass of cement and fly ash are: 35% of quartz sand, 1% of fiber, 0.15% of water reducer, 2% of starch gel, Water 20%, carbon nanotube 0.2%, graphite powder 1%, surfactant 0.2%.

Embodiment 2

[0057] An ultra-high-performance cement-based composite material for sensors, including cement, fly ash, quartz sand, fibers, water reducer, starch gel, water, carbon nanotubes (CNTs), graphite powder, and surfactants;

[0058] The mass ratio of cement and fly ash is 1:1.2, and the percentages of other ingredients relative to the total mass of cement and fly ash are: quartz sand 35%, fiber 2%, water reducer 0.2%, starch gel 3%, Water 25%, carbon nanotube 0.3%, graphite powder 2%, surfactant 0.2%.

Embodiment 3

[0060] An ultra-high-performance cement-based composite material for sensors, including cement, fly ash, quartz sand, fibers, water reducer, starch gel, water, carbon nanotubes (CNTs), graphite powder, and surfactants;

[0061] The mass ratio of cement and fly ash is 1:1.3, and the percentages of other components relative to the total mass of cement and fly ash are: 40% of quartz sand, 3% of fiber, 0.2% of water reducer, 4% of starch gel, Water 30%, carbon nanotube 0.5%, graphite powder 3%, surfactant 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com