Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

310 results about "Oxygen transmission rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen transmission rate (OTR) is the measurement of the amount of oxygen gas that passes through a substance over a given period. It is mostly carried out on non-porous materials, where the mode of transport is diffusion, but there are a growing number of applications where the transmission rate also depends on flow through apertures of some description.

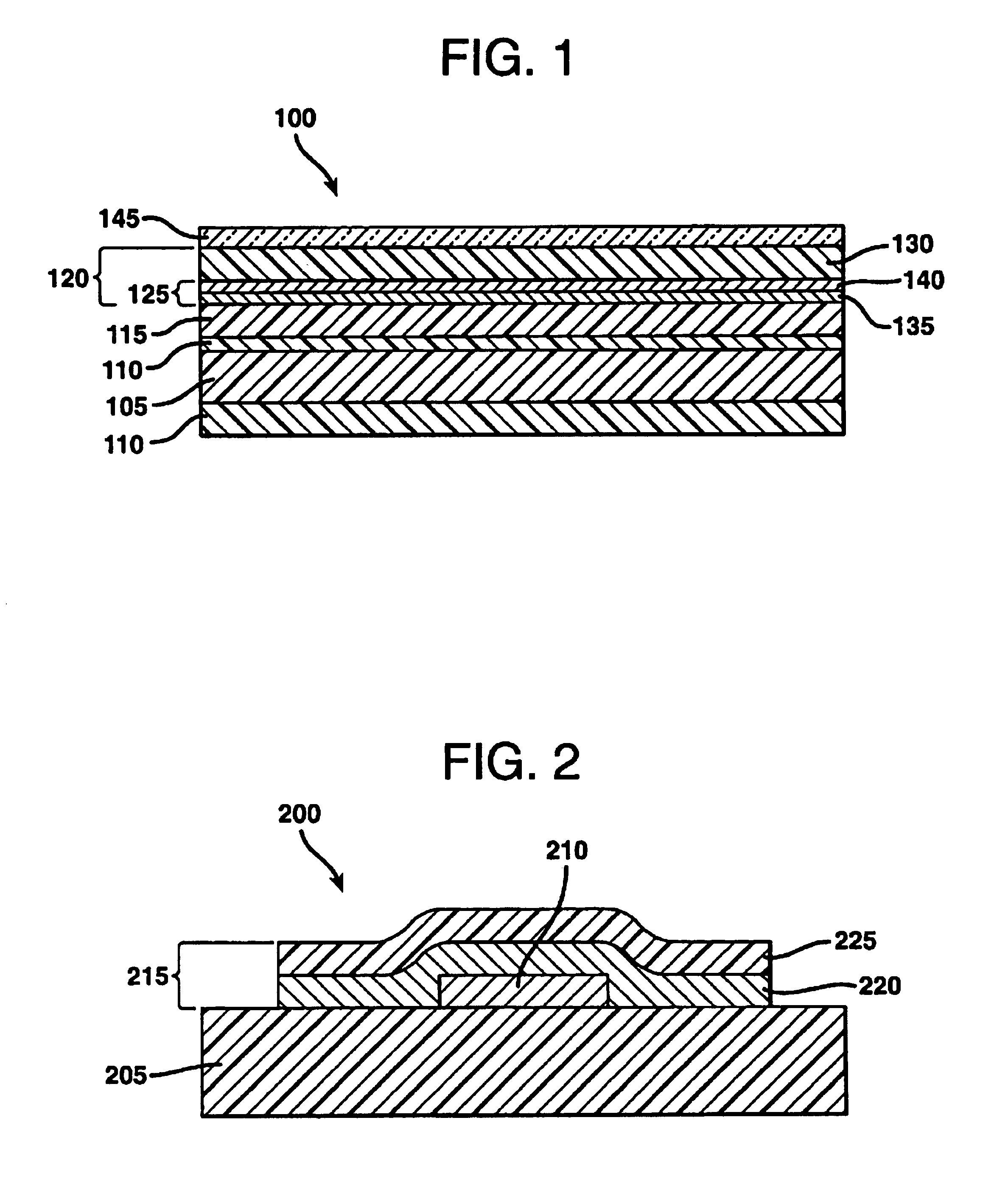

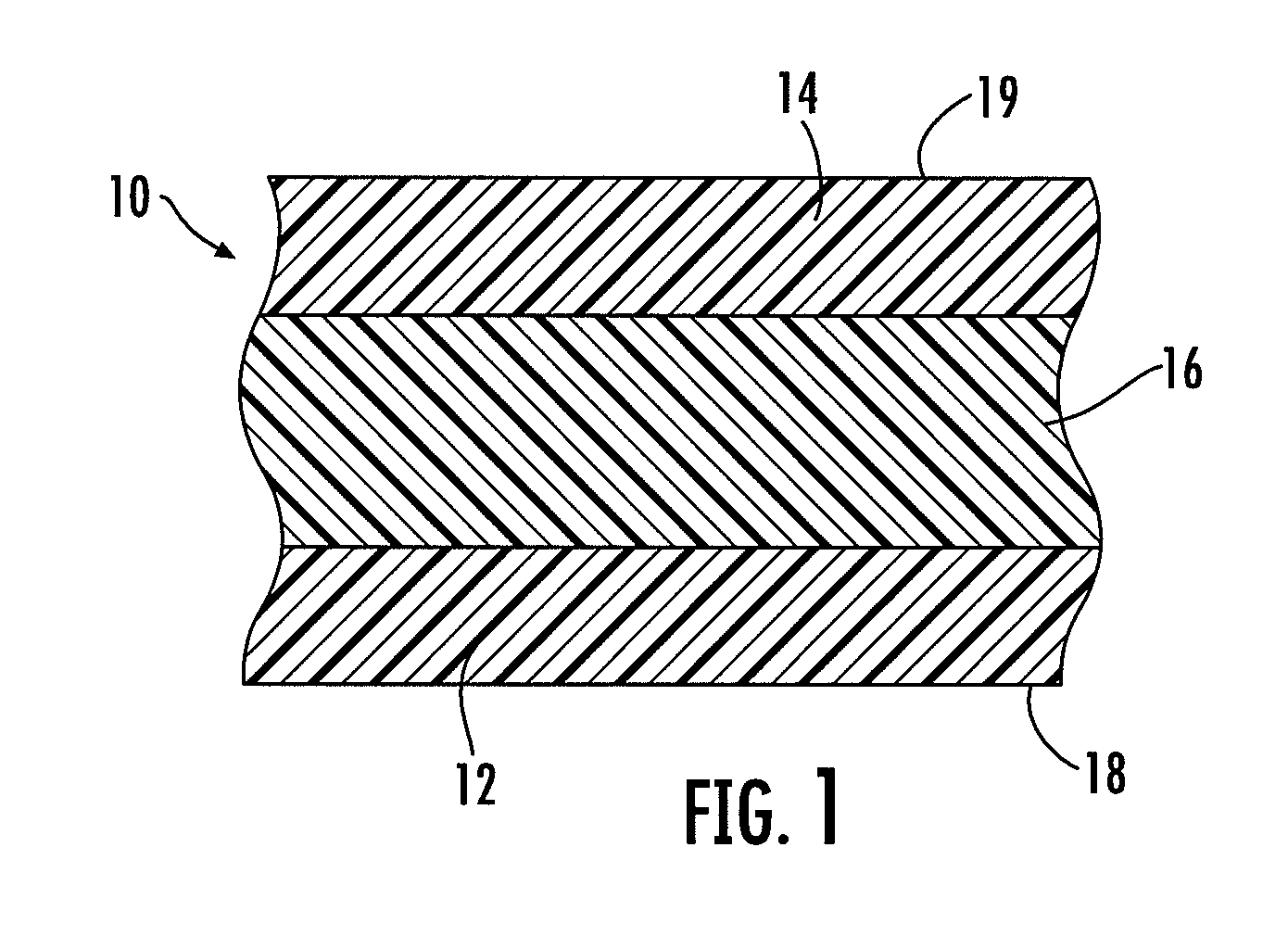

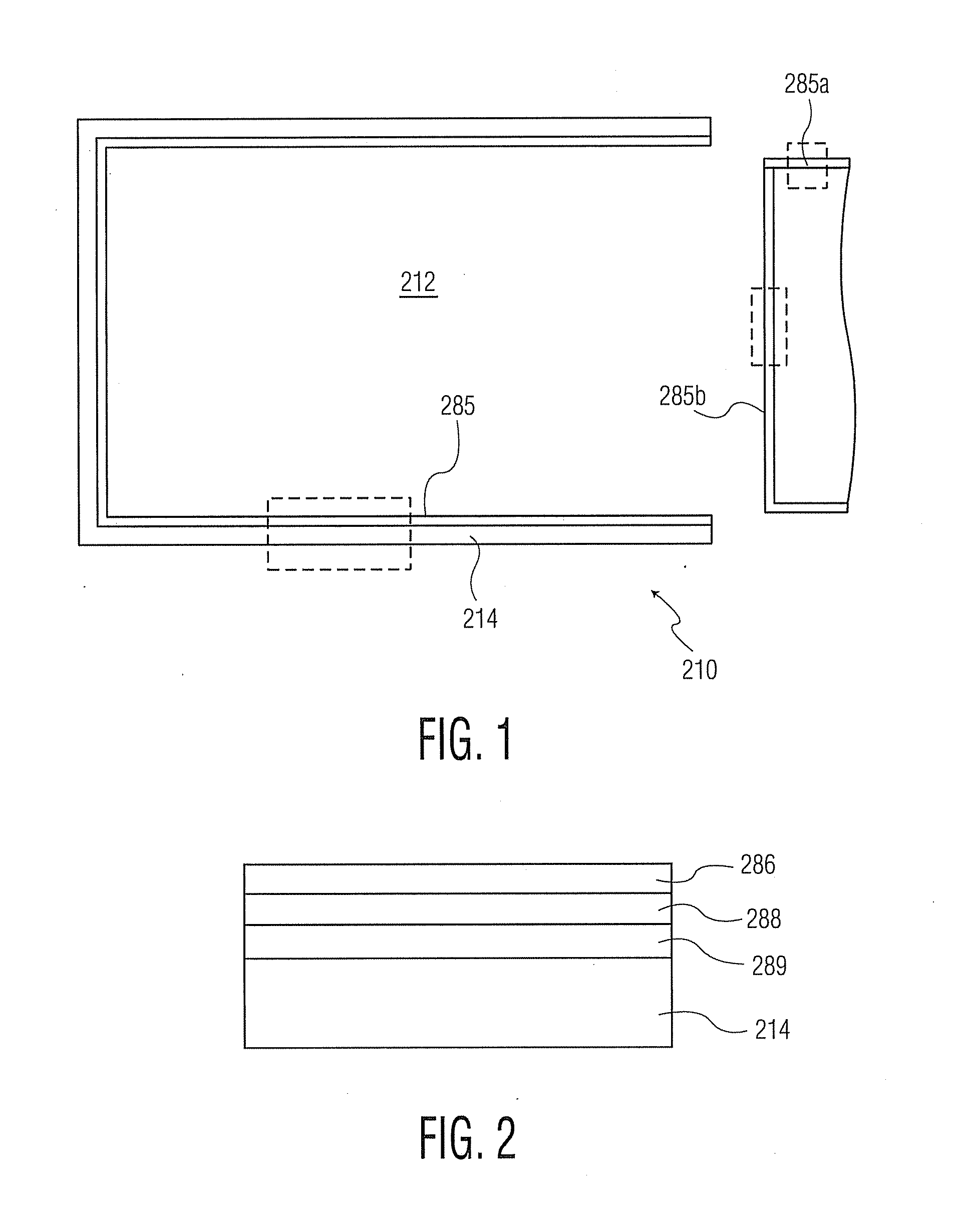

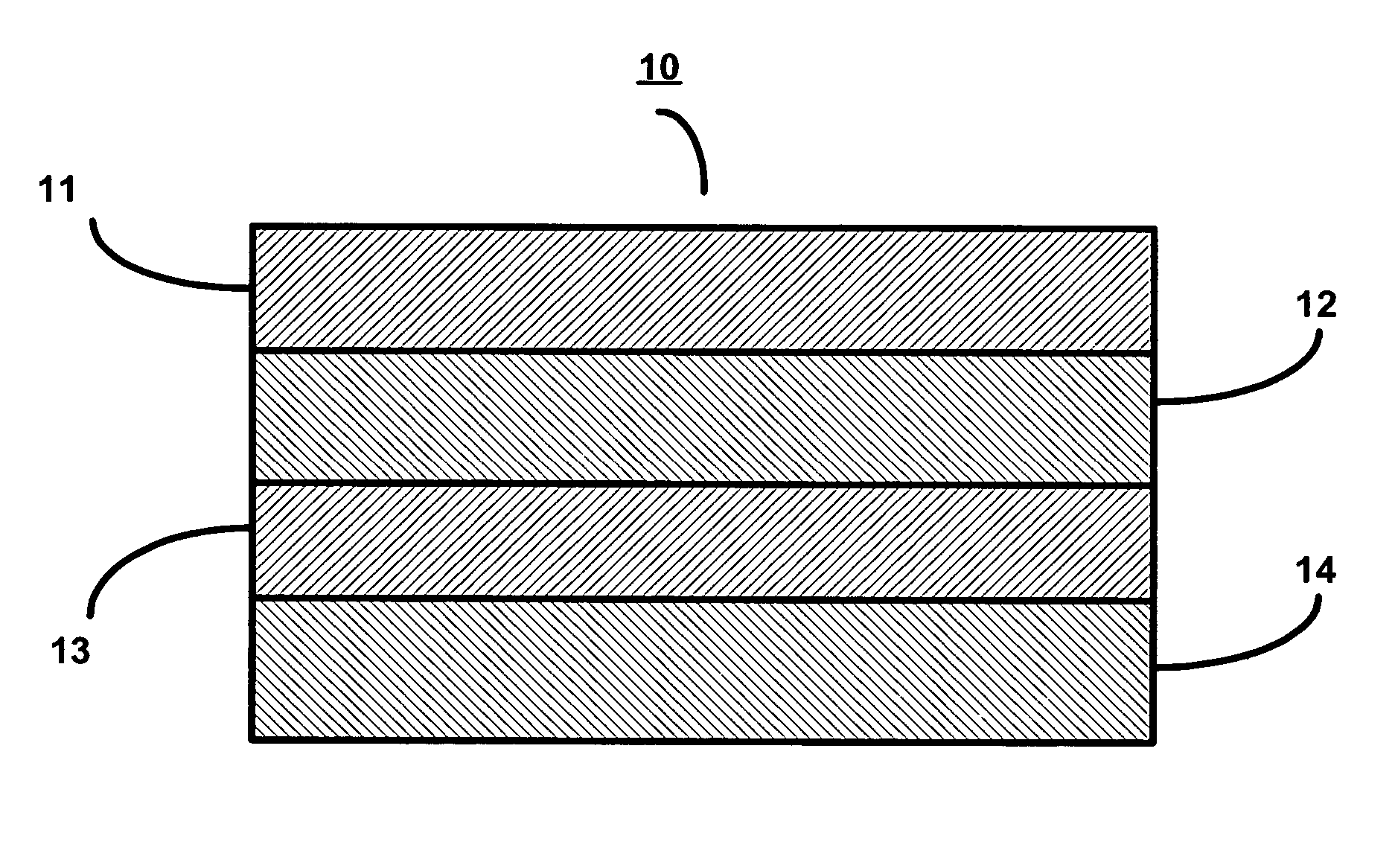

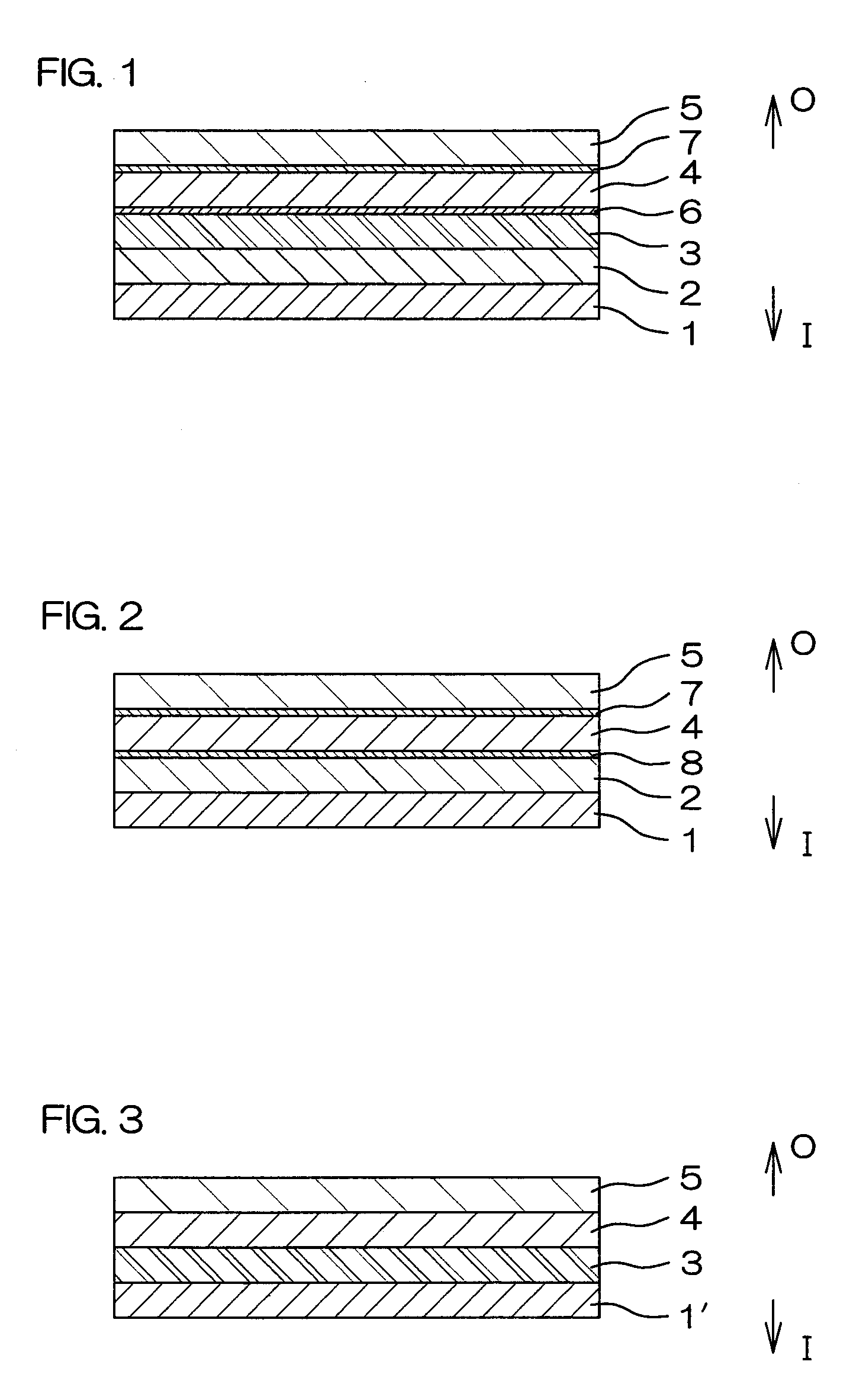

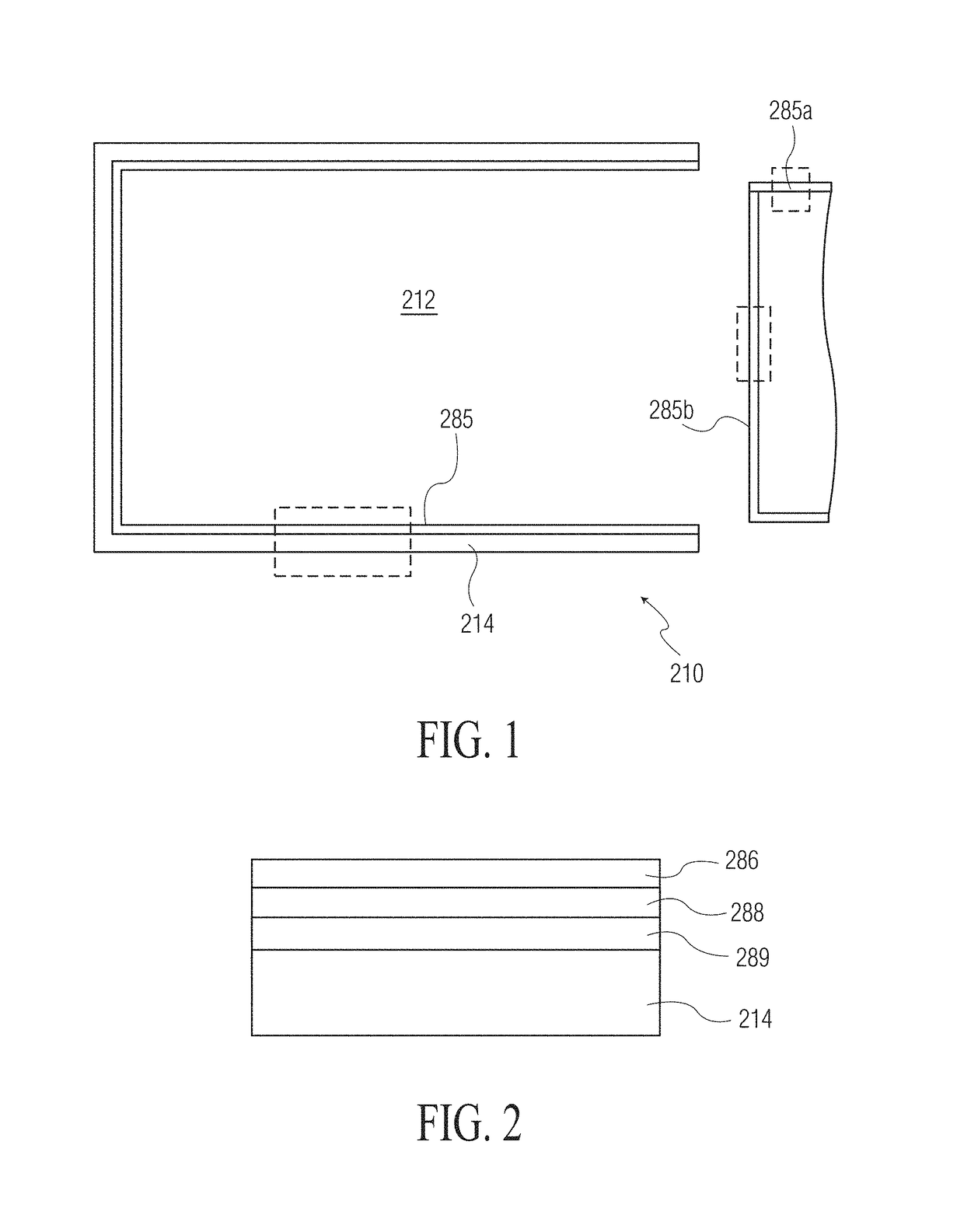

Ultrabarrier substrates

A barrier assembly. The barrier assembly includes at least one barrier stack having at least one barrier layer and at least one polymer layer. The barrier stack has an oxygen transmission rate of less than 0.005 cc / m2 / day at 23° C. and 0% relative humidity, and an oxygen transmission rate of less than 0.005 cc / m2 / day at 38° C. and 90% relative humidity. The barrier stack also has a water vapor transmission rate of less than 0.005 g / m2 / day at 38° C. and 100% relative humidity. A method for making a barrier assembly is also disclosed.

Owner:SAMSUNG DISPLAY CO LTD

Barrier Packaging Webs Having Metallized Non-Oriented Film

ActiveUS20090110888A1Improve sealingImprove barrier propertiesFlexible coversWrappersThermoplasticFiber

Owner:BEMIS COMPANY INC

Soft contact lenses displaying superior on-eye comfort

The present invention relates to soft contact lenses having an overall comfort preference of at least about 2 to 1 as compared to an Acuvue® contact lens and measured after one week of daily wear. The present invention further relates to a soft contact lens comprising an oxygen transmissibility greater than about 70 barrers / mm and physical properties suitable to provide wearer comfort over at least about 9 hours in at least about 80% of wearers, as measured in a randomized, double masked clinical study.

Owner:JOHNSON & JOHNSON VISION CARE INC

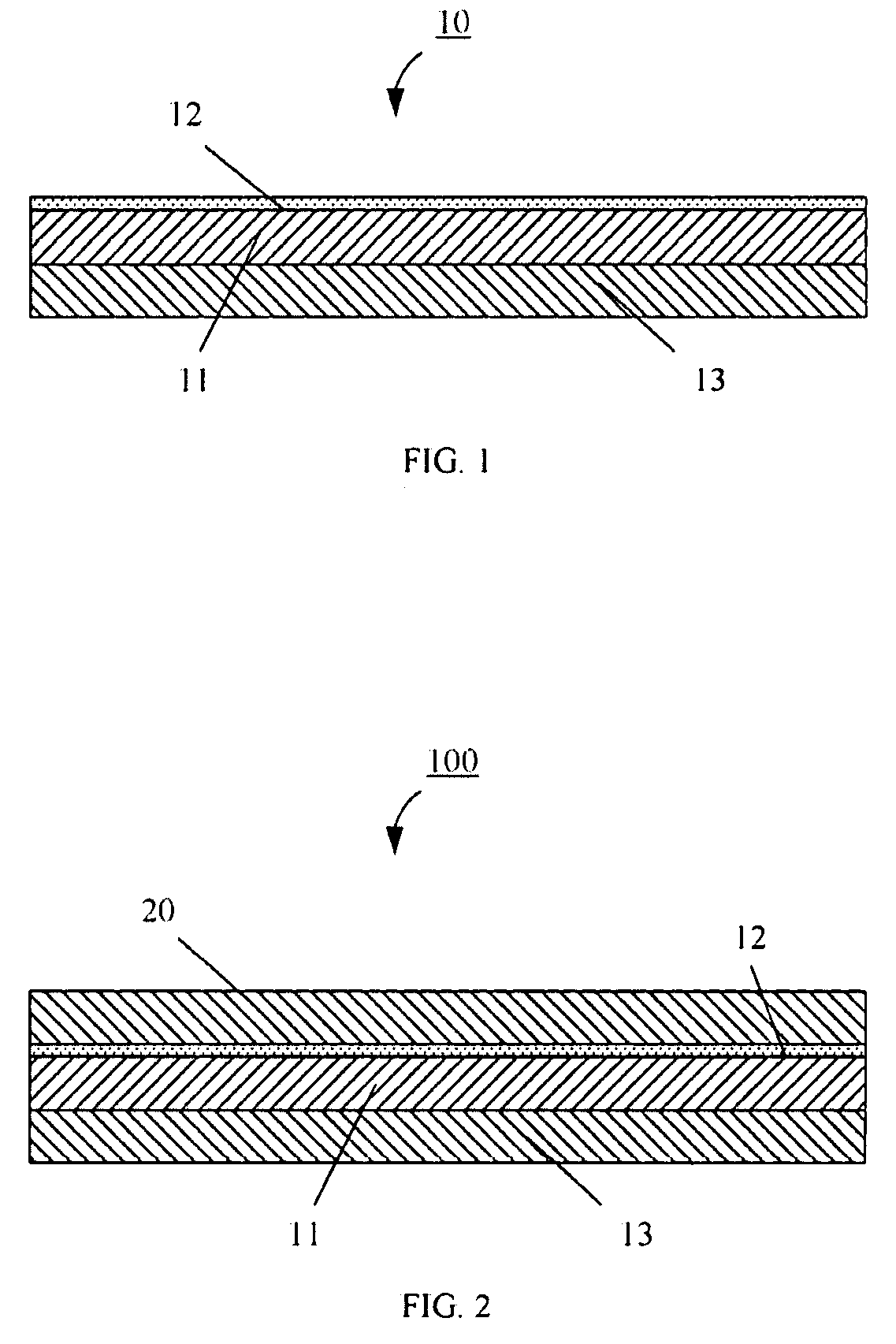

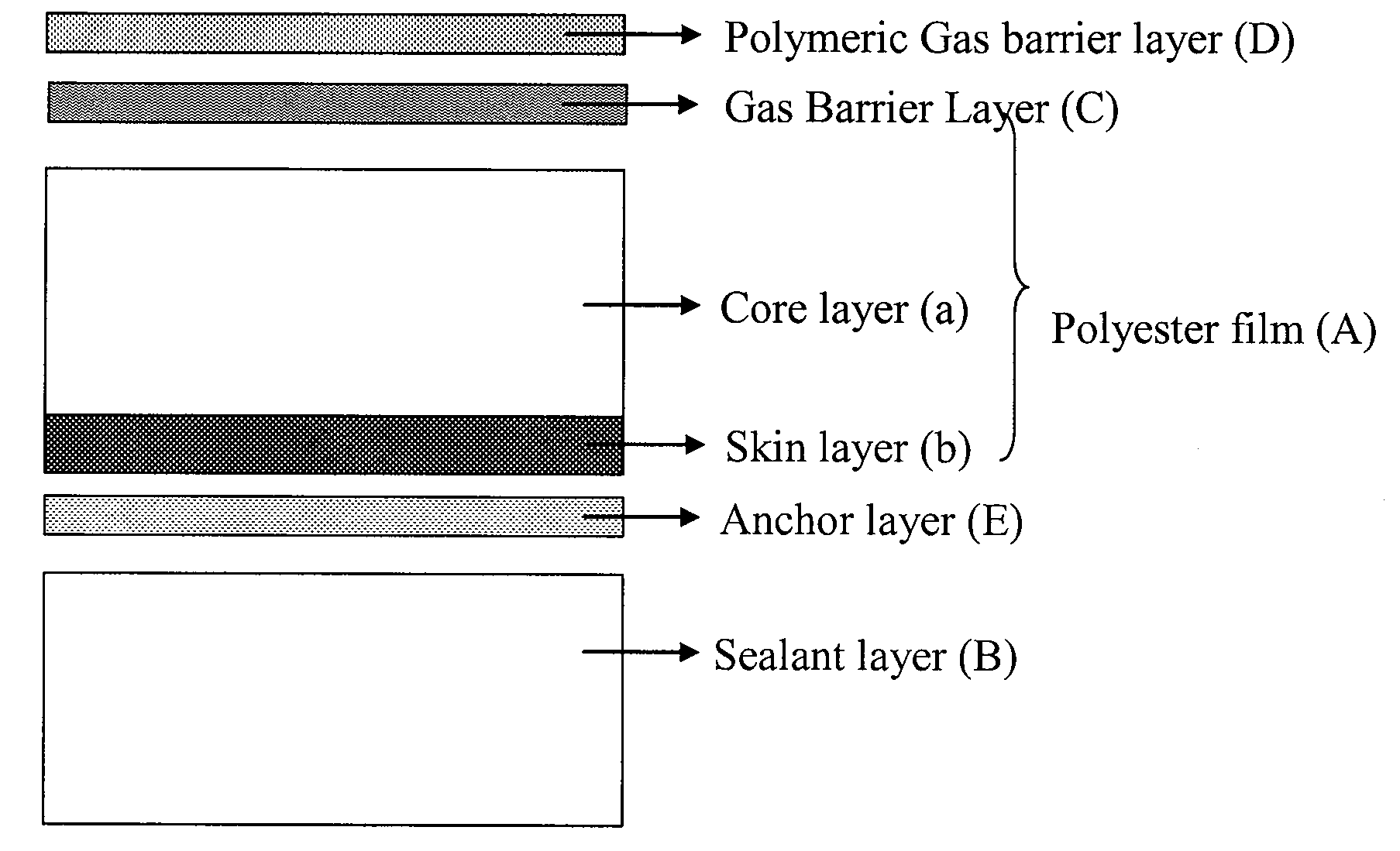

Lighter than air balloon made from a biaxially oriented polyester film

ActiveUS20090022919A1Low densityEnvelopes/bags making machineryVacuum evaporation coatingCopolyesterLighter than air

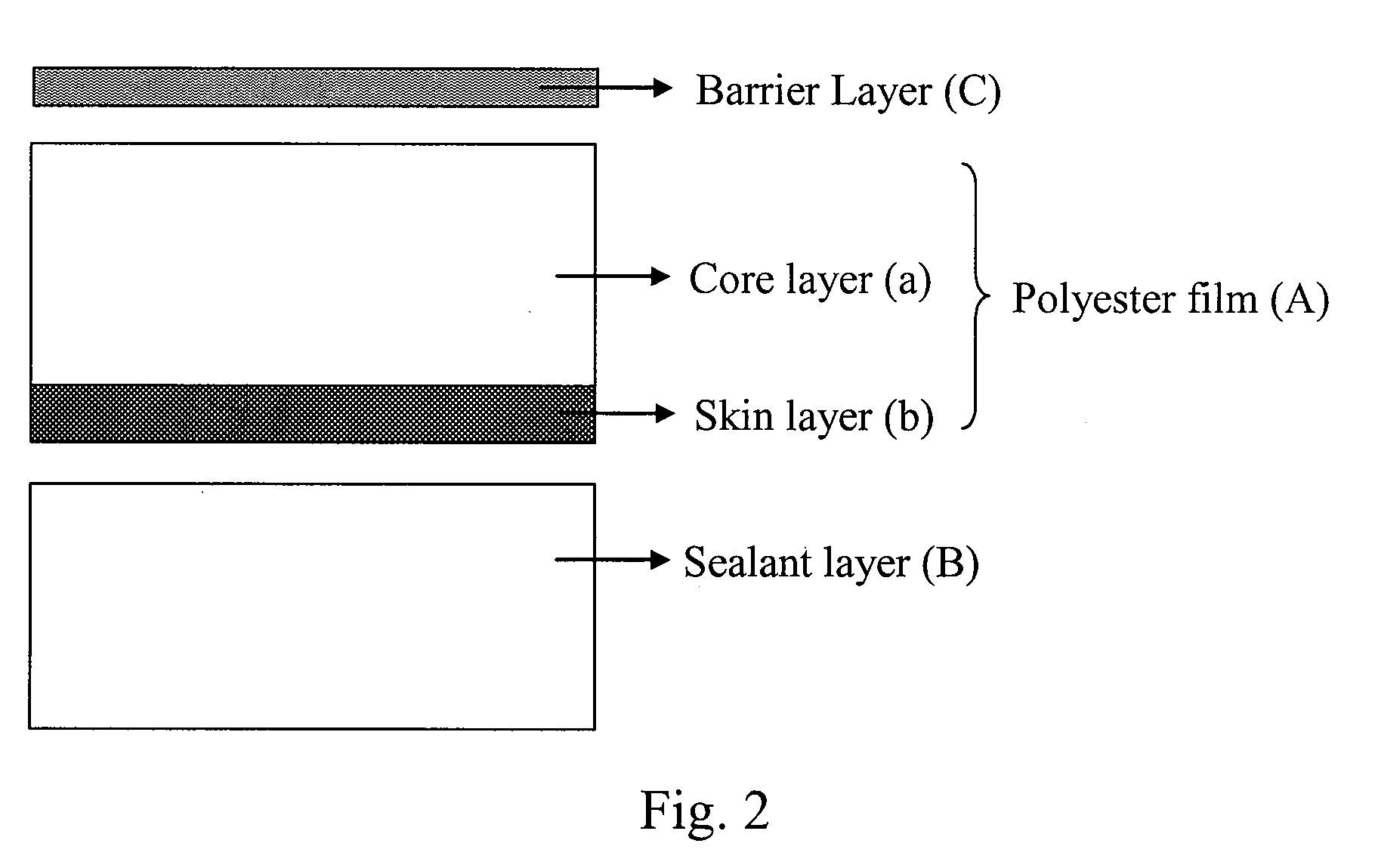

A long life balloon formed from a lamination. The lamination includes a polyester film with a total thickness of 4 μm to 12 μm. The polyester film includes a biaxially oriented polyester core layer and at least one amorphous copolyester skin layer. The lamination also includes a sealant layer and a gas barrier layer on an opposite side of the polyester film from the sealant layer. The oxygen transmission rate of the balloon is less than 0.1 cc / 100 sqin / day, a bonding strength of the gas barrier layer to the surface of the polyester film is more than 300 g / in at dry conditions, a sealing strength of the balloon is more than 3.5 kg / in, and a floating time of the balloon is more than 20 days.

Owner:TORAY PLASTICS AMERICA +1

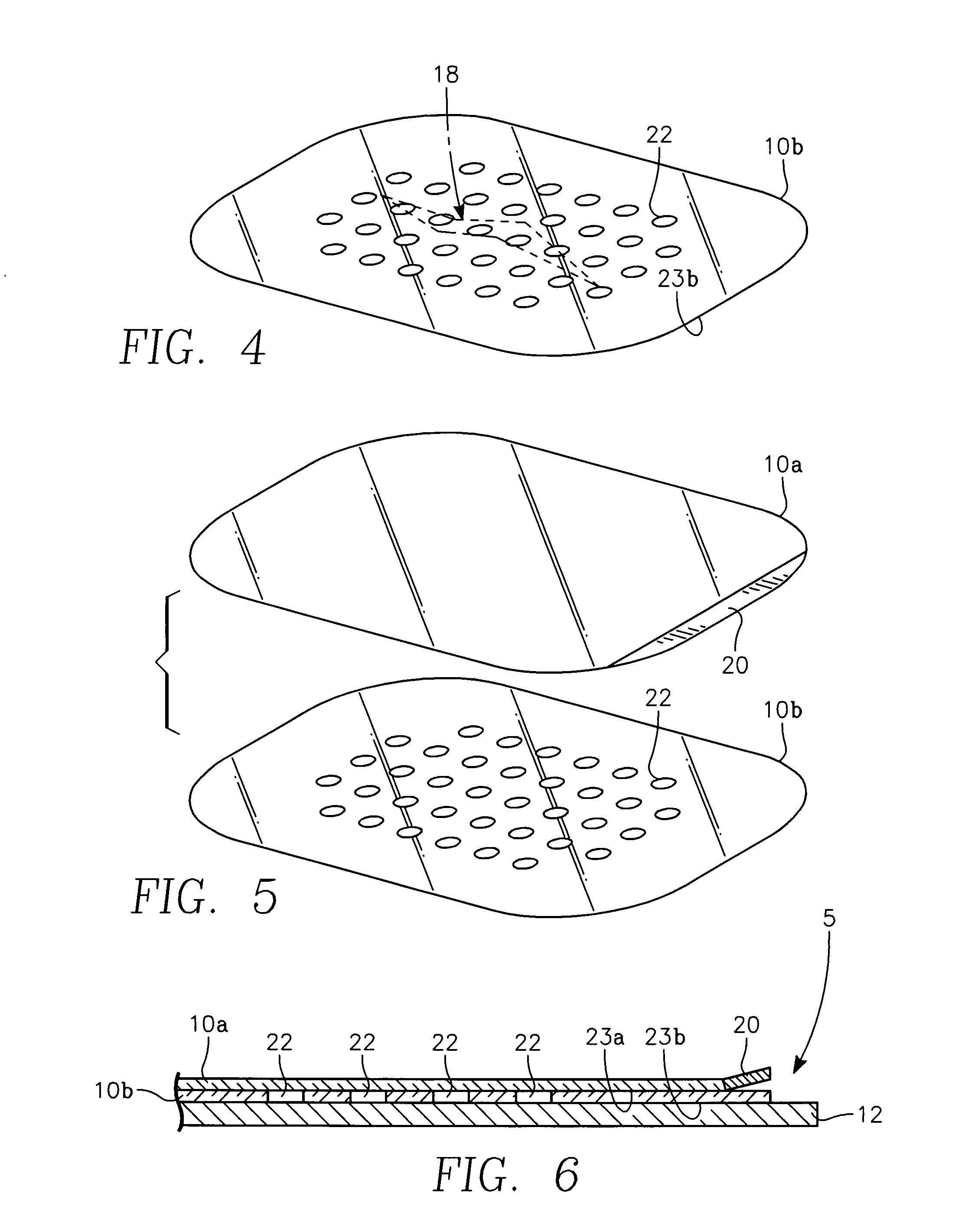

Two part wound dressing

A wound dressing that includes two layers for a two part solution to the needs of a healing skin wound. The first step involves a relatively closed system wherein moisture is kept near the skin to promote healing. The second step allows for removal of a top layer of the dressing to reveal a layer with a series of apertures that allows for 100% moisture vapor and oxygen transmission rates to avoid irritation and itching of the skin. At the same time, the bottom layer of the wound dressing maintains a significant outer perimeter that prevents the perimeter migration of microorganisms into the healing wound. The wound dressing can also be used as a means for securing medical instruments, such as intravenous catheters, to the skin of a patient while avoiding the itching and irritation associated with traditional methods.

Owner:LOWE RICHARD D

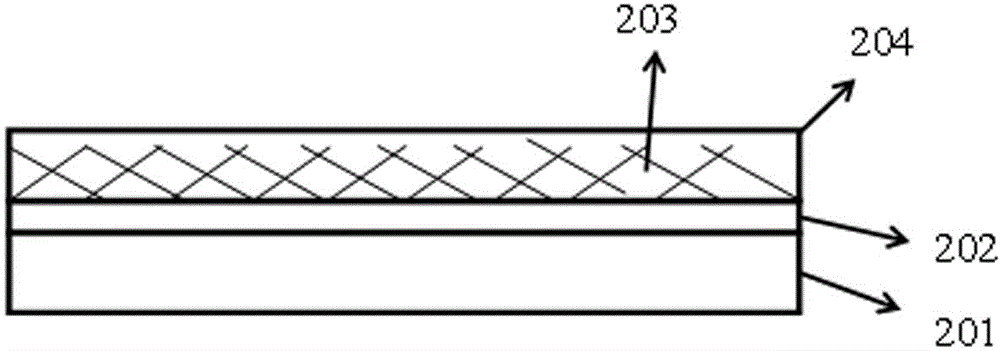

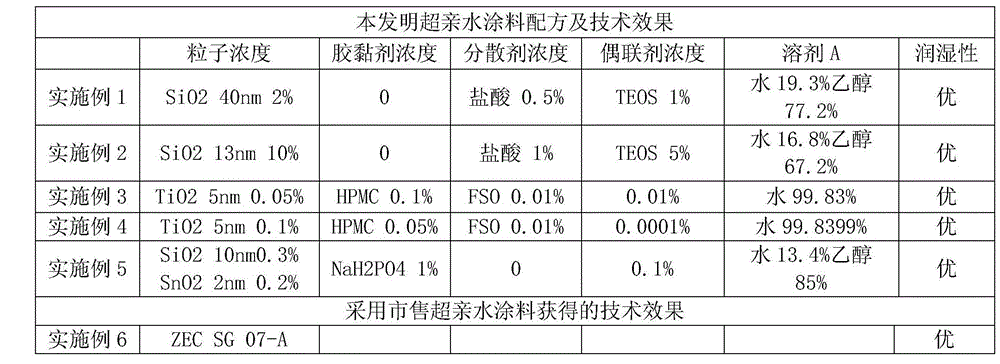

Low-haze transparent conductive film and preparation method thereof

ActiveCN104867540AEasy to apply evenlyChoose safety and environmental protectionConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialHydrophilic coatingTransmittance

The invention provides a low-haze transparent conductive film and a preparation method thereof. The low-haze transparent conductive film comprises a transparent substrate layer, wherein the transparent substrate layer is coated with a super hydrophilic coating formed by a super hydrophilic coating material, the super hydrophilic layer is coated with a transparent conductive layer formed by a conductive ink composition, and the wetting angle of water at the surface of the super hydrophilic coating is less than or equal to 5 degrees. After the super hydrophilic coating is coated, the light transmittance of the substrate is improved, the haze is reduced, an adhesive force between the transparent conductive layer and the substrate is enhanced, and the oxygen permeability of the transparent substrate is also reduced at the same time. By adopting the technical scheme provided by the invention, the total haze of the ultimately acquired transparent conductive film is reduced by 40% compared with that before super hydrophilic processing under the condition of keeping the conductivity to be unchanged, the light transmittance is improved by 2-5%, the adhesive force is also obviously improved, and the appearance is more transparent.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

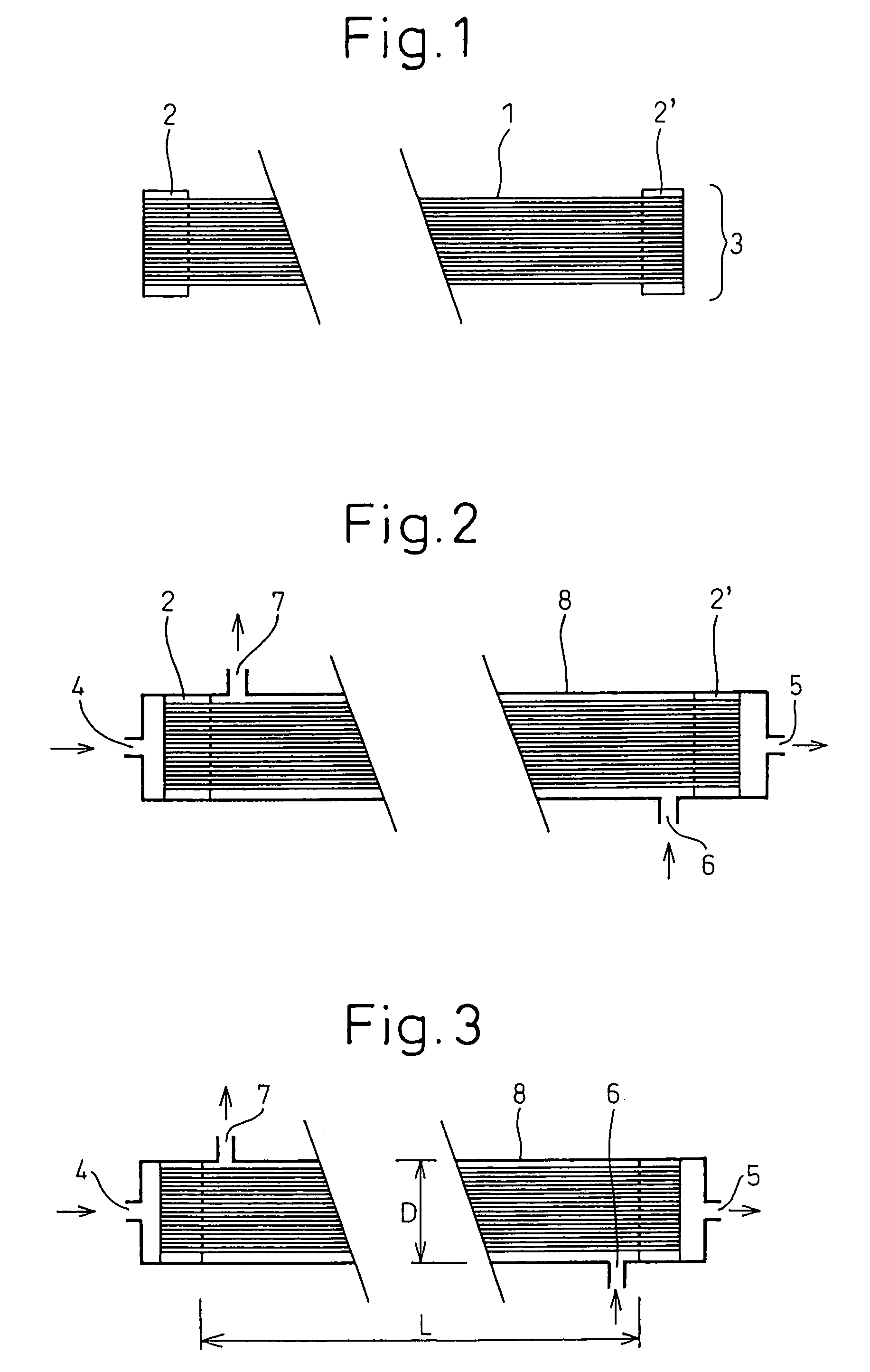

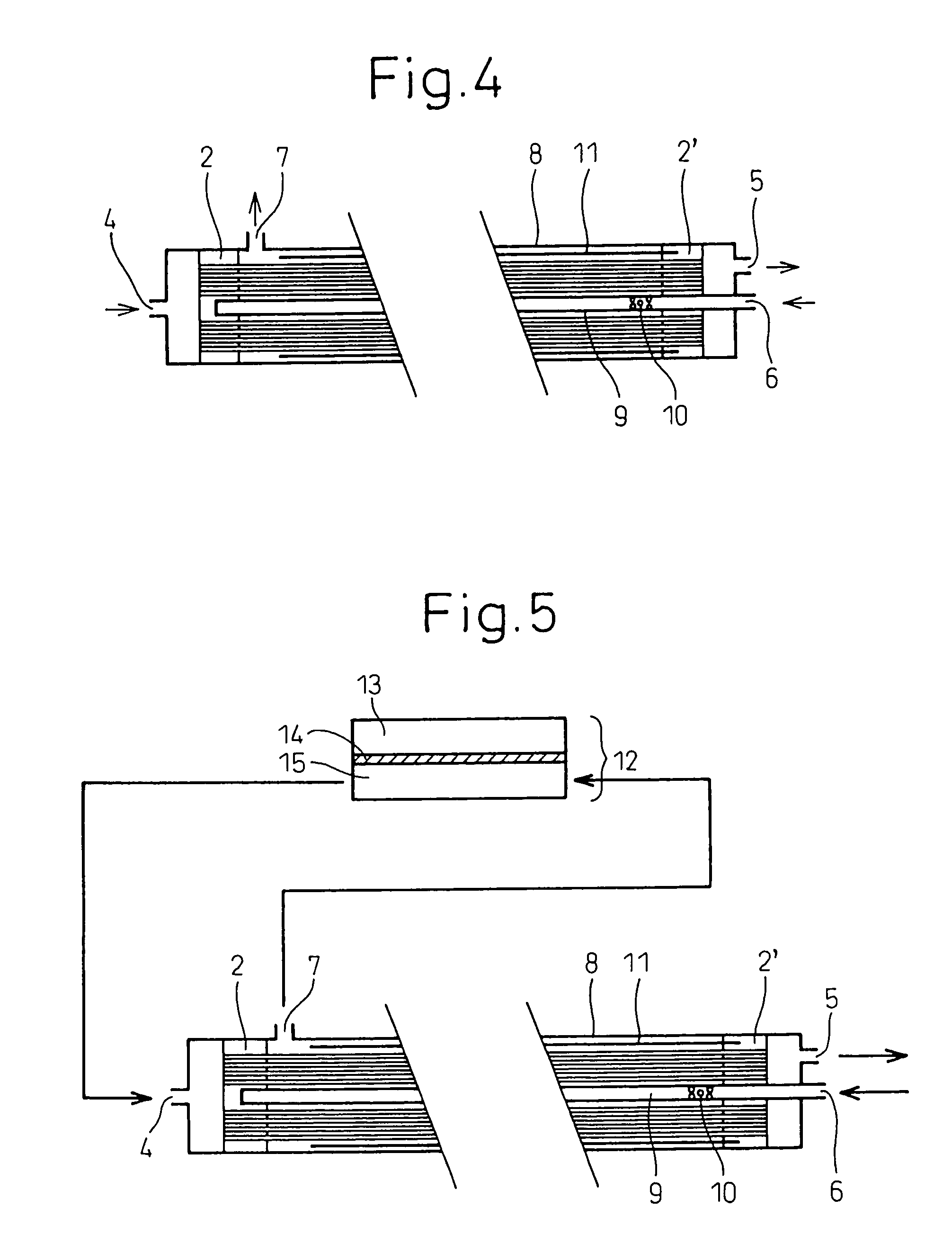

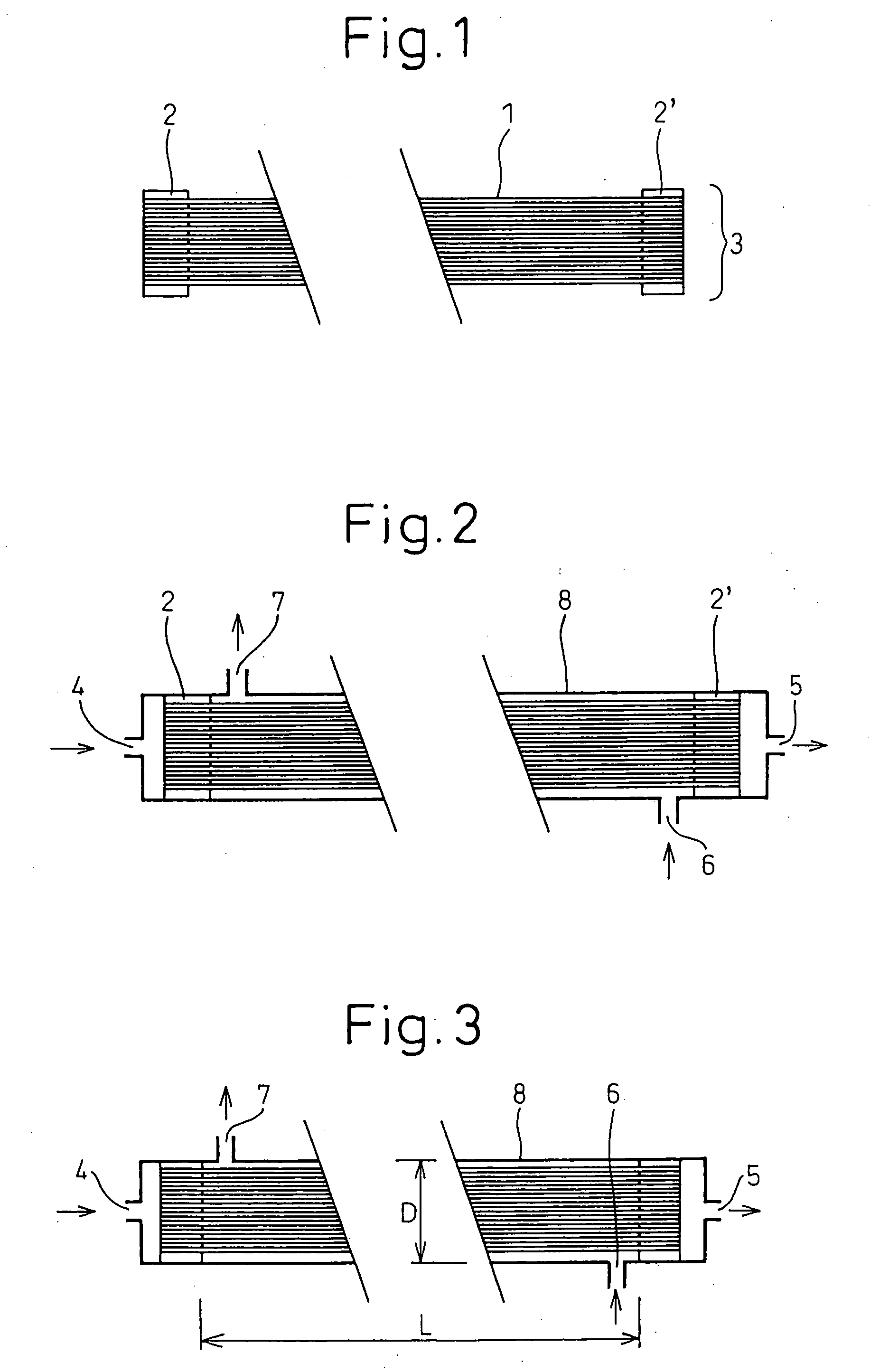

Fuel cell-use humidifier

An object of the present invention is to provide a humidifying apparatus capable of improving the humidification efficiency while lowering the pressure loss of gas even when a low-pressure gas is used, and is suitably usable for fuel cells. The present invention relates to a humidifying apparatus for fuel cells, fabricated by loading a hollow fiber membrane element into a container such that the space communicating with the hollow side of the hollow fiber membranes is isolated from the space communicating with the outer side of the hollow fiber membranes, wherein (a) the inner diameter of the hollow fiber membrane is larger than 400 μm, (b) the water vapor permeation rate (P′H2O) of the hollow fiber membranes is 0.5×10−3 cm3 (STP) / cm2·sec·cm Hg or more, (c) the ratio (P′H2O / P′O2) of the water vapor permeation rate to the oxygen gas permeation rate of the hollow fiber membranes is 10 or more, and (d) the elongation at tensile break of the hollow fiber membranes after hot water treatment in hot water at 100° C. for 50 hours is 80% or more of that before the hot water treatment; particularly, the present invention relates to a humidifying apparatus for fuel cells where, if the effective length of the hollow fiber membrane element is L and the inner diameter of the container into which the hollow fiber membrane element is loaded is D, L / D is 1.8 or more.

Owner:UBE IND LTD

Resin composition and a multilayered container

InactiveUS20030018114A1Excellent gas barrier propertiesHigh transparencySynthetic resin layered productsConductive materialPolymer scienceDouble bond

The present invention provides a resin composition having an oxygen scavenging function. The resin composition comprises a gas barrier resin (A), a thermoplastic resin (B) other than the gas barrier resin (A), and a compatibilizer (C), wherein the gas barrier resin (A) has an oxygen transmission rate of 500 ml.20 mum / m2.days.atm (20° C., 65% RH) or less, the thermoplastic resin (B) has a carbon-carbon double bond, and an oxygen absorption rate of the resin composition is 0.001 m / m2.day or more.

Owner:KURARAY CO LTD

MDO multilayer polyethylene film

A multilayer film and a method of making the film are disclosed. In the method a multilayer film is post-oriented uniaxially in the machine direction resulting in a film that has a water vapor transmission rate of less than 2.5 g-mil / m2-day and an oxygen transmission rate of less than 1.5 cm2-mil / m2-day. The film of this invention is ideal for applications requiring low water vapor and oxygen transmission rates.

Owner:EQUSR CHEM LP

Multilayer Film Having High Oxygen Transmission and High Modulus

InactiveUS20070275196A1Increasing the thicknessReducing and eliminating damageSynthetic resin layered productsDomestic containersVolumetric Mass DensityEngineering

The invention provides a multilayer film having an oxygen transmission rate of about 10,000 cc (STP) / m2 / day / atm or greater at 23° C. and 0% relative humidity, a modulus of about 15,000 psi or greater in at least one direction. The multilayer film can be used for packaging a wide variety of products requiring regulation of oxygen permeability under varying packaging conditions because the multilayer film is capable of providing a relatively high OTR without sacrificing the mechanical properties that may be necessary for many packaging applications. The multilayer film may include a sealant layer, a stiffening layer, and a core layer disposed between the sealant and stiffening layers. In one embodiment, the sealant layer comprises a polyethylene having a density of less than 0.93 g / cc; the core layer consists of an ethylene / alpha-olefin having a density of 0.90 g / cc or less; and the stiffening layer comprises a styrene / butadiene / styrene block copolymer having a modulus of about 250,000 psi.

Owner:CRYOVAC ILLC

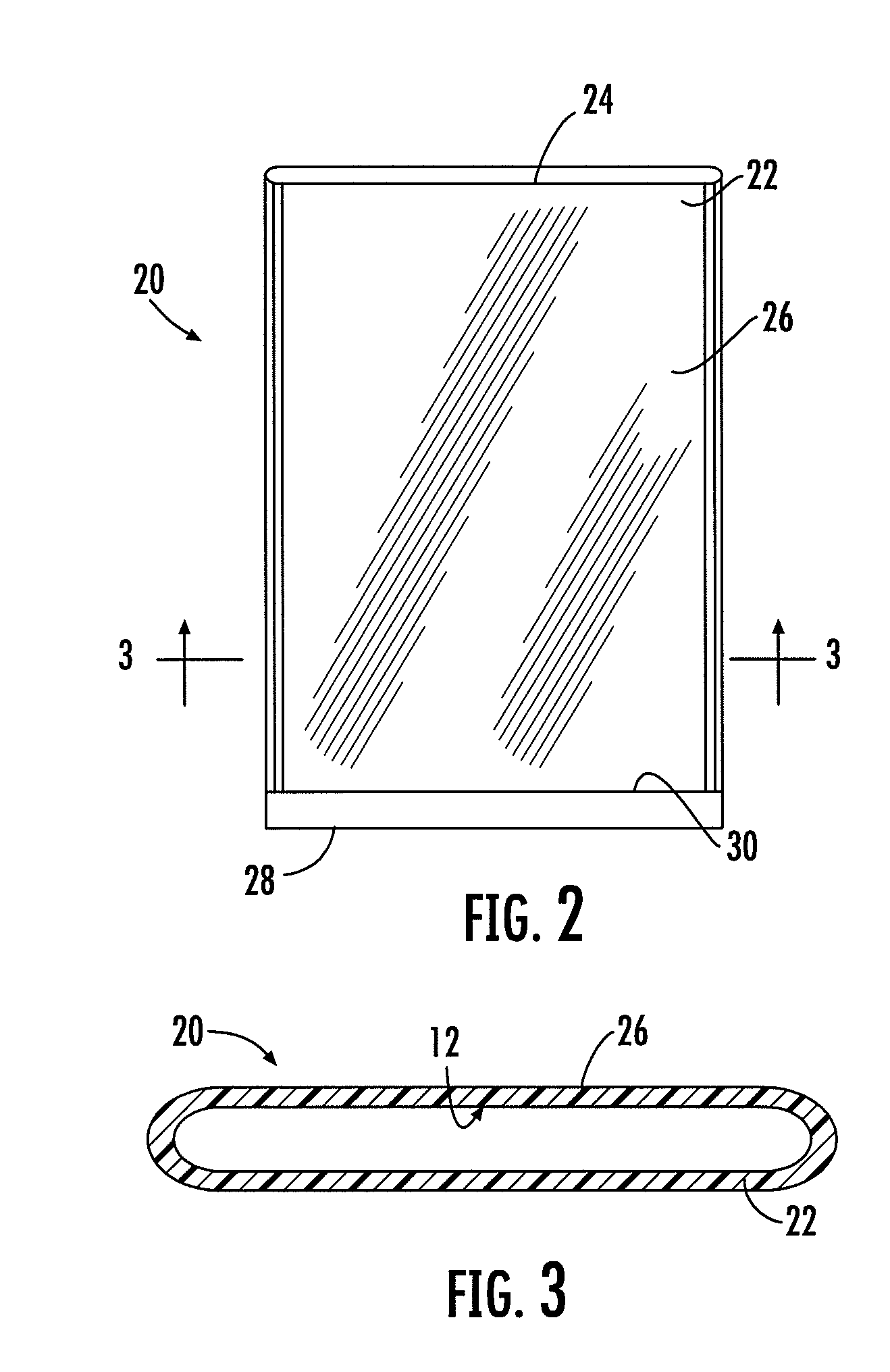

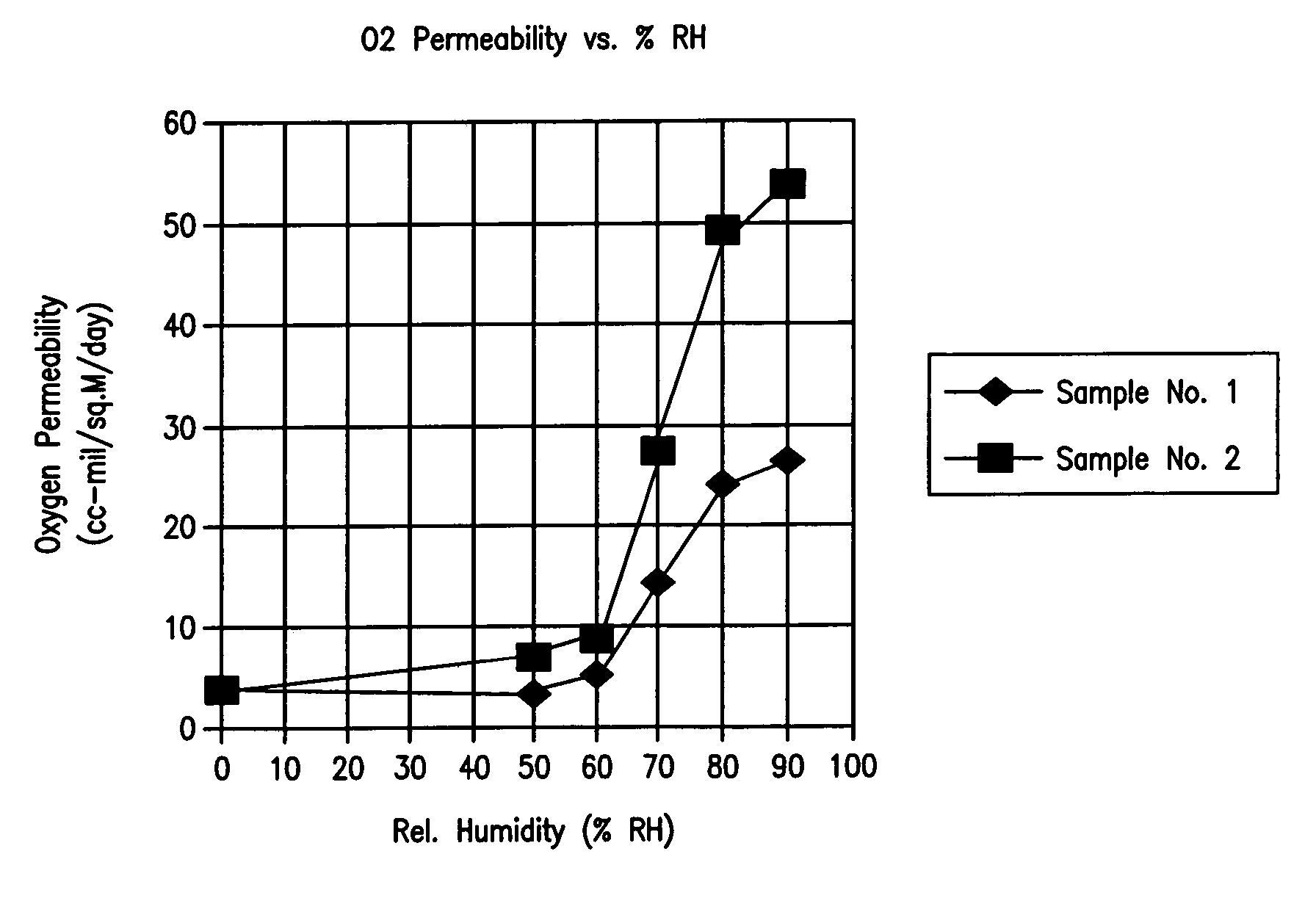

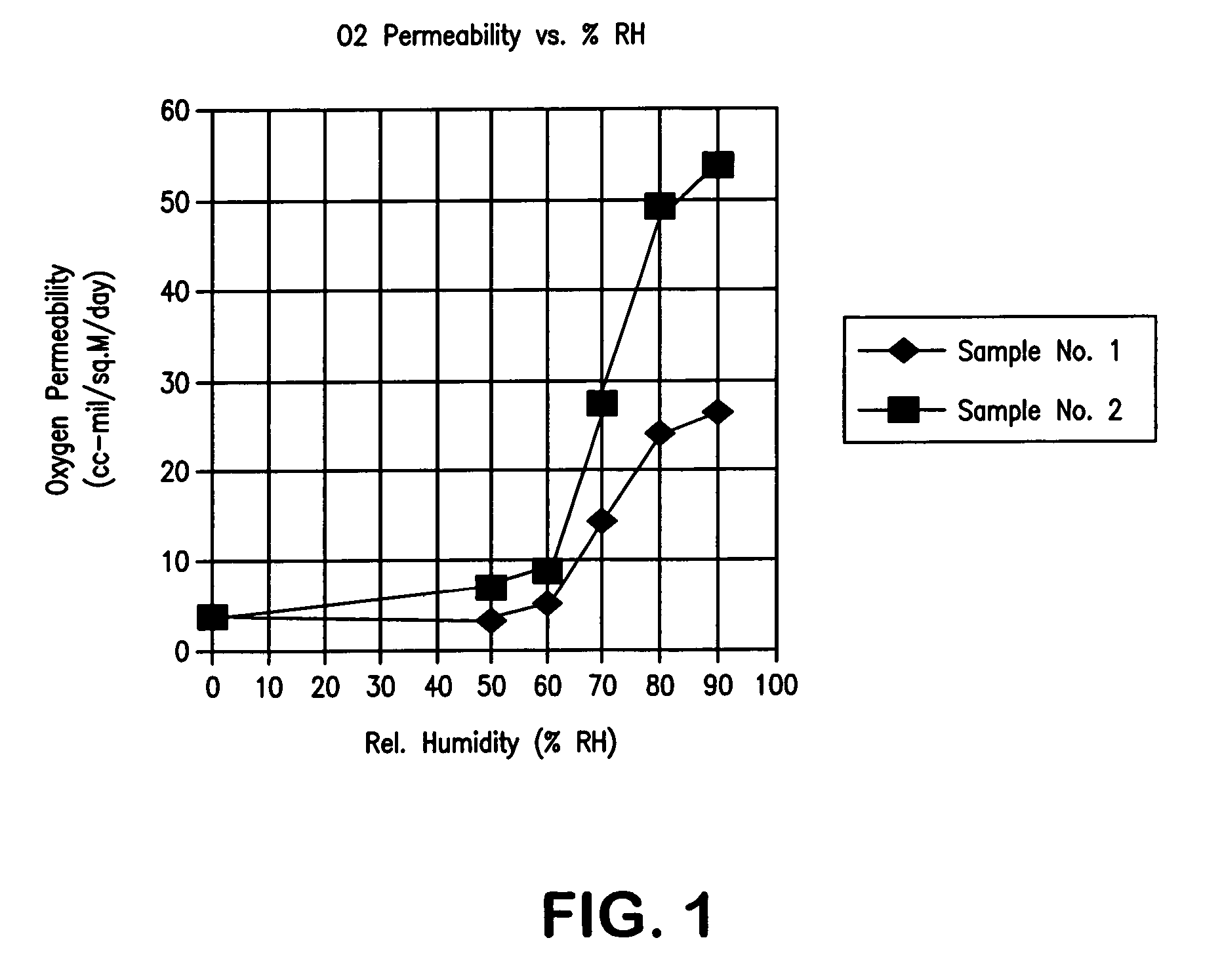

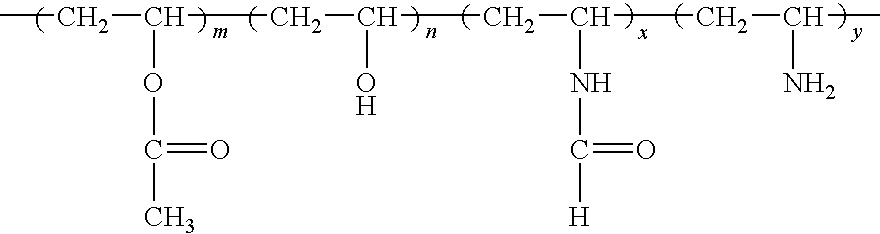

Coated polymeric film with oxygen barrier properties

ActiveUS7521103B2Excellent oxygen barrier propertiesSynthetic resin layered productsPretreated surfacesPolyesterPolymer thin films

A coating compositions for providing substrates with oxygen barrier properties is disclosed. The substrate may be, for instance, a film, such as a polyester film. The coating composition includes a copolymer of maleic acid and acrylic acid and a copolymer of vinyl alcohol and a vinylamine. The barrier coating formed from the coating composition is typically less than about 1 micron in thickness and provides reduced oxygen transmission even at relatively high relative humidities.

Owner:MITSUBISHI POLYESTER FILM

Fuel cell-use humidifier

An object of the present invention is to provide a humidifying apparatus capable of improving the humidification efficiency while lowering the pressure loss of gas even when a low-pressure gas is used, and is suitably usable for fuel cells. The present invention relates to a humidifying apparatus for fuel cells, fabricated by loading a hollow fiber membrane element into a container such that the space communicating with the hollow side of the hollow fiber membranes is isolated from the space communicating with the outer side of the hollow fiber membranes, wherein (a) the inner diameter of the hollow fiber membrane is larger than 400 μm, (b) the water vapor permeation rate (P′H2O) of the hollow fiber membranes is 0.5×10−3 cm3 (STP) / cm2·sec·cm Hg or more, (c) the ratio (P′H2O / P′O2) of the water vapor permeation rate to the oxygen gas permeation rate of the hollow fiber membranes is 10 or more, and (d) the elongation at tensile break of the hollow fiber membranes after hot water treatment in hot water at 100° C. for 50 hours is 80% or more of that before the hot water treatment; particularly, the present invention relates to a humidifying apparatus for fuel cells where, if the effective length of the hollow fiber membrane element is L and the inner diameter of the container into which the hollow fiber membrane element is loaded is D, L / D is 1.8 or more.

Owner:UBE IND LTD

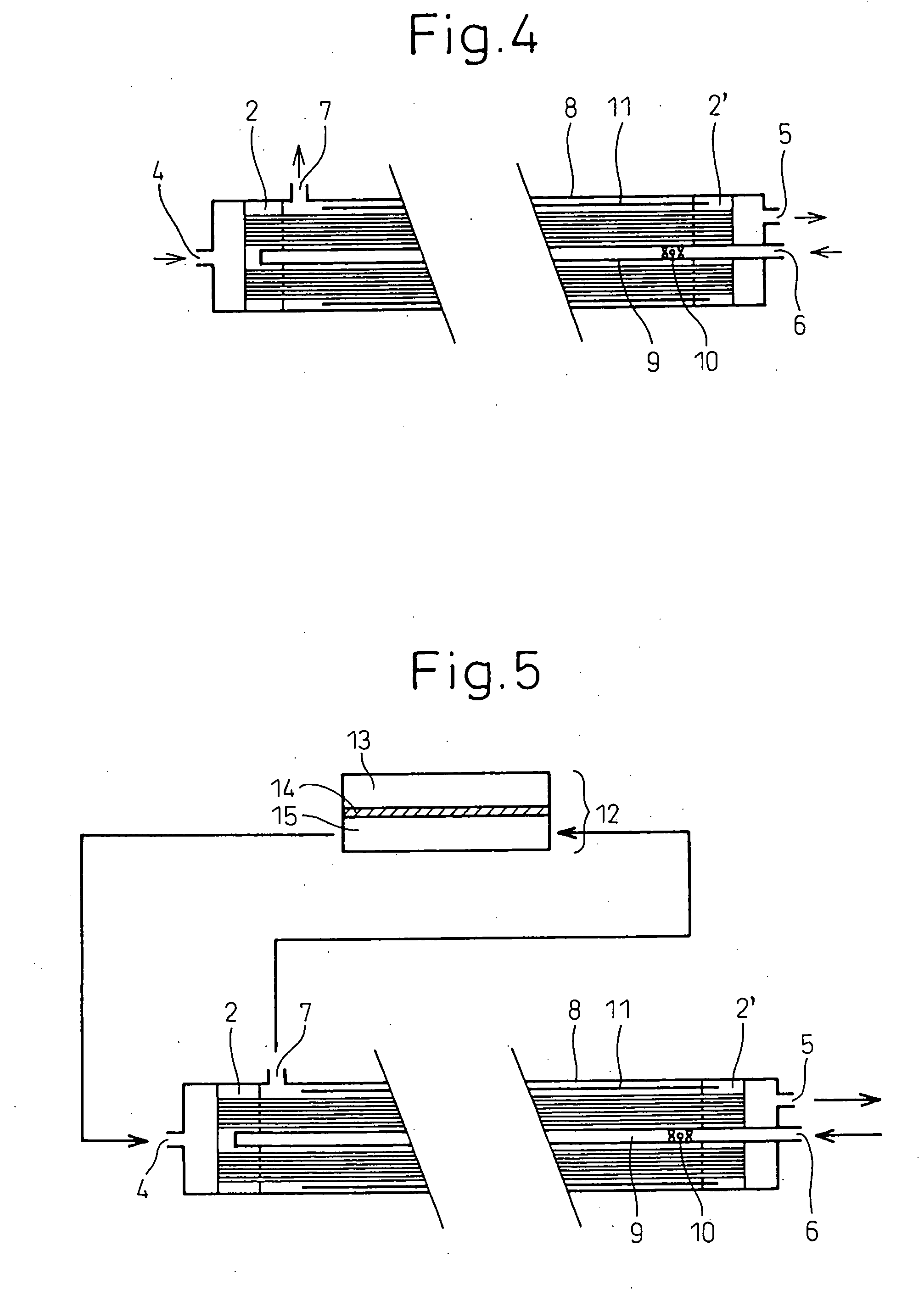

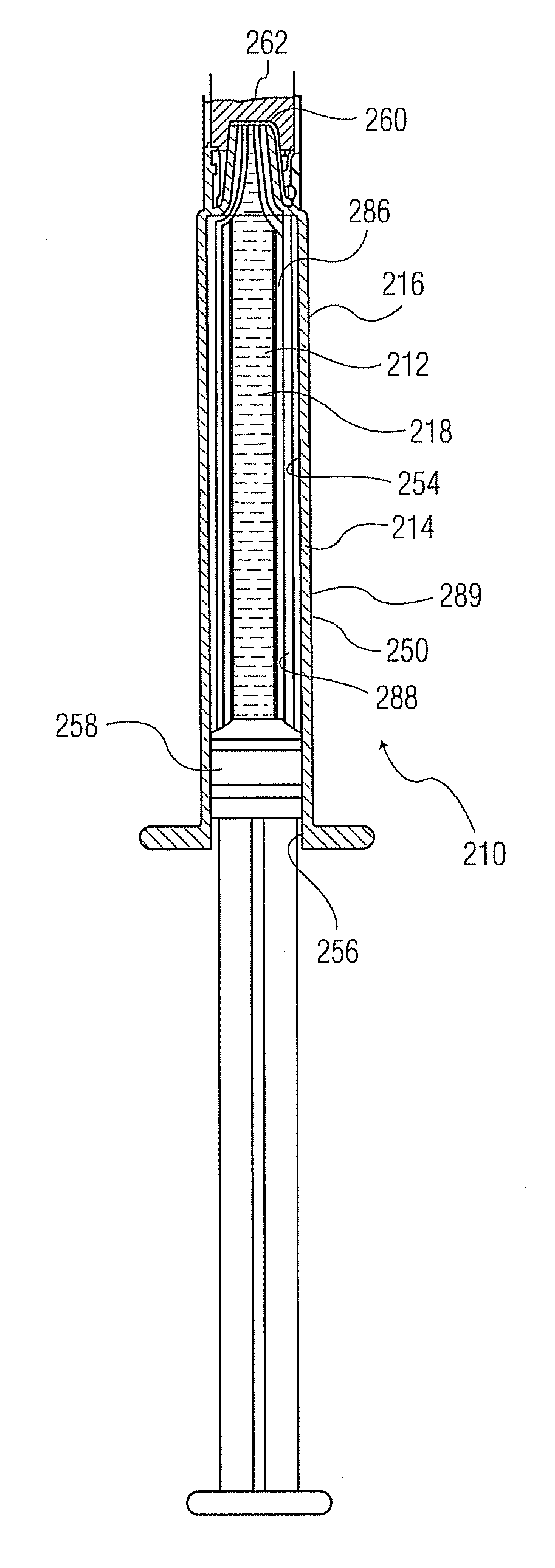

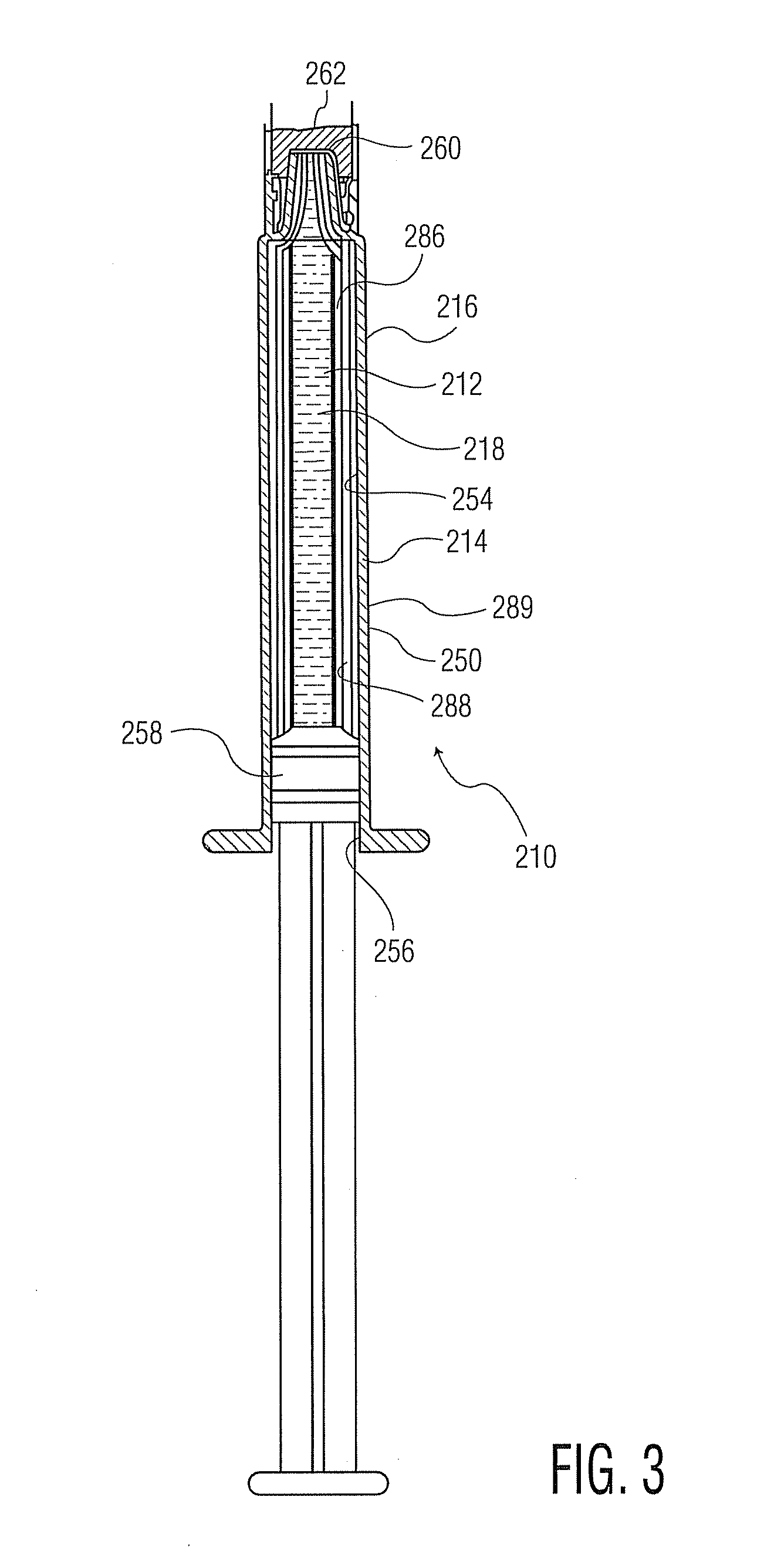

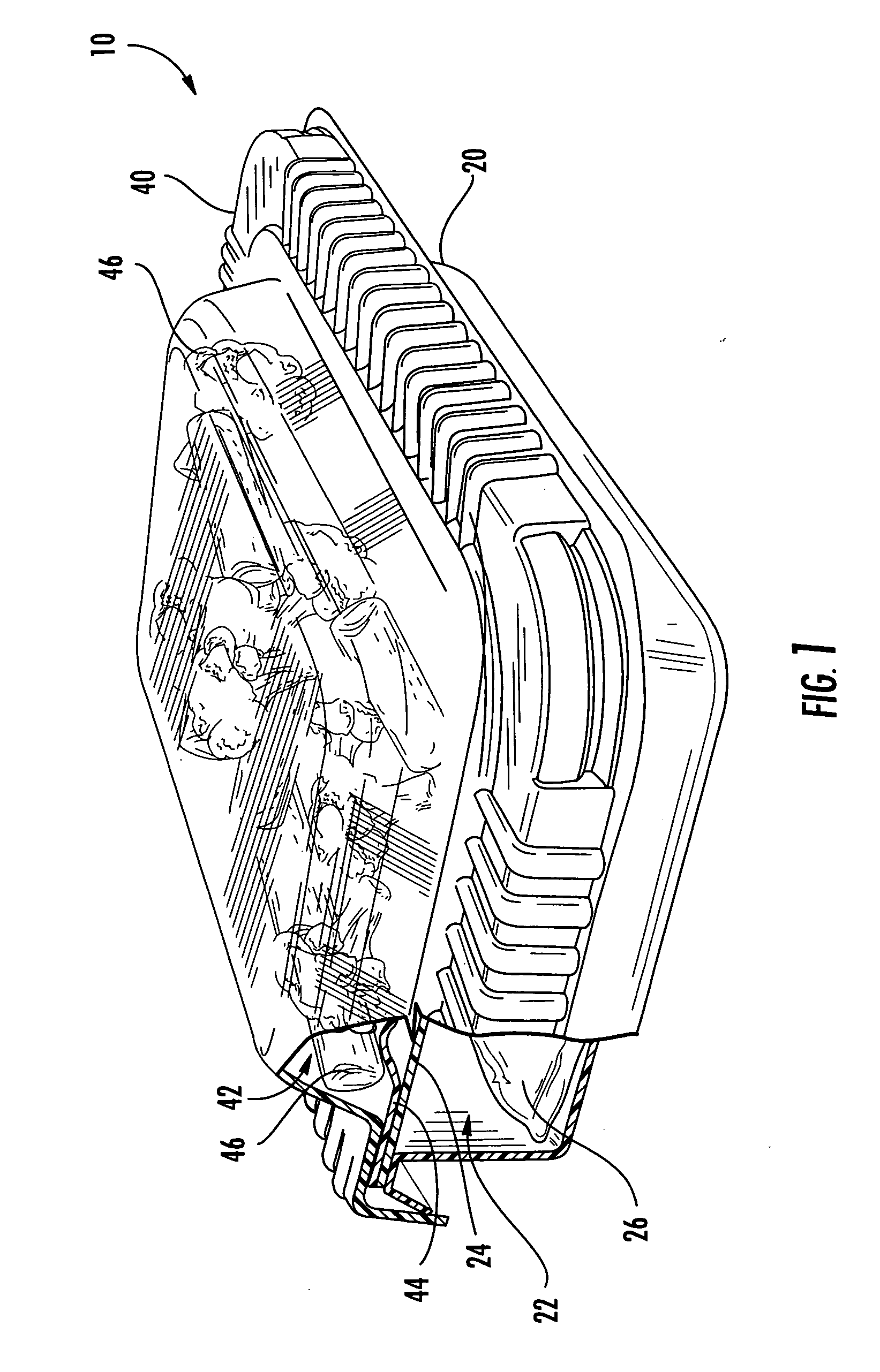

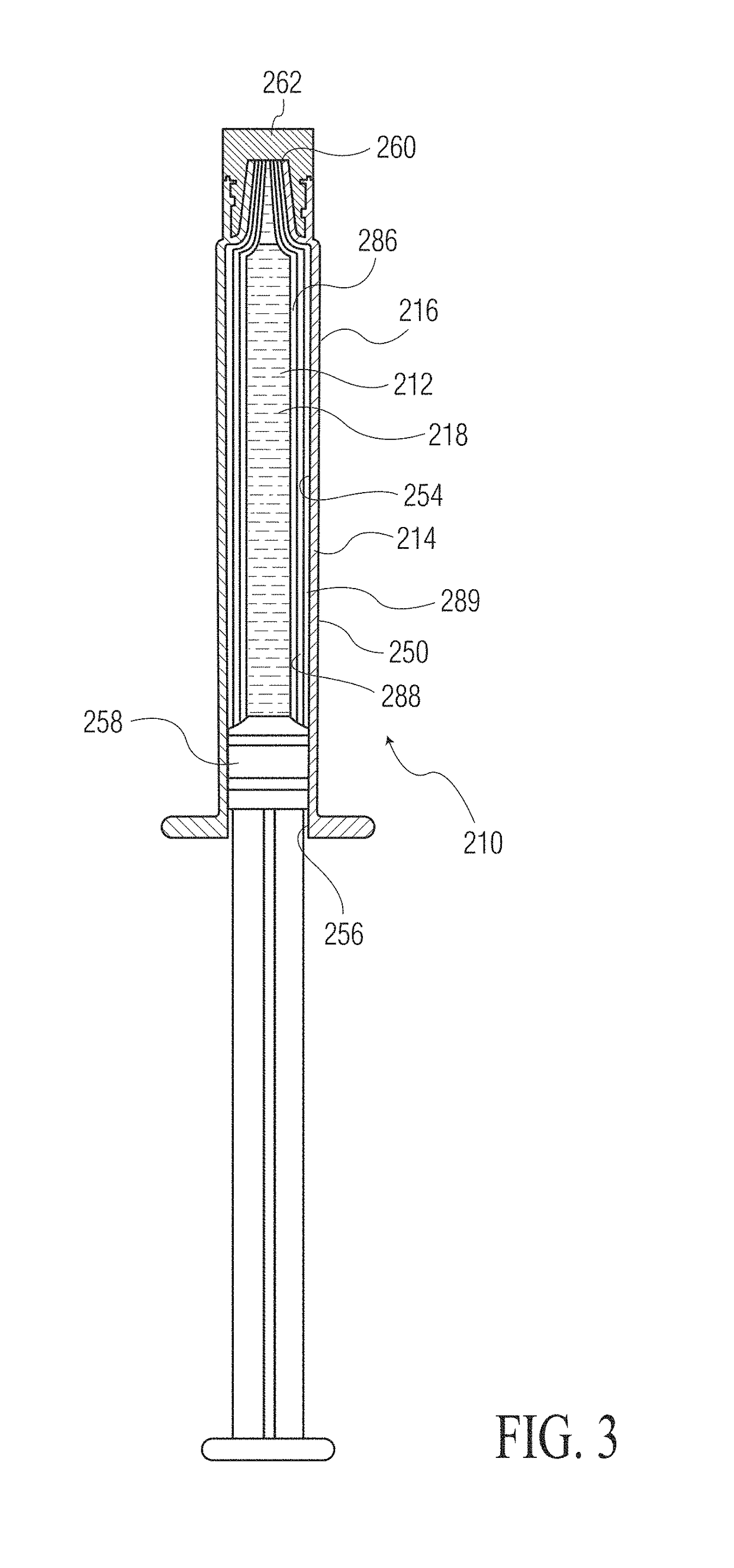

Trilayer coated pharmaceutical packaging with low oxygen transmission rate

An article is described including an article surface and a coating set comprising an optional tie coating or layer, a barrier coating or layer, and a pH protective layer. The respective coatings or layers can be applied by chemical vapor deposition of a polysiloxane or polysilazane precursor in the presence of oxygen. Examples of such an article are a prefilled thermoplastic syringe or thermoplastic pharmaceutical vial with a coated interior portion containing a pharmaceutical preparation or other fluid with a pH of 4 to 8, alternatively 5 to 9. The barrier coating or layer prevents oxygen from penetrating into the thermoplastic syringe or vial. The tie coating or layer, if present, and the pH protective coating or layer protect the barrier layer from the contents of the syringe or vial.

Owner:SI02 MEDICAL PRODS

Breathable packaging film having enhanced thermoformability

InactiveUS20060105166A1Excellent thermoformabilitySimple structureSynthetic resin layered productsDomestic containersPolyesterPolyolefin

The present invention describes thermoformable coextruded film suitable for use in packaging applications having at least a first polymeric layer serving as an outermost exterior-film layer and comprising a cycloaliphatic polyester, an aromatic polyester or blends thereof; a second polymeric layer serving as a thermoforming-assist layer and comprising a polyolefin; and a third polymeric layer serving as an innermost exterior-film layer and comprising a heat-sealing polyolefinic material. The films of the present invention are oxygen-permeable in that they exhibit an oxygen transmission rate of between 2-1000 cm3 / 100 in2 / 24 h.atm.

Owner:BEMIS COMPANY INC

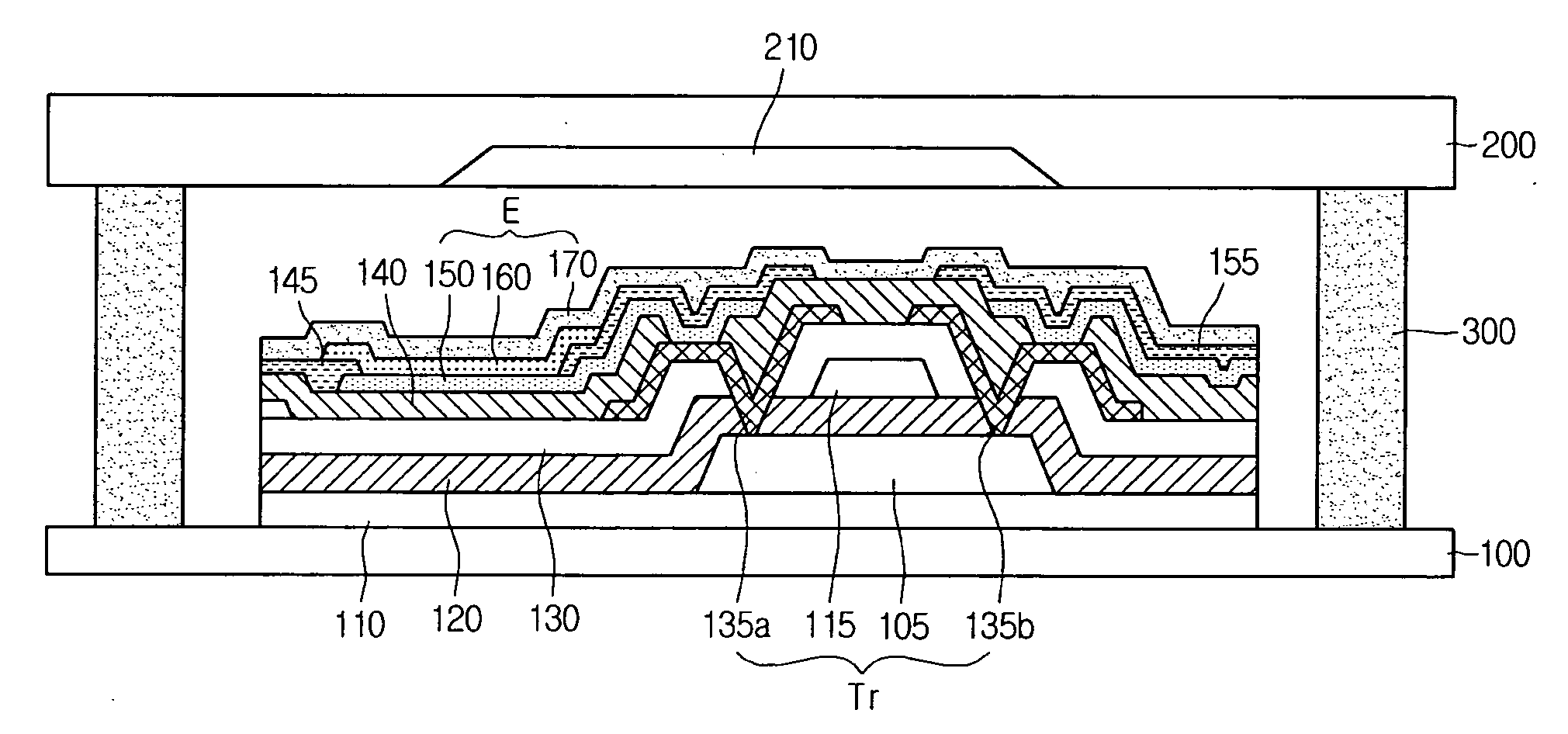

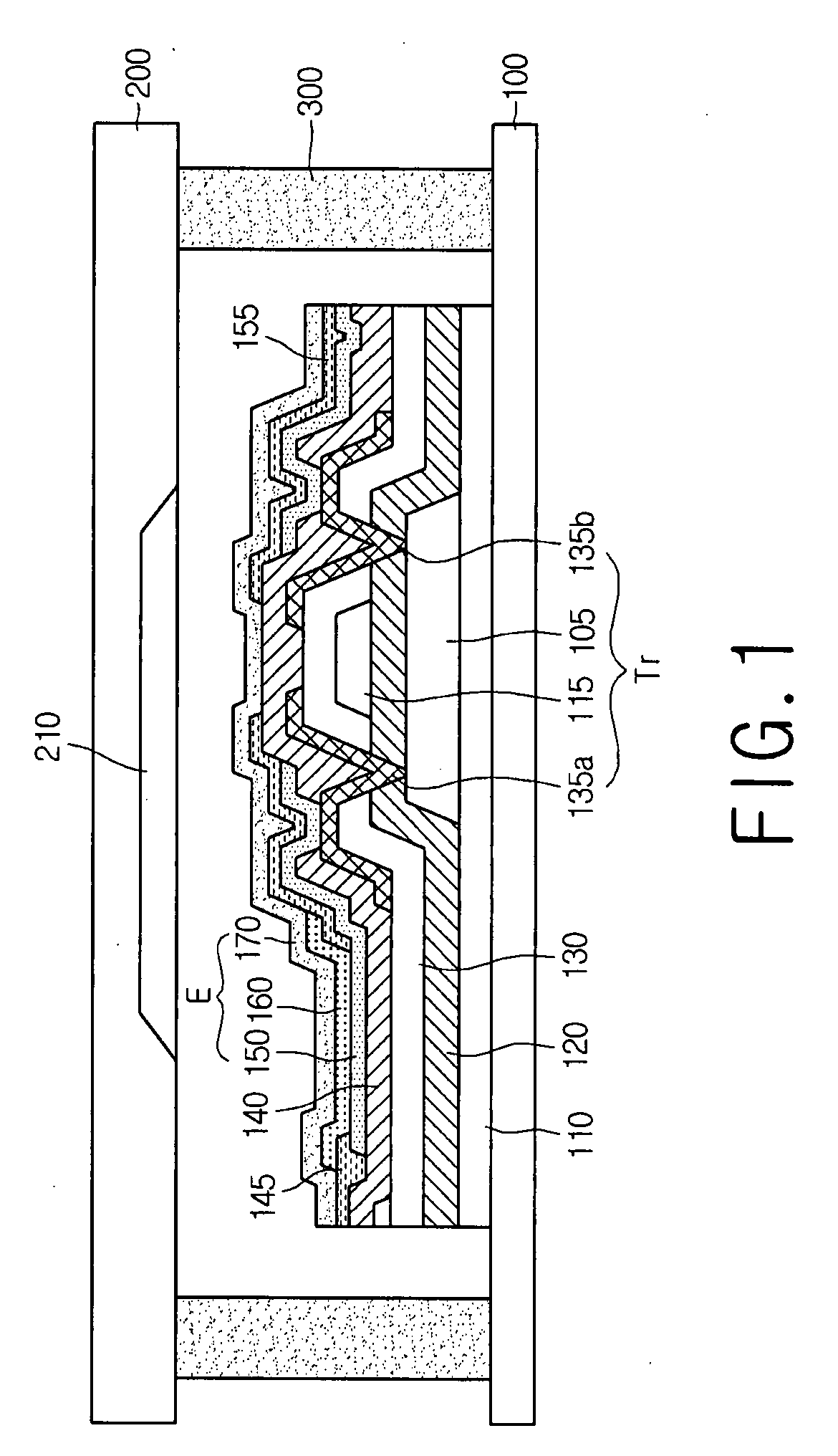

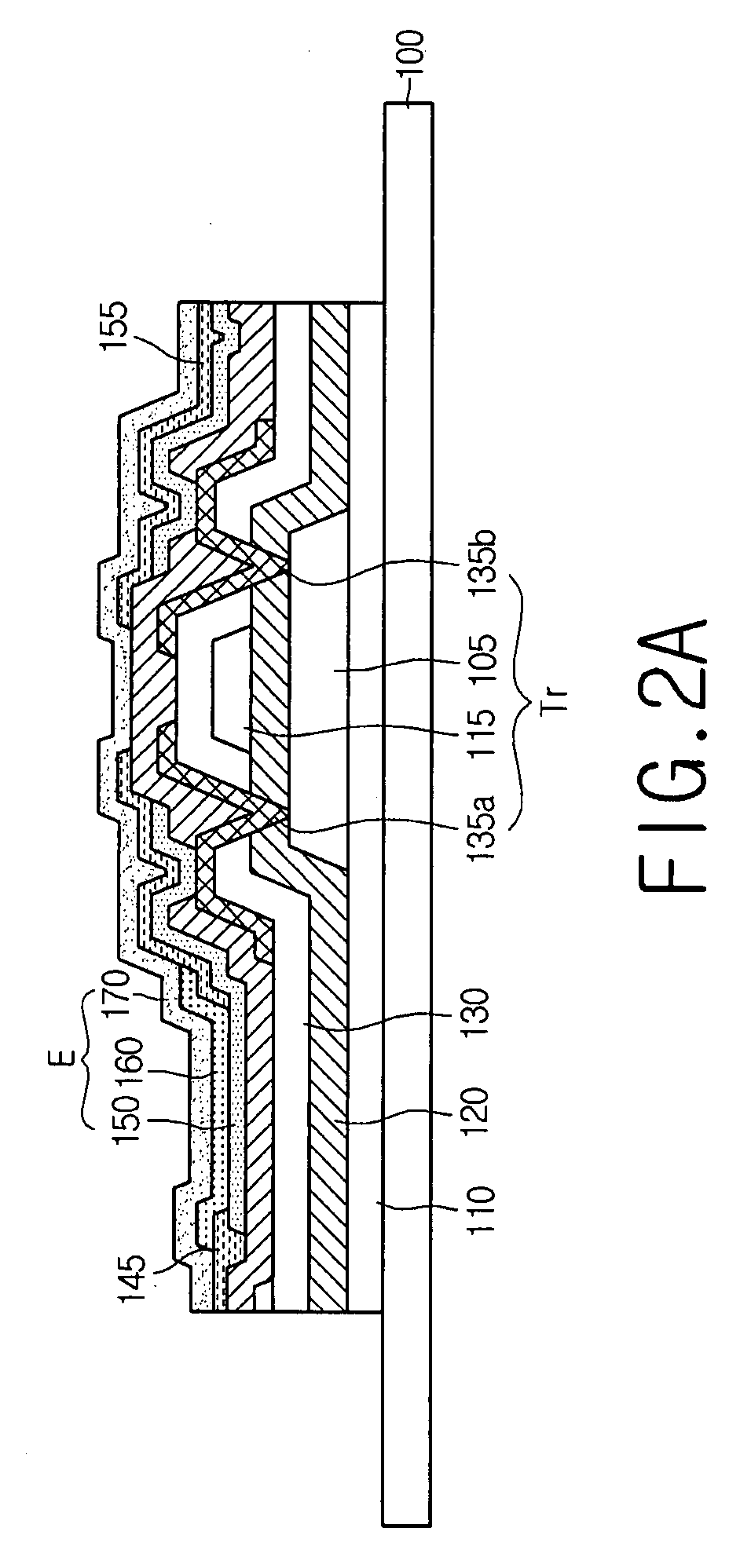

Organic electro-luminescence display device and method for fabricating the same

ActiveUS20080001533A1Increases in lifetimeImprove reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesFritDisplay device

An organic electro-luminescence display device and a method for fabricating the same are provided. A first substrate and a second substrate are sealed by a sealant. An organic electro-luminescent diode is formed on the first substrate. The sealant contains a frit glass and a light-heat converter. The frit glass can reduce the moisture and oxygen transmission rate by preventing the organic electro-luminescent diode from being thermally decomposed during a curing process. Since the two substrates are encapsulated by the frit glass, the lifetime and reliability of the organic electro-luminescence display device can be increased.

Owner:LG DISPLAY CO LTD

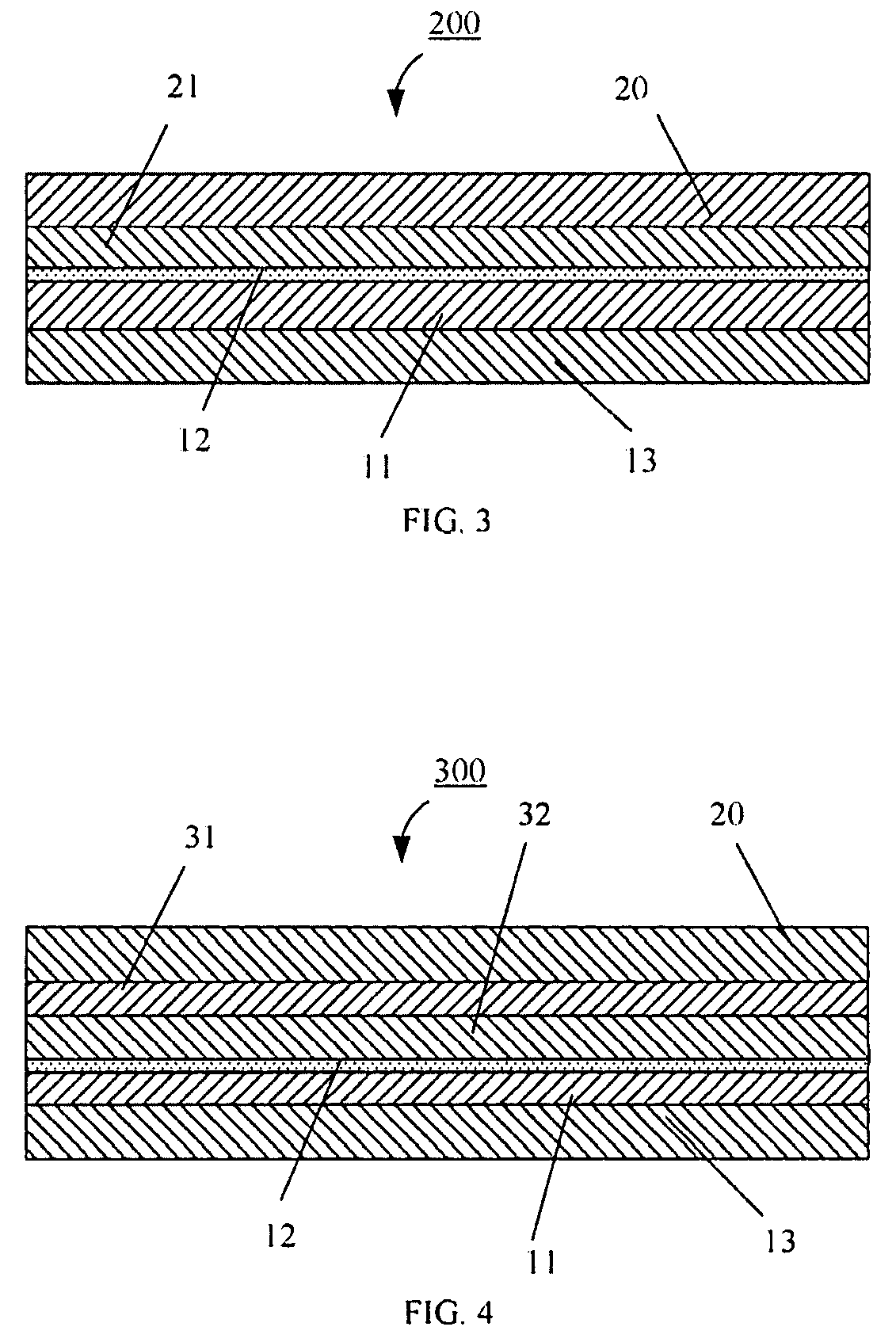

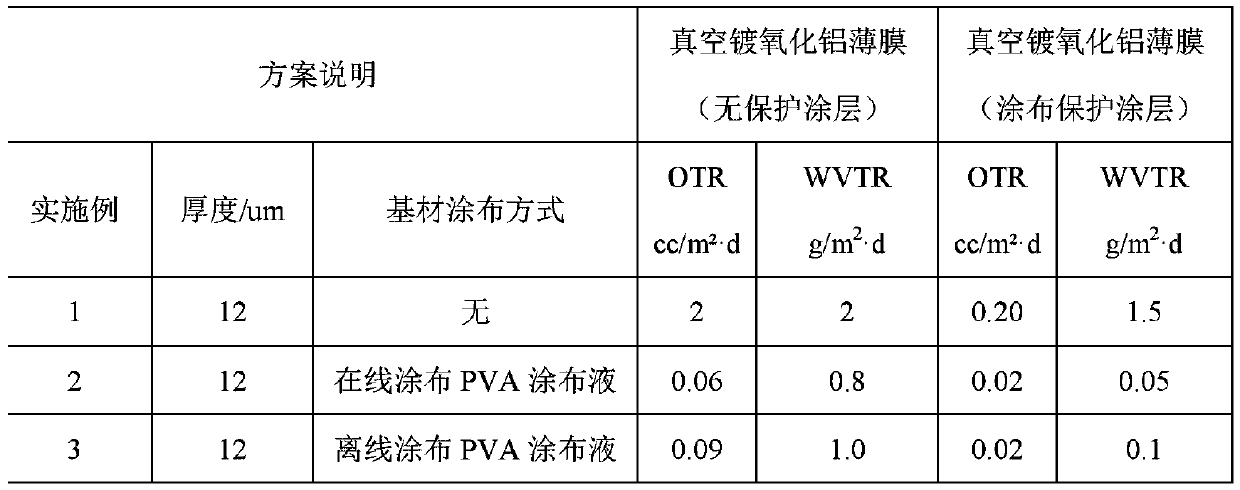

Sterilizable package with a high barrier to oxygen

InactiveUS7938580B2Minimizes oxygen transmission rateSurgical furnitureDiagnosticsScavengerEngineering

A package (599) with three layers allows sterilization of the package contents, provides a separate area for a scavenger and minimizes the oxygen transmission rate for the package and has, in one embodiment, a third layer (330) with a first section (336) of breathable polymeric material, a second section (334) of substantially non-breathable polymeric material and a third section (332) of breathable polymeric material which is positioned between a first layer (512) of substantially non-breathable polymeric material and a second layer (514) of substantially non-breathable polymeric material. The first layer (512) and the second layer (514) are fixed together to define a non-breathable pouch (516); and the third layer (330) is fixed to the first layer (512) and the second layer (514) and divides the non-breathable pouch (516) into a first compartment (592) and a second compartment (594). The outer seal (518) fixing the first layer (512) to the second layer (514) does not include any interposing first section (336) of the third layer (330).

Owner:KNPAK ACQUISITION LTD

Barrier films based on blends of polypropylene and ethylene-vinyl alcohol copolymer

InactiveUS6316114B1Improve propertiesIncrease modulusSynthetic resin layered productsWater-setting substance layered productFilm basePolypropylene

Oriented films of polypropylene and ethylene-vinyl alcohol copolymer are disclosed wherein the ethylene content of the copolymer is from about 40 to 50 mole %. The films are characterized by an improved oxygen transmission rate. Films are readily drawn to 6x by 6x. Films also exhibit improved resistance to transmission helium gas.

Owner:APPLIED EXTRUSION TECH

Resin composition and a multilayered container

InactiveUS6822031B2Maintain good propertiesHigh transparencySynthetic resin layered productsConductive materialPolymer scienceDouble bond

The present invention provides a resin composition having an oxygen scavenging function. The resin composition comprises a gas barrier resin (A), a thermoplastic resin (B) other than the gas barrier resin (A), and a compatibilizer (C), wherein the gas barrier resin (A) has an oxygen transmission rate of 500 ml.20 mum / m<2>.days.atm (20° C., 65% RH) or less, the thermoplastic resin (B) has a carbon-carbon double bond, and an oxygen absorption rate of the resin composition is 0.001 m / m<2>.day or more.

Owner:KURARAY CO LTD

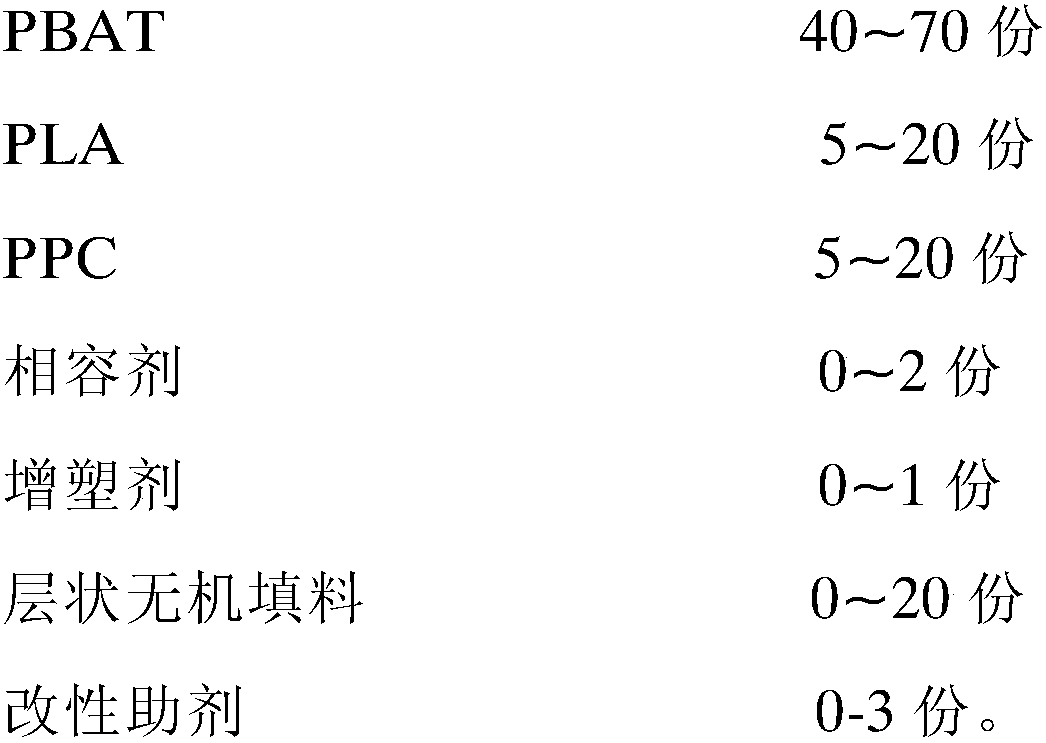

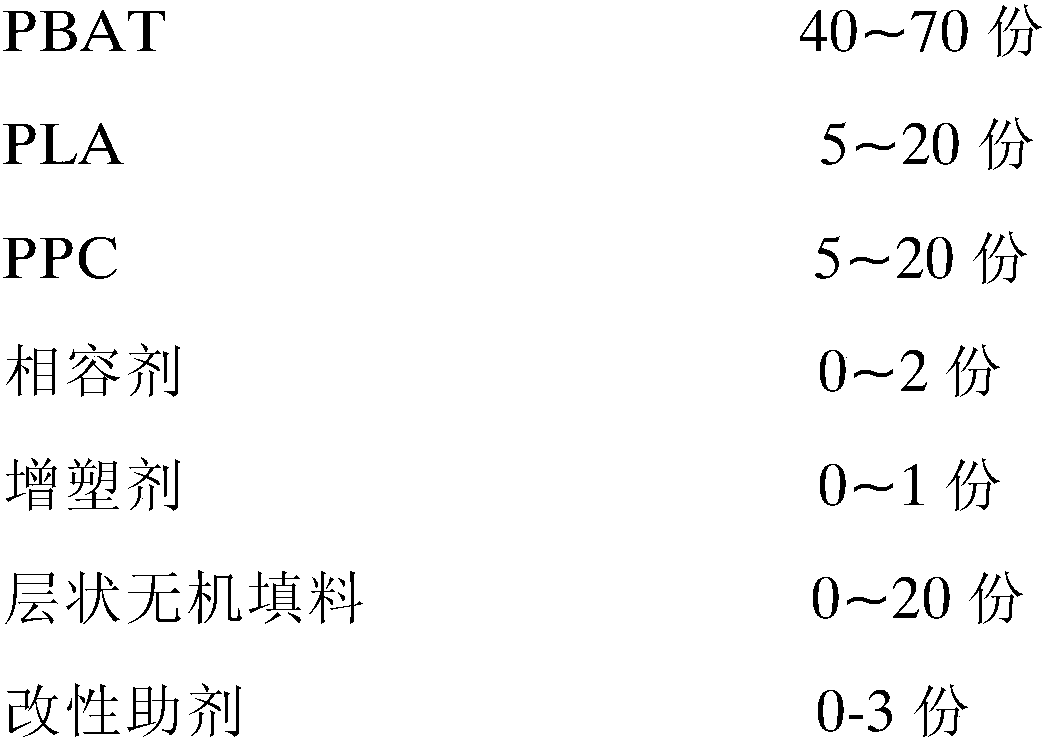

Full-degradable cushion packaging bag and preparation method thereof

The invention discloses a full-degradable cushion packaging bag and a preparation method thereof. The packaging bag comprises the following raw material components in parts by mass: 40-70 parts of PBAT (Poly(butyleneadipate-co-terephthalate)), 5-20 parts of PLA (Polylactic Acid), 5-20 parts of PPC (Chlorinated Polypropylene), 0-2 parts of a compatilizer, 0-1 part of a plasticizer, 0-20 parts of alayered inorganic filler and 0-3 parts of a performance additive. The preparation method comprises the following steps: drying raw materials; modifying the layered inorganic filler; fully and uniformly mixing the PBAT, PLA, PPC, the compatilizer and the modified layered inorganic filler; adding the mixed materials into a twin-screw extruder for performing melt blending extrusion and drawing, dicing to obtain a granular blended material; and performing blow molding through a three-layer co-extrusion film blowing machine, thereby obtaining the thin film product. The full-degradable cushion packaging bag disclosed by the invention has excellent mechanical property and barrier property, and is high in oxygen permeability and fully degradable. The full-degradable cushion packaging bag is a goodsubstitute of an existing non-degradable cushion packaging bag and is worthy of popularization and application.

Owner:WUHAN HUALI BIOLOGY CO LTD

MDO multilayer polyethylene film

A multilayer film and a method of making the film are disclosed. In the method a multilayer film is post-oriented uniaxially in the machine direction resulting in a film that has a water vapor transmission rate of less than 2.5 g-mil / m2-day and an oxygen transmission rate of less than 1.5 cm2-mil / m2-day. The film of this invention is ideal for applications requiring low water vapor and oxygen transmission rates.

Owner:EQUSR CHEM LP

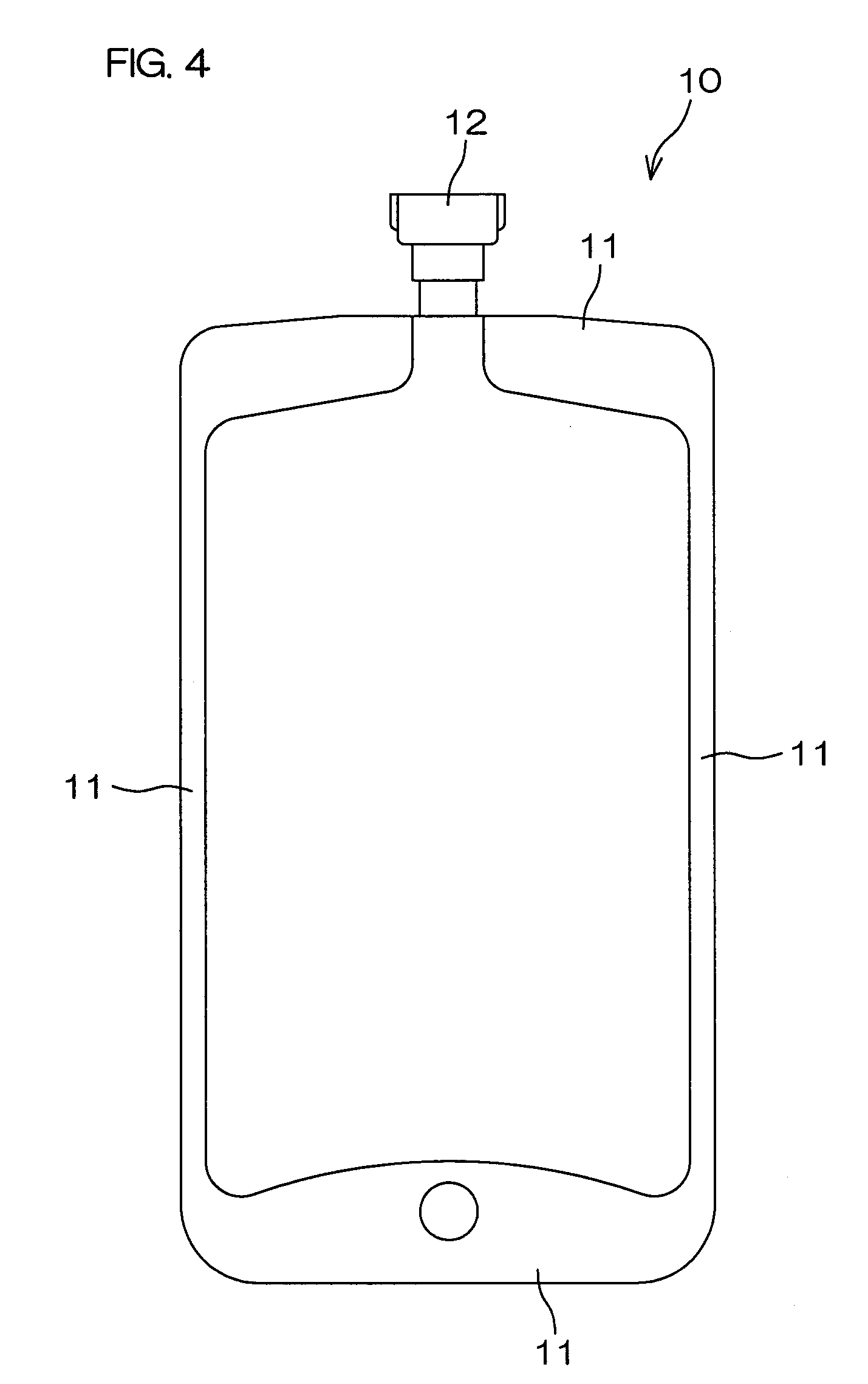

Drug Solution Container Package and Method for Manufacturing the Same

ActiveUS20090032426A1Prevent degradationAvoid spreadingSurgical needlesPackage sterilisationDrugs solutionPliability

An object of this invention is to provide a drug solution container package, which can restrain degradation of a drug solution, proliferation of microbes, etc. accompanying the transmission of oxygen in a high degree while maintaining characteristics required of plastic drug solution containers such as heat resistance, impact resistance, pliability, transparency, and resistance against elution of plastic forming material, and to provide a method for manufacturing the drug solution container package. In the present invention, to achieve the above object, a drug solution is contained and sealed in a plastic drug solution container having an oxygen gas transmission rate (25° C., 60% RH) of not less than 200 cm3 / m2·24h·atm within twelve hours after being subject to steam sterilization or hot water sterilization, and having an oxygen gas transmission rate (25° C., 60% RH) of not more than 100 cm3 / m2·24 h·atm when the oxygen gas transmission rate is in a steady state, and thereafter the plastic drug solution container is steam sterilized or hot water sterilized and then are contained and sealed along with an oxygen scavenger in an outer pouch having an oxygen barrier property.

Owner:OTSUKA PHARM FAB INC

Method of increasing the gas transmission rate of a film

InactiveUS20050119364A1Increasing gas transmission rateHigh oxygen permeabilityMaterial nanotechnologyWrappersCarbon nanotubeEngineering

A method of increasing the gas transmission rate of a packaging film comprises providing a packaging film that comprises at least about 0.001 weight % of single-walled carbon nanotube material based on the weight of the film. The packaging film is exposed to an amount of radiation energy effective to increase the oxygen transmission rate of the packaging film by at least about 100 cc (STP) / m2. day (1 atm, 0% RH, 23° C).

Owner:CRYOVAC ILLC

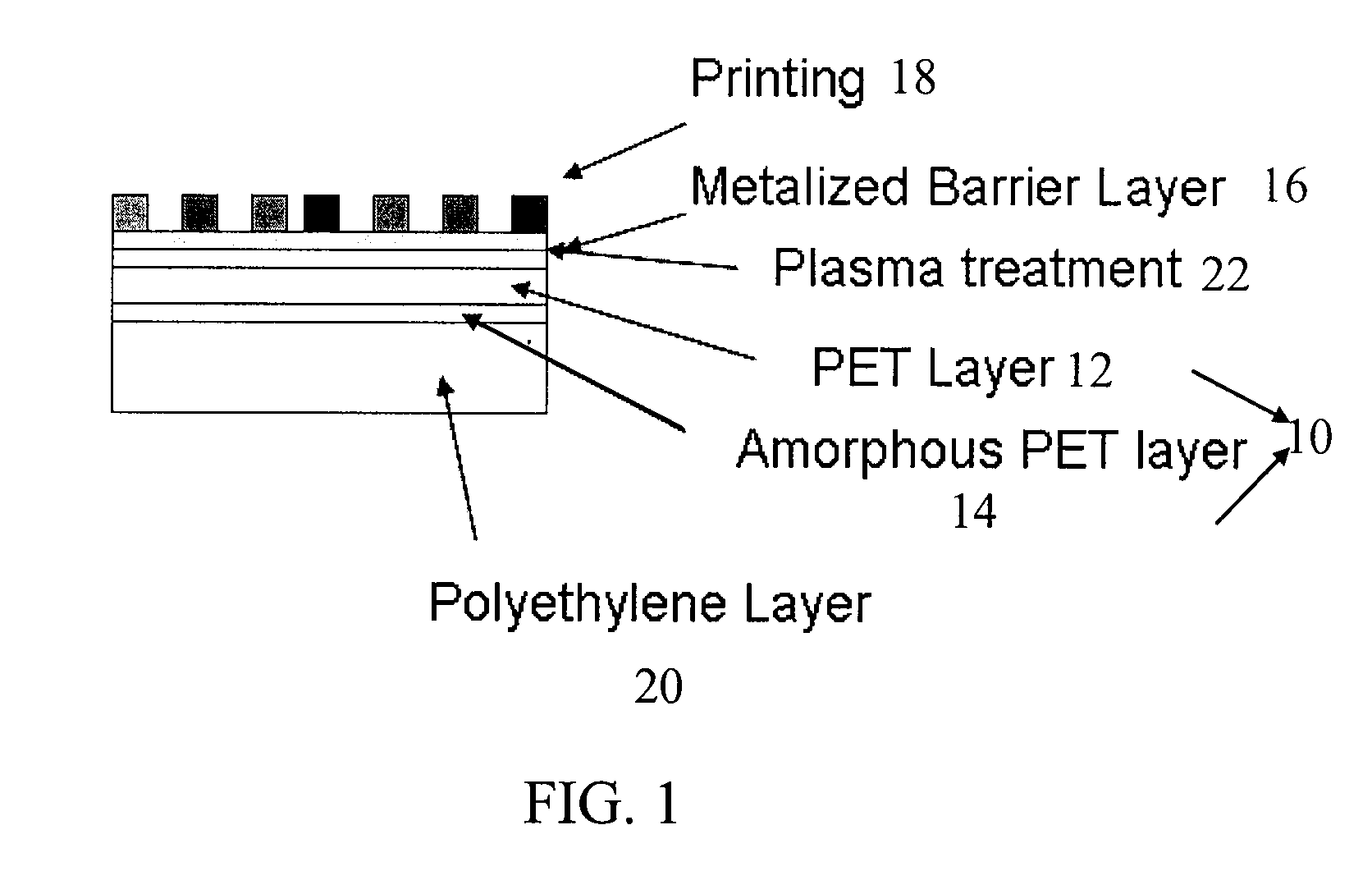

Transparent biaxially oriented polypropylene film with low moisture vapor and oxygen transmission rate

InactiveUS20080205800A1High transparencyExcellent oxygen barrier propertiesSynthetic resin layered productsBagsPolyolefinPolymer science

A laminate film comprising a polyetheramine resin-containing layer, an adhesion-promoting tie-layer, and a core layer comprising of high crystalline propylene homopolymer and crystalline Fischer-Tropsch wax with an optional amount of hydrocarbon resin which exhibits excellent transparency and oxygen and moisture barrier properties. The laminate film could further have additional layers such as a second polyolefin resin-containing layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

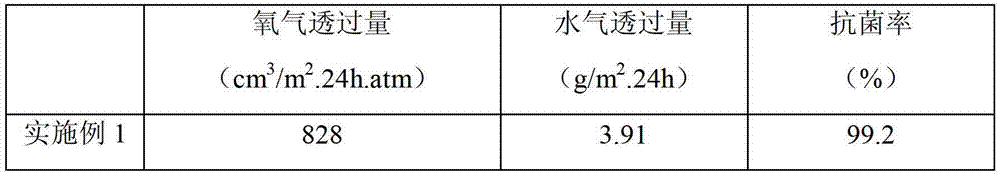

High-resistance antibacterial PE (polyethylene) film and preparation method thereof

ActiveCN103205049AImprove barrier propertiesLow oxygen transmission rateLow-density polyethyleneHigh resistance

The invention discloses a high-resistance antibacterial PE (polyethylene) film and a preparation method thereof, wherein the high-resistance antibacterial PE film is prepared in the way that nanometer composite modified master batch is added to LDPE (low density polyethylene) matrix resin and finally extrusion blown molding is carried out; the mass of the nanometer composite modified master batch is 3-8% of the mass of the LDPE matrix resin; and the nanometer composite modified master batch is prepared by carrying out blending extrusion on nanometer ZnO loaded organic montmorillonite, LDPE and maleic anhydride grafted polyethylene, the organic montmorillonite loading the nanometer ZnO is prepared by intercalation composition of nanometer ZnO loaded montmorillonite and an intercalation agent, and the nanometer ZnO loaded montmorillonite is prepared by loading the nanometer ZnO on montmorillonite. Compared with a pure PE film, the high-resistance antibacterial PE film disclosed by the invention has the advantages that the oxygen transmission rate is reduced by 31%, the water transmission rate is reduced by 40% and the antibacterial rate is up to 99.7%.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

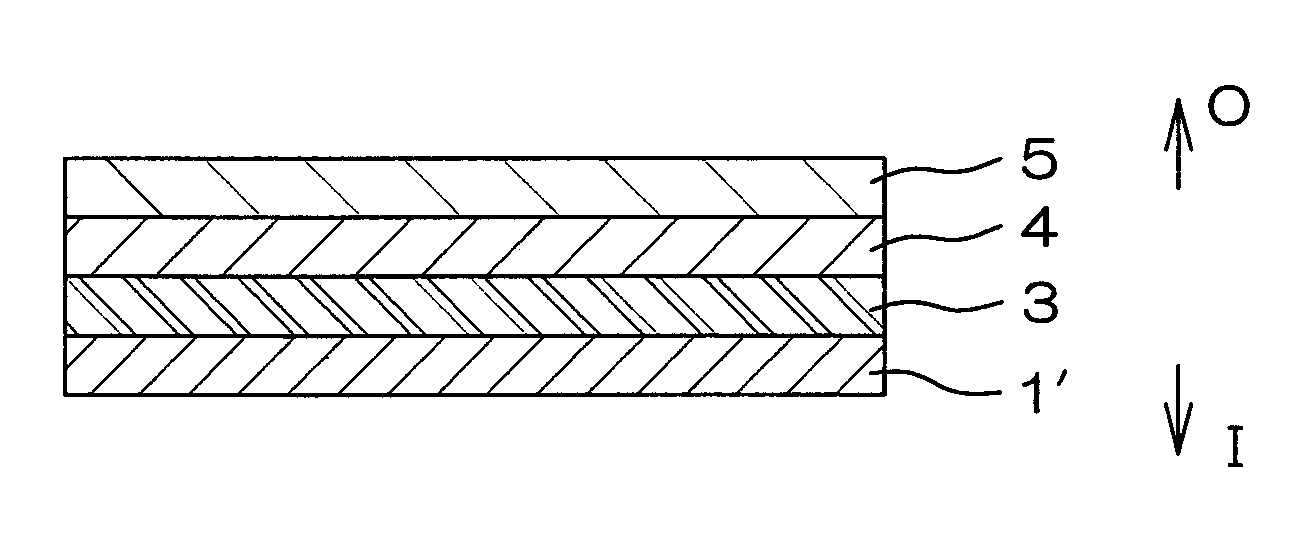

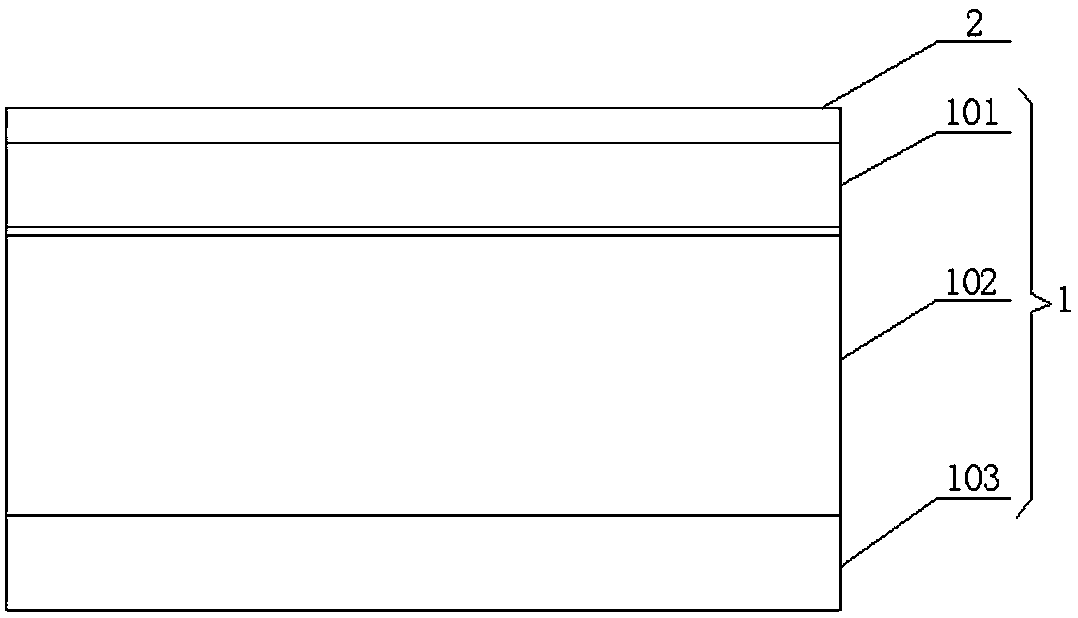

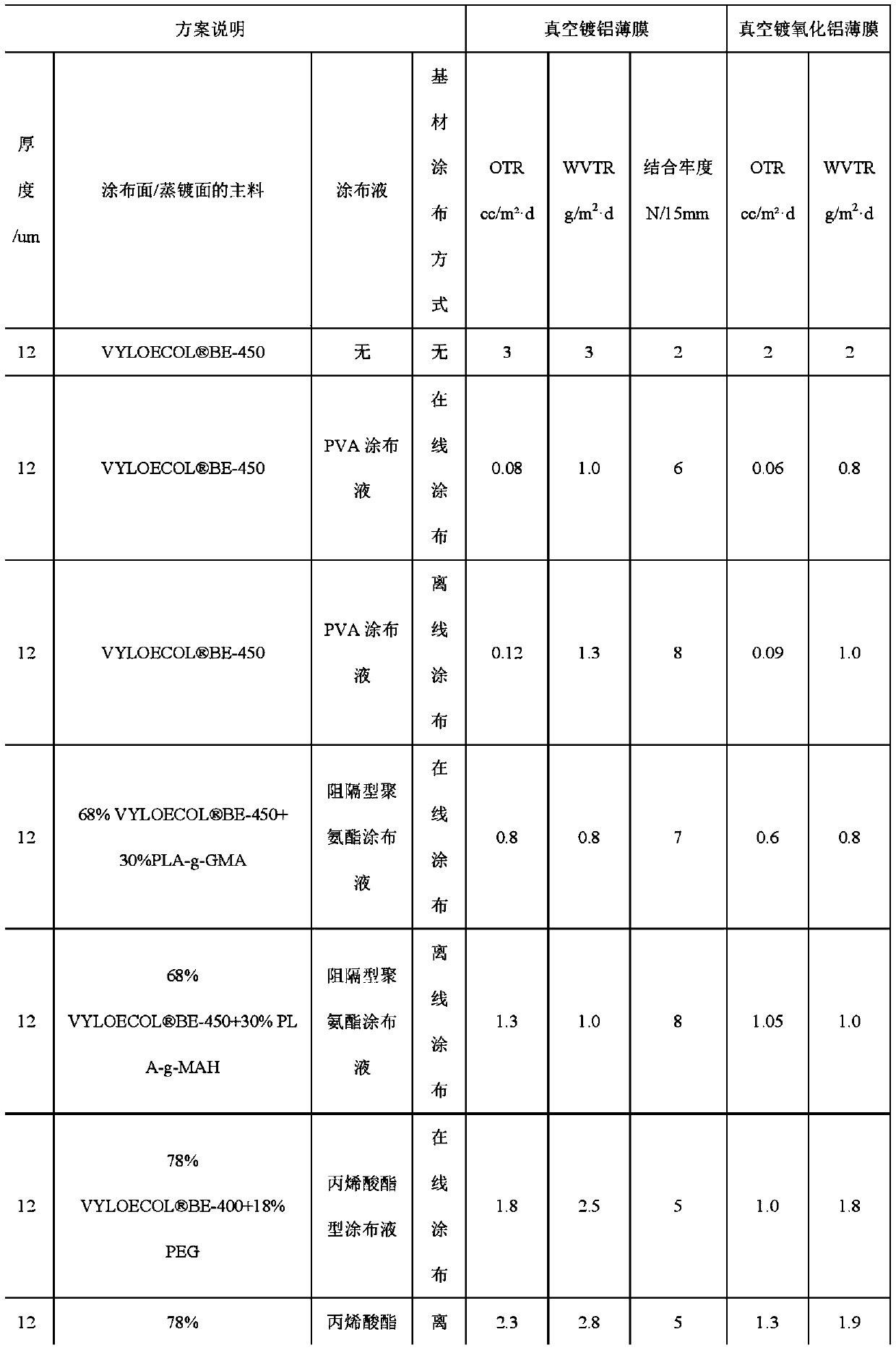

Full-biodegradable high-barrier vacuum evaporation film and preparation method thereof

InactiveCN110435277AImprove barrier propertiesImprove use valueSynthetic resin layered productsCoatingsSurface layerWater vapor

The invention discloses a biodegradable high-barrier vacuum evaporation film base material and a preparation method thereof. A film is sequentially composed of a high-barrier coating layer and a biaxially-oriented polylactic acid (BOPLA) film base material layer from top to bottom, wherein the base material layer consists of an upper surface layer, a core layer and a lower surface layer. The preparation method comprises the following two steps: firstly, preparing a polylactic acid film (BOPLA) base material meeting the coating requirement by using a horizontal drawing method, and then formingthe high-barrier coating layer on the surface of the film base material by using an online coating process or an offline coating process. According to an aluminum-plated film and an aluminum oxide-plated film which are produced by utilizing the high-barrier vacuum evaporation film base material prepared by the invention, the optimal oxygen permeability can be less than 0.02 cc / m<2>.24h, and the optimal water vapor permeability reaches 0.05 g / m<2>.24h; and the high-barrier vacuum evaporation film base material not only has an excellent barrier effect, but also is biodegradable, can effectivelysolve the environmental problem caused by waste packaging films, and is high in industrial utilization value.

Owner:广东华通新材料科技有限公司 +1

Multi-functional multi-layer composite film for preserving fruits and preparation method thereof

ActiveCN102173146ALightweightRecyclableSynthetic resin layered productsContainers preventing decayComposite filmWater vapor

The invention discloses a multi-functional multi-layer composite film for preserving fruits and a preparation method thereof, which are used for preserving fruits such as grapes, winter jujube, lychee, longan and the like. The composite film comprises four functional layers, namely a basal layer, a release agent layer, an auxiliary layer and a protective layer, wherein the basal layer is a plastic film prepared by blowing inorganic filler modified resin; the sulfur dioxide release agent layer coated on the basal layer is made of an adhesive of a suspended sulfur dioxide release agent; the auxiliary layer on the release agent layer consists of organic acid and an adhesive; and the adhesive protective layer on the auxiliary layer is a mixture of ethylene vinyl-acetate copolymer (VAE) or / andnatural rubber. The fruit preserving package has adjustable oxygen penetration rate; sulfur dioxide bactericide gas generated by the composite film has good effect of killing botrvtis cinerea and other pathogenic bacteria, and the bactericide has the characteristics of adjustable concentration and period and low release concentration, and cannot remain on the fruits; and the composite film has good barrier effect on water vapor and prevents the fruits from being damaged due to water loss.

Owner:大家智合(北京)网络科技股份有限公司

Multicomponent package

InactiveUS20070092610A1Limited amountIncrease heatReady-for-oven doughsClosure with auxillary devicesOxygen transmission rateLow oxygen

The invention is directed to a multicomponent package having an upper and lower component that are releasably attached to each other and wherein one of either the upper or lower component has high oxygen barrier properties and the other component has low oxygen barrier properties. In one embodiment, one of the components has an oxygen transmission rate of at least 4,000 cc at STP / m2 / 24 hr / atm, and the other component has an oxygen transmission rate of less than 1,000 cc at STP / m2 / 24 hr / atm. The multicomponent package can be used to package food products that may be incompatible with each other or where it may be desirable to package each food product in differing packaging environment. As a result, two or more dissimilar food products may be stored, shipped, and / or sold in the same package.

Owner:CRYOVAC ILLC

Trilayer coated pharmaceutical packaging with low oxygen transmission rate

ActiveUS9937099B2Enemata/irrigatorsLayered productsPharmaceutical packagingChemical vapor deposition

Owner:SI02 MEDICAL PRODS

Production technology of nanometer modified polyolefin resin film

The invention discloses a production technology of nanometer modified polyolefin resin film, In the technology, un-stretched polypropylene film production process comprises: preparing modified nanometer silica, preparing modified nanometer montmorillonite, adding the prepared modified silica and modified montmorillonite into polypropylene homopolymers, adding dispersant, high speed banburing, melting, extruding and granulating to obtain parent material, melting the parent material, extruding, quenching, thickness measuring, corona treating, winding, cutting and packaging; and the production process of bidirectional stretched polypropylene film comprises an extra step of bidirectional stretching after the quenching step; wherein the weight percentages of the added substances are: modified silica 2%, modified montmorillonite 1.5%, F800E polypropylene homopolymers 93.5% and dispersant 3%. The invention solves problems of poor obstructing performance, relatively high oxygen transmittance, no antibacterial effect and insufficient rigidity of material existing in present CPP and BOPP films in our country; can prolong the shelf life of packing.

Owner:浙江富陵控股集团有限公司 +2

Thermoplastic elastomer compounds exhibiting superior compression set properties

ActiveUS20140094538A1Compression set percentageIncrease elasticityAntifouling/underwater paintsPaints with biocidesThermoplasticPolyolefin

A blend of polyisobutylene-based thermoplastic vulcanizate, styrene-ethylene-ethylene-propylene-styrene, low molecular weight liquid polybutene, polyolefin, polyphenylene ether, and, optionally, filler is disclosed which has good processability, lower compression set, and more effective barrier properties for oxygen than the same blend without the styrene-ethylene-ethylene-propylene-styrene and the polyphenylene ether. The blend is superior in oxygen transmission rate properties than a conventional styrenic block copolymer containing thermoplastic elastomer.

Owner:AVIENT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com