Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Improve package strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

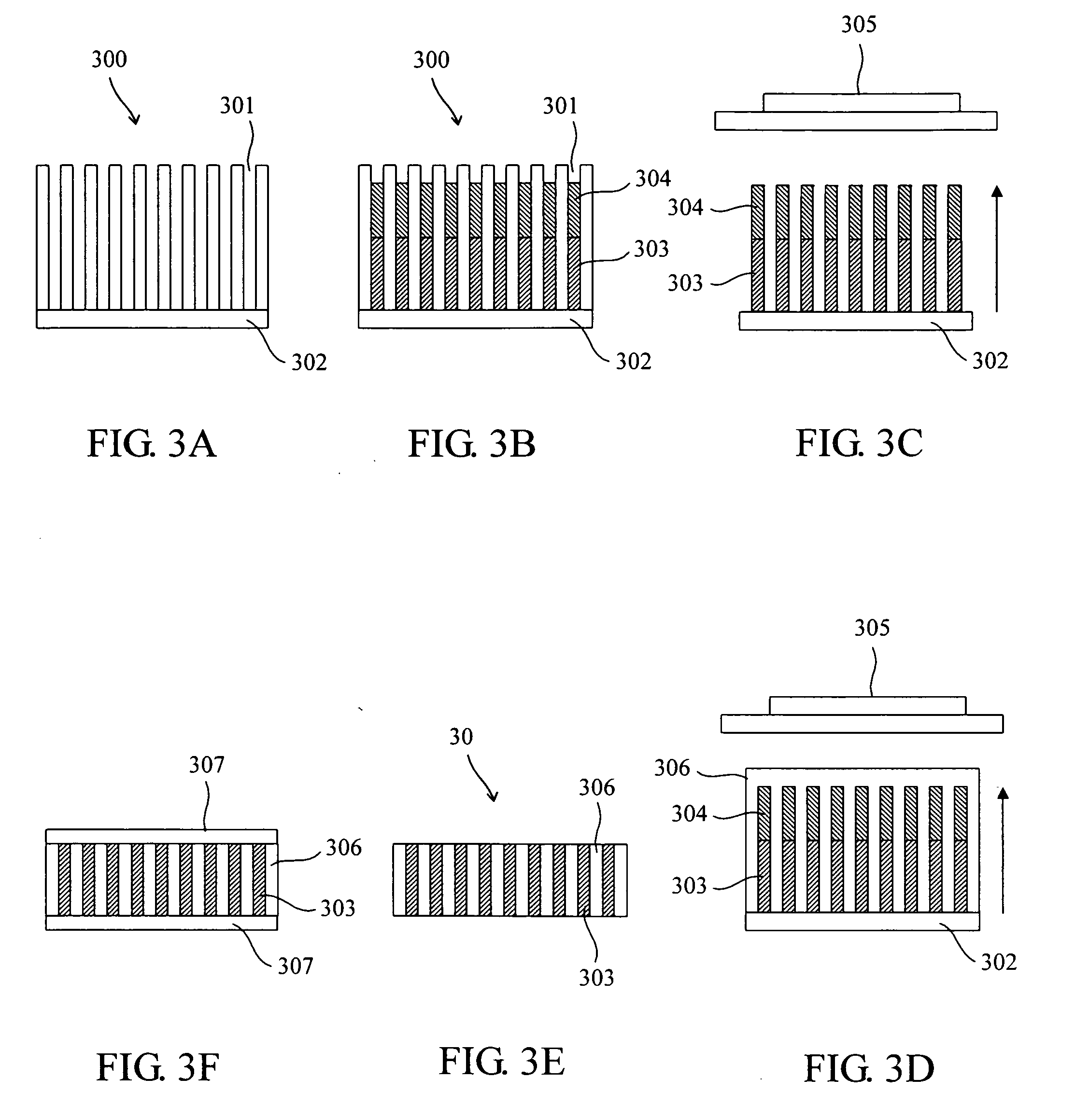

A packaging method for mems devices based on lcp multilayer stacking technology

ActiveCN107324273BImprove insulation performanceLow moisture absorptionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesRadar systemsMicrowave

The invention discloses a MEMS device packaging method based on LCP multilayer stacking technology, which is characterized in that the MEMS device is obtained by sputtering, photolithography, etching, electroplating and other processes on a double-sided polished silicon substrate, and at the same time Form silicon grooves that are easy to lead out and have accurate alignment; based on the LCP multilayer stacking technology, on the multilayer LCP substrate, the cap part of the device package is obtained through laser scribing, alignment, lamination and other processes; the device and the cap Package without assistance, high-precision integration, and obtain MEMS devices with low loss and good airtightness. The MEMS device of the invention has the advantages of low loss, high isolation and good airtightness. This method can better provide packaging protection for MEMS devices with movable parts, and is especially suitable for miniaturization applications of microwave, millimeter wave communication, radar and other systems / subsystems, and belongs to the realization of miniaturization, high performance microwave communication, radar systems / The key technology of the subsystem.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

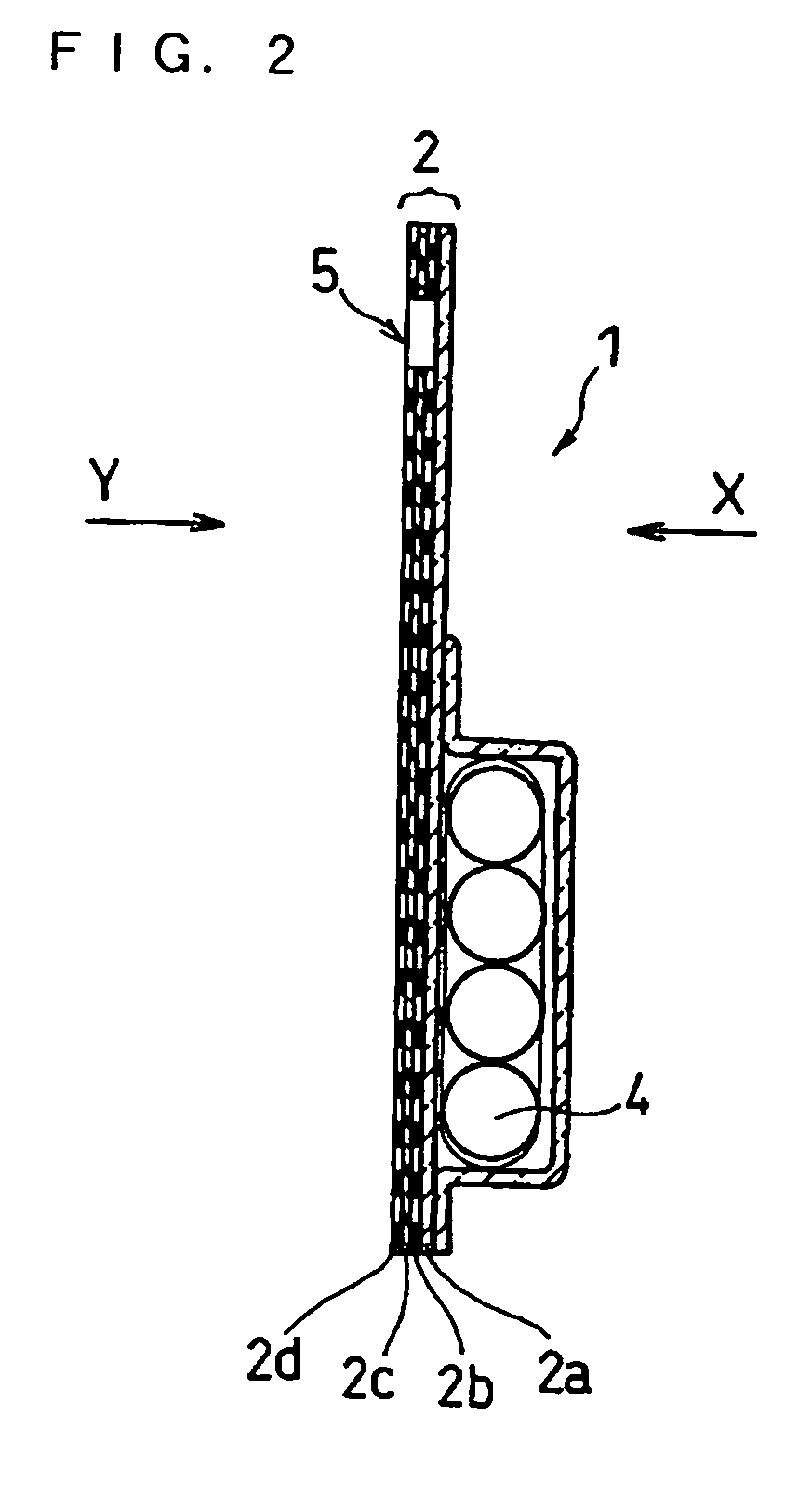

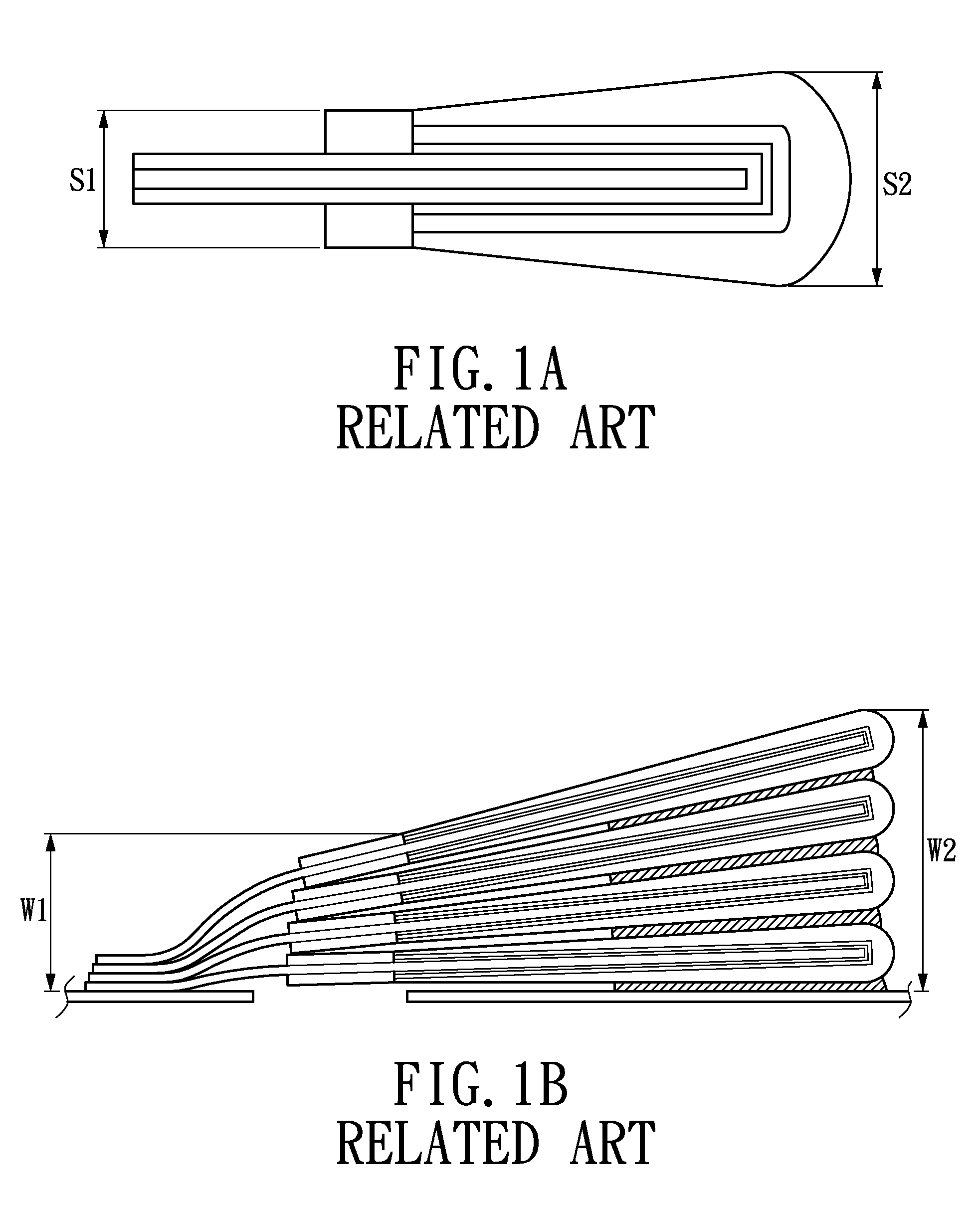

Light emitting device

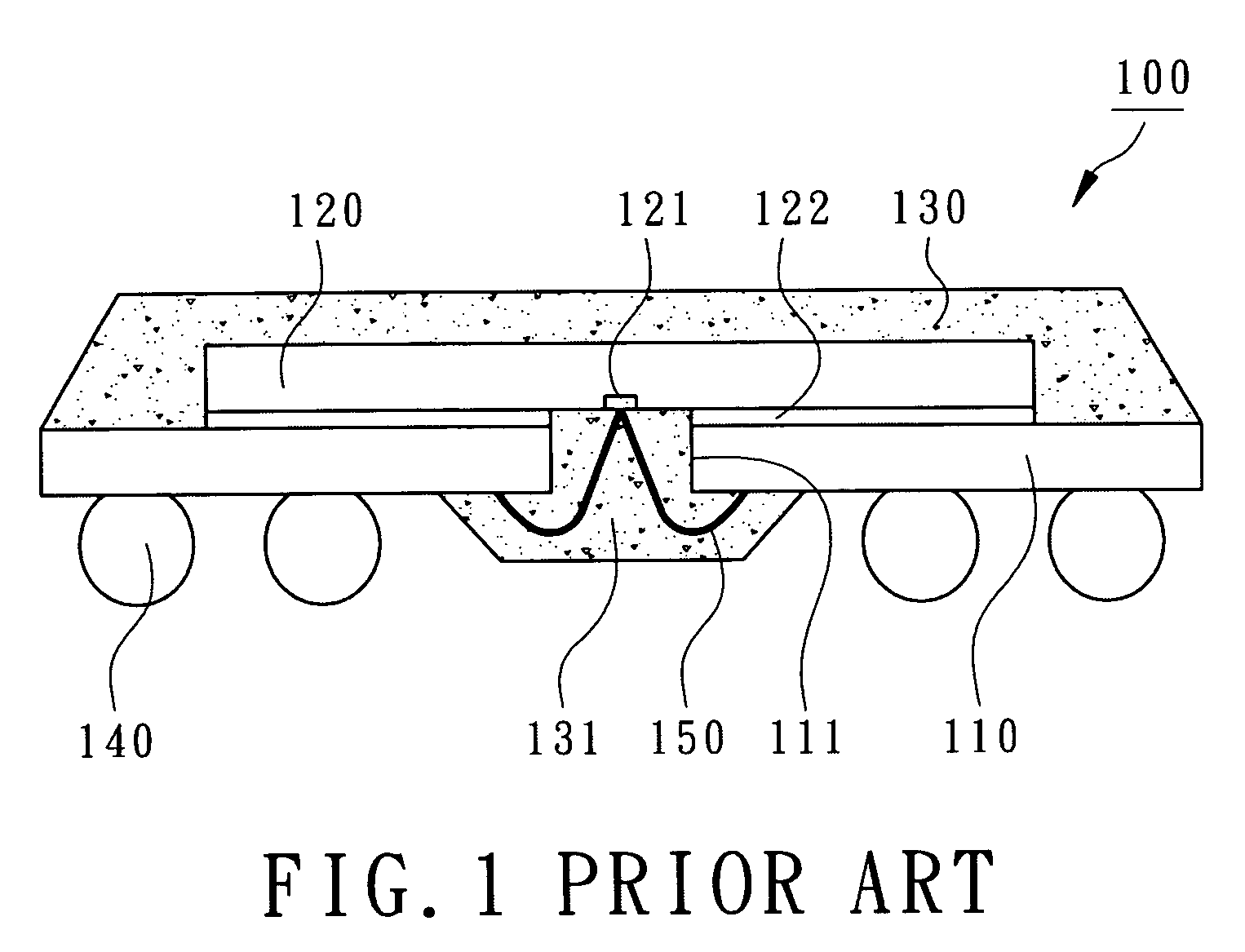

ActiveUS20070247841A1Improve package strengthImprove handlingVehicle interior lightingSolid-state devicesLead frameLight emitting device

A light emitting device comprises: a light emitting element; a plurality of lead frames to which the light emitting element is electrically connected; and a package that includes in its interior at least part of said lead frames which protrude outward at one end, that is equipped with an opening for taking off light from the light emitting element, and that extends in the lengthwise direction, wherein a concave portion is formed in the outer surface of at least part of the package wall, the lead frames protruding outward from the package are accommodated in this concave portion, and the walls that constitute said opening and are across from each other in the widthwise direction of the package comprise at least a first wall that is across from the light emitting element, a second wall that is raised up by a step from the first wall, and a third wall that links the first wall and the second wall, and the second wall and third wall are formed thicker than the first wall.

Owner:NICHIA CORP

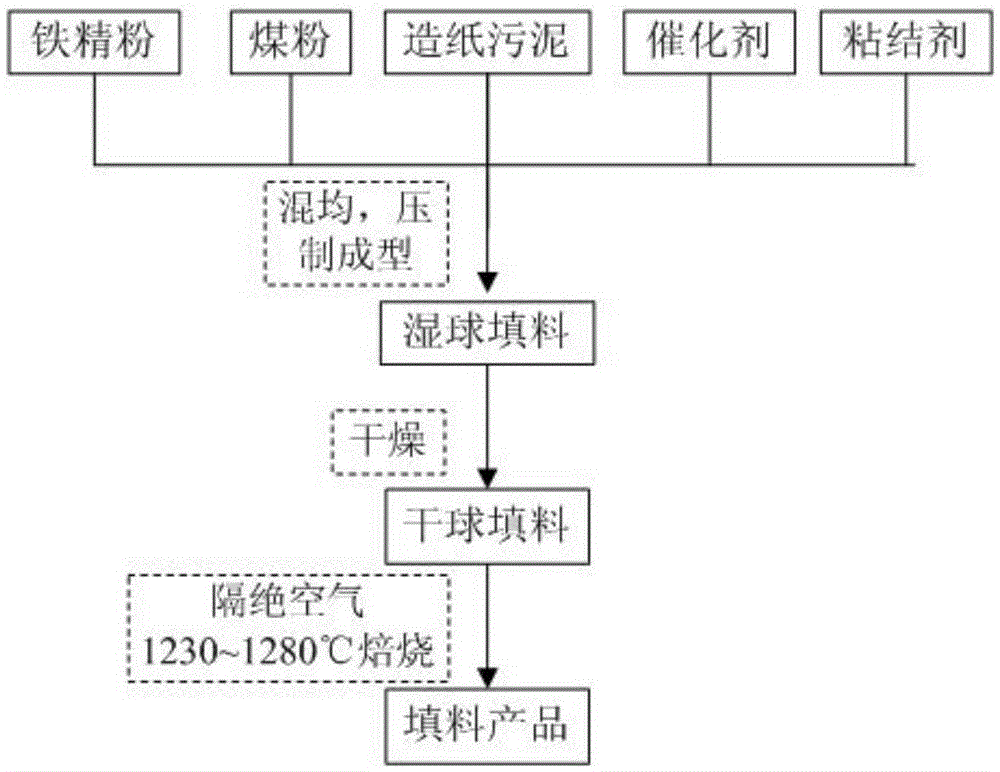

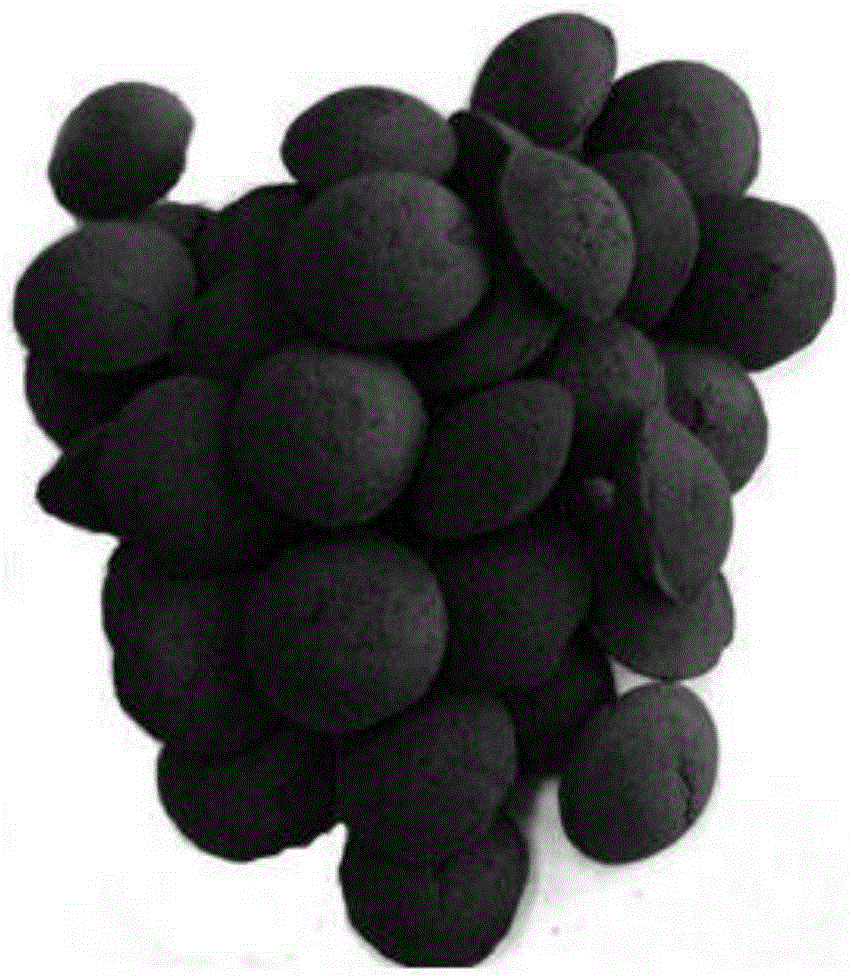

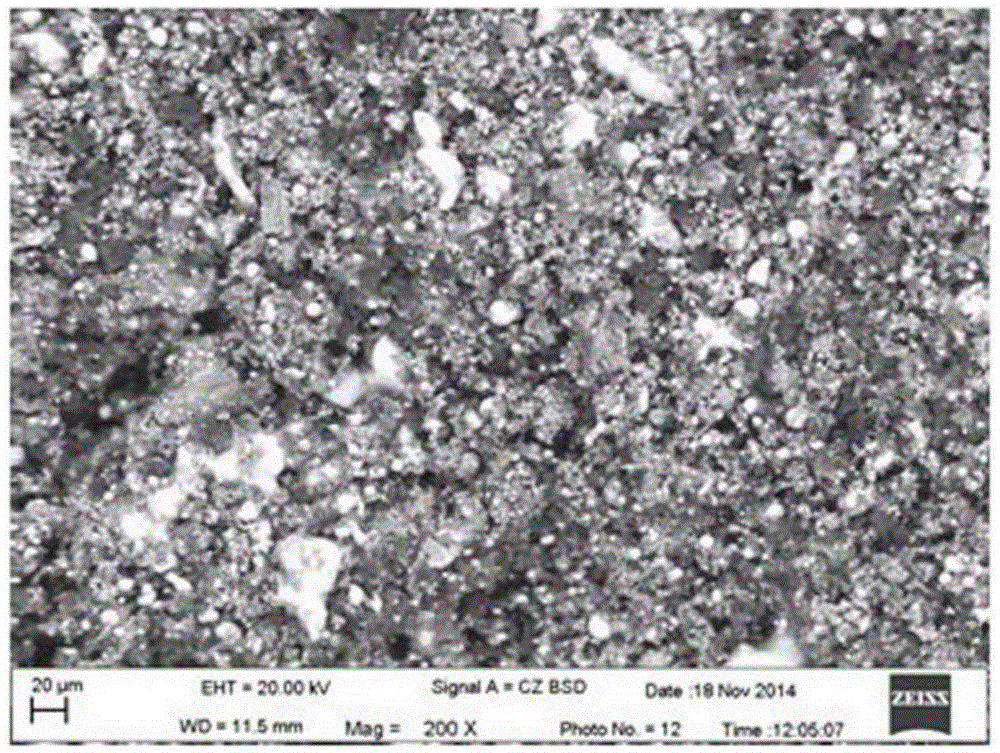

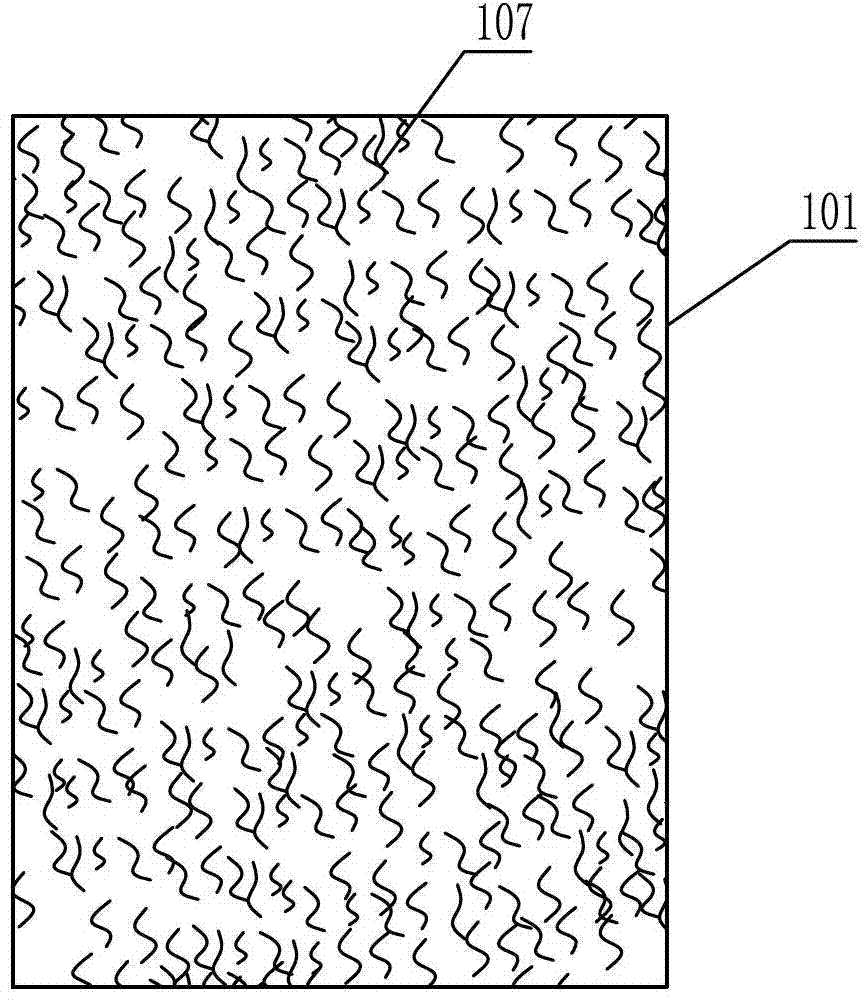

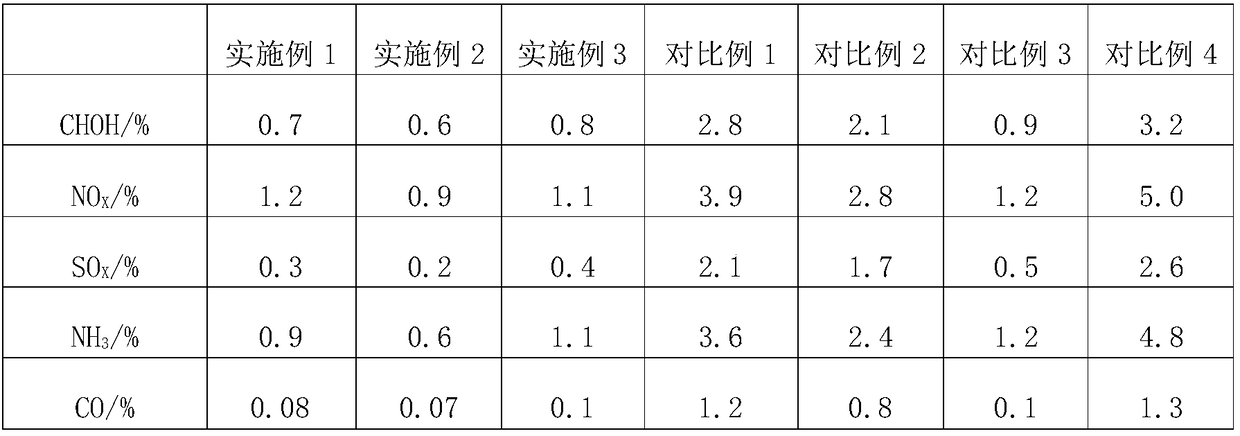

Structured iron-carbon micro-electrolysis filling material and preparation method thereof

ActiveCN105366773AFine granularityIncrease distribution densityWater/sewage treatmentWaste water treatment from food industryIndustrial wastewater treatmentPaper mill

The invention belongs to the technical field of environmental engineering materials and particularly relates to a structured iron-carbon micro-electrolysis filling material and a preparation method thereof. The preparation method comprises the steps of treating fine iron powder and bituminous coal powder as raw materials, treating paper mill sludge which is dried and pulverized as a pore-forming agent, treating copper powder as a catalyst, adding a binding agent, mixing the ingredients uniformly, conducting compression formation, drying the ingredients, obtaining a dry-bulb filling material, generating anode metal iron by conducting direct reduction on the fine iron powder in the dry-bulb filling material through high temperature roasting, and obtaining the iron-carbon micro-electrolysis filling material. The granularity of the anode metal iron of the iron-carbon micro-electrolysis filling material is less than 10 micrometers. The structured iron-carbon micro-electrolysis filling material has the advantages that iron and carbon are integrated, the filling material is of a micropore framework type alloy structure, the porosity is high, the activity is high, the current density is large, when the filling material is applied to industrial waste water treatment, COD and chromaticity of waste water can be effectively lowered, biodegradability of the waste water can be effectively improved, various heavy metal ions can be removed, and the filling material is stable in operation and application effect.

Owner:UNIV OF SCI & TECH BEIJING

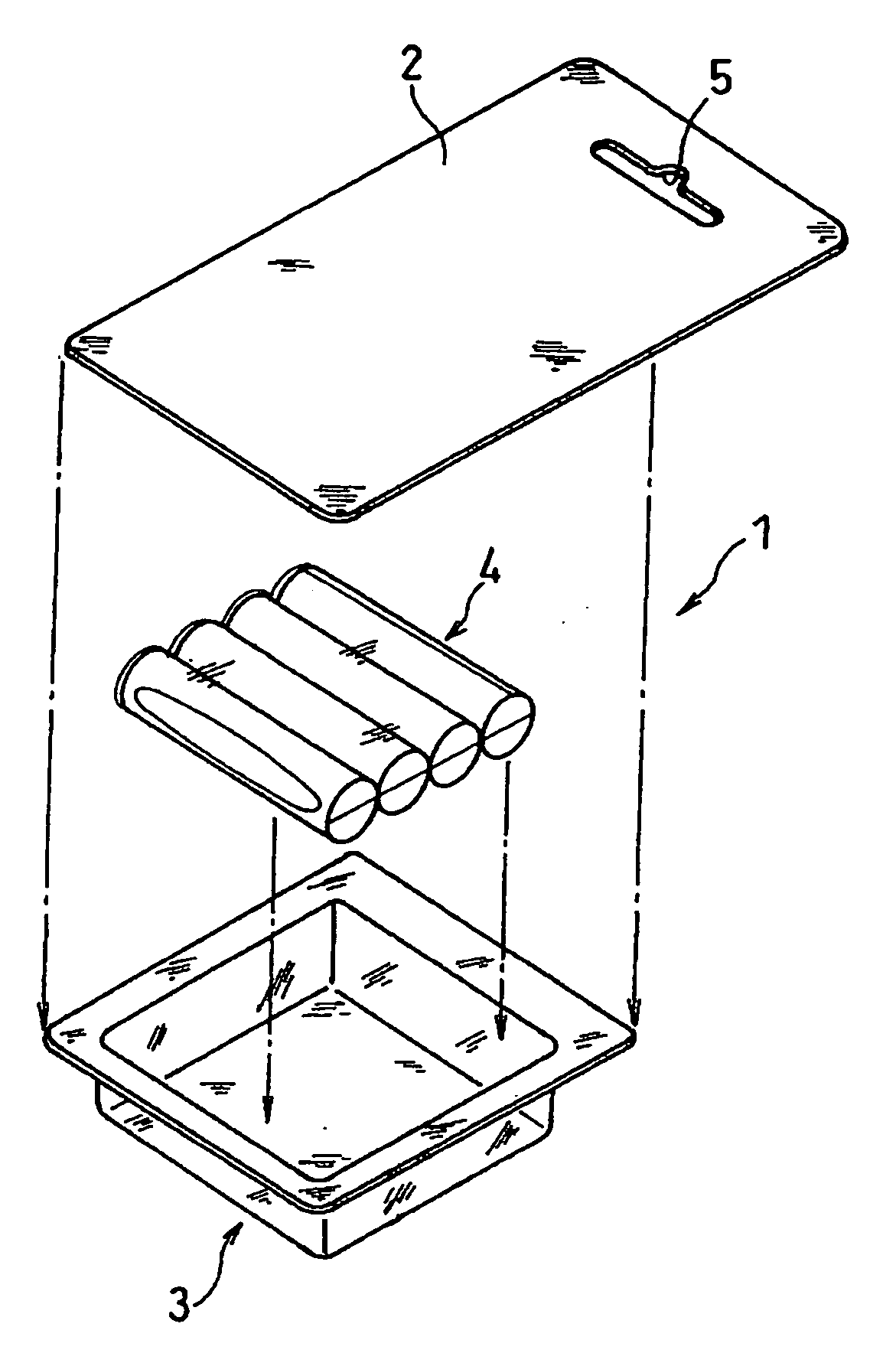

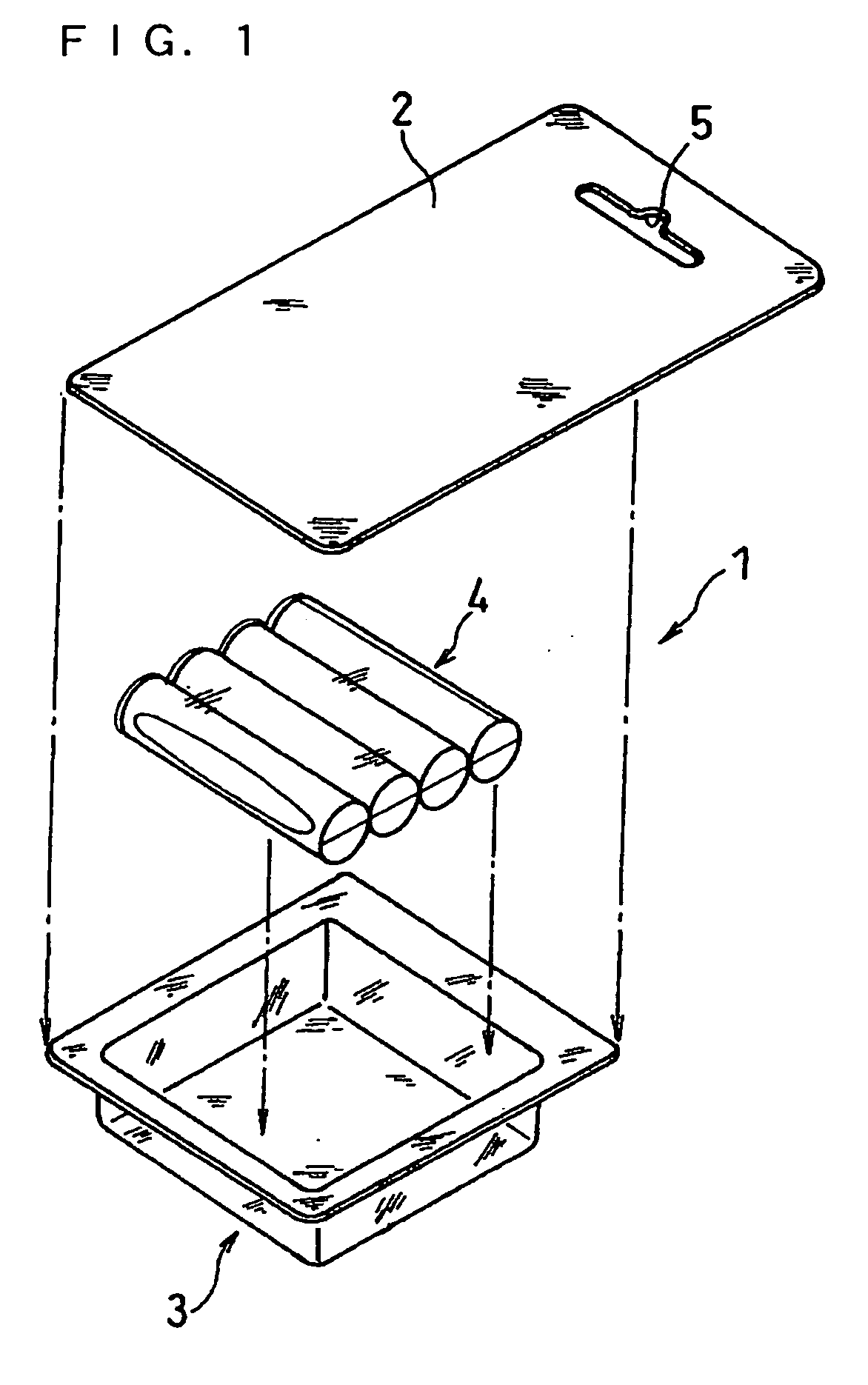

Package and process for producing same

InactiveUS20060207909A1Simple structureSimple processFlexible coversWrappersEngineeringMechanical engineering

In order to obtain a package achieving a simpler structure, simpler production process, lower product cost, lower production cost, higher strength and excellent appearance, the package is produced by forming, on only one surface of a light permeable base, a first printing layer that can be observed from the other surface of the base, an anti-offset layer and a second printing layer that can be observed from the aforesaid one surface, and providing a holding means for holding an article at the side of a second surface of the base.

Owner:PANASONIC CORP

Methods For Preventing Proppant Carryover From Fractures, And Gravel-Packed Filters

InactiveUS20080156489A1Increasing propping filler pack strengthImprove protectionFluid removalDrilling compositionProduction rateParticulates

This invention relates to the oil and gas industry, in particular, to methods affecting the formation productivity at the oil and gas production stage.A method for fracture propping in a subsurface layer, which ensures a reliable protection of wells from the proppant carryover from the fracture, has been proposed. According to the proposed method, a fracturing fluid is mixed with a propping agent and particulate binding material wherein the particles have an average length-to-width ratio of less than or equal to about 10; thereafter, a formation fracturing process is implemented. Then, the particulate binding material hardens and forms a homogenous firm mass with the propping agent, which impedes the closing of the fracture and precludes proppant carryover from the fracture. Or, a fracturing fluid composition obtained by mixing a propping agent with a binding compound in the form of a powder whose size varies from about 1 to about 500 μm. A gravel-packed filter is then constructed; the said filter is based on the application of the working fluid comprising a propping filler and particulate binder with a length-to-width ratio of less than or equal to 10, or comprising a propping filler and a binding compound in the form of a powder with a size varying from about 1 to about 500 micrometers.

Owner:SCHLUMBERGER TECH CORP

Light emitting device

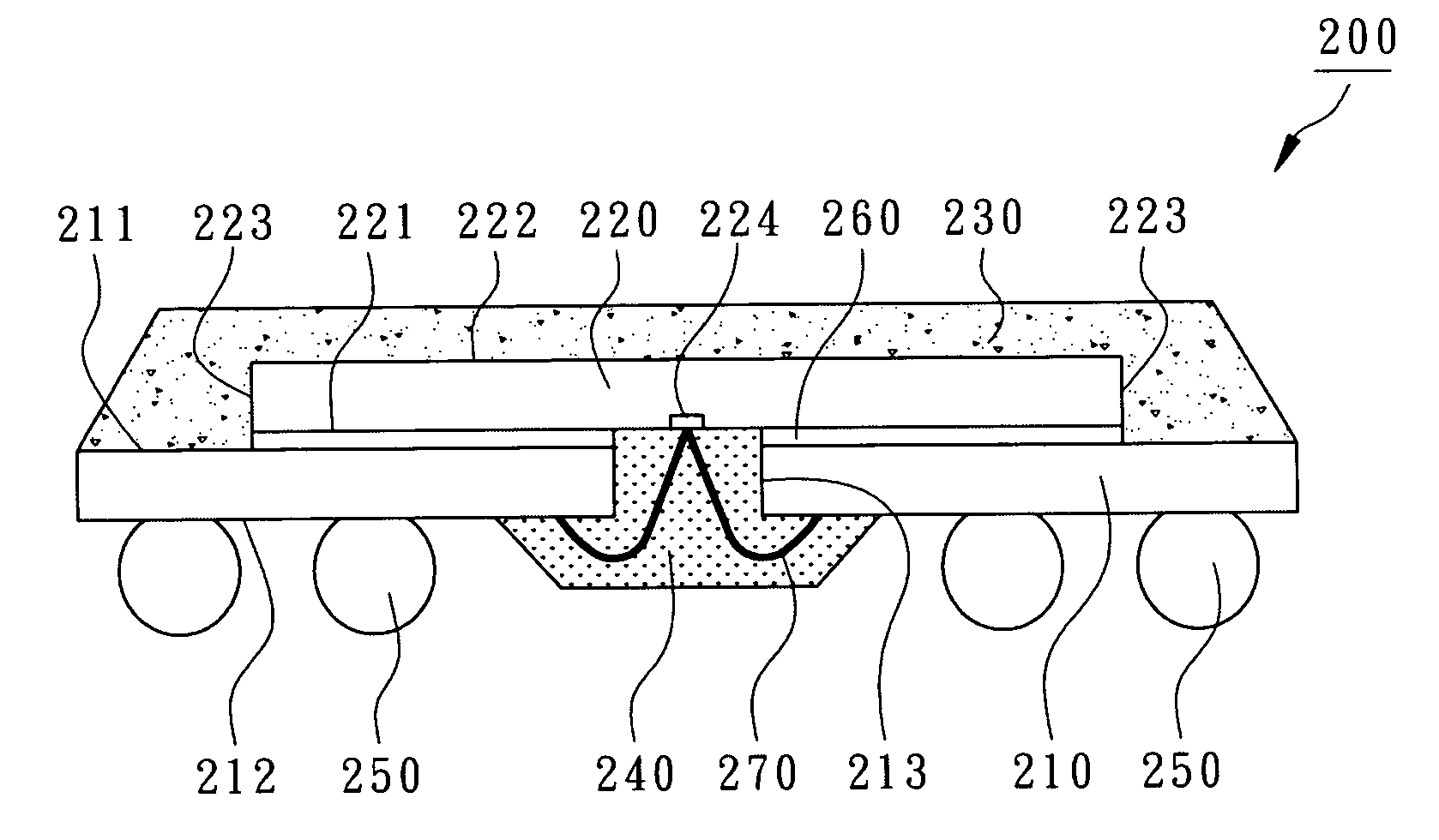

ActiveUS7422338B2Improve package strengthImprove handlingLighting support devicesMeasurement apparatus componentsLead frameLight emitting device

A light emitting device comprises: a light emitting element; a plurality of lead frames to which the light emitting element is electrically connected; and a package that includes in its interior at least part of said lead frames which protrude outward at one end, that is equipped with an opening for taking off light from the light emitting element, and that extends in the lengthwise direction, wherein a concave portion is formed in the outer surface of at least part of the package wall, the lead frames protruding outward from the package are accommodated in this concave portion, and the walls that constitute said opening and are across from each other in the widthwise direction of the package comprise at least a first wall that is across from the light emitting element, a second wall that is raised up by a step from the first wall, and a third wall that links the first wall and the second wall, and the second wall and third wall are formed thicker than the first wall.

Owner:NICHIA CORP

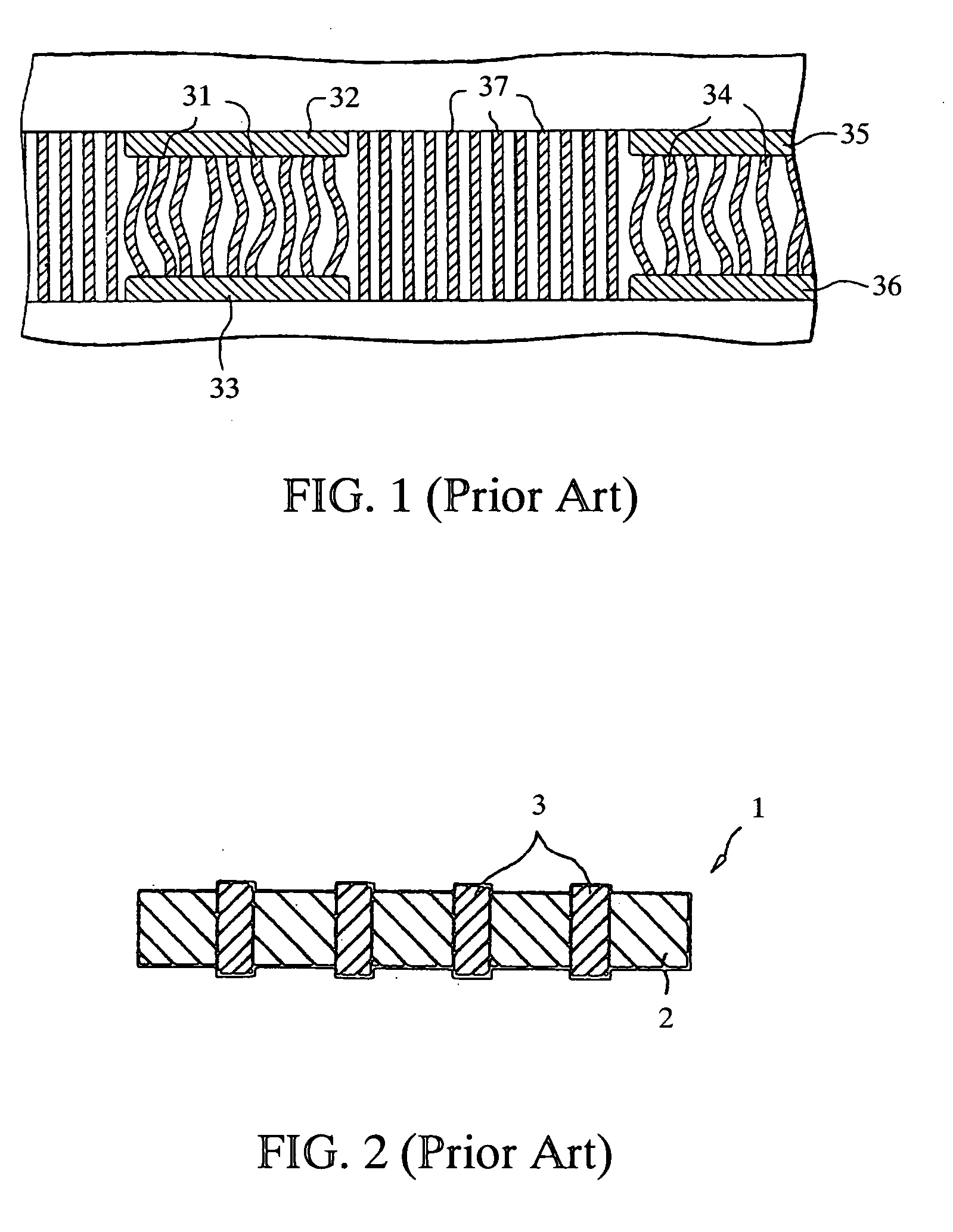

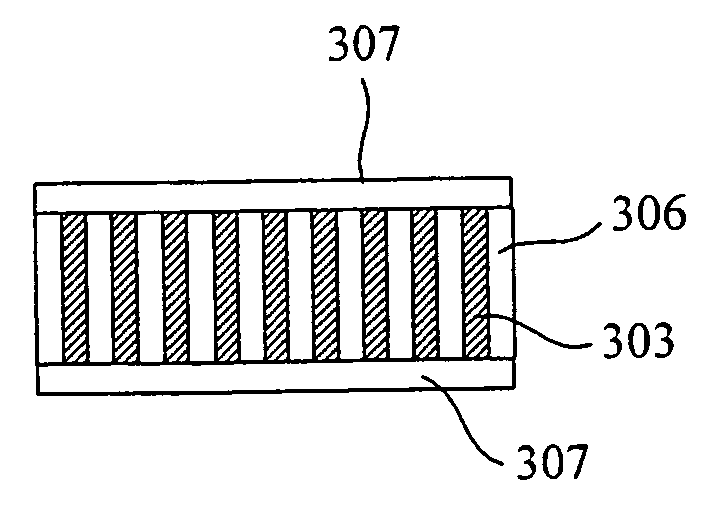

Structure of polymer-matrix conductive film and method for fabricating the same

InactiveUS20060081989A1Increase the areaEasy to packSemiconductor/solid-state device detailsNanoinformaticsElectrical connectionEngineering

A composite conductive film formed of a polymer-matrix and a plurality of conductive lines less than micro-sized and its fabricating method are provided. The conductive lines are arranged parallel and spaced apart from each other so as to provide anisotropic conductivity. The present conductive film can serve as an electrical connection between a fine-pitch chip and a substrate. Additionally, an adhesive layer is formed on two opposite sides of the conductive film along its conductive direction to increase adhesive areas. The strength and reliability of the package using the conductive film are thus enhanced.

Owner:IND TECH RES INST

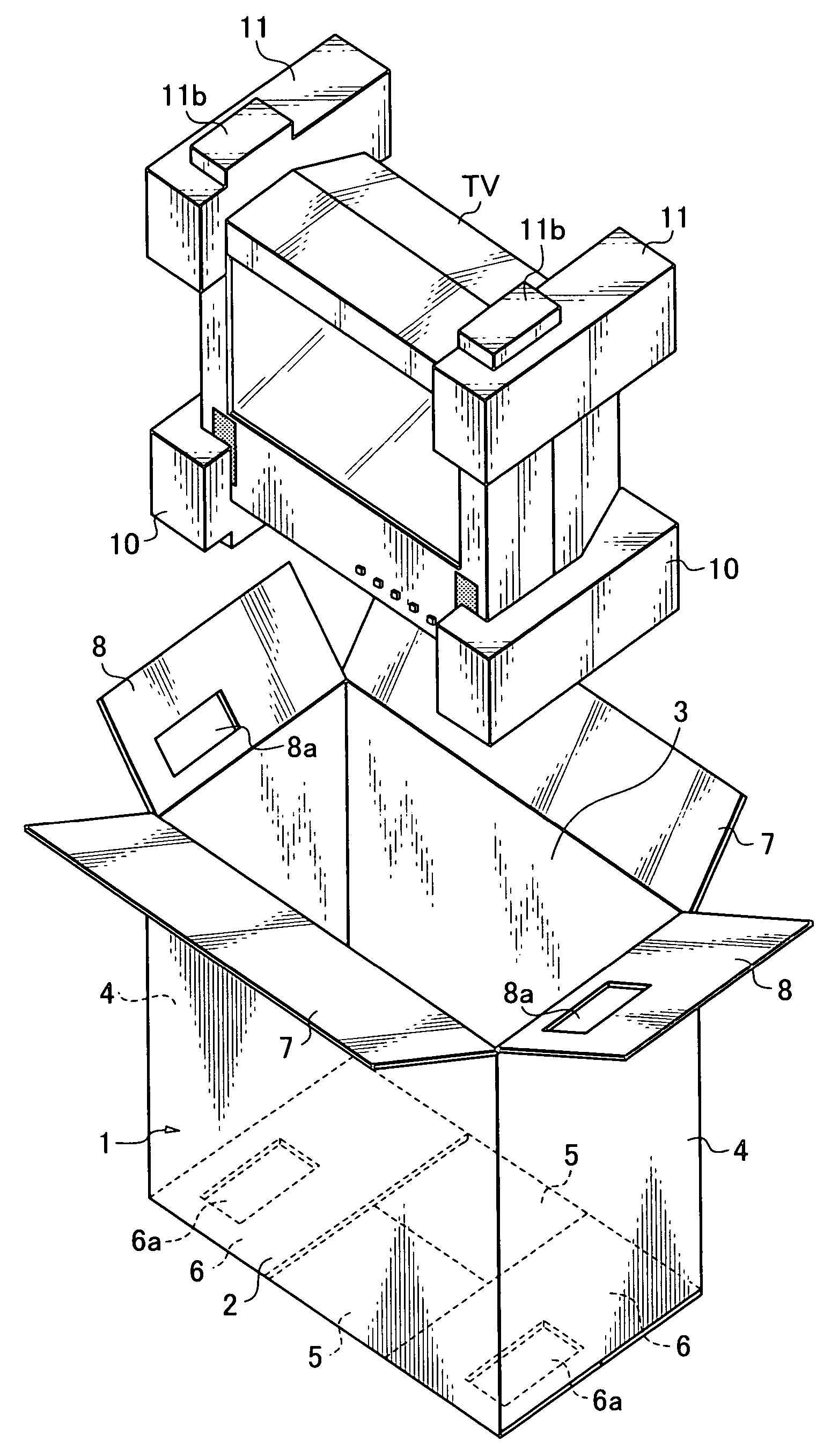

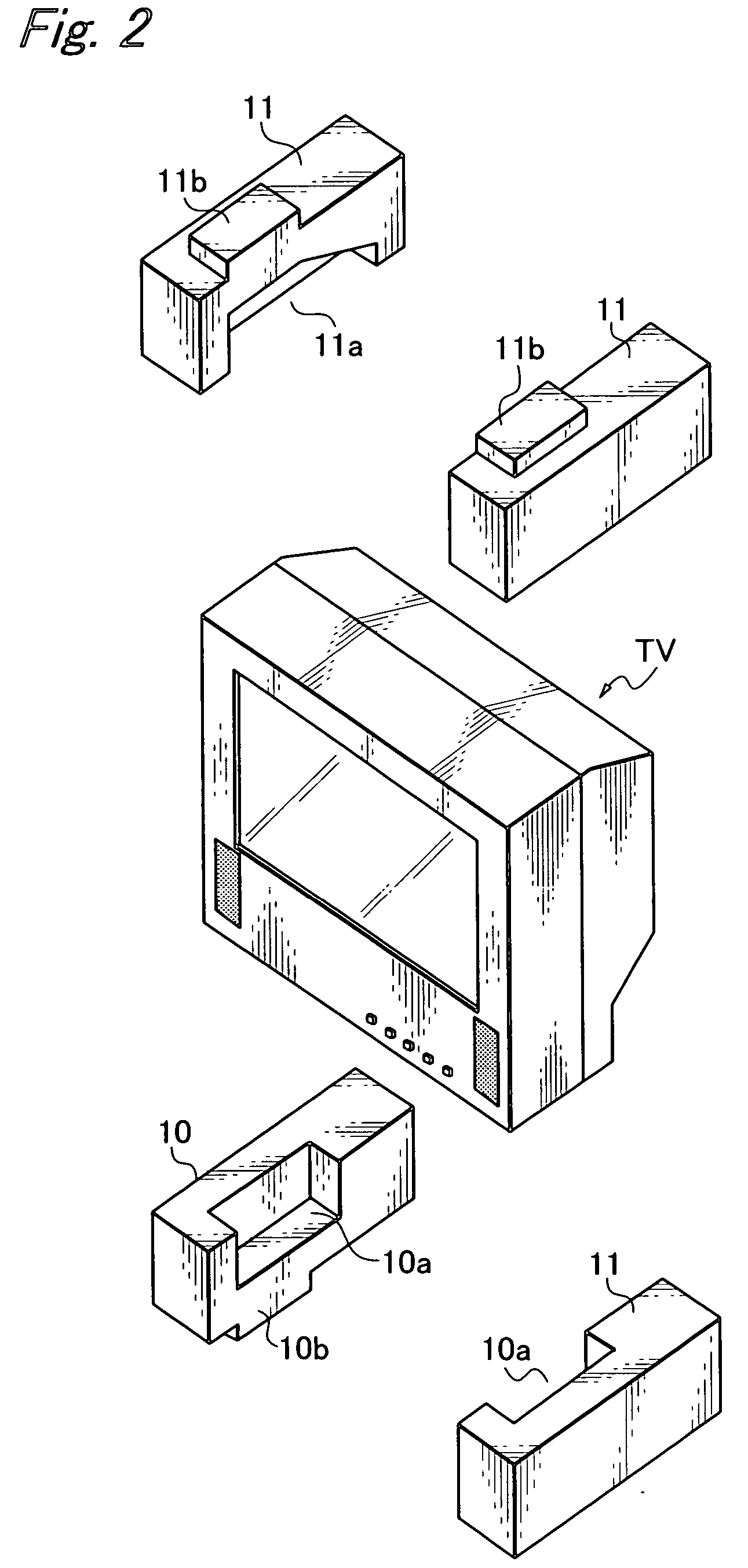

Packaging material provided with cushioning members

InactiveUS20050161366A1Improve package strengthExternal appearance is not spoiledContainers to prevent mechanical damagePaper/cardboard containersCushioningEngineering

To improve cushioning effect for a packaged object without causing cost increase and prevent positional shift of cushioning members without causing lowering of the strength and durability of a packaging box, a packaging material includes a packaging box and cushioning members, a bottom panel and a cover panel of the packaging box being made of inwardly bendable inner flaps and outer flaps respectively, each of the inner flaps being provided with at least a through hole, the cushioning members being provided in inner side surfaces thereof with recesses in which corner portions or side portions of an object to be packaged are fitted, and on outer side surfaces thereof with cushioning projections fitted in the through holes of the inner flaps, the length of the cushioning projections being set larger than the thickness of the inner flaps so as to form a clearance between the inner flaps and cushioning projections when the cushioning members are housed in the packaging box.

Owner:ORION ELECTRIC CO LTD

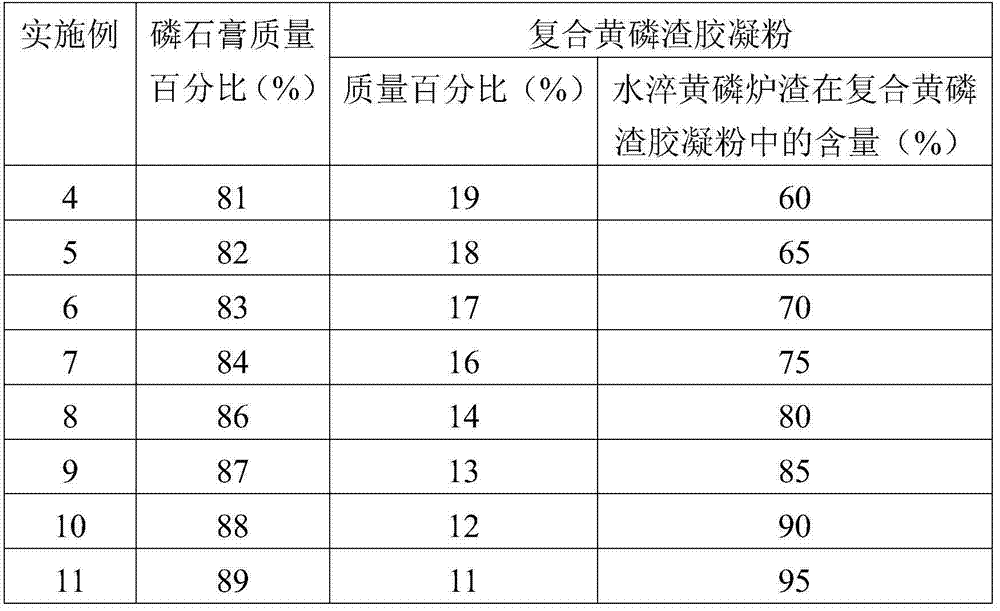

Modified phosphogypsum material used for sea reclamation

The invention discloses a modified phosphogypsum material used for sea reclamation. Phosphogypsum is modified by raw material selection and proportioning so as to make the phosphogypsum suitable for sea reclamation. The materials comprise phosphogypsum and composite yellow phosphorus slag gelling powder. The composite yellow phosphorus slag gelling powder is mixed powder composed of crushed water-quenched yellow phosphorus slag generated in a yellow phosphorus production process and cement clinker. With the characteristics of high fill strength, fast curing speed, good water resistance and high compressive strength, the modified phosphogypsum material used for sea reclamation provided by the invention not only can meet the compressive strength requirements of road building, wharf construction and the like, but also can make heavy use of the solid waste in the phosphorus chemical industry, thus solving the constraint bottleneck problem of waste residue utilization during sustainable development of the phosphorus chemical industry. And the modified phosphogypsum material suitable for sea reclamation is provided.

Owner:GUIZHOU KAILIN GRP CO LTD

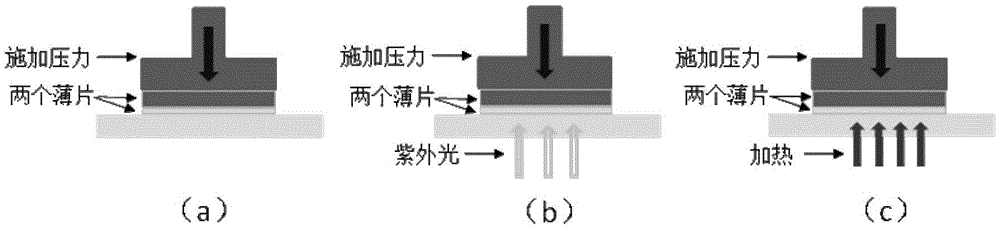

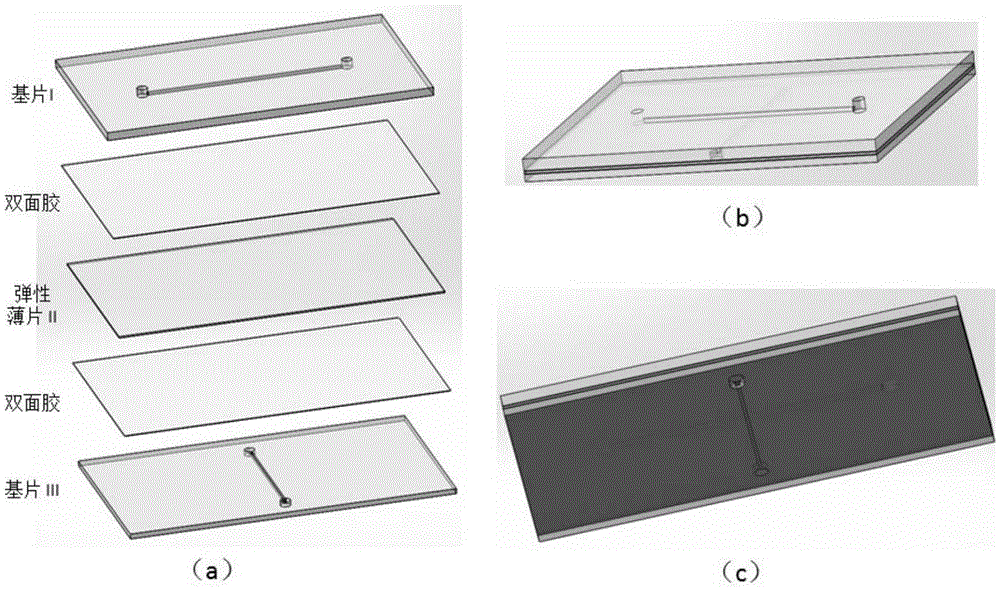

Encapsulation method for plastic micro-flow control analysis chip

InactiveCN1557967AImprove fidelityNo deformationMicrobiological testing/measurementAdhesiveUltraviolet

The packing method for plastic chip for micro flow control includes copying the micro channel pattern via micro-copying process to plastic substrate, mixing dimethyl siloxane pre-polymer and curing agent in certain ratio, vacuum deairing, casting and curing to form polydimethyl siloxane set on the plastic substrate; painting ultraviolet cured adhesive around the substrate, adhering one layer of plastic sheet to constitute three-layer structure with raised packing strength; and irradiating with ultraviolet ray to complete the package of plastic chip. The present invention has simple technological process, less micro channel deformation, no jamming and very high packing strength.

Owner:SHANGHAI JIAO TONG UNIV

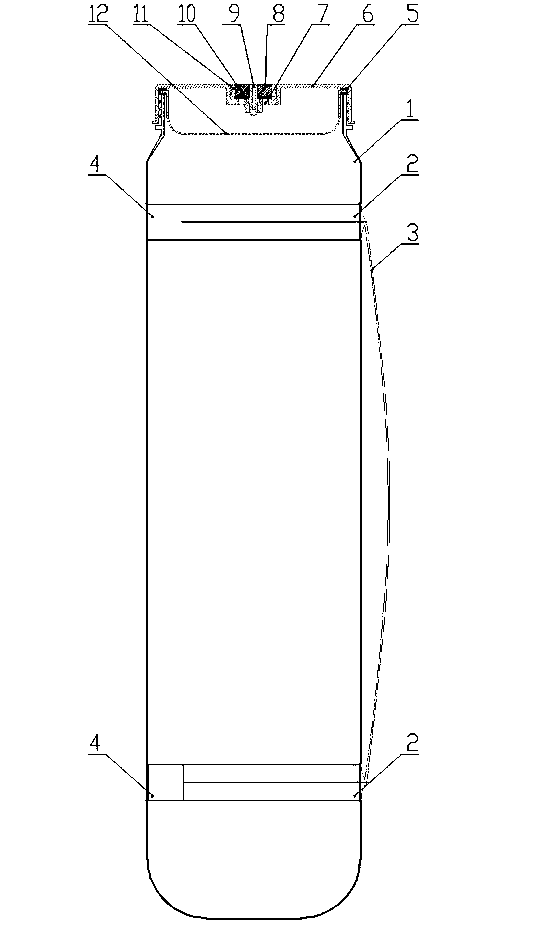

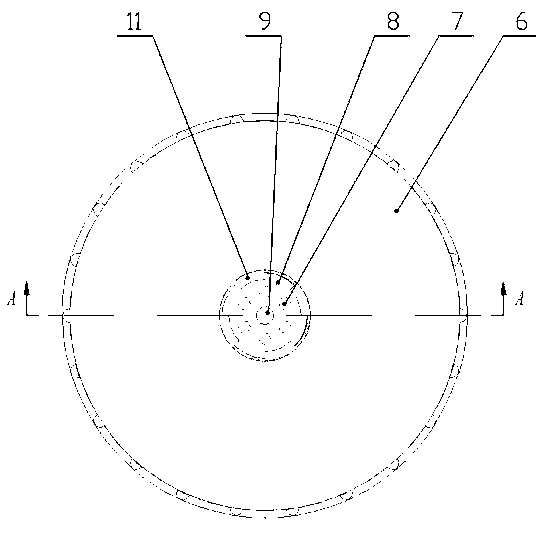

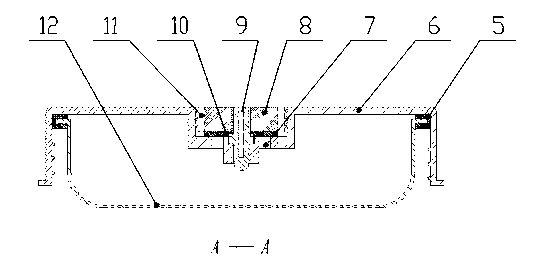

Live fish barrel and method of storage and transportation of live fishes through live fish barrel

A live fish barrel and a method of storage and transportation of live fishes through the live fish barrel are suitable for packaging and selling rare marketable fishes and transporting special fry and fingerling. The live fish barrel is composed of a barrel body and a barrel cover. The barrel body is connected with the barrel cover through threads. A drain plug and an aeration core are arranged in a circular base of the barrel cover. A filter screen is arranged in the barrel cover. The barrel body is made of transparent plastic. The barrel body is a cuboid or cylindrical container. Two protruding ribs or grooves are arranged in the barrel body so that a sleeve ring and a handle can be arranged. An anti-skidding base is arranged at the bottom of the sleeve ring of the circular barrel body. The live fishes are placed in the barrel and then the barrel is filled with water, the barrel cover is screwed down after water quality buffer agent is put in the barrel, oxygen is filled in the barrel through a drainage method, and the live fishes are kept to be alive for 3 days to 10 days. The live fish barrel has the advantages of being attractive, elegant, easy to carry, simple and convenient to operate, long in keep-alive time, high in packaging strength, capable of being repeatedly used and the like.

Owner:林衍峰

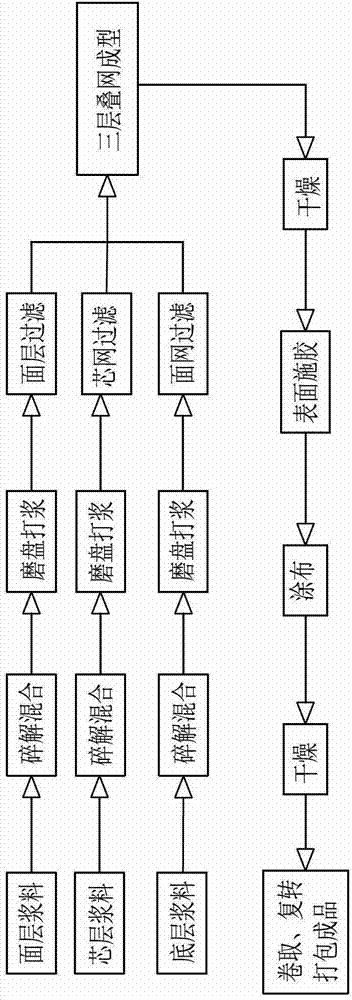

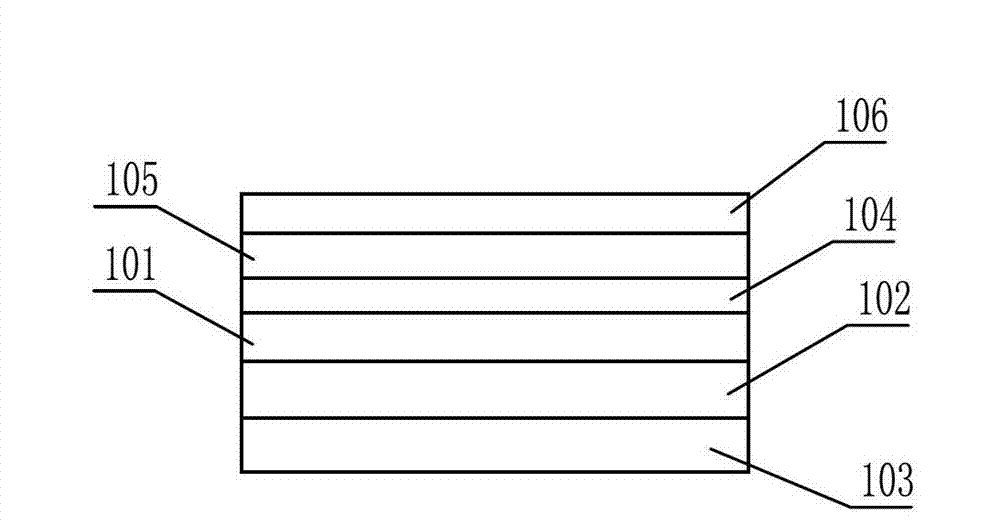

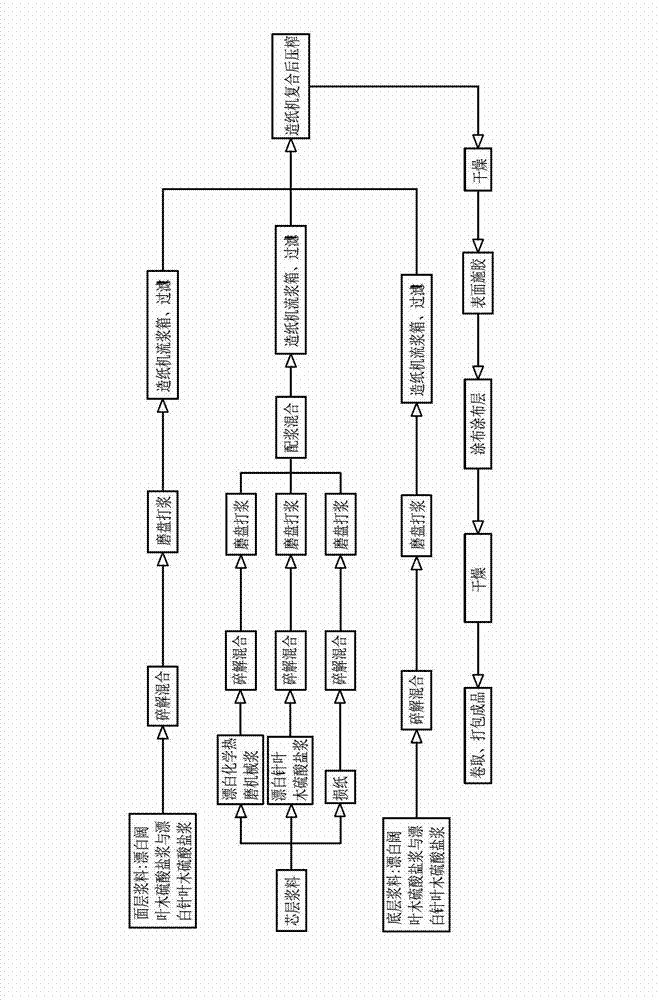

Coating white cardboard and production process thereof

ActiveCN103321096AEasy to identifyEmission reductionDefoamers additionCoatings with pigmentsCardboardSurface layer

The invention provides a coating white cardboard comprising a raw paper and a coating layer, wherein the raw paper comprises a surface layer, a core layer and a bottom layer which are orderly overlaid, the bottom layer is distributed with natural color fibers accounting for 5-10% by weight of the bottom layer, and the coating layer is coated on the surface layer. Because the natural color fibers which are distributed on the bottom layer form textures, the coating white cardboard is easy to be distinguished and recognized from conventional white cardboards. The natural color fibers do not need to be bleached through chemical processing, thereby influence of environment from bleaching chemicals is reduced, and COD emission load when in pulping is effectively reduced. The flexible performance and the bond strength of the coating white cardboard are increased by adopting a fiber structure, binding force between layers is increased, and therefore packaging strength is increased.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER +1

Manufacturing method for hard micro-fluid chip

ActiveCN107305214AHigh light transmittanceReduced autofluorescenceMaterial strength using tensile/compressive forcesTransmissivity measurementsEpoxyMicron scale

The invention discloses a manufacturing method for a hard micro-fluid chip. The manufacturing method comprises the following steps: preparing an upper chip and chemically bonding and packaging the upper chip under a semi-cured state with a substrate, thereby acquiring the hard micro-fluid chip. The upper chip can be prepared from epoxy resin or amino resin; when the upper chip is prepared, the heating curing temperature is 45-85 DEG C and the time is 15 minutes to 8 hours; a thermal polymerized epoxy resin material is used after the two materials of prepolymer and curing agent are mixed, the viscosity thereof after mixing is low (approximate to mineral oil viscosity), the rolling printing for a tiny structure at micron scale and even nanometer scale is convenient and the rolling precision is high; the mixture can be solidified within 40min under the temperature of 80 DEG C, the preparation time of the micro-fluid chip is shortened, the period is short, the consumption of a reagent is less and the batch production is convenient; the hard micro-fluid chip can be flexibly packaged and combined with various substrates; the packaging is independent of external high temperature and high pressure environments; and the packaging strength is high and the speed is high.

Owner:TSINGHUA UNIV +1

IC package

InactiveUS20080054494A1Large Young 's modulusImprove warpage resistanceSemiconductor/solid-state device detailsSolid-state devicesYoung's modulusEngineering

An IC package mainly includes a substrate having slot(s), a chip, a protective encapsulant, a stiffening encapsulant, and a plurality of external terminals. The Young's modulus of the stiffening encapsulant is greater than the one of the protective encapsulant and the curing shrinkage of the stiffening encapsulant is smaller than the one of the protective encapsulant. The protective encapsulant is formed on one of the surfaces of the substrate for encapsulating the chip. The stiffening encapsulant protrudes from the other surface of the substrate where the external terminals are disposed. Moreover, the stiffening encapsulant is formed inside the slot and is contacted with the chip. Since the stiffening encapsulant is embedded and formed inside the slot, therefore, the contact area of the stiffening encapsulant with the substrate is increased to enhance the warpage resistance of the IC package.

Owner:POWERTECH TECHNOLOGY

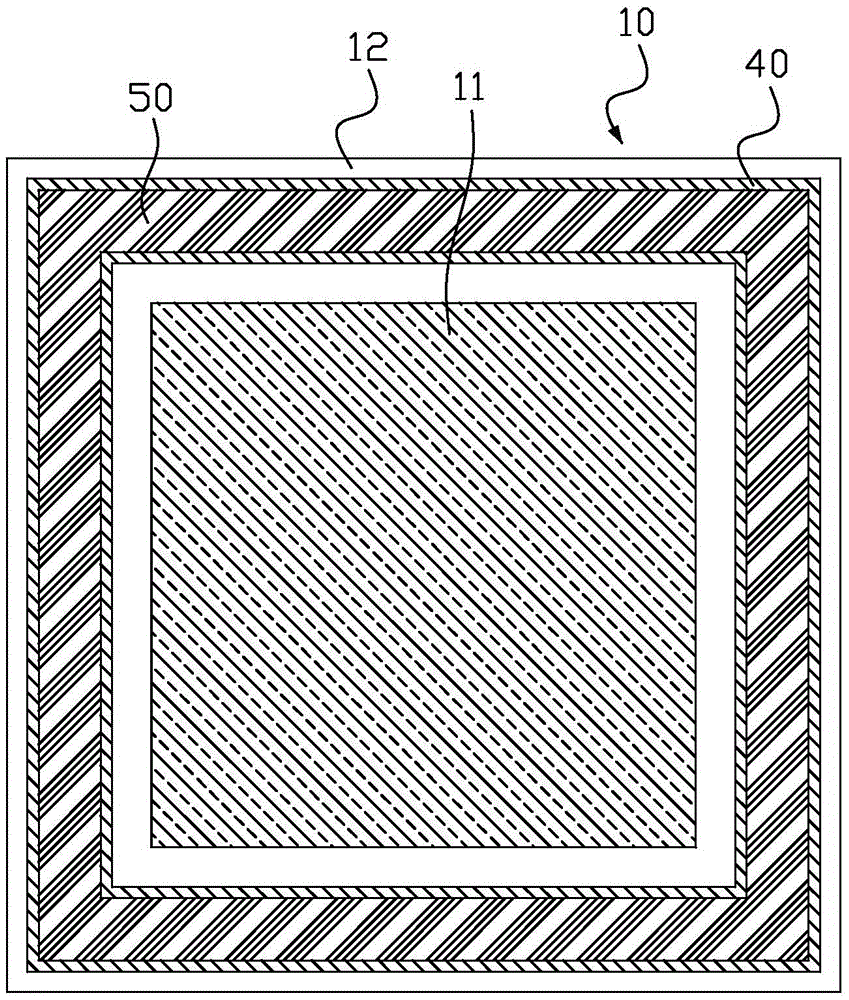

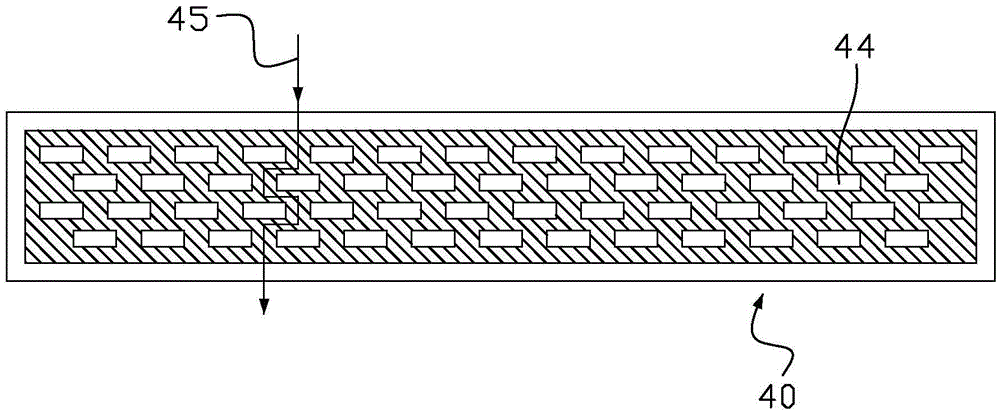

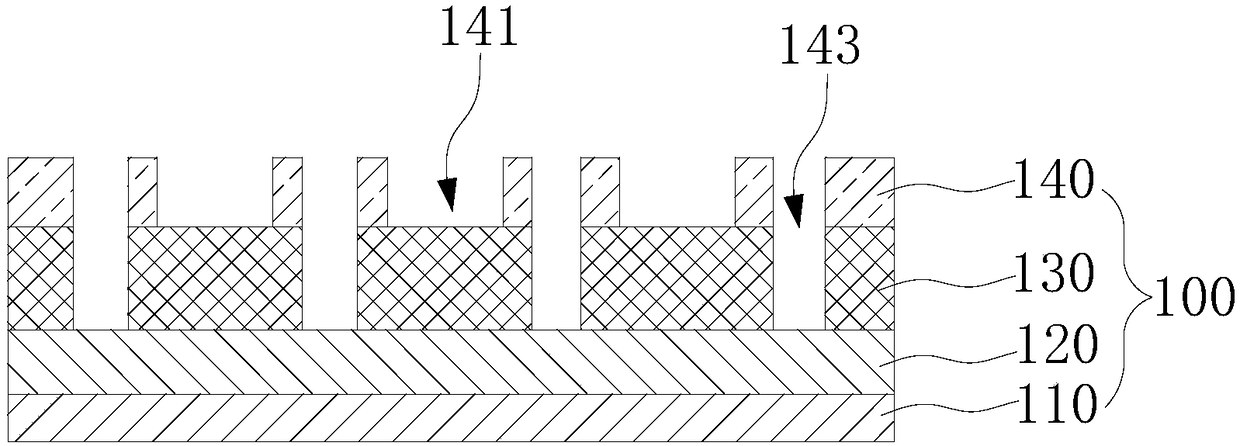

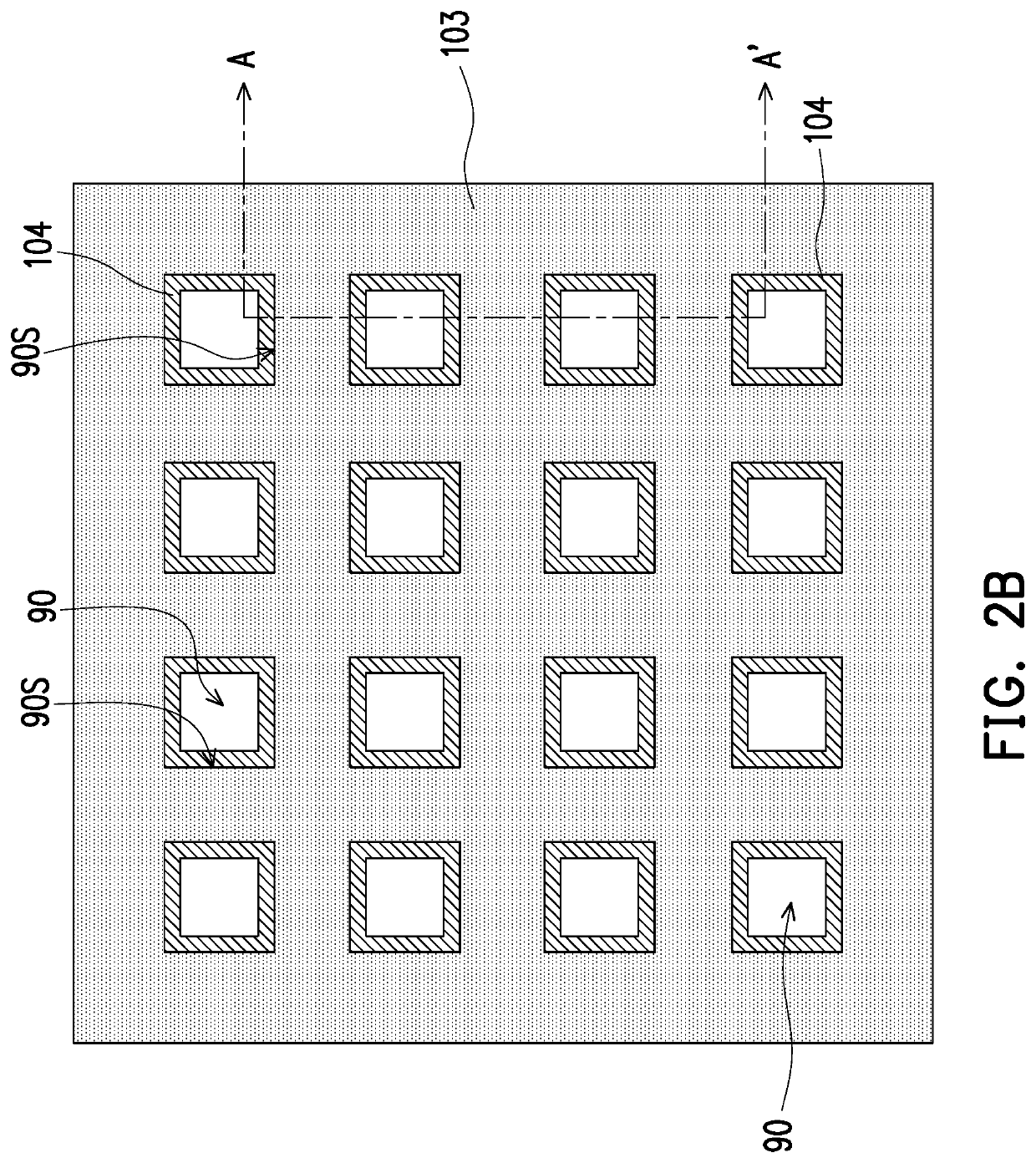

Frit contact membrane layer and OLED packaging structure with frit contact membrane layer

InactiveCN105576149AImprove package strengthImprove water and oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingFritOxygen

The invention provides a frit contact membrane layer and an OLED packaging structure with the frit contact membrane layer. The OLED packaging structure comprises a glass substrate, the frit contact membrane layer and a frit, wherein the frit contact membrane layer is positioned on the glass substrate; the frit is in contact with the frit contact membrane layer; the frit contact membrane layer is provided with a plurality of openings in an area corresponding to a frit coating area; the openings are arranged at intervals and arranged into a plurality of rows along the extension direction of the frit; corresponding openings in the adjacent rows are mutually staggered; one part of the frit fills the openings; and one part of the frit is in contact with the upper surface of the frit contact membrane layer. According to the OLED packaging structure disclosed by the invention, the mutually staggered openings are formed in the frit contact membrane layer; therefore, the contact area between the frit and the frit contact membrane layer is increased; the OLED packaging strength is increased; furthermore, a channel for water and oxygen to enter can also be extended through the mutually staggered openings; and the water and oxygen obstructing capability of the frit can be improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Solid bleached sulphate (SBS) coating white cardboard and process for producing the same

InactiveCN102926293AEasy to identifyImprove rheologyDefoamers additionCoatings with pigmentsCardboardChemical oxygen demand

The invention provides a solid bleached sulphate (SBS) coating white cardboard, which comprises a raw paper and a coating layer, wherein the raw paper comprises a surface layer, a core layer and a bottom layer which are orderly overlaid, the bottom layer is distributed with natural color fibers, the bottom layer comprises, by weight, from 5 to 10% of natural color fibers, and the coating layer is coated on the surface layer. Because the natural color fibers which are distributed on the bottom layer form textures, the SBS coating white cardboard is easy to be distinguished and recognized from common white cardboards. The natural color fibers do not need to be bleached through chemical processing, thereby reducing influences of environment from bleaching chemicals, and being capable of effectively reducing emission load of chemical oxygen demand (COD) when pulping. The SBS coating white cardboard increases flexible performance and bond strength of papers by adopting an SBS fiber structure, and increases binding force between layers, thereby increasing packaging strength.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER +1

Structure of polymer-matrix conductive film and method for fabricating the same

InactiveUS20060243972A1Increase the areaEasy to packSemiconductor/solid-state device detailsNanoinformaticsElectrical connectionEngineering

A composite conductive film formed of a polymer-matrix and a plurality of conductive lines less than micro-sized and its fabricating method are provided. The conductive lines are arranged parallel and spaced apart from each other so as to provide anisotropic conductivity. The present conductive film can serve as an electrical connection between a fine-pitch chip and a substrate. Additionally, an adhesive layer is formed on two opposite sides of the conductive film along its conductive direction to increase adhesive areas. The strength and reliability of the package using the conductive film are thus enhanced.

Owner:IND TECH RES INST

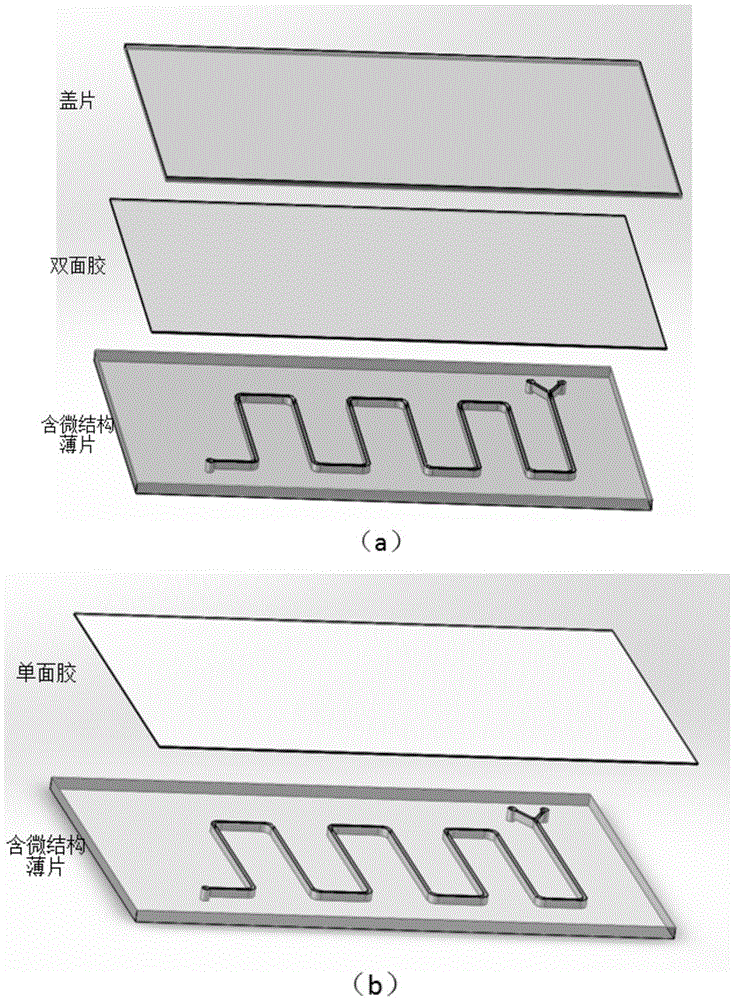

Chip packaging method

InactiveCN105460888AAchieve scaleAchieve high volumePrecision positioning equipmentSoldering apparatusVacuum pumpingBonding process

The invention discloses a chip packaging method. In the method, one-step vacuum-pumping pressurization packaging is performed after a substrate and a cover plate of a micro-fluidic chip are laminated with a double-sided adhesive or a single-sided adhesive. Through adoption of the method, the problems of poor firmness of a bonding surface and remaining of a large quantity of blisters on the surface of the chip after bonding in a conventional solid-state double-sided adhesive bonding method are solved; the problems of micro-channel distortion and micro-channel blockage in a current micro-fluidic chip bonding process are solved; and an outer packaging procedure of a finished chip is implemented synchronously. The chip packaging method is simple and effective in auxiliary equipment and manufacturing process, and high fidelity of a chip micro-channel and high packaging strength of a packaged chip are ensured. A packaging procedure provided by the invention is particularly suitable for the field of manufacturing of micro-fluidic chips on a large scale at low cost.

Owner:CAPITALBIO CORP

Packaging device and method

InactiveUS20050218030A1Less-expensive to manufactureLess raw materialMultiple wrapper applicationPackaging by pressurising/gasifyingSynthetic resinFlange

The invention basically includes an outer layer made of flexible sheets of synthetic resinous or impervious materials, and / or rigid and / or semi-rigid materials while the wrapping of each article may be held inside the packaging system by flexible linkages. The portion of the wrapping that is not directly wrapping the article should be considered as the flange of the wrapping which will become the “linkage” in the glossary of this invention. The wrapping may be designed with openings for the protruded, fragile or sharp members of the article to avoid damage to these parts. The wrapping may be made as a closed cell and a negative pressure (vacuum) may be applied to securely grasp the article. For those articles that are not suited for tight wrap, certain fluids (e.g., air) may be provided to the inside of the sealed wrapping to counteract the inflation pressure at the outside of the wrapping.

Owner:MAK CHI YIN

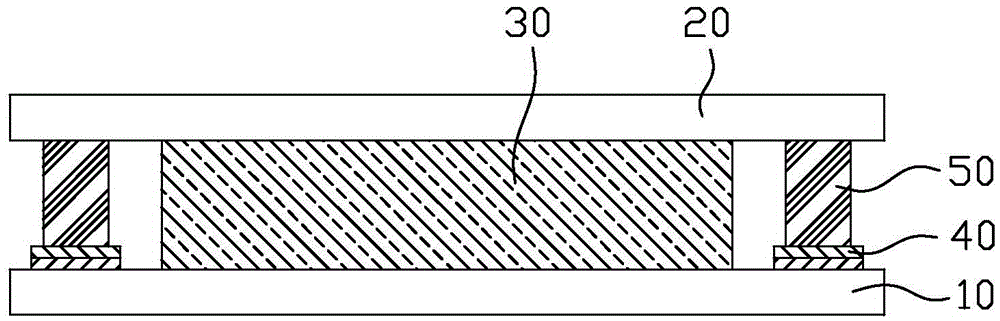

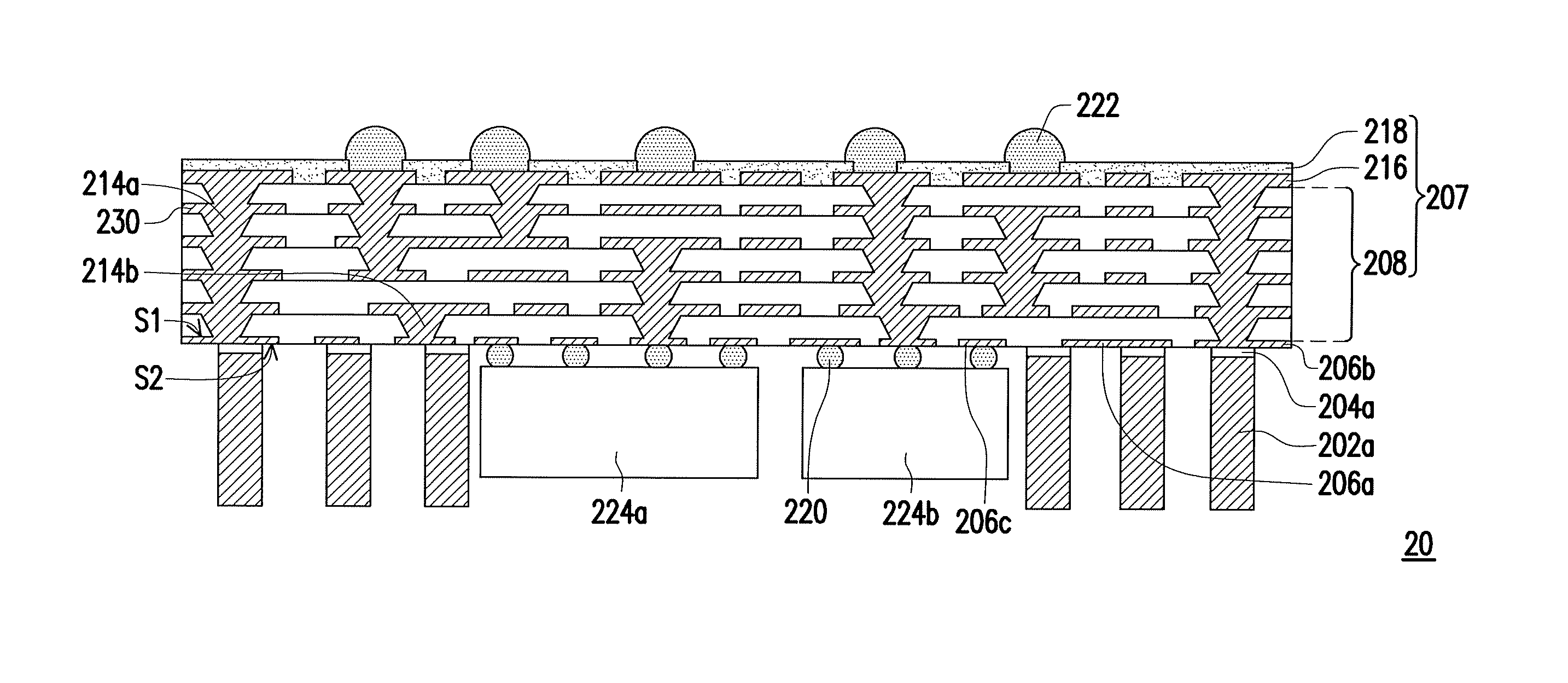

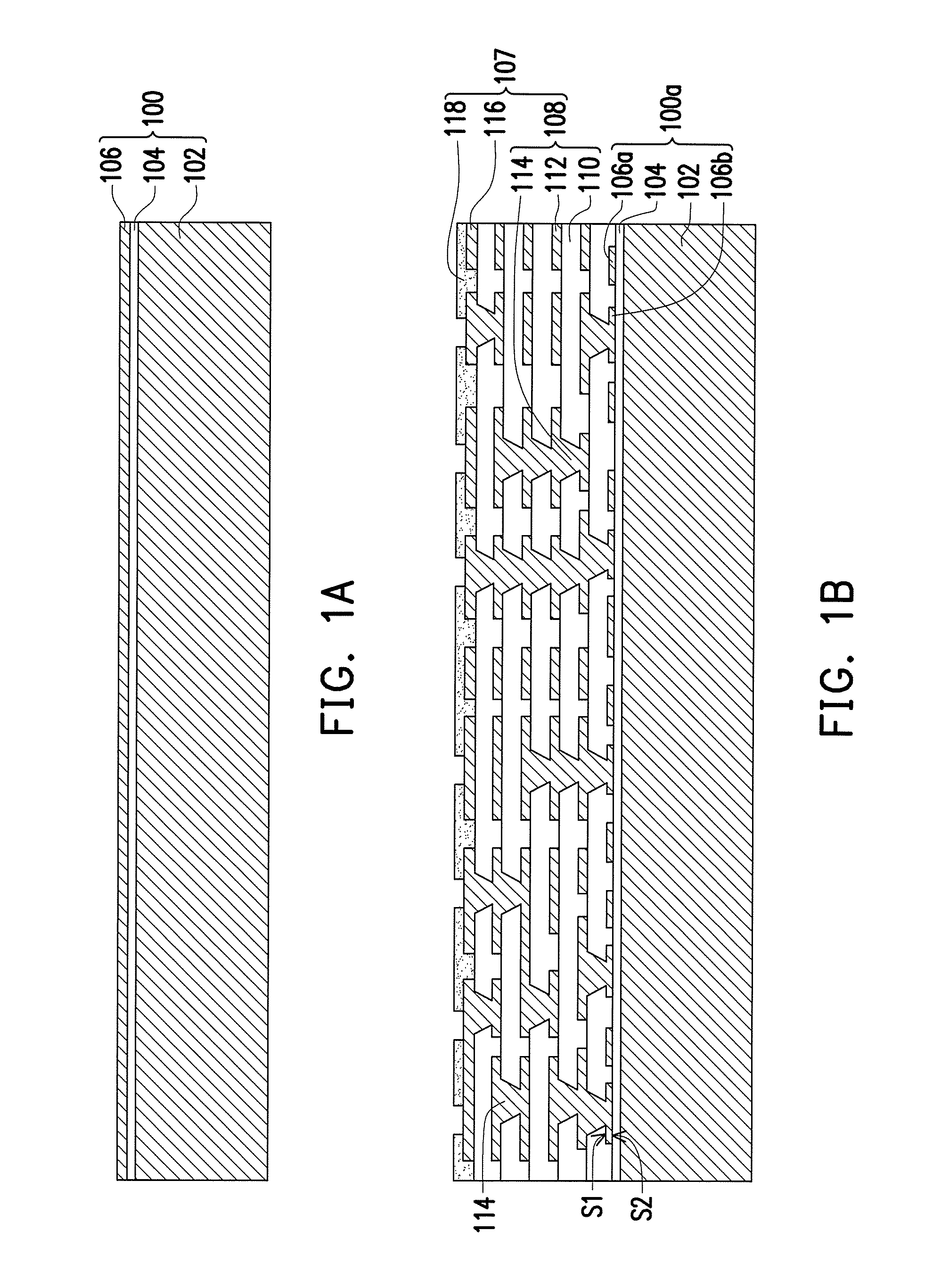

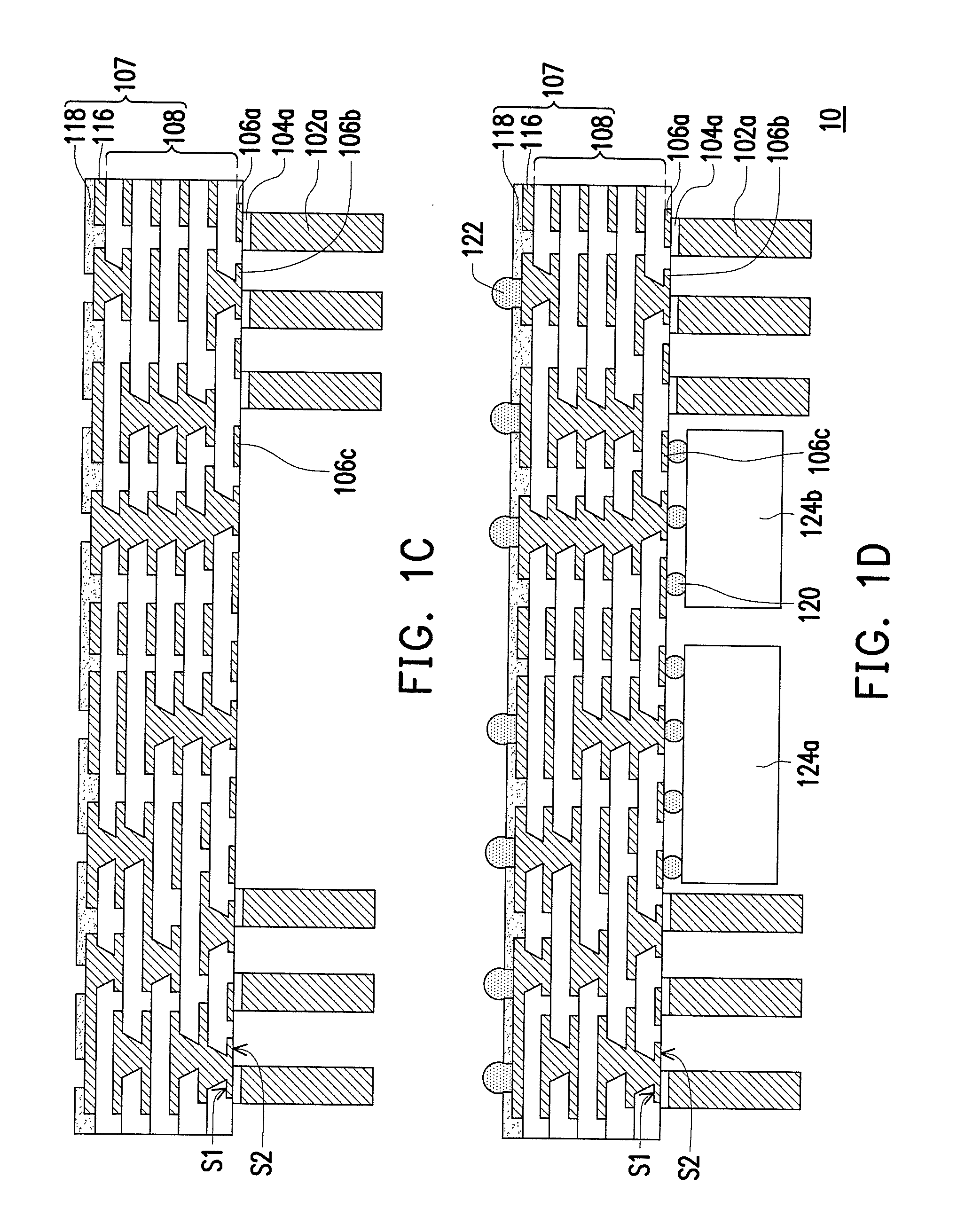

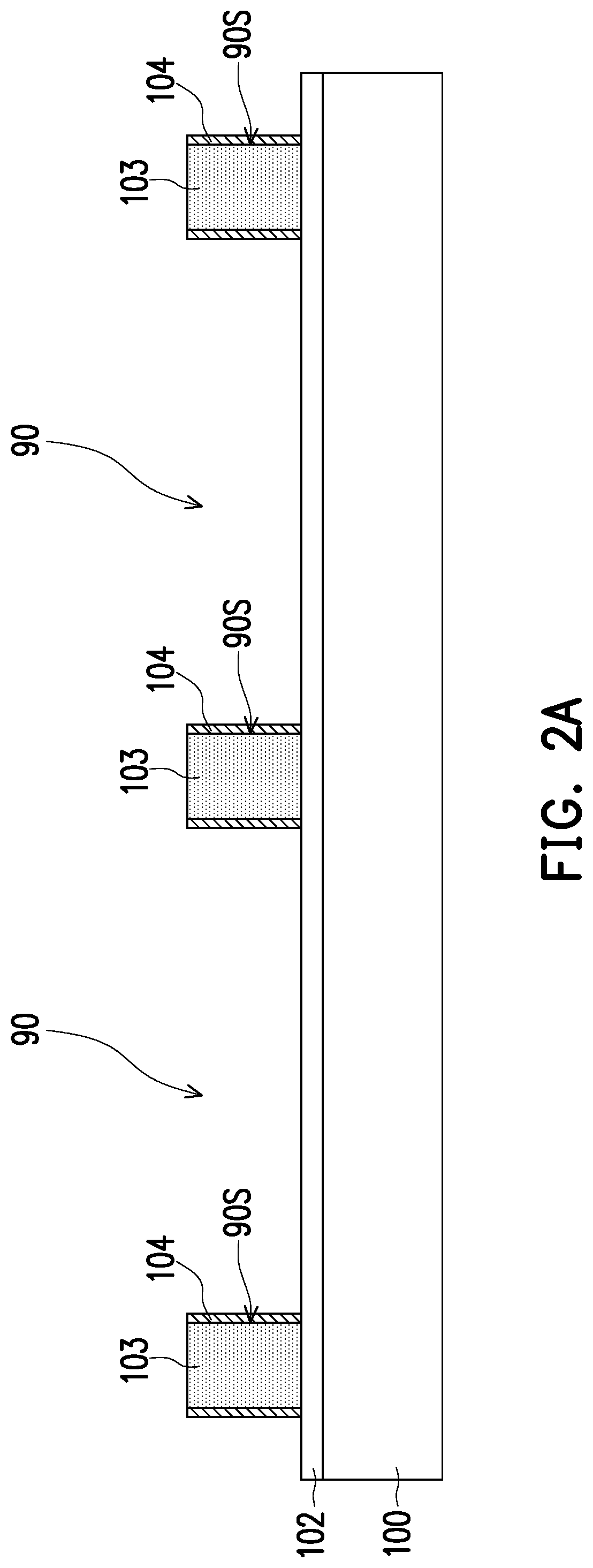

Package structure and method for manufacturing the same

ActiveUS20160343645A1Increase productionHigh strengthSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringMetal

Provided is a package structure including a circuit board, a plurality of first contact pads, a plurality of metal pillars and at least one chip. The first contact pads are disposed on the circuit board. The chip is disposed on one portion of the first contact pads. The metal pillars are disposed on the other portion of the first contact pads, where the chip is surrounded by the metal pillars. A method for manufacturing the package structure is also provided.

Owner:UNIMICRON TECH CORP

Preparation method of bacteriostatic air purifier

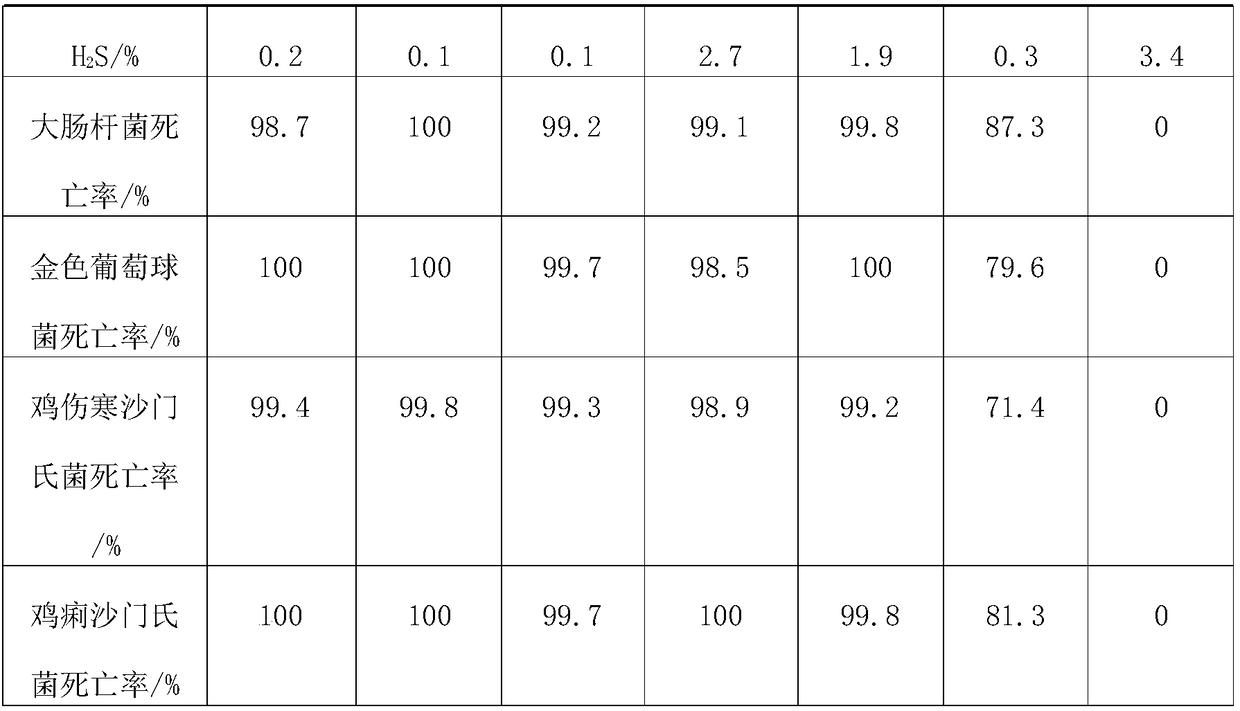

InactiveCN108452673AIncrease the number of holesImprove absorption rateBiocideGas treatmentHydrazine compoundLanthanum

The invention discloses a preparation method of a bacteriostatic air purifier. The preparation method comprises the following steps: step I: acid leaching, calcining, and producing modified maya blue;step II: fermenting various plants by virtue of probiotics, filtering a fermented solution, and preparing plant enzymes; step III: under a condition of argon charged, dissolving zirconium dioxide andtitanium dioxide in tartaric acid, and then preparing a lanthanum-doped composite photocatalyst by virtue of the coupling bonding of lanthanum oxide; step IV: mixing tea polyphenols, quercetin and hydrazine carbonate according to a weight ratio of 1: (1.2 to 1.6): (0.3 to 0.5), condensing by using a coating agent, and preparing a coated synergist; and step V: mixing 20 to 30 parts of modified maya blue, 40 to 60 parts of plant enzymes, 12 to 16 parts of lanthanum-doped composite photocatalyst, and 15 to 20 parts of coated synergist, thus obtaining the air purifier. By adopting the preparationmethod, the pathogenic bacteria can be effectively eliminated, the air spreading route of the pathogenic microorganism can be blocked, the air pollutants can be effectively degraded, and the air quality can be improved.

Owner:HUAIBEI ZHIHUAI TECH CO LTD

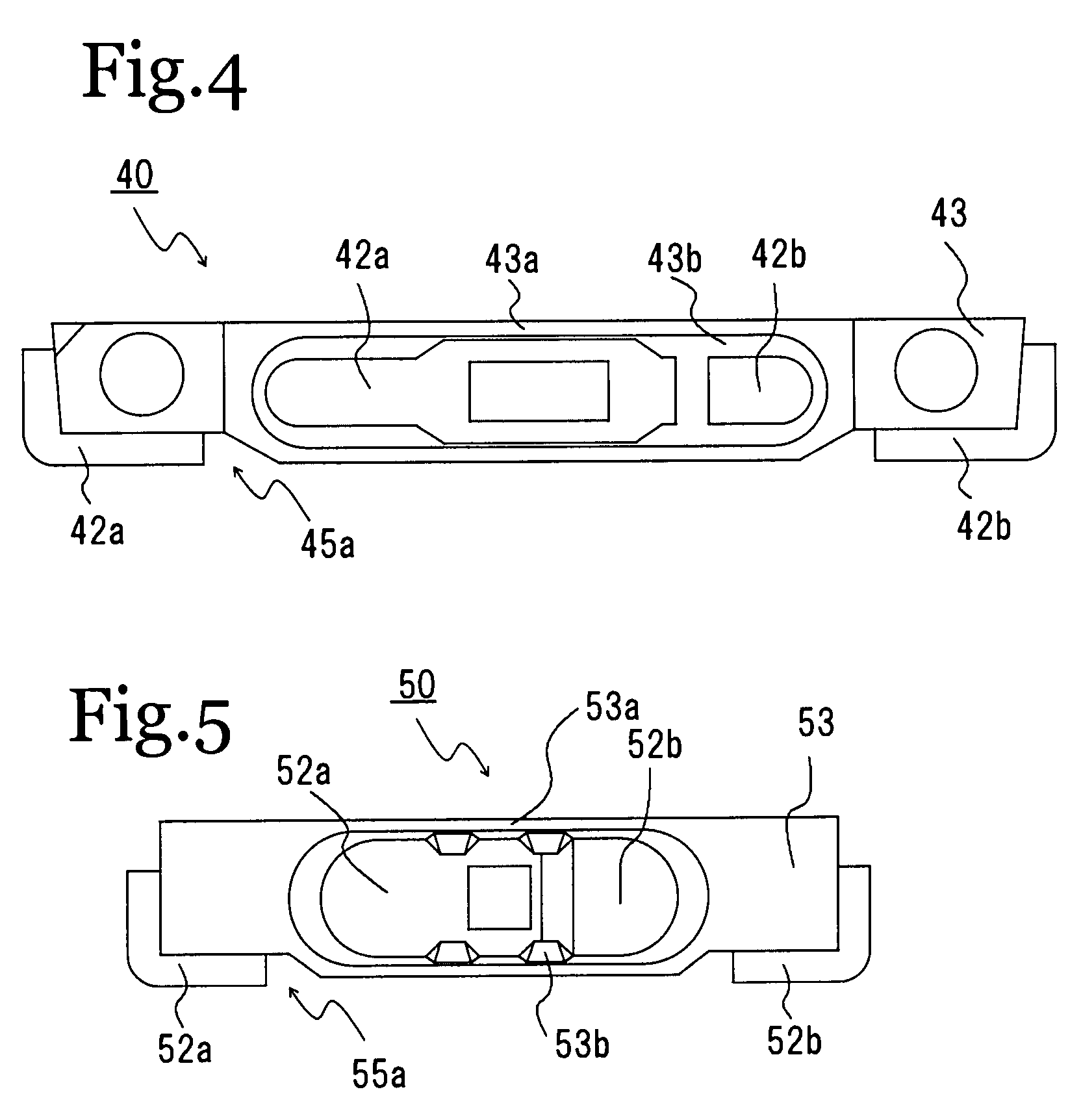

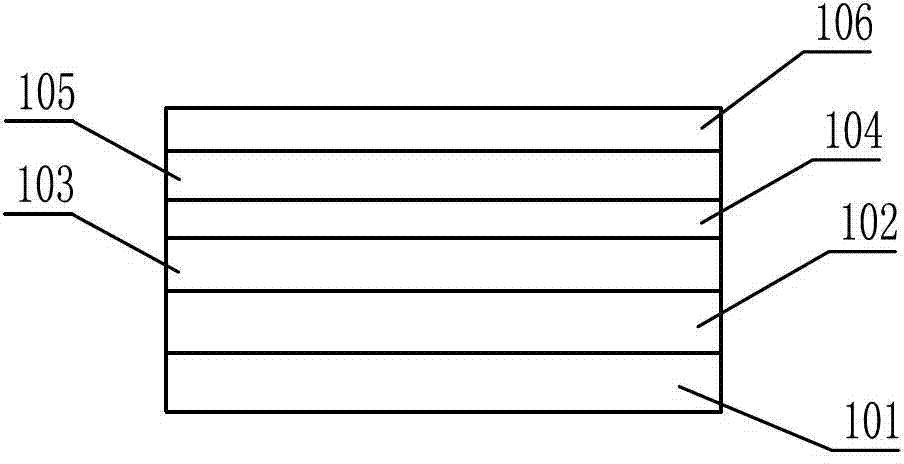

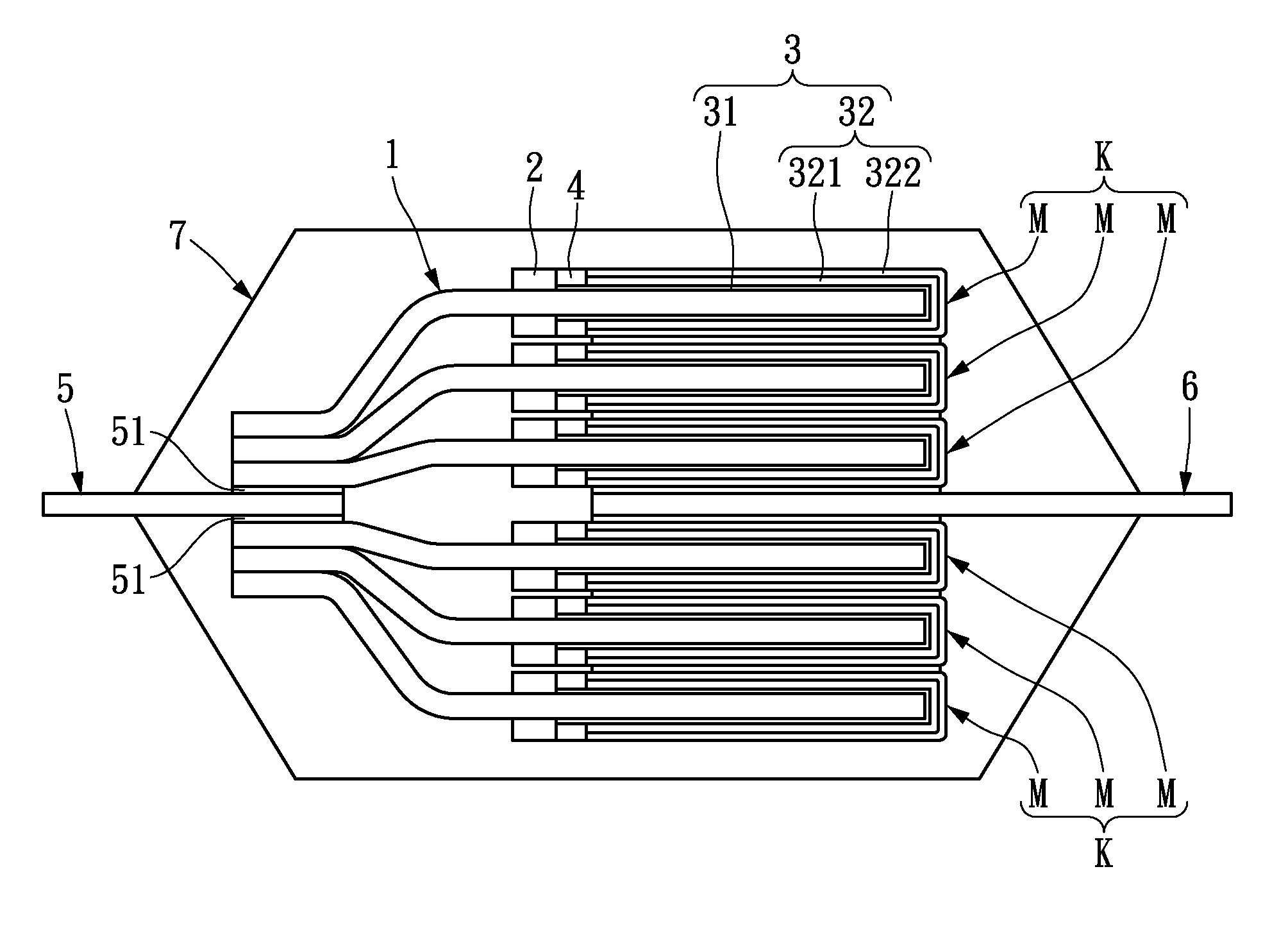

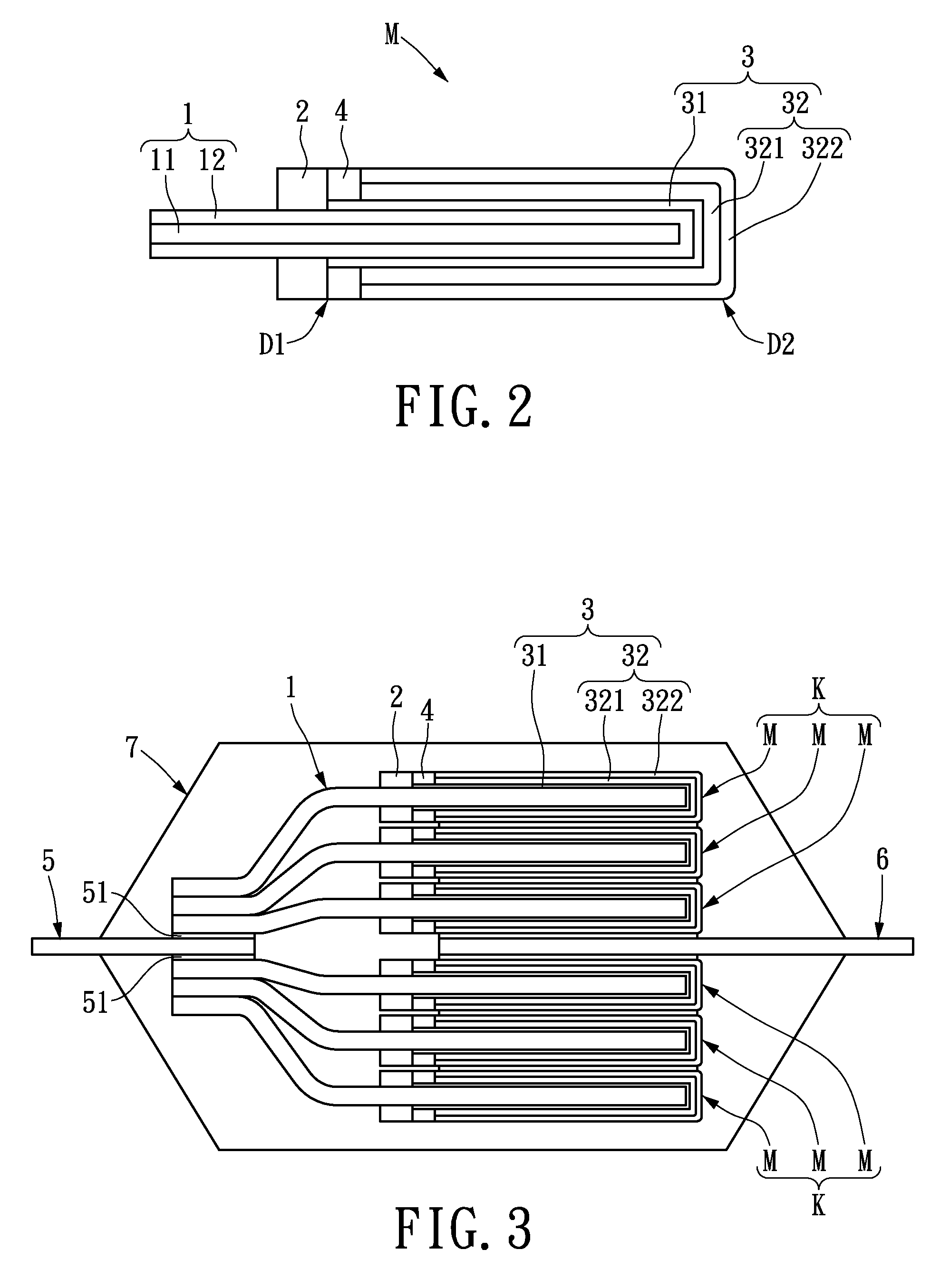

Capacitance unit and stacked solid electrolytic capacitor

ActiveUS20130010404A1Package strength be improveImprove airtightnessSolid electrolytic capacitorsNon-aqueous electrolyte cellsCapacitanceEngineering

A capacitance unit includes an anode portion, an insulating portion, a cathode portion and a colloid portion. The front end of the anode portion extends to from an anode terminal. The insulating portion surrounds the anode portion and covers a first partial surface of the anode portion. The cathode portion is disposed next to the insulating portion, and the cathode portion covers a second partial surface of the anode portion. The colloid portion is disposed next to the insulating portion, and the colloid portion surrounds the cathode portion and covers a partial surface of the cathode portion.

Owner:APAQ TECH

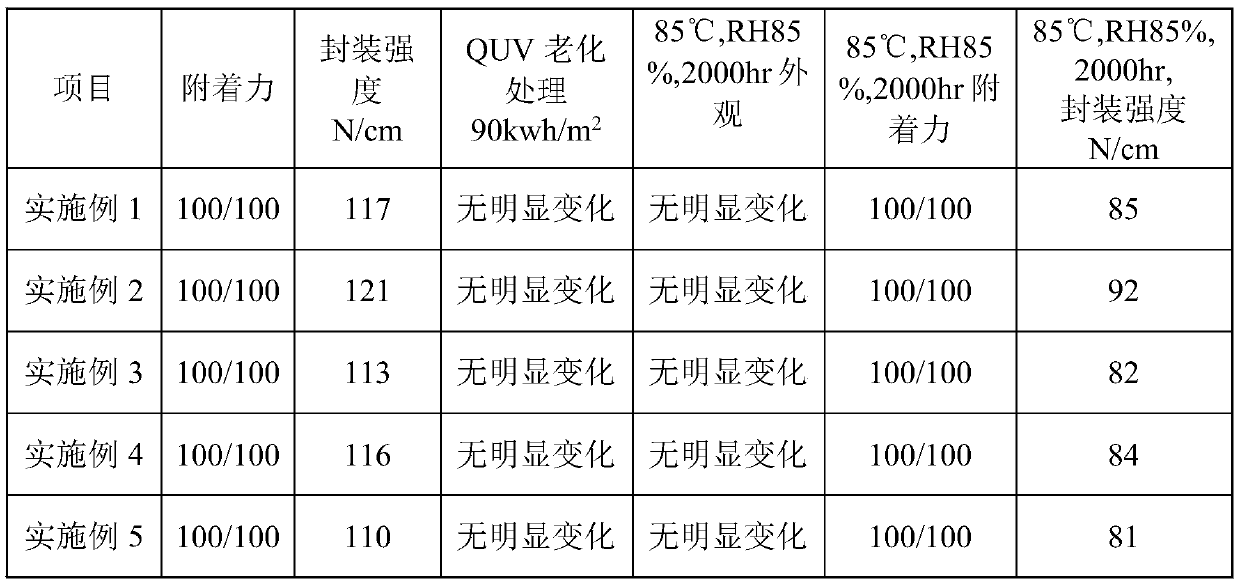

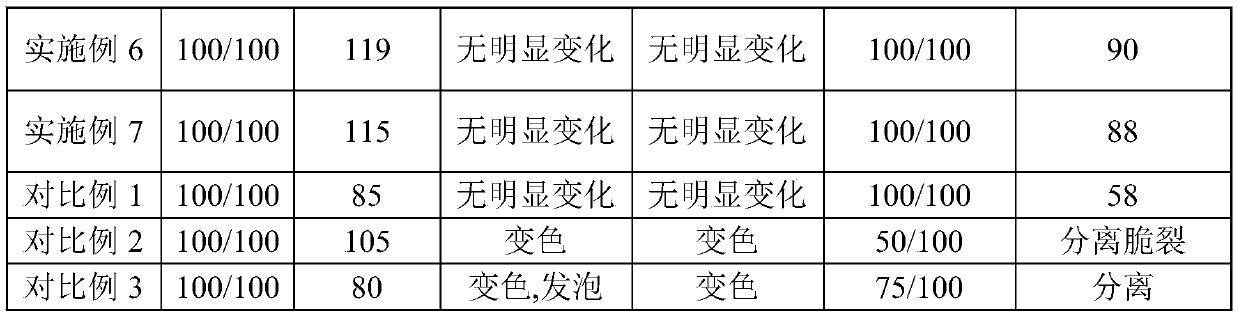

Coating liquid for fluorocarbon coating layer and solar back plate using coating layer

ActiveCN110144149AImprove package strengthImprove bonding abilityCoatingsPhotovoltaic energy generationPet substrateSolid content

The invention relates to the technical field of solar back plates, and in particular relates to a coating liquid for a fluorocarbon coating layer and a solar back plate using the coating layer. In order to improve encapsulation strength of a fluorocarbon coating layer of a current solar back plate, the invention provides the coating liquid for the fluorocarbon coating layer and the solar back plate using the coating layer. The coating liquid for the fluorocarbon coating layer comprises the following components, in percentages by weight: 40%-70% of fluorocarbon resin, 20%-40% of titanium dioxide, 1%-5% of extinction powder, 0.2%-0.8% of polyacrylate, 1%-5% of adhesion promoting resin, and 3%-10% of isocyanate, wherein the solid content is controlled at 40%-60%. The coating liquid provided by the invention forms the highly-dense fluorocarbon coating layer on the surface of a PET substrate, and the fluorocarbon coating layer can exhibit excellent encapsulation strength during lamination with EVA and remains to keep the high encapsulation strength after undergoing a damp heat aging test.

Owner:安徽激智科技有限公司

Preparation method and application of aqueous split leather

InactiveCN106948185AImprove wear resistanceImprove corrosion resistanceTextiles and paperOrganic solventSurface layer

The invention discloses a preparation method and application of an aqueous split leather. According to the preparation method, regenerated leather or split leather is taken as the base material; then aqueous slurry is applied to bottom layer coating, foam layer coating, and surface layer spraying; and finally embossing or line suction is performed to prepare the split leather. An aqueous material is used to process regenerated leather and split leather so as to produce split leather for preparing cases, sofa, and the like. The problems such as safety problems, environment protection problems, residual toxic organic solvent problems, and the like can be solved. At the same time, the peeling strength, anti-aging performance, and anti-hydrolysis performance of split leather are all greatly improved. Compared with the split leather processed by a conventional solvent coating agent, the peeling strength is increased from 2-3 kilograms to 5-7 kilograms, and the hydrolysis resistant period is prolonged from 3 years to 5-8 years.

Owner:HUAIAN KAIYUE TECH DEV

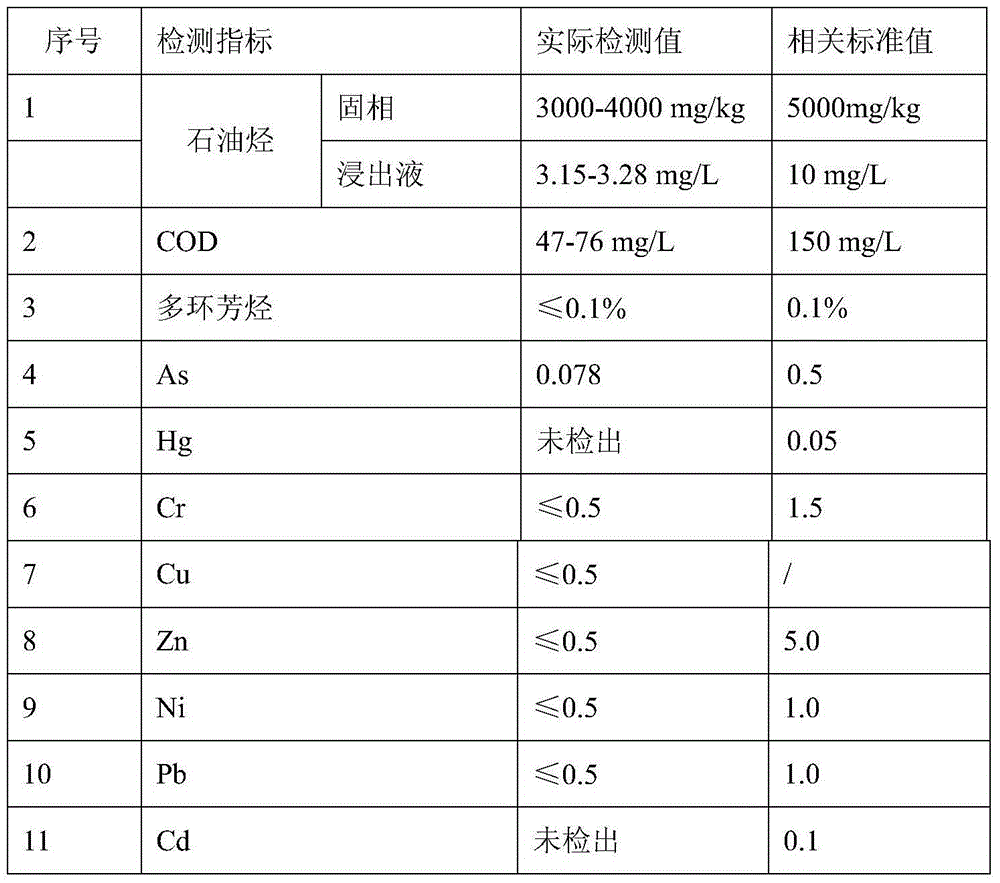

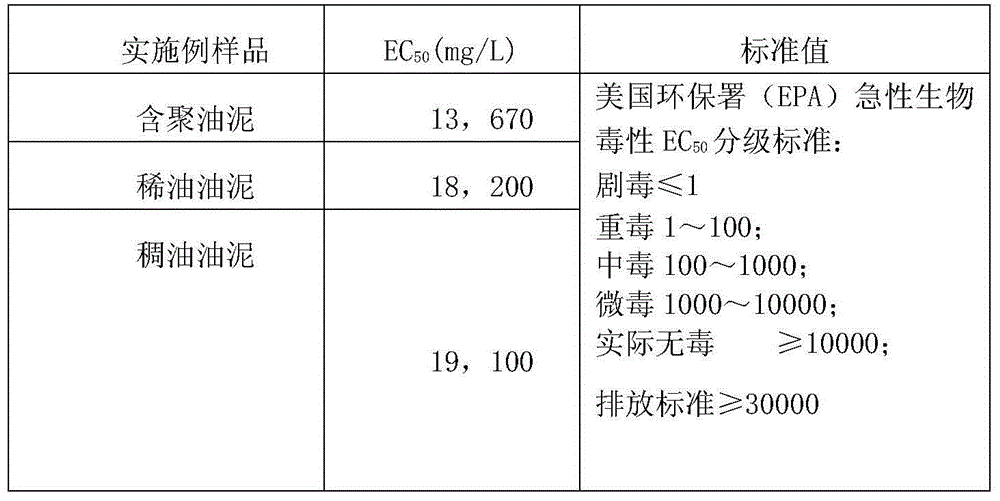

Method for preparation of drifting road subgrade filler from oil field oily sludge

ActiveCN104649637AGood load ratioSatisfy road construction packing requirementsSolid waste managementResource utilizationOil sludge

The invention relates to a method for preparation of a drifting road subgrade filler from oil field oily sludge. The method includes: conducting heat treatment on oily sludge by anaerobic heating; conducting solid-liquid separation, and recovering polluted oil and sewage to conduct treatment; adding a curing agent, a drying agent, fine aggregate and an improved additive into the remaining solid, and placing the mixture into a curing box to conduct curing; measuring the CBR values of the molded sample respectively on 3d, 7d and 28d, unconfined compressive strength, and plasticity index parameters; selecting a qualified oil sludge sample, fully mixing the sample with local soil according to an adding ratio of 0.5t / m<3>, performing rolling according to a compaction degree of 94%, after meeting the requirements, conducting soaking in water for 24h, and measuring the total petroleum hydrocarbon amount and the content of polycyclic aromatic hydrocarbon and heavy metals in the leachate according to national standards; and respectively comparing the engineering technological indexes and leachate pollutant indexes of the oily sludge improved filler with relevant national standard specifications, and judging the product performance. The method provided by the invention improves the resource utilization level of oily sludge and reduces the treatment cost.

Owner:PETROCHINA CO LTD

Special paper for external standard of cup bowl and manufacturing technology thereof

InactiveCN103074822AAvoid safety hazardsImprove stiffnessSpecial paperPaper coatingSurface layerManufacturing technology

The invention provides a piece of special paper for external standard of a cup bowl. The special paper comprises ground paper and a coating layer, wherein the ground paper comprises a surface layer, a core layer and a bottom layer which are sequentially stacked; the coating layer consists of a surface coating, a core coating and a pre-coating which are sequentially stacked; the pre-coating is coated on the surface layer; the surface layer consists of LBKP (Leaves Bleached Kraft Pulp) and NBKP (Needle Bleached Kraft Pulp); the core layer consists of BCTMP (Bleached Chemi Thermo Mechanical Pulp), NBKP and broke; and the bottom layer consists of LBKP and NBKP. According to the invention, phosphor-free protogenetic pulp (chemical pulp and chemi-mechanical pulp) is adopted to manufacture the special paper for external standard of the cup bowl, so that potential safety hazards caused by poisonous substances to food safety are avoided; and meanwhile, the BCTMP with better bulk is used in the core layer to increase the stiffness of the paper and the binding force between the paper layers, so that the packaging strength is improved.

Owner:ZHUHAI HUAFENG PAPER

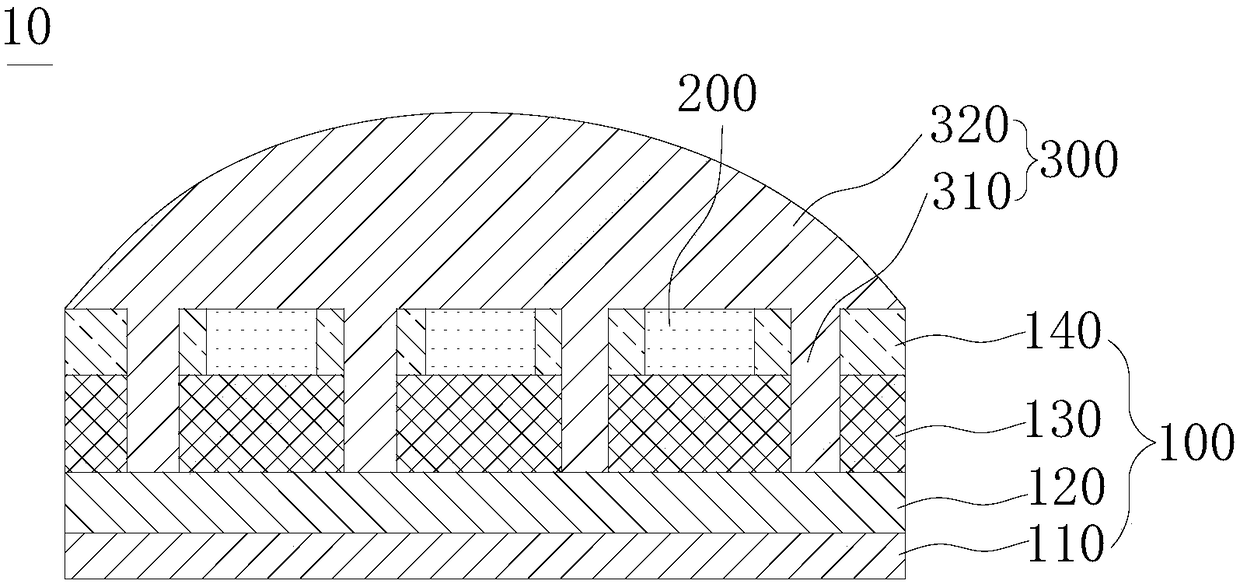

Display panel, production method of display panel and display device

InactiveCN108538901AExtended service lifePrevent peelingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a display panel, a production method of the display panel and a display device. The display panel comprises a display area, wherein the display area comprises a pixel limitinglayer, organic light emitting units and a packaging structure, wherein the pixel limiting layer comprises multiple pixel definition areas distributed in array and pixel limiting areas surrounding thepixel definition areas; pixel definition openings are formed in the pixel definition areas and packaging definition openings are formed in the pixel limiting areas; organic light-limiting units are formed in the pixel definition openings; the packaging structure comprises first packaging parts filling the packaging definition openings and a second packaging part covering the pixel definition areasand the pixel limiting areas and connected with the first packaging part to package the organic light-emitting units. The second packaging part is used for packaging the organic light-emitting units,and the first packaging parts are used for enhancing the packaging strength, so that the problem that cracks or stripping is easily caused under the action of internal force or external force with aconventional packaging structure is solved, the packaging reliability is improved, and the service life of the display panel is prolonged.

Owner:YUNGU GUAN TECH CO LTD

Semiconductor package and manufacturing method thereof

ActiveUS20190378803A1Enhances warpage controlGood electromagnetic interference (EMI) shieldingSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSemiconductor chip

A package structure including at least one semiconductor chip, an insulating encapsulant, a conductive frame, a supporting frame, a conductive layer and a redistribution layer is provided. The at least one semiconductor chip has an active surface and a backside surface opposite to the active surface. The insulating encapsulant is encapsulating the at least one semiconductor chip. The conductive frame is surrounding the insulating encapsulant. The supporting frame is surrounding the conductive frame. The conductive layer is disposed on the backside surface of the semiconductor chip. The redistribution layer is disposed on and electrically connected to the active surface of the semiconductor chip.

Owner:POWERTECH TECHNOLOGY

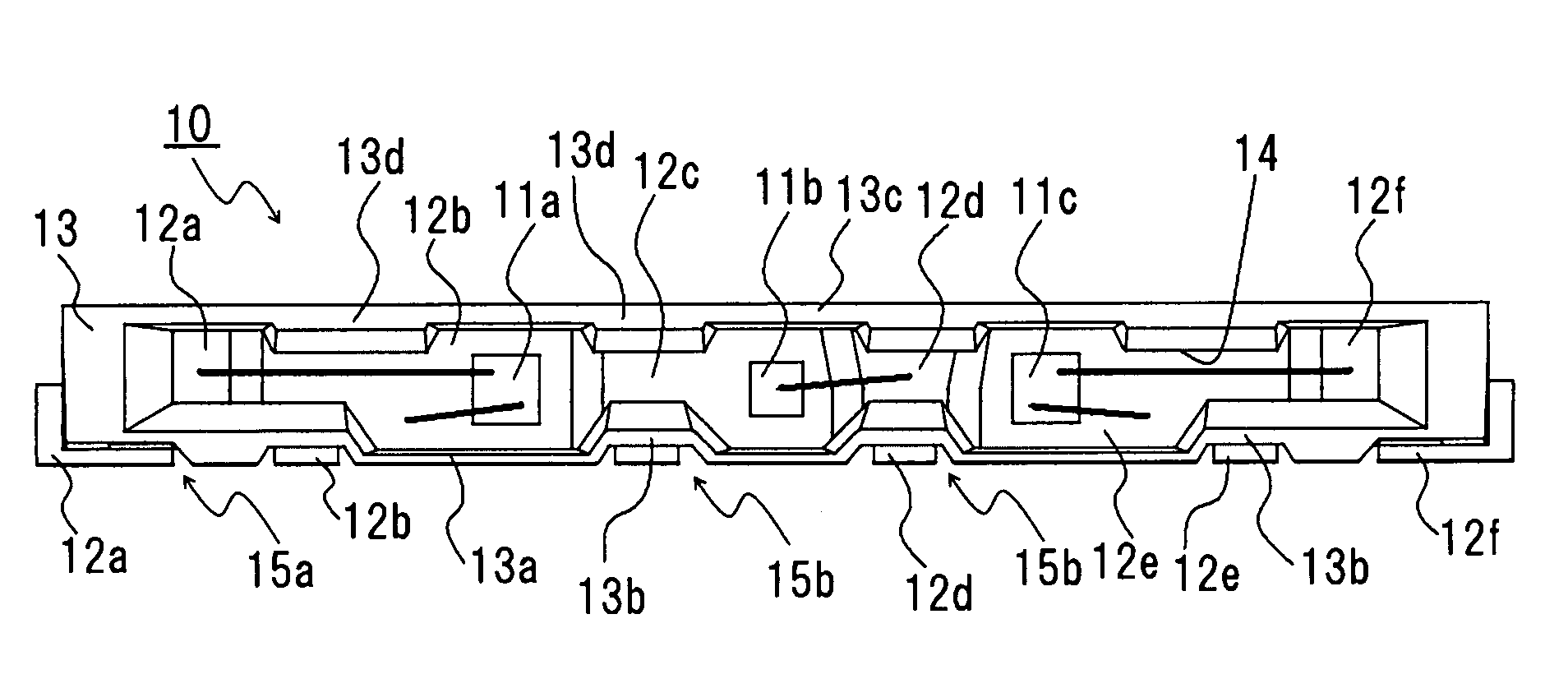

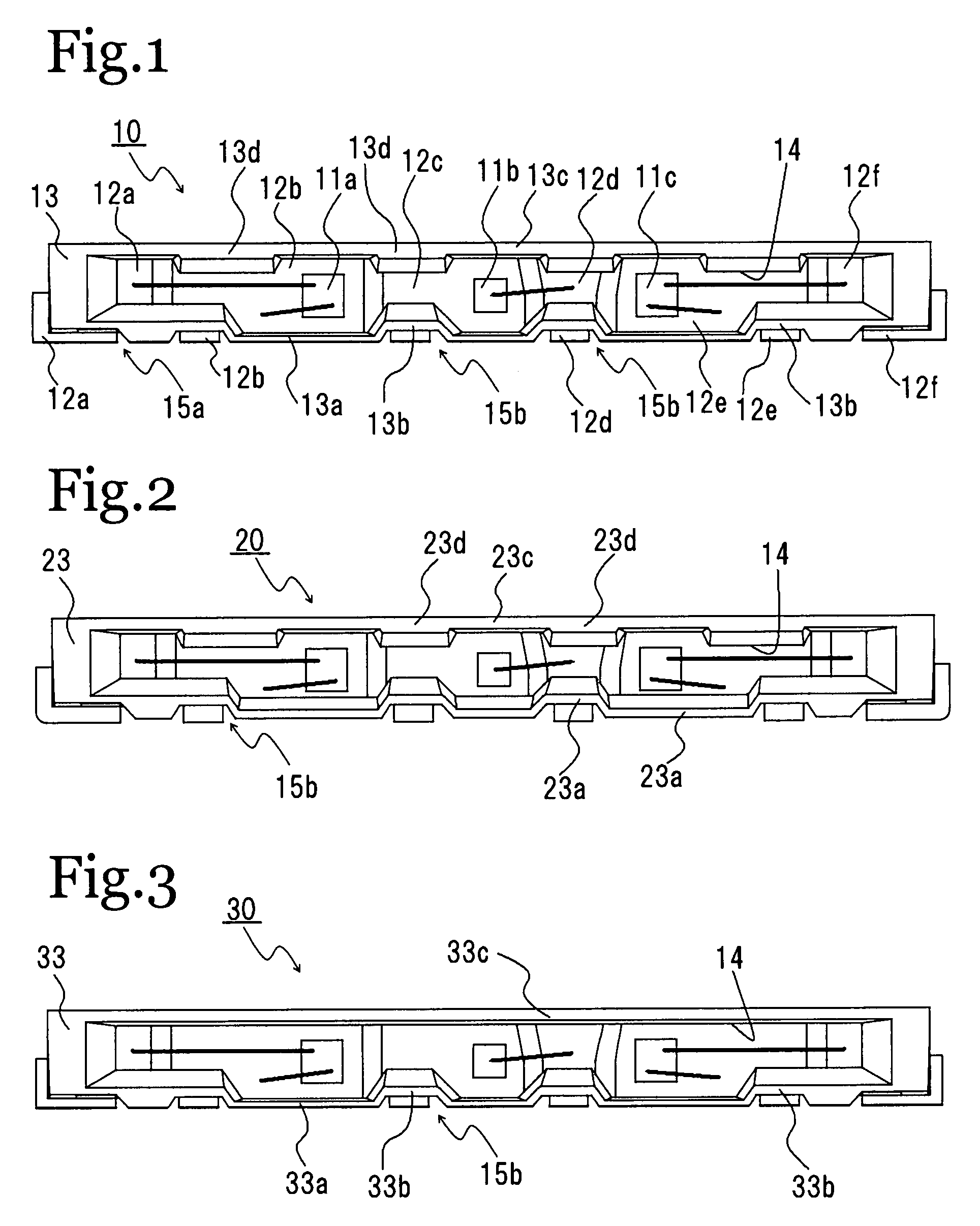

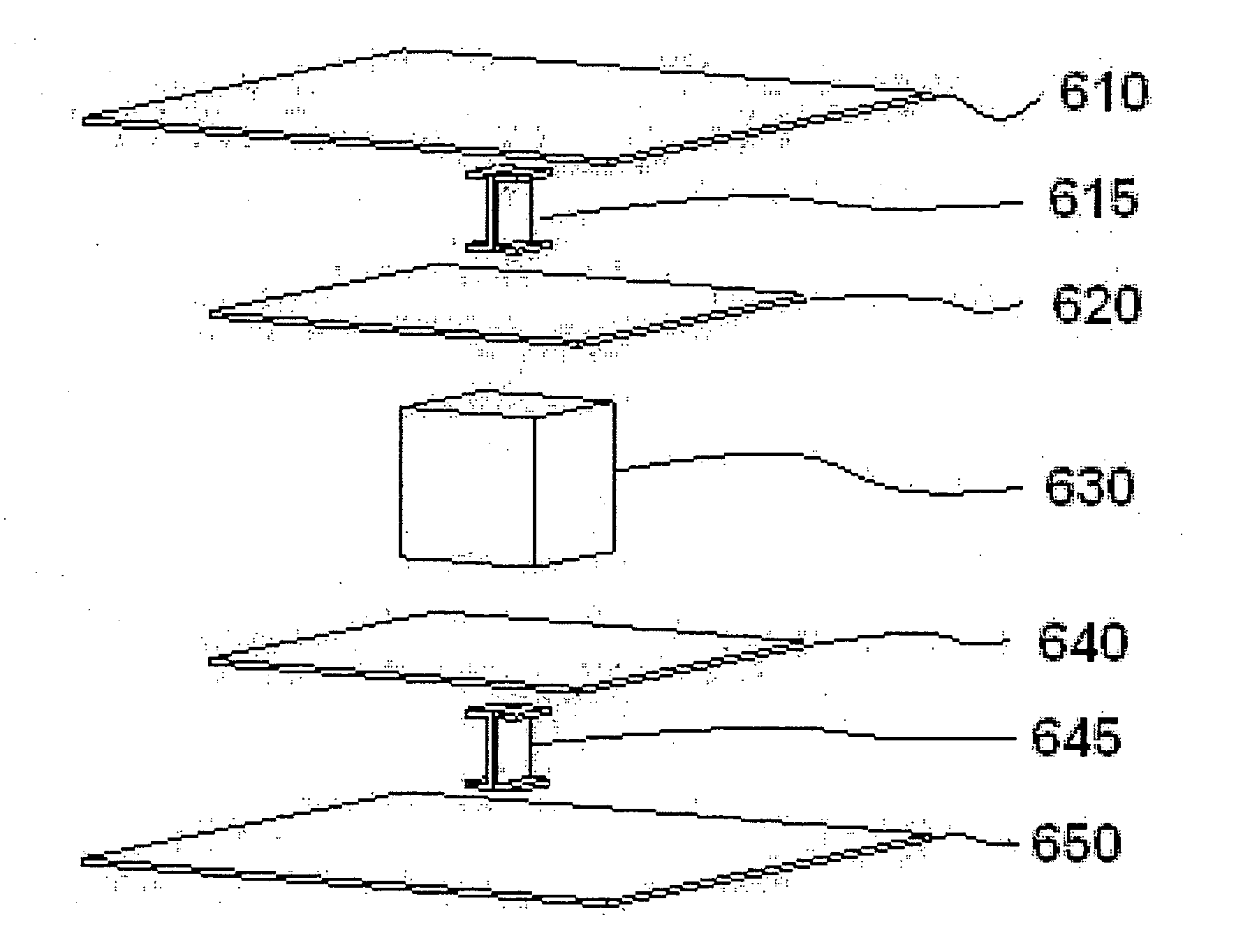

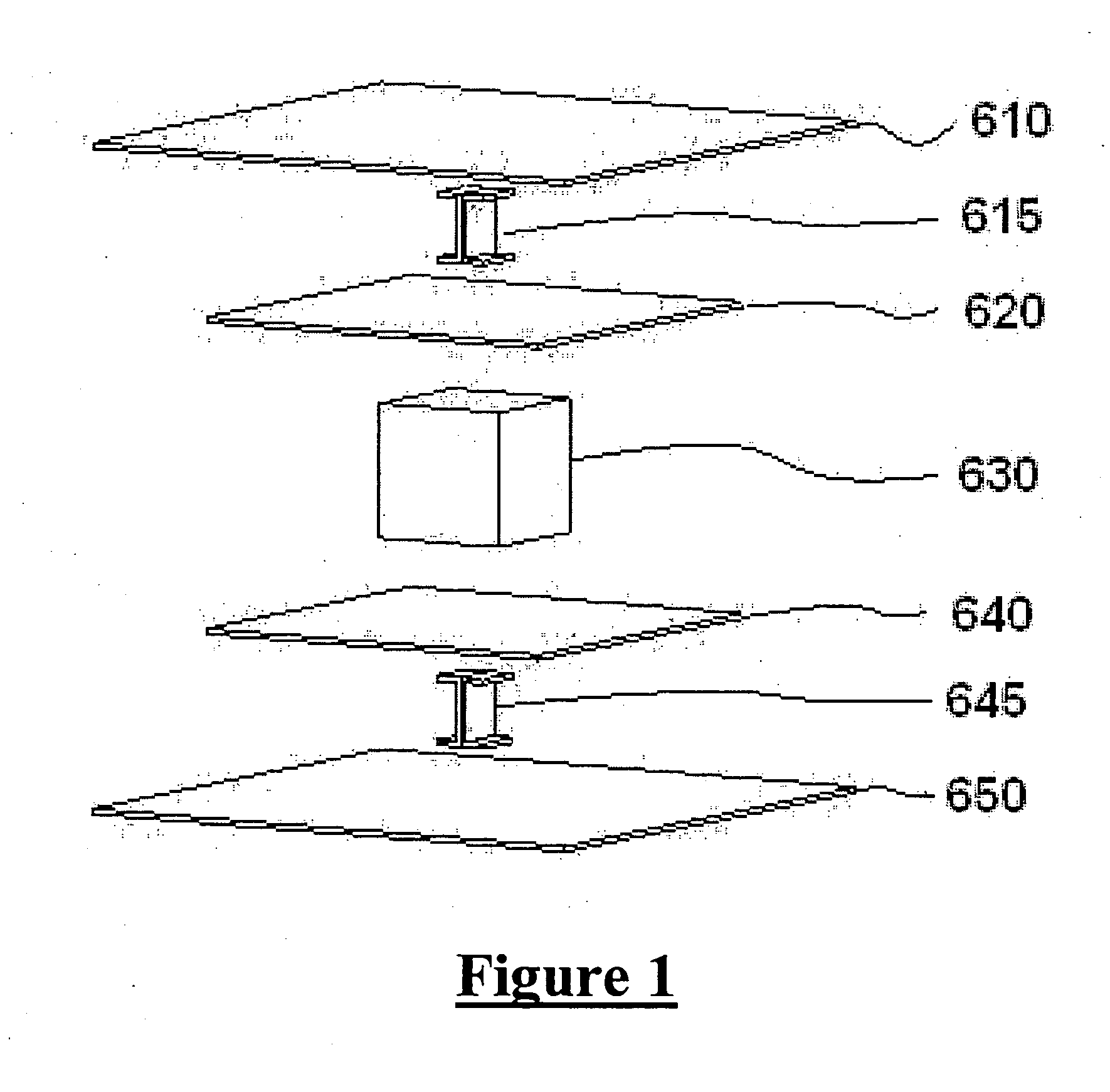

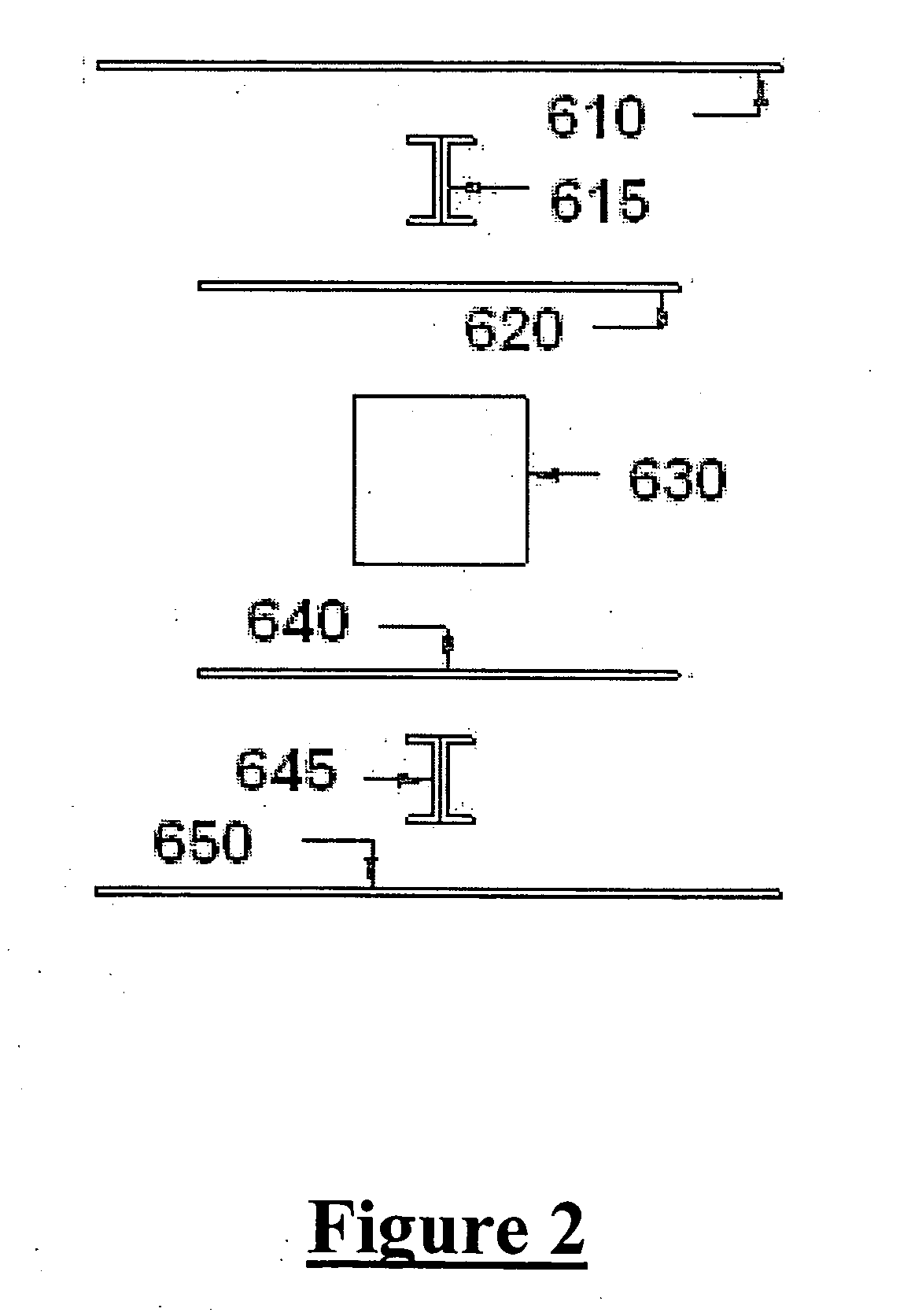

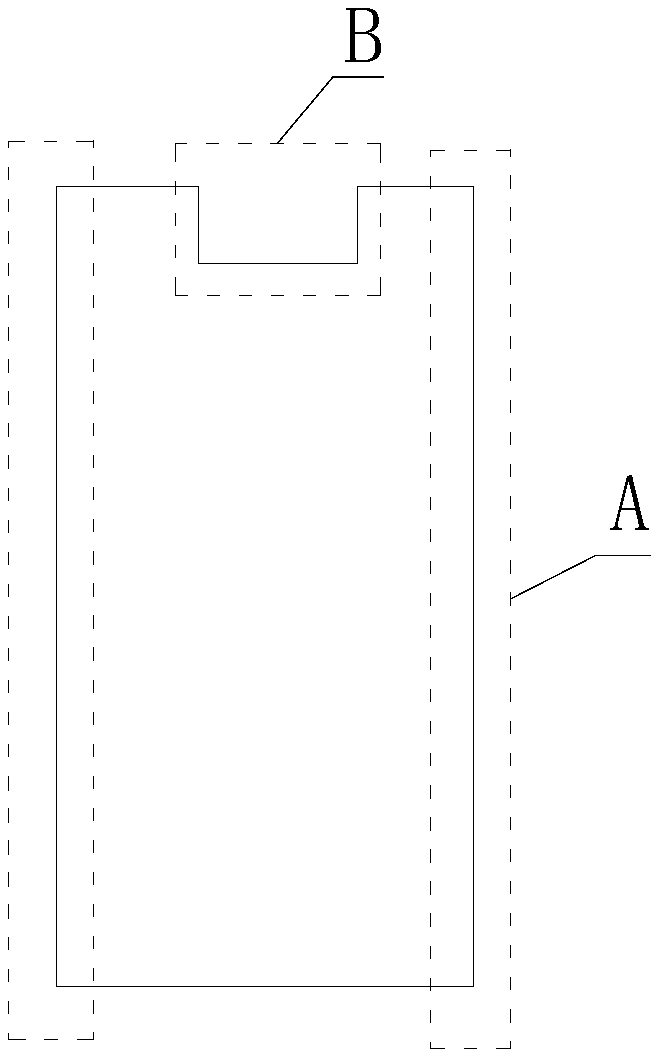

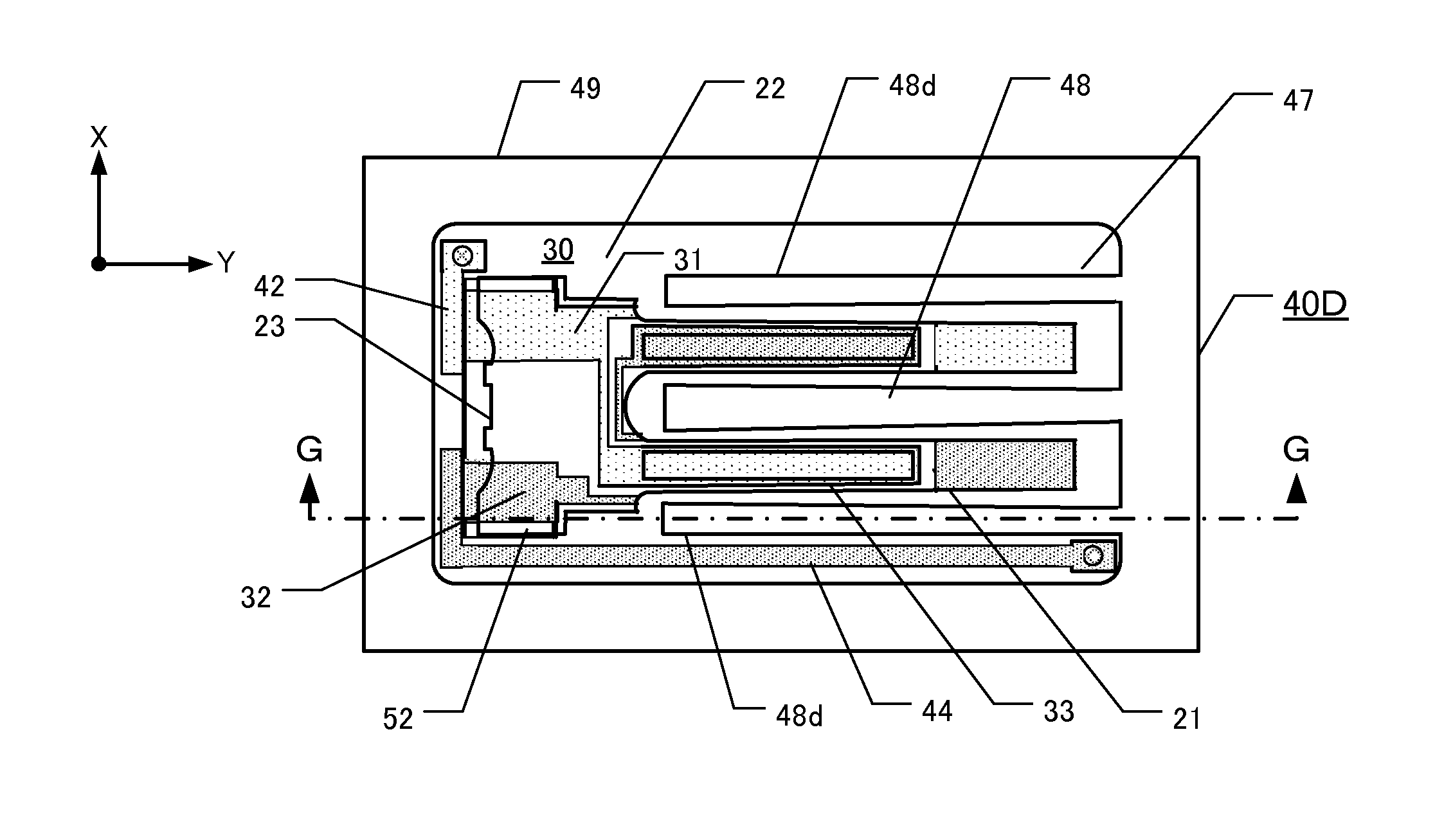

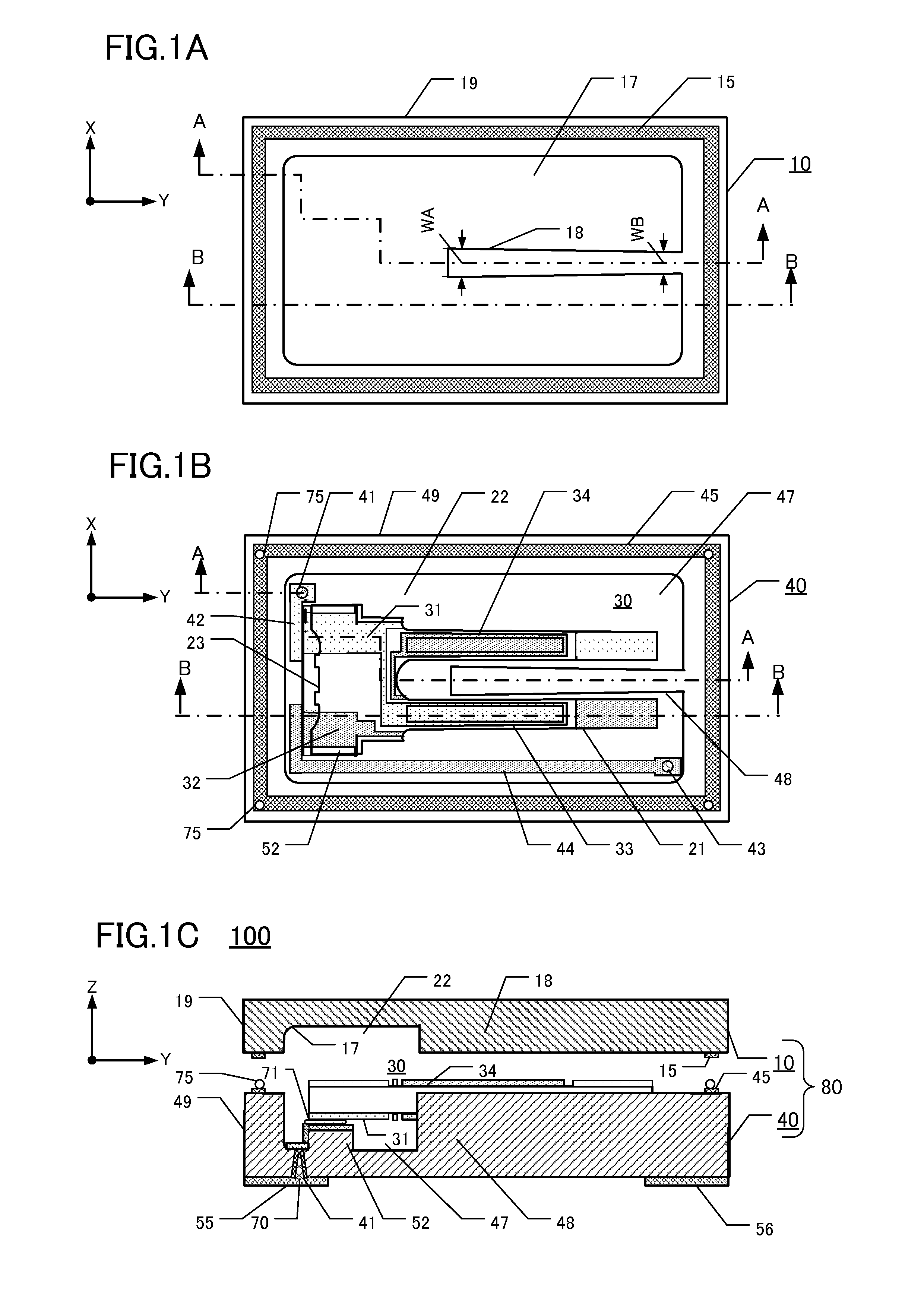

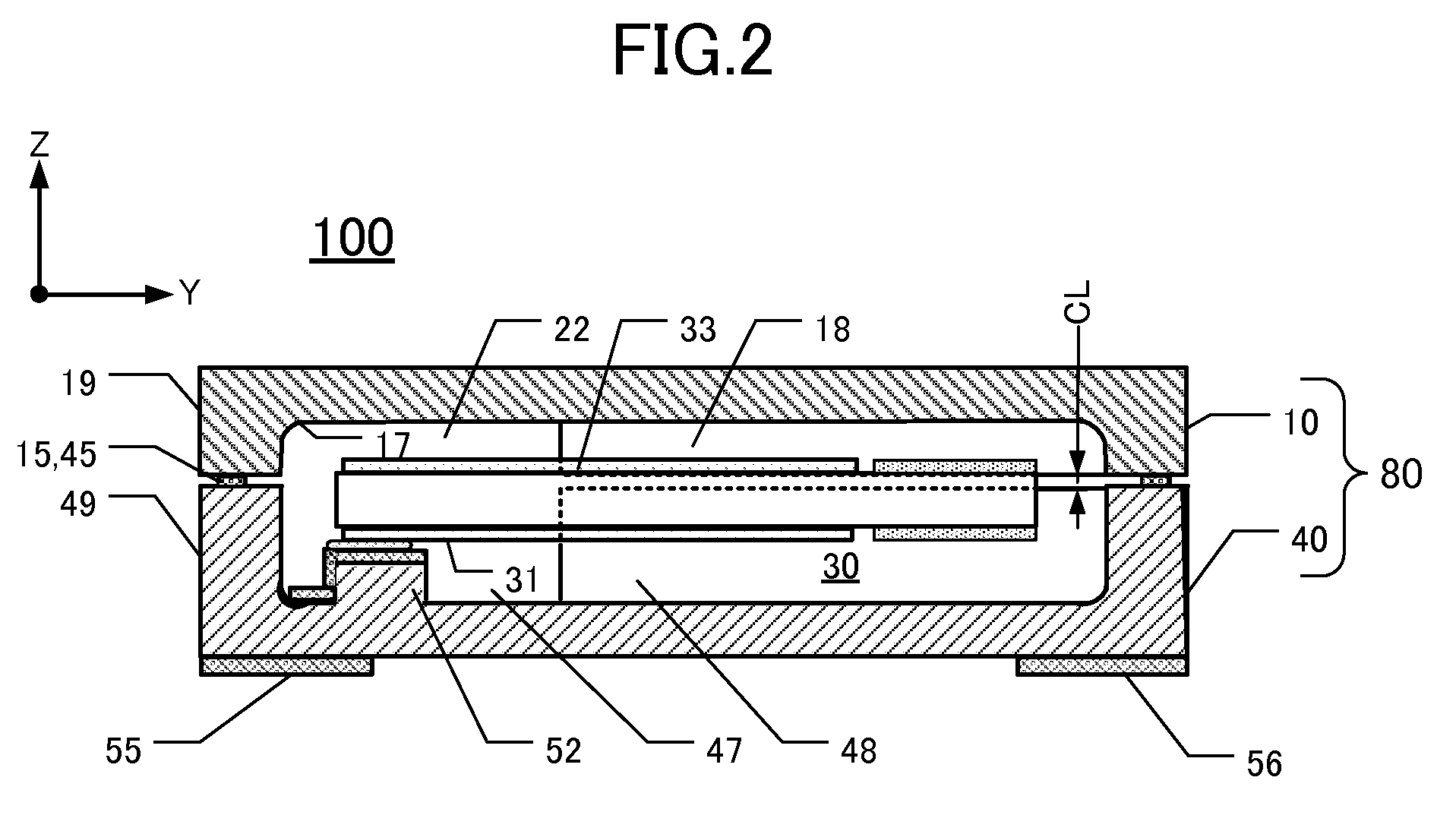

Stiffness-enhanced surface-mounted piezoelectric devices

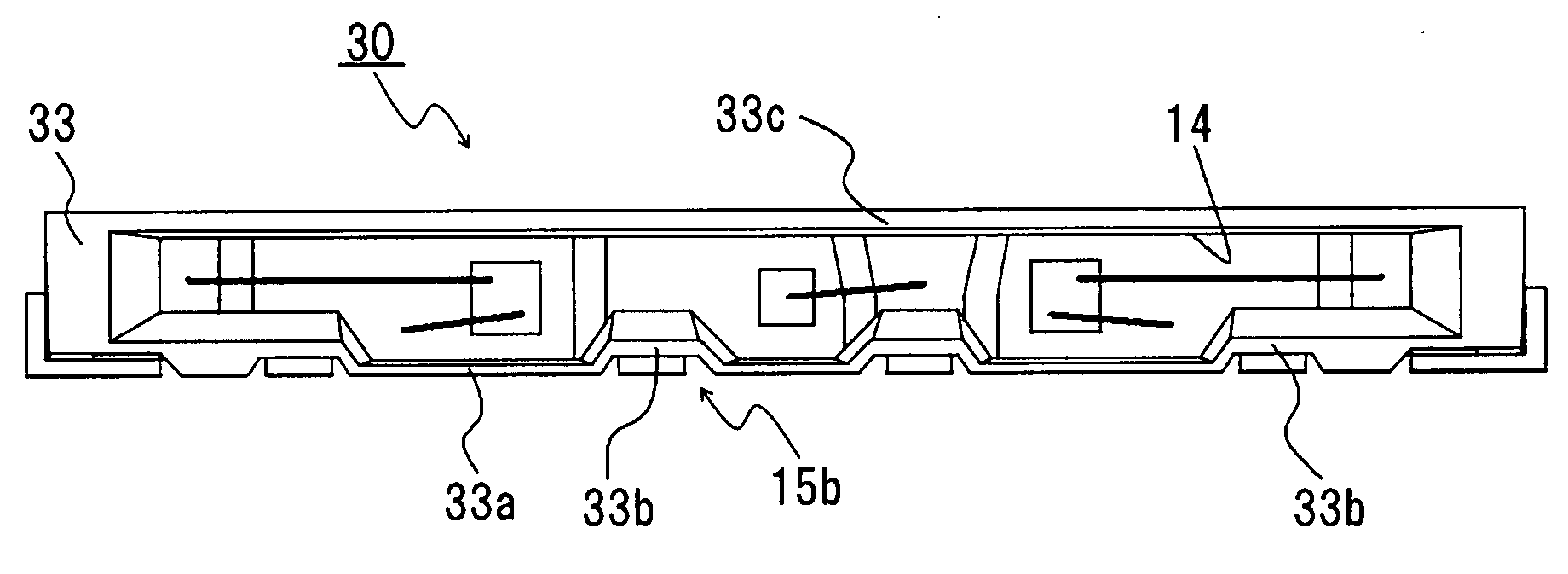

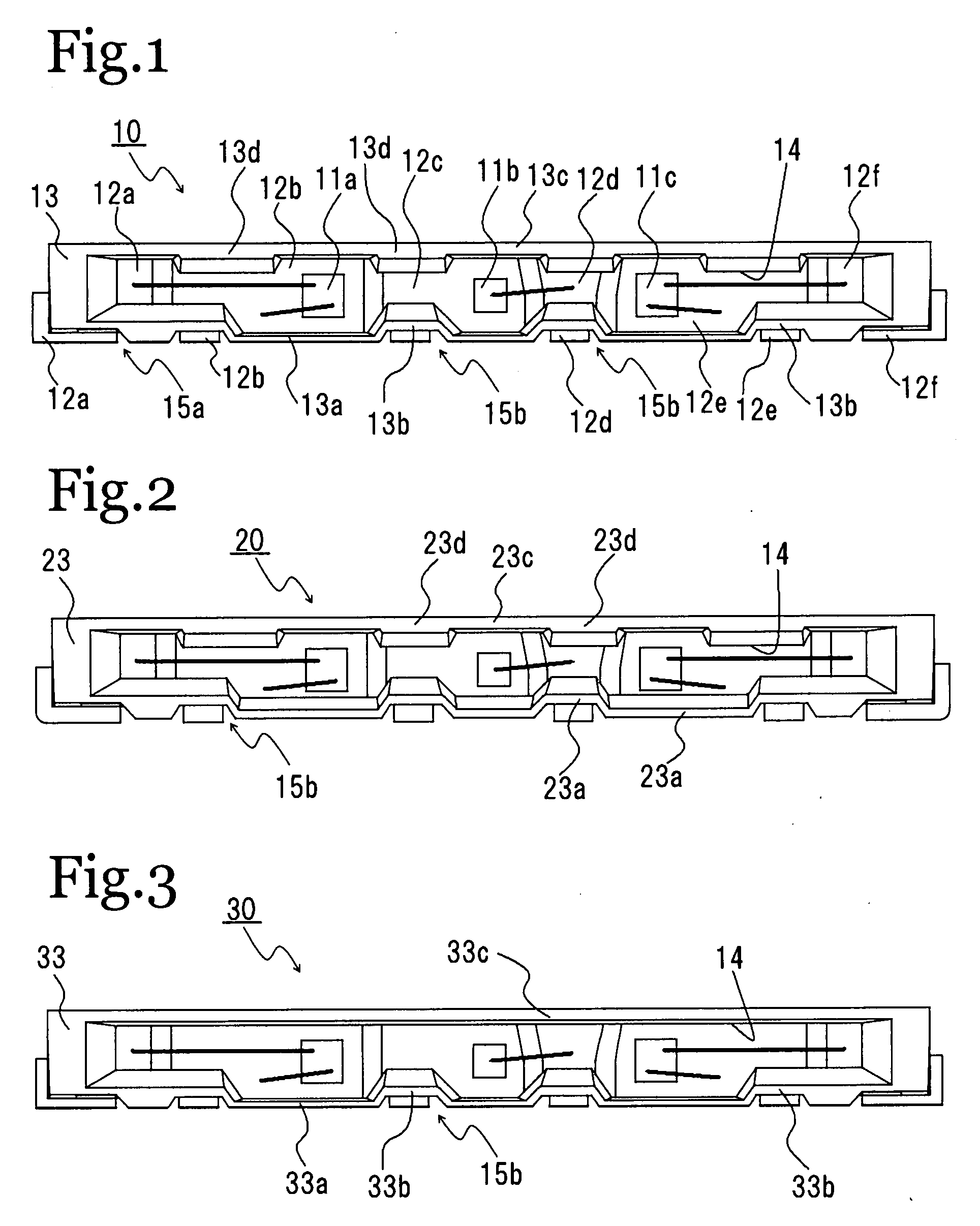

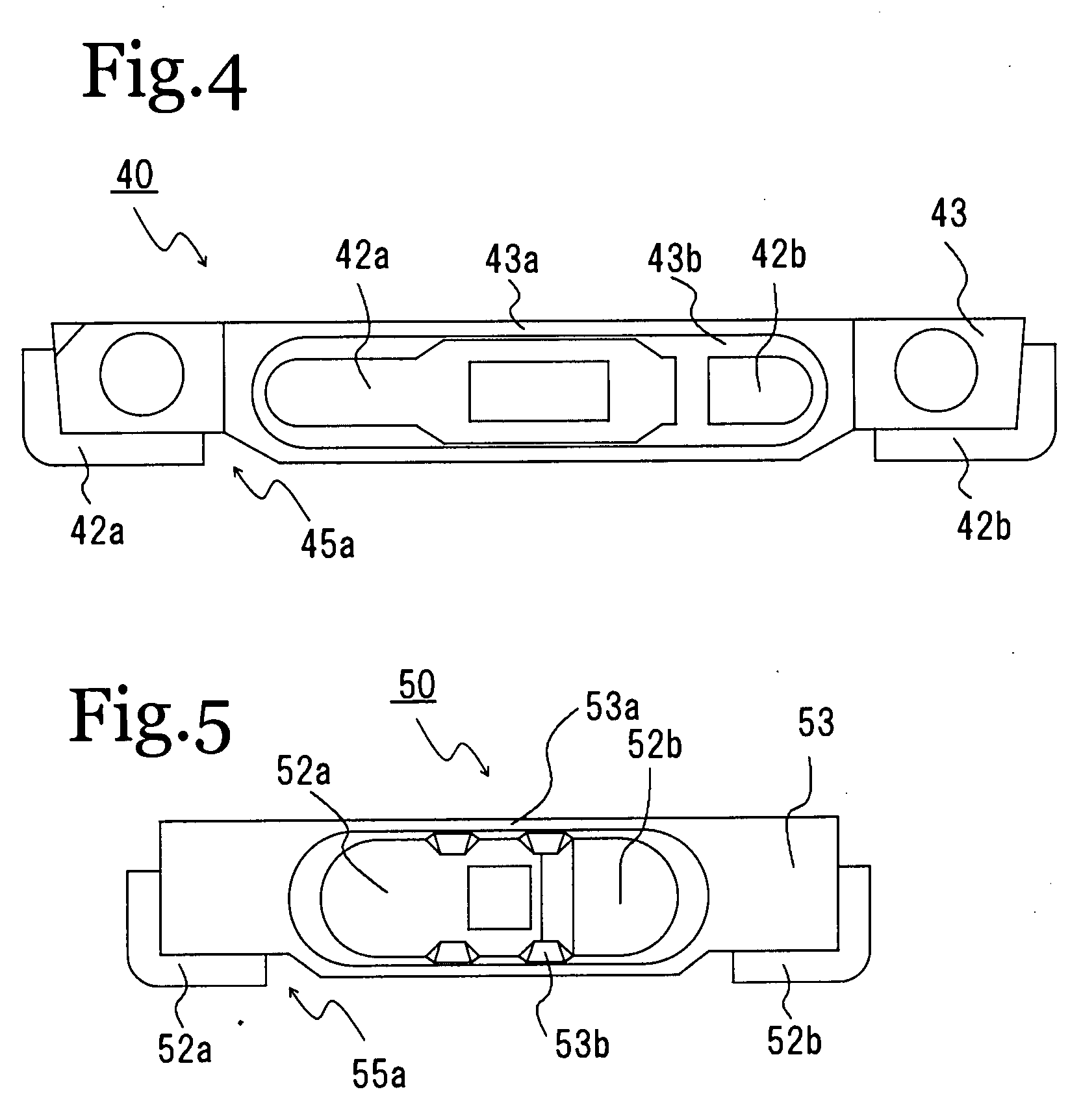

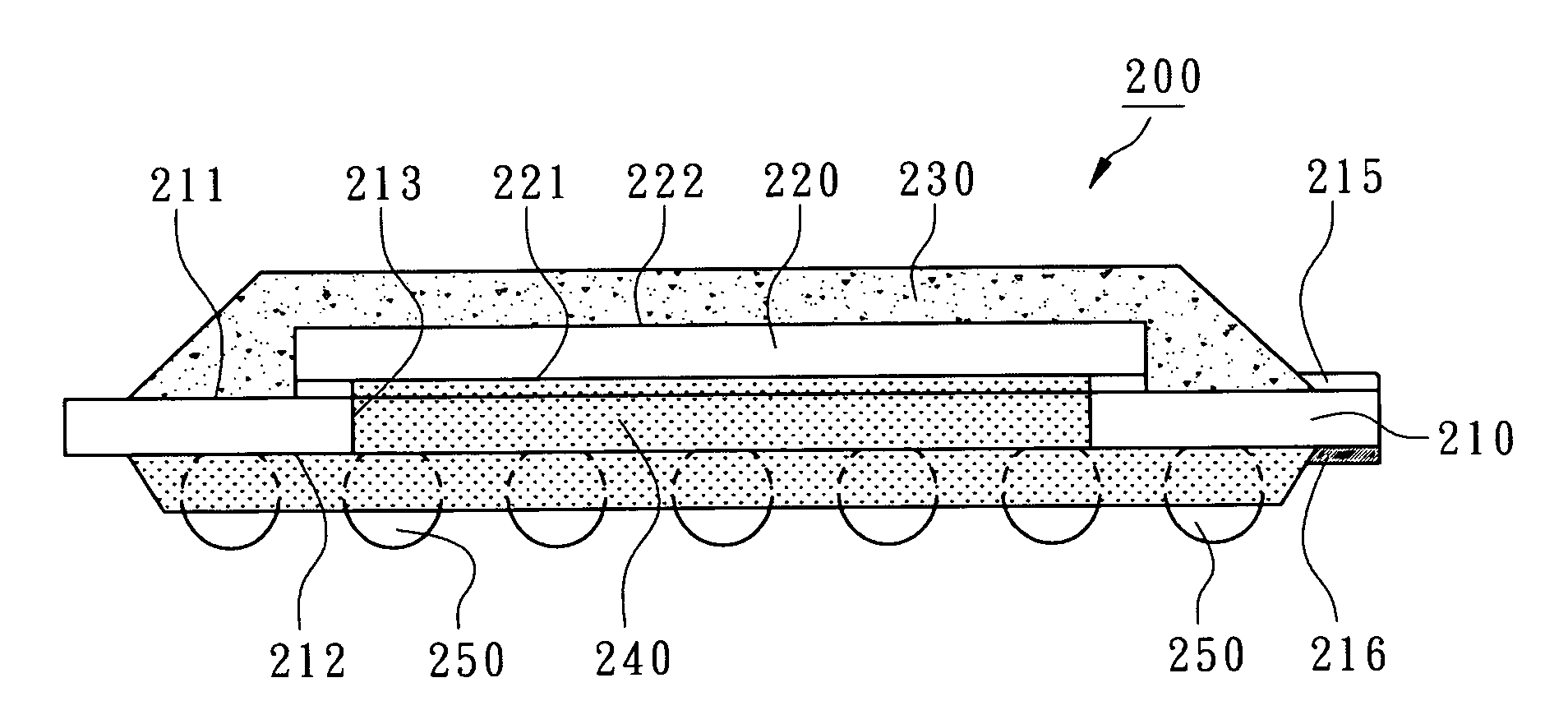

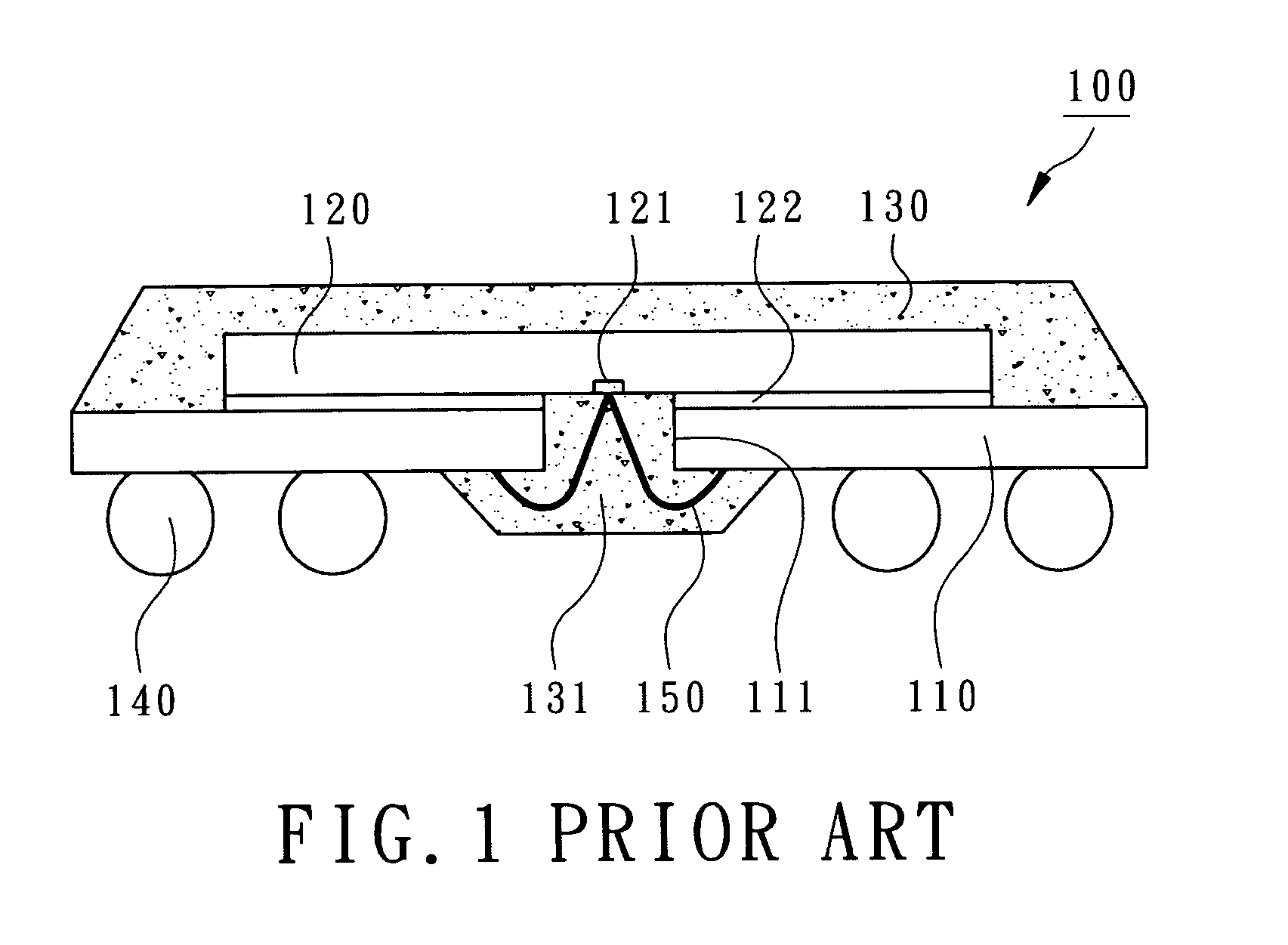

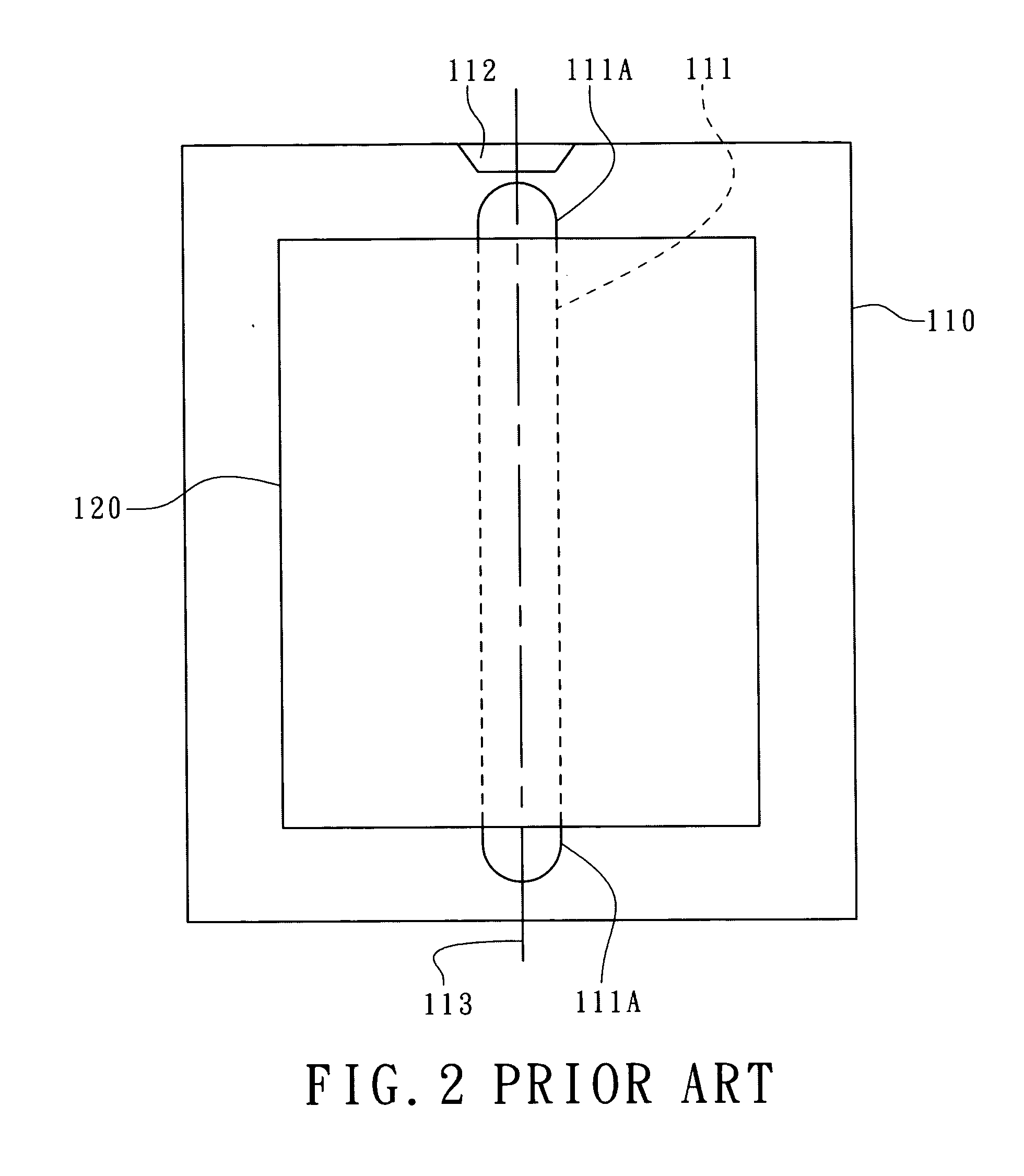

InactiveUS8456065B2Thin profileImprove package strengthImpedence networksPiezoelectric/electrostriction/magnetostriction machinesTuning forkSurface mounting

Surface-mounted piezoelectric devices are disclosed, of which an exemplary device includes a tuning-fork type piezoelectric vibrating piece having a base portion and a pair of vibrating arms extending from the base portion. The device includes a package defined by a wall. The package includes a cavity accommodating the tuning-fork type piezoelectric vibrating piece and at least one columnar body situated between the vibrating arms in the cavity.

Owner:NIHON DEMPA KOGYO CO LTD

IC package with a protective encapsulant and a stiffening encapsulant

InactiveUS7675186B2Large Young 's modulusImprove warpage resistanceSemiconductor/solid-state device detailsSolid-state devicesYoung's modulusEngineering

An IC package mainly includes a substrate having slot(s), a chip, a protective encapsulant, a stiffening encapsulant, and a plurality of external terminals. The Young's modulus of the stiffening encapsulant is greater than the one of the protective encapsulant and the curing shrinkage of the stiffening encapsulant is smaller than the one of the protective encapsulant. The protective encapsulant is formed on one of the surfaces of the substrate for encapsulating the chip. The stiffening encapsulant protrudes from the other surface of the substrate where the external terminals are disposed. Moreover, the stiffening encapsulant is formed inside the slot and is contacted with the chip. Since the stiffening encapsulant is embedded and formed inside the slot, therefore, the contact area of the stiffening encapsulant with the substrate is increased to enhance the warpage resistance of the IC package.

Owner:POWERTECH TECHNOLOGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com