Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Improve warpage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

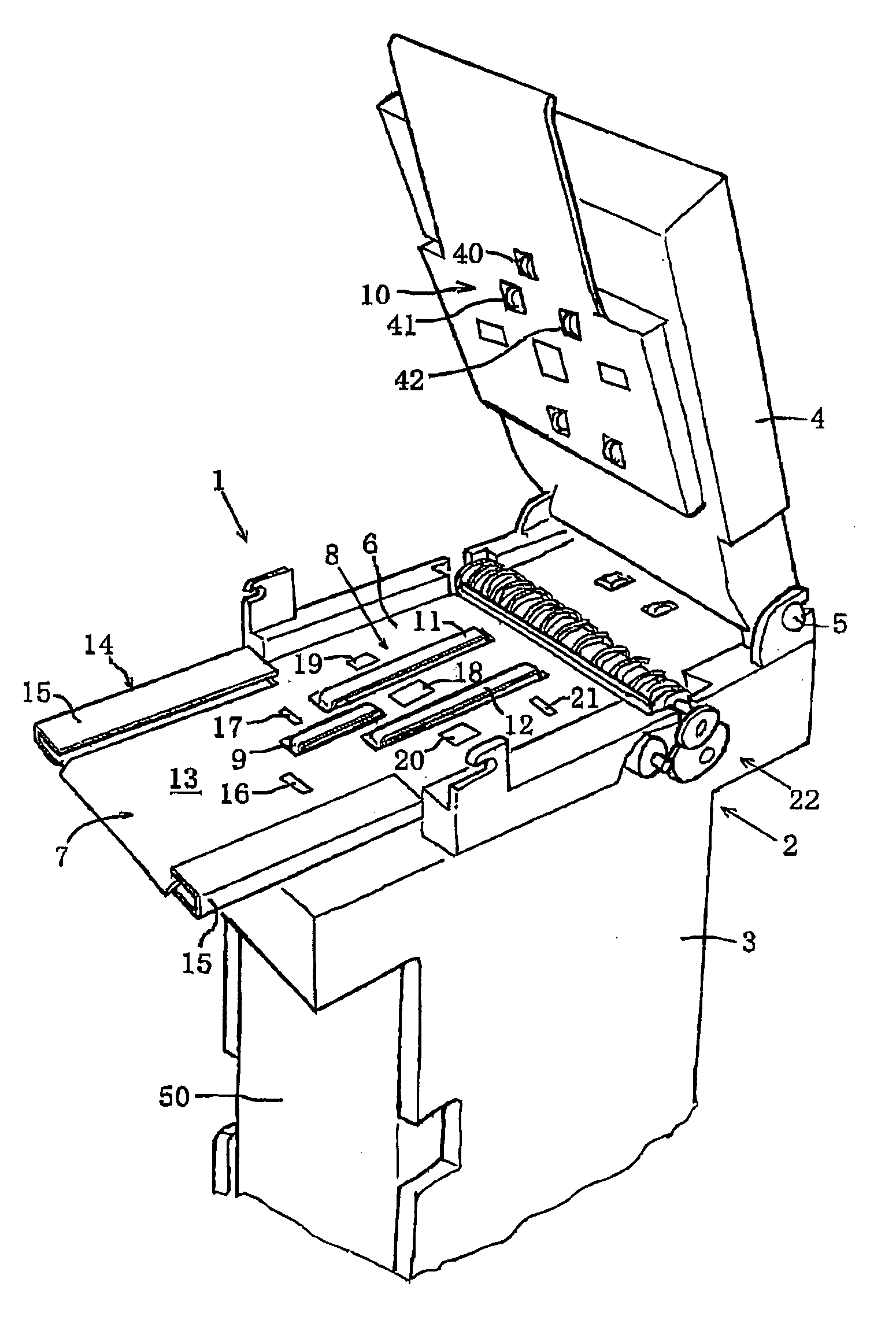

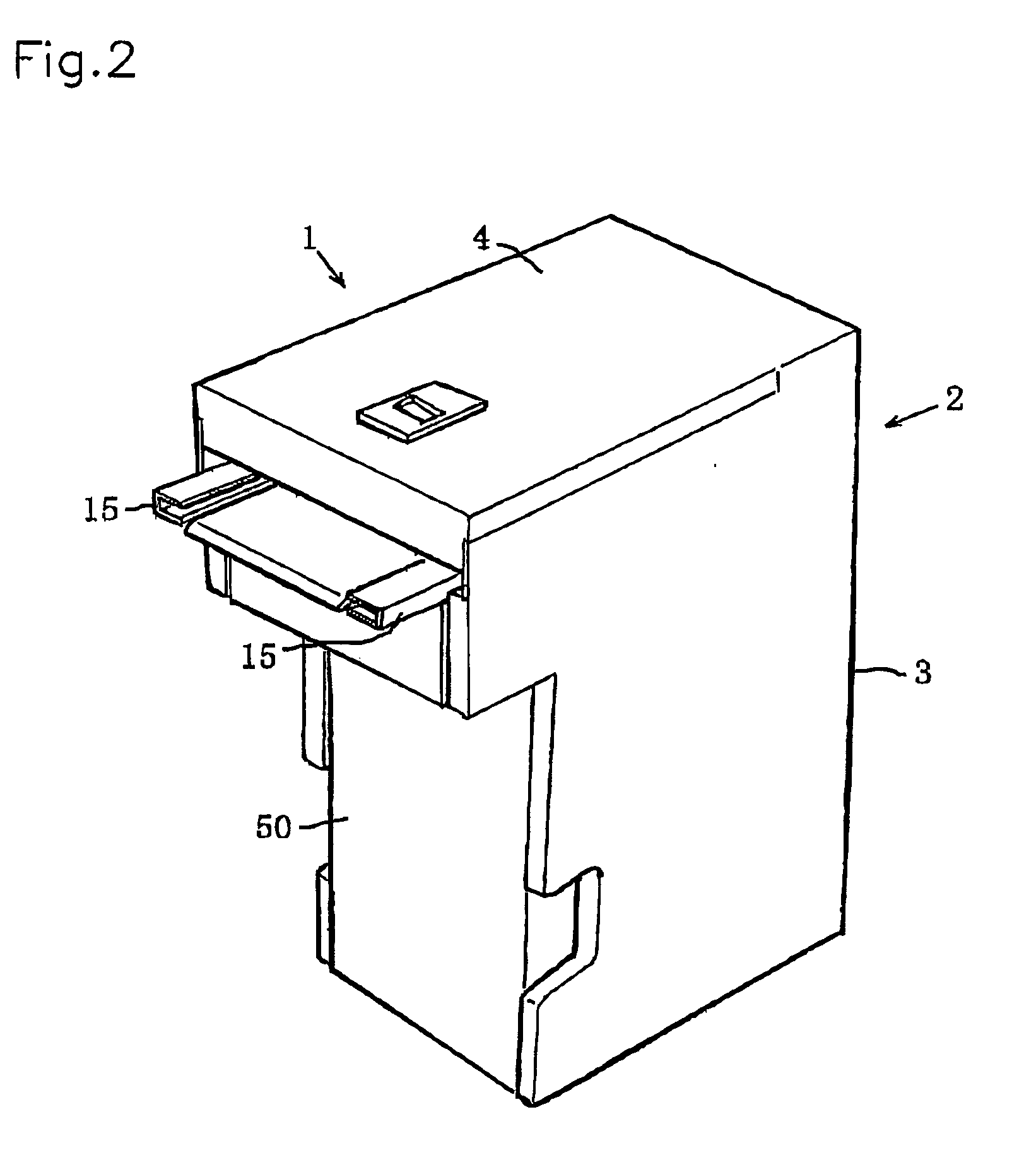

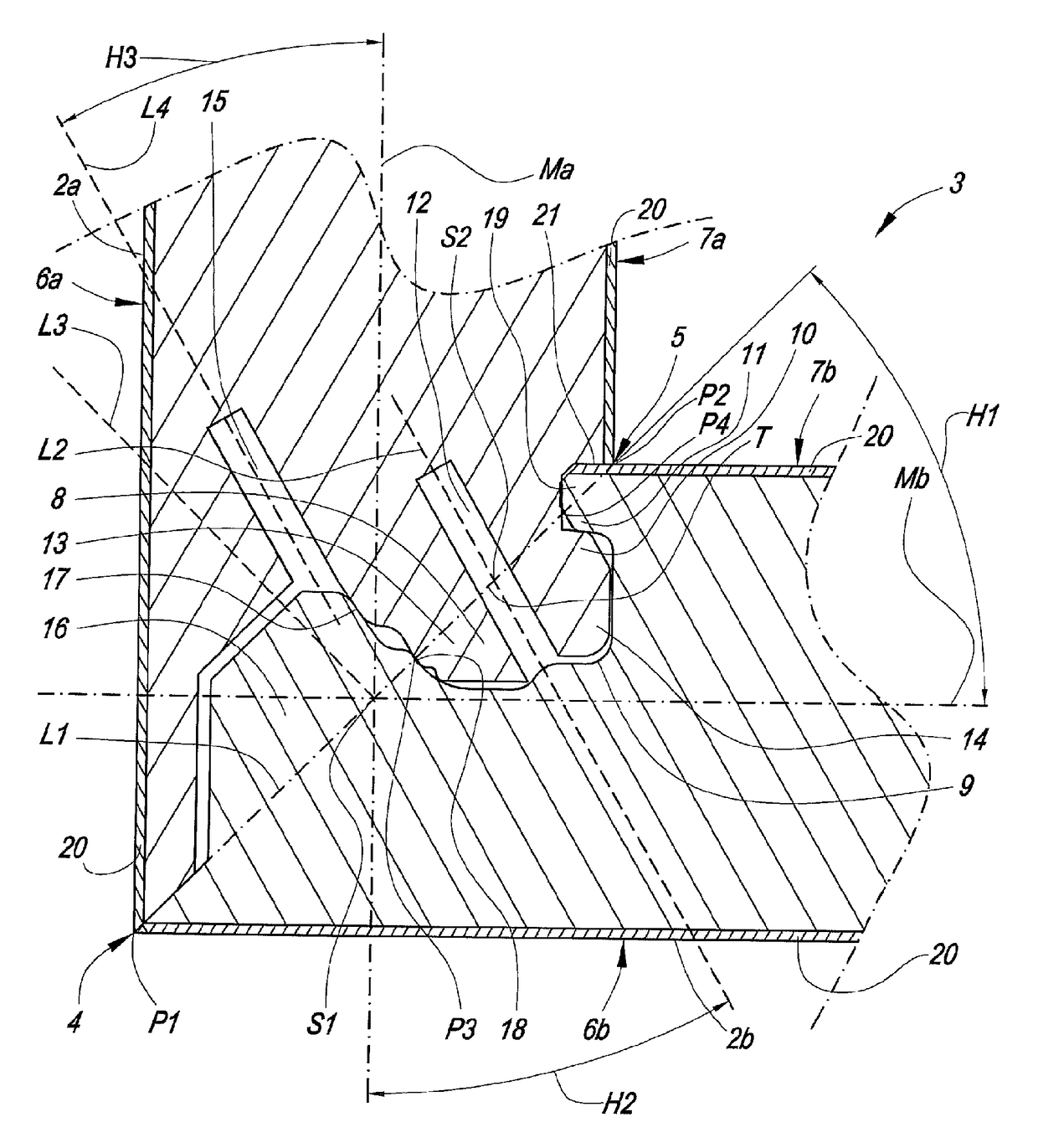

Bill validator with centering device

ActiveUS20050045449A1Simple structureReduce in quantityConveying record carriersFunction indicatorsEngineeringMechanical engineering

Centering device 14 of a bill validator comprises a pair of pinch jaws 15 positioned on the opposite sides of a passageway 6, and a centering motor 30 for moving pinch jaws 15 toward and away from each other for reciprocation of pinch jaws 15 so that pinch jaws 15 come into contact with side edges of a bill between pinch jaws 15 to align a central line of bill with a central line of passageway 6. As centering motor 30 stalls when warpage resistance by centered bill is greater than inherent holding torque of centering motor 30, centering device 14 has the simplified structure with reduced number of structural components for light weight and reliable centering operation.

Owner:JAPAN CASH MASCH CO LTD

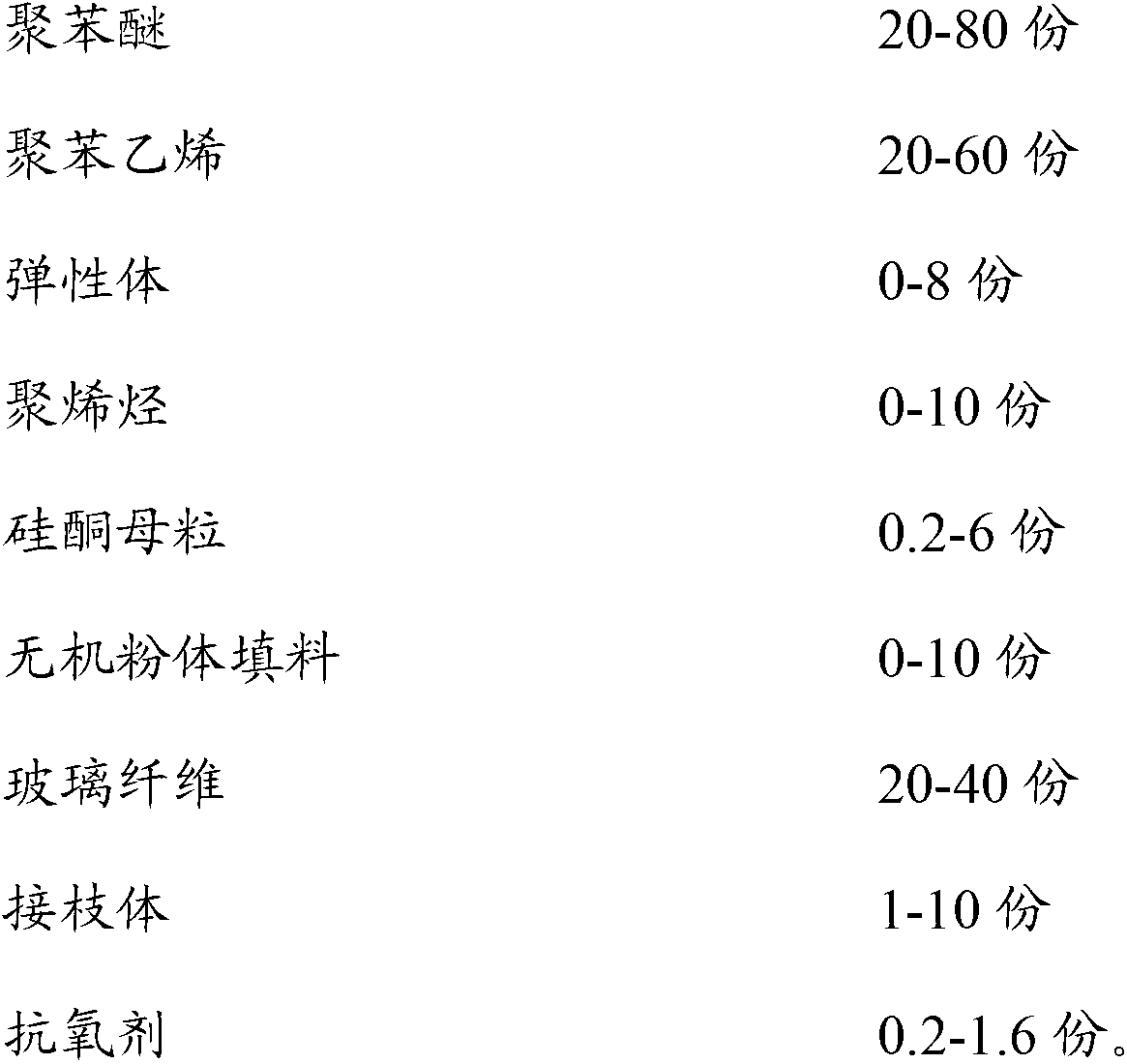

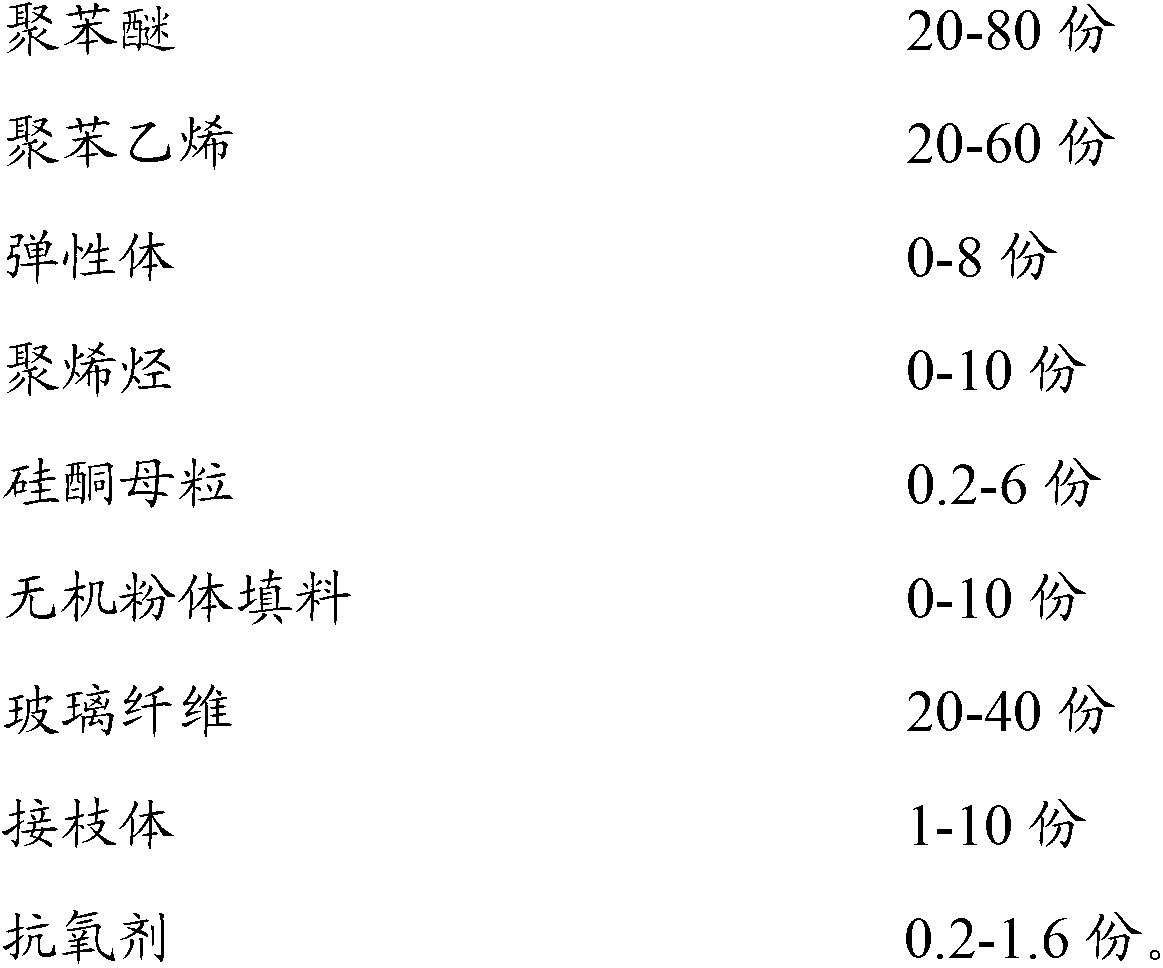

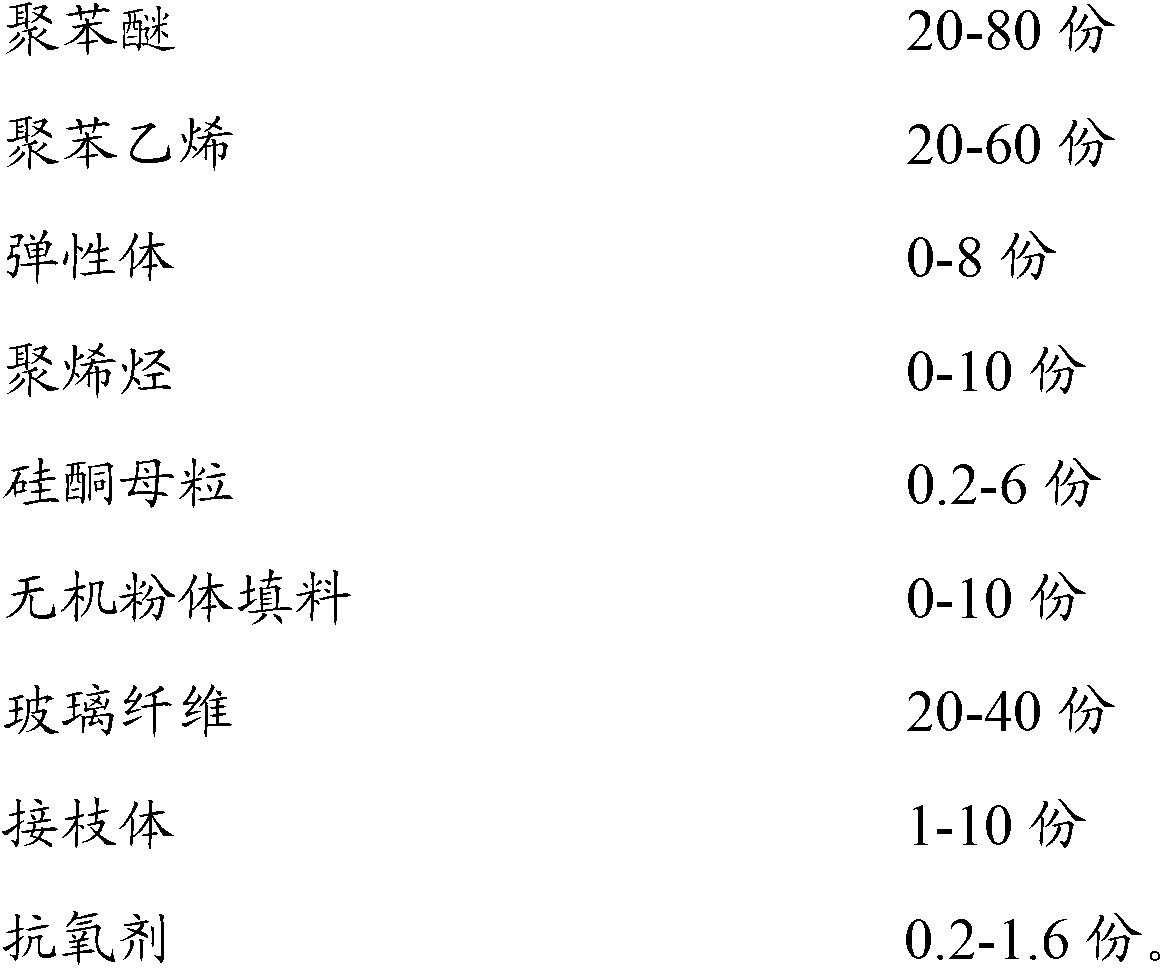

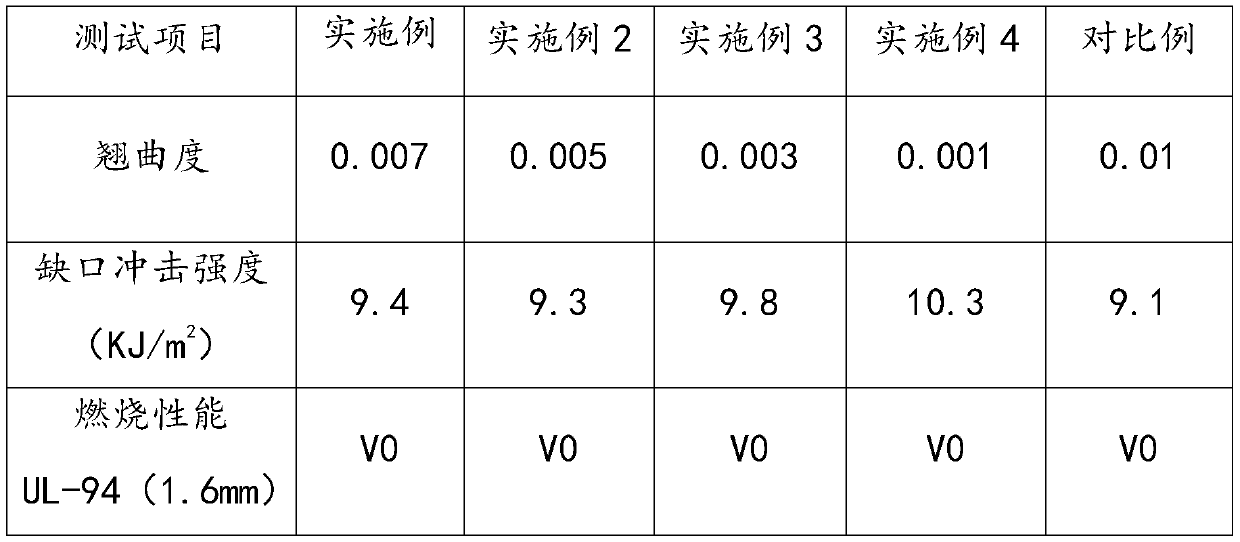

Polyphenylether composite material, and preparation method and application thereof

The invention is applicable to the field of new materials, and provides a polyphenylether composite material, a preparation method and application thereof. The polyphenylether composite material provided by the invention is specifically used for an impeller or guide blades of a hot water pump. Usually, the maximum temperature in the hot water pump can be up to 150-170 DEG C, so that the impeller and guide blades thereof are commonly formed by metal processing; and buckling deformation can exist ordinarily in case of a general high molecular resin alloy material, followed by damage caused by a large amount of friction occurring between the impeller and the inside of a motor or even the breakdown of the whole water treatment system. According to the polyphenylether composite material provided by the invention, through the coordination and combination of being used with polyphenylether, polyethylene, elastomer, polyolefin, silicone master batches and the like, and under the reinforcement action of special glass fibers, the polyphenylether composite material has superhigh physical and mechanical properties; and the high-temperature buckling resistance of the polyphenylether composite material product can be obviously improved. Thus, the invention can be applicable to an impeller or guide blades of a hot water pump.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

Rotomolding process with reduced cycle times

ActiveUS20050017409A1Improve impact resistanceResistant to warpageWood working apparatusCeramic shaping apparatusVolumetric Mass DensityLow density

The cycle time for a rotomolding process is improved through the use of a molding material comprising a blend of at least two polyethylenes having narrow molecular weight distributions and homogeneous comonomer distributions. Alternatively, the molding temperature may be reduced to conserve energy and reduce energy costs. The polyethylene blend also has a narrow molecular weight distribution of less than 3 and a density of from 0.930 to 0.950 g / cc. Rotomolded parts prepared from the blend composition have excellent impact resistance and are also resistant to warpage. A preferred process employs a blend composition which contains a blend component having a higher molecular weight and a lower density than another blend component—this blend may be used to prepare rotomolded parts with warpage resistance and improved environmental stress crack resistance (ESCR). A highly preferred process uses a blend composition which further contains aminor amount (from 0.5 to 10 weight %) of a third ethylene blend component which has a higher molecular weight and density—this highly preferred composition may be used to prepare rotomolded parts having warpage resistance, very good ESCR and comparatively high modulus (or stiffness).

Owner:NOVA CHEM (INT) SA

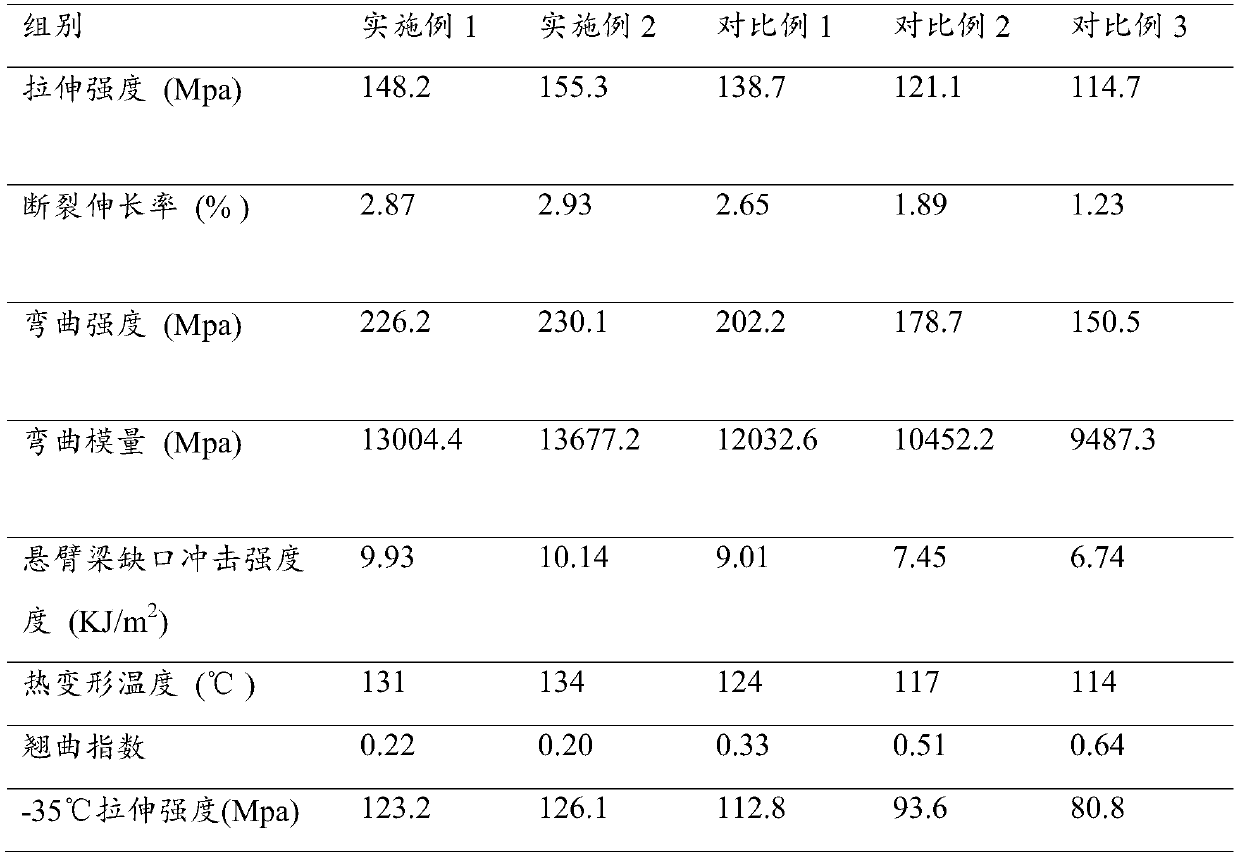

Reinforced flame-retardant low-warpage PBT alloy material and preparation method thereof

The invention discloses a reinforced flame-retardant low-warpage PBT alloy material and a preparation method thereof. The alloy material comprises the following components in parts by weight: 35-50 parts of polybutylene terephthalate, 5-15 parts of polycarbonate, 15-30 parts of glass fiber, 5-15 parts of an inorganic filler, 5-20 parts of a compound flame retardant, 5-10 parts of a toughening agent, 0.2-0.4 parts of a compound antioxidant, 0.1-0.3 parts of a lubricant, 0.1-0.3 parts of an ester exchange inhibitor, and 0.1-0.3 parts of an anti-dripping agent. The preparation method comprises the following steps: uniformly mixing all the materials except the glass fiber at a high speed, respectively feeding the mixed material and the glass fiber into a main feeding hole and a side feeding hole of a double-screw extruder, and finally forming the material. The amorphous polymer PC is introduced into the raw materials, so that the crystallinity of the system is reduced, the warping propertyof the PBT material is improved, and the PBT can be reinforced and toughened; and a compound flame retardant is introduced, so that the product has a flame-retardant characteristic. Finally, the PBT / PC alloy material has good mechanical properties, flame retardance and warping resistance, so that the application range of the PBT / PC alloy material in the fields of high-grade electrical components,household electrical shells and the like is expanded.

Owner:中广核瑞胜发(厦门)新材料有限公司

Nanometer-material-compounded long-glass-fiber-reinforced polypropylene material and preparing method thereof

The invention relates to a nanometer-material-compounded long-glass-fiber-reinforced polypropylene material and a preparing method thereof. The reinforced polypropylene material is prepared from, by weight, 40%-85% of polypropylene, 10%-50% of long glass fibers, 1%-5% of nanometer-material master batches, 1%-5% of compatibilizing agent and 0.2%-1% of antioxidant. According to the preparing method, nanometer materials are prepared to master batches to participate in the molding technology, the nanometer-material particles are evenly dispersed in polypropylene melt, and the performance of the composite material is greatly improved. The nanometer-material-compounded long-glass-fiber-reinforced polypropylene material has the excellent mechanical performance, and meanwhile has the excellent warping resistance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

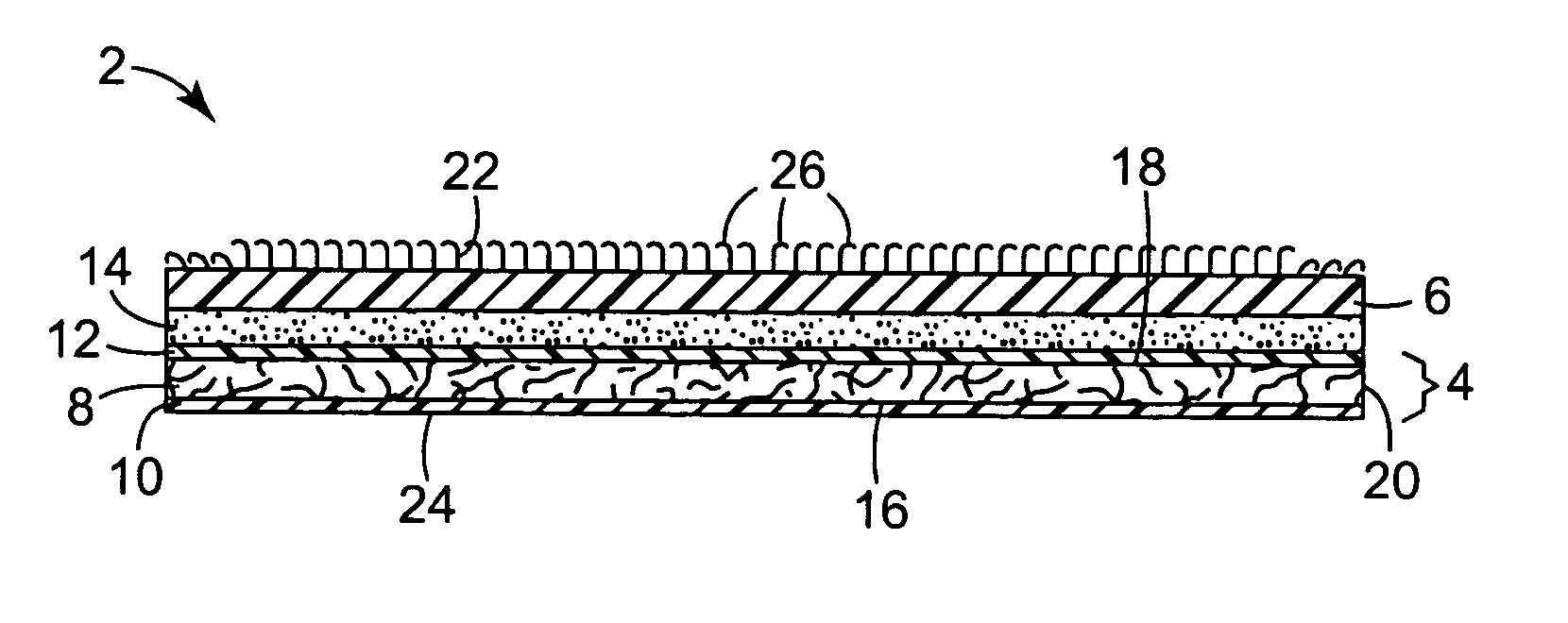

Conversion pad with moisture barrier

InactiveUS20050227599A1Improved sanding characteristicEasy to manufactureSupport wheelsBelt grinding machinesEngineeringMoisture barrier

A conversion pad for attaching an abrasive article to a sanding tool includes a supporting layer comprising a backing material and a moisture barrier arranged on at least a portion of the supporting layer, thereby to protect the backing material from moisture, and a layer of attachment material affixed to the supporting layer for attaching the abrasive article to the conversion pad.

Owner:3M INNOVATIVE PROPERTIES CO

Bill validator with centering device

ActiveUS8276734B2Simple structureReduce in quantityConveying record carriersFunction indicatorsEngineeringMechanical engineering

Centering device 14 of a bill validator comprises a pair of pinch jaws 15 positioned on the opposite sides of a passageway 6, and a centering motor 30 for moving pinch jaws 15 toward and away from each other for reciprocation of pinch jaws 15 so that pinch jaws 15 come into contact with side edges of a bill between pinch jaws 15 to align a central line of bill with a central line of passageway 6. As centering motor 30 stalls when warpage resistance by centered bill is greater than inherent holding torque of centering motor 30, centering device 14 has the simplified structure with reduced number of structural components for light weight and reliable centering operation.

Owner:JAPAN CASH MASCH CO LTD

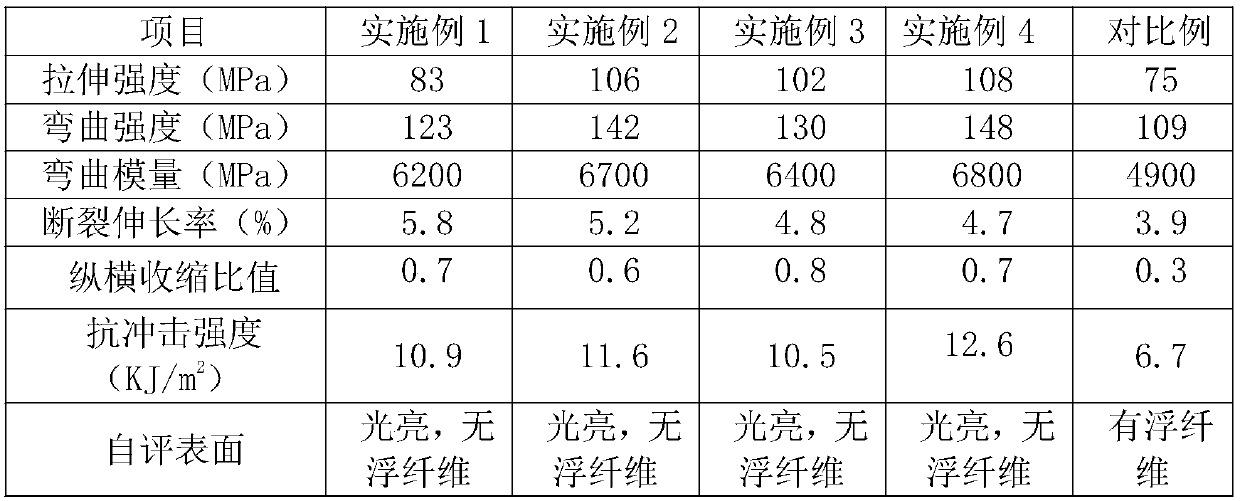

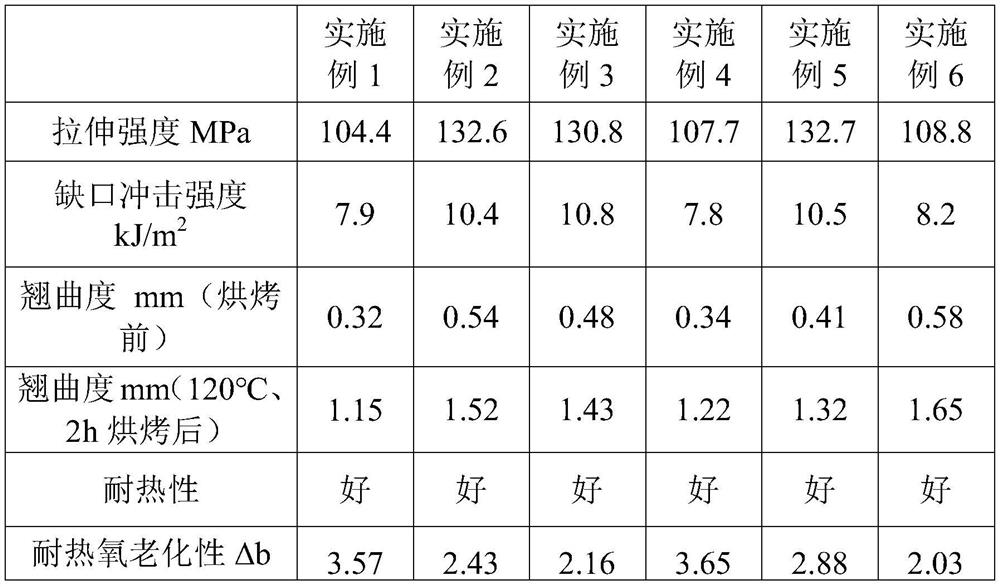

PBT composite material reinforced by modified flat glass fibers, and preparation method of PBT composite material

ActiveCN110804282AOvercoming Floating Fiber ProblemsMeet the requirements of parts with high heat resistance requirementsThermal deformationMesoporous silica

The invention discloses a PBT composite material. The composite material comprises the following preparation raw materials in parts by weight: 70-80 parts of PBT composite resin, 10-30 parts of a PET-ABS mixed material composition, 20-30 parts of composite glass fibers, 5-20 parts of a compatible toughening agent, 3-5 parts of surface-treated hollow glass micro-beads, 1-5 parts of mesoporous silica nanoparticles treated by a silane coupling agent and 0-3 parts of an auxiliary agent. According to the prepared PBT composite material, the defect of poor compatibility of an inorganic material andan organic polymer is effectively improved, and the composite material can obtain balanced mechanical properties on the basis of good notch impact strength, thermal deformation temperature and shrinkage rate.

Owner:福建华塑新材料有限公司

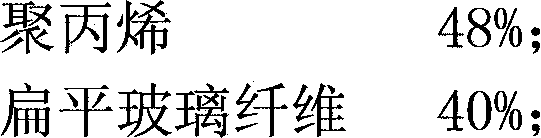

High-strength and anti-warping polyolefin composite material and preparation method thereof

The invention relates to a high-strength and anti-warping polyolefin composite material. The polyolefin composite material is prepared from components in parts by weight as follows: 50-90 parts of polyolefin resin, 0.4-1 part of a heat stabilizer, 0.2-1 part of an ultraviolet stabilizer, 2-6 parts of nucleating agent master batch, 0.5-5 parts of high-molecular-weight silicone master batch, 10-50 parts of flat glass fiber and 1-6 parts of a compatilizer. The compatilizer is selected from maleic anhydride grafted polypropylene or maleic anhydride grafted methacrylate containing organosilicone; the maleic anhydride grafting rate is 0.8%-1.2%. In the high-molecular-weight silicone master batch, the molecular weight of an organosiloxane ultrahigh molecular weight polymer is larger than or equalto 1 million and the silicone content is 40%-60%. The length of the flat glass fiber is 2-5 mm, and the cross section of the flat glass fiber is a rectangular structure 20-32 mu m long and 4-10 mu mwide. The polyolefin composite material has excellent resin mechanical performance, so that a product has high mechanical performance and anti-warping performance.

Owner:厦门德丰行塑胶工业有限公司

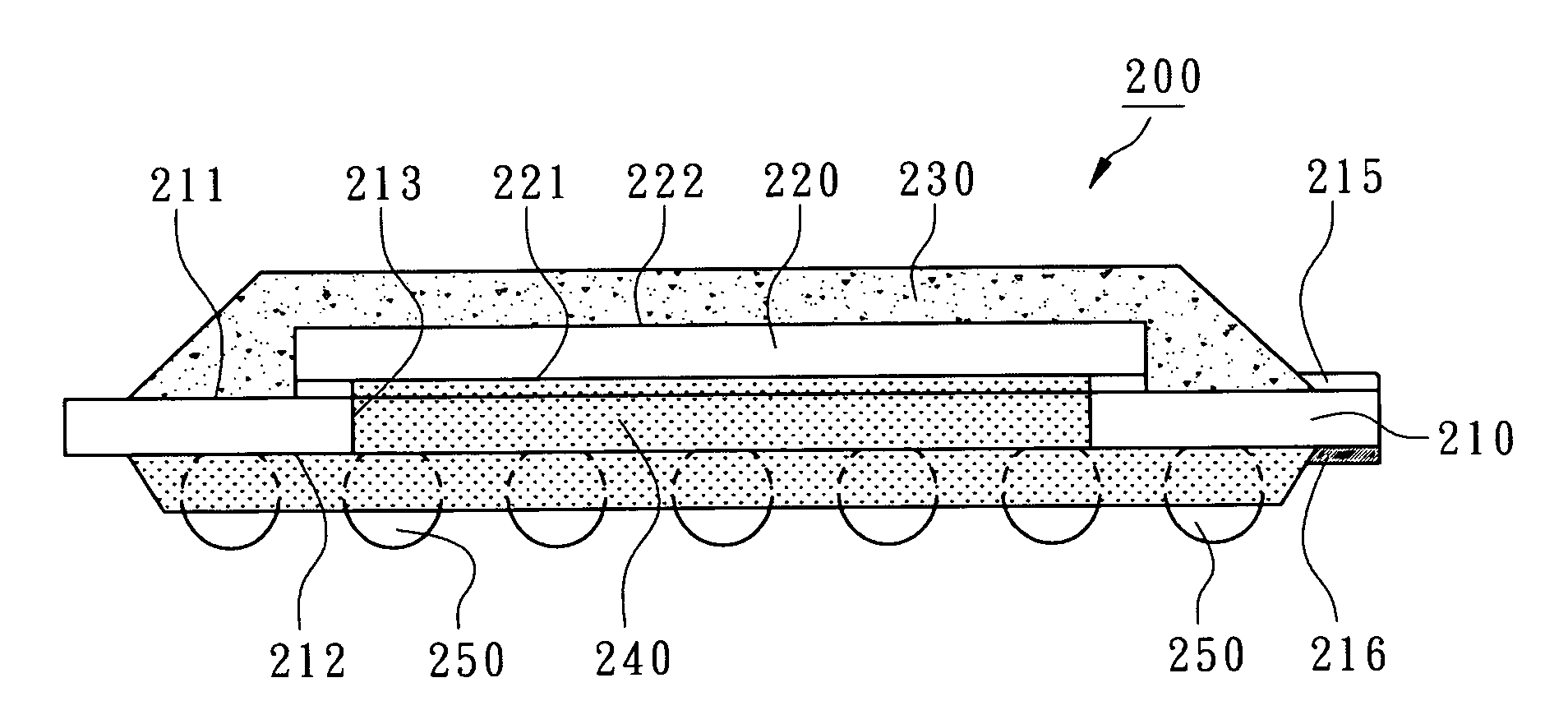

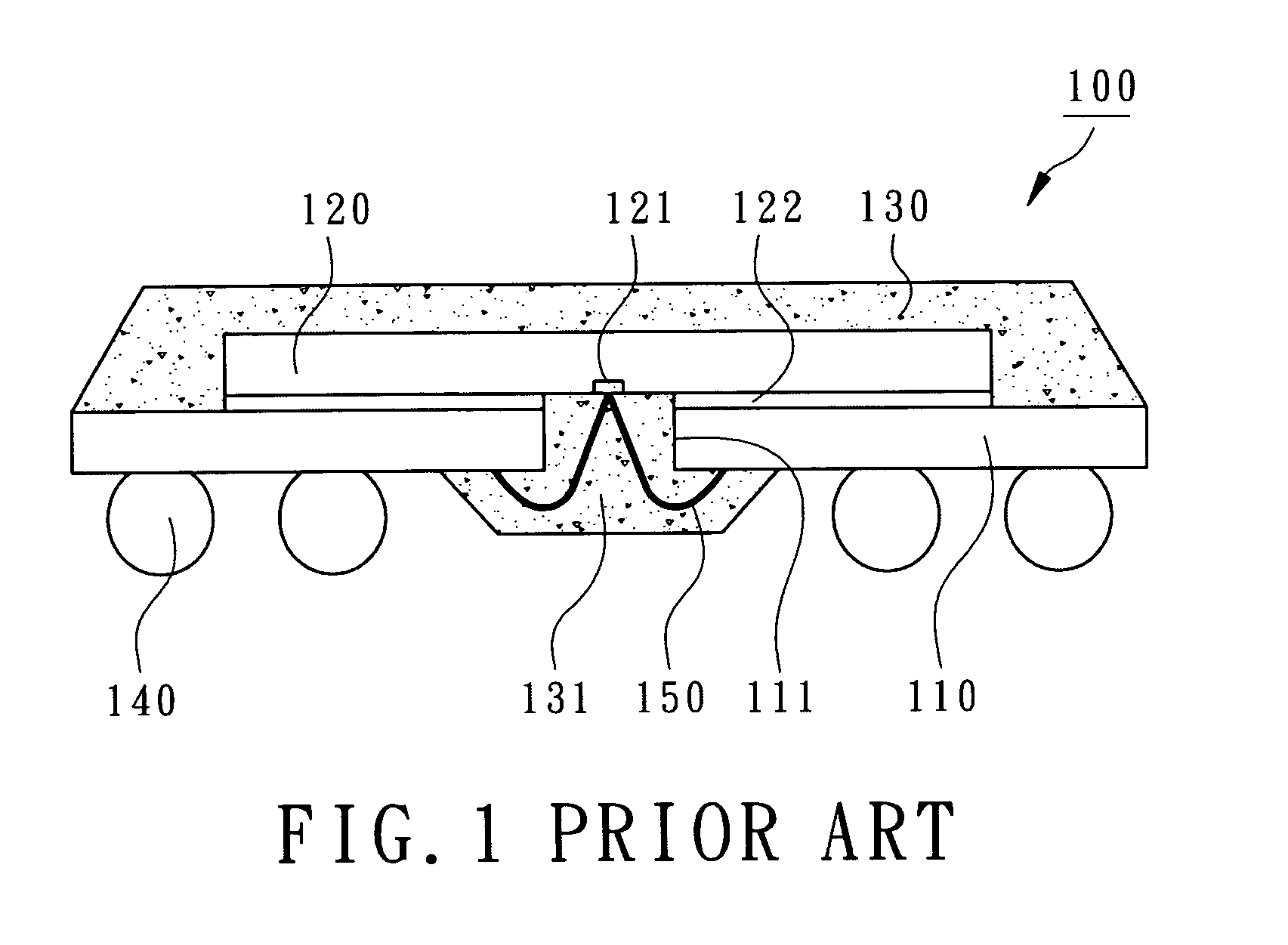

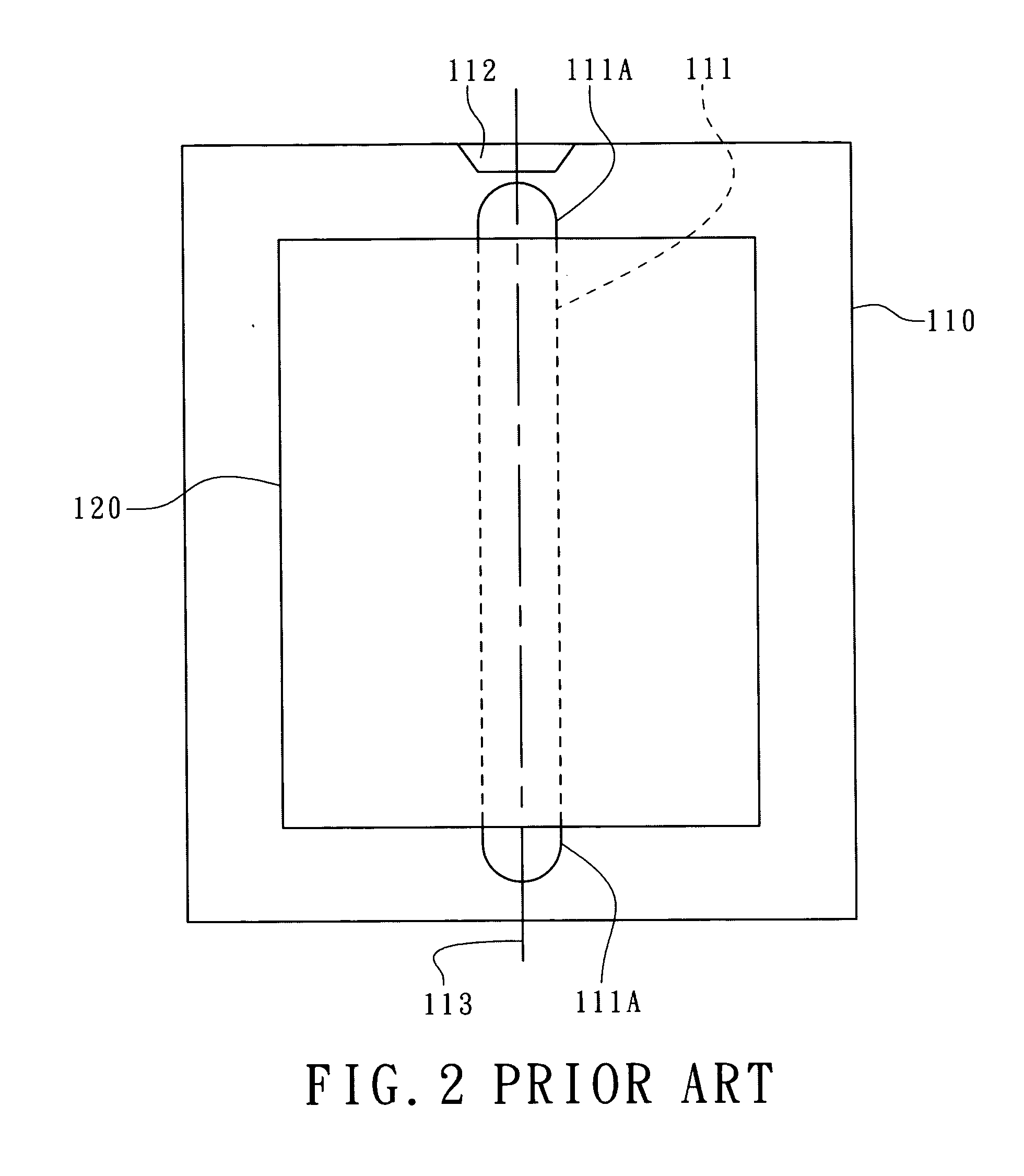

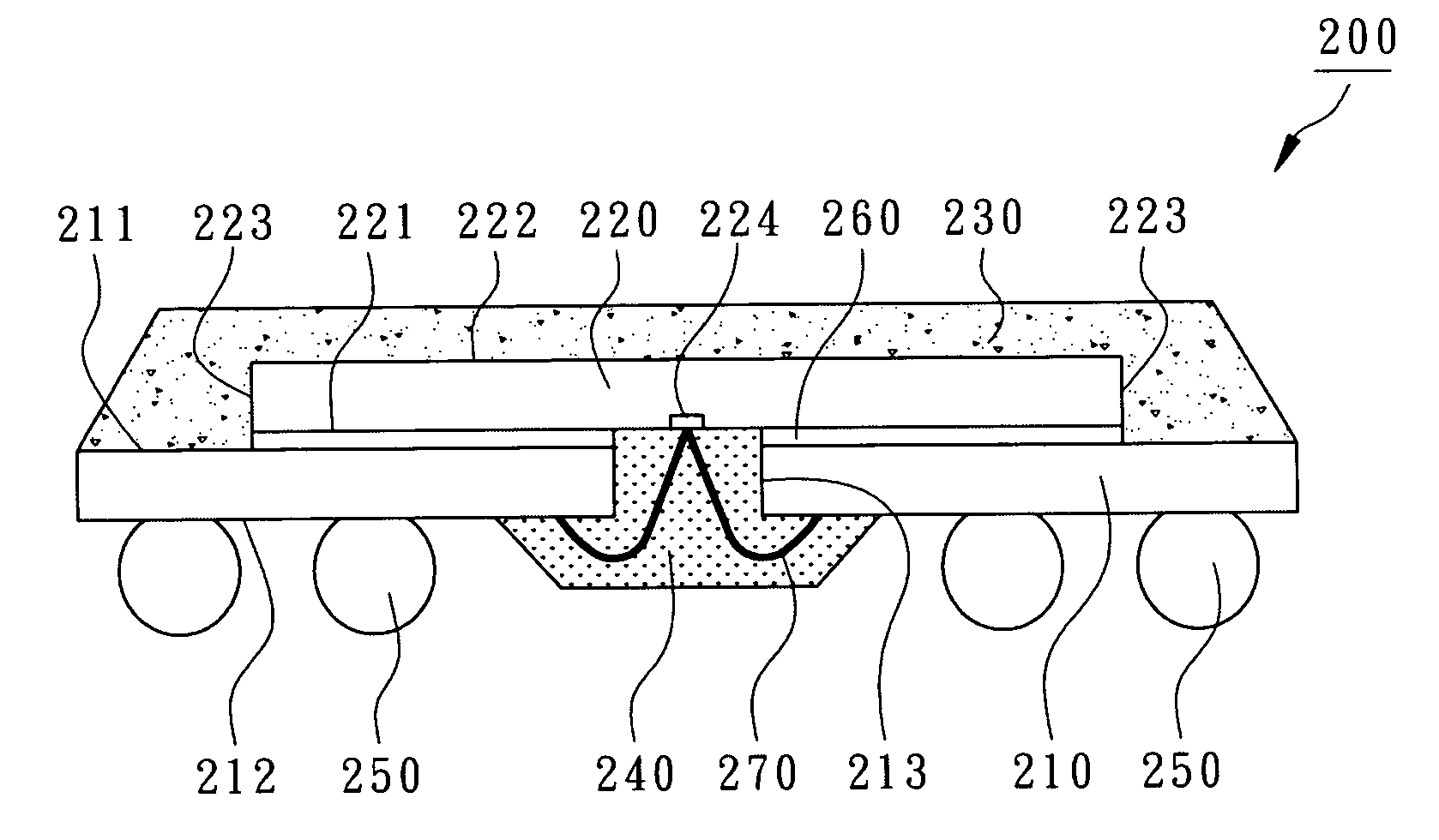

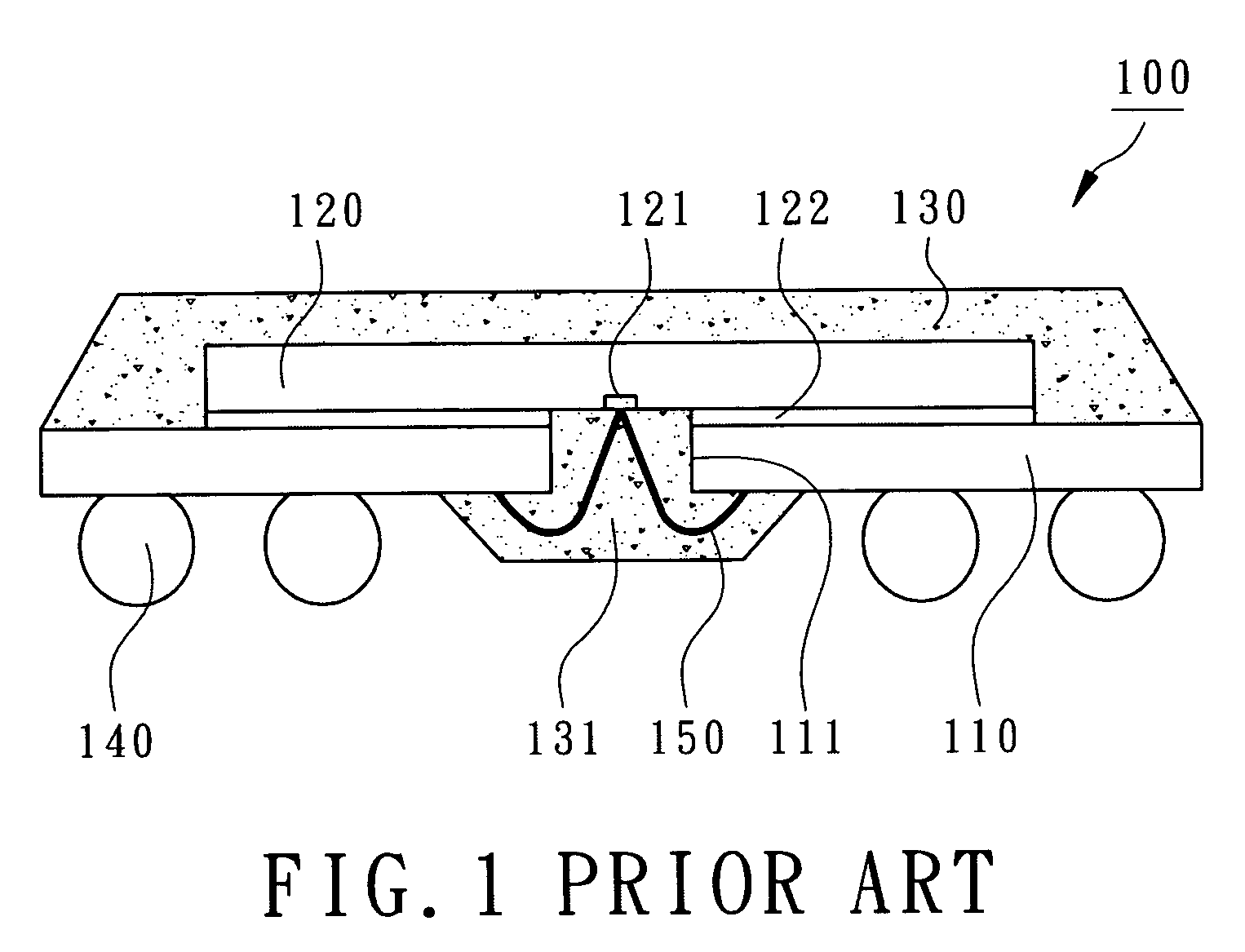

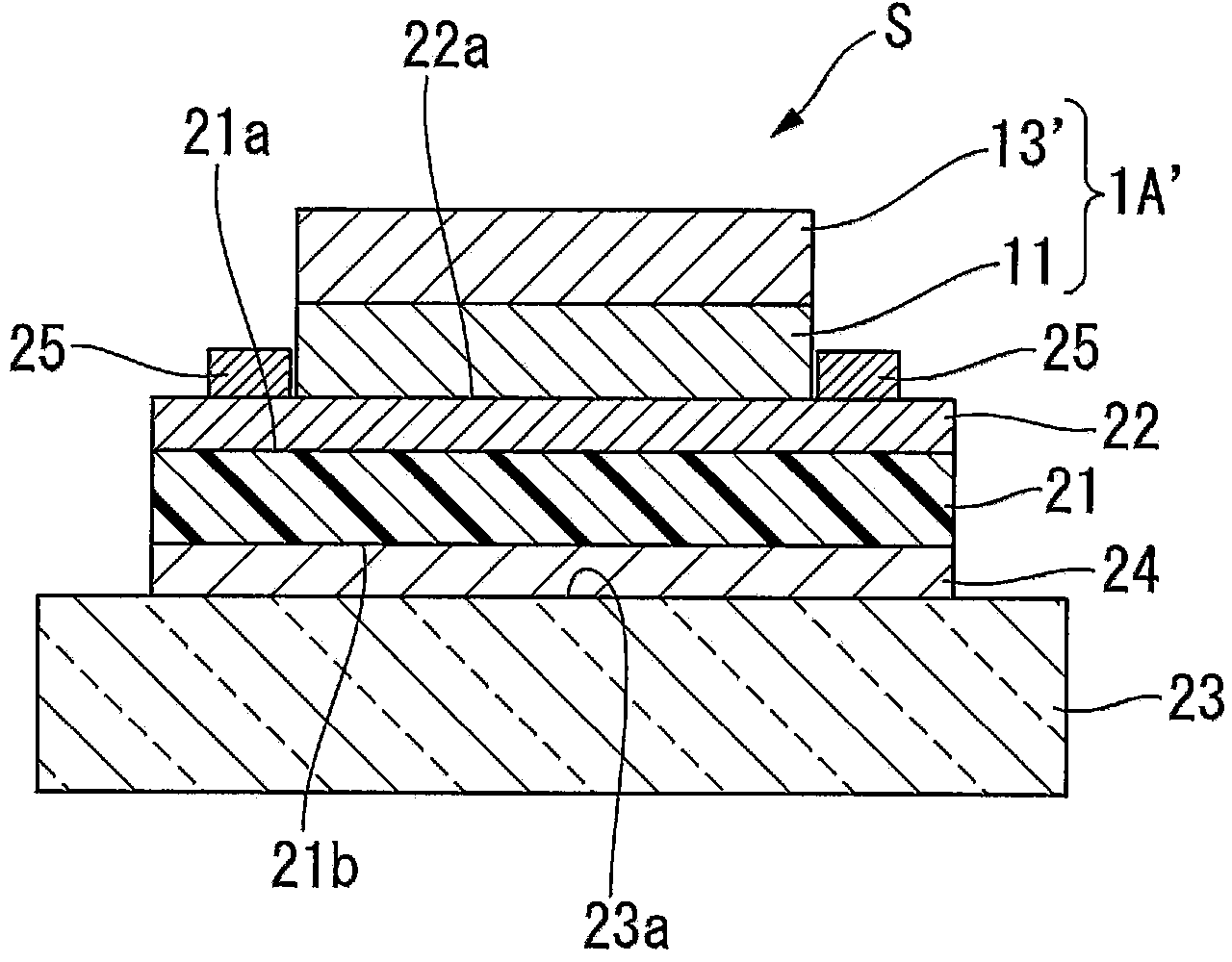

IC package

InactiveUS20080054494A1Large Young 's modulusImprove warpage resistanceSemiconductor/solid-state device detailsSolid-state devicesYoung's modulusEngineering

An IC package mainly includes a substrate having slot(s), a chip, a protective encapsulant, a stiffening encapsulant, and a plurality of external terminals. The Young's modulus of the stiffening encapsulant is greater than the one of the protective encapsulant and the curing shrinkage of the stiffening encapsulant is smaller than the one of the protective encapsulant. The protective encapsulant is formed on one of the surfaces of the substrate for encapsulating the chip. The stiffening encapsulant protrudes from the other surface of the substrate where the external terminals are disposed. Moreover, the stiffening encapsulant is formed inside the slot and is contacted with the chip. Since the stiffening encapsulant is embedded and formed inside the slot, therefore, the contact area of the stiffening encapsulant with the substrate is increased to enhance the warpage resistance of the IC package.

Owner:POWERTECH TECHNOLOGY

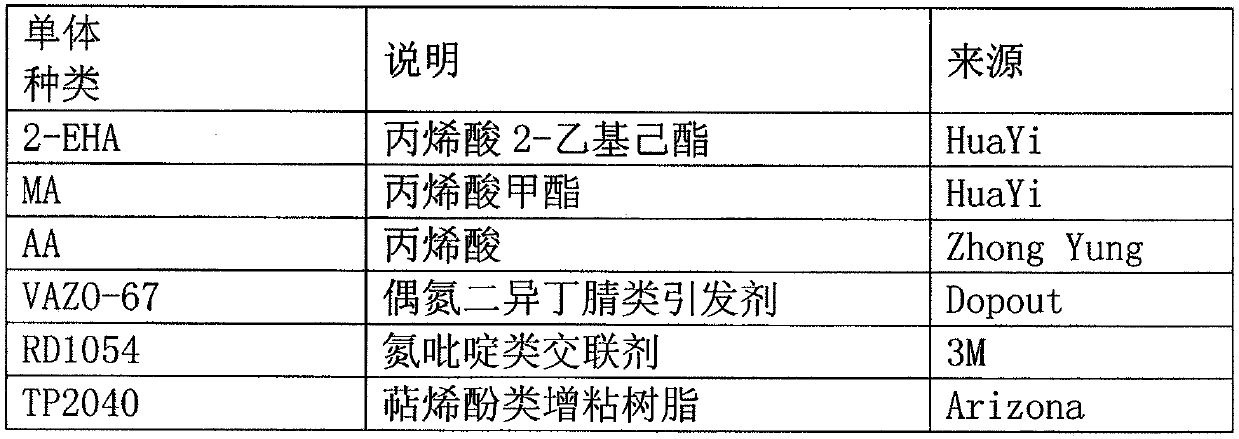

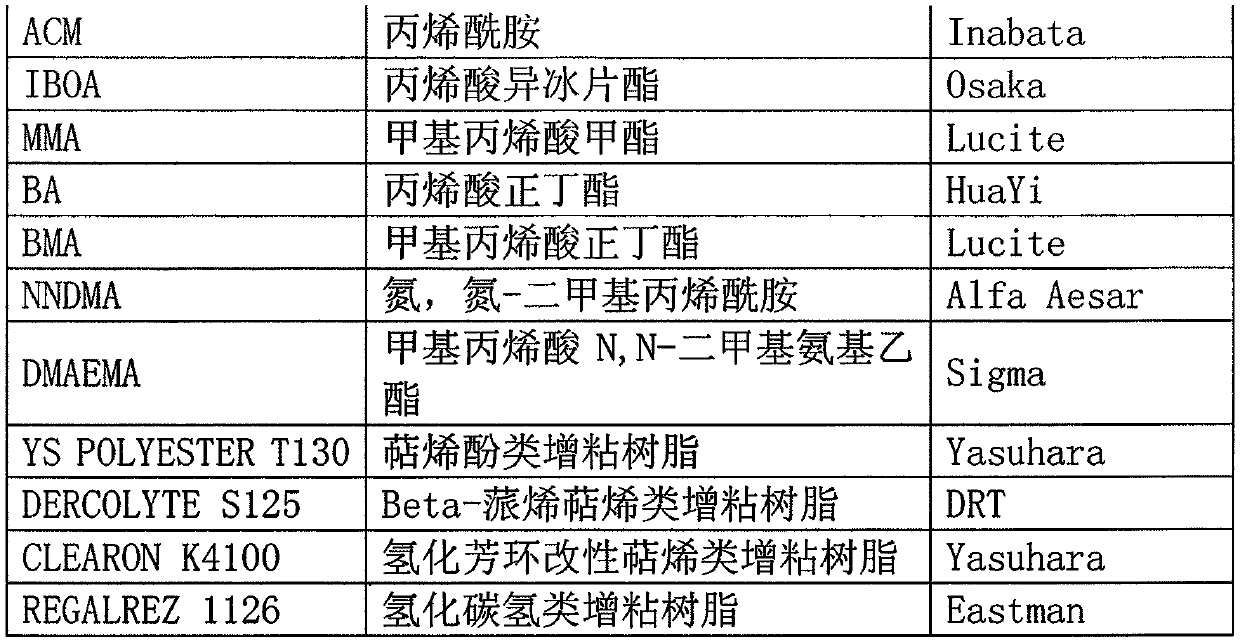

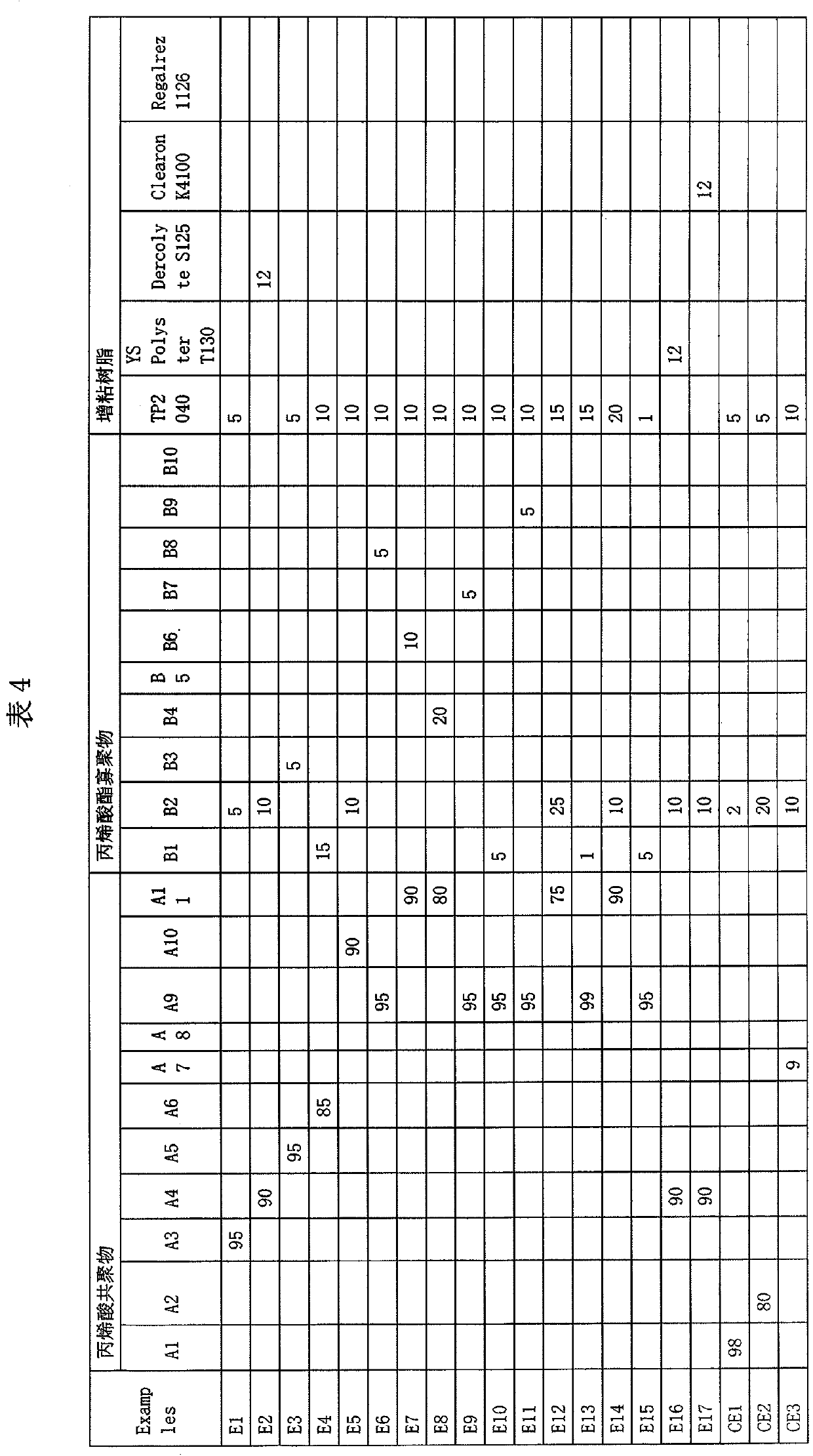

Pressure sensitive adhesive composition and product thereof

InactiveCN105505263APrevent slippingImprove arrangement tightnessMacromolecular adhesive additivesEster polymer adhesivesVitrificationOligomer

The invention relates to a pressure sensitive adhesive composition. The pressure sensitive adhesive composition comprises acrylate copolymer which is prepared from a first monomer mixture containing carboxyl-containing monomer and has side carboxy groups, wherein the content of the carboxyl-containing monomer ranges from, by weight, 0.1% to 10%, and provided that the total weight of the first monomer mixture which forms the acrylate copolymer having the side carboxy groups is 100%, the glass-transition temperature Tg of the acrylate copolymer having the side carboxy groups is equal to or greater than minus 55 DEG C and less than or equal to minus 30 DEGC. The pressure sensitive adhesive composition further comprises acrylate oligomer and terpenic tackifying resin, wherein the weight-average molecular weight of the acrylate oligomer is greater than or equal to 20, 000Da, the glass-transition temperature Tg of the acrylate oligomer is greater than or equal to 25 DEG C, and provided that the total weight of the acrylate copolymer having the side carboxy groups and the acrylate oligomer is 100%, the content of the acrylate oligomer ranges from 1%-25%, and the content of the terpenic tackifying resin ranges from 1% to 20%. The pressure sensitive adhesive composition achieves high peel strength at the room temperature and high cohesion at the high temperature simultaneously and excellent warping resistance and blistering resistance.

Owner:3M INNOVATIVE PROPERTIES CO

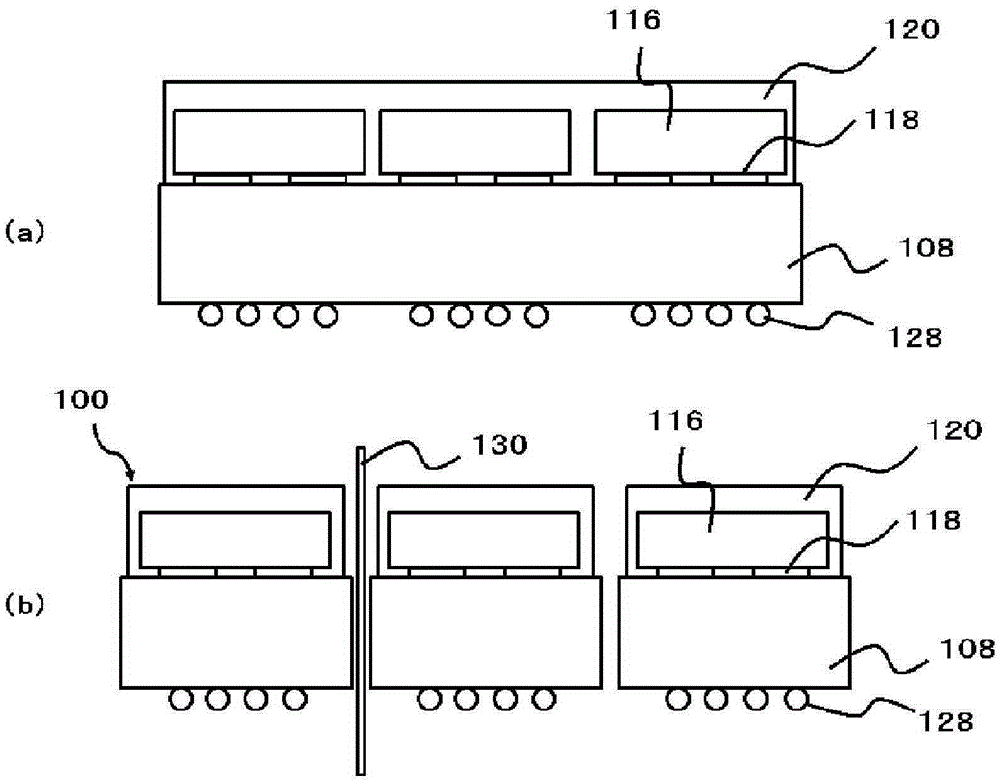

Process for producing semiconductor devices, and semiconductor device

InactiveCN105377980AImprove heat resistanceExcellent resistance to temperature cyclingEpoxySemiconductor chip

A process for semiconductor device production which comprises: a preparation step in which a substrate for element mounting (108) equipped with a plurality of package areas (114) separated by dicing regions (112) is prepared; a mounting step in which semiconductor chips (116) are mounted respectively on the package areas (114) of the substrate for element mounting (108); a molding step in which the semiconductor chips (116) are simultaneously encapsulated by molding with an encapsulating epoxy resin composition; and a chip formation step in which the resultant structure is diced along the dicing regions (112) to separate the individual encapsulated semiconductor chips (116). The encapsulating epoxy resin composition comprises (A) an epoxy resin, (B) a hardener, (C) a silicone resin, (D) an inorganic filler, and (E) a hardening accelerator, wherein the silicone resin (C) is a branched silicone resin that is a methylphenyl-type thermoplastic silicone resin and has repeating structural units represented by general formulae (a), (b), (c), and (d). (In the formulae, symbol * indicates a bond with the Si atom contained in a repeating structural unit of another or the same kind; and R1a, R1b, R1c, and R1d are each a methyl or phenyl group and may be the same as or different from one another. The content of Si-bonded phenyl groups is 50 mass% or higher of the molecule, and the content of Si-bonded OH groups is less than 0.5 mass% of the molecule.) The formulae is shown in the specification.

Owner:SUMITOMO BAKELITE CO LTD

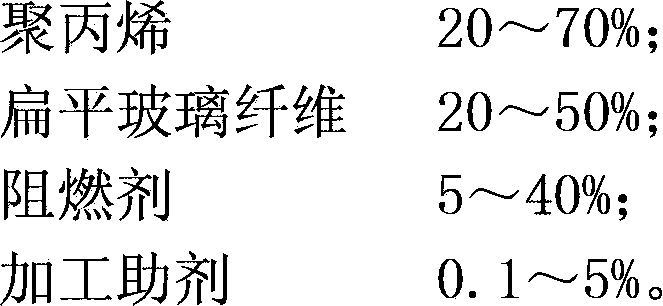

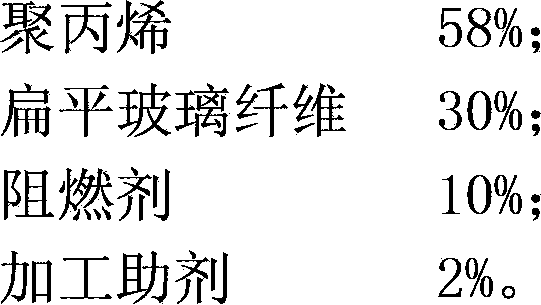

Glass fiber reinforced polypropylene resin and preparation method thereof

The invention relates to glass fiber reinforced polypropylene resin and a preparation method thereof. The resin comprises the following components by weight percent: 20%-70% of polypropylene, 20%-50% of flat glass fiber, 5%-40% of flame retardant and 0.1%-5% of processing agent. The preparation method comprises the following steps of: (a) drying polypropylene resin in an oven with a dehumidification drying machine at the temperature of 90-110 DEG C for 4-8 hours; (b) weighing the flame retardant and the processing agent and adding into a high-speed mixer for high-speed premixing; and (c) sequentially adding polypropylene in step (a), a mixture in step (b) and the weighed flat glass fiber into a double-screw extruder for pelletizing by melt extrusion.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

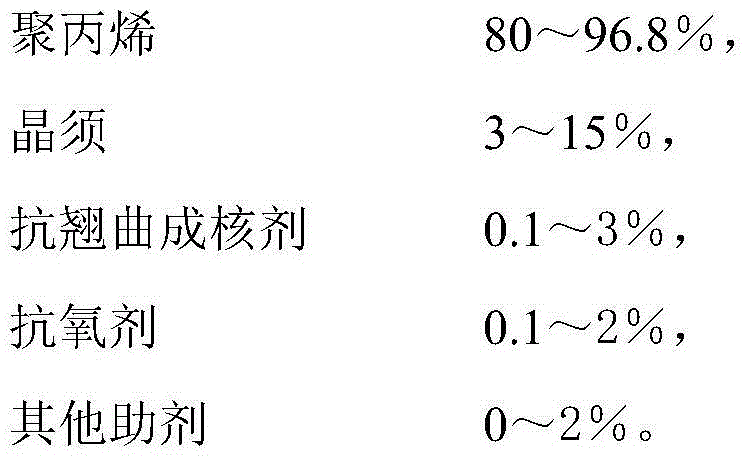

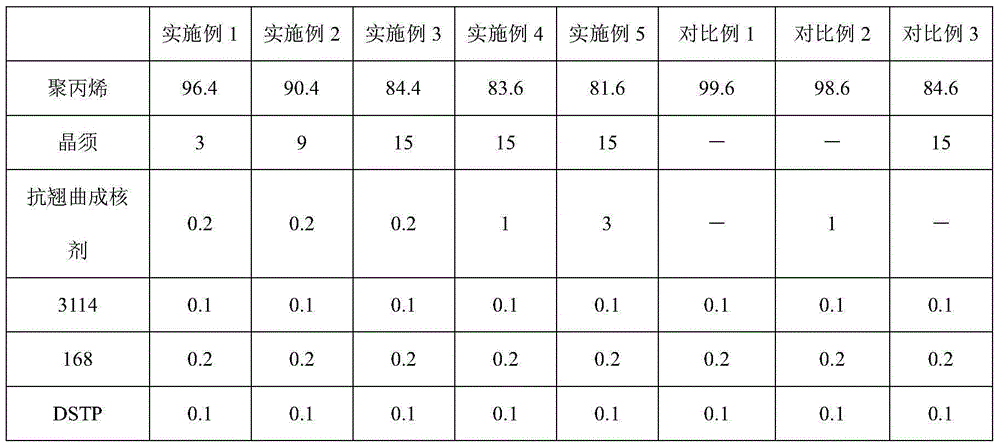

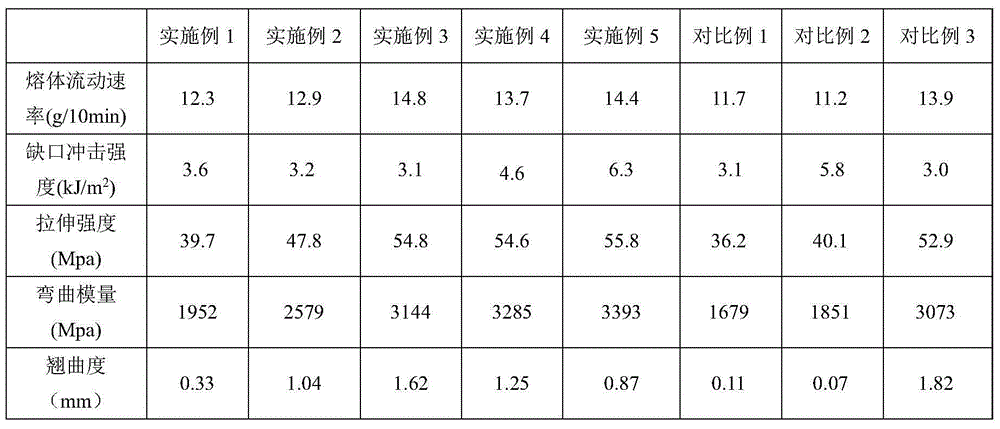

Low-warpage high-modulus modified polypropylene material and preparation method thereof

The invention discloses a low-warpage high-modulus modified polypropylene material and a preparation method thereof. The low-warpage high-modulus modified polypropylene material is prepared from the following raw materials in percentage by weight: 80-96.8 percent of polypropylene, 3-15 parts of a crystal whisker, 0.1-3 percent of an anti-warpage nucleating agent, 0.1-2 percent of an antioxidant and 0-2 percent of other auxiliaries. By the utilization of the anti-warpage property of the anti-warpage nucleating agent, the anti-warpage capability of a PP (Polypropylene) matrix is improved; the crystal whisker is combined with the anti-warpage nucleating agent to perform synergetic enhancement, and the prepared modified polypropylene material also solves the product warpage problem caused by the addition of the crystal whisker while the high rigidity of polypropylene is kept; meanwhile, the prepared material has good liquidity and can be used for preparing thin-walled, high-strength and high-modulus plastic products.

Owner:SHANGHAI PRET COMPOSITES +2

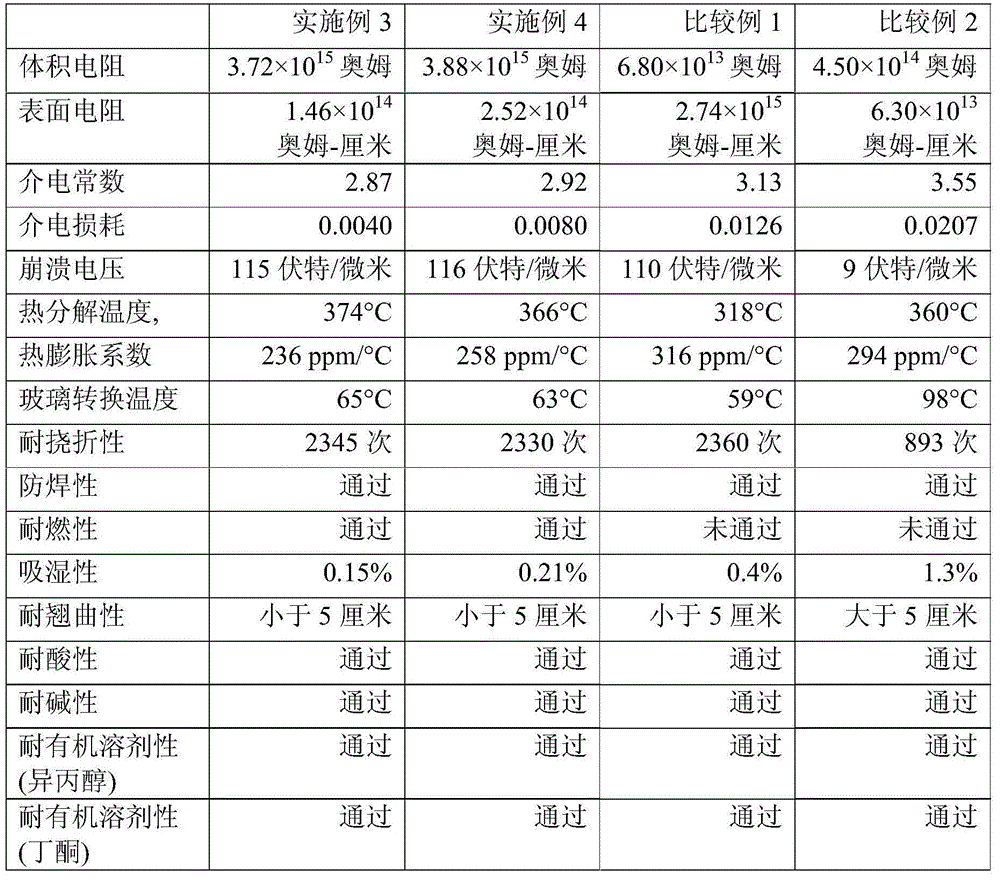

Thermosetting anti-welding printing ink with low dielectric constant and dielectric loss and preparation method of thermosetting anti-welding printing ink

The invention provides thermosetting anti-welding printing ink with low dielectric constant and dielectric loss and a preparation method of thermosetting anti-welding printing ink. The preparation method comprises the steps of reacting by virtue of long-carbon-chain aliphatic diamine monomers, aromatic diamine monomers with acid groups, aromatic dianhydride monomers with the acid groups and mono-anhydride monomers with the acid groups, cyclizing polyamide acid to obtain modified polyimide, and finally crosslinking modified polyimide with a hardening agent, so as to prepare the thermosetting anti-welding printing ink, wherein the dielectric constant of the thermosetting anti-welding printing ink is less than 3, the dielectric loss of the thermosetting anti-welding printing ink is less than 0.01, and the thermosetting anti-welding printing ink is applicable to high-frequency electronic equipment. Besides, tests show that the thermosetting anti-welding printing ink prepared by virtue of the preparation method has the characteristics of good electrical property, rupture resistance, welding resistance, warping resistance, flame resistance, acid resistance, alkali resistance and organic solvent resistance, low moisture rate and the like.

Owner:TAIFLEX SCI

Continuous fiber enhanced PEEK (Polyether-Ether-Ketone) resin and forming method thereof

The invention provides continuous fiber enhanced PEEK (Polyether-Ether-Ketone) resin and a forming method thereof, and belongs to the field of the forming method of PEEK resin, and solves the problemsof an existing fiber enhanced PEEK forming method that continuous fiber cannot be prepared, and the mechanical performance of a prepared product is poor. The forming method comprises the following steps: firstly, mixing a dispersing agent with PEEK ultrafine powder, and then putting and dispersing the mixture in a high-speed dispersing machine, thus obtaining a premix; secondly, putting and dispersing purified water, the premix and a suspending agent in the high-speed dispersing machine, thus obtaining a dispersing solution; finally, putting the dispersing solution in an impregnating tank provided with ultrasonic dispersion, enabling the continuous fiber to pass through the impregnating tank, dispersing the continuous fiber under the action of ultrasonic waves, then extruding residual suspending solution through a smooth pair roller, drying, melting and rolling, thus obtaining the continuous fiber enhanced PEEK resin. The invention also provides the continuous fiber enhanced PEEK resin obtained through the forming method. The continuous fiber enhanced PEEK resin prepared through the forming method has excellent mechanical performance and excellent warping resistance.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

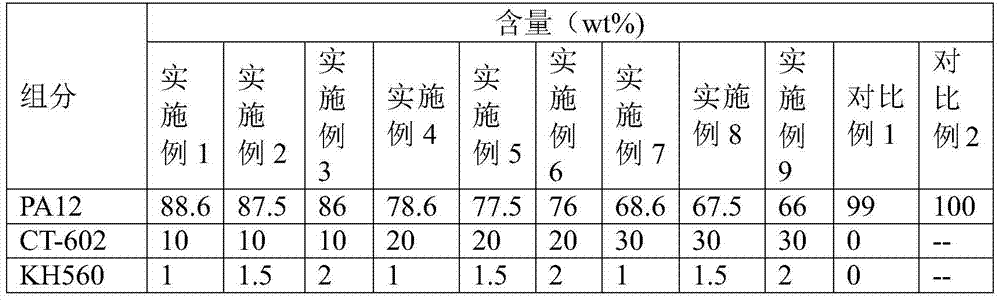

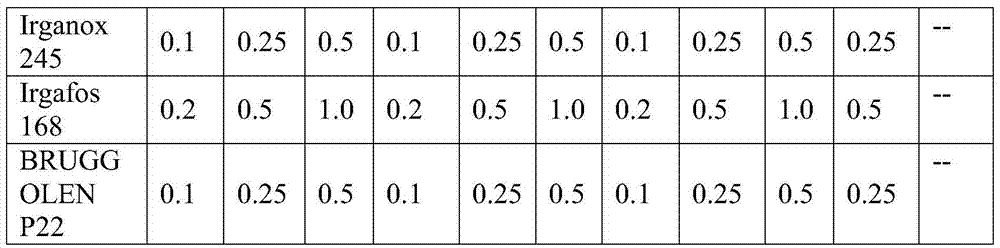

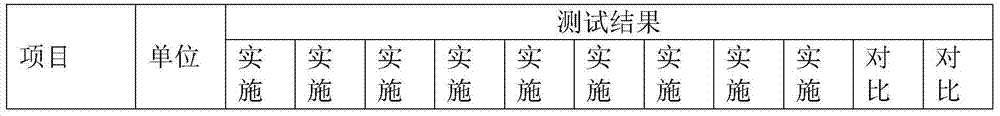

A kind of low-warpage nylon powder composite material for 3D printing and its preparation method

ActiveCN104910614BGood dimensional stabilityImprove warpage resistanceAdditive manufacturing apparatusNylon 66Phenol

The invention discloses a low-warpage nylon powder composite material for 3D printing and a preparation method thereof. The low-warpage nylon powder composite material is characterized by consisting of the following raw materials in percentage by weight: 66-88.6% of nylon, 10-30% of micron-order inorganic filler, 1-2% of coupling agent, 0.1-0.5% of hindered phenol antioxidant, 0.2-1.0% of phosphite antioxidant and 0.1-0.5% of other aids, wherein the other aids refer to one or a combination of more of a dispersing agent, a nucleating agent and a lubricating agent. In the invention, by combining the micron-order inorganic filler, coupling agent, hindered phenol antioxidant and phosphite antioxidant, the low-warpage nylon powder composite material for 3D printing, prepared by spray drying, has excellent warpage resistance and good bonding property; the distribution of spherical particles is narrow, the fluidity is good, and the problem of layered powder drop is avoided; and moreover, the preparation efficiency is high, the energy consumption is low, and the material is simple and easy to process.

Owner:QINGDAO UNIV OF SCI & TECH +2

Flame-retardant glass fiber reinforced polyethylene terephthalate (PET)/ polytrimethylene terephthalate (PTT)/ polybutylene terephthalate (PBT) alloy material and preparation method thereof

The invention relates to a flame-retardant glass fiber reinforced polyethylene terephthalate (PET) / polytrimethylene terephthalate (PTT) / polybutylene terephthalate (PBT) alloy material and a preparation method thereof. The alloy material comprises the following raw materials in part by weight: 10 to 30 parts of PET, 10 to 30 parts of PTT, 20 to 40 parts of PBT, 3 to 10 parts of compatilizer, 5 to 20 parts of composite flame retardant, 0.1 to 0.5 part of antioxidant, 0.1 to 0.5 part of lubricating agent, and 10 to 30 parts of glass fibers. The preparation method comprises the following steps of: putting all the raw materials into an efficient mixer, mixing the raw materials for 5 to 10 minutes, and then discharging the uniformly mixed raw materials; and putting the uniformly mixed raw materials into a screw extruder, and performing extrusion and water cooling granulation. The produced PET / PTT / PBT alloy has the characteristics of excellent flame-retardant performance, high crystallization speed, good comprehensive physical and mechanical performance, low shrinkage rate, stable size, low warping, high surface glossiness, excellent processing performance and the like, and can be used for replacing a flame-retardant reinforced PBT material or bakelite under certain occasions.

Owner:SHANGHAI SUNNY

IC package with a protective encapsulant and a stiffening encapsulant

InactiveUS7675186B2Large Young 's modulusImprove warpage resistanceSemiconductor/solid-state device detailsSolid-state devicesYoung's modulusEngineering

An IC package mainly includes a substrate having slot(s), a chip, a protective encapsulant, a stiffening encapsulant, and a plurality of external terminals. The Young's modulus of the stiffening encapsulant is greater than the one of the protective encapsulant and the curing shrinkage of the stiffening encapsulant is smaller than the one of the protective encapsulant. The protective encapsulant is formed on one of the surfaces of the substrate for encapsulating the chip. The stiffening encapsulant protrudes from the other surface of the substrate where the external terminals are disposed. Moreover, the stiffening encapsulant is formed inside the slot and is contacted with the chip. Since the stiffening encapsulant is embedded and formed inside the slot, therefore, the contact area of the stiffening encapsulant with the substrate is increased to enhance the warpage resistance of the IC package.

Owner:POWERTECH TECHNOLOGY INC

Cement-based polystyrene material and insulation board production process based thereon

InactiveCN104119046AMeet fire resistance requirementsImprove fire resistancePolymer scienceThermal insulation

The invention discloses a cement-based polystyrene material, which comprises the following components: (1) according to a dry powder ratio (by mass percentage): 65-85 of portland cement; 10-25 of fly ash; 0.15-0.25 of polypropylene fiber; 0.2-0.4 of a concrete admixture; and 0.15-0.25 of an emulsion; and (2) the volume ratio of the dry powder to expanded polystyrene particles being 1:4-1:6. The production process for preparation of a composite insulation board based on the cement-based polystyrene material includes the steps of proportioning, stirring, molding transportation, curing and molding packaging, and a final product can be obtained thereby. The composite insulation board obtained on the basis of the formula and the preparation process has the advantages of high fire resistance, high thermal insulation, high strength, light weight, high bonding strength, and no toxicity or harm, etc.

Owner:江苏省苏安能节能建材科技有限公司

Composed element and corner connection applied herewith

InactiveUS10104960B2Reduce riskImprove warpage resistanceDismountable cabinetsFurniture joiningMiter jointSplit tongue

Composed element, with at least two wood-based panel-shaped elements; wherein said panel-shaped elements can be coupled to each other at an angle and with a miter joint by means of a locking tongue and groove connection; wherein the tongue consists of a split tongue, with thus at least a first tongue portion and a second tongue portion, as well as a slit situated there between; characterized in that said slit, seen in cross-section, globally extends according to a direction which deviates from the direction of the center line of the panel-shaped element on which the tongue is provided.

Owner:UNILIN BVBA

Adhesive Composition, Adhesive And Adhesive Sheet

ActiveCN104250536AImprove warpage resistanceIncreased durabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The present invention provides an adhesive composition, an adhesive and an adhesive sheet, which do not influence the adhered objects, such as the transparent conductive film, etc., at the same time, are excellent in durability and light leakage resistance, and are excellent in buckling resistance of a laminator containing an adhesive layer. and In order to solve the above subject, the adhesive composition which contains a (methyl) acrylate polymer (A), an isocyanate class cross-linking agent (B) and a silane coupling agent possessing sulfydryl (C) is provided, and the weight-average molecular weight of the above (methyl) acrylate polymer (A) is 1.4-2.5 millions. A monomeric unit as the polymer contains a monomer possessing the hydroxy, a monomer possessing the aromatic nucleus and a monomer possessing the carboxyl. The (methyl) acrylate polymer (A) as the monomeric unit of the polymer, contains 5-30% by mass of the monomer possessing the aromatic nucleus, and 0.1-0.8 % by mass of the monomer possessing the carboxyl.

Owner:LINTEC CORP

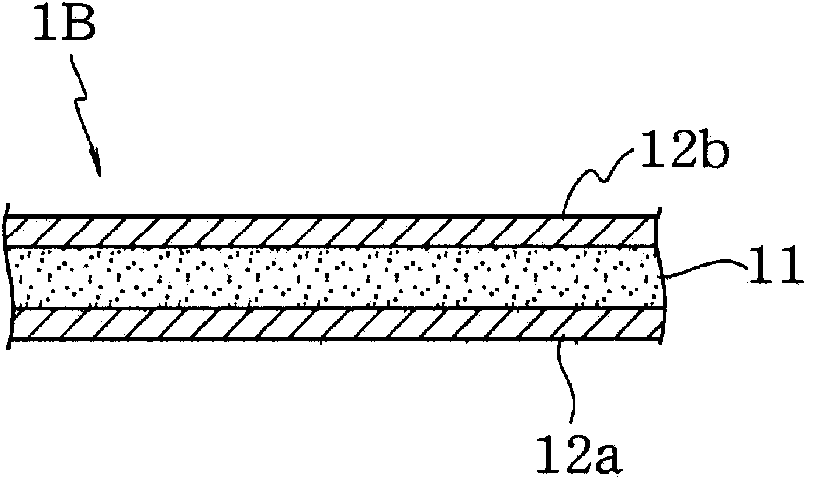

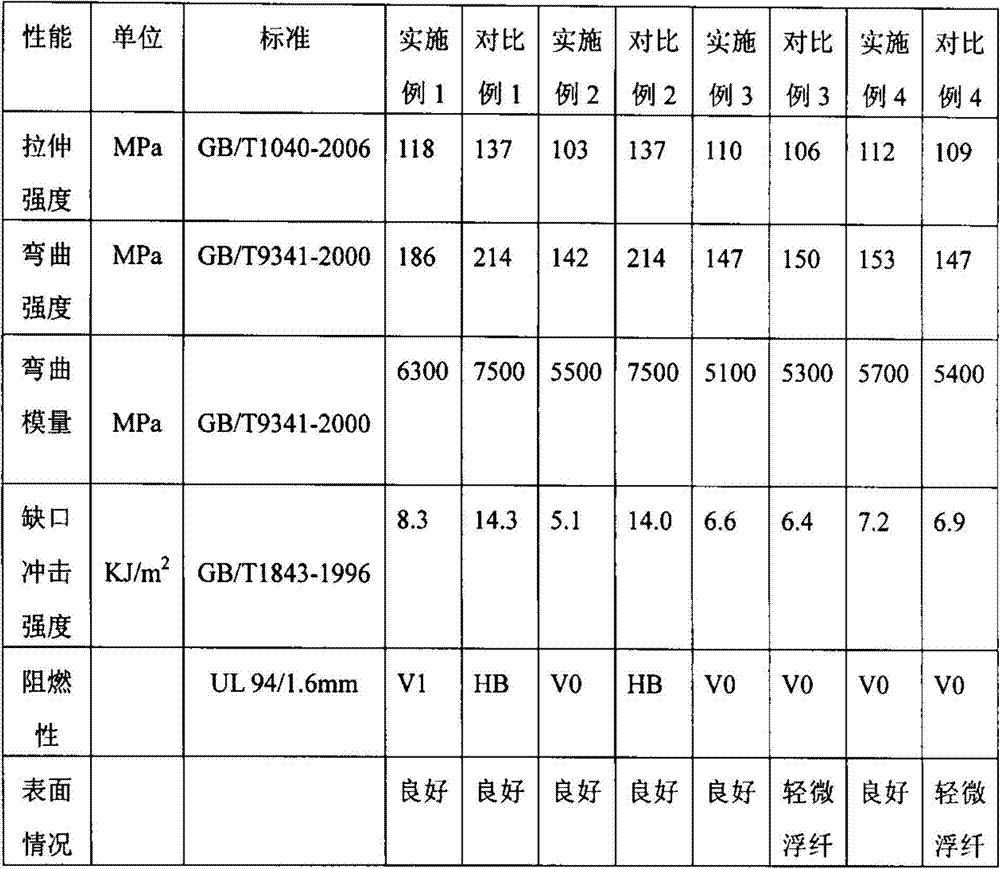

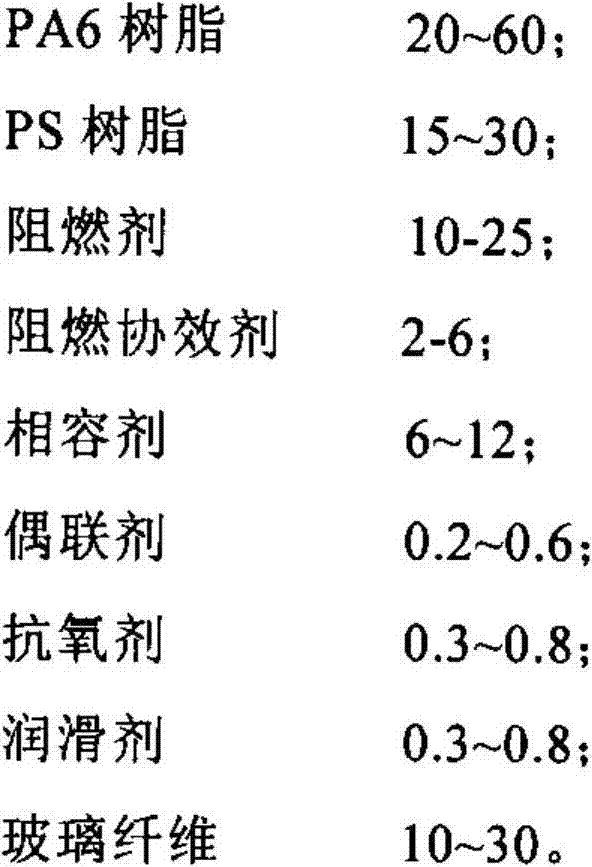

Glass fiber reinforced halogen-free flame-retardant PA6 (Poly Amide 6)/PS (Poly Styrene) alloy material and preparation method thereof

InactiveCN103694695AImprove mechanical propertiesImprove flame retardant performanceGlass fiberAlloy

The invention relates to a glass fiber reinforced halogen-free flame-retardant PA6 (Poly Amide 6) / PS (Poly Styrene) alloy material and a preparation method thereof. The PA6 / PS alloy material is prepared from the following raw materials in parts by weight: 20 to 60 parts of PA6 resin, 15 to 30 parts of PS resin, 10 to 25 parts of flame retardant, 2 to 6 parts of flame retardant synergist, 6 to 12 parts of compatilizer, 0.2 to 0.6 part of coupling reagent, 0.3 to 0.8 part of antioxidant, 0.3 to 0.8 part of lubricant and 10 to 30 parts of glass fibers. Compared with the prior art, the PA6 / PS alloy material provided by the invention has the characteristics of good comprehensive mechanical performance, good flame retardance, stable size, low warping, oil resistance, high-temperature resistance, excellent machining performance and the like. Thus, the PA6 / PS alloy material can be conveniently applied to the fields of electric appliances, automobiles, mining machinery and the like.

Owner:SHANGHAI SUNNY

Rotomolding process with reduced cycle times

ActiveUS7201864B2Improve impact resistanceResistant to warpageWood working apparatusCeramic shaping apparatusVolumetric Mass DensityLow density

Owner:NOVA CHEM (INT) SA

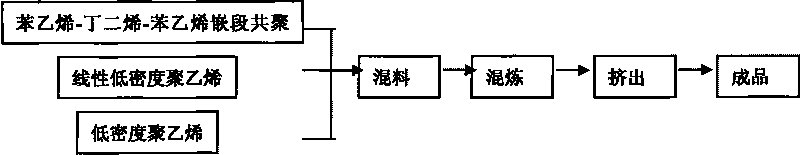

Sealing material and application thereof

InactiveCN101701144AIncrease elasticityHigh strengthOther chemical processesSealingLow-density polyethyleneLinear low-density polyethylene

The invention discloses sealing material and carbonated beverage bottle cap sealing gasket produced from the same. The sealing material comprises the following components by weight percent: 30-70 percent of styrene-butadiene-styrene block copolymer and 30-70 percent of the polyolefin resin, wherein the polyolefin resin is prepared by mixing low-density polyethylene and linear low-density polyethylene which are at the mass ratio of 5-13:1. The sealing material is poisonless and tasteless, has good sealing performance, good resilience and good adhesiveness. The carbonated beverage bottle cap sealing gasket is produced with the high-productivity injecting and molding process, has excellent sealing performance, low cost and no peculiar smell, can meet the corresponding food safety requirement and is particularly suitable for the rapid and massive flow-line production. The production process of the invention involves no adhering process and no adhesive, thereby causing no chemical pollution and meeting the environmental protection requirement.

Owner:SOUTH CHINA UNIV OF TECH

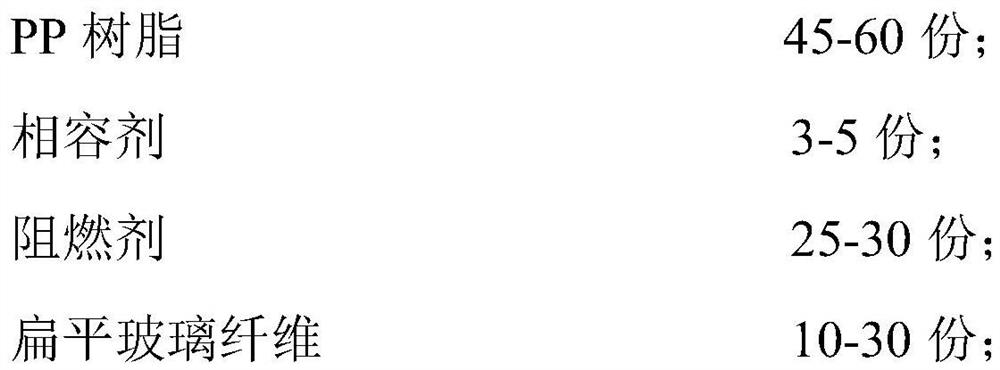

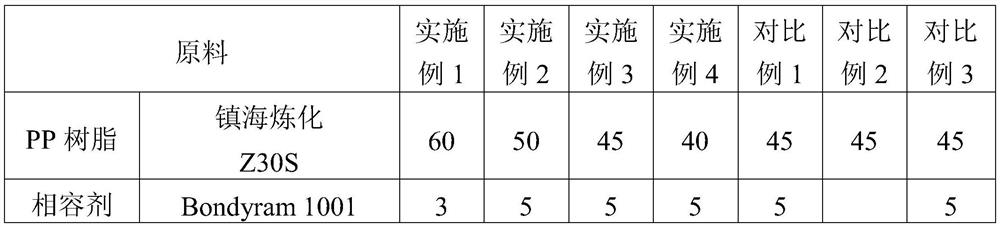

Flat glass fiber reinforced flame-retardant PP composite material and preparation method thereof

The invention belongs to the field of high polymer material processing, and discloses a flat glass fiber reinforced flame-retardant PP composite material and a preparation method thereof. The flat glass fiber reinforced flame-retardant PP composite material is prepared from the following components in parts by weight: 45-60 parts of PP resin, 3-5 parts of compatilizer; 10-30 parts of flat glass fiber, 3-7 parts of glass flakes, 25-30 parts of flame retardant, 0.1-0.5 part of antioxidant and 0.1-0.5 part of lubricant, wherein the flat glass fiber is microcosmic flat E glass fiber, the width ofthe flat glass fiber is 20-30 [mu] m, the thickness of the flat glass fiber is 4-10 [mu] m, and the length of the flat glass fiber is 2500-3000 [mu] m. According to the composite material, PP resin isused as a base material, and flat glass fiber reinforced matrix resin is selected so that the composite material has very good physical rigidity and warping resistance.

Owner:横店集团得邦工程塑料有限公司

Low-warpage, damp-heat-aging-resistance high-pressure-resistant flame-retardant polyester material and preparation method

InactiveCN112852125AImprove flatnessImprove warpage resistancePolytetramethylene terephthalateGlass fiber

The invention discloses a low-warpage damp-heat-aging-resistant high-pressure-resistant flame-retardant polyester material and a preparation method. The material mainly comprises the following components: polybutylene terephthalate resin, a main flame retardant, an auxiliary flame retardant, a filler or other resins, glass fibers, a flexibilizer, a composite antioxidant, a stabilizer and other auxiliaries. The prepared low-warpage damp-heat aging resistant halogen-free flame-retardant polyester material is high in dimensional stability in the use process, high in retention rate of various mechanical properties under long-term high-temperature and high-humidity conditions and excellent in electrical property, mainly meets the requirements of high-pressure-resistant parts under severe environmental conditions in the fields of electronic and electrical products and new energy automobiles, such as a plug for charging, peripheral parts of a high-voltage battery, a leakage protector, a junction box and the like.

Owner:NANTONG DONGFANG PLASTIC CO LTD

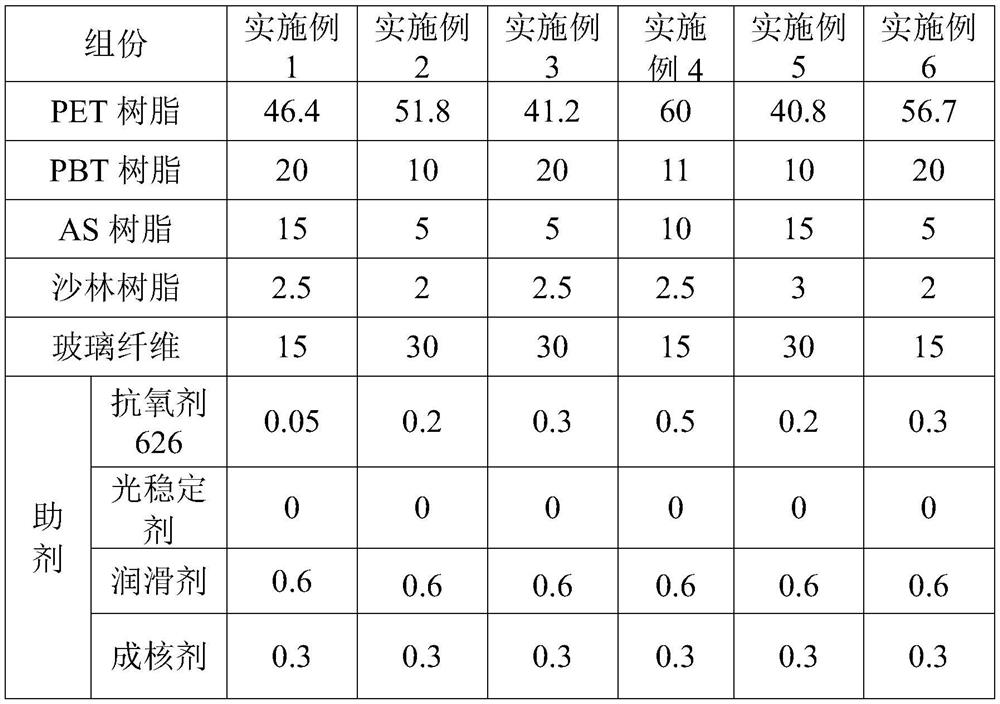

Low-warpage PET/PBT composite material and preparation method thereof

The invention provides a low-warpage PET / PBT composite material. The composition is prepared from the following raw materials in parts by weight: 40-60 parts of PET resin, 10-20 parts of PBT resin, 5-15 parts of AS resin and 10-40 parts of glass fiber. According to the low-warpage PET / PBT composite material disclosed by the invention, the PBT resin and the AS resin are added into the components, so that the warpage degree of the composite material can be greatly reduced, and the formability, heat resistance and yellowing resistance of the composite material are improved.

Owner:TIANJIN KINGFA NEW MATERIAL

Glass fiber reinforced polypropylene composite material and preparation method thereof

The present invention discloses a glass fiber reinforced polypropylene composite material. The glass fiber reinforced polypropylene composite material consists of the following raw materials: polypropylene, long glass fiber, an antioxidant, flat glass fiber, epoxy resin, silica sol, graphene, tungsten carbide, an auxiliary agent and an appropriate amount of water. The present invention also discloses a preparation method of the glass fiber reinforced polypropylene composite material. The glass fiber reinforced polypropylene composite material overcomes a warpage problem of components due to glass fiber orientation in a production process of long glass fiber reinforced polypropylene. A modification method for improving the fluidity and the warpage resistance of the polypropylene is provided. The modified polypropylene material with excellent fluidity, compatibility, rigidity and toughness is prepared. At the same time, the modified polypropylene material also has excellent wear resistance and toughness.

Owner:合肥岑遥新材料科技有限公司

Low-temperature resistant buckle-against toughening nylon alloy and preparation method thereof

The invention provides a nylon alloy, comprising 50 to 80 percent of matrix nylon and 20 to 50 percent of modifying composition, wherein, the percentage is calculated according to the total weight of the nylon alloy, the matrix nylon is prepared by the lactam monomer anionic ring-opening polymerization, the number average molecular weight of the matrix nylon is between 10,000 and 80,000, the lactam monomer is chosen from urolactam or a mixture of an urolactam monomer and other urolactam monomers; the weight percentage of other urolactam monomers in the urolactam monomer is less than or equal to 50; the modifying composition is chosen from a polymer with an active functional group and / or a polymer with a lateral chain ester group, the number average molecular weight of the polymer is between 10,000 and 4x10<5>; the flexural modulus of the nylon alloy is between 500 and 1,000MPa; moreover, the socle beam nick impact strength at a temperature of 40 DEG C below zero is more than or equal to 200J / m. The nylon alloy has good impact strength and warp resistance at a low temperature.

Owner:宁波帕斯卡新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com