Packaging material provided with cushioning members

a technology of cushioning and packaging material, which is applied in the field of packaging materials, can solve the problems of box collapse, box durability decline, and easy damage to electrical equipment, and achieve the effects of improving the reliability of transportation of products, and ensuring the safety of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

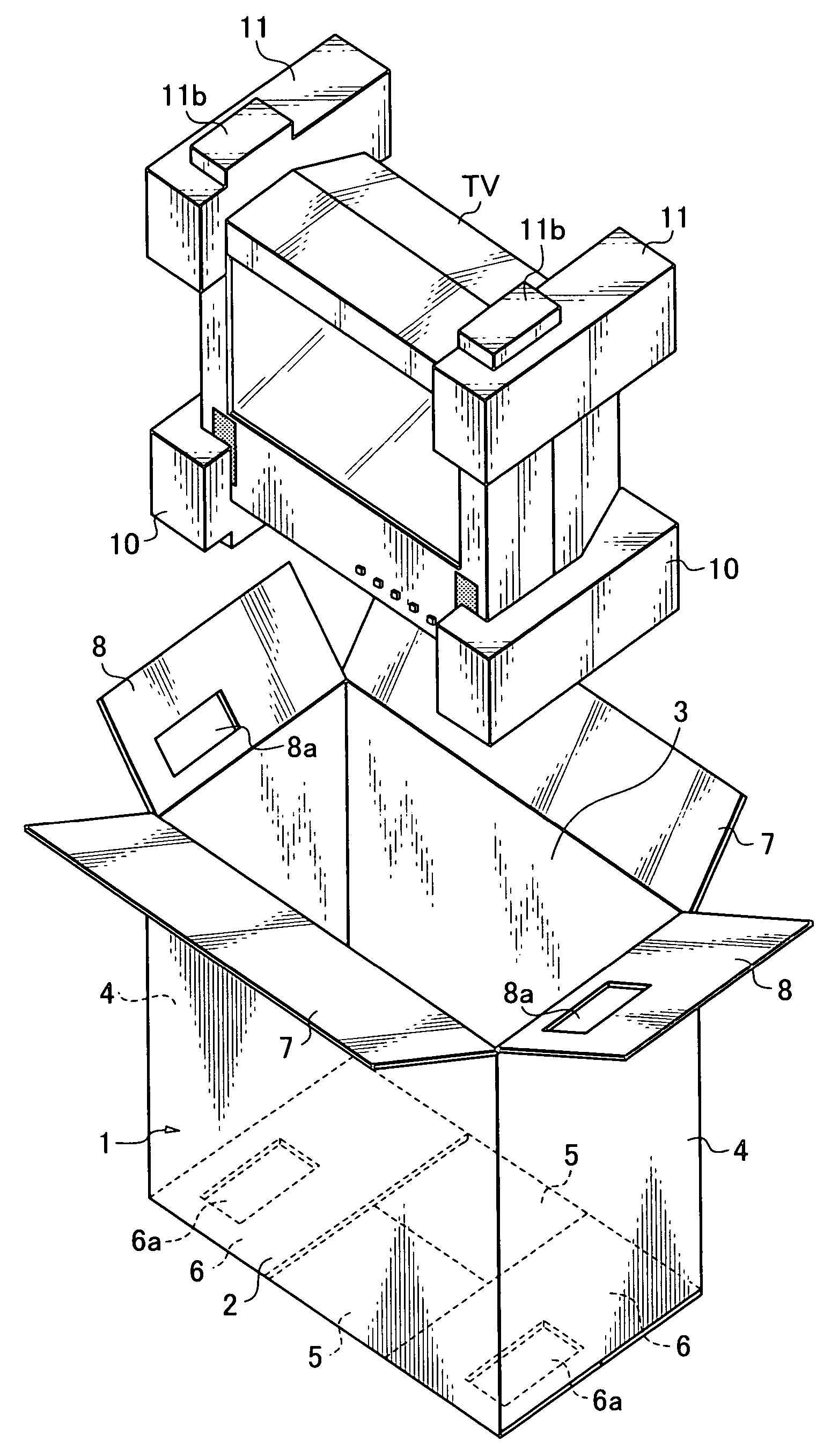

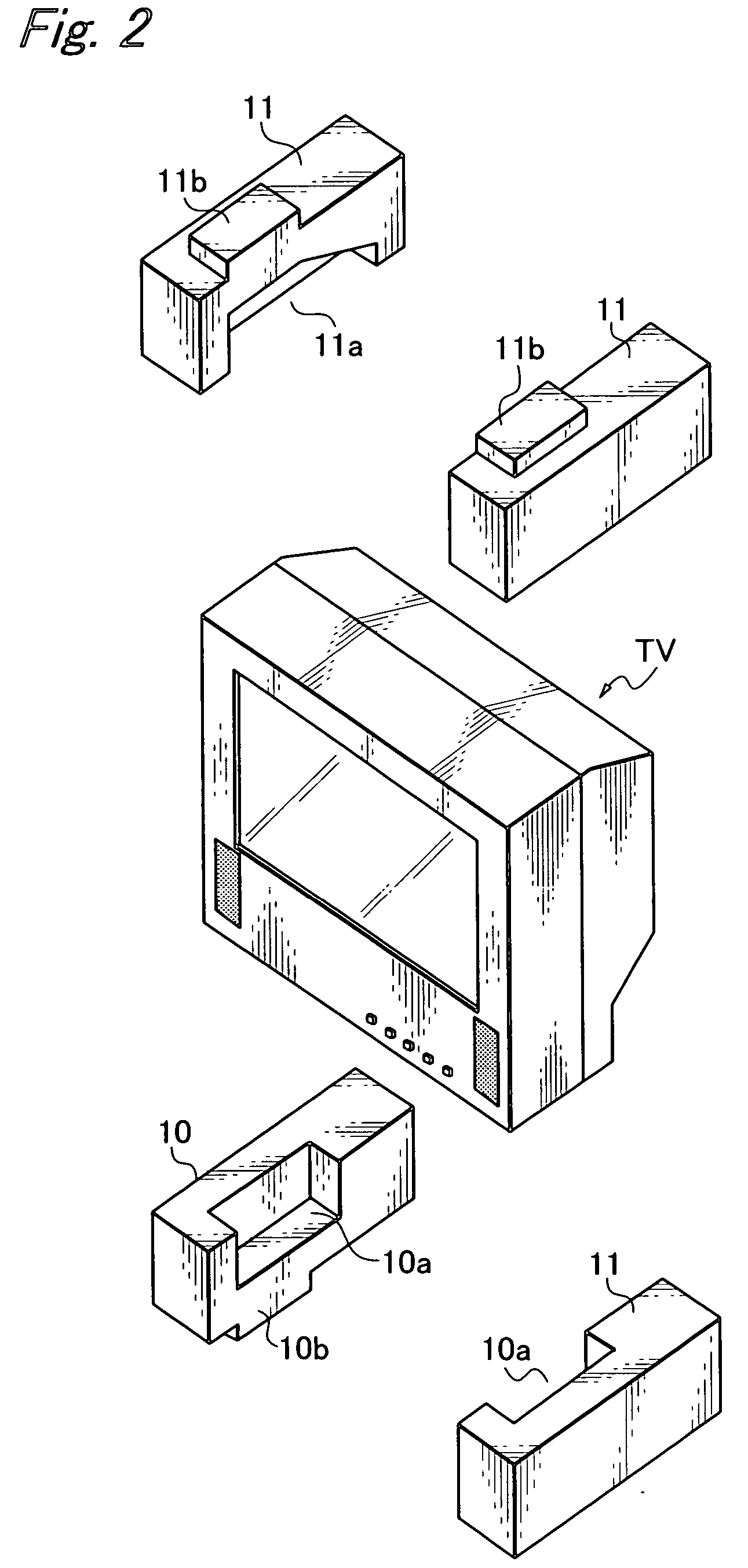

[0030] FIGS. 1 to 8 show the packaging material according to the present invention, which includes a packaging box 1 made of a corrugated board, and cushioning members 10, 10 and 11, 11 made of expanded polystyrene, and which is formed so as to package a television set TV. The packaging box 1 is formed rectangular of a front panel 2 constituting a front wall, a rear panel 3, left and right side panels 4, 4, bottom side front and rear outer flaps 5, 5 constituting a bottom panel, bottom side left and right inner flaps 6, 6, cover side front and rear outer flaps 7, 7 and cover side left and right inner flaps 8, 8. The bottom side left and right inner flaps 6, 6 and cover side left and right inner flaps 8, 8 are provided with through holes 6a, 6a, 8a, 8a in which parts of the cushioning members are fitted. After the bottom side left and right inner flaps 6, 6 are folded, the bottom side front and rear outer flaps 5, 5 are folded to form the bottom panel. Therefore, the through holes 6a...

second embodiment

[0038] FIGS. 9 to 10 show the packaging material according to the present invention, which includes a packaging box 20 of corrugated board, and cushioning members 30, 30 of expanded polystyrene, and which is formed for packaging a disk apparatus DR The packaging box 20 is formed to a shape substantially similar to that of the rectangular disk apparatus DP, and a bottom panel and a cover panel have bottom side left and right inner flaps 21, 21 and outer flaps 22, 22, and cover side left and right inner flaps 23, 23 and outer flaps 24, 24. The bottom side and cover side inner flaps 21, 23 are provided with through holes 21a, 23a respectively.

[0039] The cushioning members 30, 30 are formed symmetrically, and provided in inner surfaces thereof with recesses 30a, 30a in which left and right portions of the disk apparatus DP are fitted. Each cushioning member 30 is provided on the portion of an upper surface thereof which corresponds to the through hole 23a of the inner flap 23 with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com