Solid bleached sulphate (SBS) coating white cardboard and process for producing the same

A production process and technology for white cardboard, applied in the field of papermaking, can solve the problems of easy failure of anti-counterfeiting measures, high cost, and inability to popularize and implement, and achieve the effects of improving uniformity and surface performance, improving printability and inking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

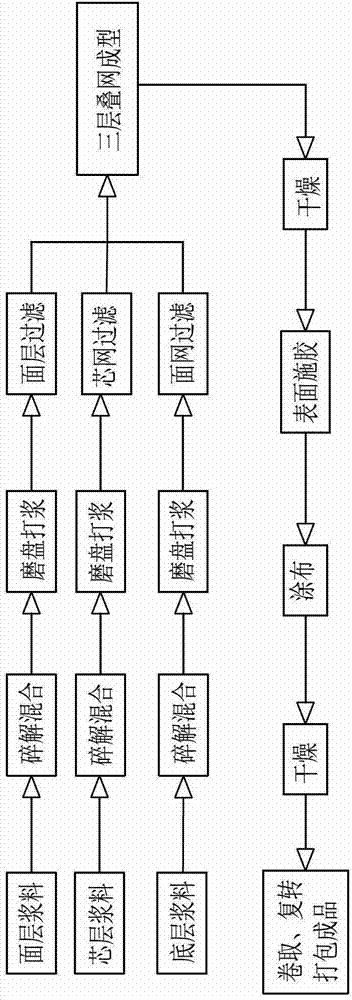

[0034] Surface pulp: wood pulp (weight percentage: bleached hardwood kraft pulp 70%, bleached softwood kraft pulp 30%), crushed and mixed by a pulper, refined by a disc refiner, and entered into the surface of the paper machine net filter;

[0035] Core layer pulp: wood pulp (weight percentage: bleached hardwood kraft pulp 50%, bleached softwood kraft pulp 25%, broken paper 25%), crushed and mixed by a pulper, refined by a disc refiner , enter the paper machine core mesh to filter;

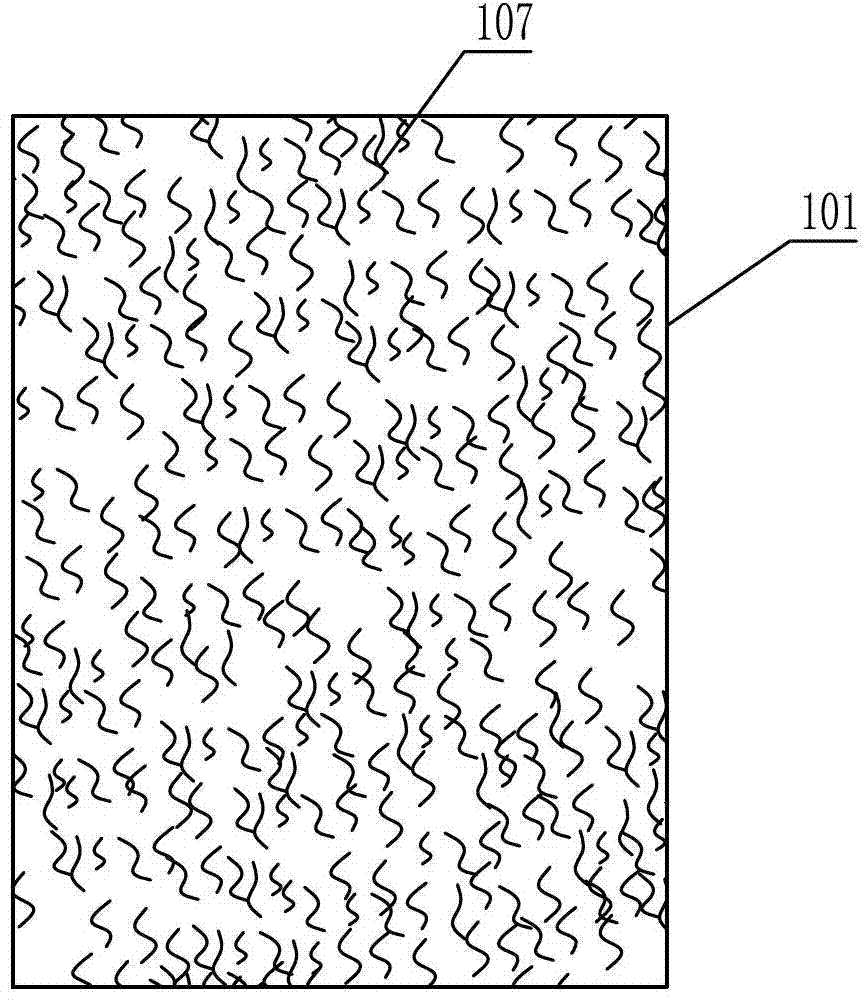

[0036] Bottom pulp: wood pulp (weight percentage: 5% natural fiber, 85% bleached hardwood kraft pulp, 10% bleached softwood kraft pulp), crushed and mixed by a pulper, refined by a disc refiner, Enter the paper machine face mesh for filtration;

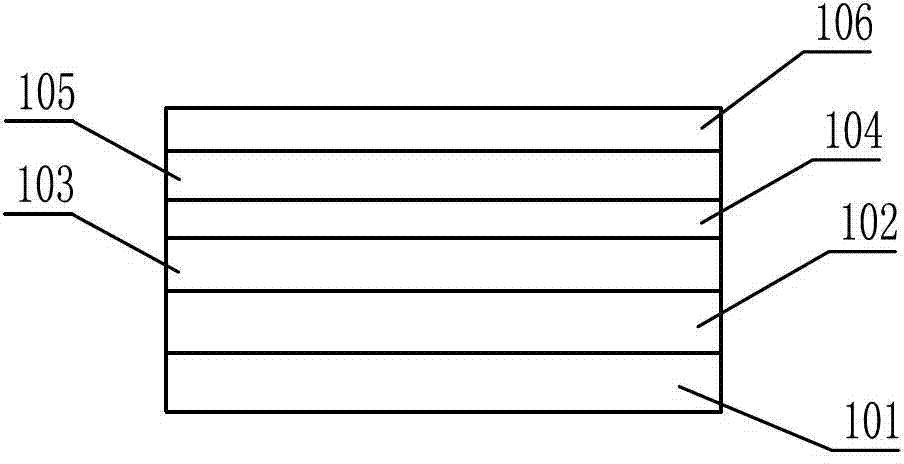

[0037] Then, through the three-layer web forming of the paper machine, a wet paper sheet with a surface layer 103, a core layer 102 and a bottom layer 101 distributed with natural fibers is produced. After coating and drying, it enters the coiling sect...

Embodiment 2

[0046] The production process of this embodiment is the same as that of the above-mentioned embodiment 1, the difference lies in: the slurry ratio of the surface layer slurry, the core layer slurry, and the bottom layer slurry, and the coating ratio of the pre-coating and core coating.

[0047] Surface pulp (percentage by weight): bleached hardwood kraft pulp 85%, bleached softwood kraft pulp 15%;

[0048] Core layer pulp (weight percentage): bleached hardwood kraft pulp 53%, bleached softwood kraft pulp 17%, broken paper 30%;

[0049] Bottom pulp (weight percent): natural fiber 8%, bleached hardwood kraft pulp 72%, bleached softwood kraft pulp 20%;

[0050] The coating ratio of precoating and core coating is (parts by weight): 100 parts of calcium carbonate, 8 parts of latex, 3 parts of soybean protein, 0.4 parts of carboxymethyl cellulose, 0.09 parts of dispersant, 0.8 parts of water repellent, lubricating 0.3-1.2 parts of antifoaming agent and 0.035 parts of antifoaming ag...

Embodiment 3

[0056] Surface pulp (percentage by weight): bleached hardwood kraft pulp 90%, bleached softwood kraft pulp 10%;

[0057] Core pulp (weight percent): 55% bleached hardwood kraft pulp, 5% bleached softwood kraft pulp, 40% broken paper;

[0058] Bottom pulp (weight percent): natural fiber 10%, bleached hardwood kraft pulp 60%, bleached softwood kraft pulp 30%;

[0059] The coating ratio of pre-coating and core coating is (parts by weight): 100 parts of calcium carbonate, 10 parts of latex, 1.0 parts of soybean protein, 0.6 parts of carboxymethyl cellulose, 0.12 parts of dispersant, 1.0 parts of water-resistant agent, lubricating 1.2 parts of agent, 0.035 parts of defoamer.

[0060] The coating amounts of the precoat layer 104, the core coat layer 105, and the top coat layer 106 were applied at 10 g / m2, 12 g / m2, and 12 g / m2, respectively.

[0061] The produced SBS coated white cardboard is compared with FBB ordinary white cardboard of the same grammage on the market, and its phy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com