Package and process for producing same

a technology of packaging and process, applied in the field of packaging, can solve the problems of increasing cost, complicated structure, and adhesion layer, and achieve the effects of simple production process, reduced cost, and simplified structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

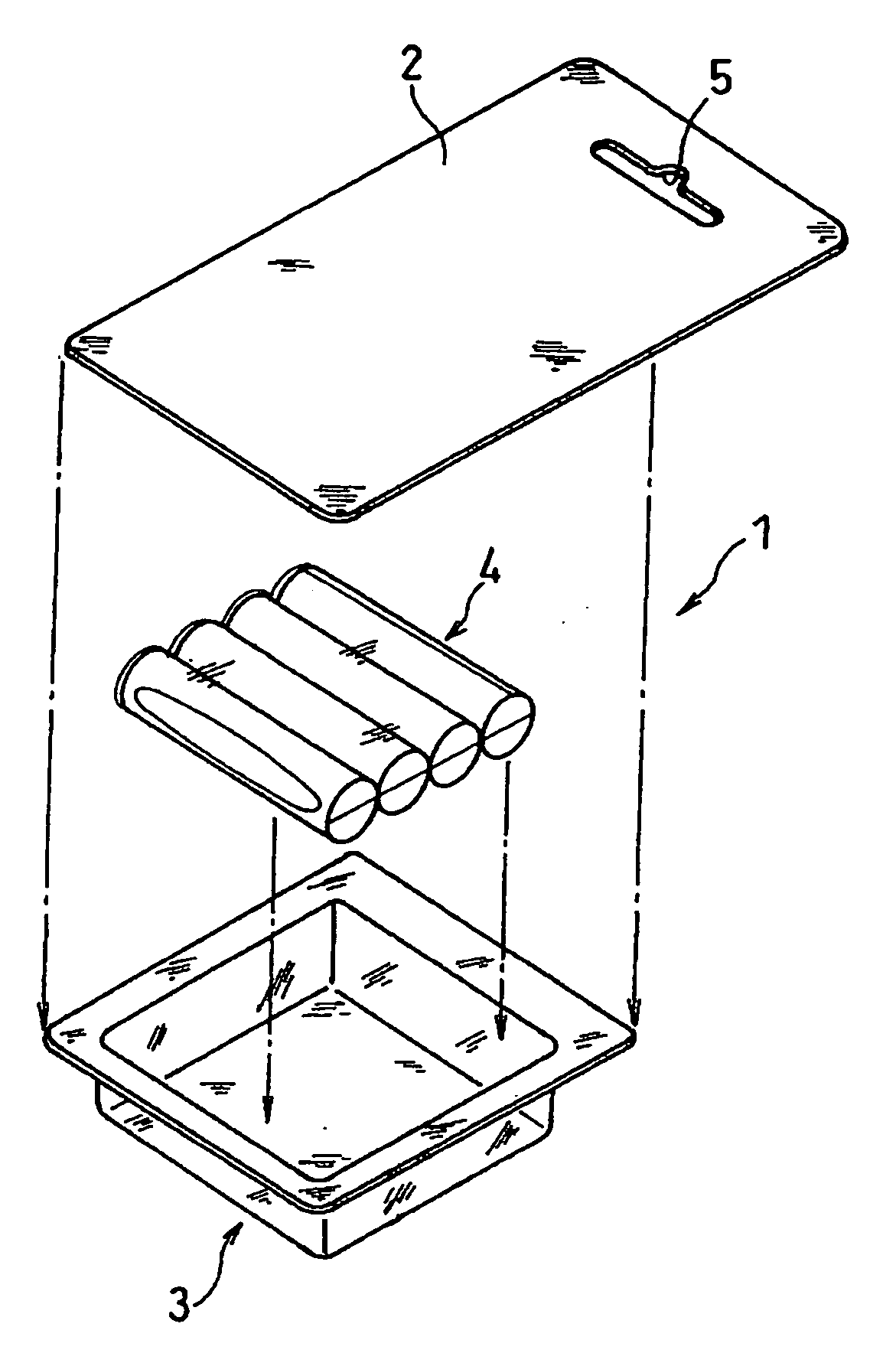

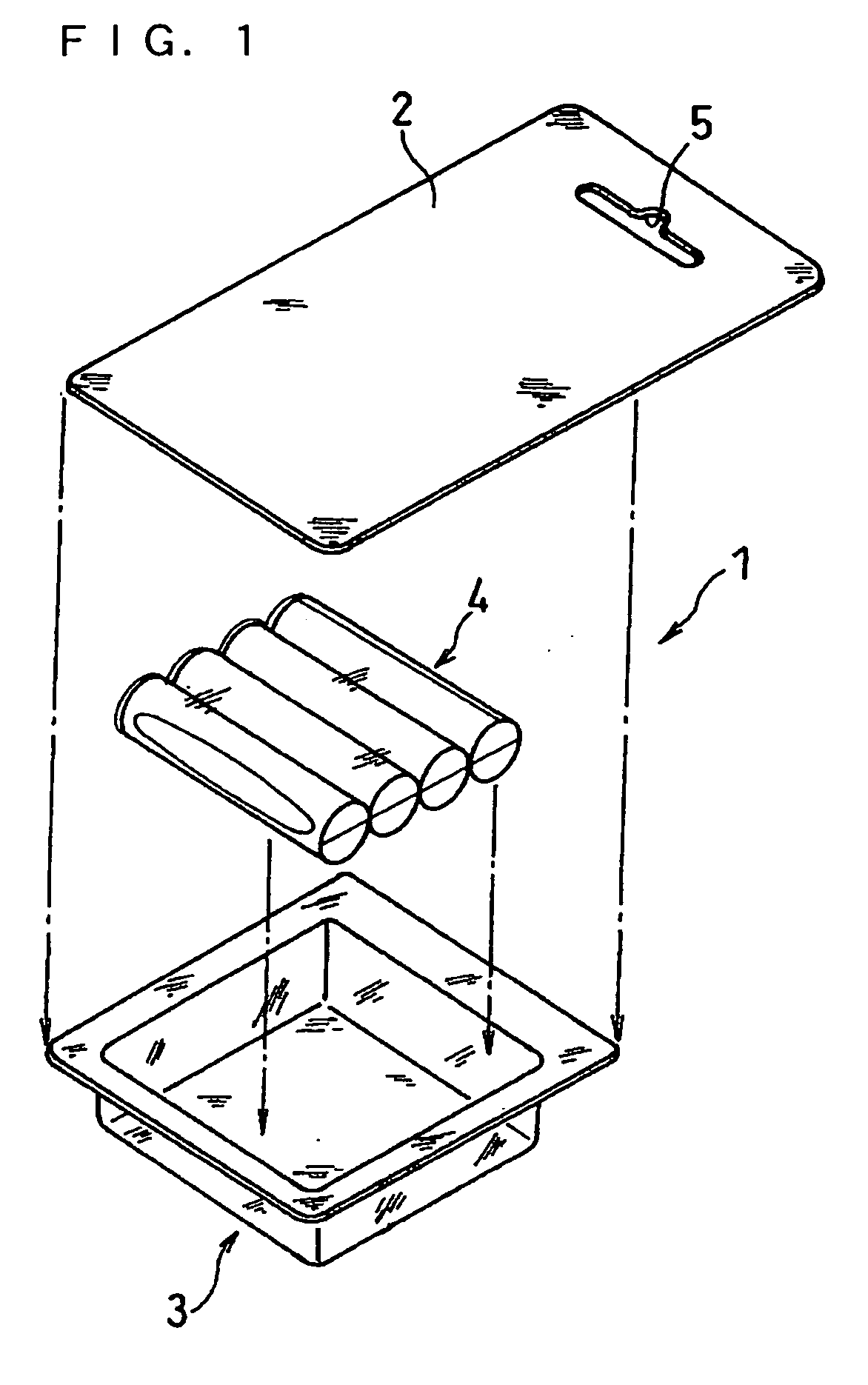

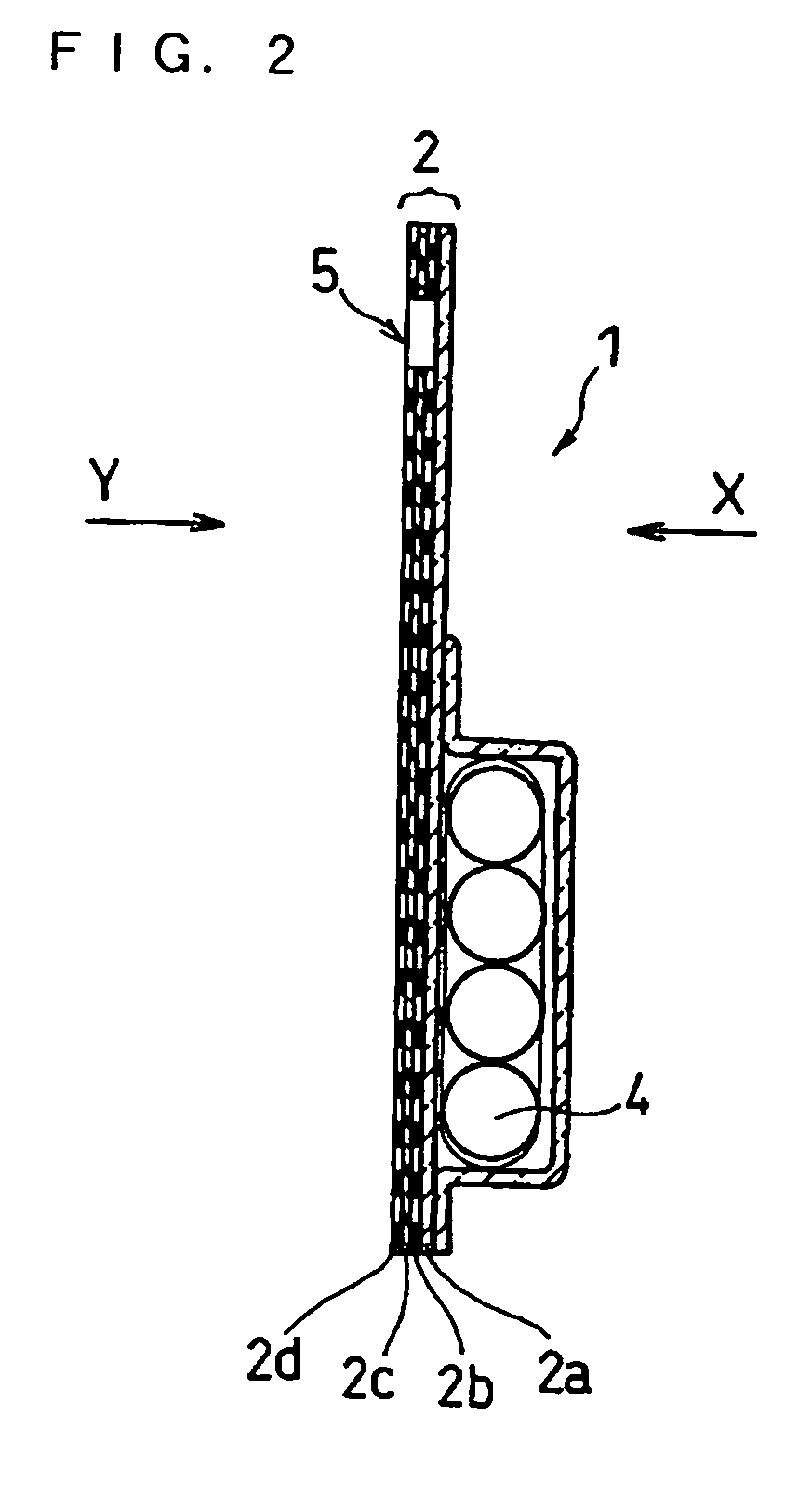

[0057] In this example, a package according to the present invention having the structure shown in FIGS. 1 and 2 was produced.

[0058] As the light permeable base 2a, a 150 μm thick translucent drawn sheet made of polylactic acid (PLA) was prepared. The base had a tensile strength (breaking strength) of 110 MPa both in length and width directions, and a tensile elasticity of 3.8 GPa in length direction and 4.3 GPa in width direction. The heat shrinkage of the base was measured according to JIS Z 1712 in which a test specimen was heated at 120° C. for 5 minutes. As a result, the base had a heat shrinkage of 2.7% in length direction and 0.3% in width direction.

[0059] On one surface of the base 2a were successively formed a 5 μm thick first printing layer 2b made of UV ink by relief printing, a 12 μm thick anti-offset layer 2c made of UV ink by flexographic printing, and a 5 μm thick second printing layer 2d by relief printing in a single rotary printing step. Thus, a backing sheet 2 w...

example 2

[0062] A package “B” according to the present invention was produced in the same manner as in Example 1 except that the base 2a of the backing sheet 2 and the container 3 were made using a drawn sheet of polyethylene terephthalate (PET) having a tensile strength (breaking strength) of 68 MPa both in length and width directions, a tensile elasticity of 2.1 GPa in length direction and 2.2 GPa in width direction, and a haze of less than 1%, instead of using a drawn sheet of PLA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com