Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Less raw material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

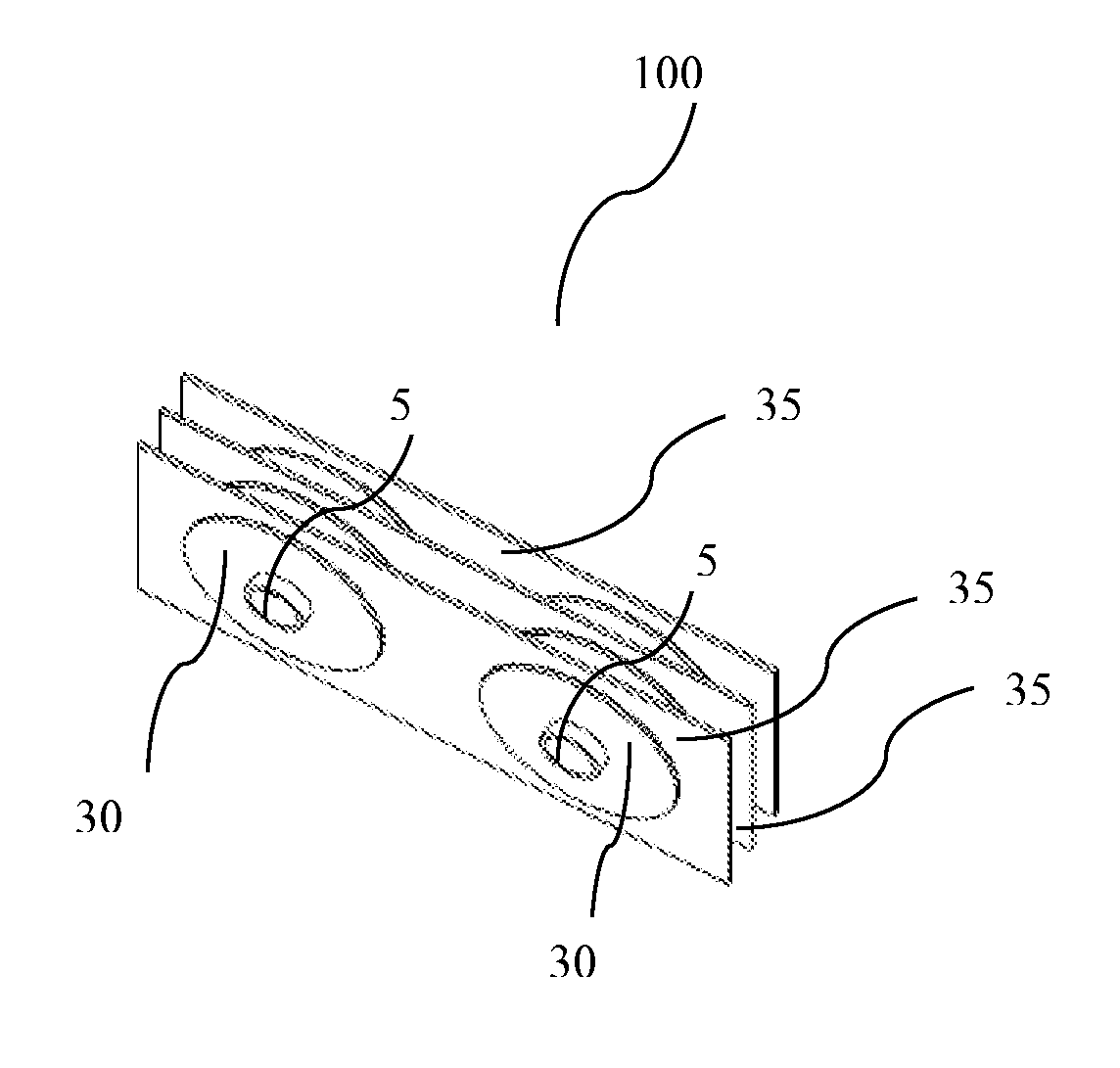

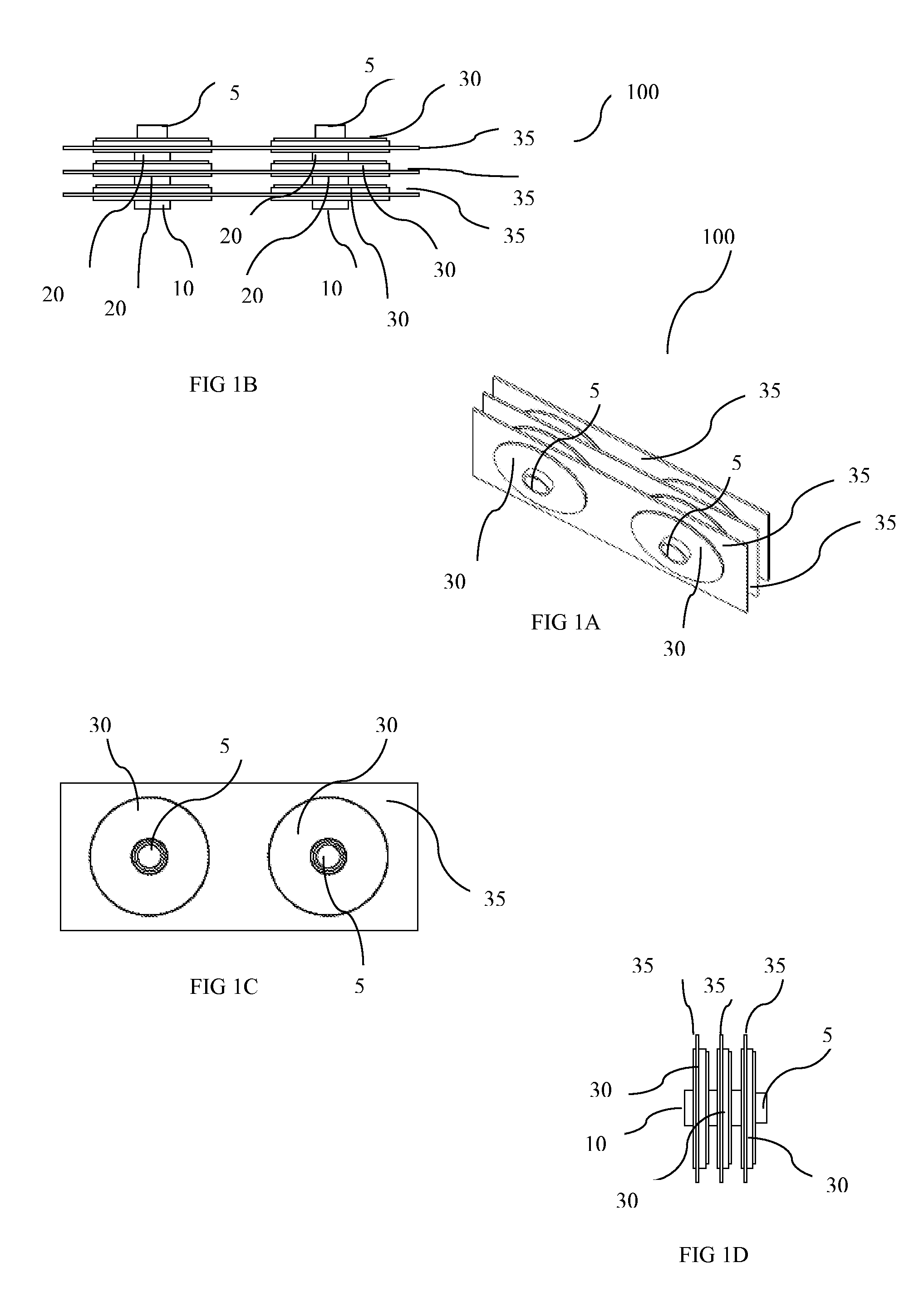

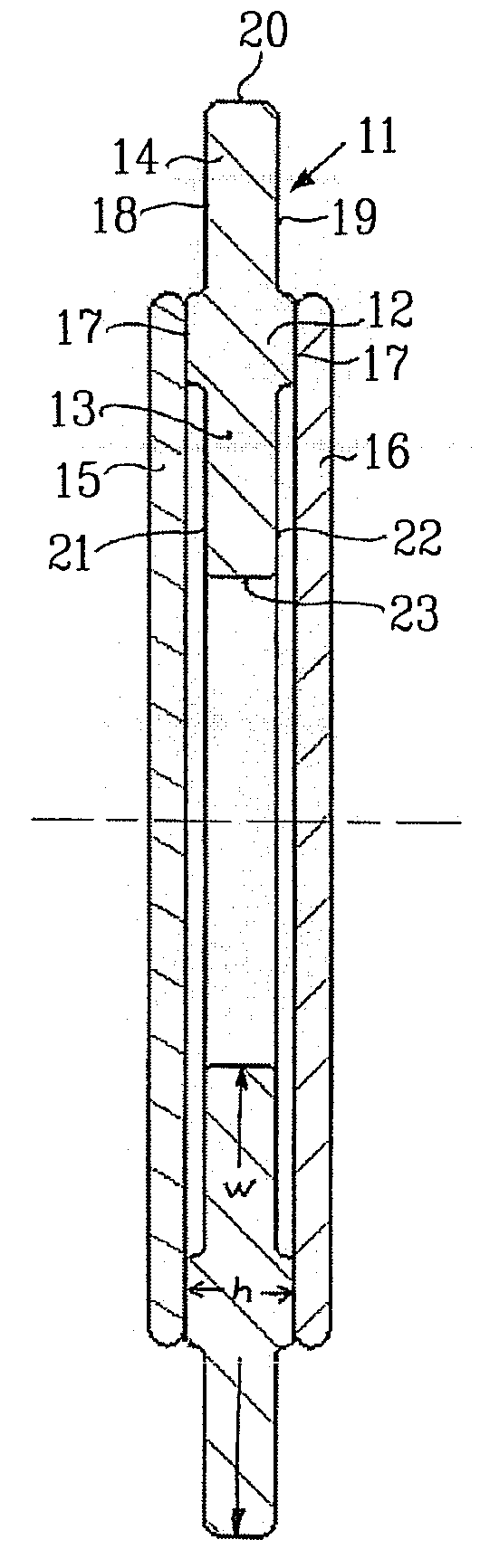

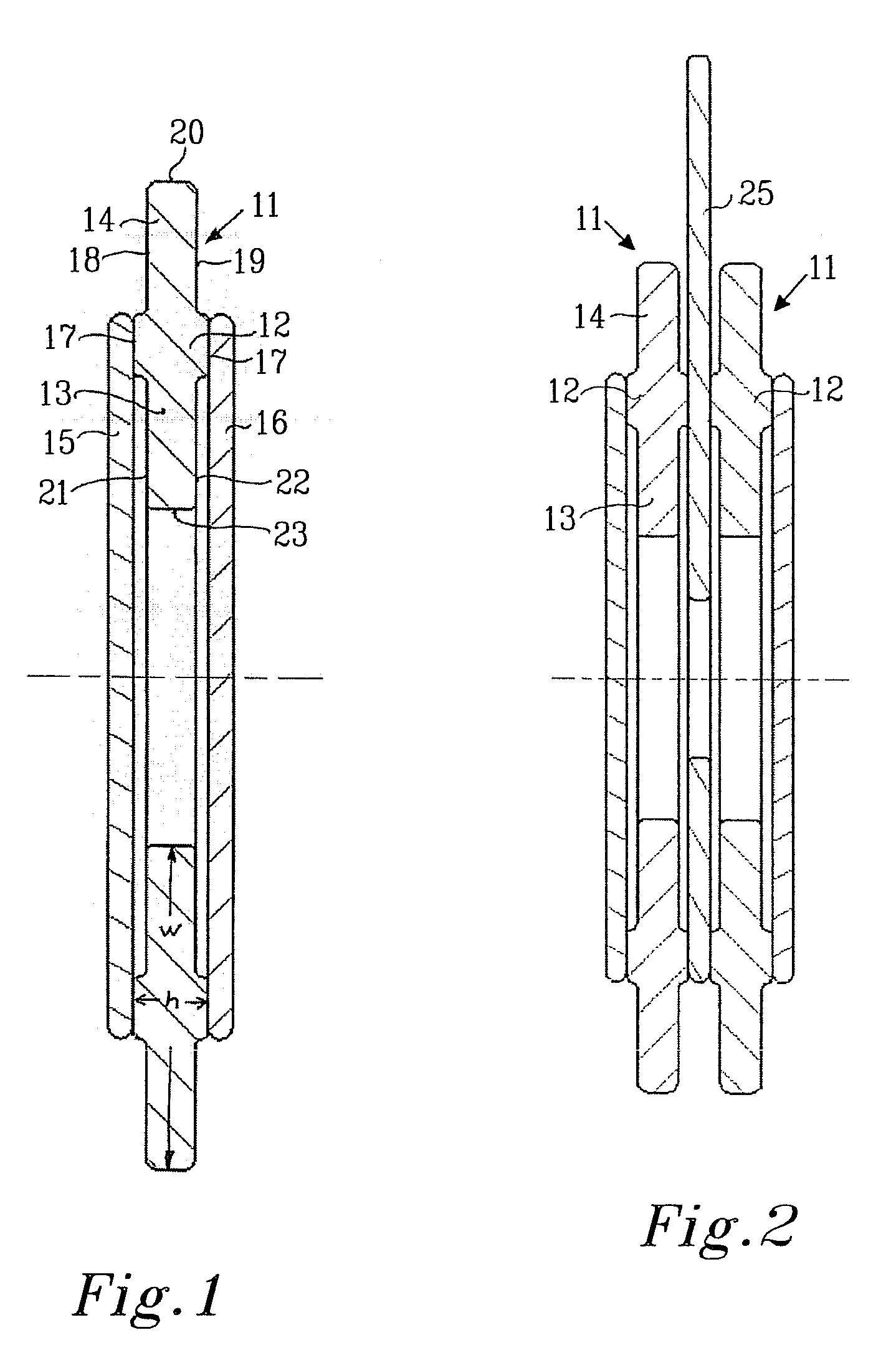

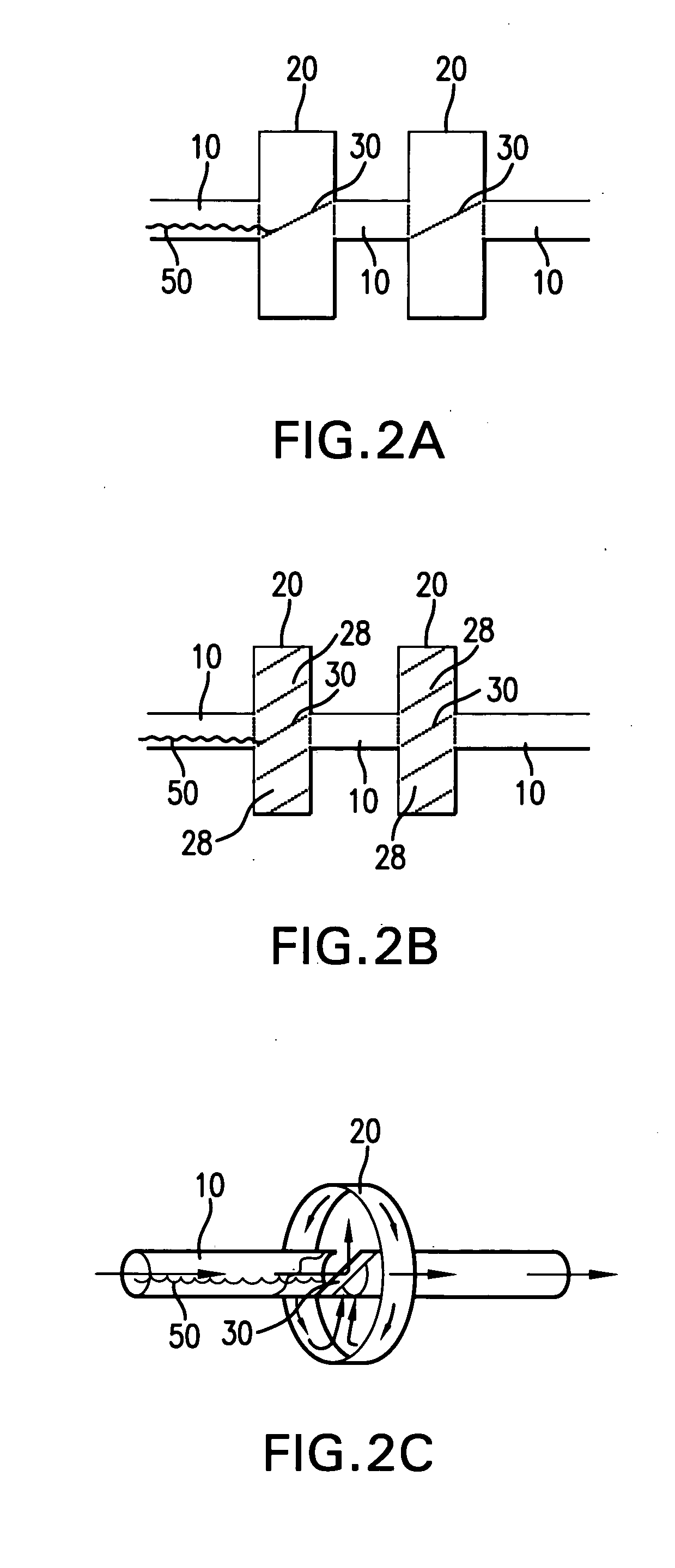

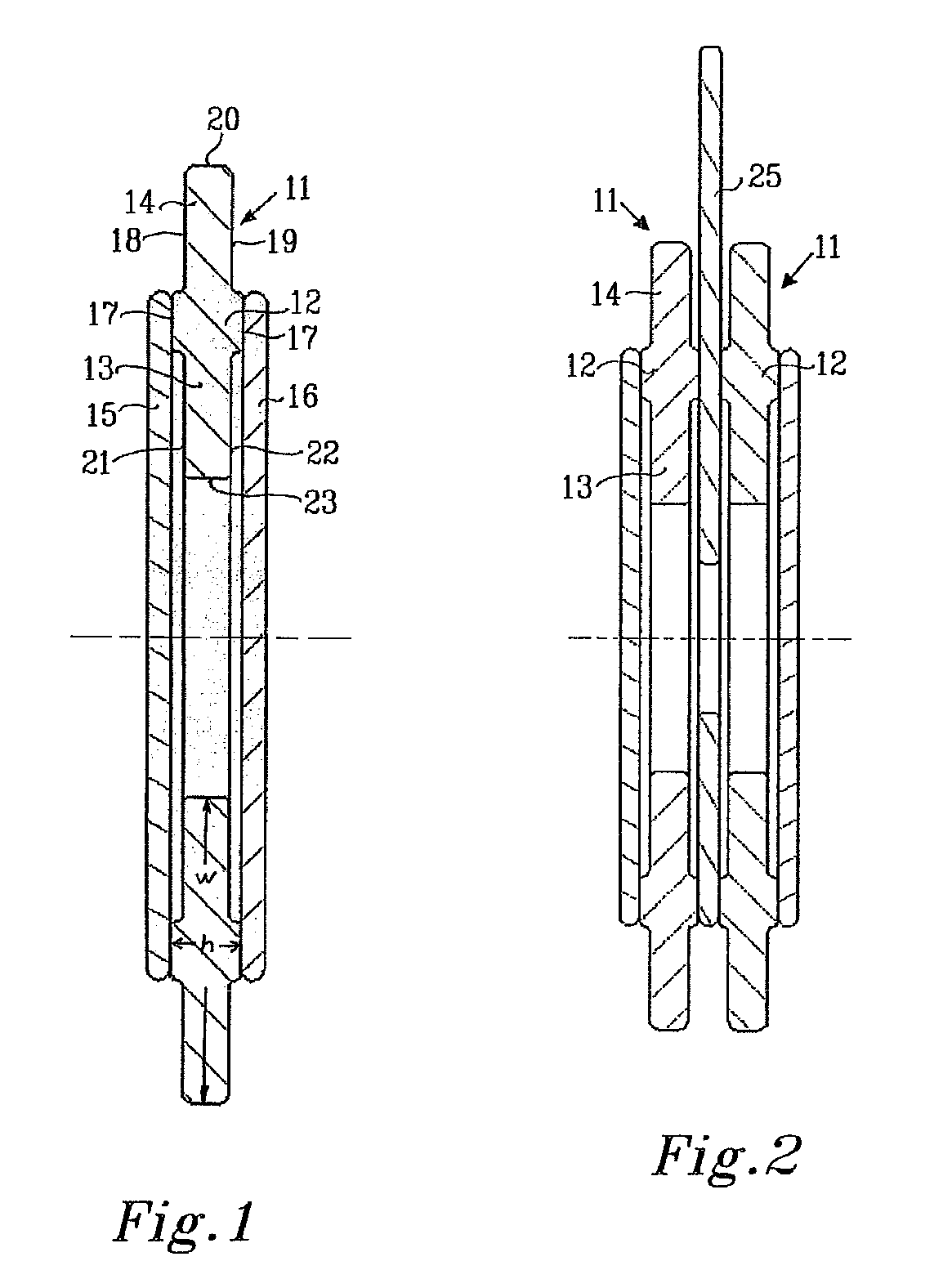

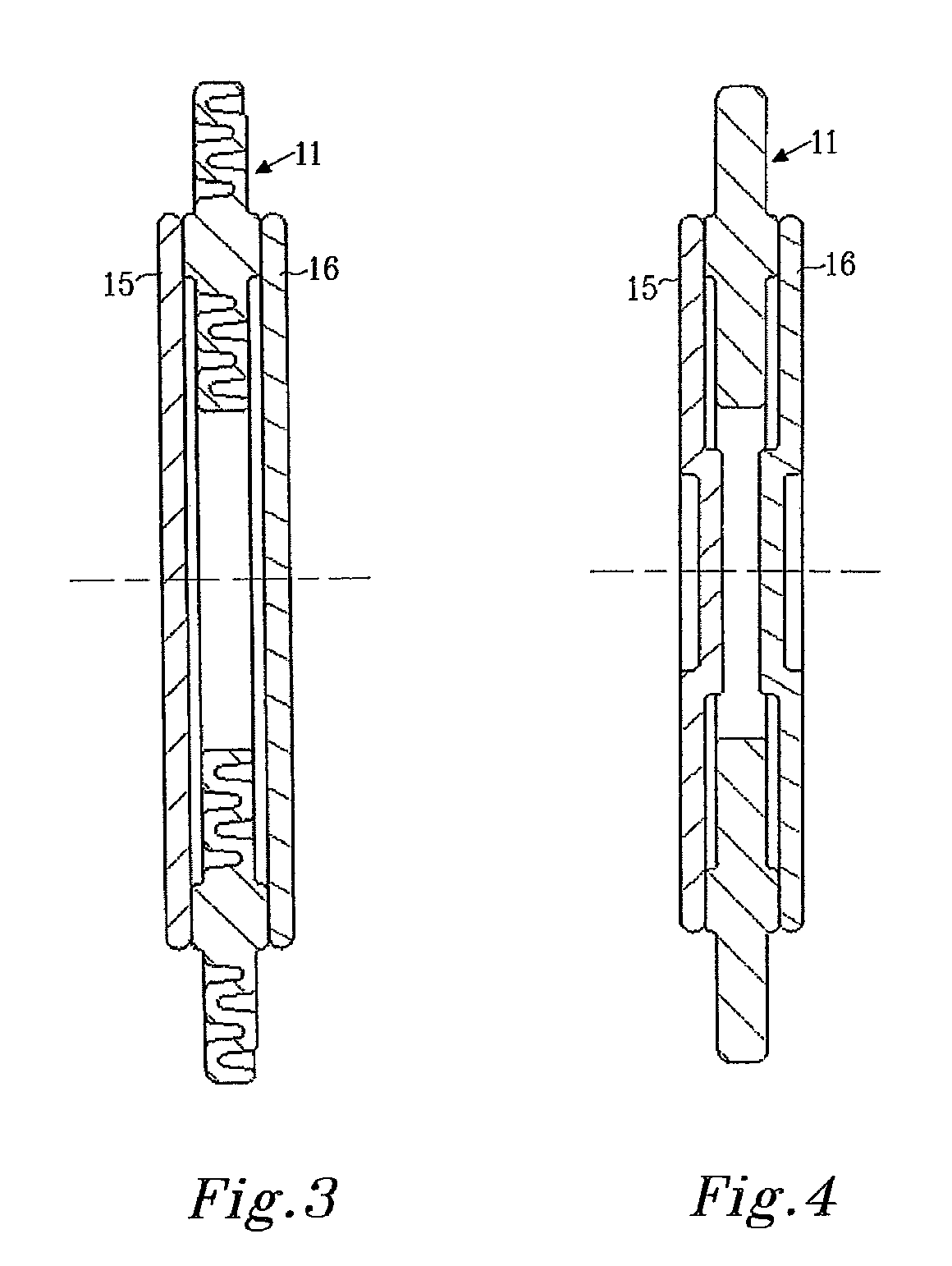

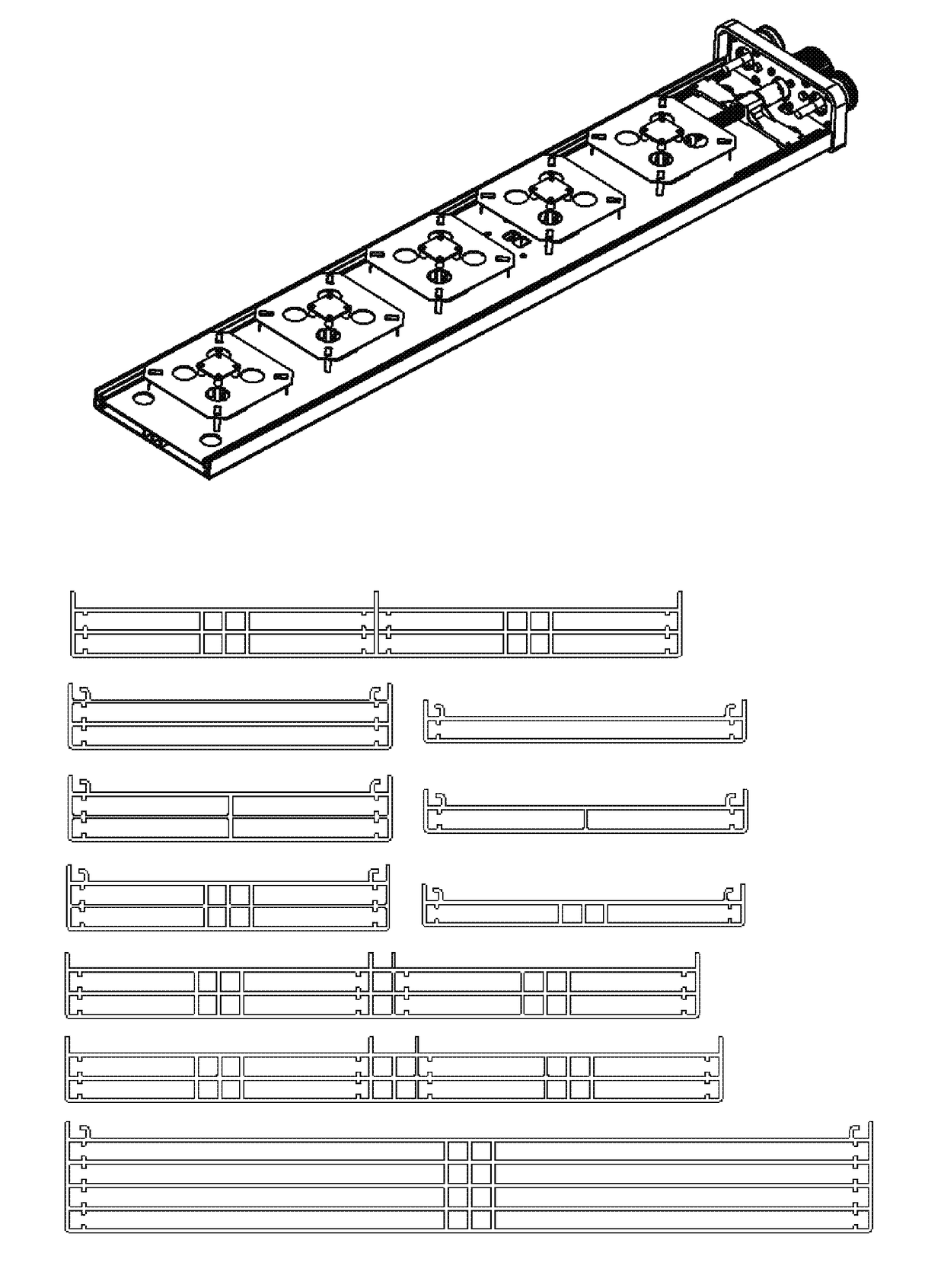

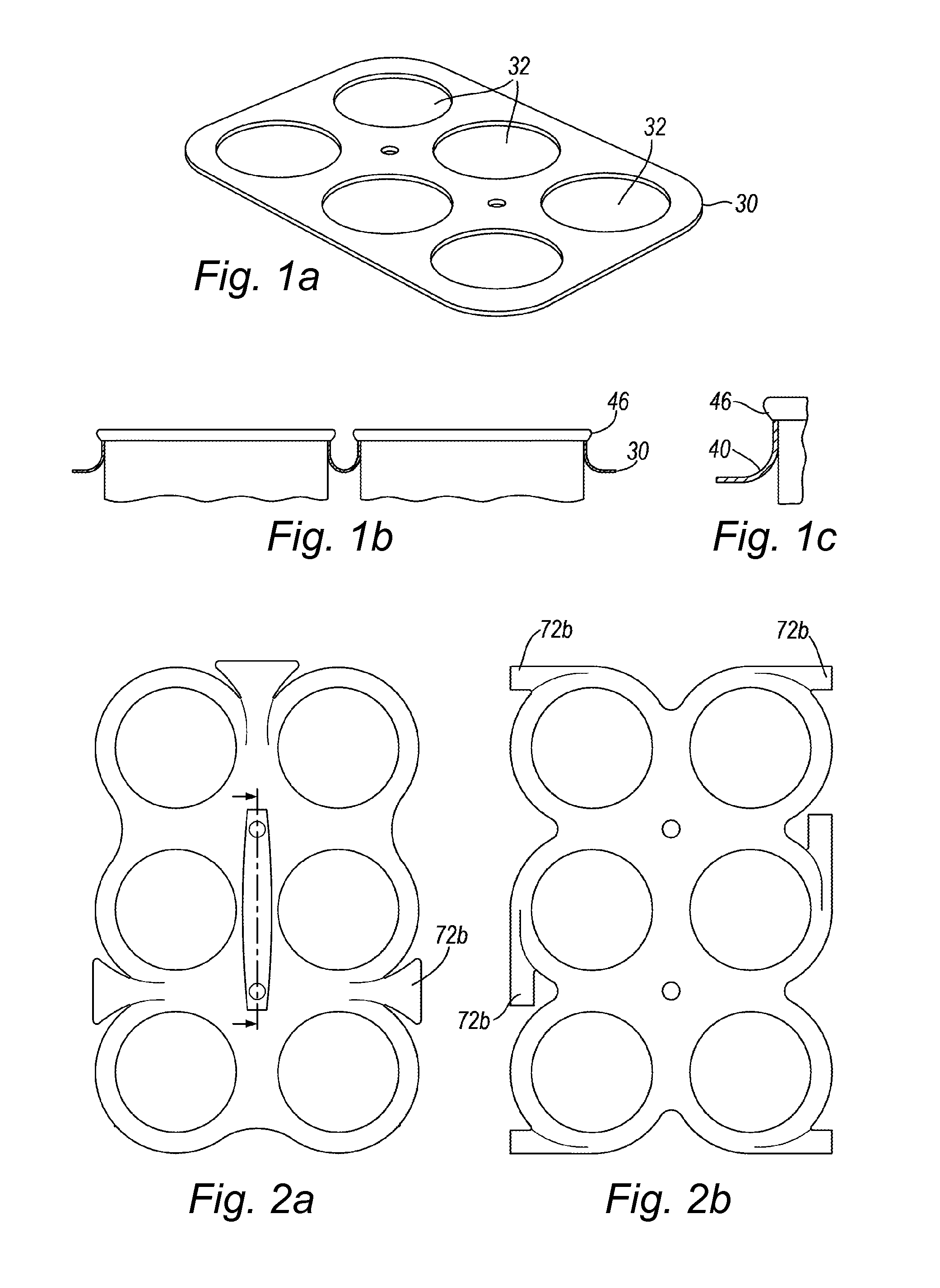

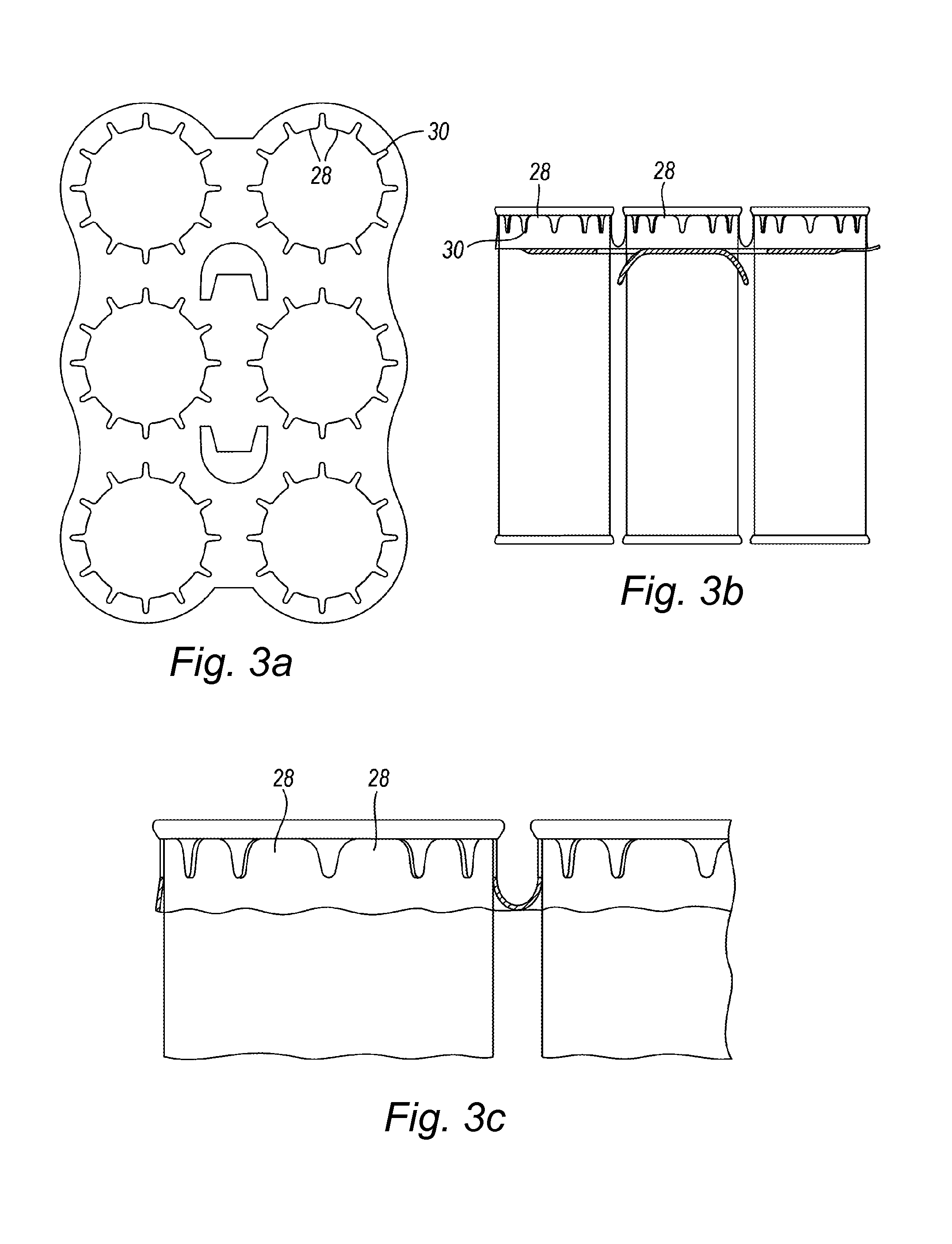

Open Mesh Material and Bags Made Therefrom

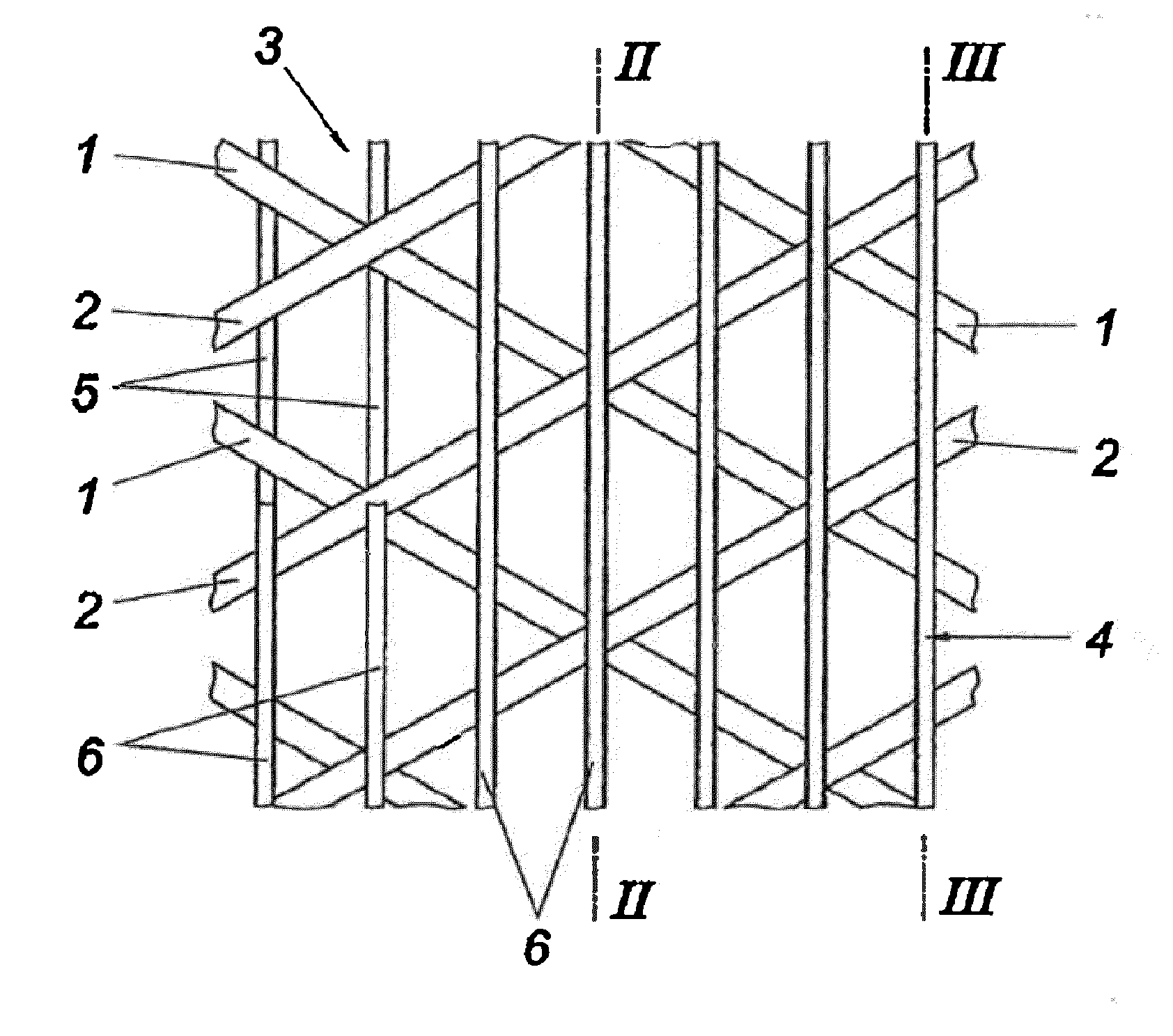

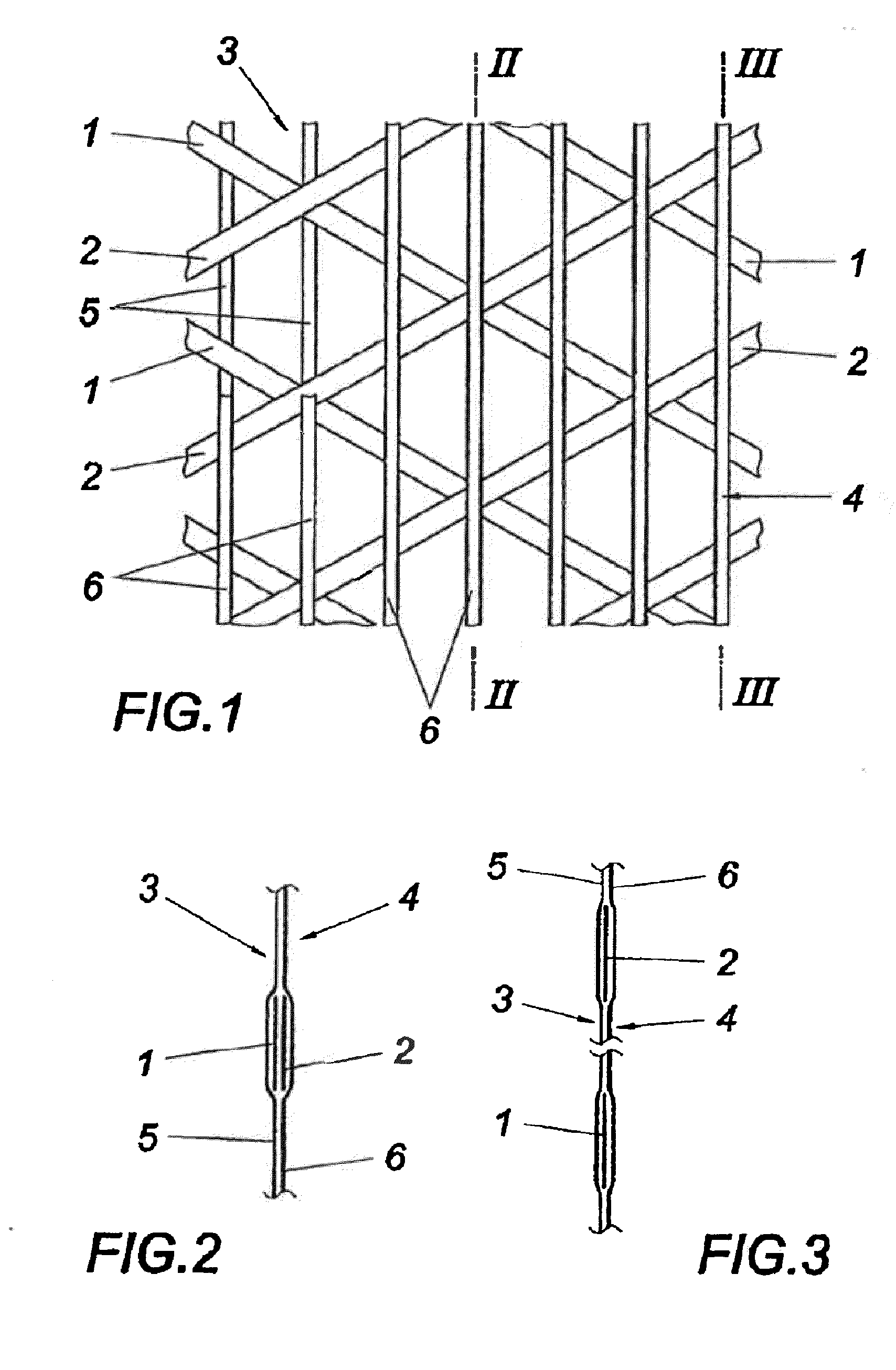

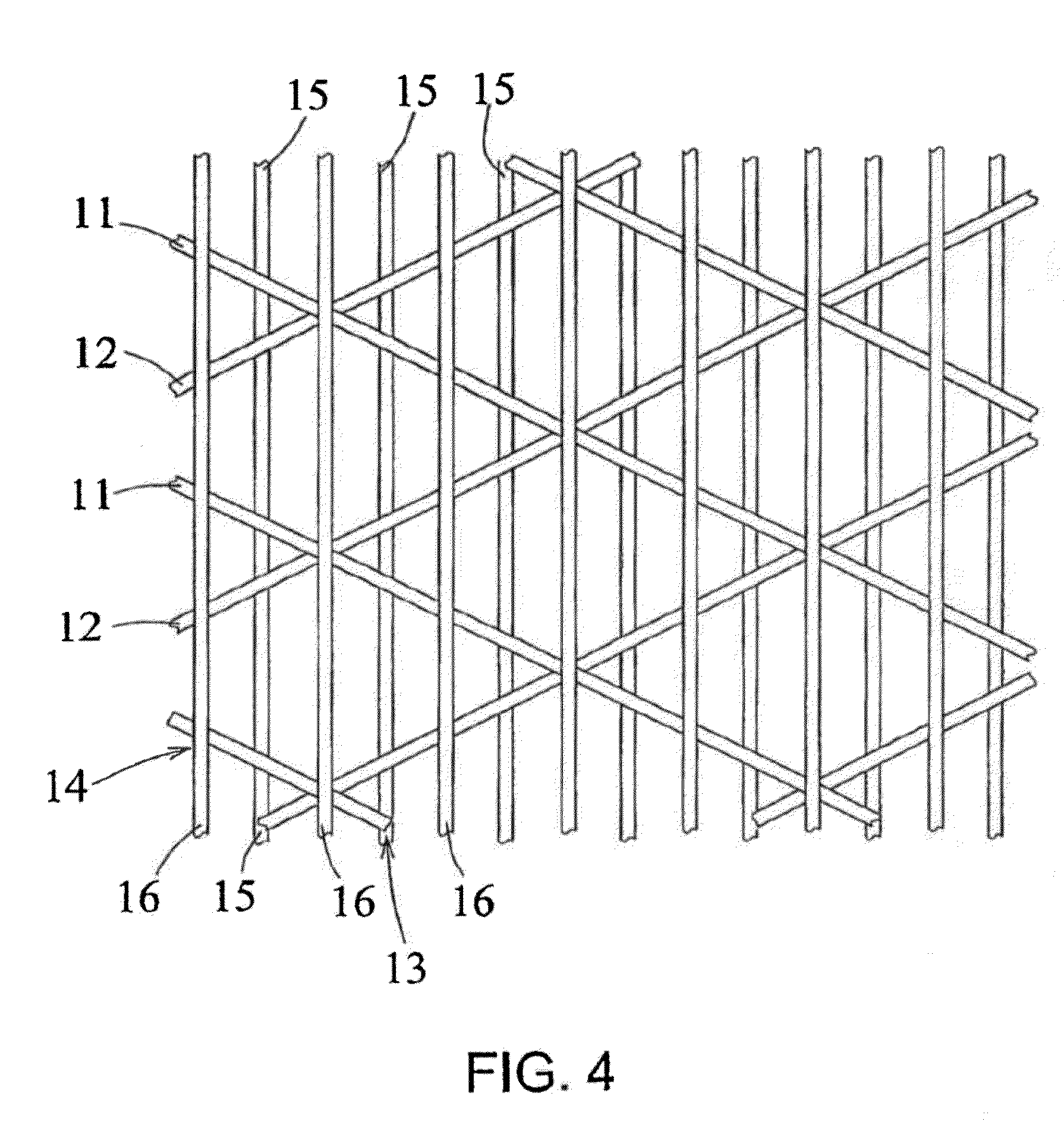

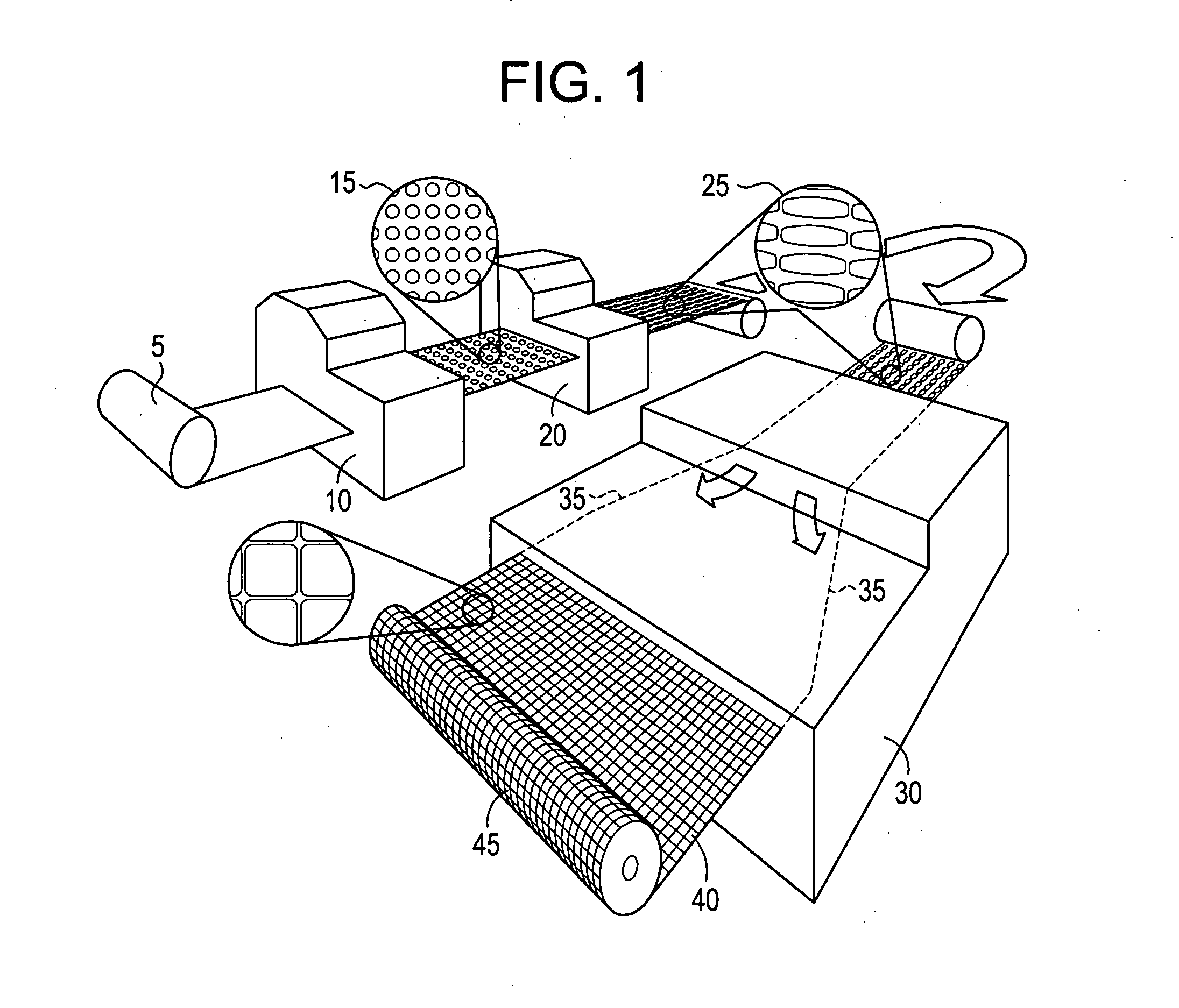

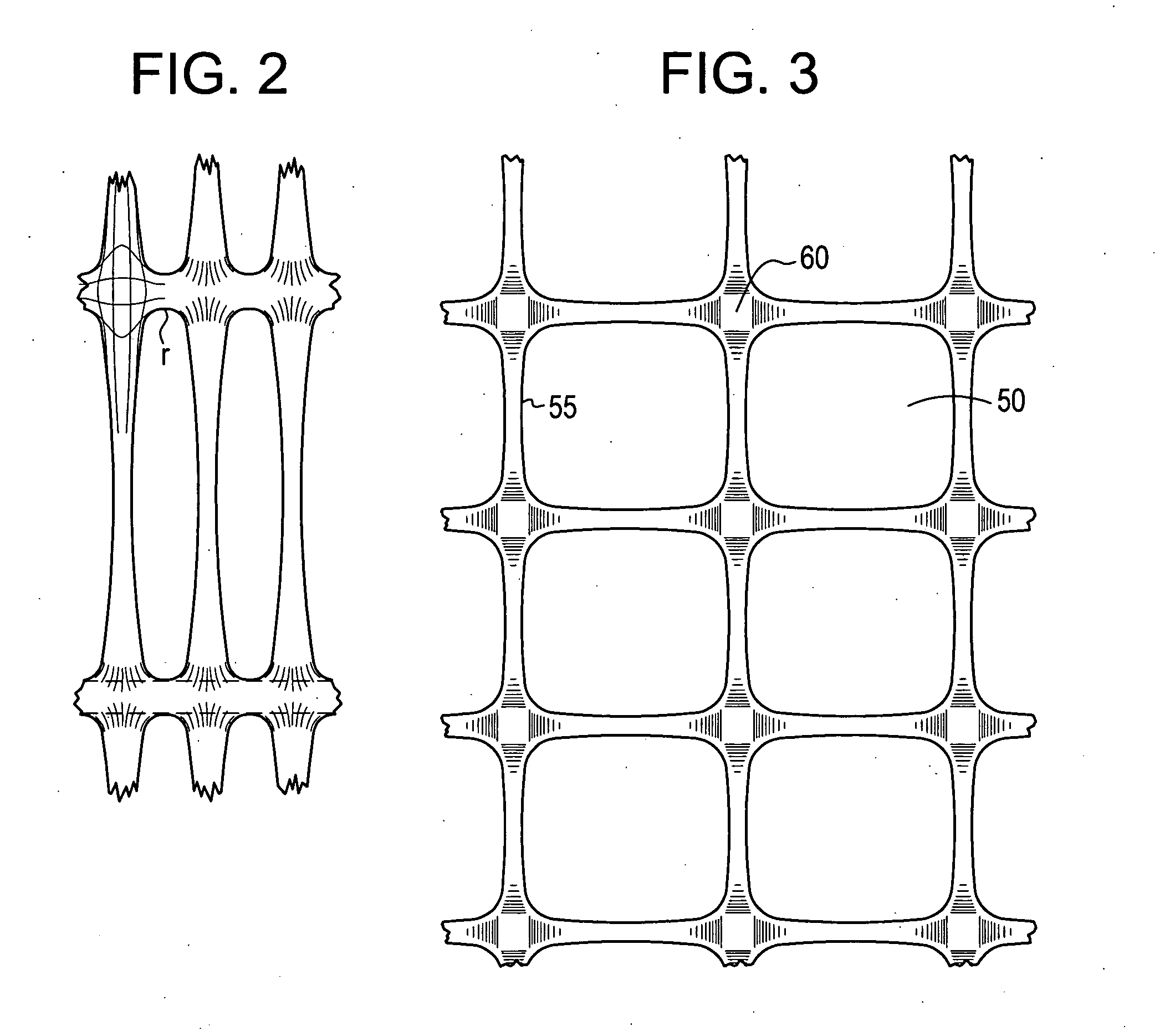

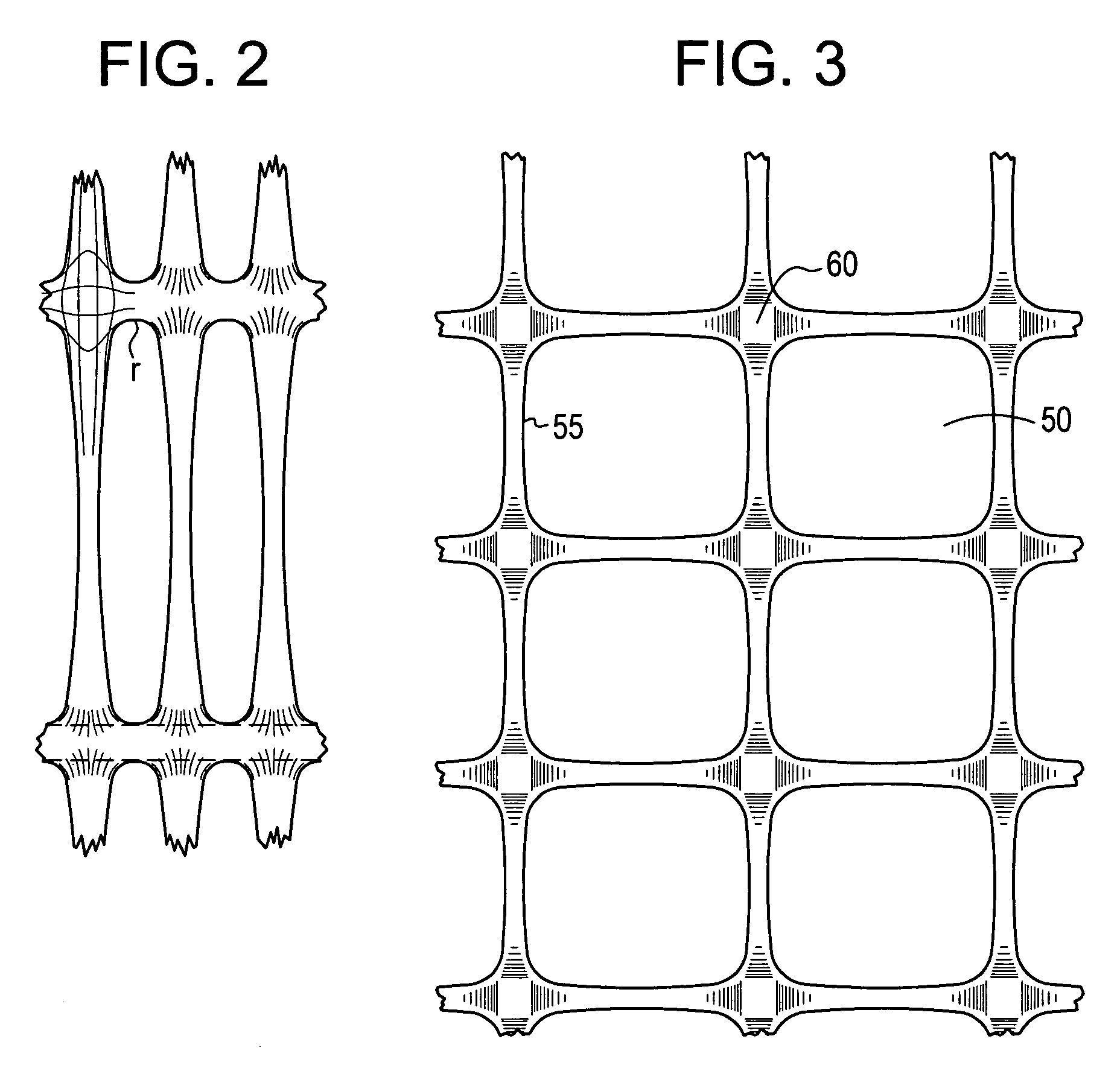

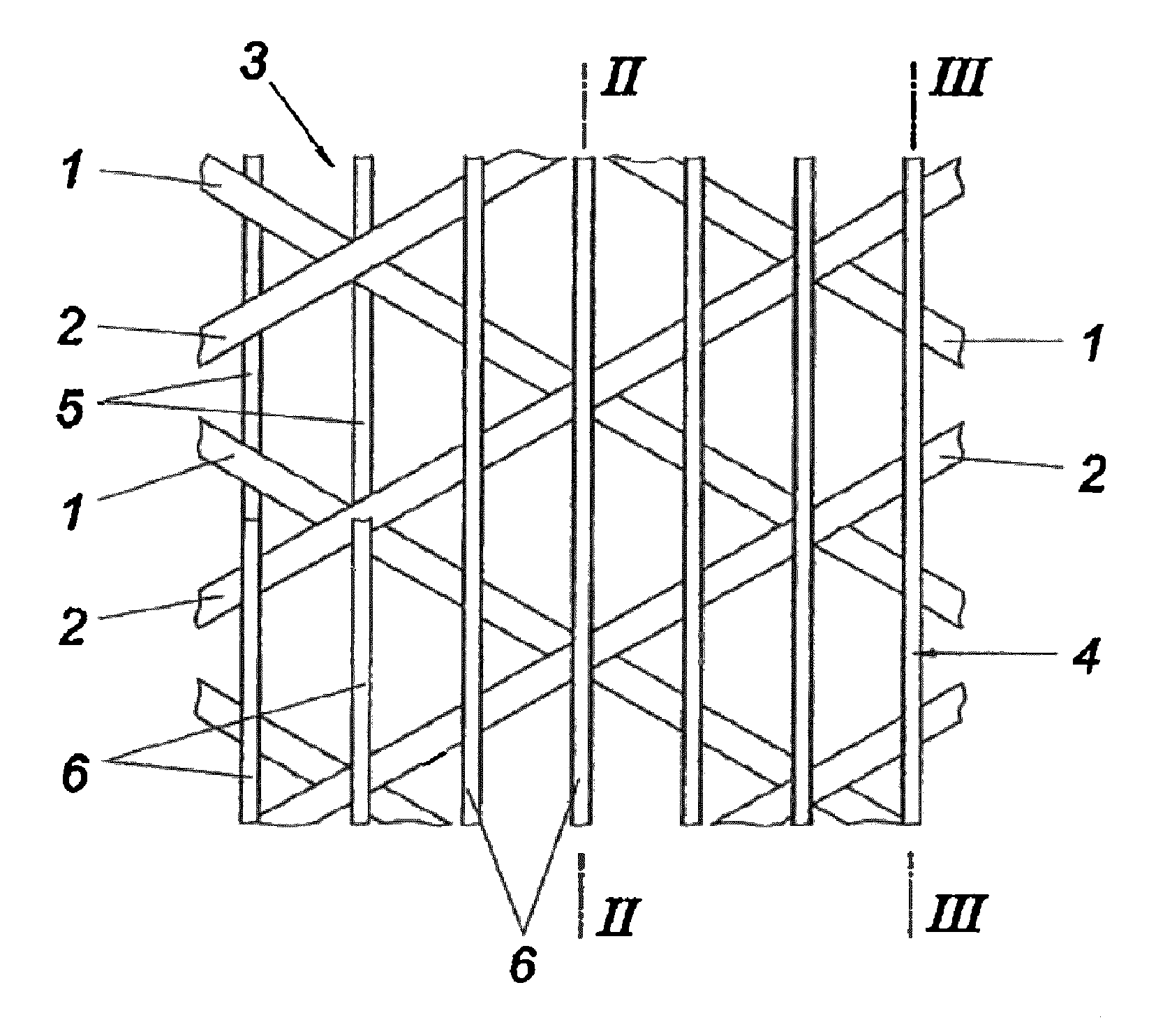

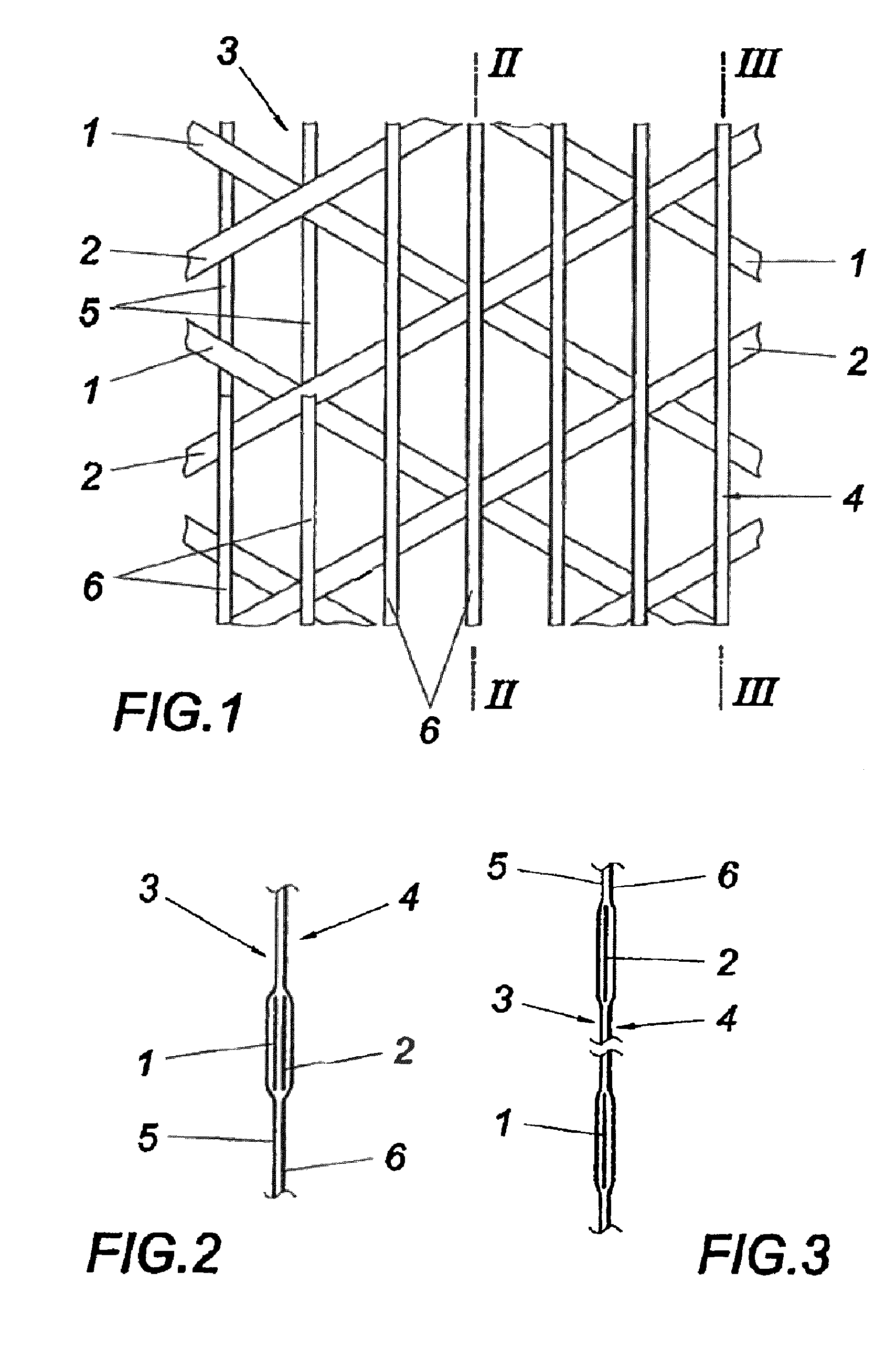

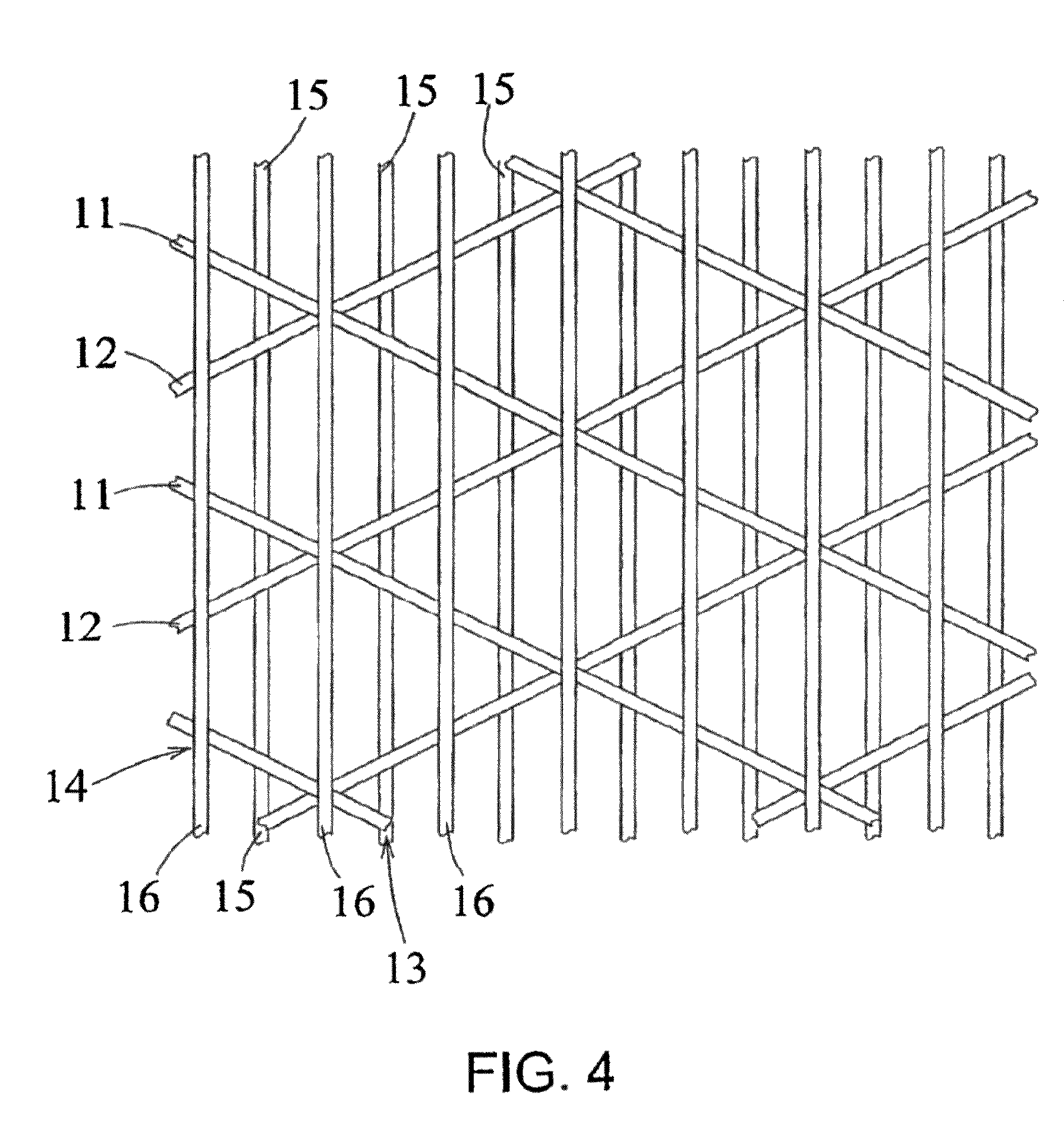

An open mesh material includes filaments (1, 2, 3, 4, 11, 12, 15, 16) that intersect one another. At least some of the filaments are composite filaments having a carrier portion of a relatively high melting point and a bonding portion of a relatively low melting point, the bonding portion of each composite filament being thermally bonded to other filaments at points of intersection. The material may be a non-woven fabric that contains at least two layers of weft filaments (1, 2, 11, 12) that may be bordered on one or both sides by a layer of warp filaments (3,4, 15, 16). When compared to other open mesh materials, the open mesh material disclosed herein has a superior combination of some or all of high strength, light weight, high dimensional stability, and openness. Also disclosed herein are articles can be made at least in part from the material including L-seam bags (20), form fill and seal (FFS) bags (1020), and multi-substrate bags (2,020). Methods of making those bags also are disclosed.

Owner:VOLM

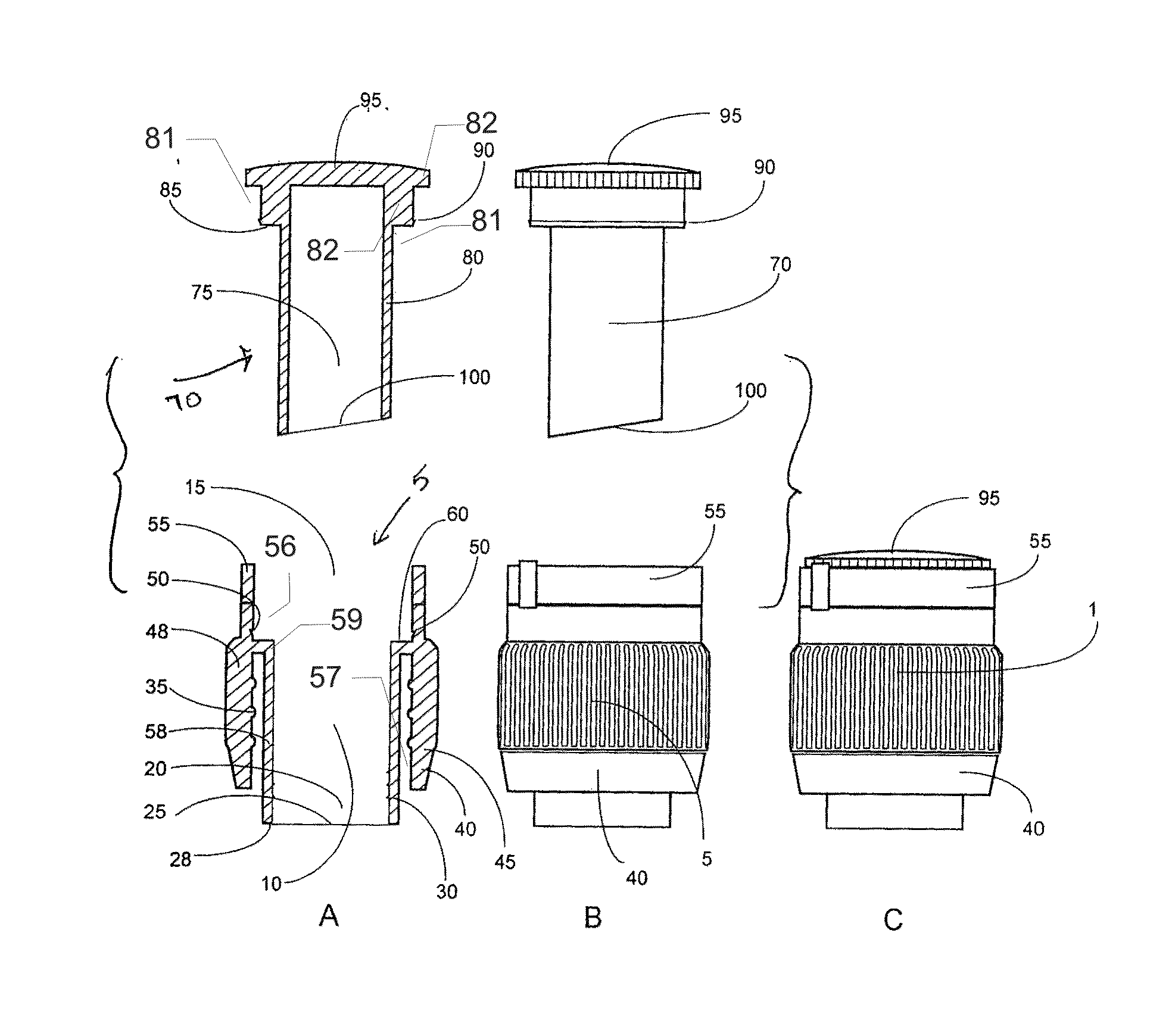

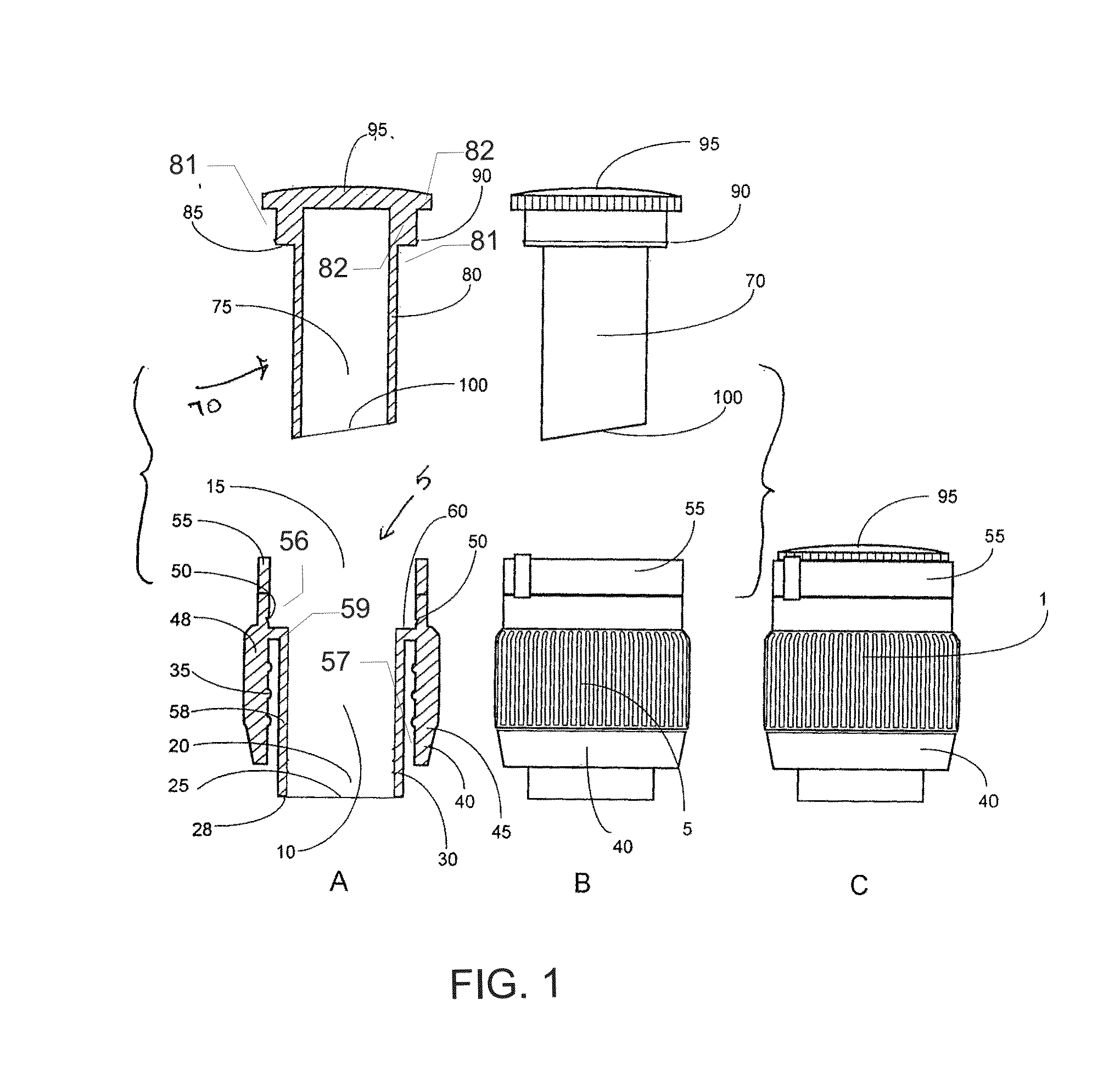

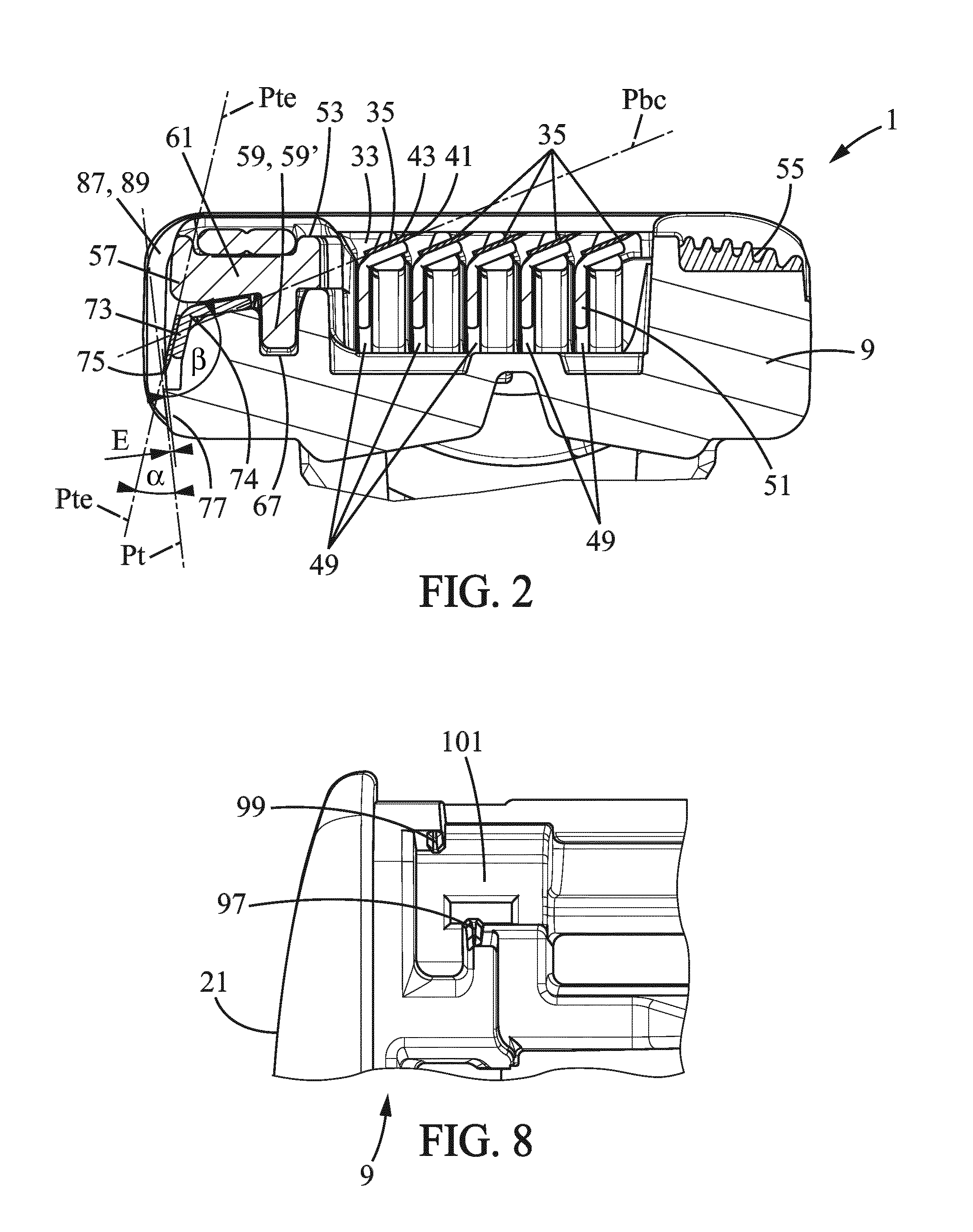

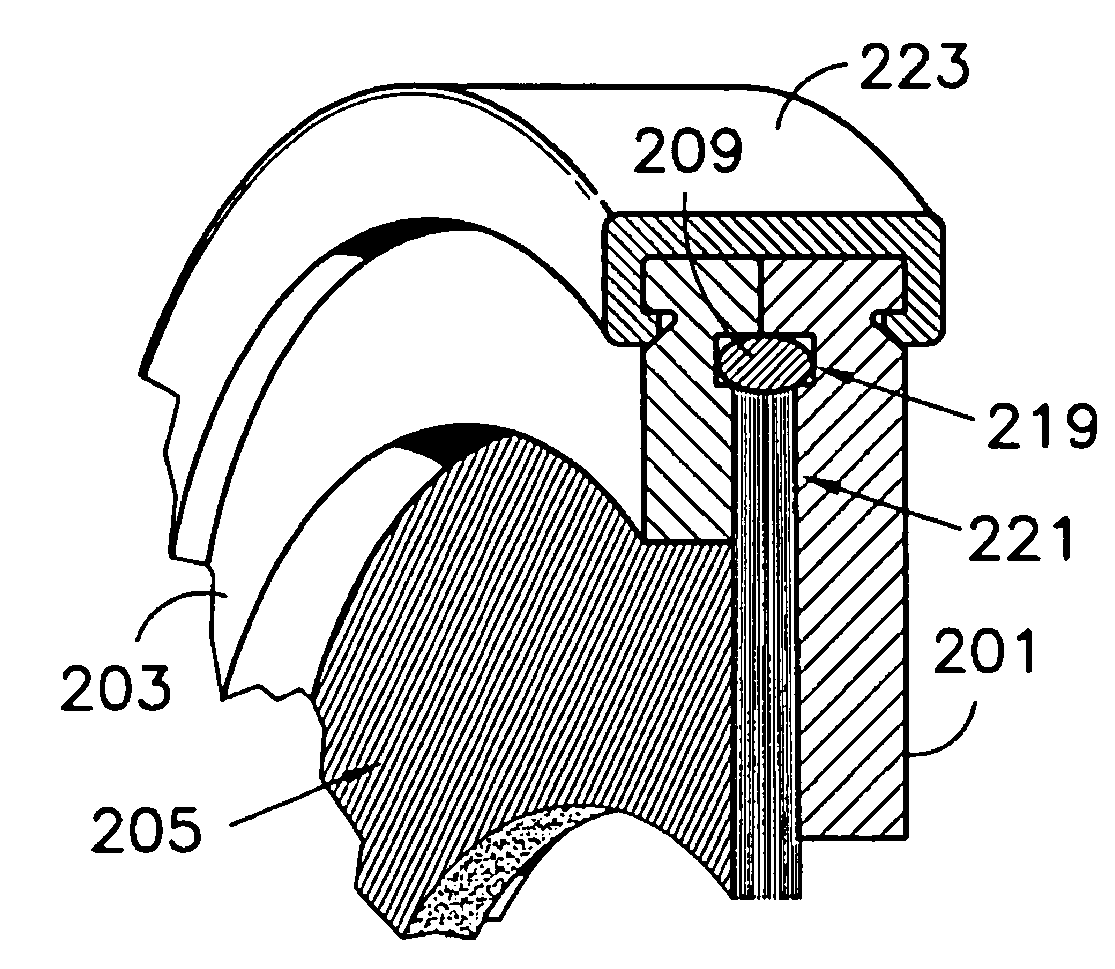

Safety sealed reservoir cap

ActiveUS9126731B2Less complicated to assembleLess raw materialCapsClosure using stoppersEngineeringBottle

A sealed reservoir cap for attaching to a bottle includes an annular part slidably received into another annular part to define an enclosed reservoir there between that is closed off by a punchable seal.

Owner:THE SUNRIDER CORP SUNRIDER INT

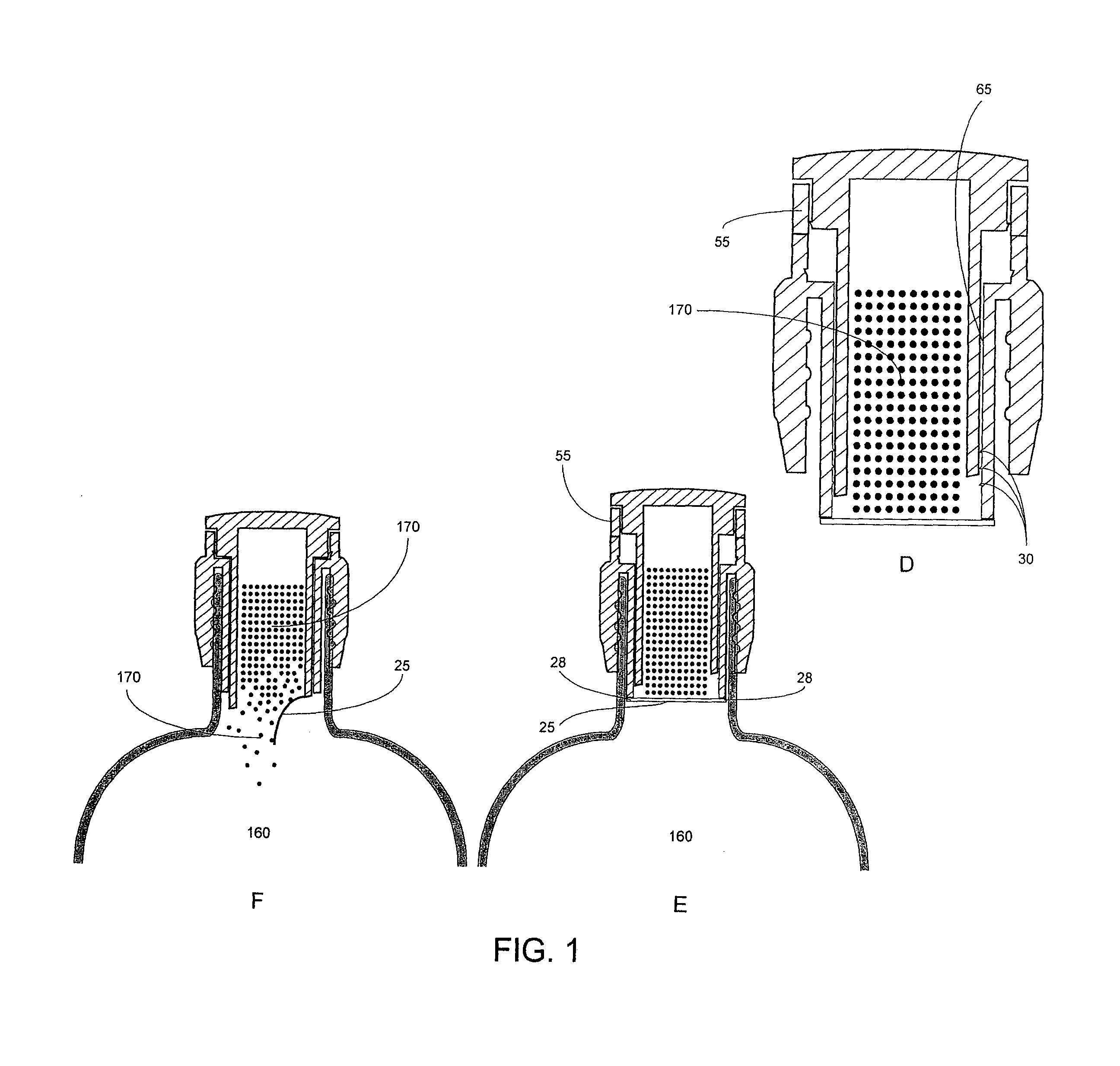

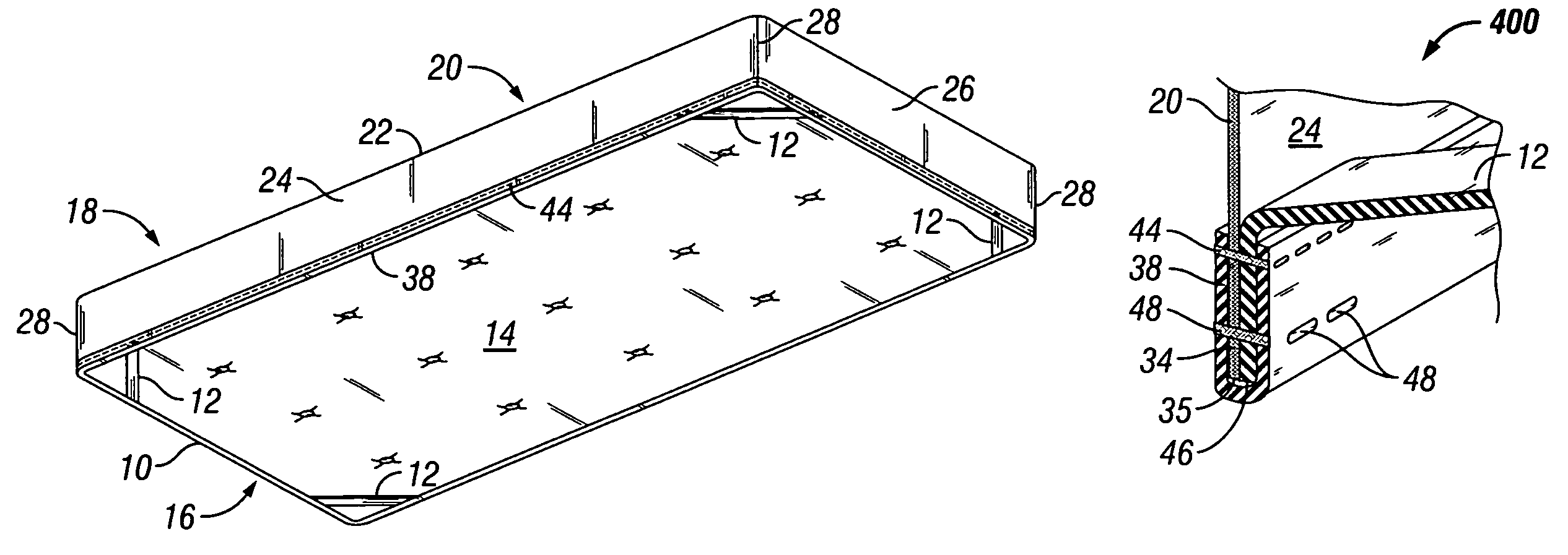

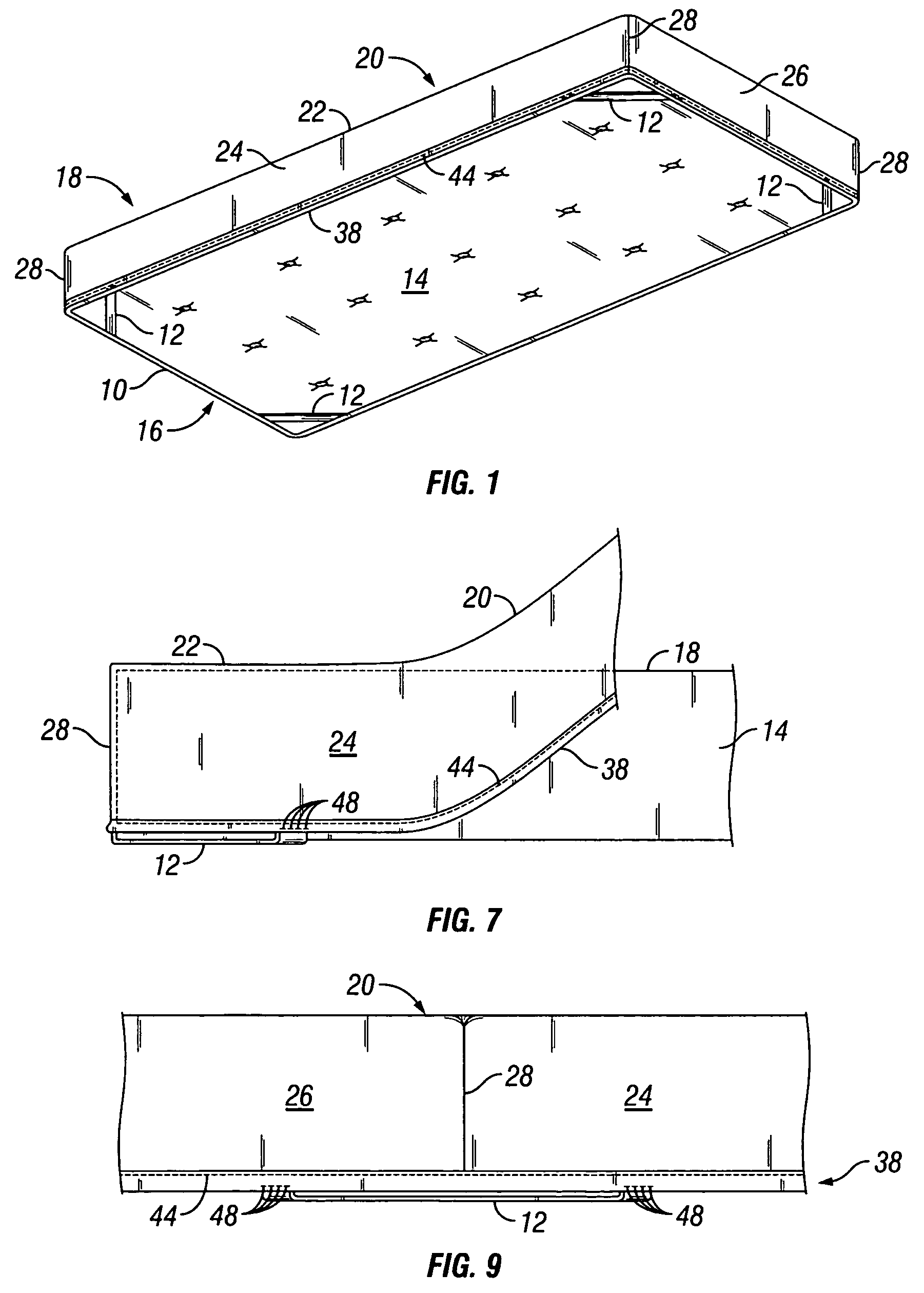

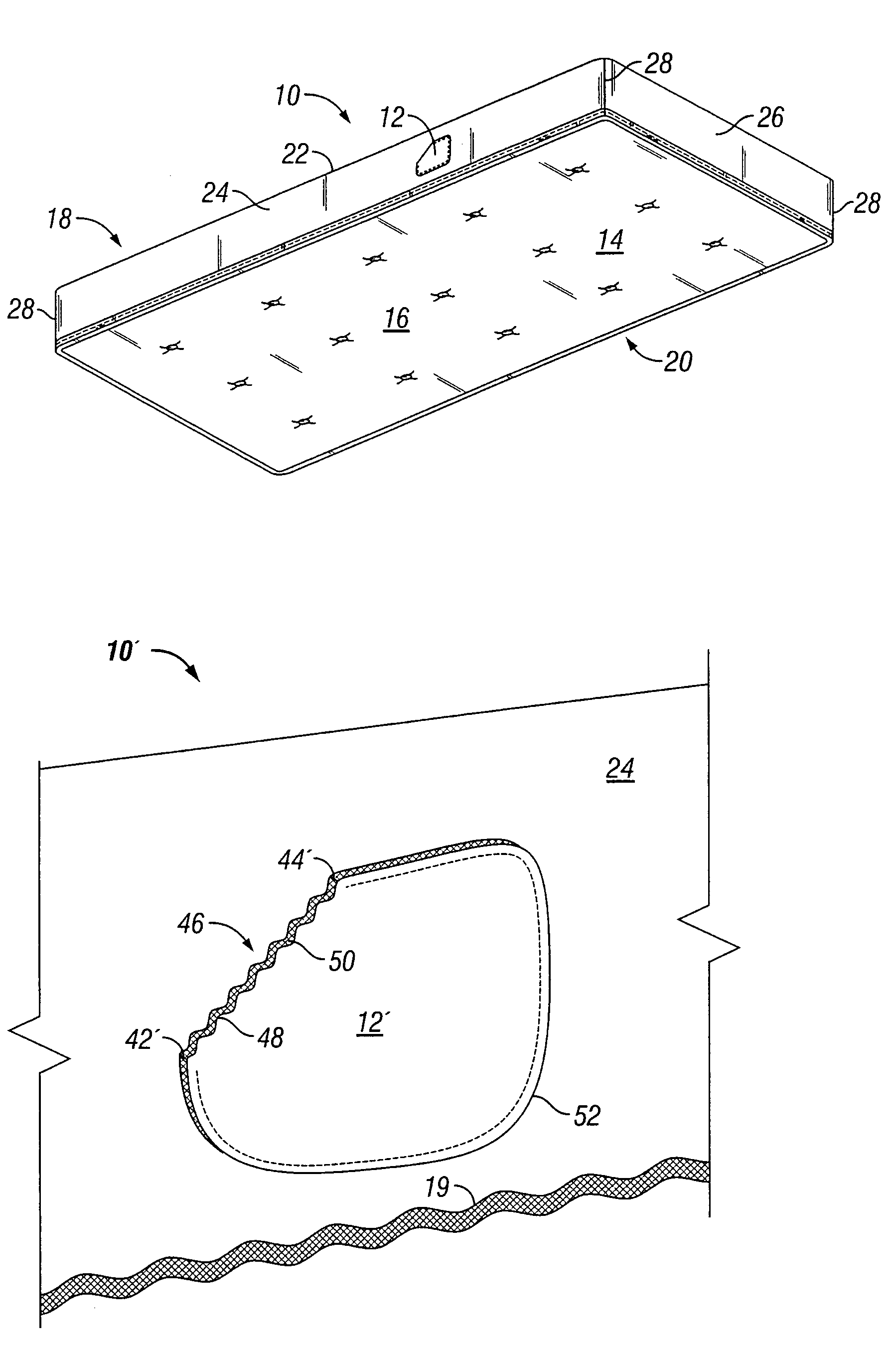

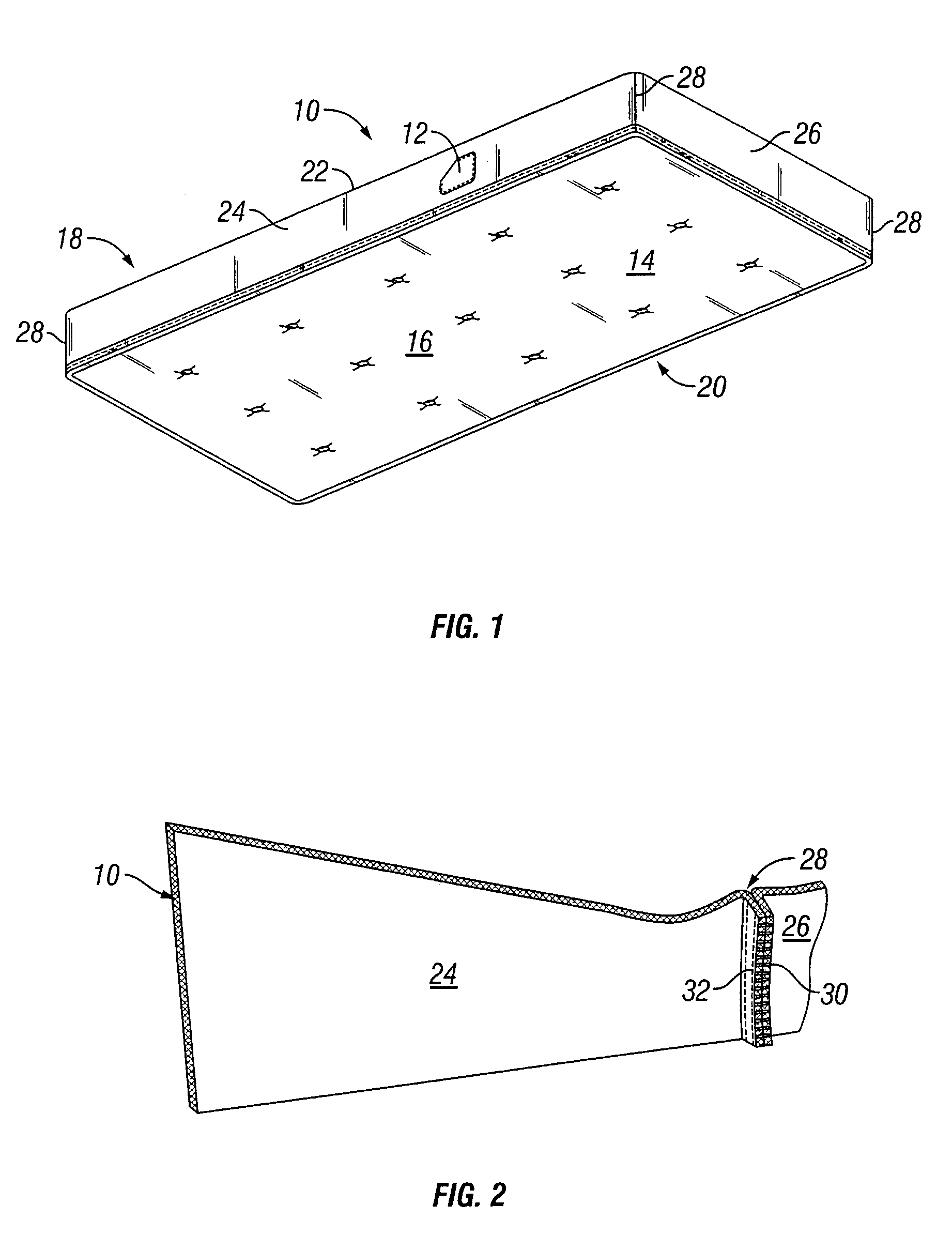

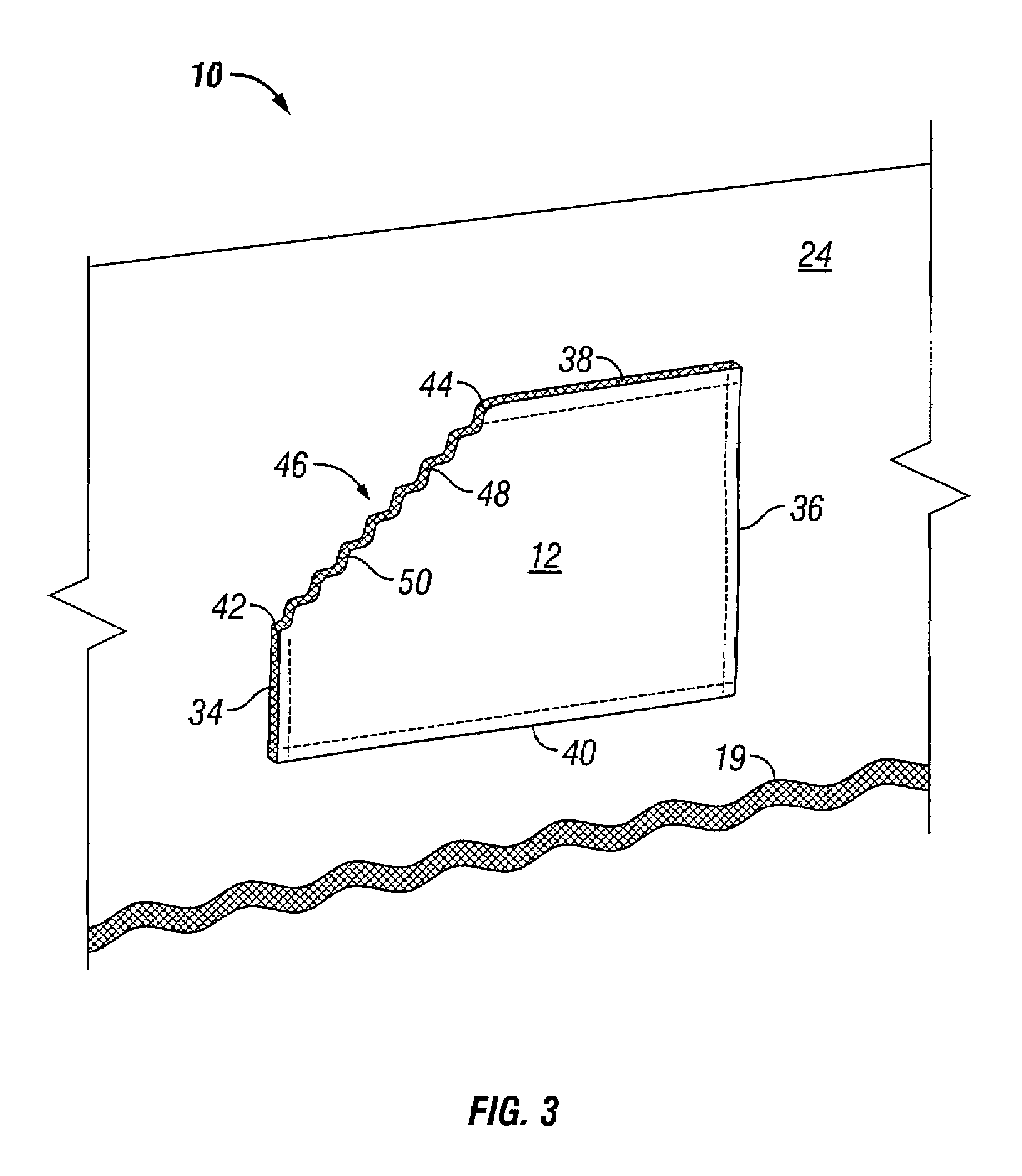

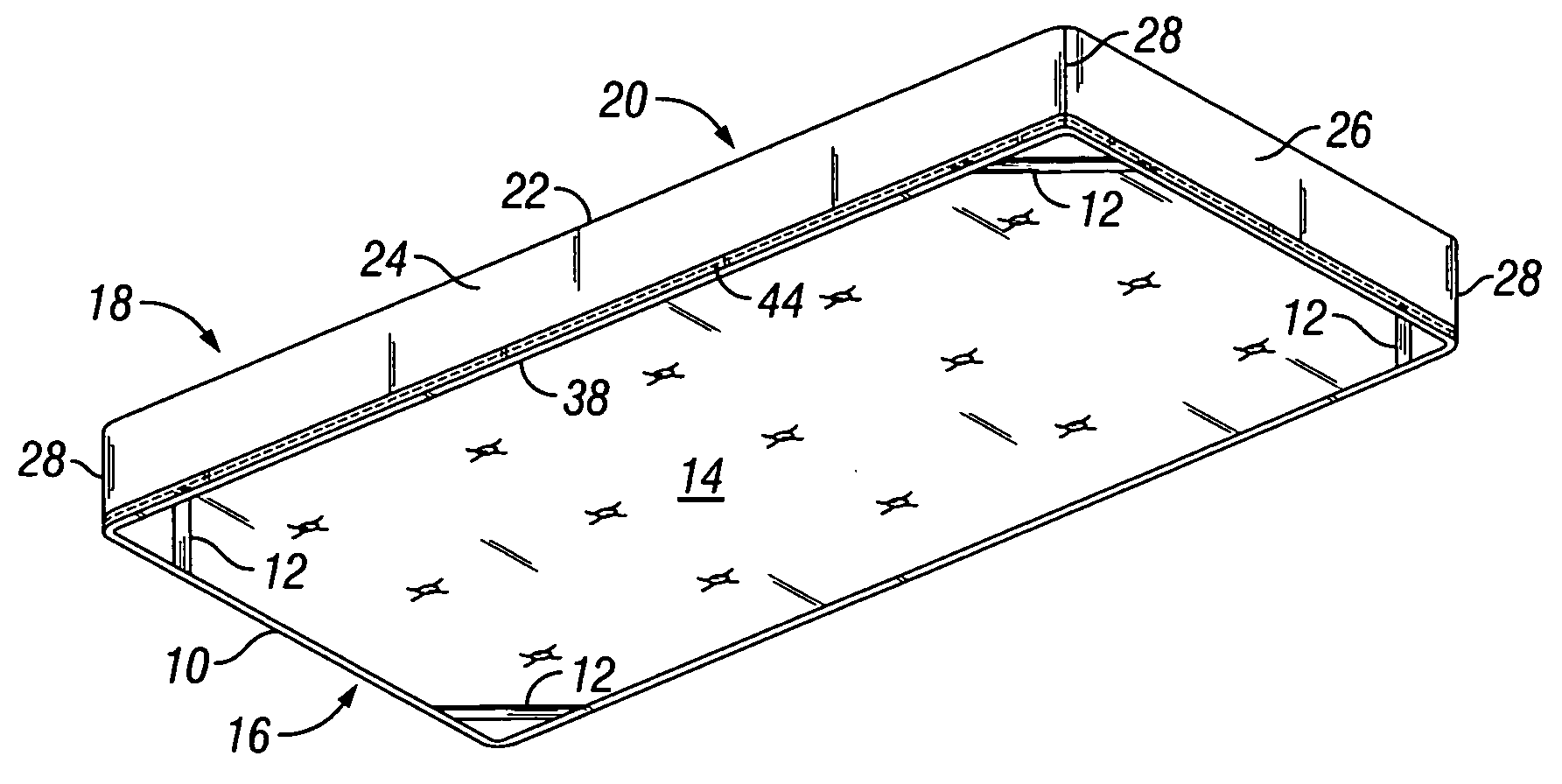

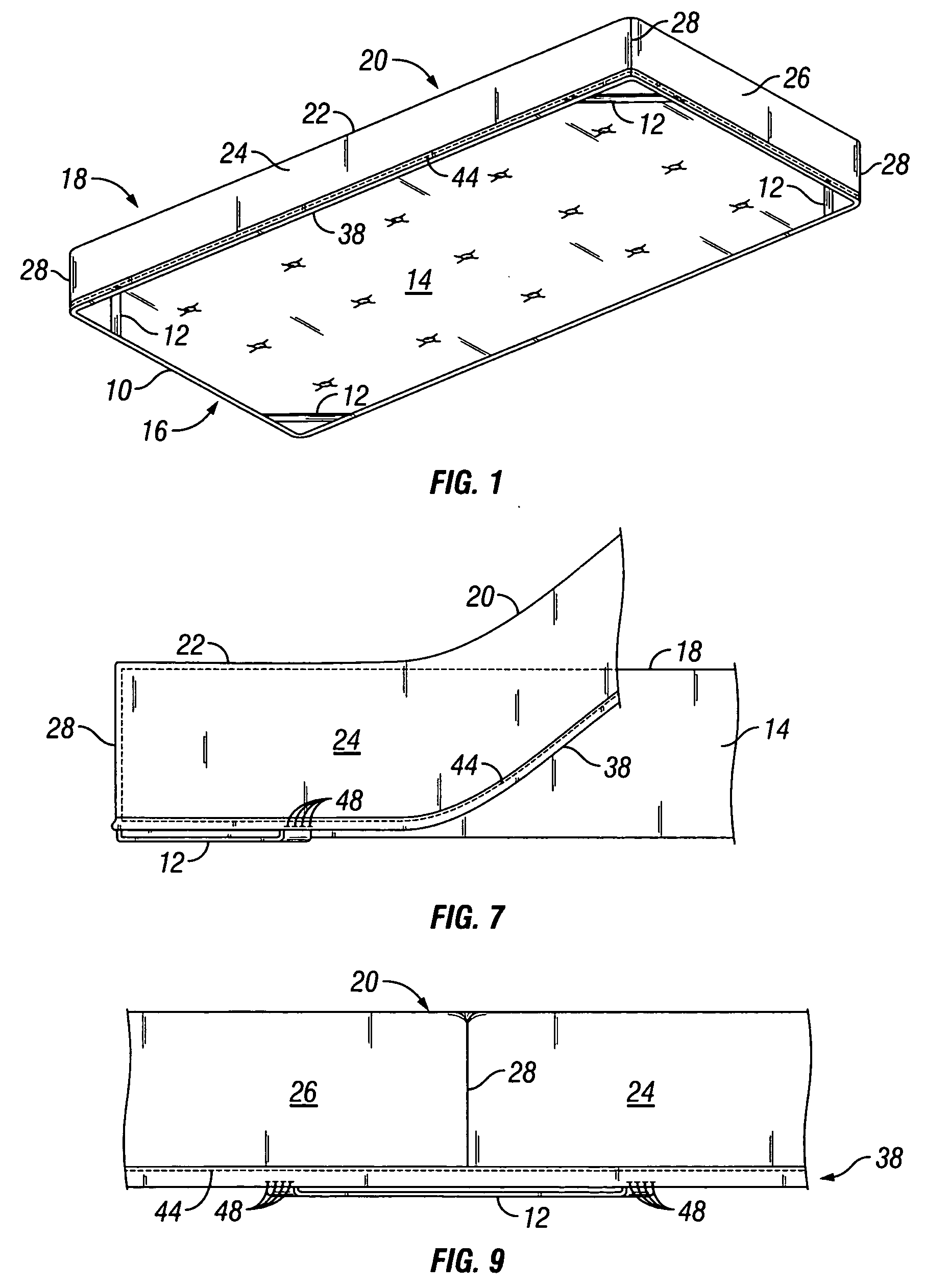

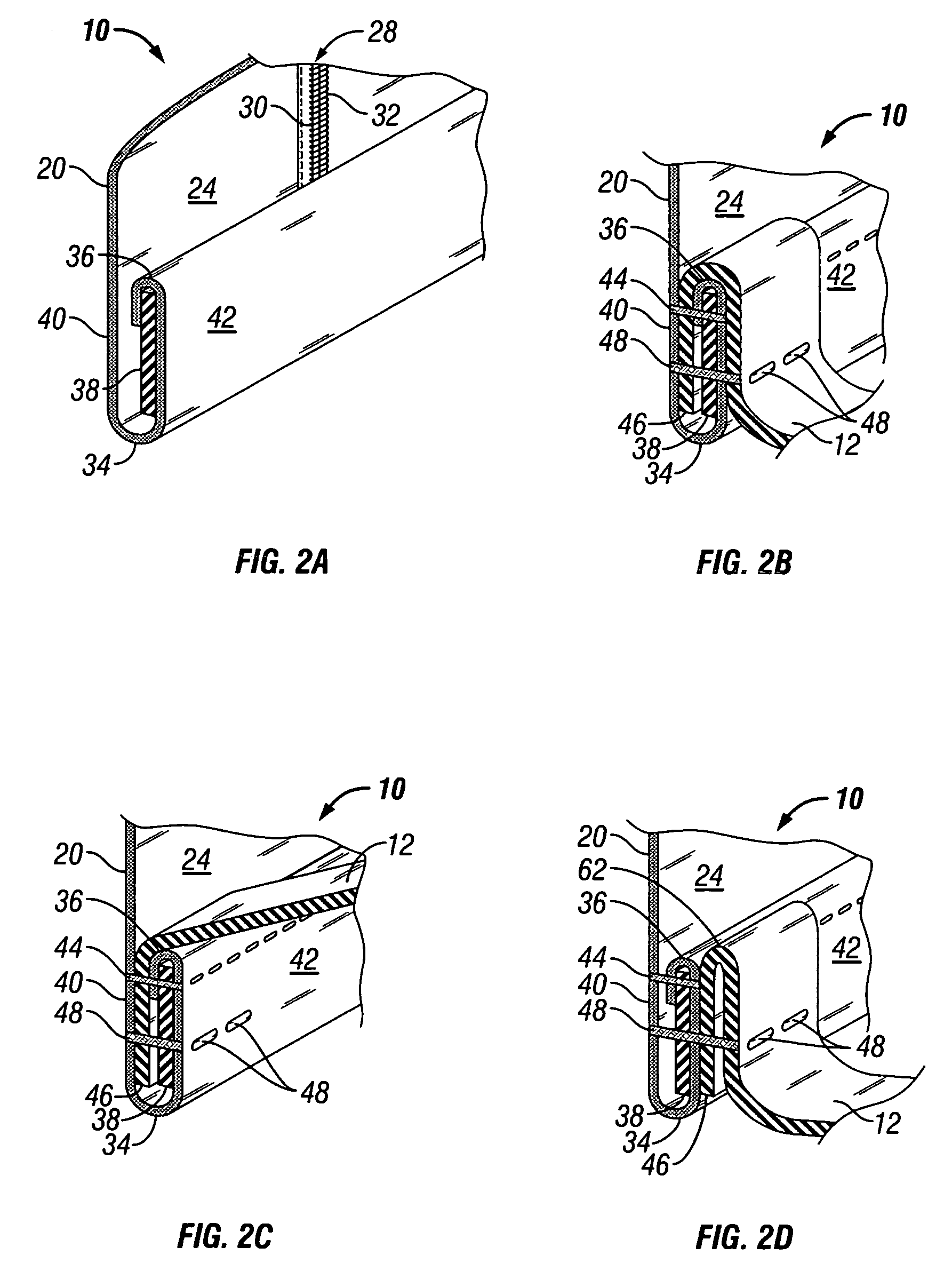

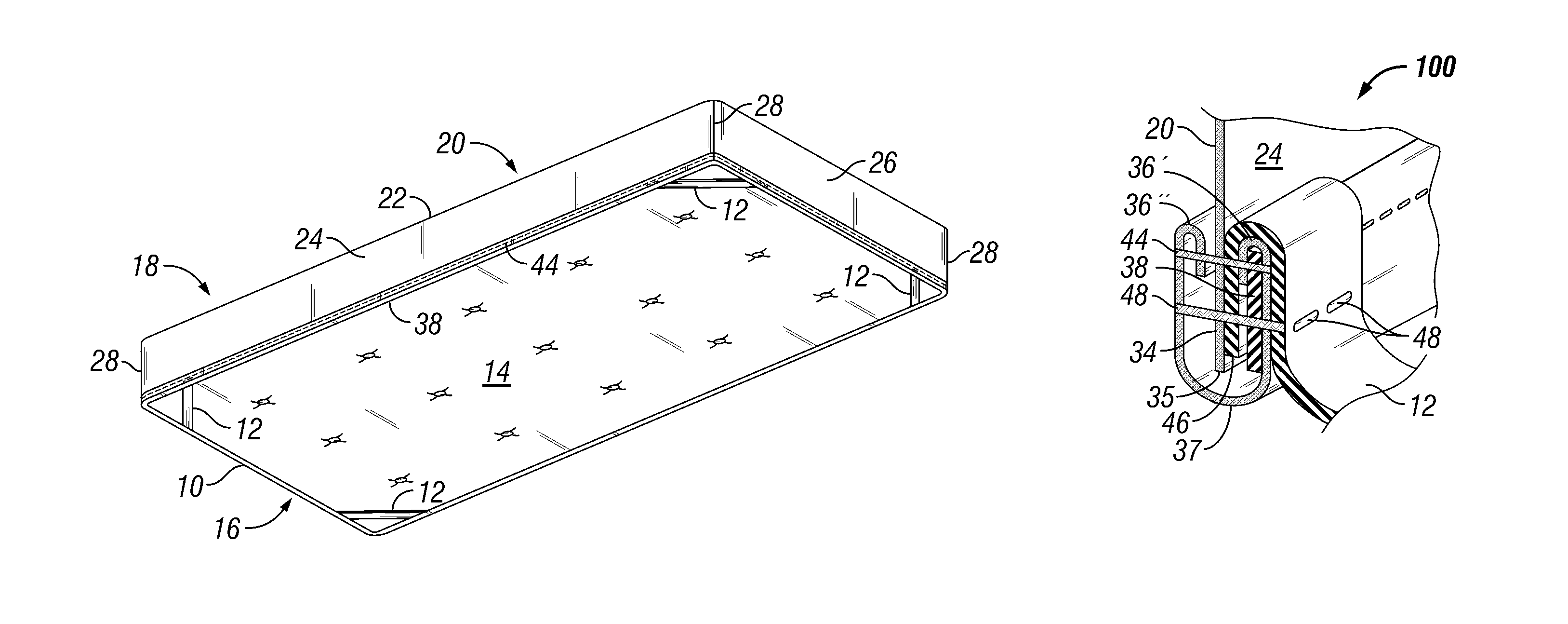

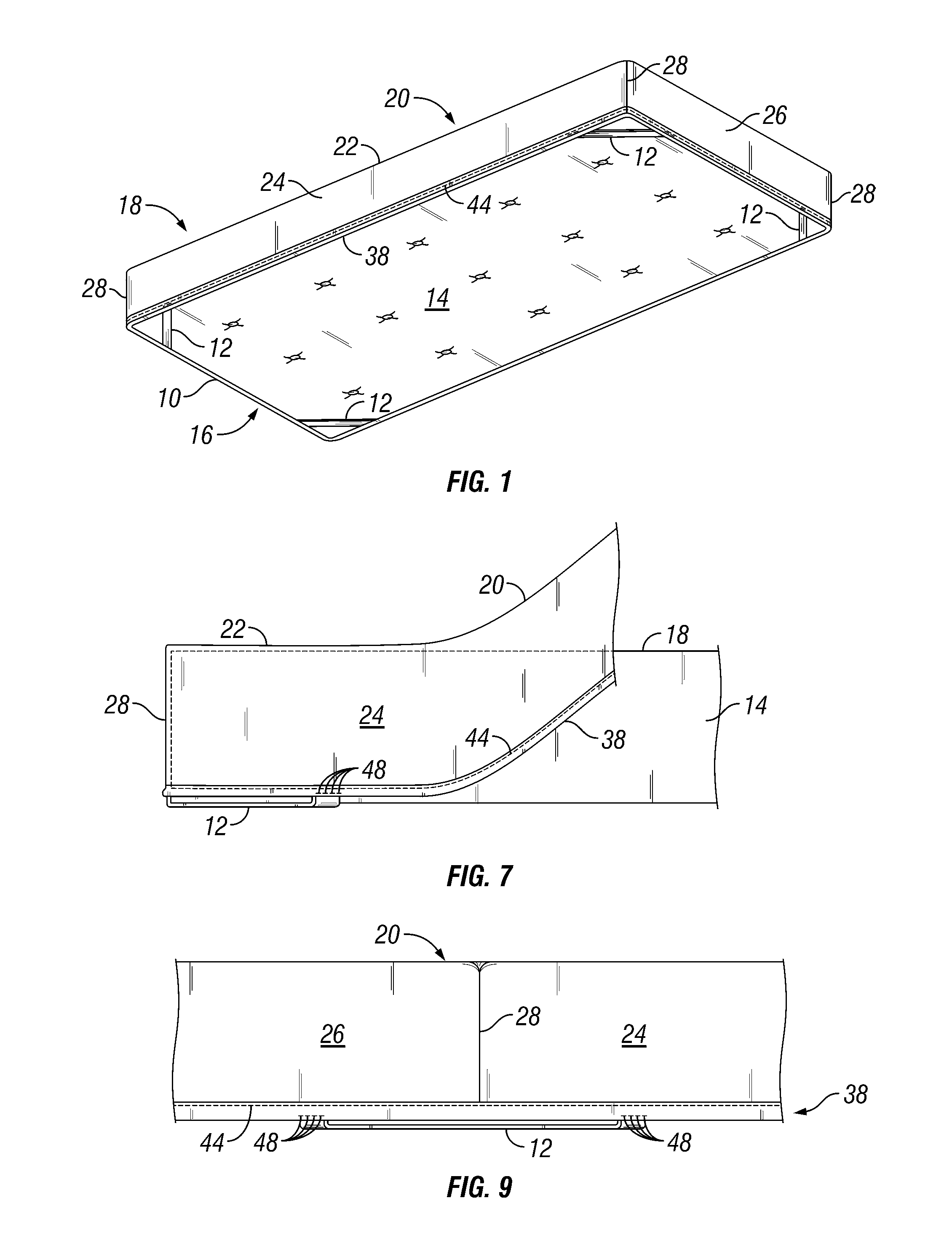

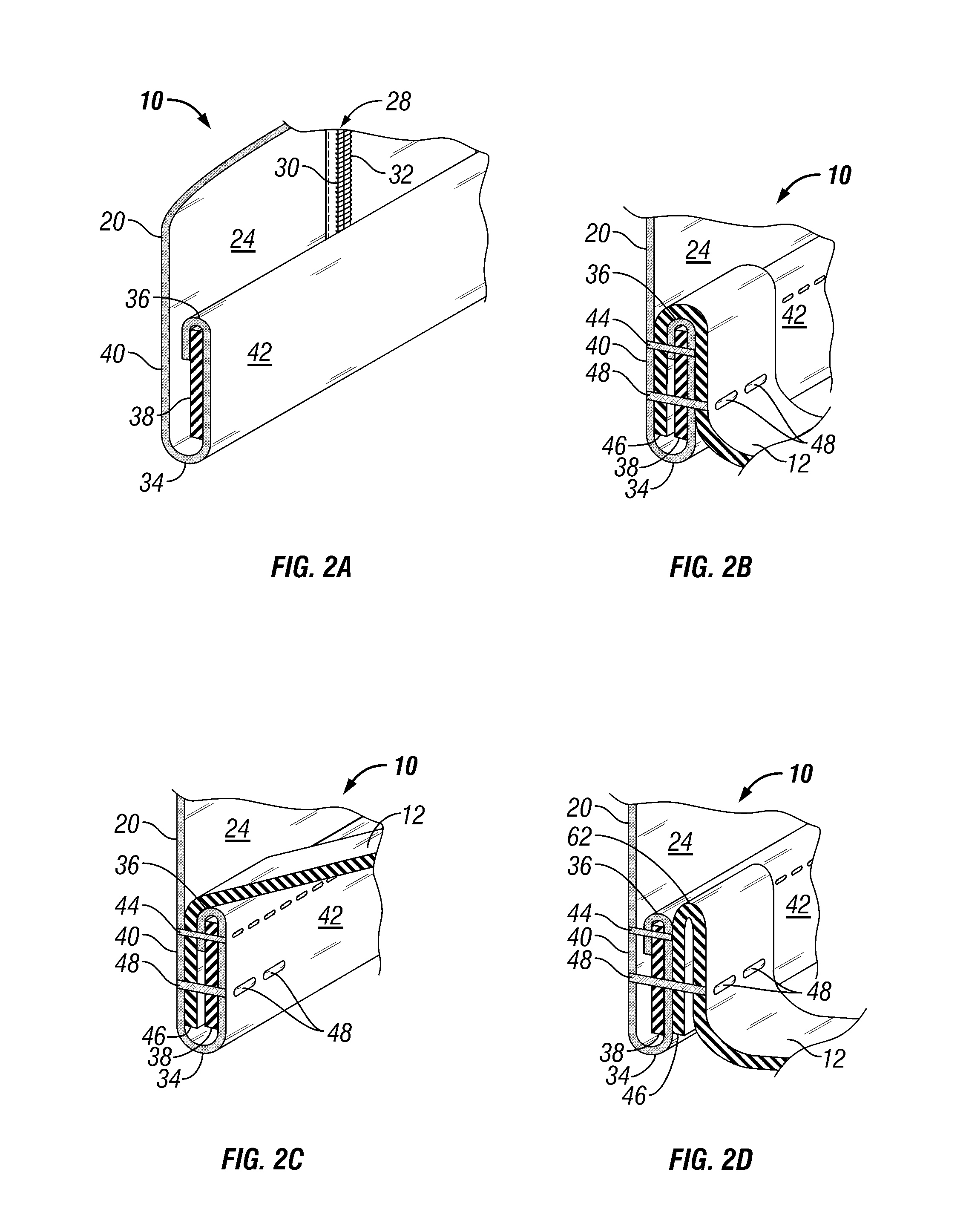

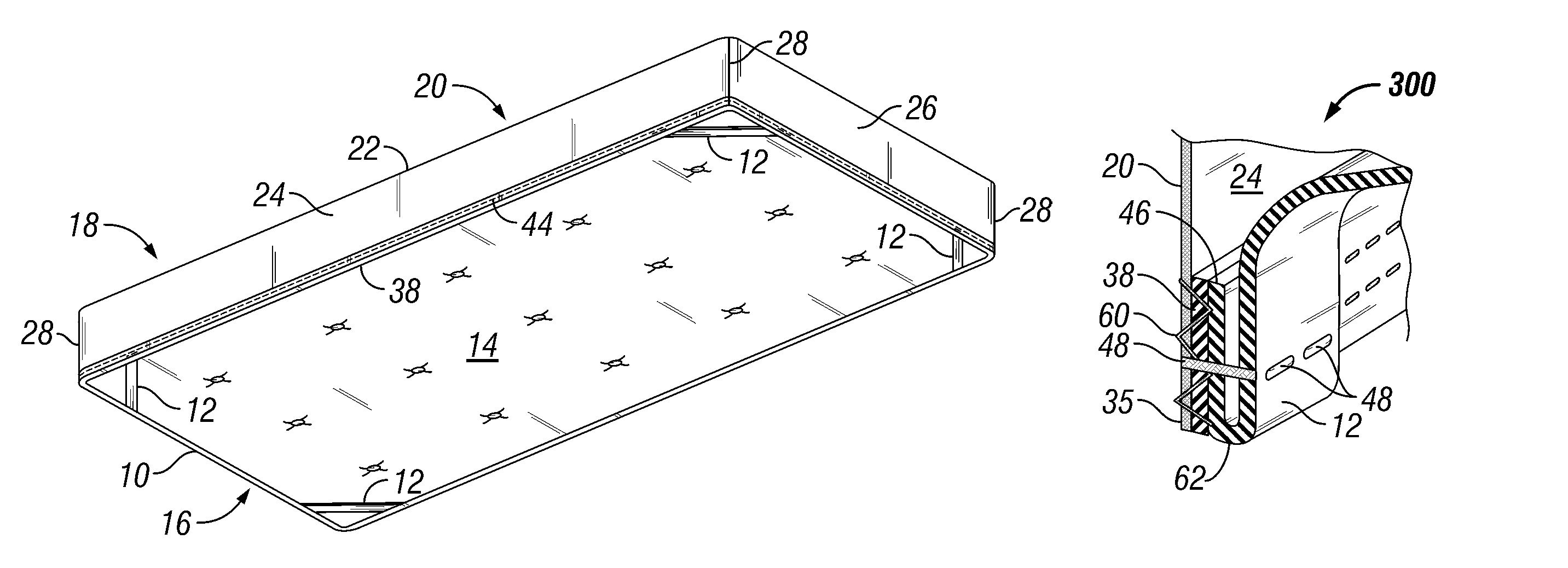

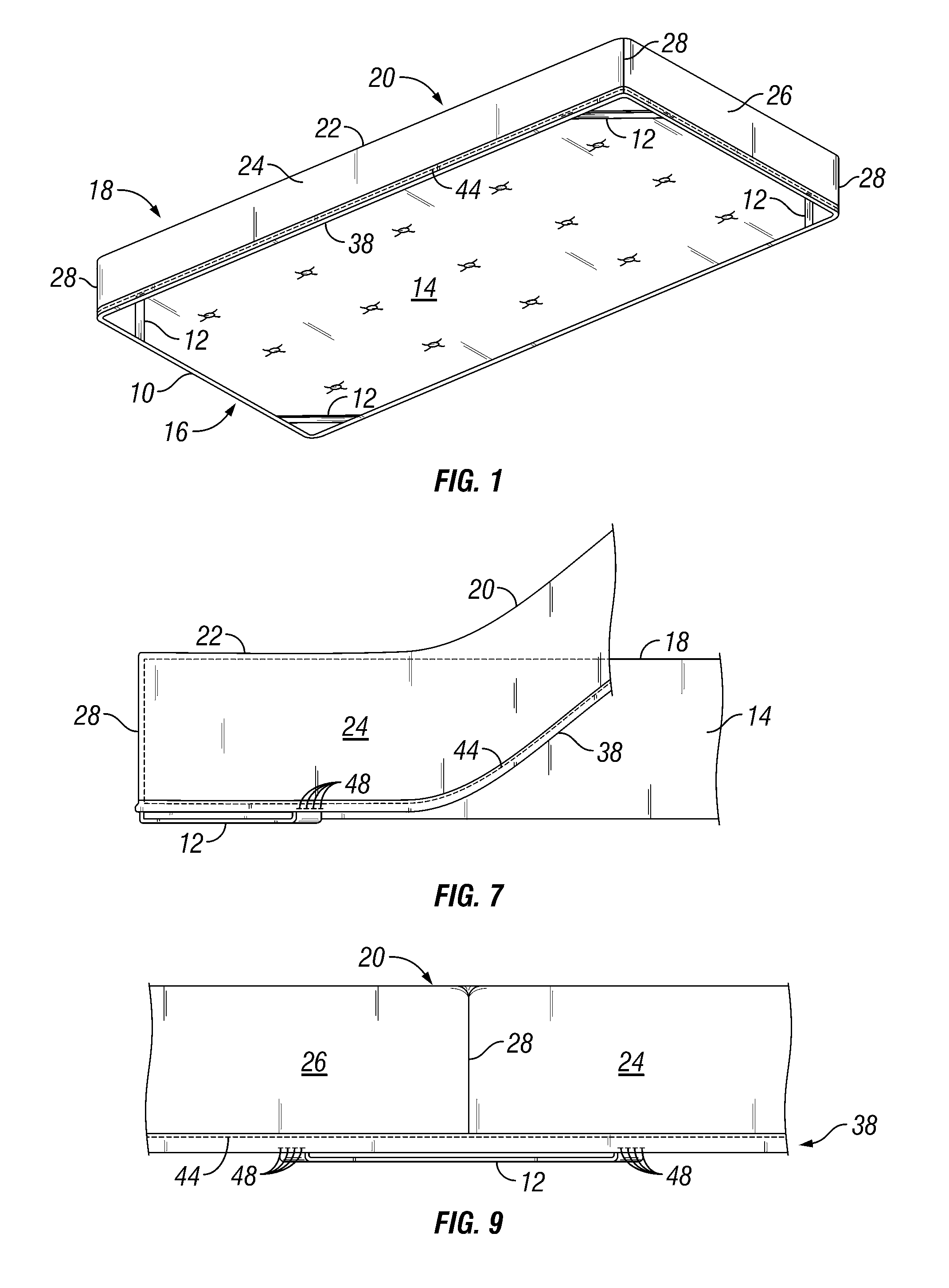

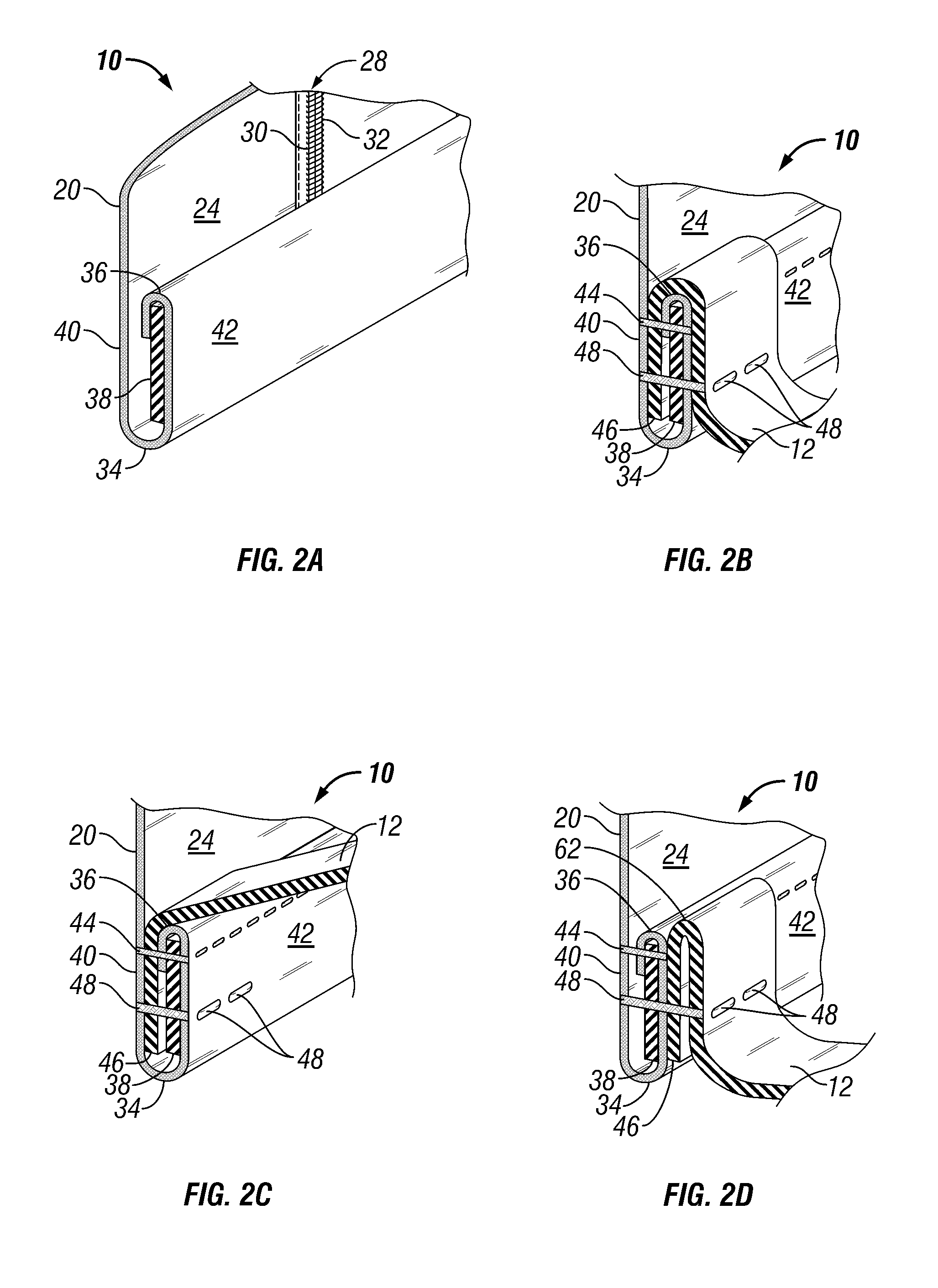

Fitted covering having diagonal elastic bands

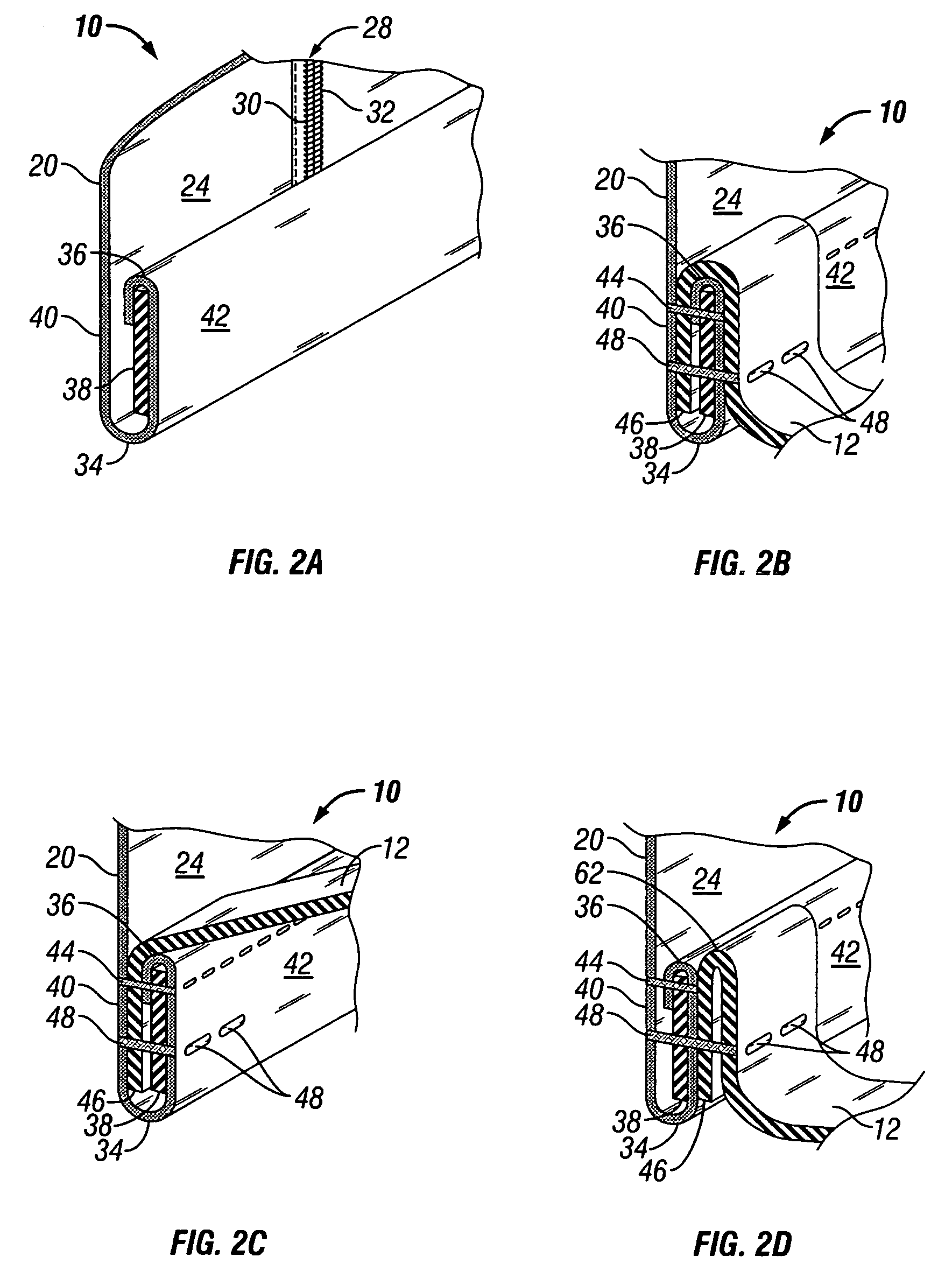

A fitted mattress covering for a mattress includes lower edge portions, which may be inverted J-shaped portions, mirror-image inverted J-shaped portions, portions that terminate at an end, or inverted U-shaped portions. The covering side and end portion lower edges may join one another to form a continuous lower edge of the covering. For the J-shaped portion, an elastic binding may be disposed under a downwards folded portion. The elastic binding may extend at least partially along the length of the lower edge of the covering. An elastic band may be disposed at each corner of the covering and extend diagonally across the associated corner and have opposite ends secured adjacent one of the side portions and adjacent one of the adjacent end portions, respectively. The bands may be secured in place by stitching and / or by supplementary securing means to ensure that the bands do not pull away from the covering.

Owner:HOMTEX

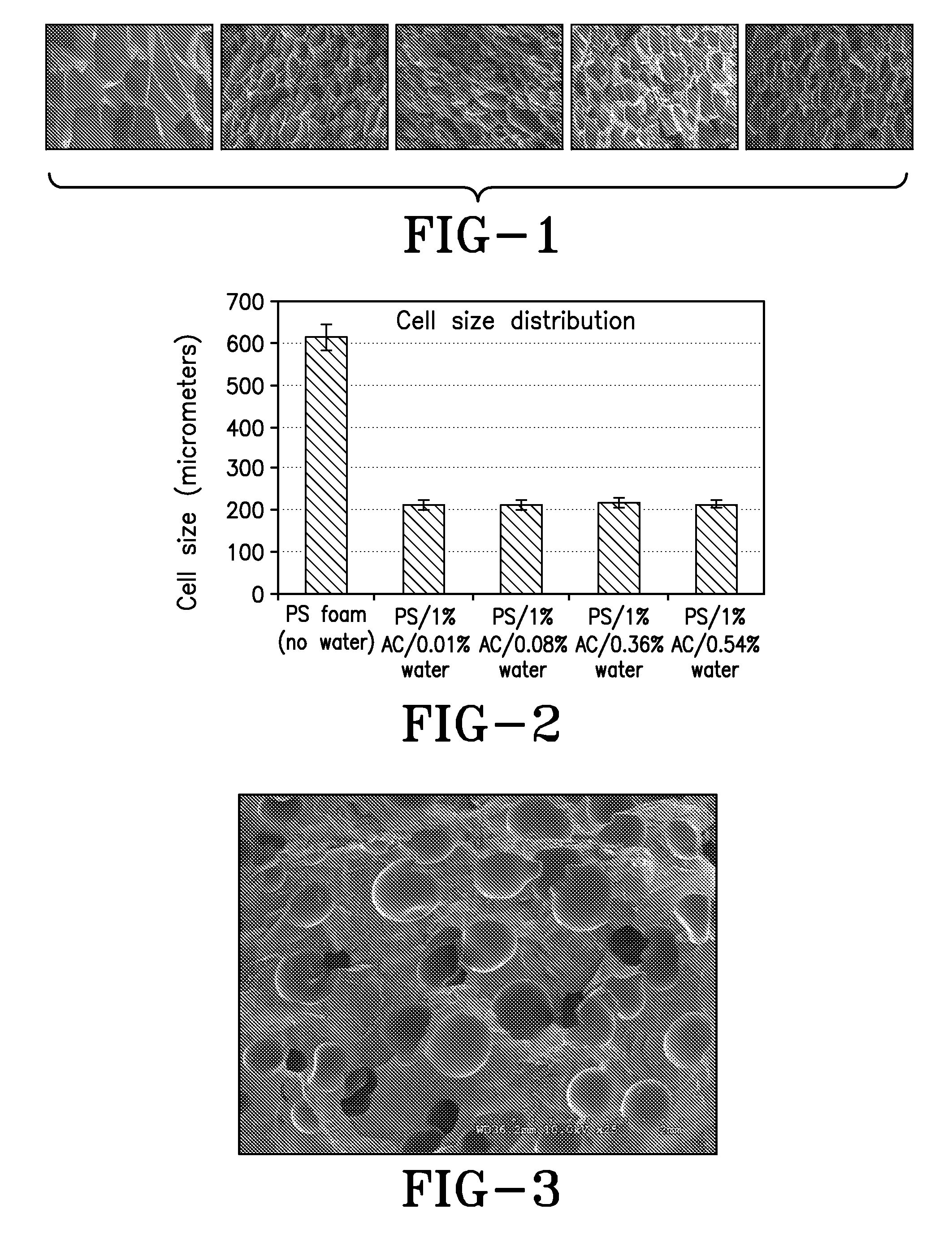

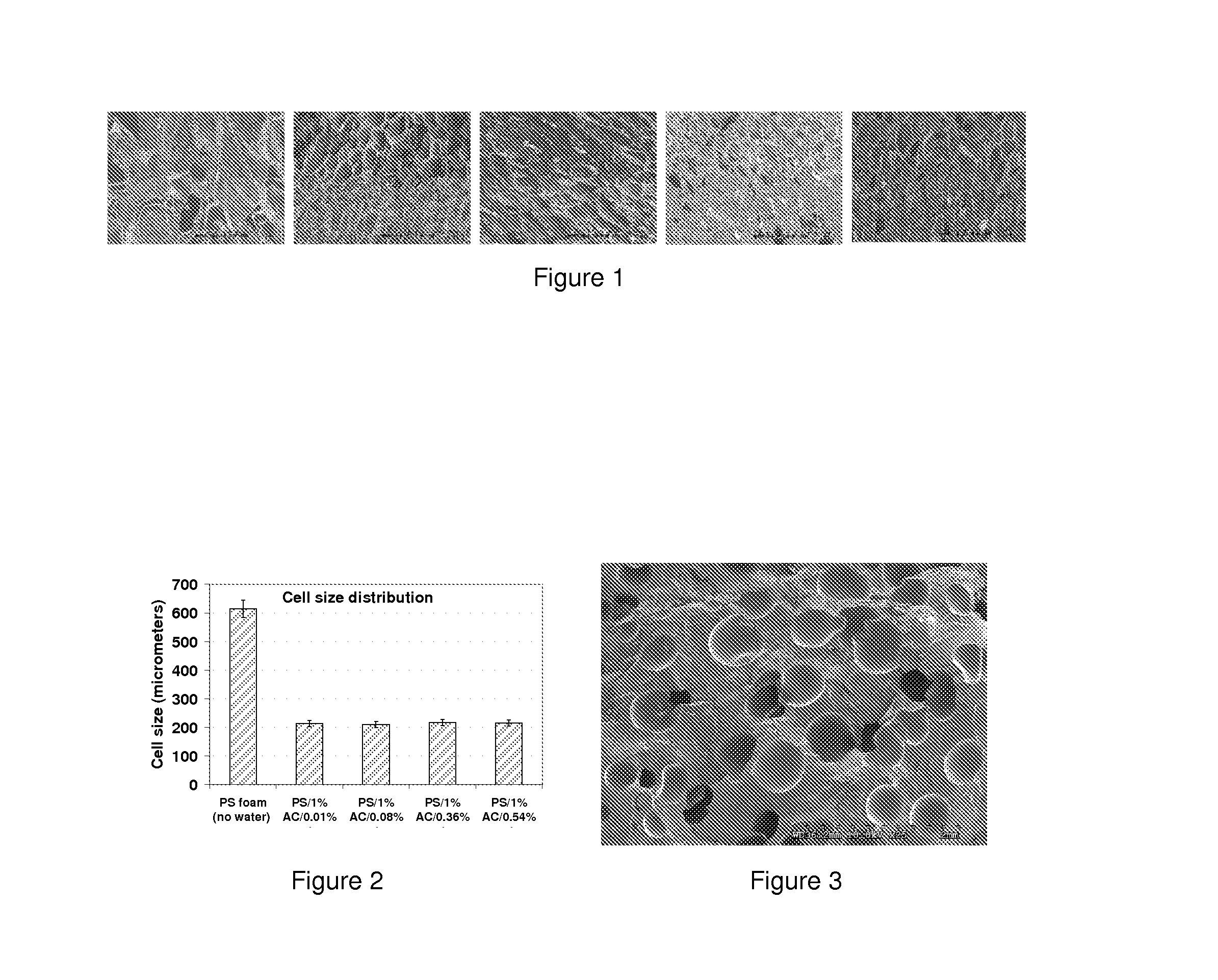

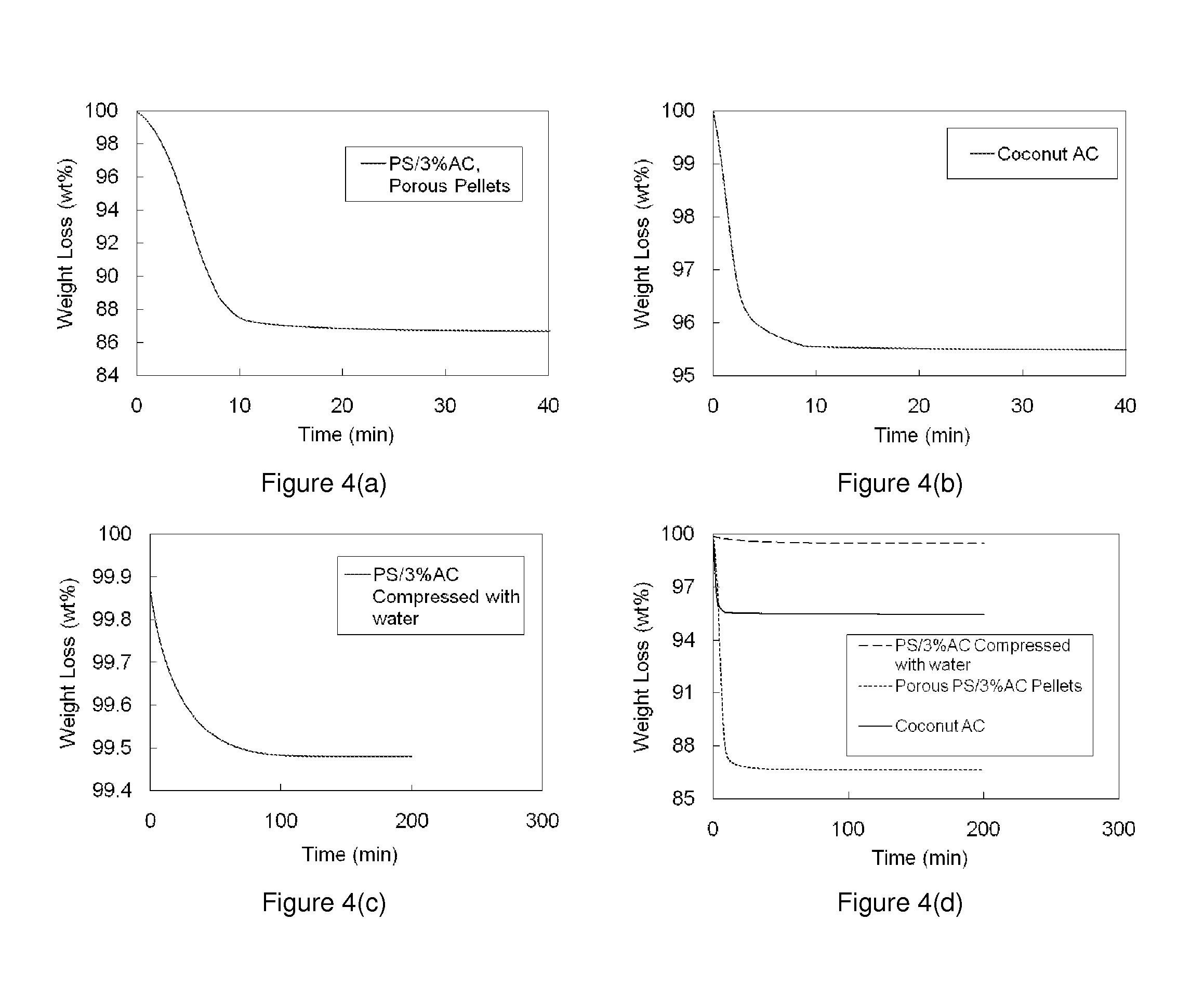

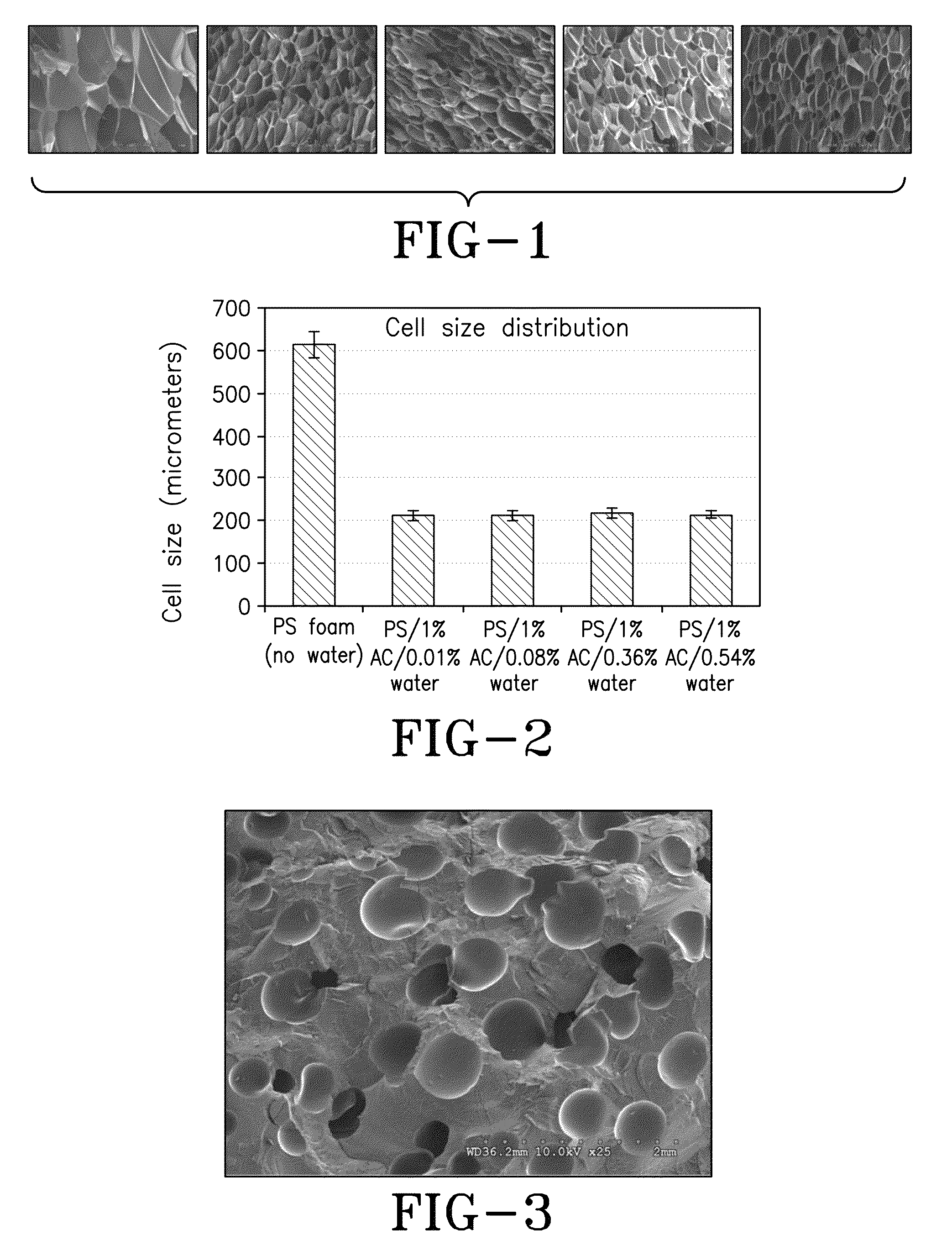

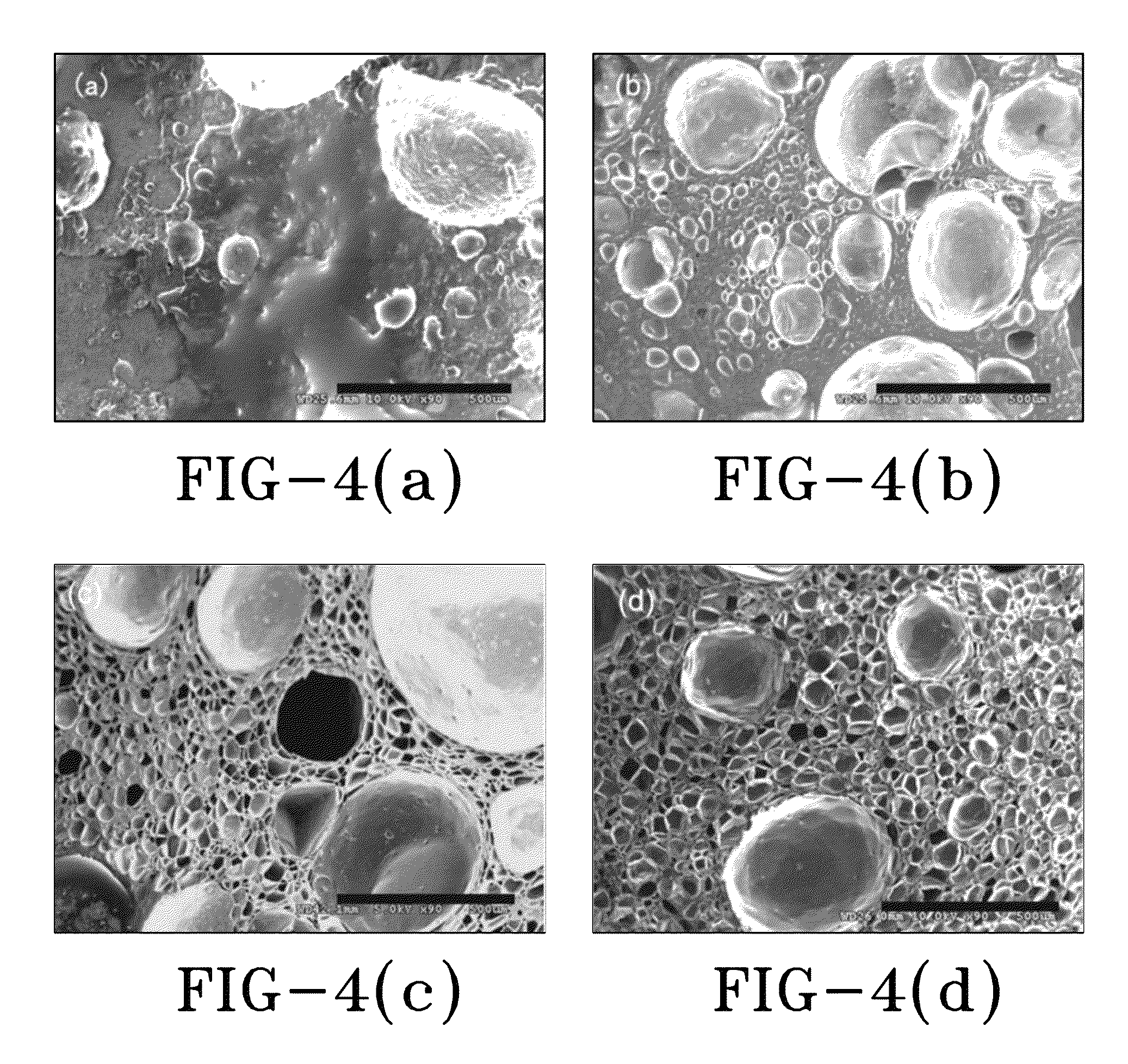

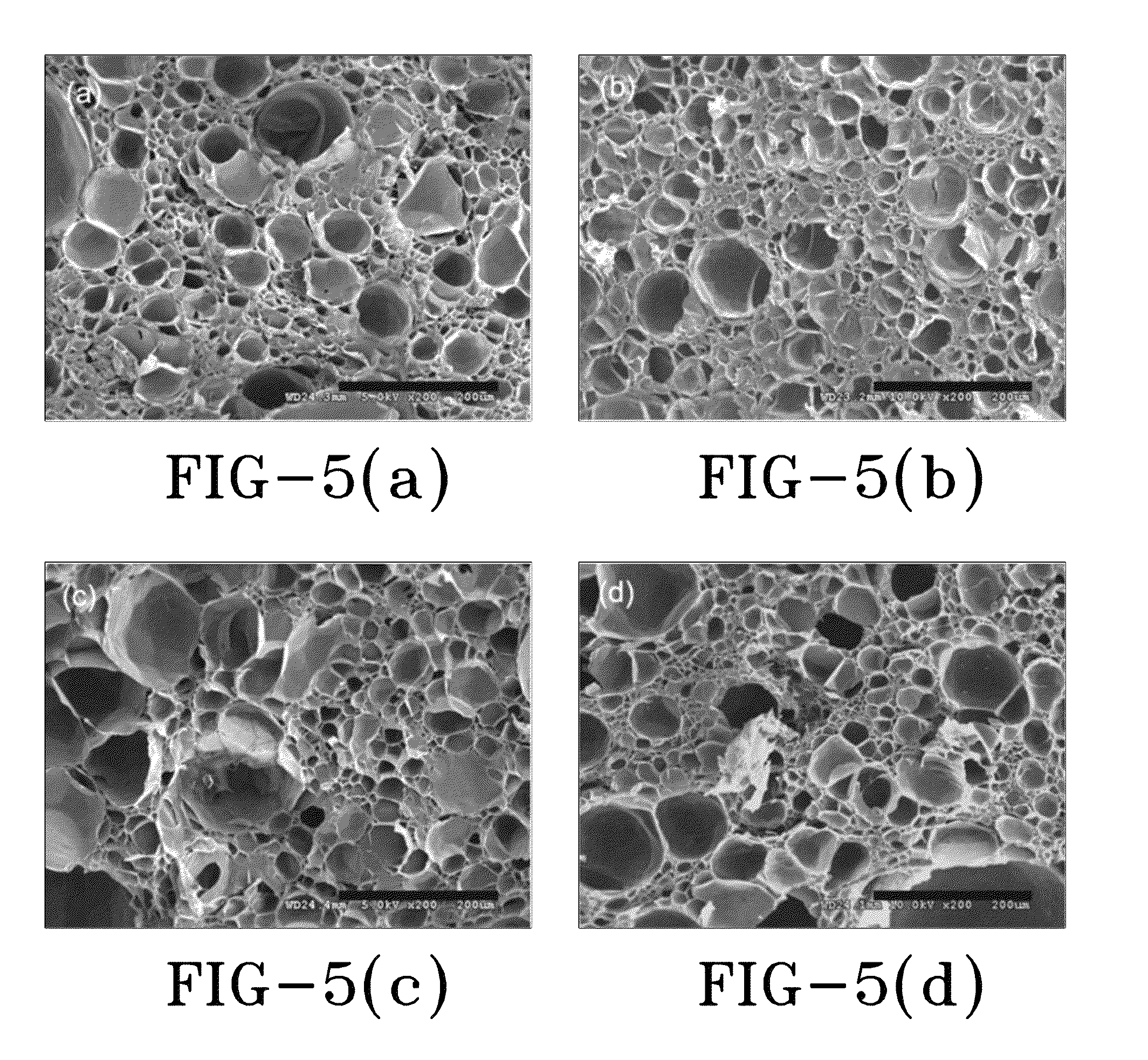

Suspension polymerization and foaming of water containing activated carbon-nano/microparticulate polymer composites

InactiveUS20100099782A1Good performanceHigh structural strengthCoatingsActivated carbonPolymer composites

Synthesis of polystyrene and / or other thermoplastic polymers or polymer blends which, for example, contain activated carbon and / or bamboo carbon carrying a co-blowing agent such as water and / or at least one of 1-dimensional, 2-dimensional, and 3-dimensional nano / micro-materials in suspension polymerization without using the inverse emulsion process. CO2 or other blowing agent based foaming processes such as extrusion, batch foaming, and injection molding may then be carried out to produce polymer foams that have low density, high-R value, bimodal structures, good mechanical properties, and high fire retardance.

Owner:NANOMATERIAL INNOVATION +1

Extruded polypropylene sheets containing beta spherulites

ActiveUS20050003151A1Improve the level ofLow densityLayered productsFlat articlesPolymer sciencePolypropylene mesh

An improved extruded polypropylene sheet that contains a high level of beta crystallinity and a process for making such sheets are disclosed herein. The polypropylene sheet contains at least one layer of a resinous polymer of propylene and an effective amount of beta spherulites. The beta spherulites in the sheet are produced by the incorporation of a beta nucleating agent in the polymer. The presence of the beta spherulites in the sheet facilitates the process of post-stretching the perforated sheet to produce a uniaxially or biaxially oriented mesh structure, and also broadens the temperature range over which this stretching can be performed. The final mesh has a lower density than a polypropylene mesh without beta spherulites. The perforated beta nucleated sheet also exhibits different stretching characteristics during the orientation steps such that more resinous polymer is drawn out of the node junction region between the machine direction and transverse direction oriented strands and a greater percentage of the web area has a solid polymer structure. This altered stretching behavior results in an oriented web that has higher strength and torsional rigidity characteristics. Thus lighter weight mesh structures which meet all of the physical property requirements for end-use applications, such as reinforcing grids to stabilize concrete and soil in civil engineering and landfill applications, are produced. The lighter weight extruded beta nucleated sheet can also be stretched at higher line speeds, thereby reducing the manufacturing costs.

Owner:MAYZO

Bed sheet with side pocket

ActiveUS7131152B2Overcomes drawback and deficiencySolve the real problemBlanketBed linenEngineeringWell control

An improved pocketed bed sheet is provided that avoids inadvertent placement of objects in a pocket, better controls placement and removal of objects from within its pocket, and deters babies and toddlers from accessing such pocket, all without the need for engagement or disengagement of a fastening member. The improved pocketed bed sheet includes a fabric body configured to substantially cover a mattress and a pocket provided on the fabric body. The pocket includes a wall configured to hold objects in the pocket and a diagonal fabric edge that defines a diagonal opening for predetermined angular ingress and egress into the pocket for controlling the placement and removal of objects within the pocket. The diagonal fabric edge is disposed at an angle relative to an edge of the fabric body.

Owner:HOMTEX

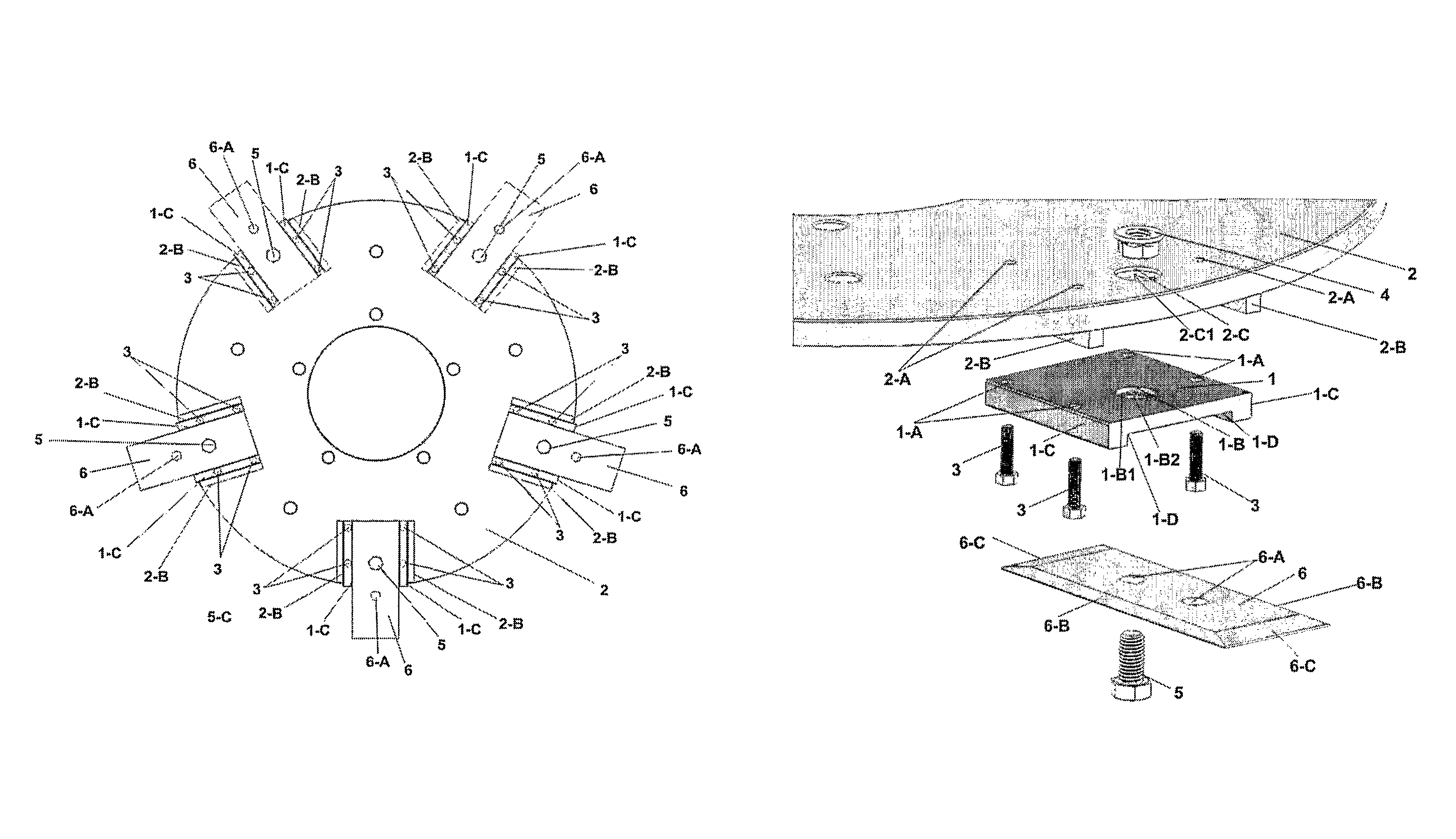

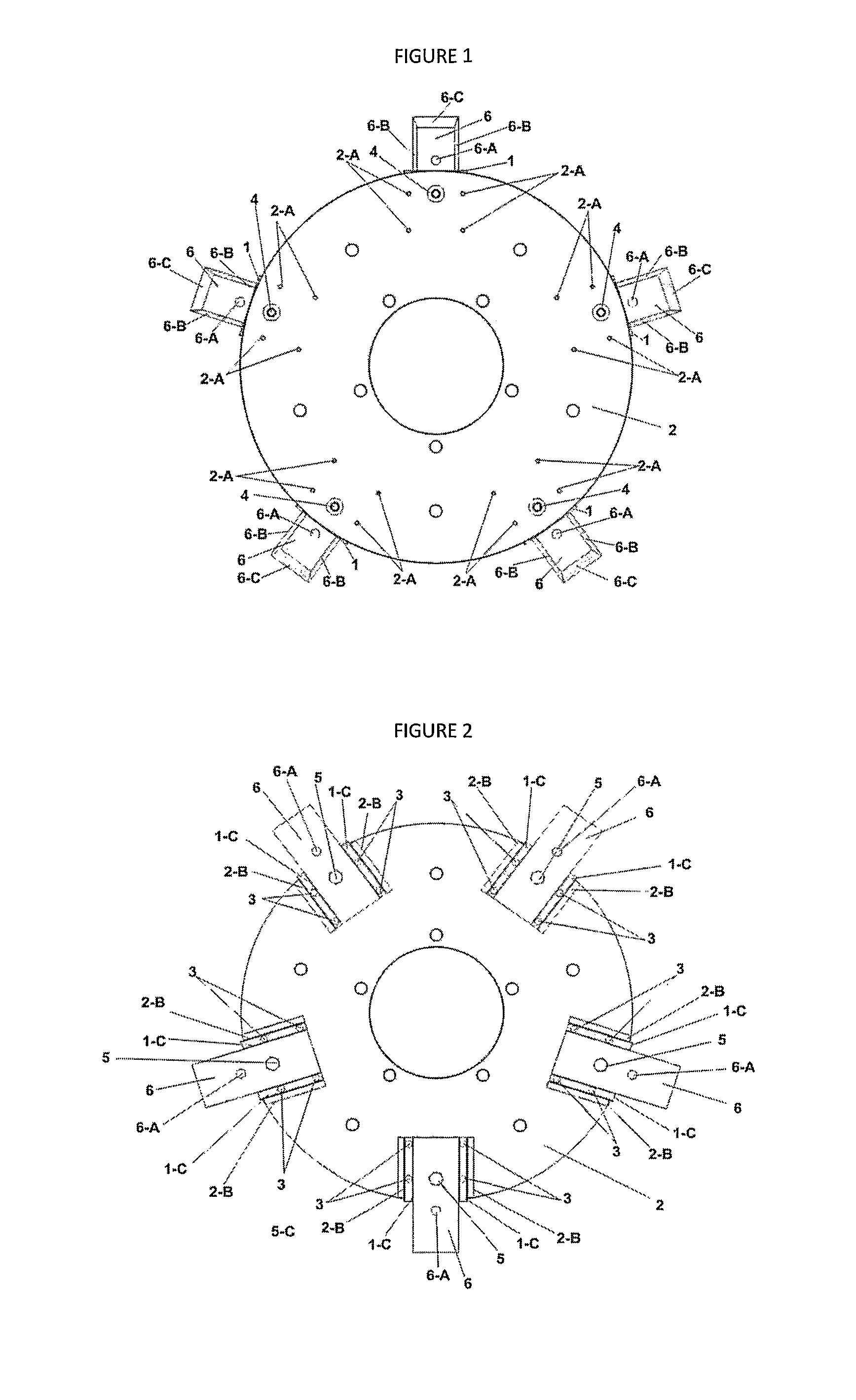

Knife and counter knife in machine disk

A rectangular counter knife with a larger diameter hole, the counter knife has two lateral, longitudinal, parallel, rectangular and vertical walls inferiorly forming a rectangular recess, the two rectangular, inferior and transversal guides of the rotating disk, support the rectangular knife, adjusting a hex-nut in a larger diameter hole, coincident to the hole, receiving these holes on inferior-superior direction, a hex-head screw initially by-pass one of the two holes centralized along one rectangular knife with two side cutting edges and their ends have, a constructive variant comprising a rectangular knife with a longitudinal, central and oblong opening, with two central, opposite and semi-circular projections forming a circular central opening in the middle of the knife; the rectangular knife has two side cutting edges and two cutting edges on the ends.

Owner:OREGON TOOL INC

Fitted covering having diagonal elastic bands

A fitted mattress covering for a mattress includes lower edge portions, which may be inverted J-shaped portions, mirror-image inverted J-shaped portions, portions that terminate at an end, or inverted U-shaped portions. The covering side and end portion lower edges may join one another to form a continuous lower edge of the covering. For the J-shaped portion, an elastic binding may be disposed under a downwards folded portion. The elastic binding may extend at least partially along the length of the lower edge of the covering. An elastic band may be disposed at each corner of the covering and extend diagonally across the associated corner and have opposite ends secured adjacent one of the side portions and adjacent one of the adjacent end portions, respectively. The bands may be secured in place by stitching and / or by supplementary securing means to ensure that the bands do not pull away from the covering.

Owner:HOMTEX

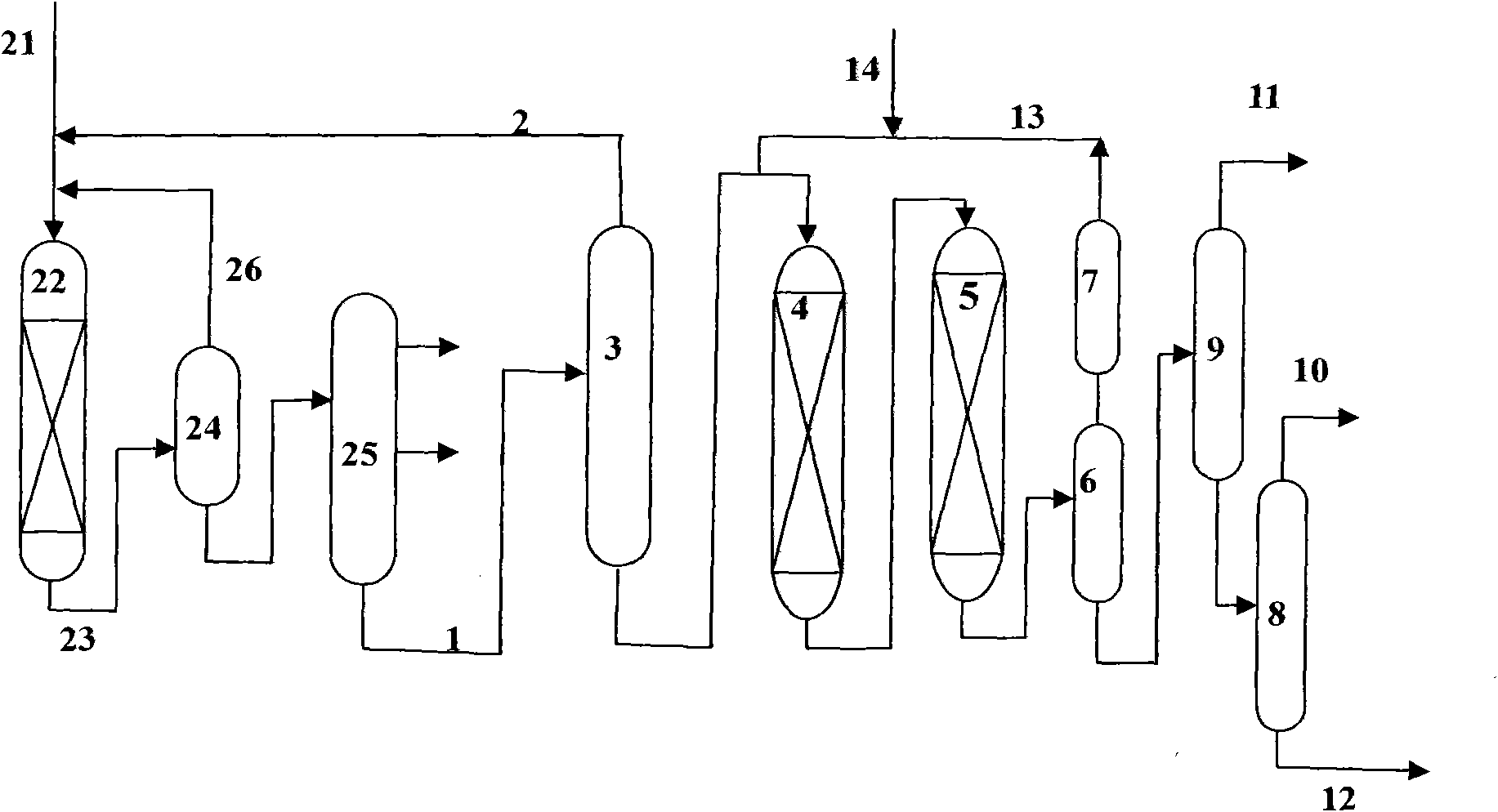

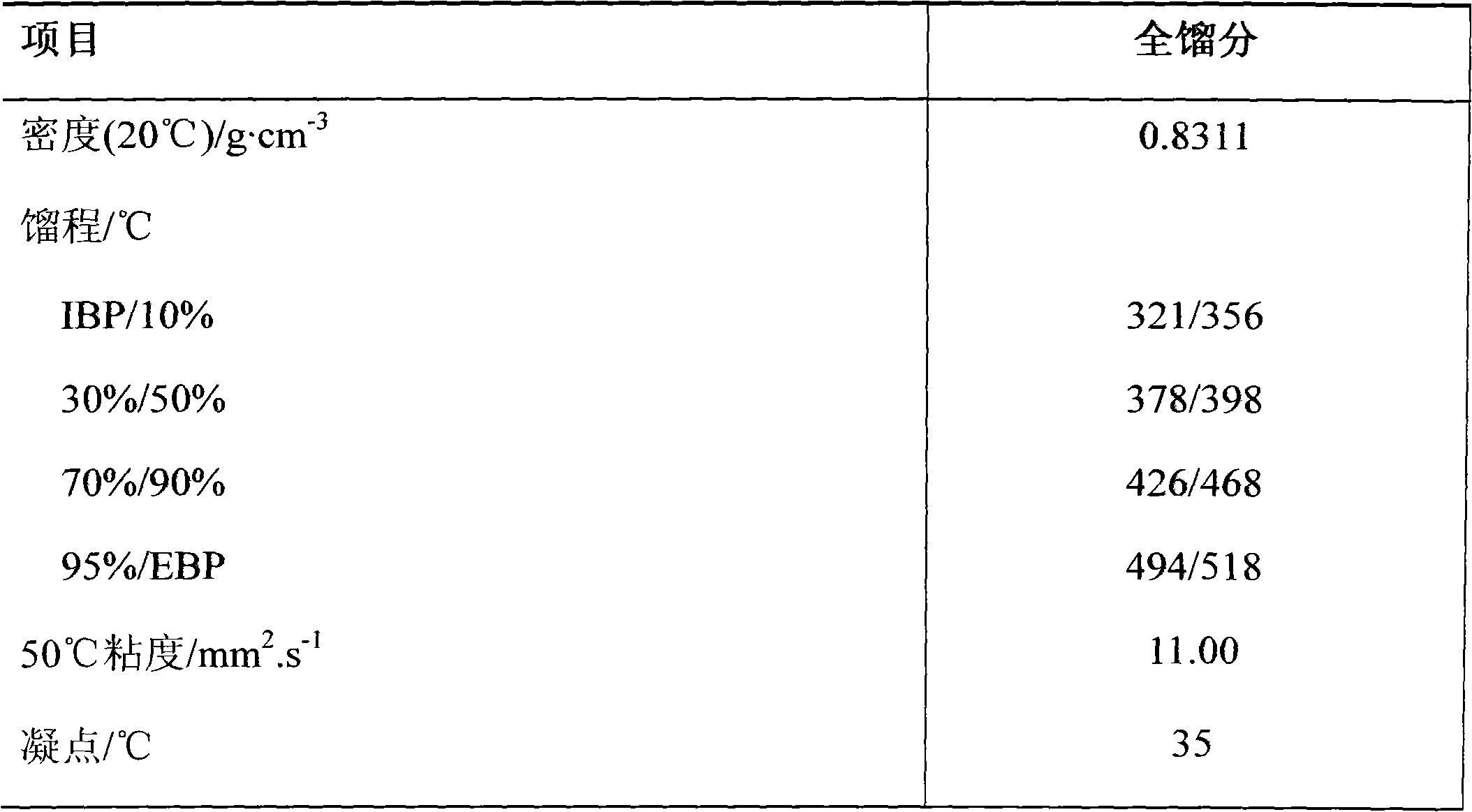

Combined method of hydrocracking and producing lubricant oil base oil

InactiveCN102041081AHigh yieldEasy to operateTreatment with hydrotreatment processesCombined methodBase oil

The invention relates to a combined method of hydrocracking and producing lubricant oil base oil, which comprises the following steps of: firstly, carrying out pressure reduction on hydrocracking tail oil; and carrying out heavy fraction on the fractionated hydrocracking tail oil used as a raw material for producing the lubricant oil base oil. The heavy fraction of the hydrocracking tail oil can obtain excellent lubricant oil base oil through the technique process of heterogeneous dewaxing-supplemental refining. The hydrocracking tail oil is subjected to light fraction and circulated back to a hydrocracking device to be mixed with a hydrocracking raw material for further hydrocracking. Compared with the prior art, the method improves the yield of the lubricant oil base oil, reduces the cost of the product and effectively solves the problem of insufficient raw material for producing the lubricant oil base oil in enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

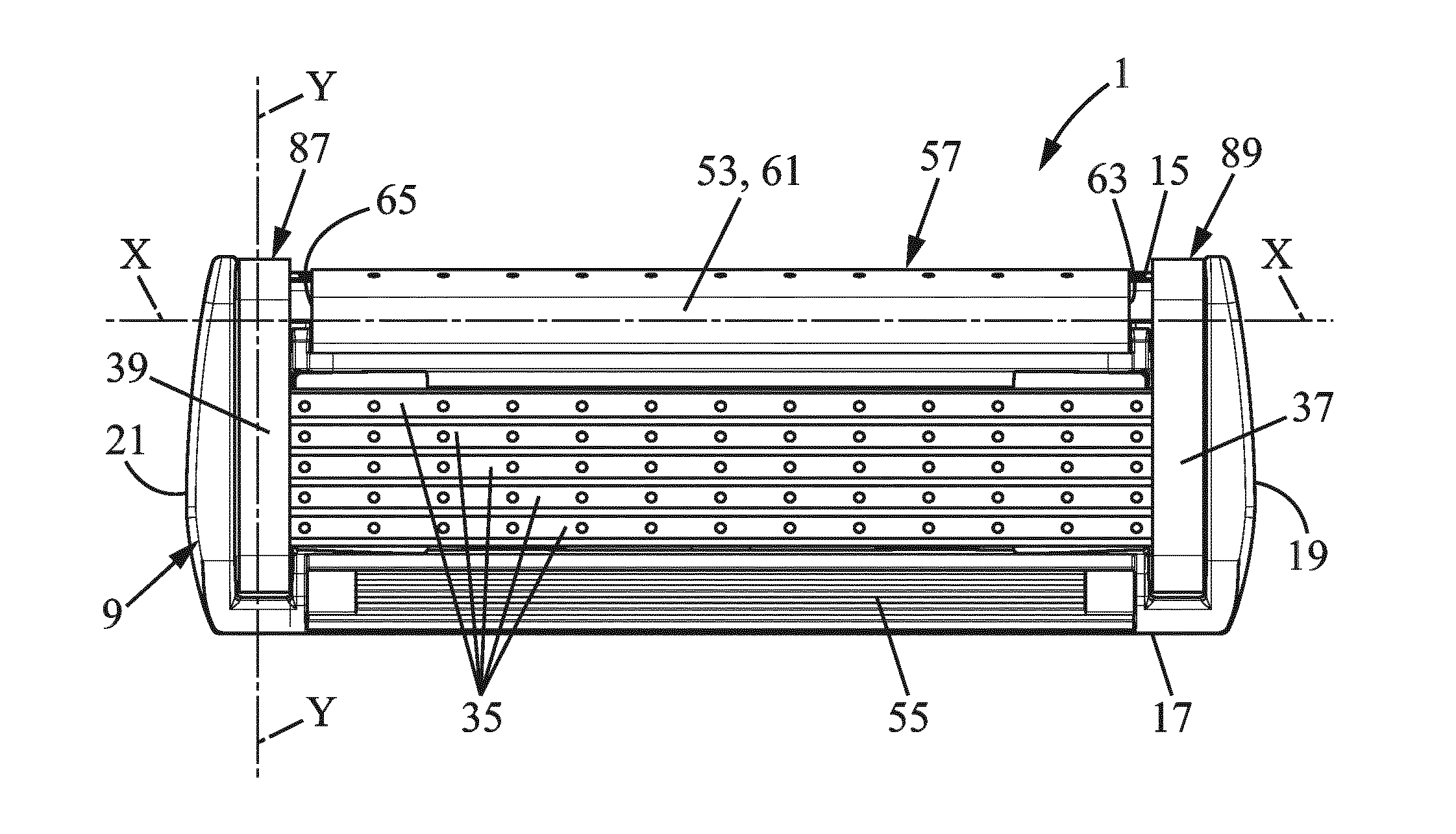

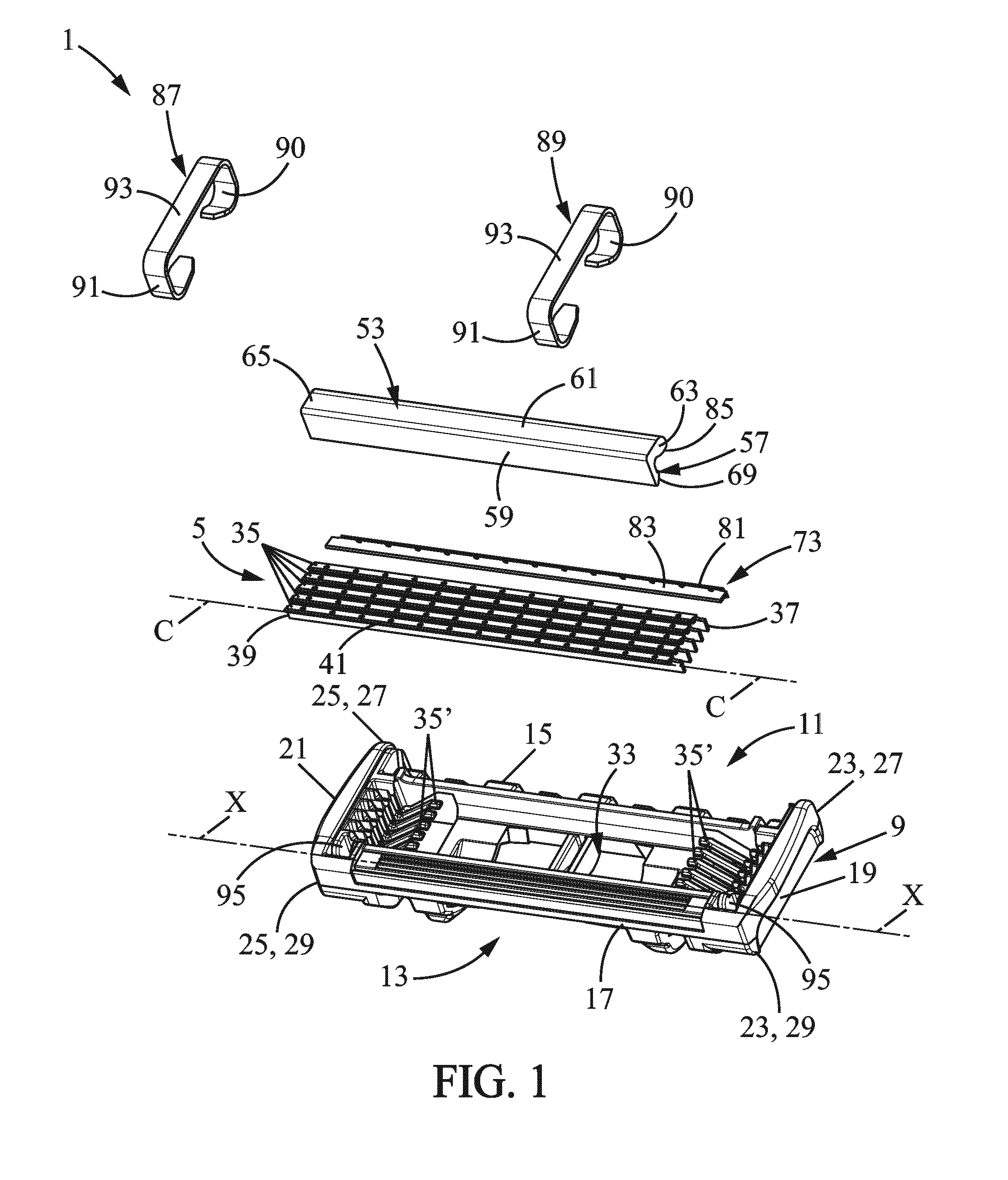

A shaving blade cartridge, a shaver comprising such shaving blade cartridge and a method of manufacturing such a shaving blade cartridge

A shaving blade cartridge includes a housing extending along a longitudinal axis having a top side, a bottom side opposite to the top side, and first and second longitudinal sides each extending longitudinally along the longitudinal axis between the top and bottom sides. A primary cutting blade is mounted on the housing between the first and second longitudinal sides, and has a cutting edge. A primary cap is located rearward of the cutting edge. A primary guard is located forward of the cutting edge. A trimming element, mounted on the housing, has a trimming edge. The trimming edge and the cutting edge are opposite one another. The primary cap is provided on a rear element, and the rear element is fitted on the housing. The trimming element is sandwiched between the housing and the primary cap.

Owner:BIC VIOLEX SA

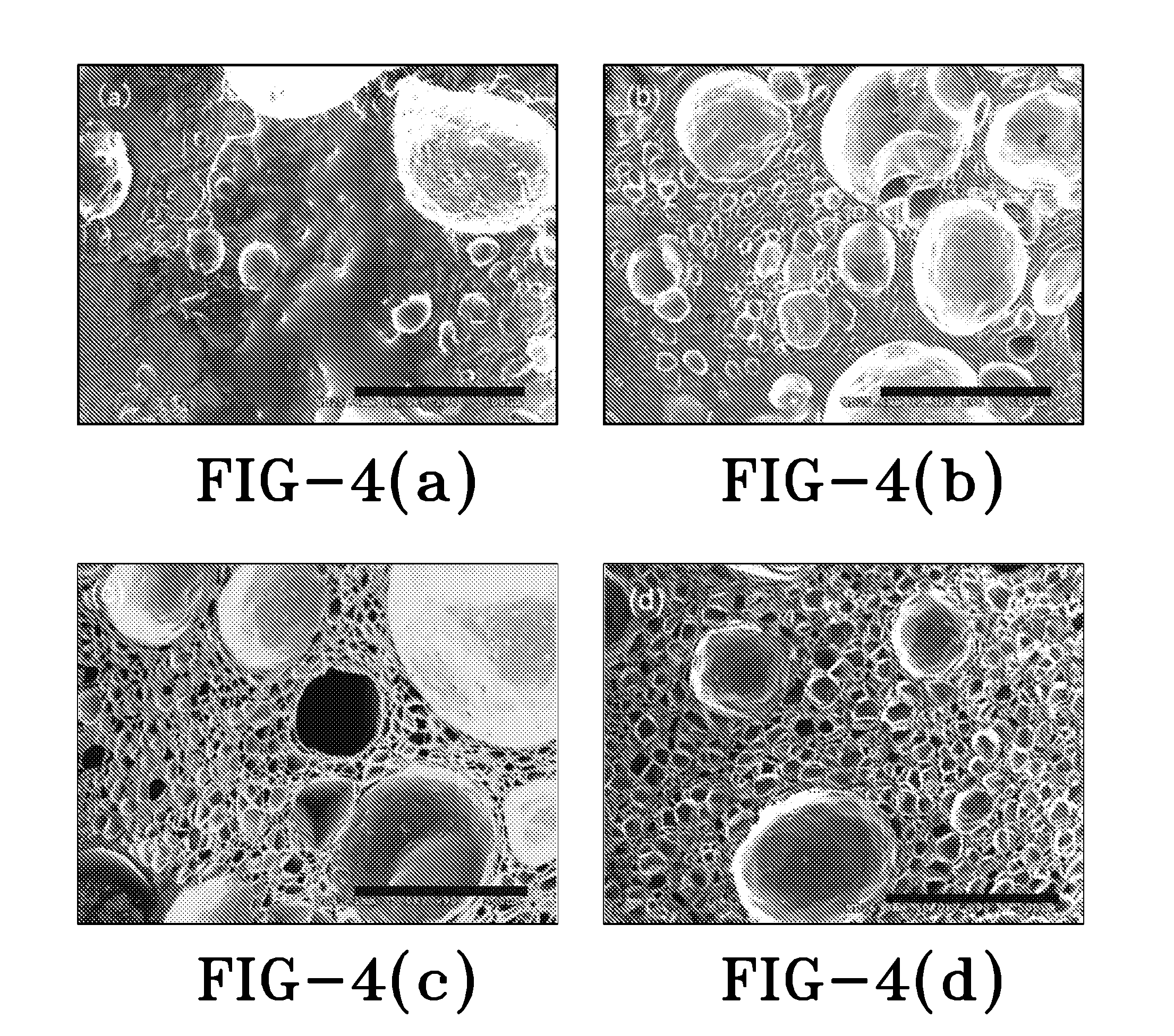

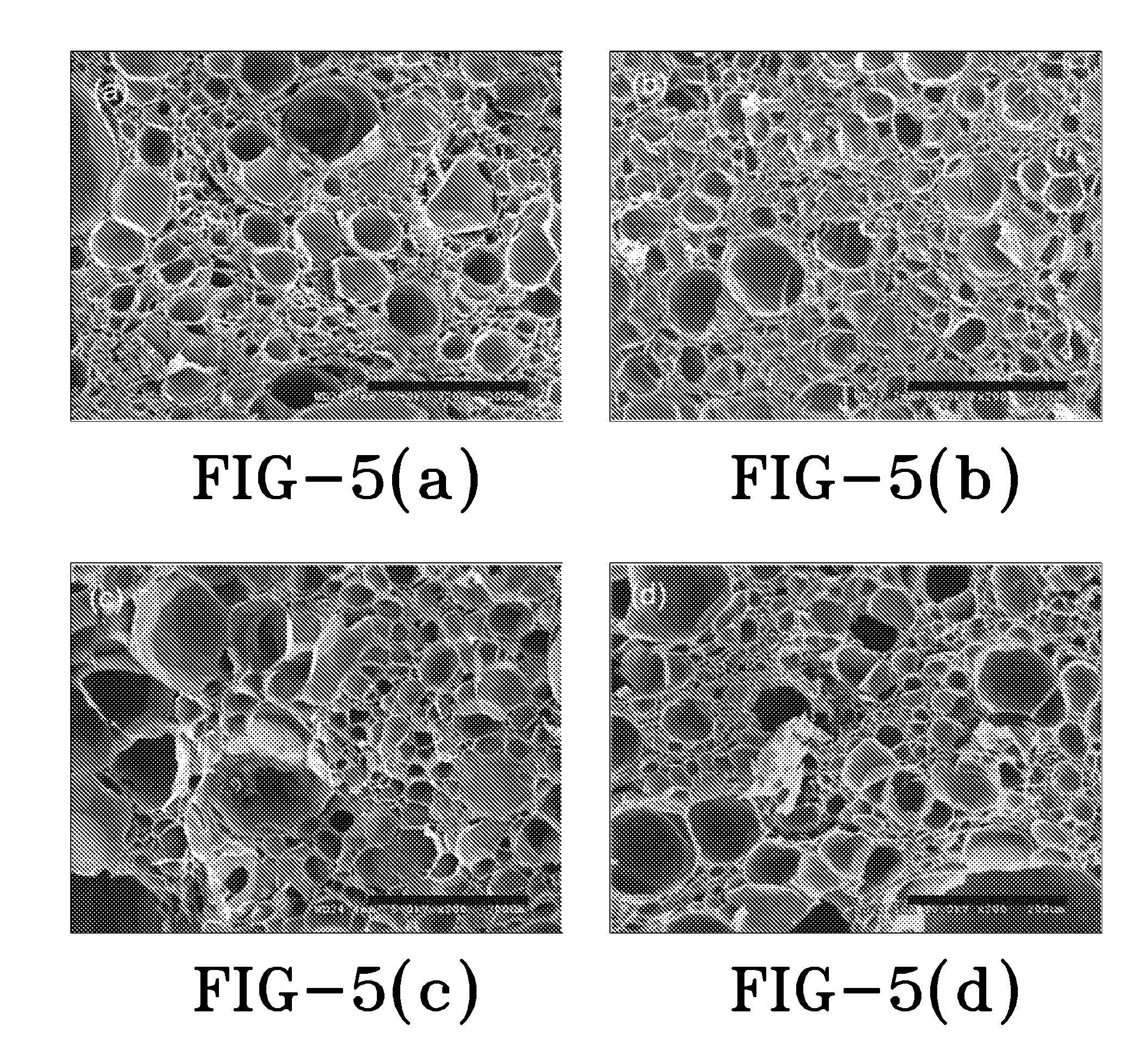

Surfactant-free synthesis and foaming of liquid blowing agent-containing activated carbon-nano/microparticulate polymer composites

InactiveUS20110240904A1Good performanceHigh structural strengthHeat proofingActivated carbonPolystyrene

Exemplary embodiments of the present invention relate to polystyrene and / or thermoplastic polymer or polymer blend composite foam or a foamable polymeric material precursor, which contains activated carbon and / or at least one of 1-dimensional, 2-dimensional, and 3-dimensional nano / micro-materials in polystyrene and / or thermoplastic polymer and / or polymer blend matrix to carry a co-blowing agent such as water without using any surfactant-like molecules and / or polymers, having or adapted to have the properties of low density, high-R value, good mechanical properties, and fire retardance thereof. Exemplary embodiments of the present invention include various manufacturing methods that may be employed including, but not limited to, extrusion, batch molding, and injection molding. One example includes synthesis and CO2 and water-based extruded foaming of such a material.

Owner:THE OHIO STATE UNIV RES FOUND +1

Extruded polypropylene sheets containing beta spherulites

ActiveUS7407699B2Improve the level ofLow densityLayered productsDomestic articlesManufacturing cost reductionEngineering

Improved extruded polypropylene sheets containing a high level of beta crystallinity and A process for making such sheets are disclosed herein. The polypropylene sheets comprise a resinous polymer of propylene and an effective amount of beta spherulites. Uniaxially or biaxially oriented mesh structures produced from the disclosed sheets exhibit lower density, higher strength, and higher torsional rigidity than polypropylene meshes without beta spherulites. Thus, lighter weight mesh structures which meet all of the physical property requirements for end-use applications, such as reinforcing grids to stabilize concrete and soil in civil engineering and landfill applications, are produced. The lighter weight extruded beta-nucleated sheet can also be stretched at higher line speeds, thereby reducing manufacturing costs.

Owner:MAYZO

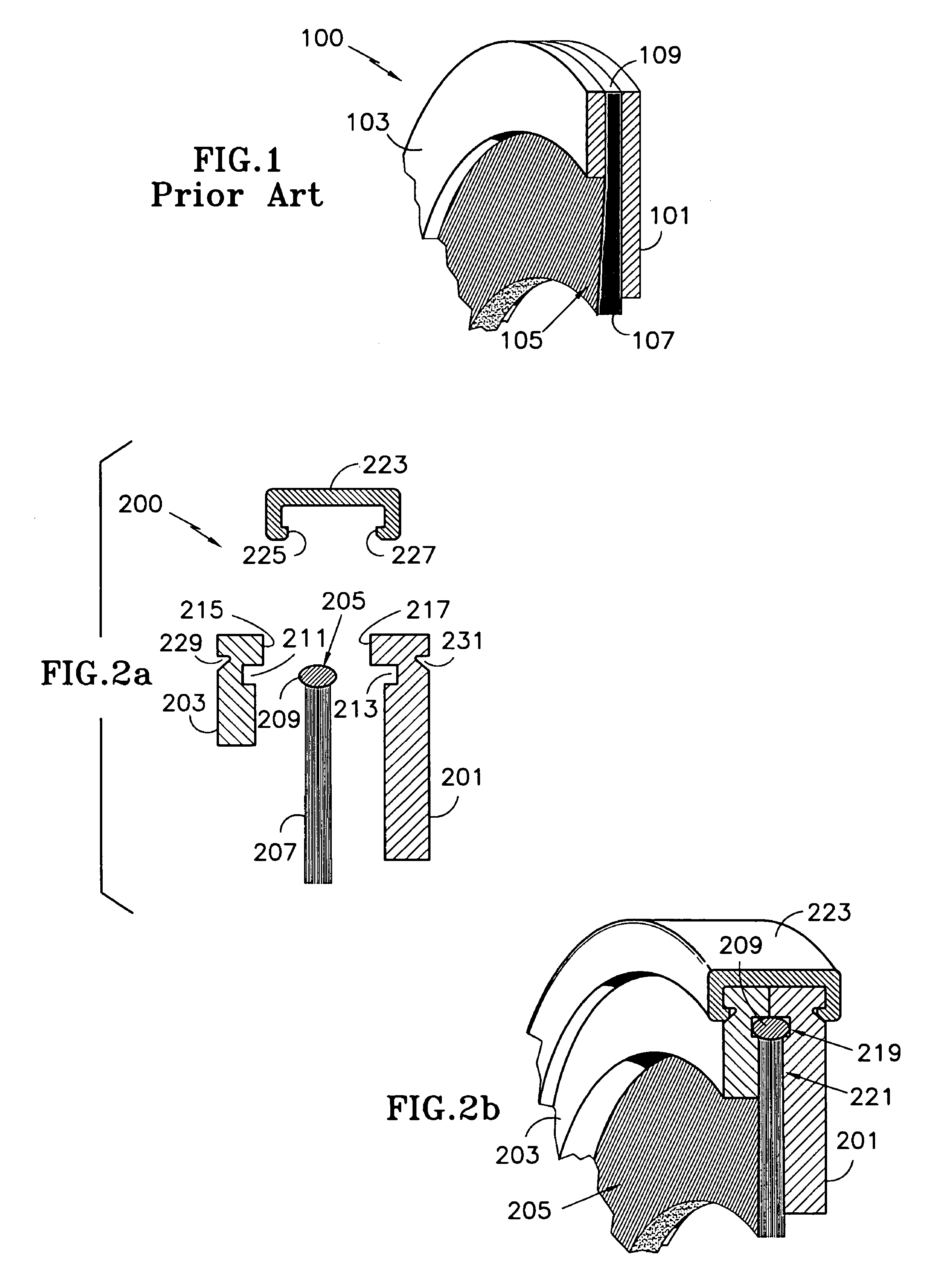

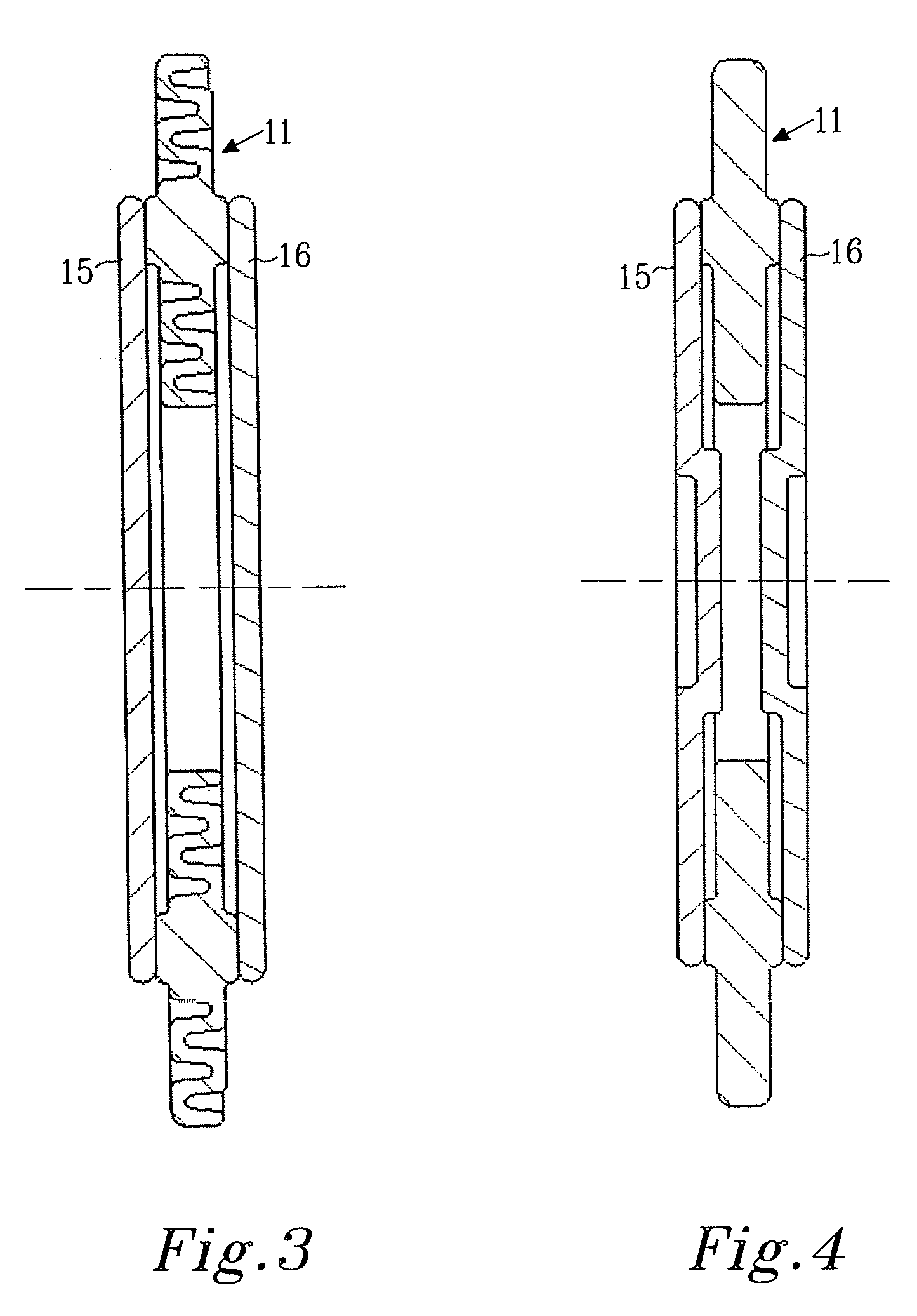

Brush seal

A brush seal, comprising: a bristle arrangement with a plurality of bristles; and a joint securing the bristles together; plates flanking the bristle arrangement; and a feature on the plates to receive the joint. A brush seal, comprising: a plurality of bristles, each having a first end and an opposed second end; and plates receiving the bristles therebetween, each having a first end and a second end. The first ends of the bristles extend past the first end of the plates and the second ends of the bristles reside between the first and second ends of the plates. A method of repairing a brush seal, comprising the steps of: providing a brush seal having a bristle arrangement secured between plates; removing the bristle arrangement from the plates; providing a replacement bristle arrangement; and placing said replacement bristle arrangement between the plates.

Owner:RTX CORP

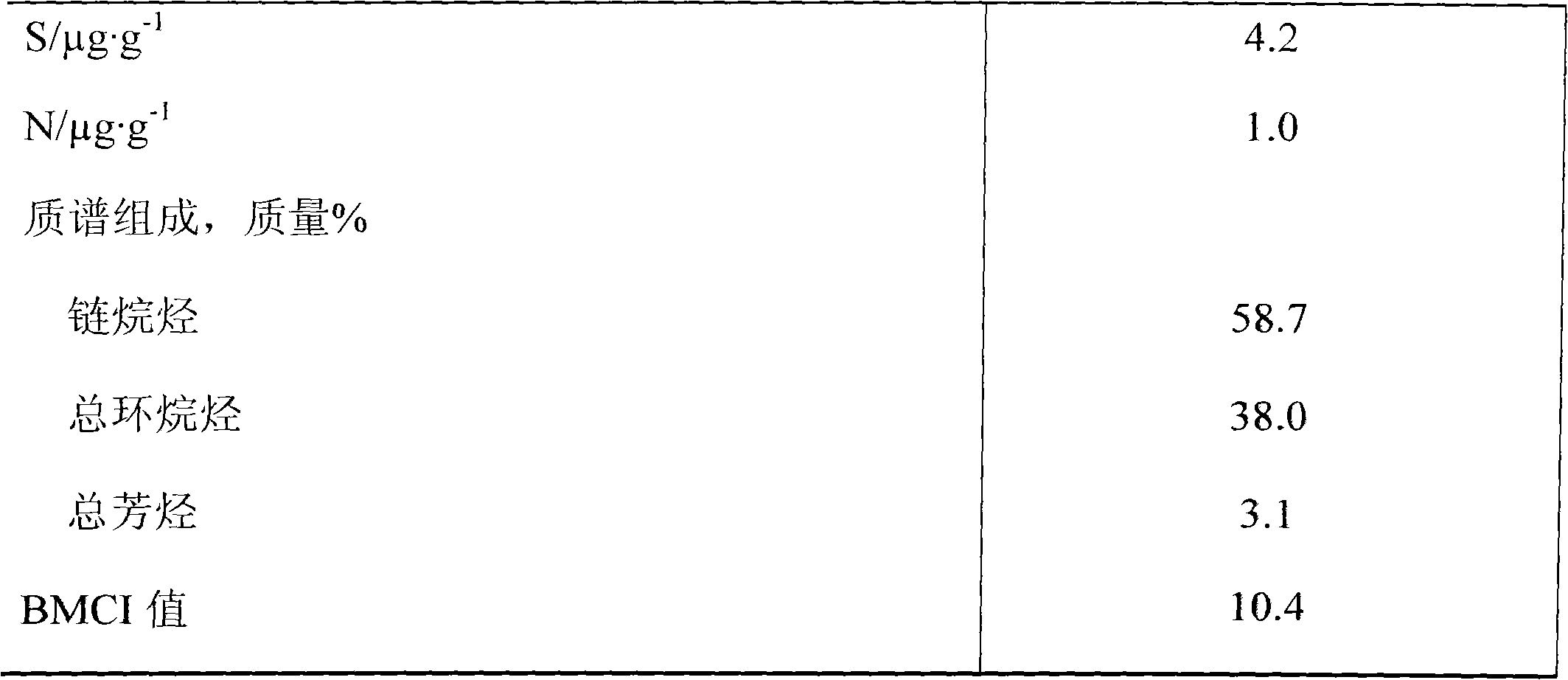

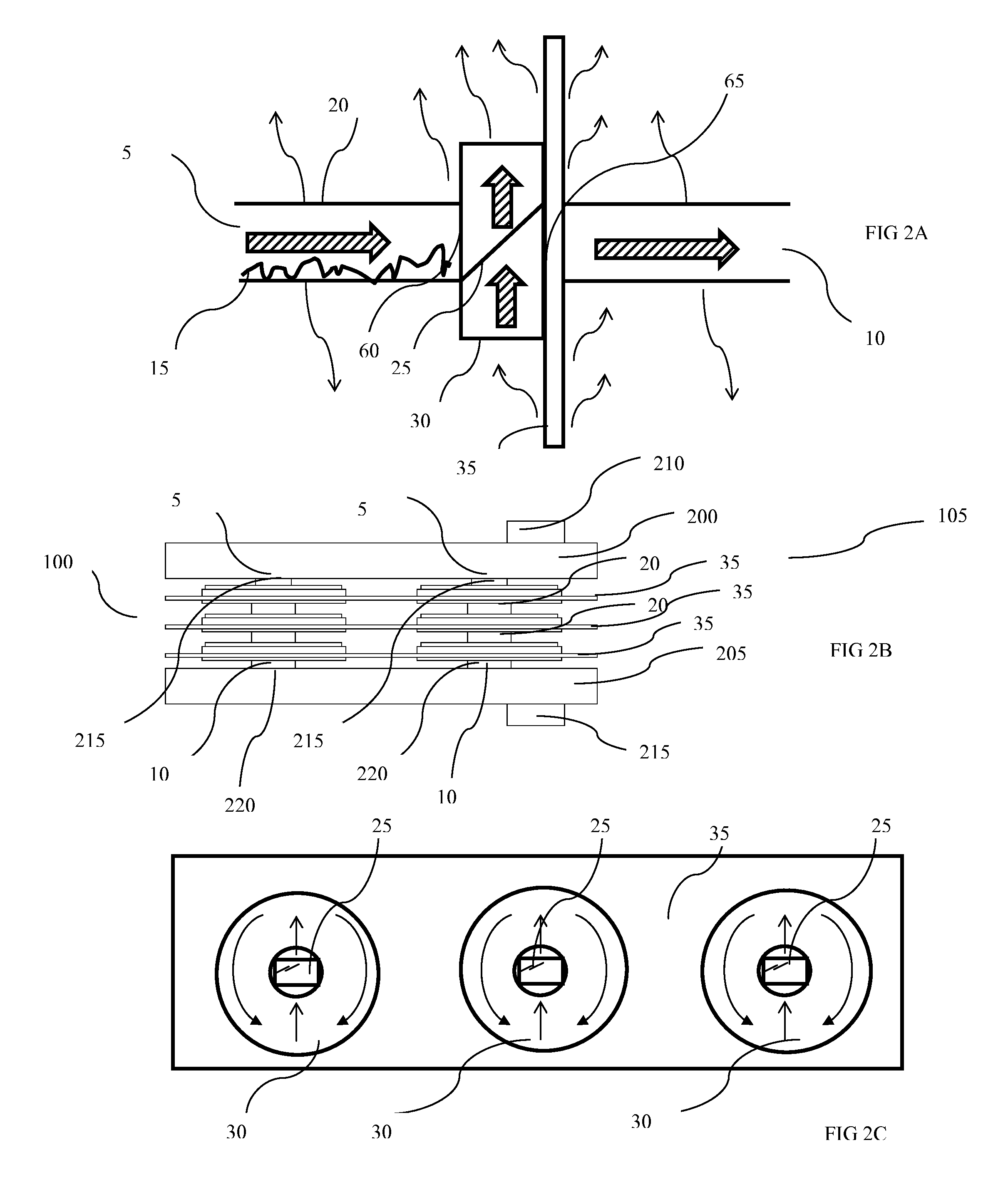

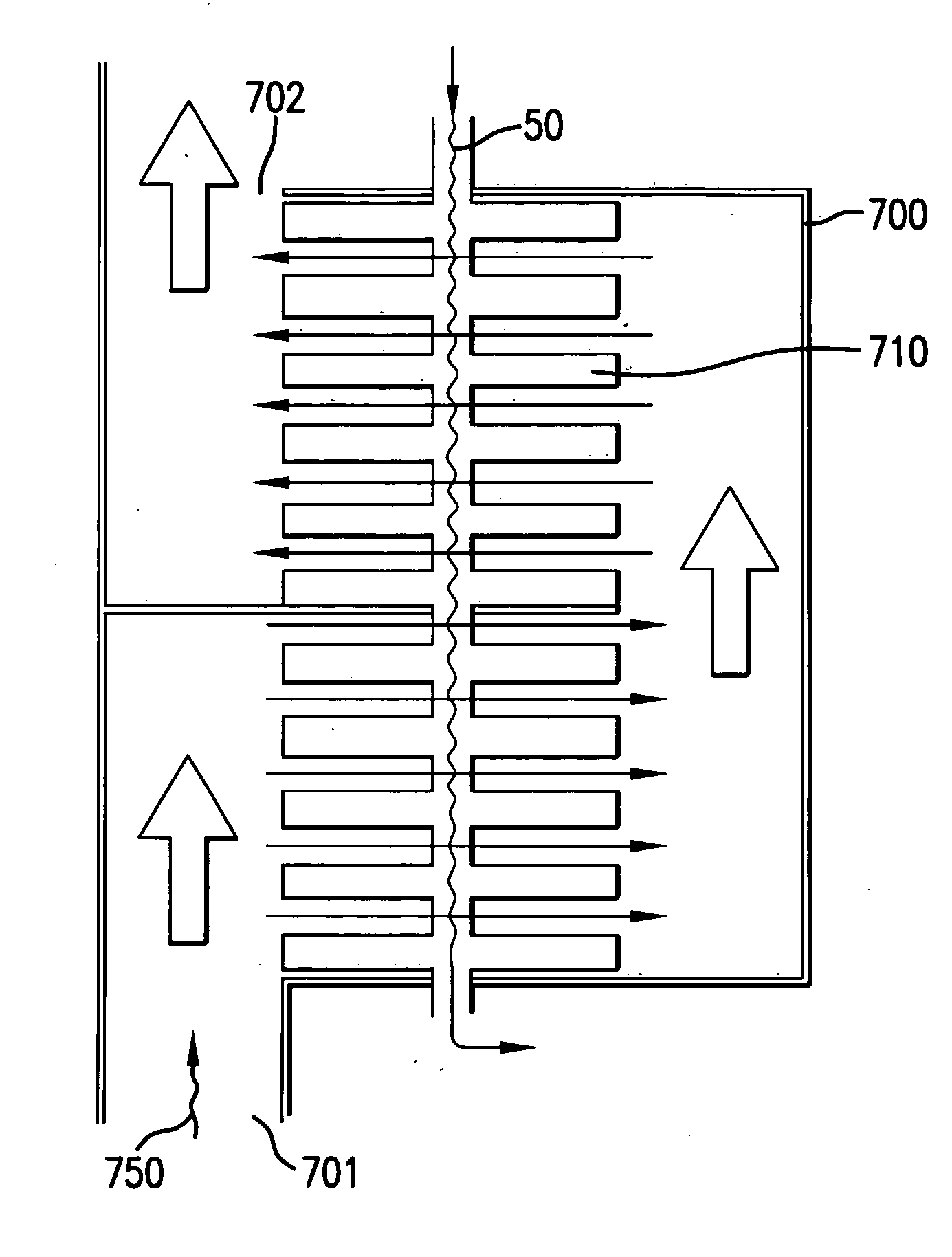

Heat Exchanger with heat exchange chambers and plate members utilizing respective medium directing members and method of making same

InactiveUS20130098590A1Increase surface areaMaximize heat exchanging capability of heat exchangerHeat exhanger conduitsMetal-working apparatusEngineeringInlet flow

A heat exchange unit having a plurality of chamber assembly coupled to a plate member, said chamber assembly including an inlet flow tube, an outlet flow tube, and a plurality of walls defining a chamber interior. Disposed within the chamber interior is a medium-directing member, having an inclined surface, diverting the heat exchange medium from the initial flow direction so that it disperses within the chamber interior, in to at least two distinct flow patterns. The heat exchange medium exits the chamber, via the outlet, in the initial line of flow. The chambers are interconnected by tubes to form assemblies. A plurality of plate member having plurality of chamber assembly is arranged on a spaced relation between manifolds to complete the medium flow.

Owner:MIKUTAY CORP

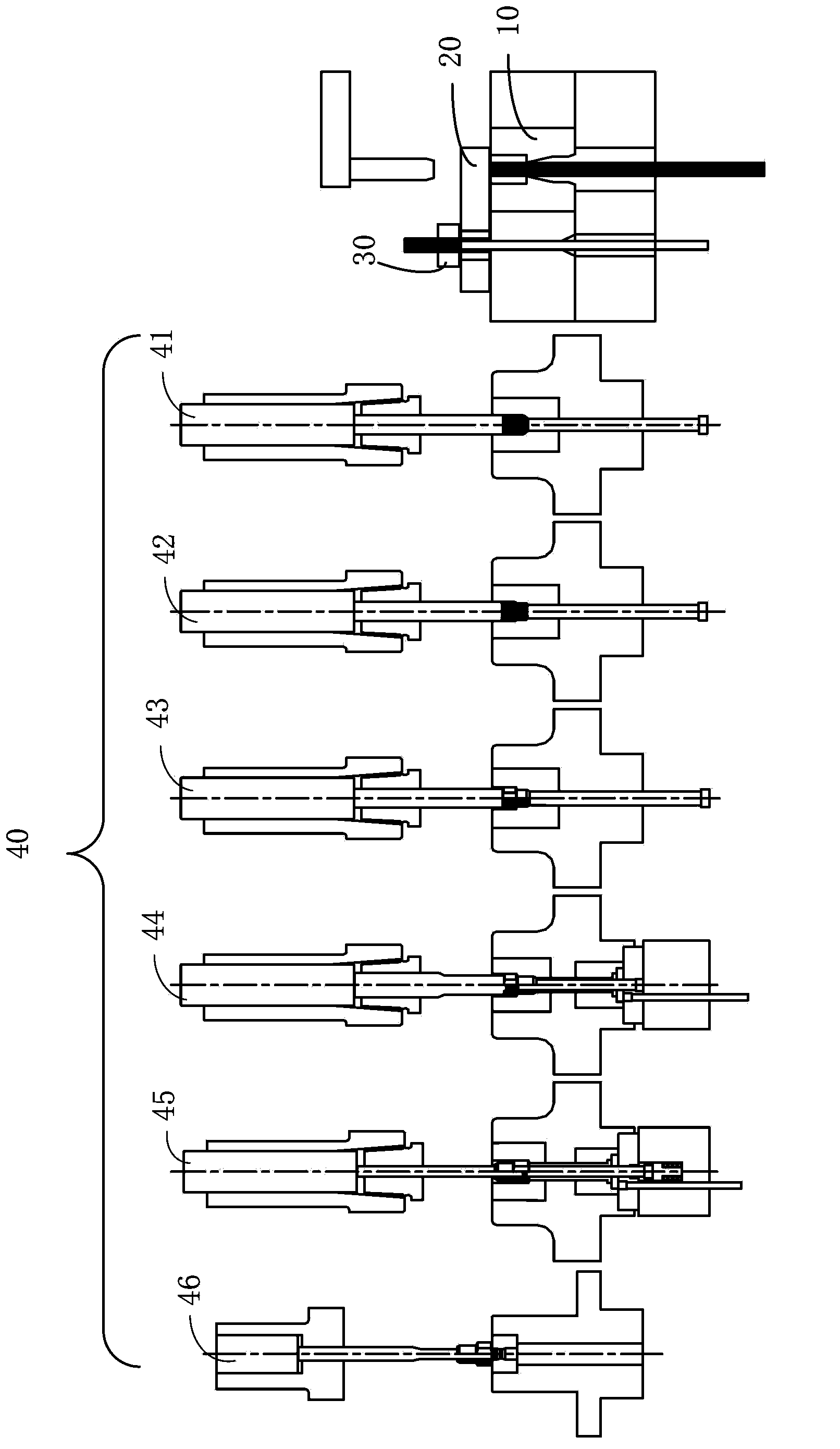

Cold heading device and process for pipe nuts

InactiveCN103909205AReduce manufacturing costSimple processNutsForging/hammering/pressing machinesTransfer mechanismMachining process

The invention discloses a cold heading device and process for pipe nuts. The device comprises a cutting-off mechanism, a feeding mechanism, a transfer mechanism and six molds. The positions of the feeding mechanism and the cutting-off mechanism are corresponding, and the transfer mechanism moves and transfers materials between the feeding mechanism and the molds. The molds comprise a first mold for pre-heading chamfering, a second mold for forming rod diameters, a third mold for pre-heading head hexagonal shapes, a four mold and a fifth mold for inverted extrusion of inner holes and fine heading of the head hexagonal shapes and a sixth mold for punching holes. The six molds are arranged successively. According to the device and the process, expensive hexagonal rods are not needed to be used as raw materials, so that the cost is saved; station materials are formed directly in the molds, so that the process is simple; the material usage rate is high, and compared with the prior art, the amount of raw materials required by a single pipe nut is saved by half; the subsequent machining process is not needed, the pipe nut production speed is improved to be 85 nuts / minute, and the production efficiency is greatly improved.

Owner:BINKE AUTOMOBILE FASTENER KUNSHAN

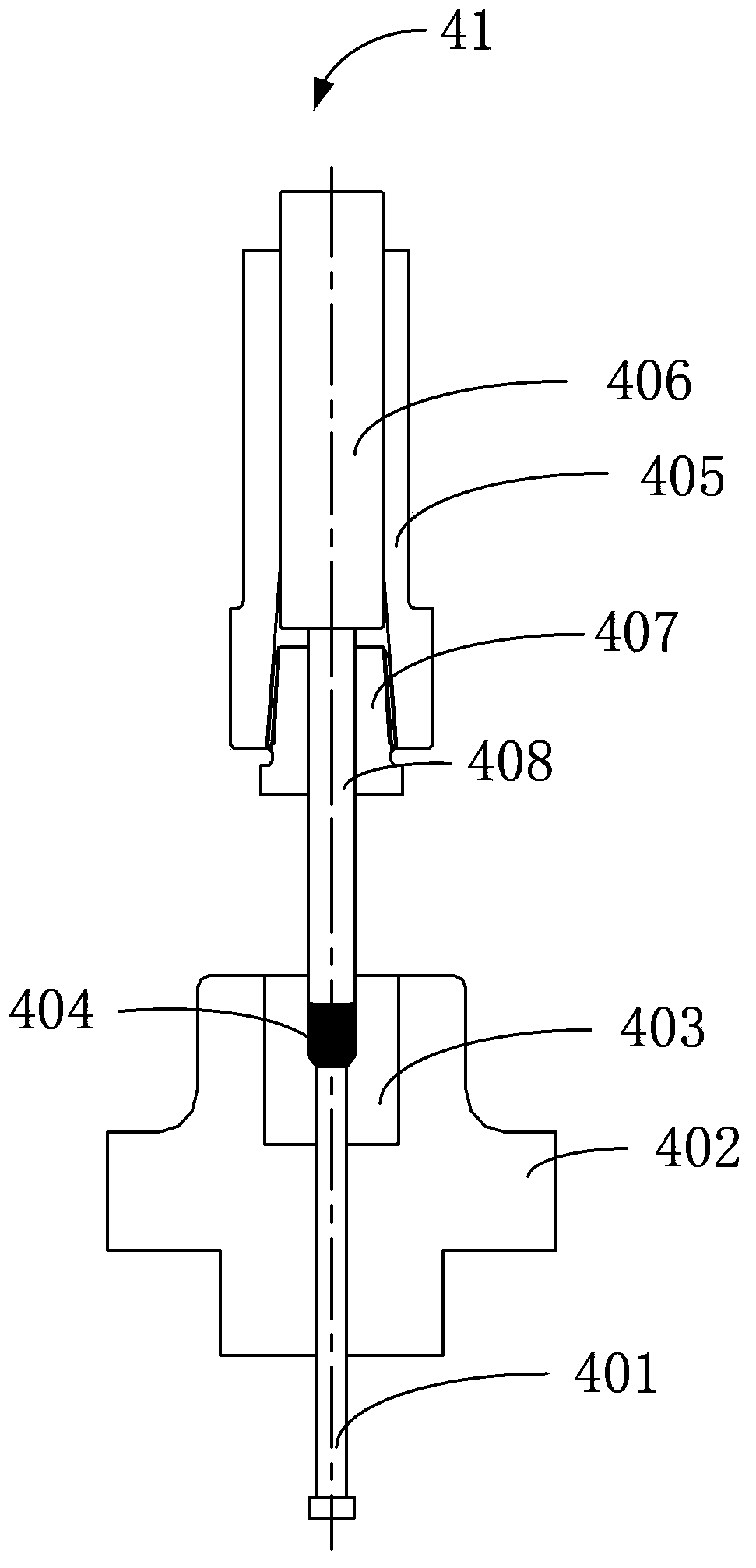

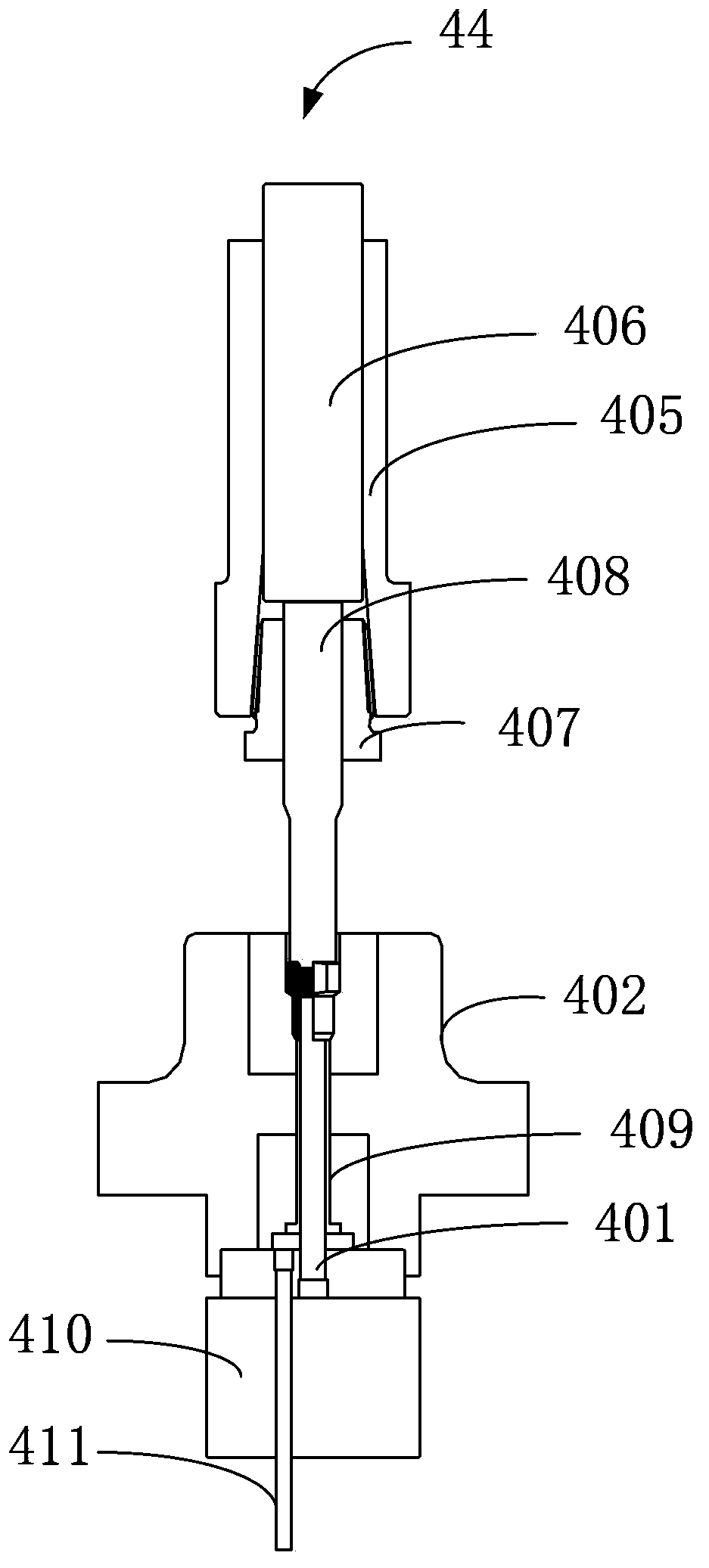

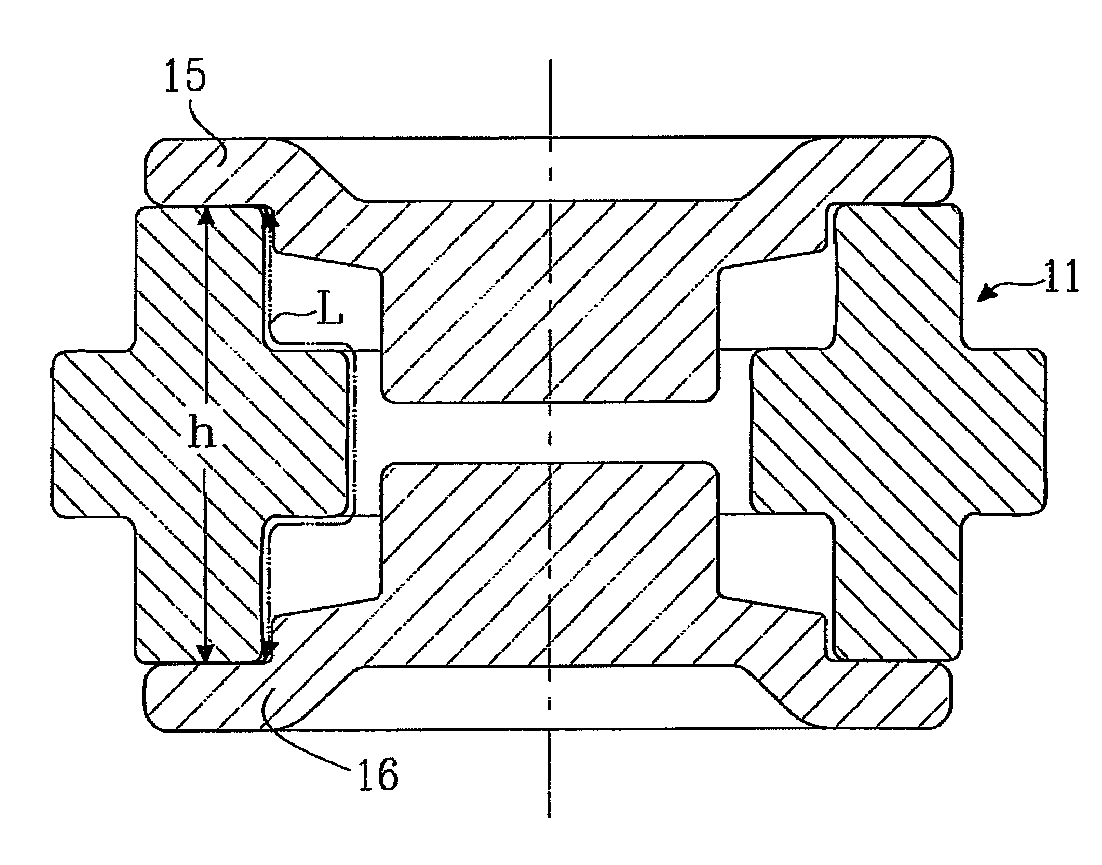

Gas discharge tube

ActiveUS20090102377A1Less raw materialLess volumeSolid cathodesGas discharge lamp detailsEngineeringElectrode

A new gas discharge tube comprising at least two electrodes and at least one hollow insulator ring fastened to at least one of the electrodes, wherein the insulating ring has an extended length for a creeping current on at least one of the surfaces inside and / or outside compared to its height thereby providing a long distance to any possible creeping current.

Owner:BOURNS INC

Heat exchanger with heat exchange chambers utilizing respective medium directing members

ActiveUS7987900B2Improve heating efficiencyIncrease the lengthHeat exchanger casingsHeat transfer modificationEngineeringMicro heat exchanger

A heat exchange chamber includes an inlet, an outlet and a plurality of walls defining a chamber interior. The inlet receives a heat exchange medium flowing in a first flow direction in an initial line of flow. Disposed within the chamber interior is a medium directing member, having an inclined surface, which diverts the medium from the initial flow direction so that it disperses within the chamber interior. The medium exits the chamber, via the outlet, in the initial line of flow. The chambers are interconnected by tubes to form assemblies. Plural sets of chamber and tube assemblies are arranged between manifolds to provide a heat exchanger.

Owner:MIKUTAY CORP

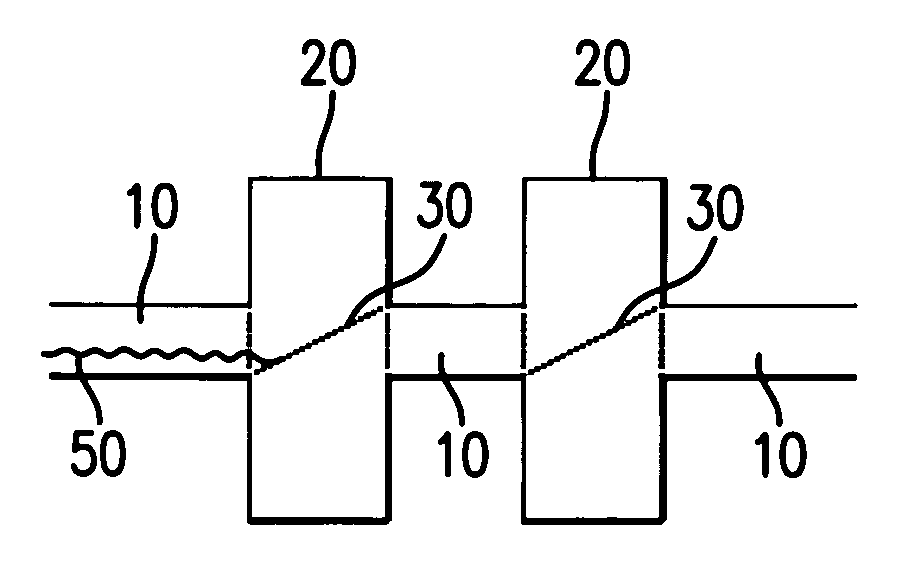

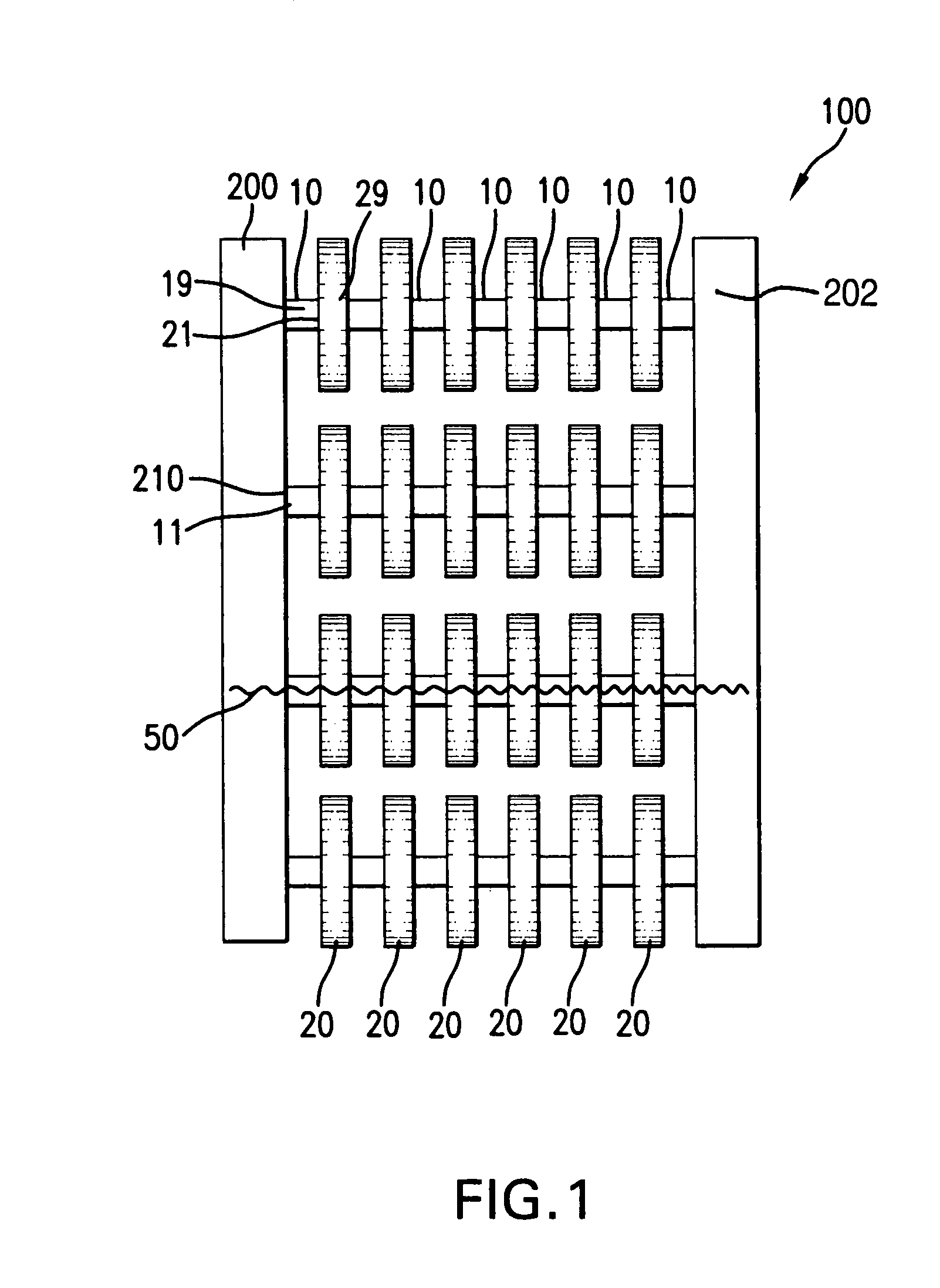

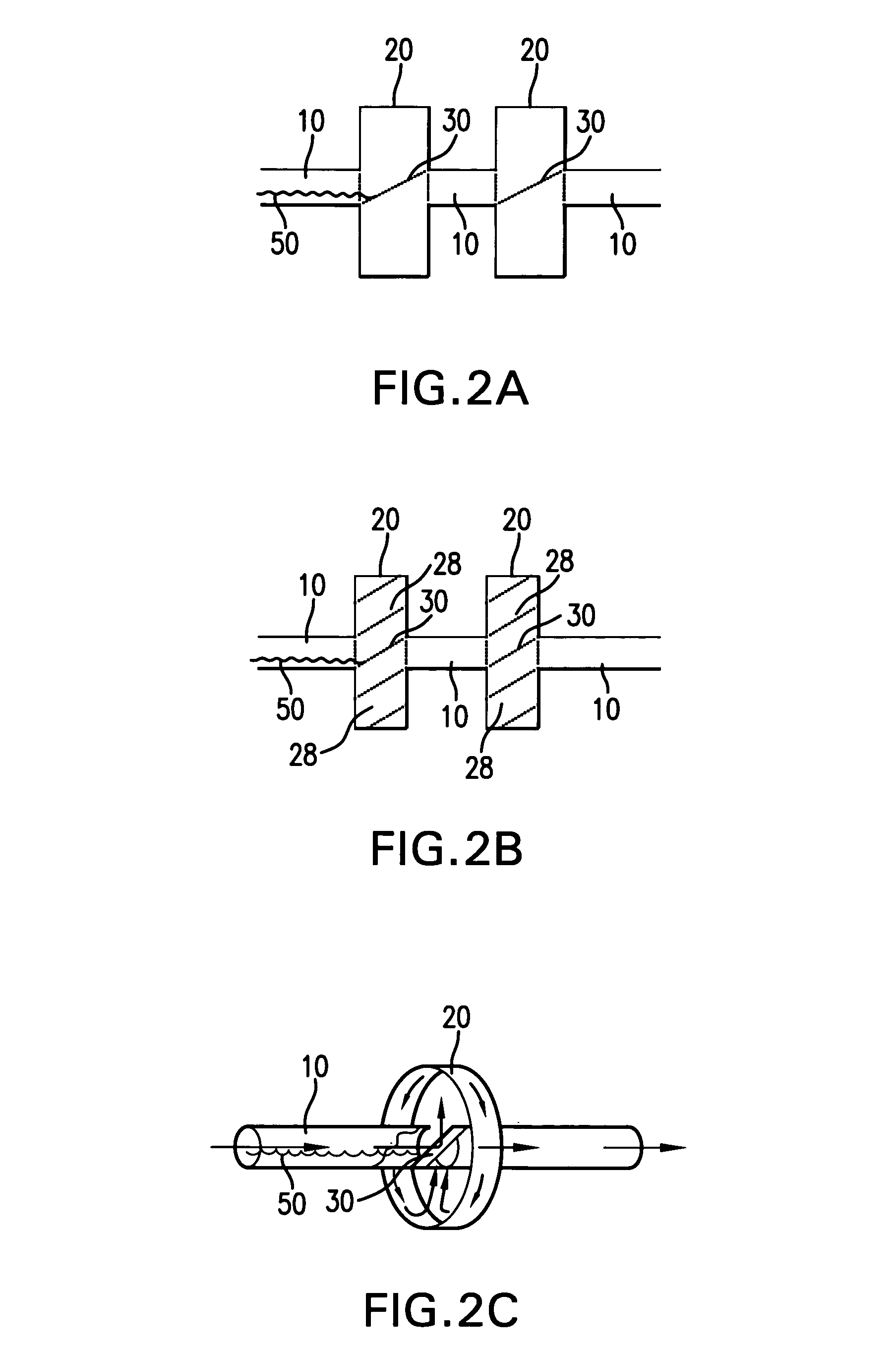

Open mesh material and bags made therefrom

An open mesh material includes filaments (1, 2, 3, 4, 11, 12, 15, 16) that intersect one another. At least some of the filaments are composite filaments having a carrier portion of a relatively high melting point and a bonding portion of a relatively low melting point, the bonding portion of each composite filament being thermally bonded to other filaments at points of intersection. The material may be a non-woven fabric that contains at least two layers of weft filaments (1, 2, 11, 12) that may be bordered on one or both sides by a layer of warp filaments (3,4, 15, 16). When compared to other open mesh materials, the open mesh material disclosed herein has a superior combination of some or all of high strength, light weight, high dimensional stability, and openness. Also disclosed herein are articles can be made at least in part from the material including L-seam bags (20), form fill and seal (FFS) bags (1020), and multi-substrate bags (2,020). Methods of making those bags also are disclosed.

Owner:VOLM

Method for producing biogas and organic fertilizer by dry fermentation of livestock and poultry feces

InactiveCN102344232ANo need to diluteReduce lossesBio-organic fraction processingClimate change adaptationBiotechnologyFeces

The invention discloses a method for producing biogas and organic fertilizer by dry fermentation of livestock and poultry feces. The method comprises the following steps of feeding directly solid livestock and poultry feces of which dry matter concentration is above 15% into a biogas fermentation device, or mixing the solid livestock and poultry feces and livestock and poultry feces fermentation residues and then feeding the mixture into the biogas fermentation device to carry out biogas production, wherein the fermentation residues obtained by the previous step can be utilized as organic fertilizer or the fermentation residues are subjected to composting and then are utilized for organic fertilizer production. Through the method provided by the invention, livestock and poultry feces is subjected directly to dry fermentation without dilution and desanding pretreatment; scum is not formed in the biogas fermentation device; temperature rise and heat preservation are easy; nutrient loss is less; and produced organic fertilizer has high fertilizer efficiency.

Owner:BIOGAS SCI RES INST MIN OF AGRI

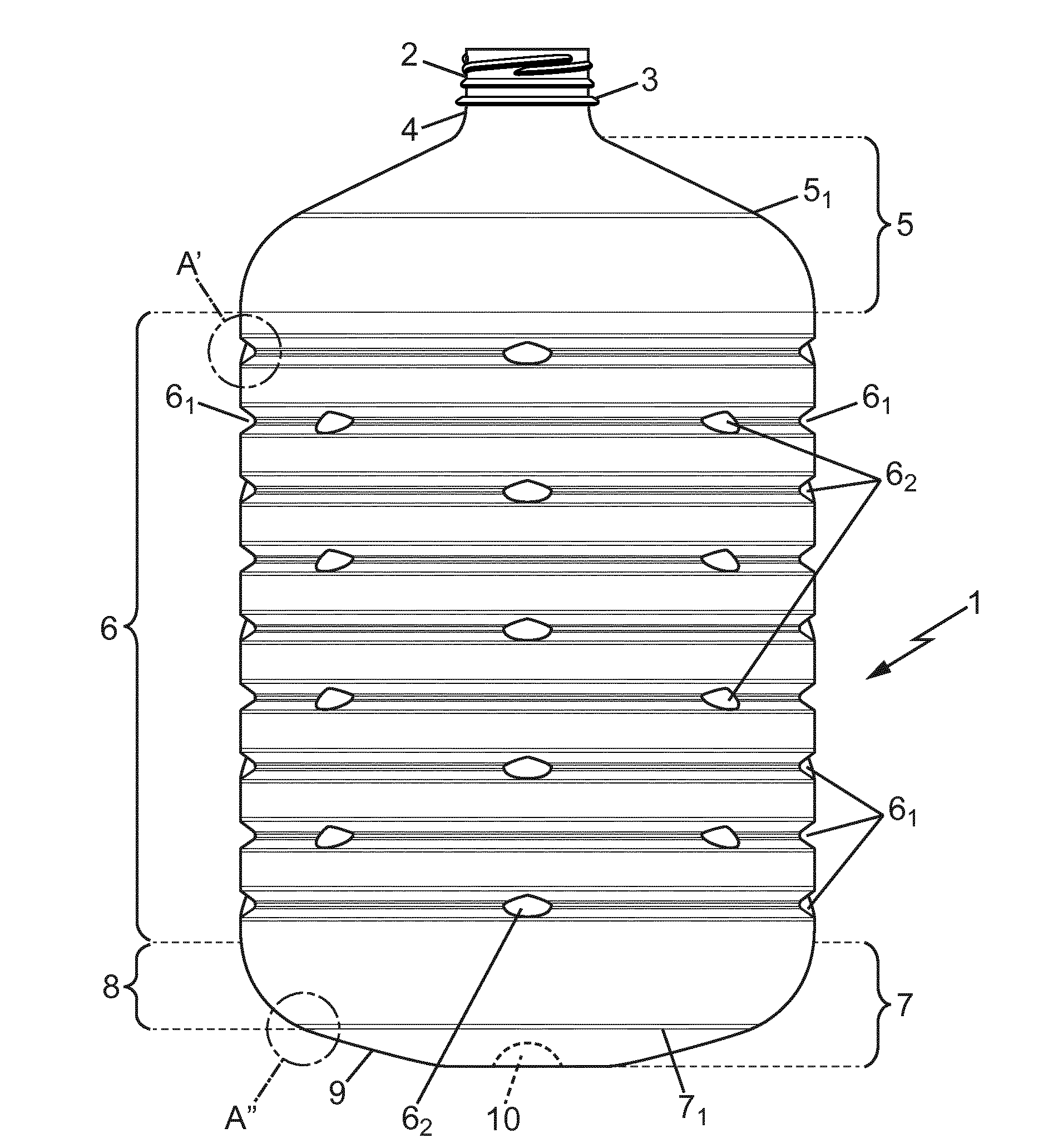

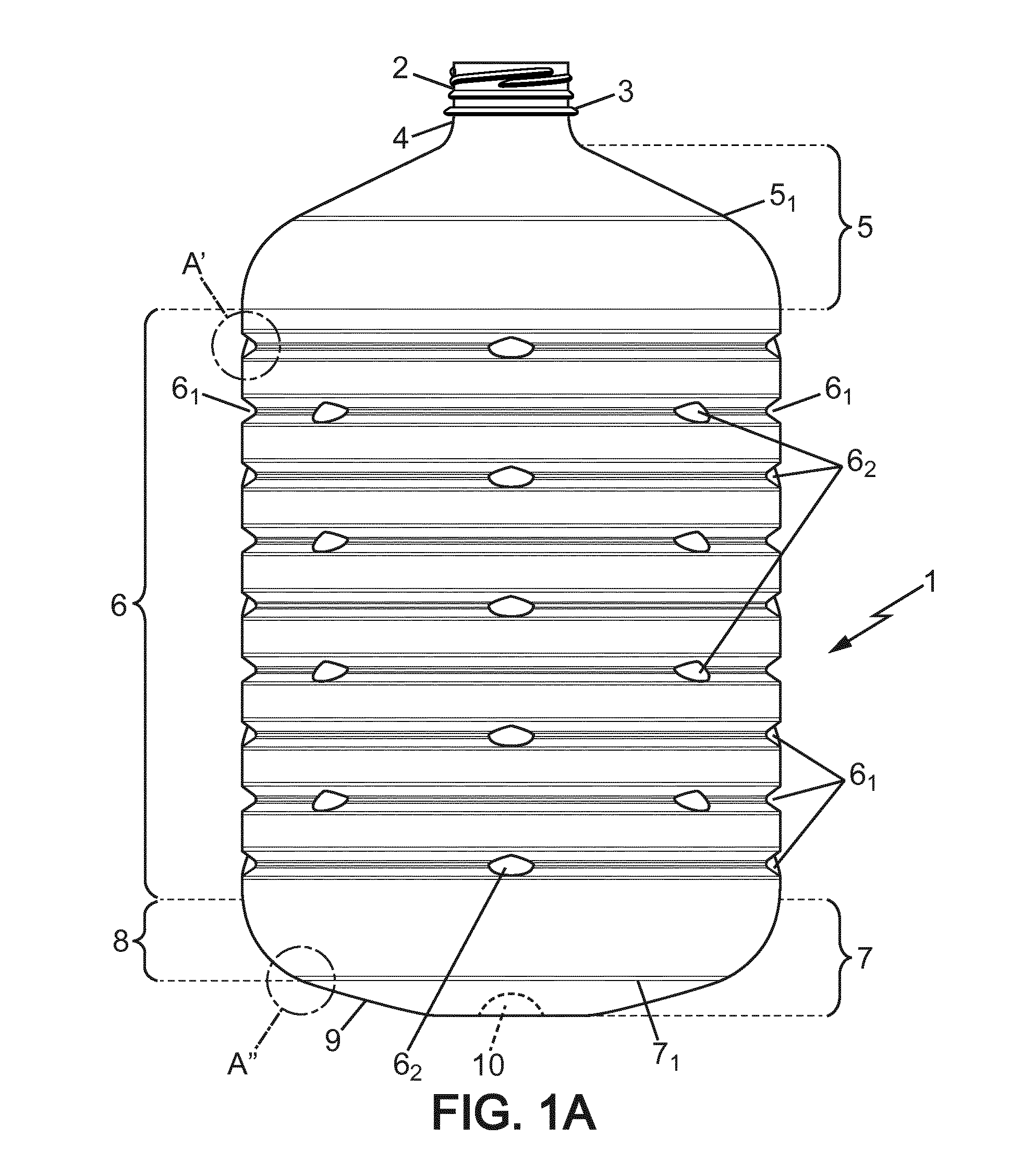

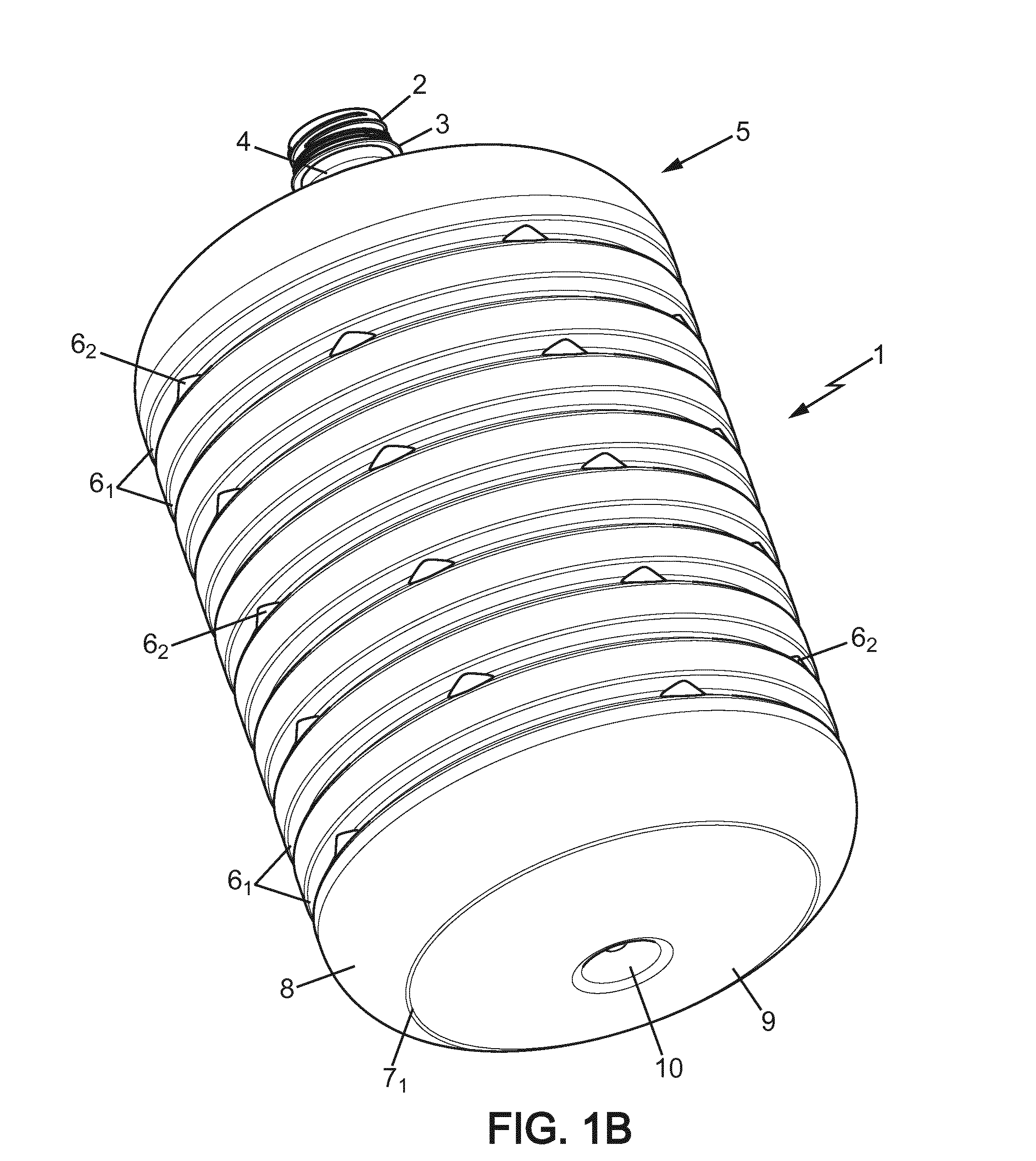

Self collapsable blow moulded plastic thin-walled containers, their manufacturing process and their applications in water dispensing units

ActiveUS20150321826A1Easy to handleEasy to storePower operated devicesBottlesPolymer scienceEngineering

The invention pertains to self collapsable blow moulded plastic thin-walled PET bottle (1) manufactured by Injection moulding of a preform (100), as well as Stretching, Blowing and Moulding (ISBM) of said preform (100).Said container (1) having:a top part (2,3,4,5);a tubular body portion (6);and a bottom structure (7) opposite to the top part (2,3,4,5); preferably a bottle (1), notably for beverages, is characterized:a) in that it is self-collapsable during its emptying;b) in that it comprises at least two transversal grooves and / or ribs (6.1), preferably located in the tubular body portion (6), optionally with at least some of them being each equipped with at least 2, preferably at least 4, and more preferably between 4 and 8 collapse starters (6.2);c) in that the mean wall thickness (Tmean) of the tubular body portion (6) is—in an increasing order of preference—less than or equal to 200; 180; 160; 150 μM; preferably comprised between 65 and 150; and more preferably comprised between 90 and 130 μm.The invention also concerns a method, a preform (100) and a mold for the manufacture of said aforementioned container by blow moulding.The invention also concerns a method for bottling liquid into said bottles (1), a method for dispensing said liquid, a dispenser for implementing said method and a method for packing the thin-walled bottles, in view of storage and transportation.

Owner:DES EAUX MINERALES DEVIAN S A E M E

Tube for a heat exchanger

ActiveUS20090260788A1Improve heating efficiencyIncrease the lengthHeat exchanger casingsHeat transfer modificationNuclear engineeringHeat exchanger

A tube for a heat exchanger includes a first segment that couples to a chamber for transportation of heat exchange media. The chamber receives the heat exchange media that disperses throughout the chamber and mixes within the chamber. The heat exchange media is then transported from the chamber. The chamber may include redirection members for controlling the direction in which the heat exchange media travels throughout the chamber. The tube may be connected to a header or manifold. The tube and chamber combination alone may be used as a heat exchanger.

Owner:MIKUTAY CORP

Gas discharge tube

ActiveUS7932673B2Small volumeSame efficiencySolid cathodesGas discharge lamp detailsEngineeringElectrode

A new gas discharge tube comprising at least two electrodes and at least one hollow insulator ring fastened to at least one of the electrodes, wherein the insulating ring has an extended length for a creeping current on at least one of the surfaces inside and / or outside compared to its height thereby providing a long distance to any possible creeping current.

Owner:BOURNS INC

Suspension polymerization and foaming of water containing activated carbon-nano/microparticulate polymer composites

InactiveUS8507568B2Improve insulation effectImprove structural strengthCoatingsPolymer sciencePolystyrene

Synthesis of polystyrene and / or other thermoplastic polymers or polymer blends which, for example, contain activated carbon and / or bamboo carbon carrying a co-blowing agent such as water and / or at least one of 1-dimensional, 2-dimensional, and 3-dimensional nano / micro-materials in suspension polymerization without using the inverse emulsion process. CO2 or other blowing agent based foaming processes such as extrusion, batch foaming, and injection molding may then be carried out to produce polymer foams that have low density, high-R value, bimodal structures, good mechanical properties, and high fire retardance.

Owner:NANOMATERIAL INNOVATION +1

Fitted covering having diagonal elastic bands

A fitted mattress covering for a mattress includes lower edge portions, which may be inverted J-shaped portions, mirror-image inverted J-shaped portions, portions that terminate at an end, or inverted U-shaped portions. The covering side and end portion lower edges may join one another to form a continuous lower edge of the covering. For the I-shaped portion, an elastic binding may be disposed under a downwards folded portion. The elastic binding may extend at least partially along the length of the lower edge of the covering. An elastic band may be disposed at each corner of the covering and extend diagonally across the associated corner and have opposite ends secured adjacent one of the side portions and adjacent one of the adjacent end portions, respectively. The bands may be secured in place by stitching and / or by supplementary securing means to ensure that the bands do not pull away from the covering.

Owner:HOMTEX

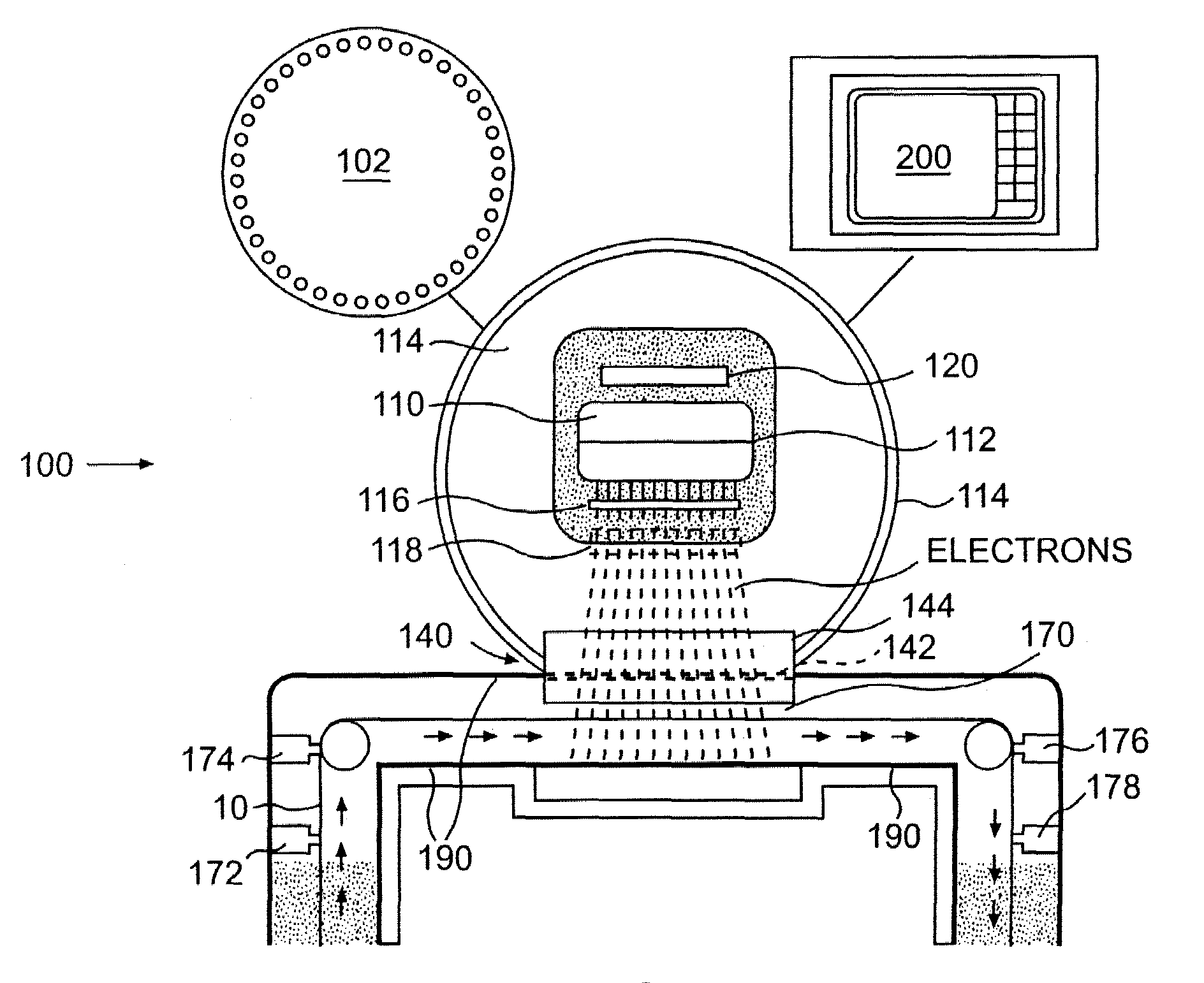

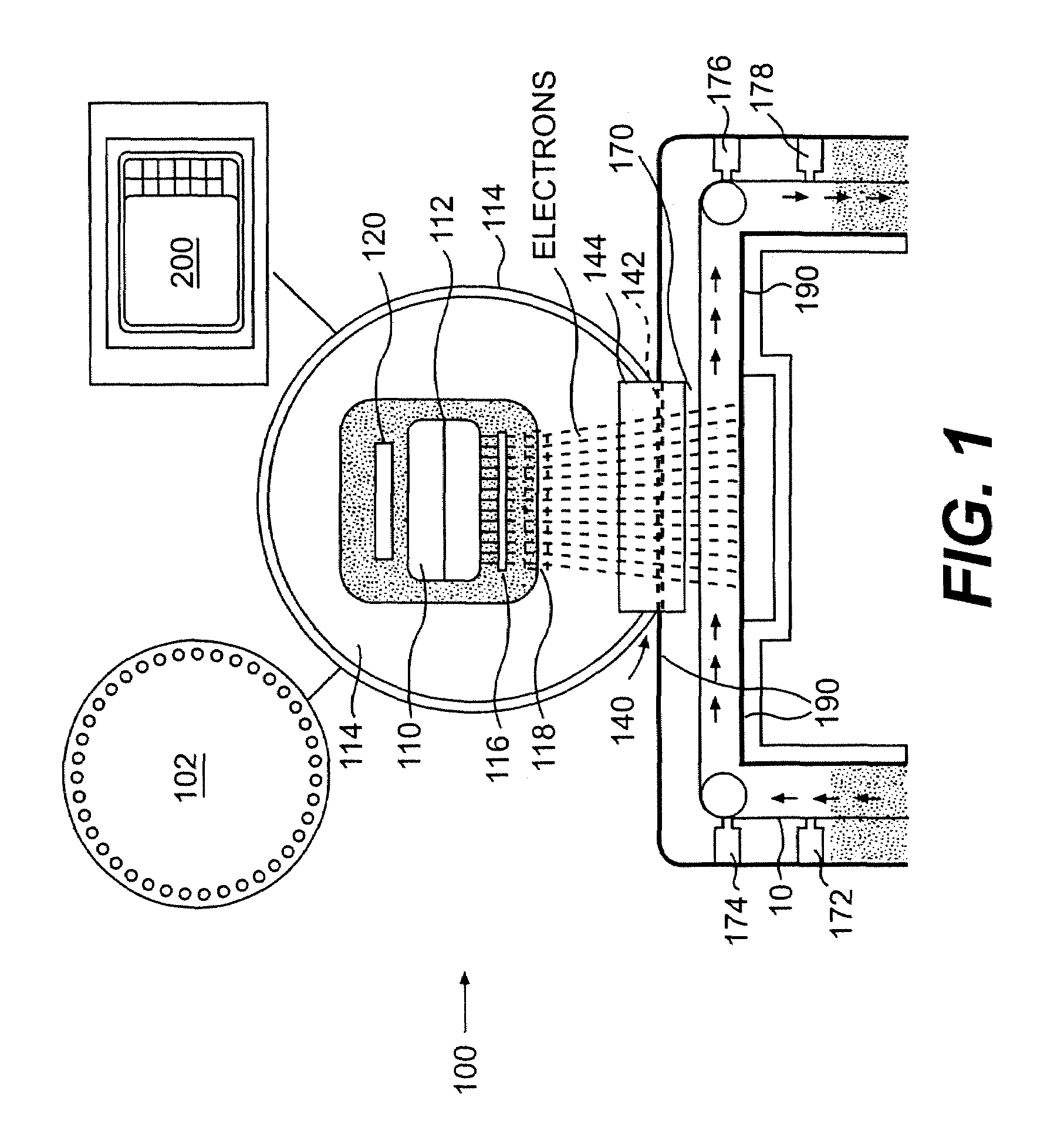

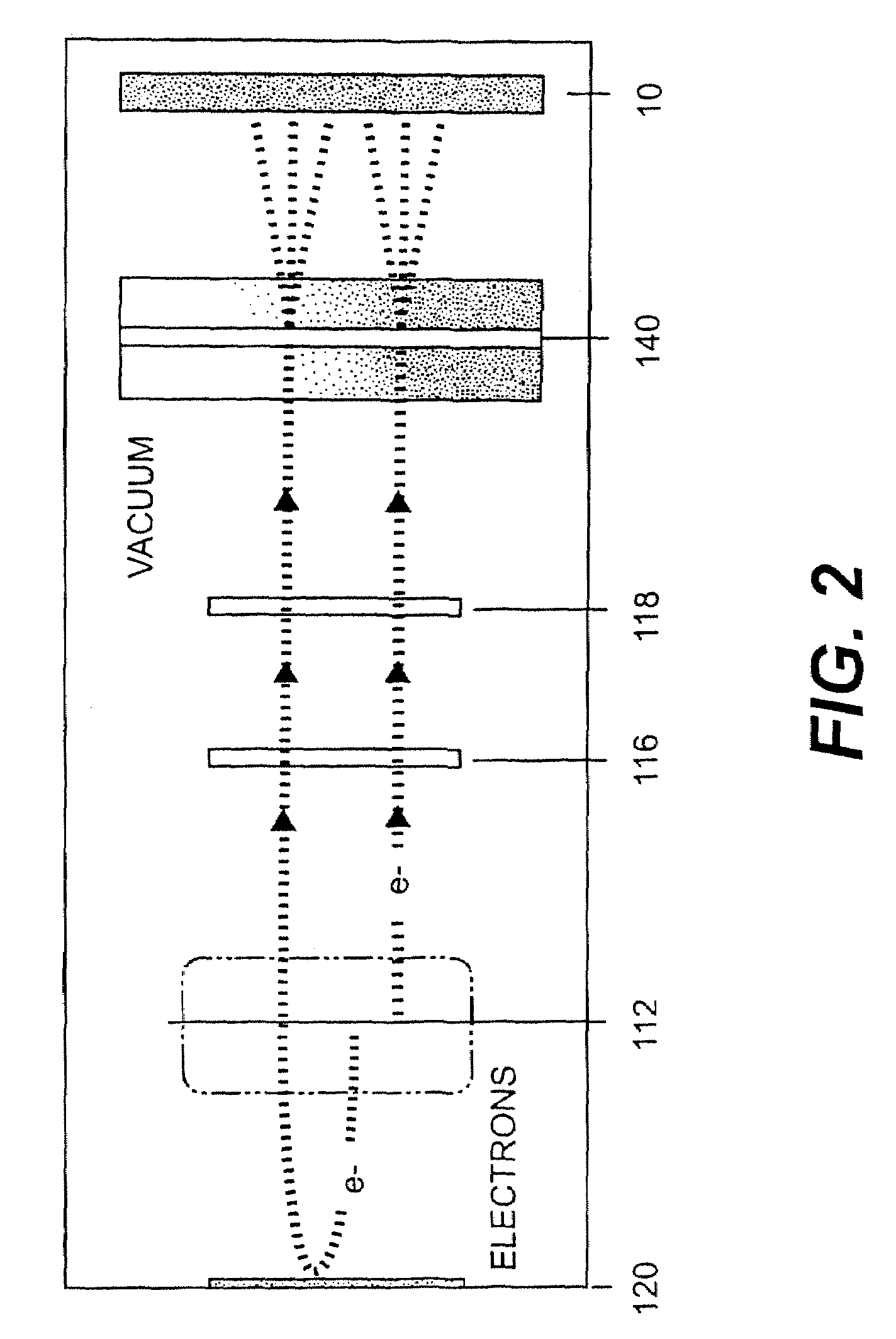

Particle beam processing apparatus and materials treatable using the apparatus

InactiveUS7348580B2Less raw materialSignificant energy savingThermometer detailsBeam/ray focussing/reflecting arrangementsLow voltageParticle beam

The present invention is directed to a particle beam processing apparatus that is smaller in size and operates at a higher efficiency, and also directed to an application of such apparatus to treat a coating on a substrate of a treatable material, such as for flexible packaging. The processing apparatus includes a particle beam generating assembly, a foil support assembly, and a processing assembly. In the particle beam generating assembly, electrons are generated and accelerated to pass through the foil support assembly. In the flexible packaging application, the substrate is fed to the processing apparatus operating at a low voltage, such as 110 kVolts or below, and is exposed to the accelerated electrons to treat the coating on the substrate.

Owner:ENERGY SCI

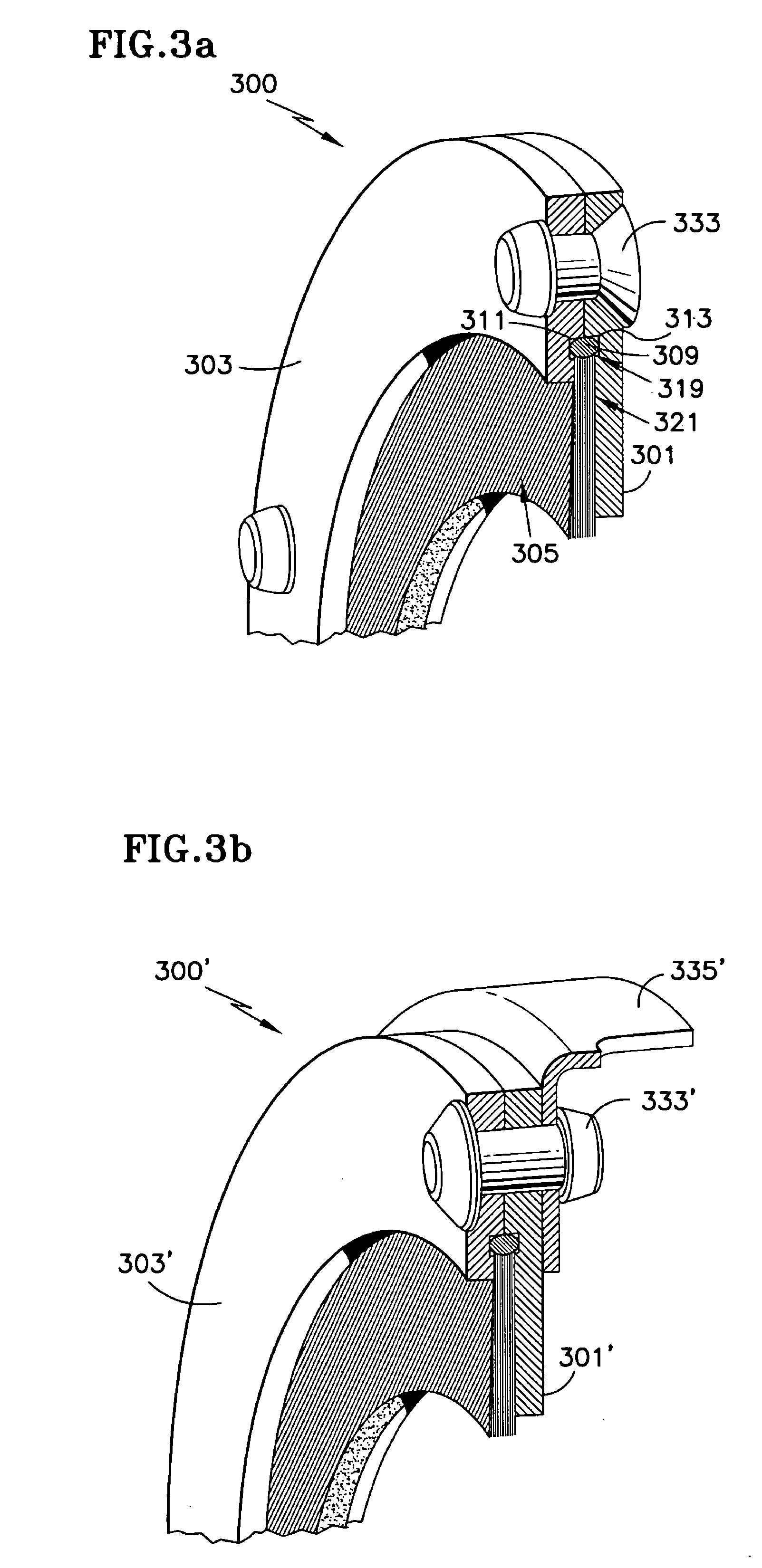

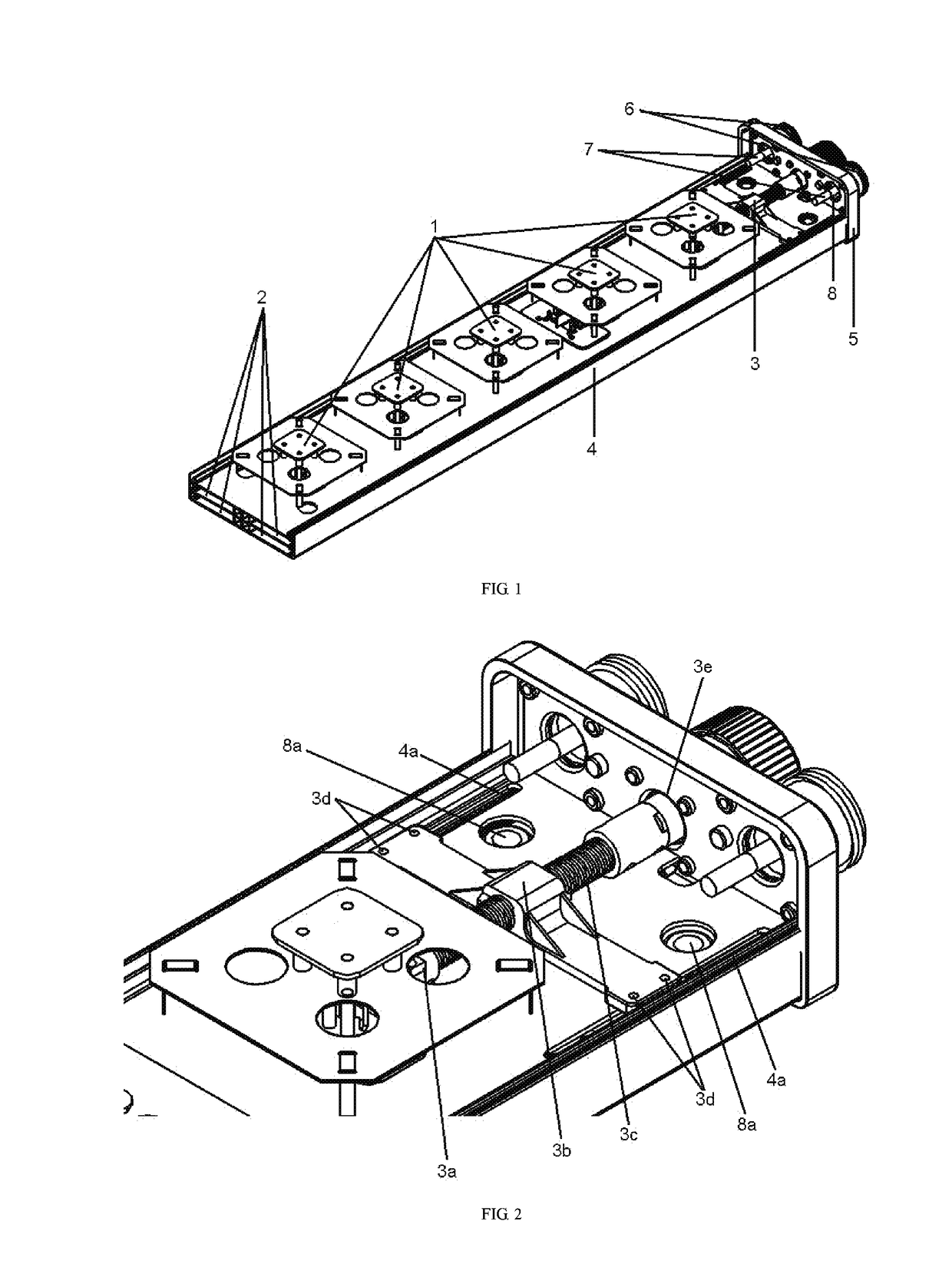

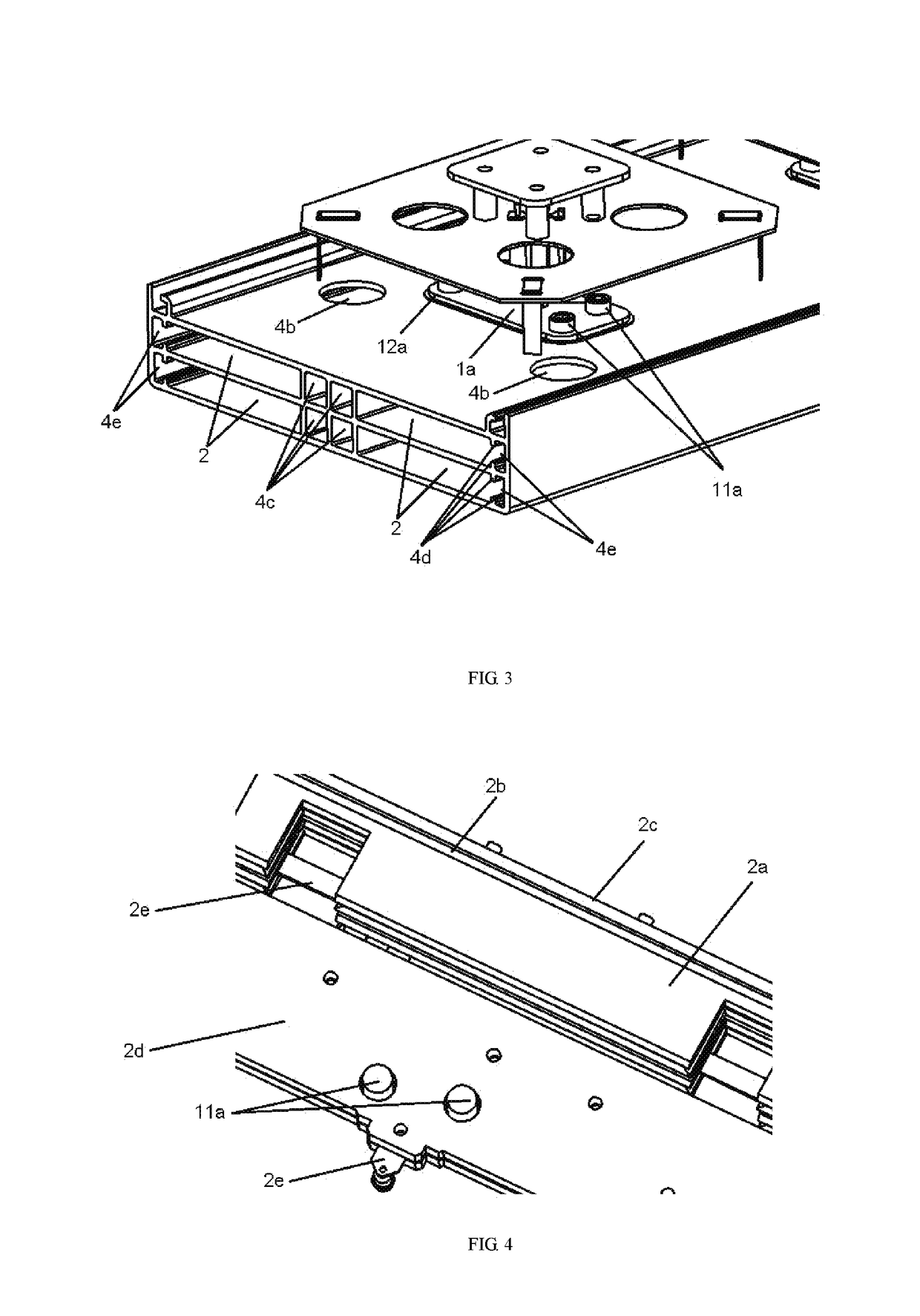

Baffle board for base station antenna and base station antenna array structure

ActiveUS20170358865A1Improve consistencyLess weldingParticular array feeding systemsAntenna supports/mountingsPhase shiftedBase station antenna array

This application discloses a type of reflecting plate and base station array for base station antennas. The main part of the reflecting plate is mono- or multi-layer reflector chamber, the inside of each layer placed with at least one phase shift cavity, guide groove and projection, the phase shift cavity for holding components of the phase shifter, while guide groove and projection for fixing them, allowing removable dielectric insulation medium of the phase shifter to move within the guide groove. The reflecting plate and the phase shift cavity are designed in integrative structure, achieving good consistency, less soldering and easy installation, costing less time and fewer raw materials, and high efficiency and low cost as well.

Owner:GUANGZHOU SIGTENNA TECH CO LTD

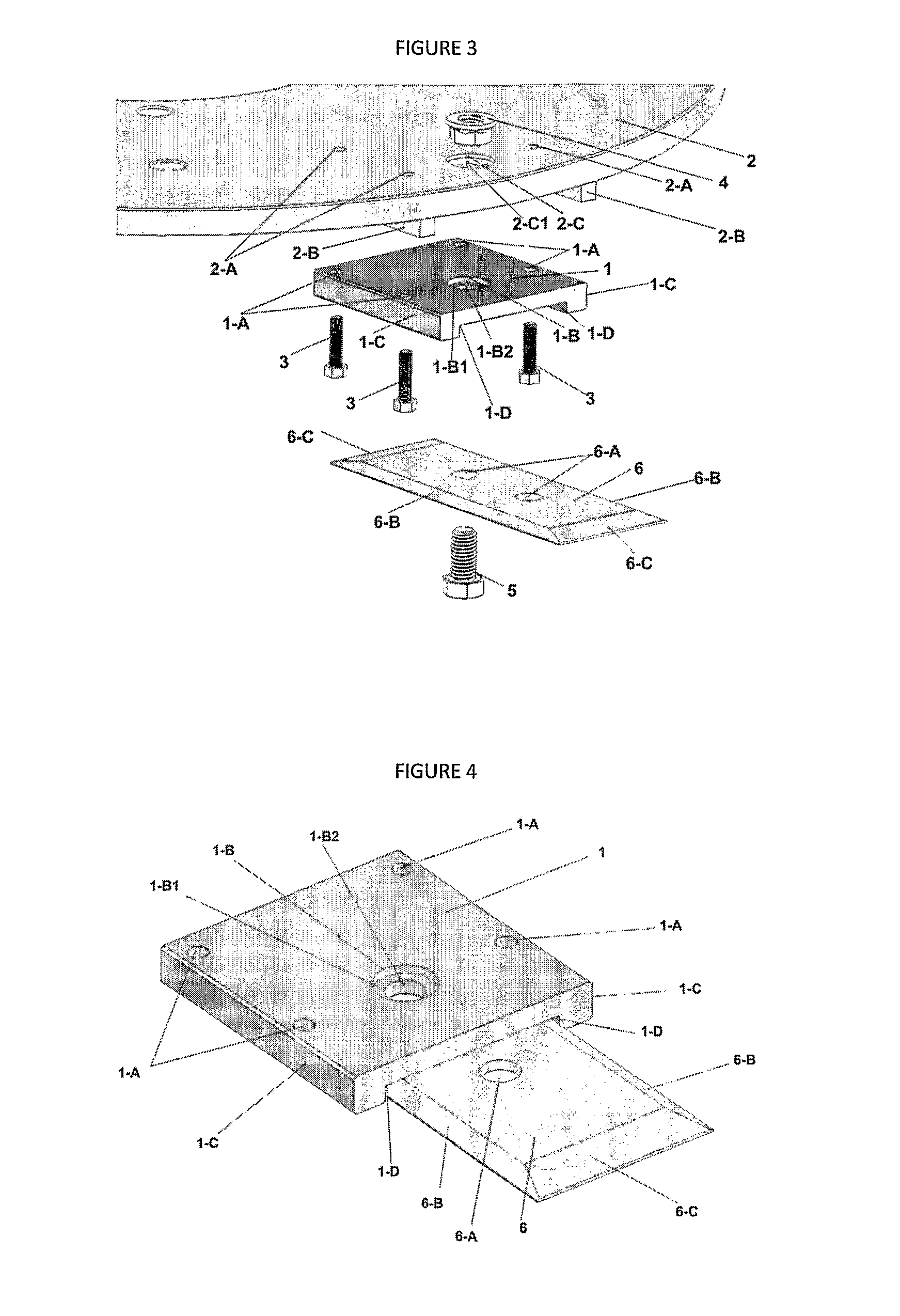

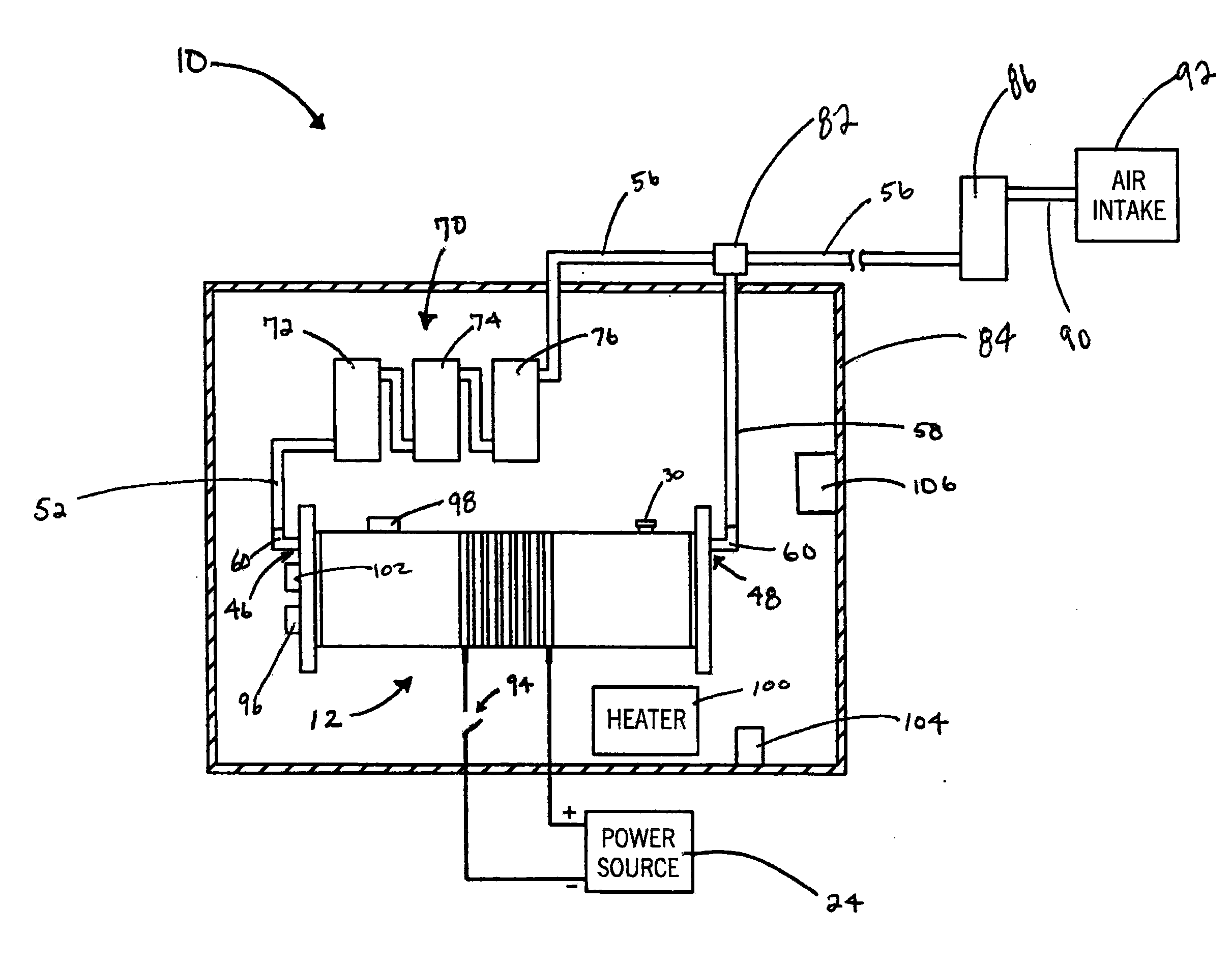

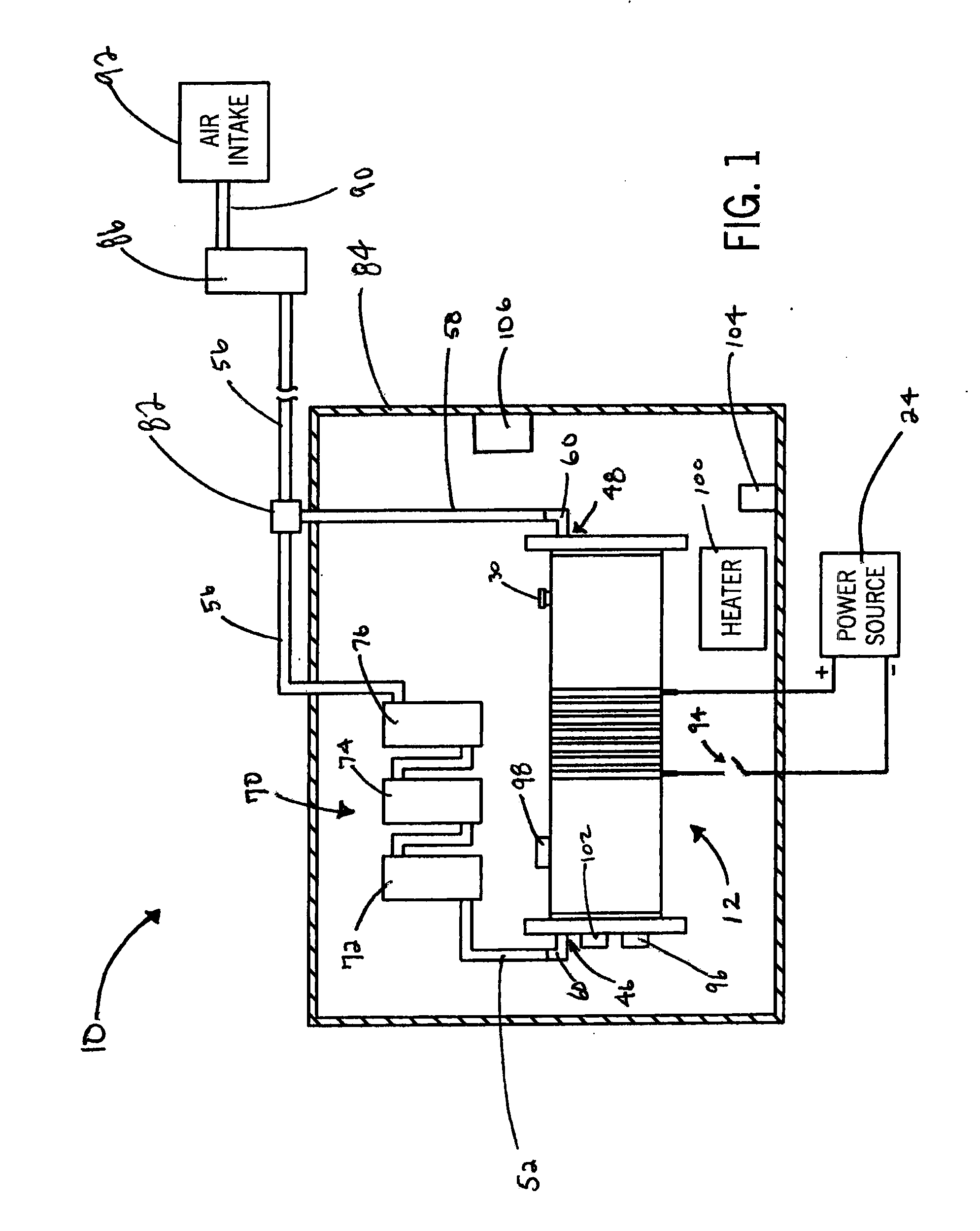

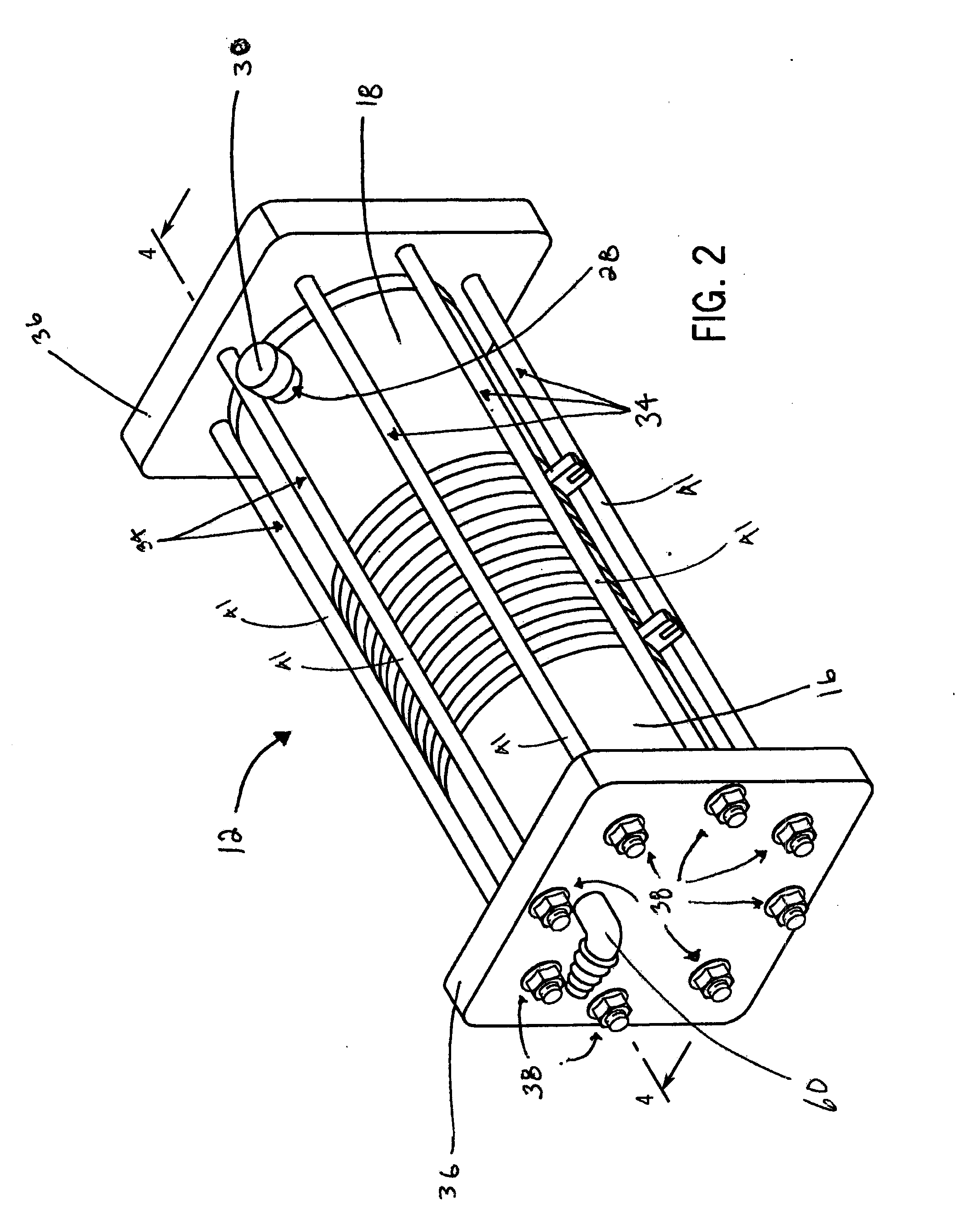

Hydroxy booster system

InactiveUS20120216759A1Fashion designUse in some applicationCellsCombustion enginesElectricityHydrogen

An electrolysis system is provided for supplementing the petroleum fuel supply of an internal combustion engine. The electrolysis system may include a reservoir tank including a solution of water and electrolyte and at least two plates disposed therein. The plates are in electrical communication with a source of electrical power such that the plates create an electrical current in the solution to produce a gas including oxygen and hydrogen. A filter system is in fluid communication with the reservoir tank and includes a filter that has interconnected particles configured to capture electrolyte particles in the gas. A conduit is also provided as part of the electrolysis system to deliver the gas from the filter system to the internal combustion engine. A filter system and a method of supplying a gas that includes oxygen and hydrogen to supplement the petroleum fuel supply for an internal combustion engine are also disclosed.

Owner:IRVIN WALLACE TAYLOR

Fitted covering having diagonal elastic bands

A fitted mattress covering for a mattress includes lower edge portions, which may be inverted J-shaped portions, mirror-image inverted J-shaped portions, portions that terminate at an end, or inverted U-shaped portions. The covering side and end portion lower edges may join one another to form a continuous lower edge of the covering. For the J-shaped portion, an elastic binding may be disposed under a downwards folded portion. The elastic binding may extend at least partially along the length of the lower edge of the covering. An elastic band may be disposed at each corner of the covering and extend diagonally across the associated corner and have opposite ends secured adjacent one of the side portions and adjacent one of the adjacent end portions, respectively. The bands may be secured in place by stitching and / or by supplementary securing means to ensure that the bands do not pull away from the covering.

Owner:HOMTEX

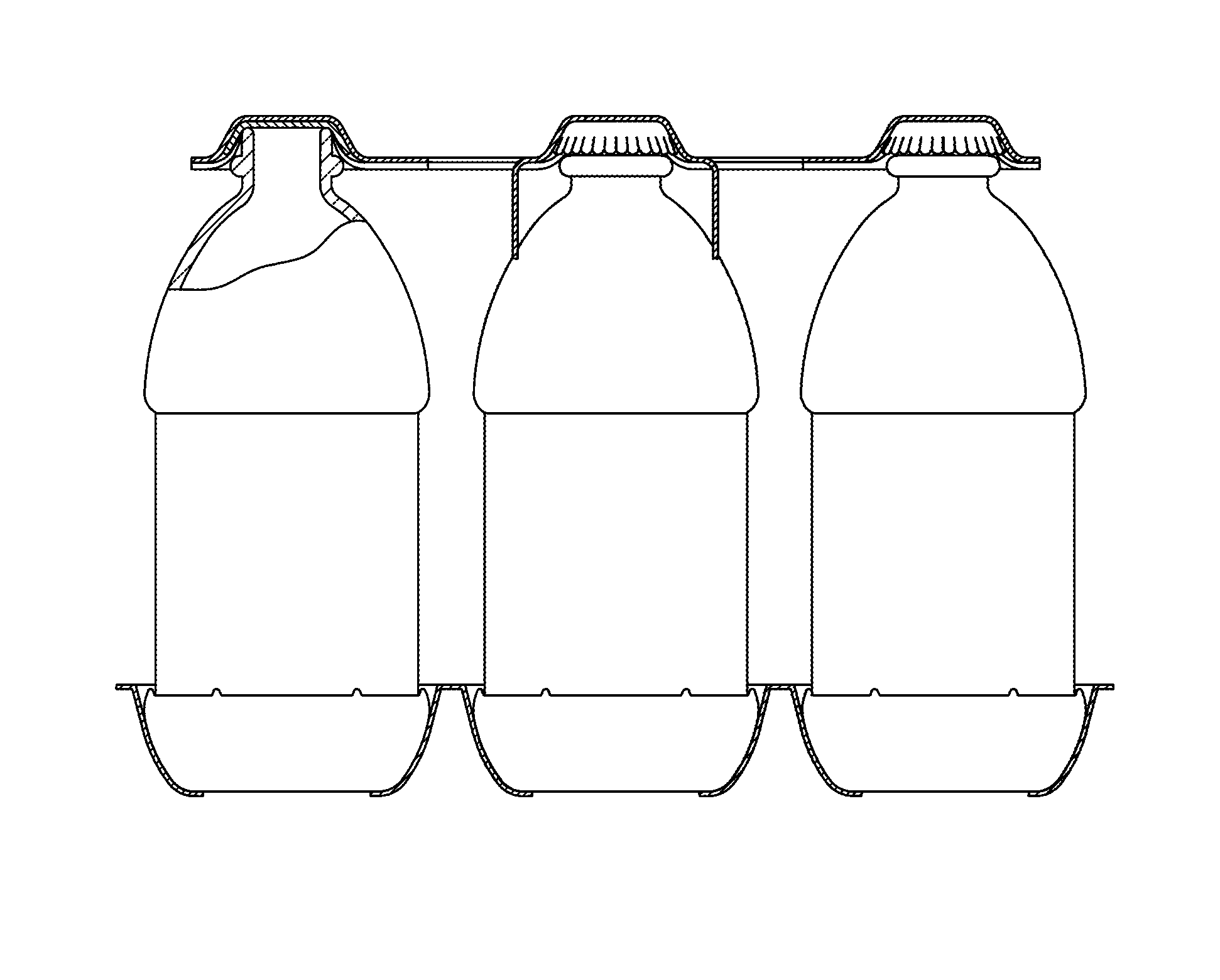

Machine and system for applying container carriers to containers

InactiveUS20130263557A1Effective continuous operation of systemSecurely holdWrappers shrinkagePackaging bottlesEngineeringPlastic film

A container packaging system for containers applies an apertured plastics film carrier stock to substantially identical containers such as beverage cans having annular chimes, cylindrical side walls, and frusto-conical walls between the chimes and the side walls. The carrier stock has shaped apertures to securely retain drinks cans, food cans, bottles and similar containers, as a multi-pack unit. The carrier stock is rolled onto suitably juxtaposed containers engaging a tabbed aperture edge portion progressively from above to below the upper edge of the respective containers to be multi-packed and assumes a waveform 3D conformation to unitise the containers. The rolling method contrasts prior stretch application methods and enables cheaper and thinner carrier stock to be used.

Owner:BRITISH POLYTHENE

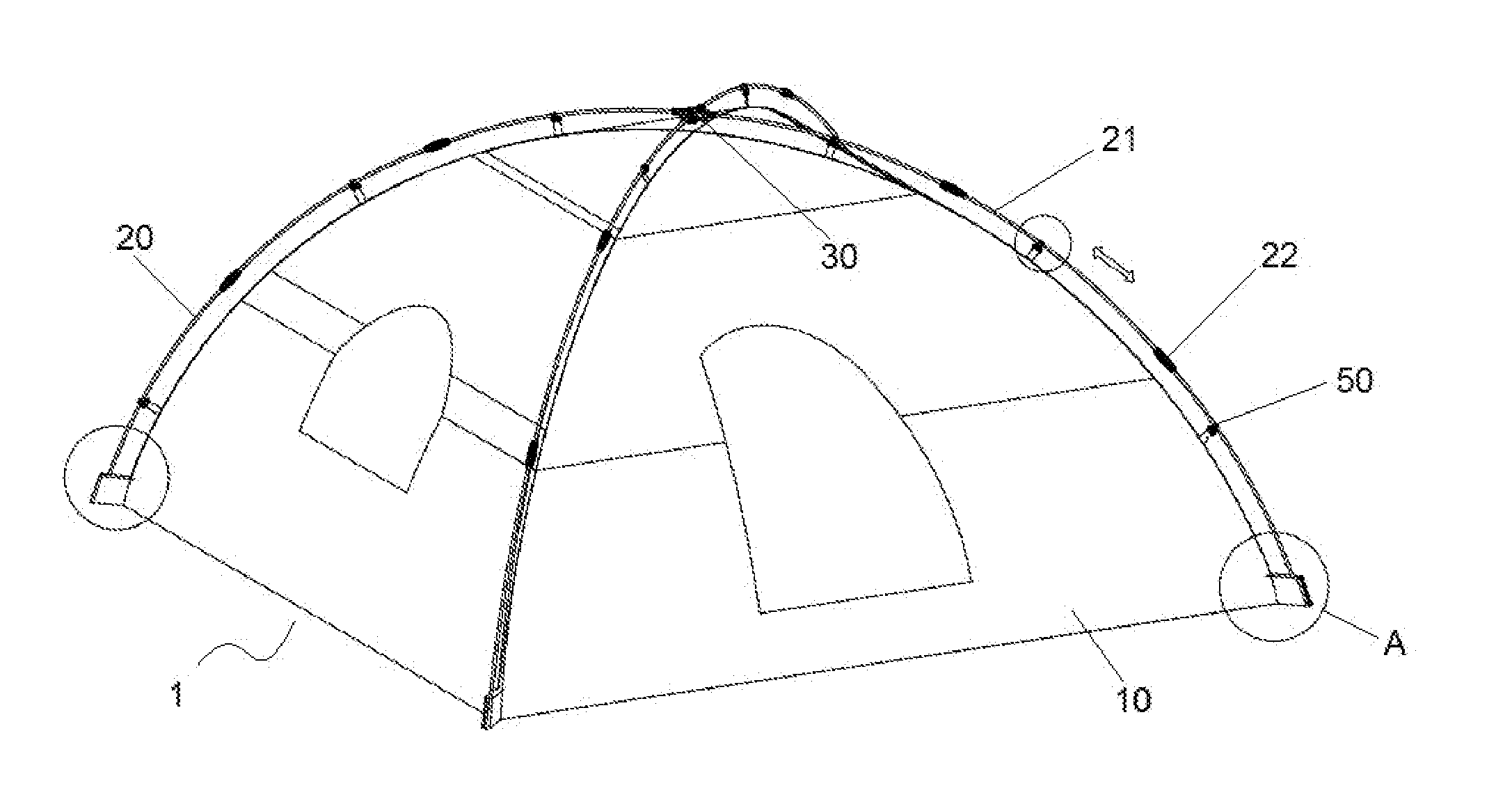

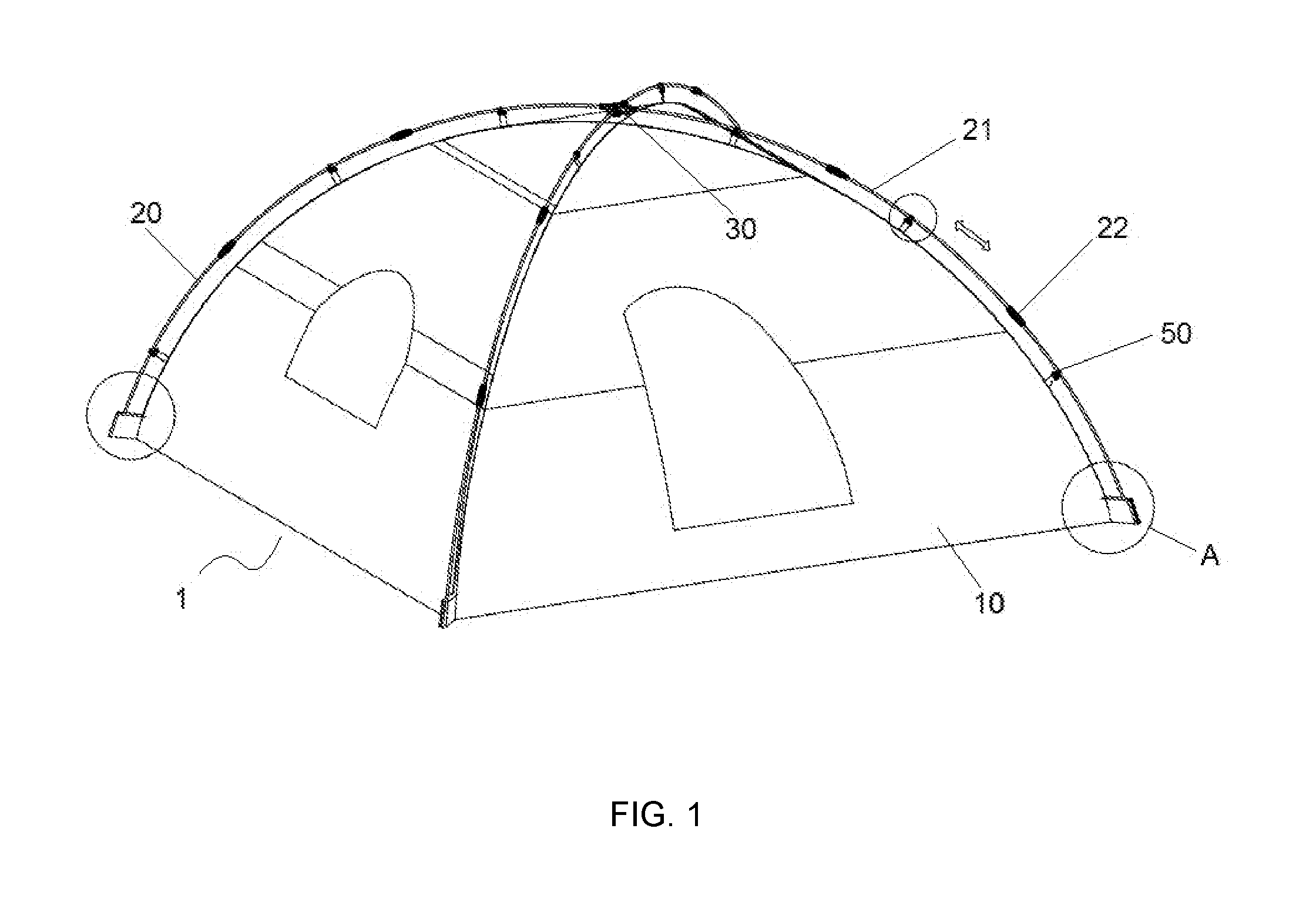

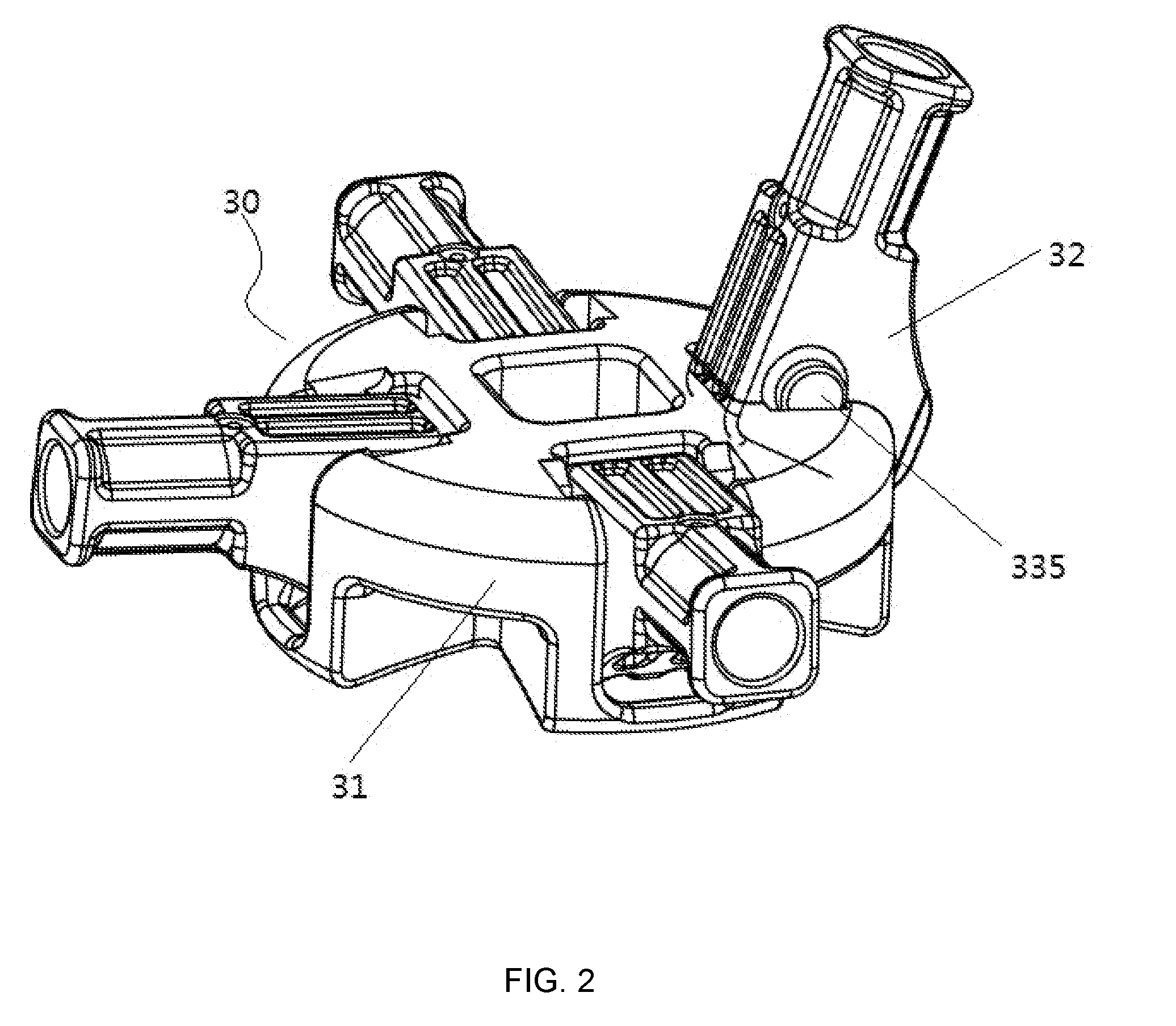

Foldable tent

ActiveUS20170022732A1Reduce the difficulty of productionLess raw materialTents/canopiesBraced frameEngineering

A foldable tent includes a tent cloth, a plurality of support frame poles to support the tent cloth, and a tent top supporting device. The tent top supporting device includes a cover, a plurality of connection sleeves, and a plurality of inwardly concave recesses. The plurality of inwardly concave recesses is disposed at a peripheral side of the cover. Each recess includes a first side wall and a second side wall disposed on two sides of the recess, and an inner side wall adjacent a center of the cover. Each respective connection sleeve is flippably or rotatably disposed in a corresponding recess, and has one end connected to an end of a corresponding support frame pole. When the foldable tent is unfolded, a side wall of the other end of the corresponding connection sleeve comes into contact and matches with the inner side wall of the corresponding recess.

Owner:XIAMEN INNOVATION METAL PRODUCING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com