Heat Exchanger with heat exchange chambers and plate members utilizing respective medium directing members and method of making same

a technology of heat exchange chamber and plate member, which is applied in the direction of metal-working apparatus, stationary conduit assembly, tubular elements, etc., can solve the problems of reduced pressure resistance, limited efficiency of pipe heat exchanger, and increased damage of thinner tubes, so as to maximize the heat exchange capacity of a heat exchanger and increase the overall surface area of the heat exchanger. , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

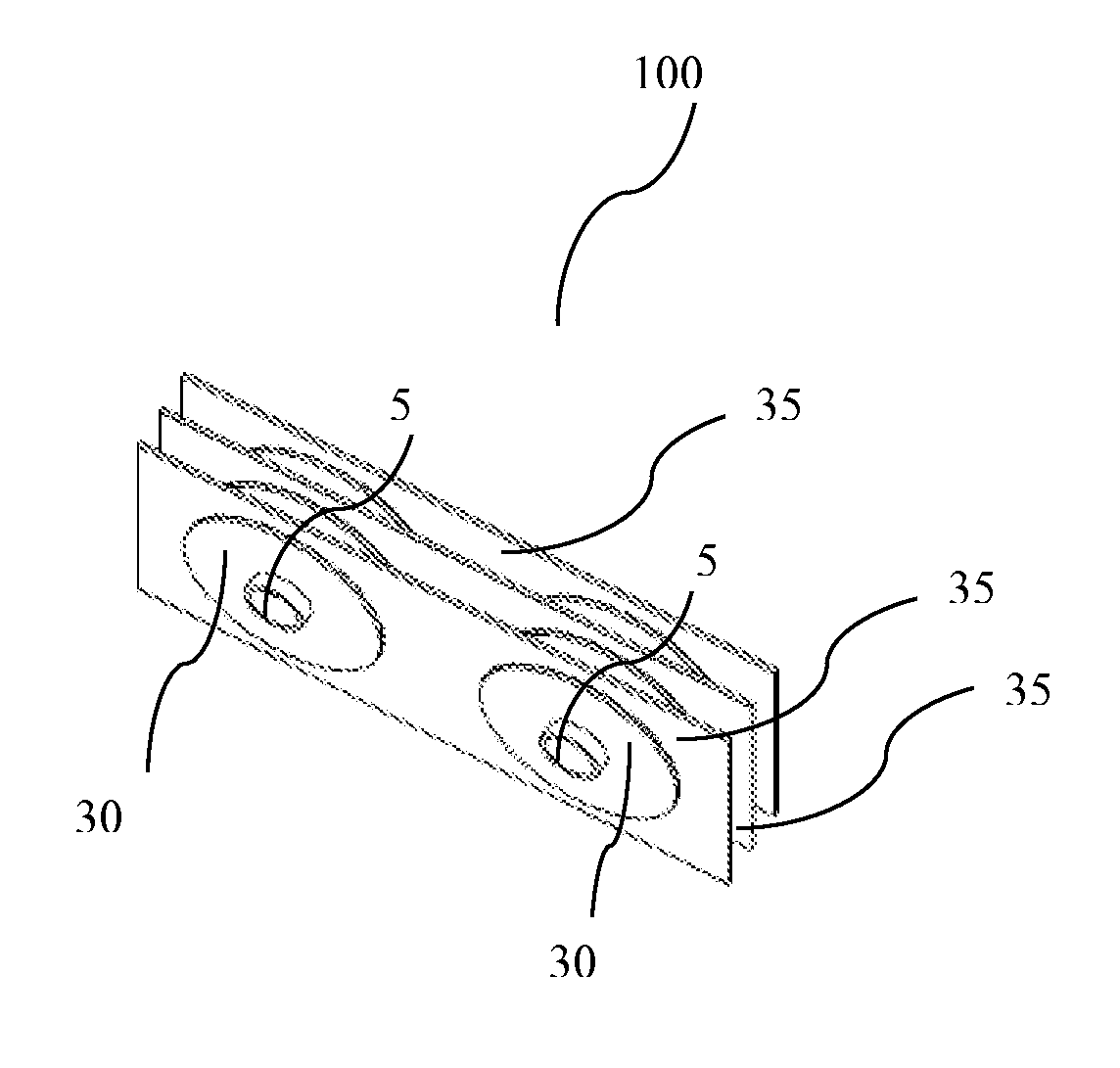

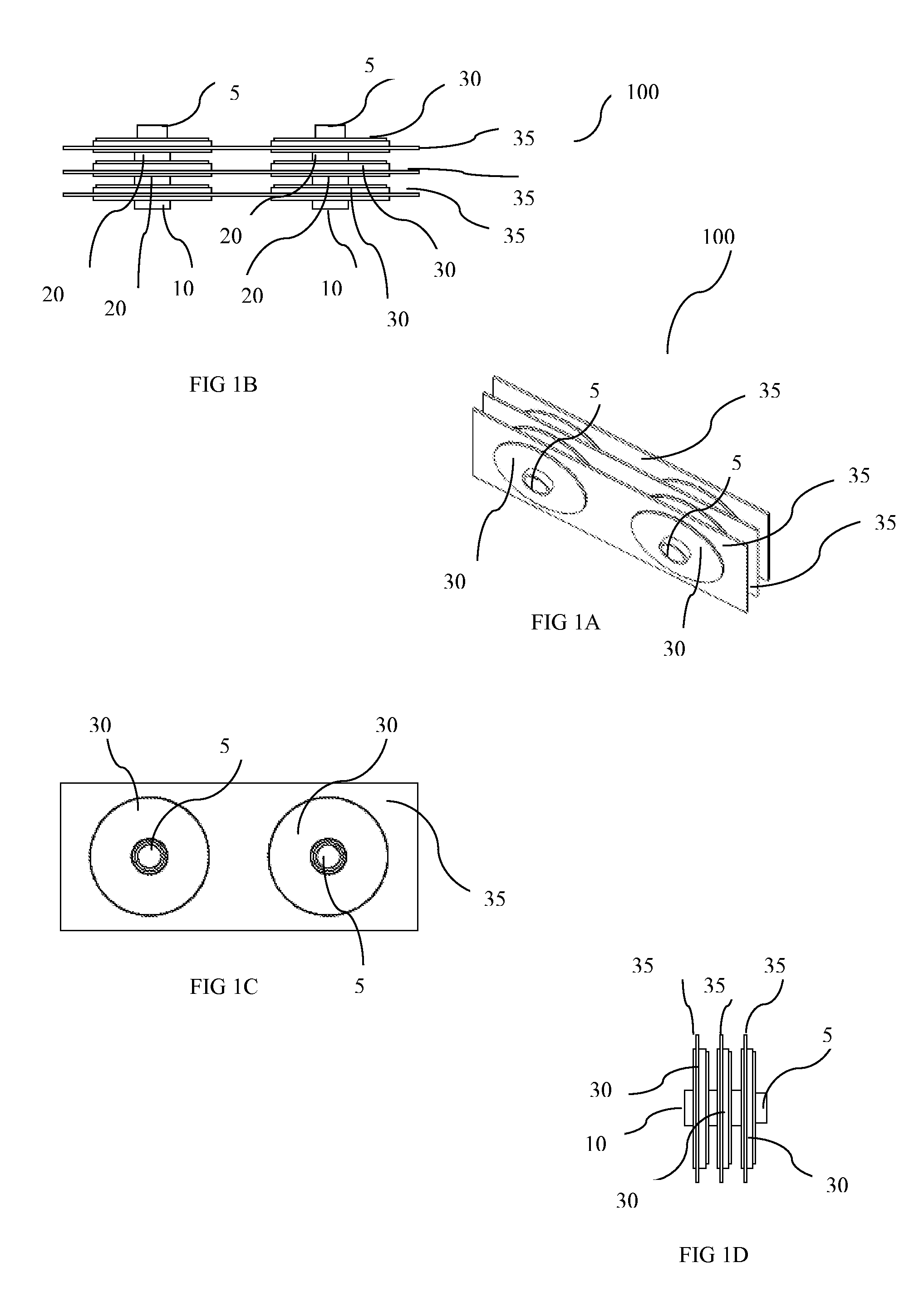

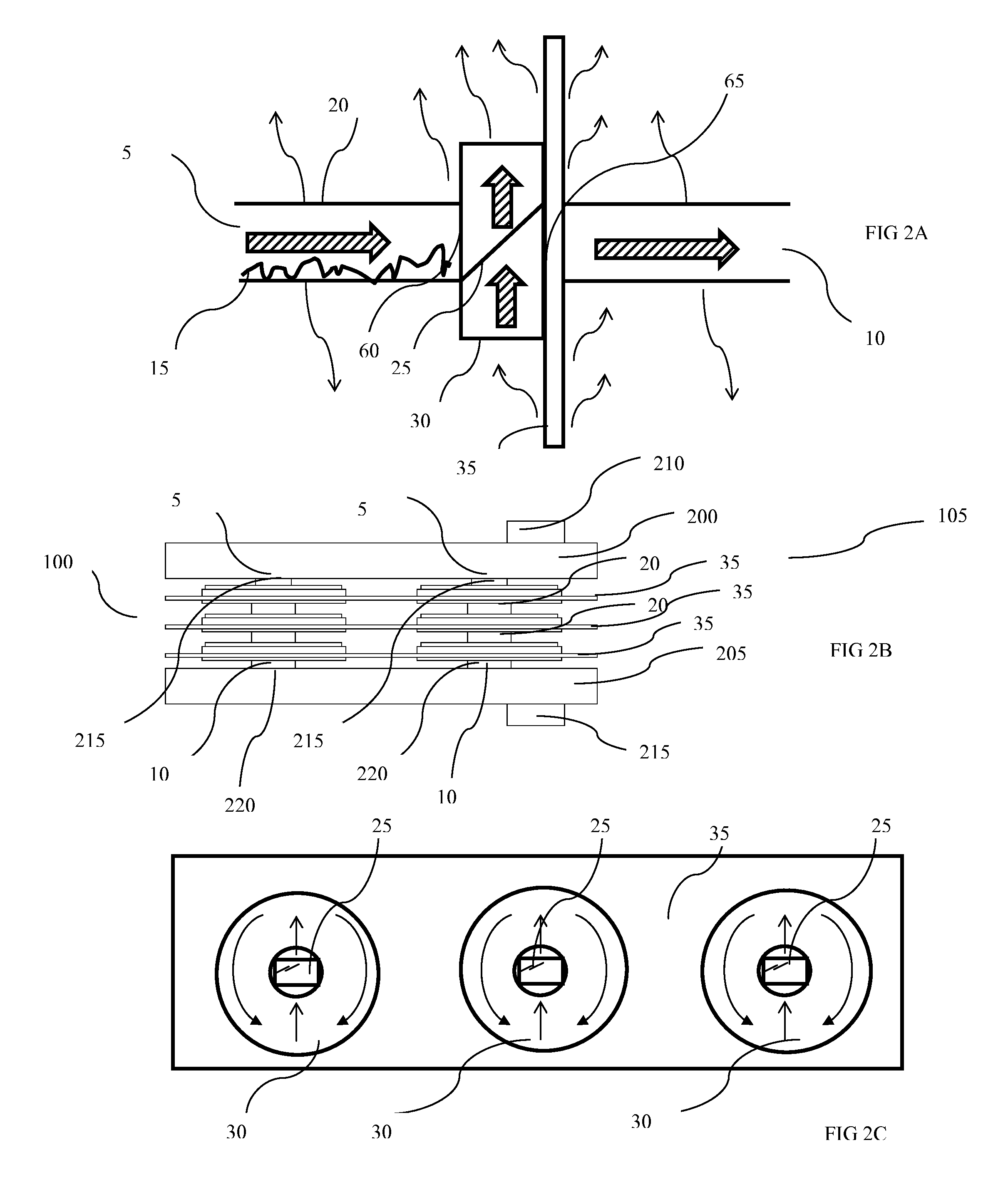

[0056]Referring to the drawings and in particular FIG. 1B and FIG. 2B, an embodiment of a heat exchanger 105 is shown. The heat exchanger 105 includes a pair of manifolds 200 and 205. Plurality of tube 20, chamber 30, and plate member 35 extend in spaced relation between a pair of manifolds 200 and 205, comprising a core 100 of the heat exchanger 105. One free end of tubes 20 coupled to manifold 200, and the other free end of tubes 20 coupled to manifold 205. Heat exchange medium 15 flows from the outlet 215 of the manifold 200 into the inlet 5 of the tube 20. The heat exchange medium 15 passes through the outlet 10 of the tube 20 into the inlet 60 of the chamber 30. The chamber 30 is coupled to a plate member 35. The heat exchange medium 15 then flow out outlet 65 of the chamber 30. The process of going from a tube 20 to a chamber 30 may repeat several times until the heat exchange medium 15 is received by another manifold 205. There may also be several rows of the tube 20, chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersion potential | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com