Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improved seam strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

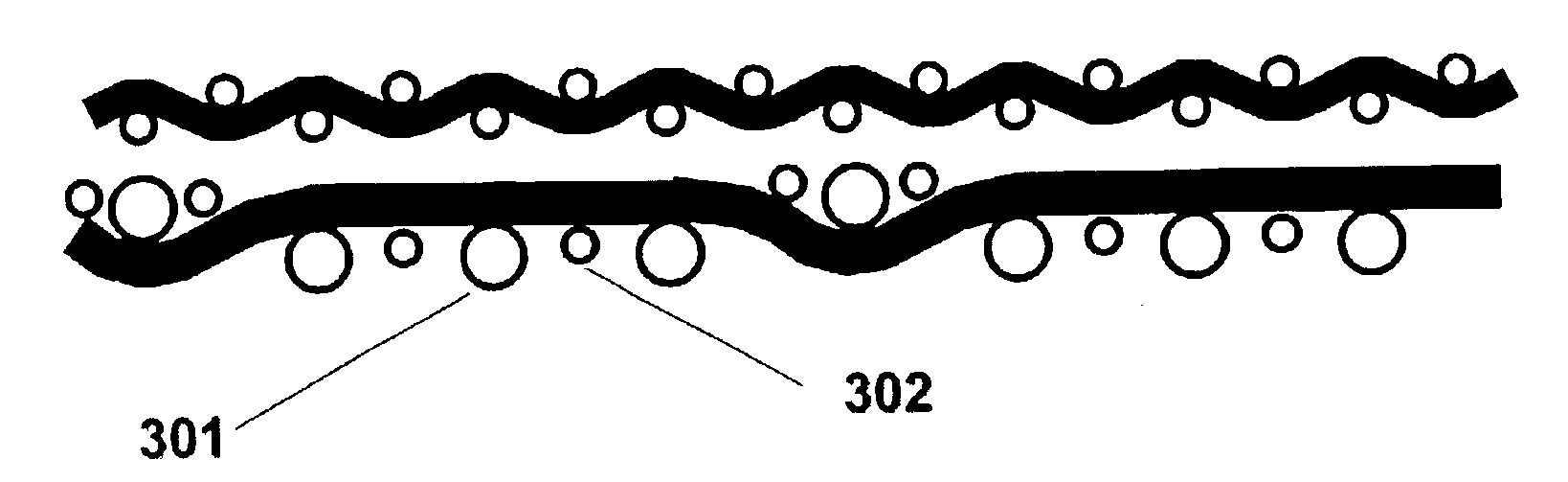

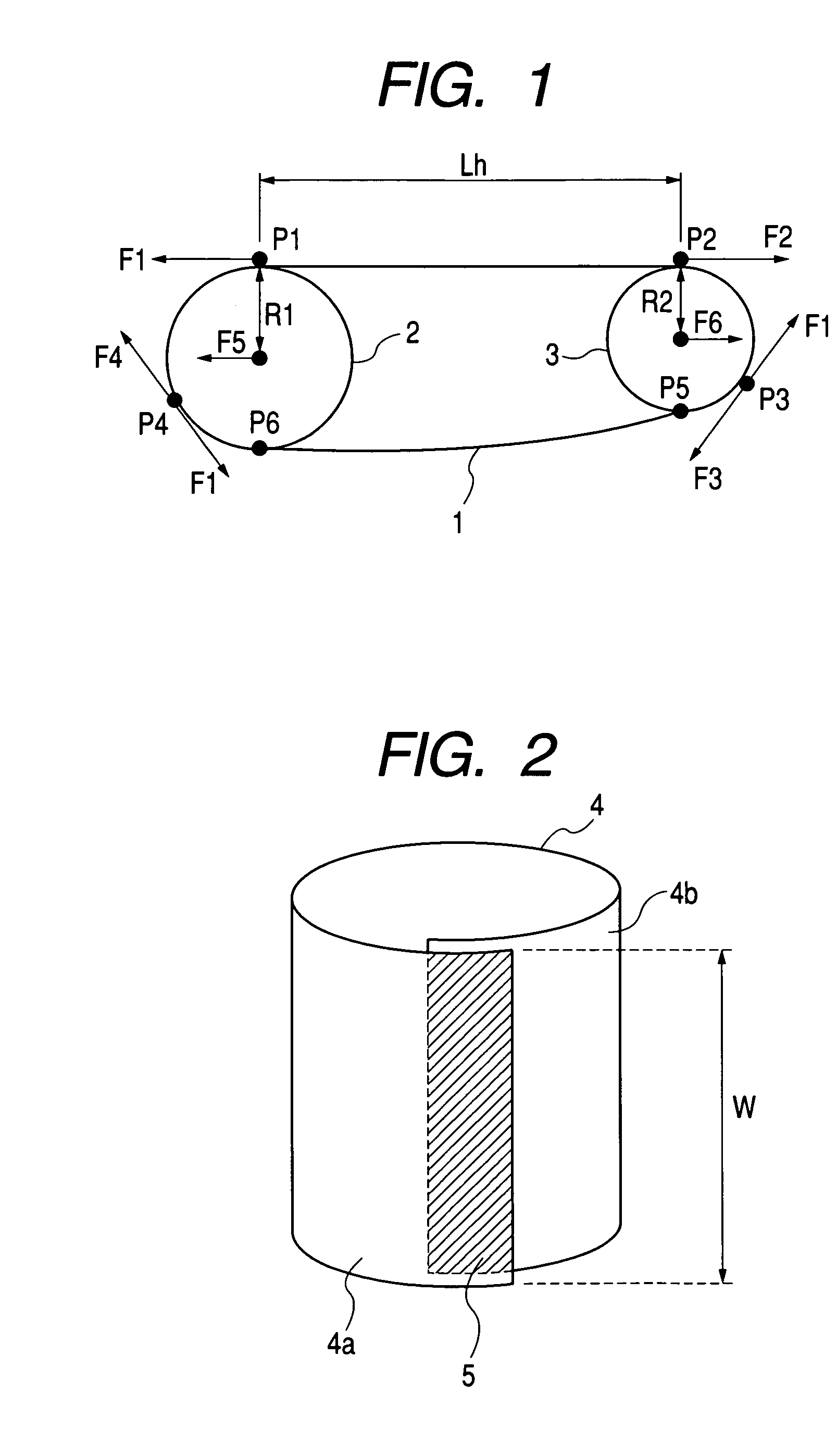

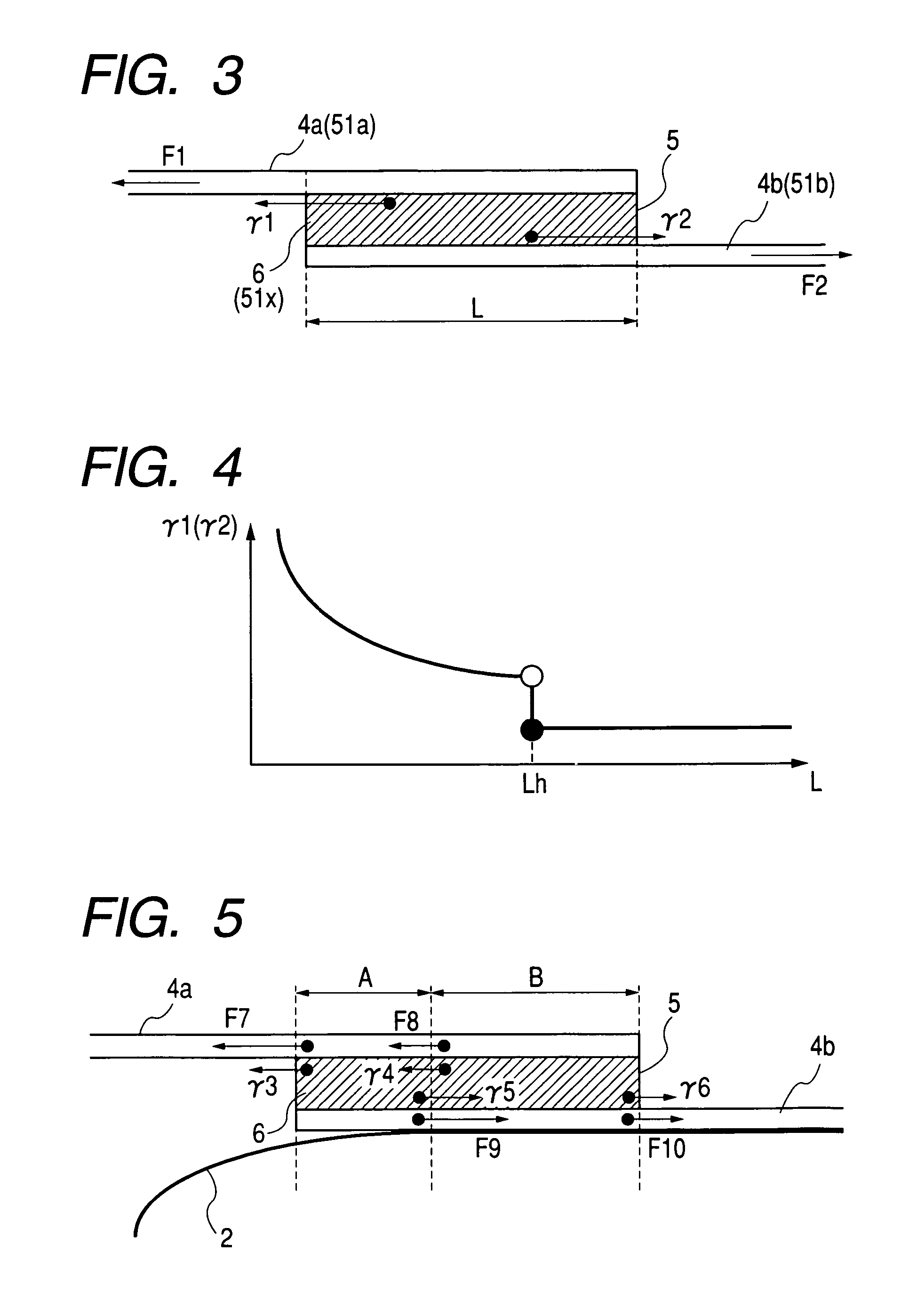

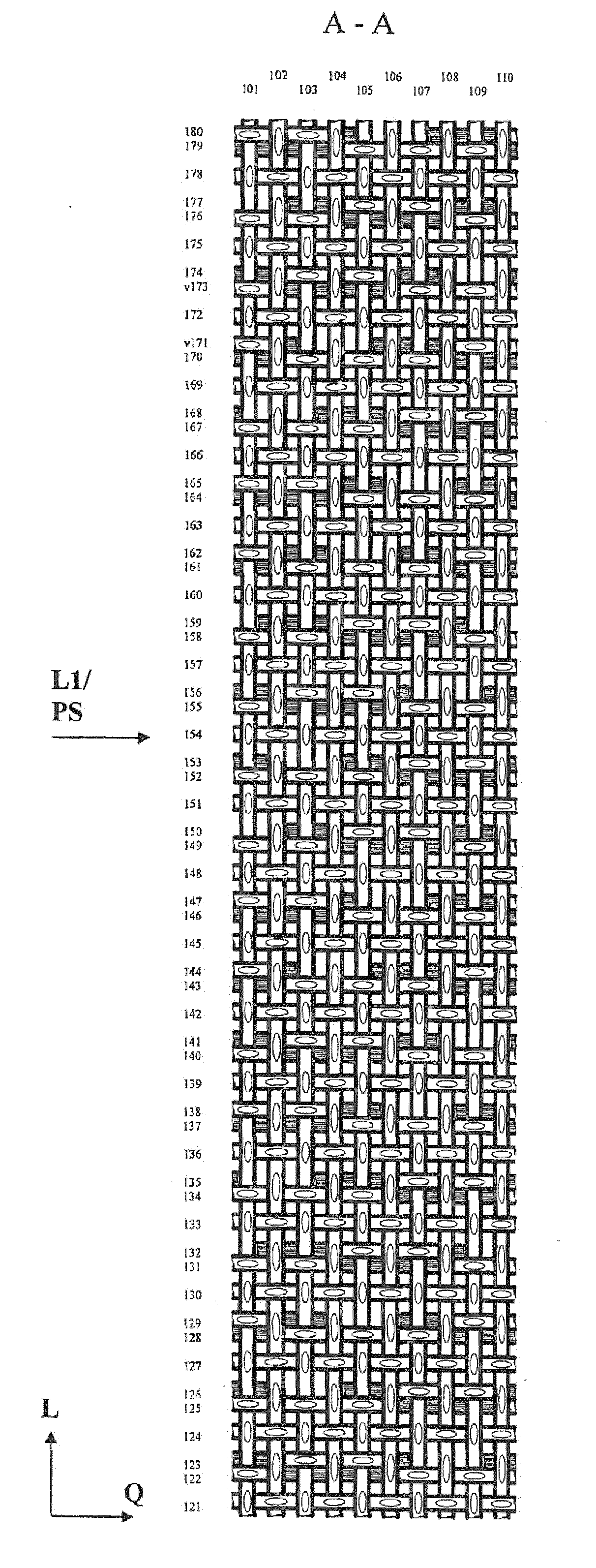

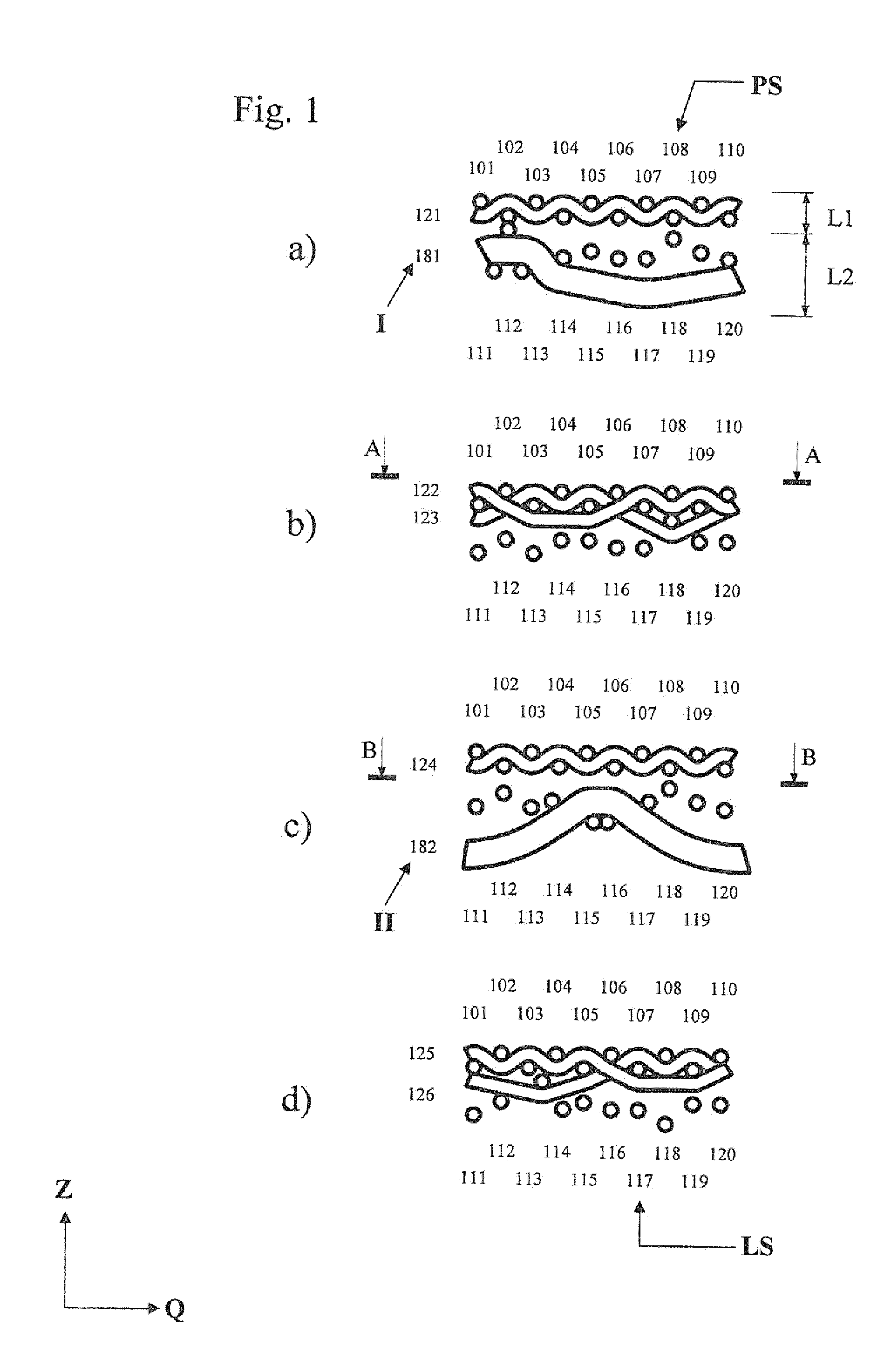

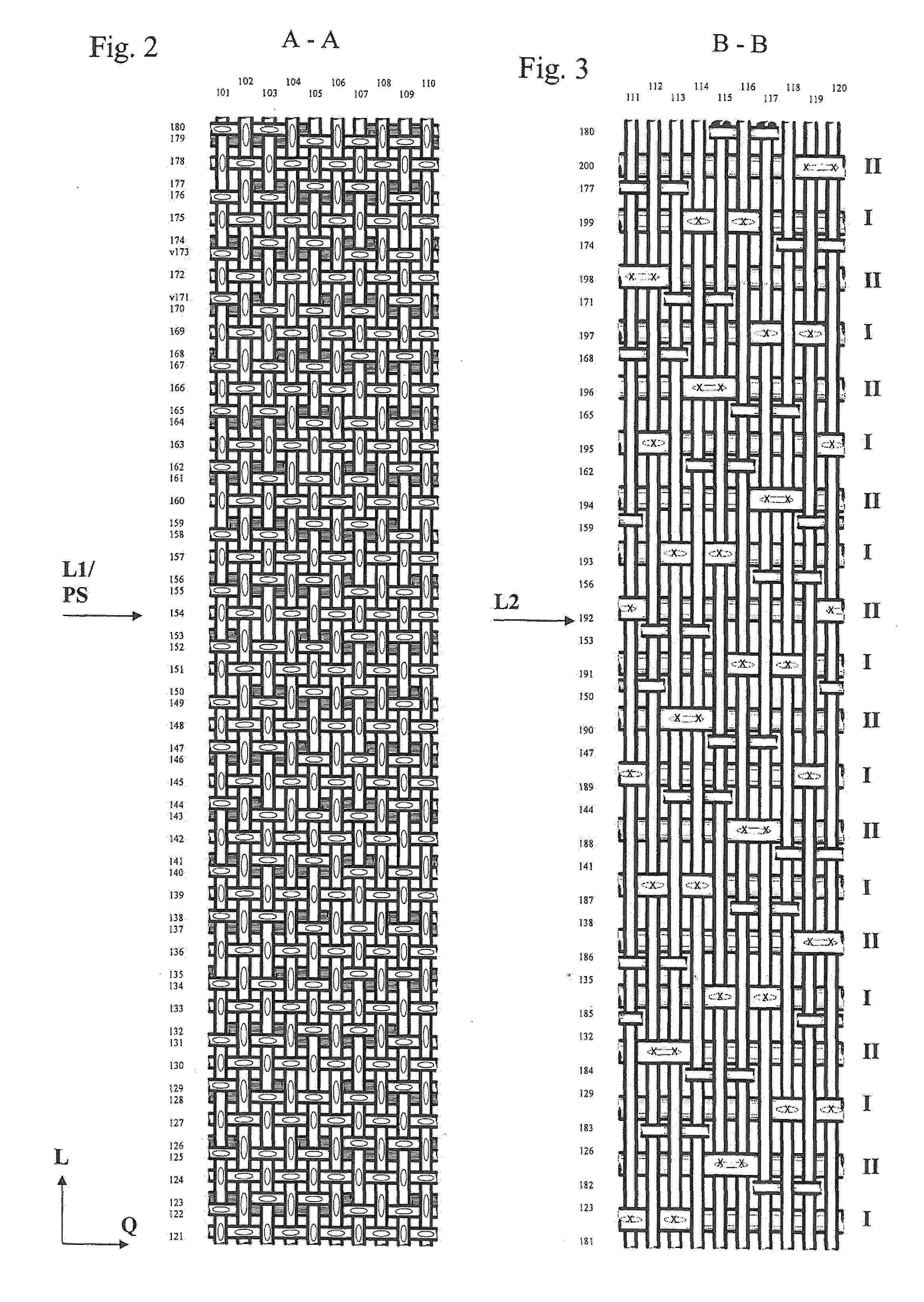

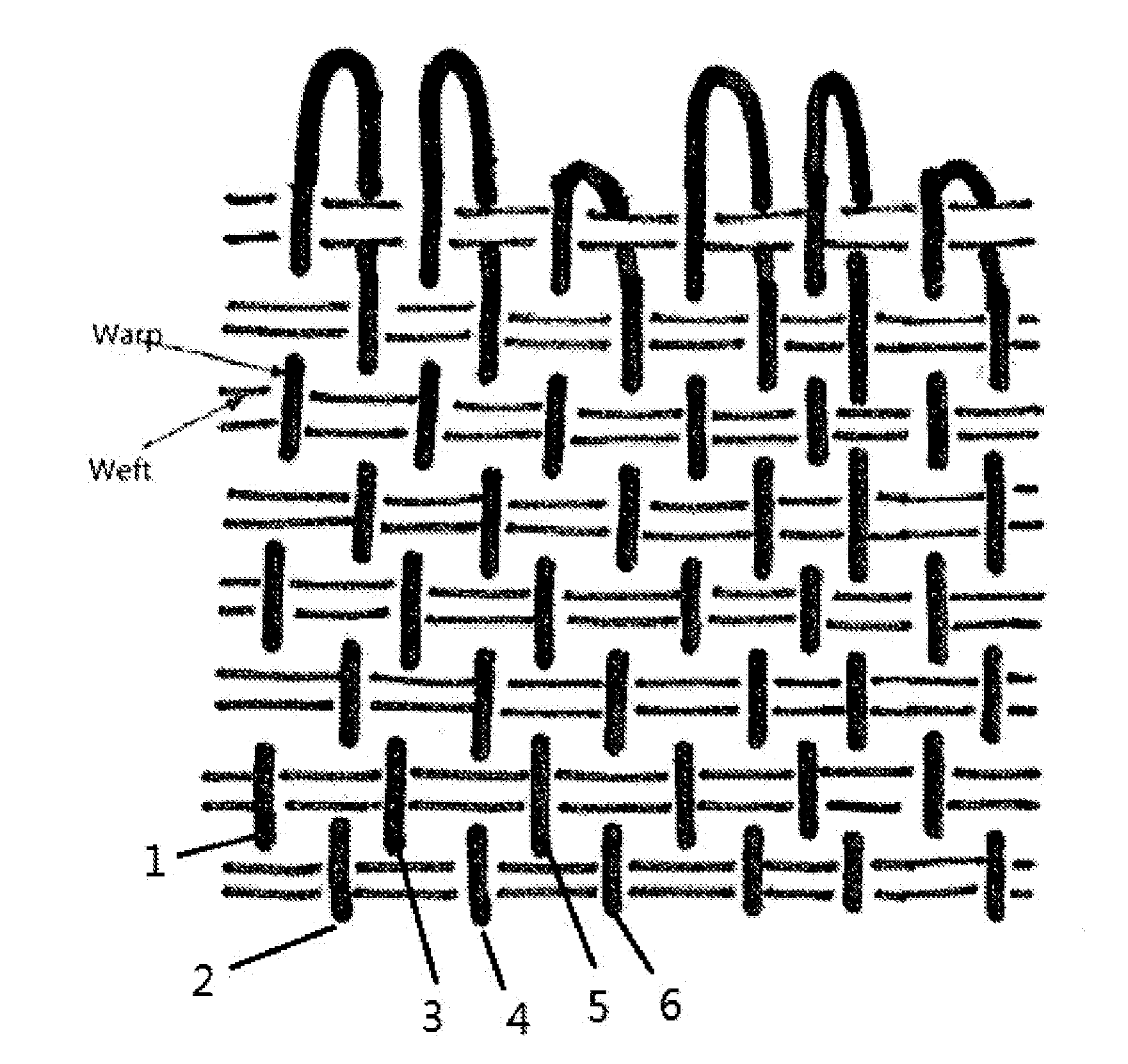

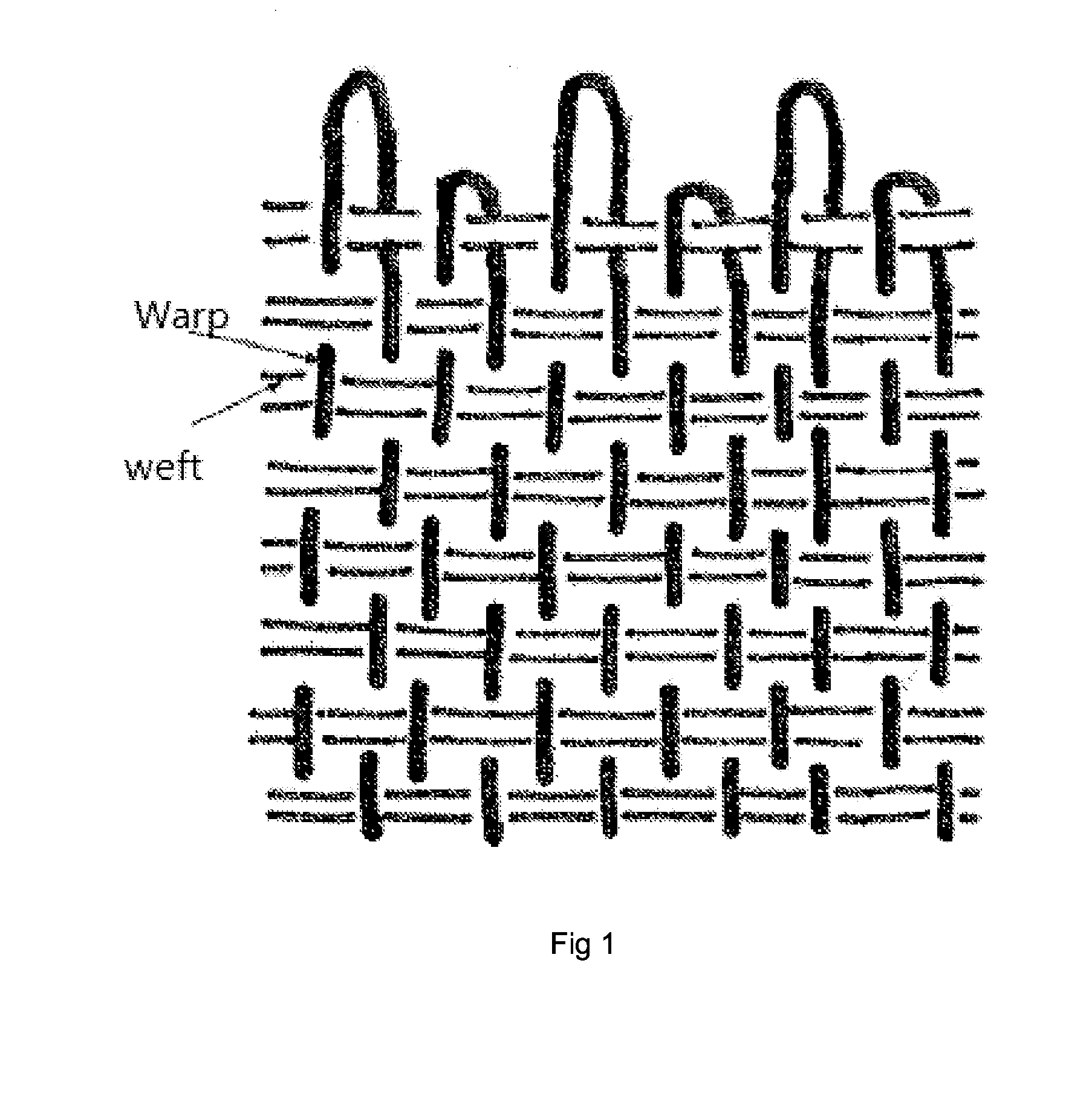

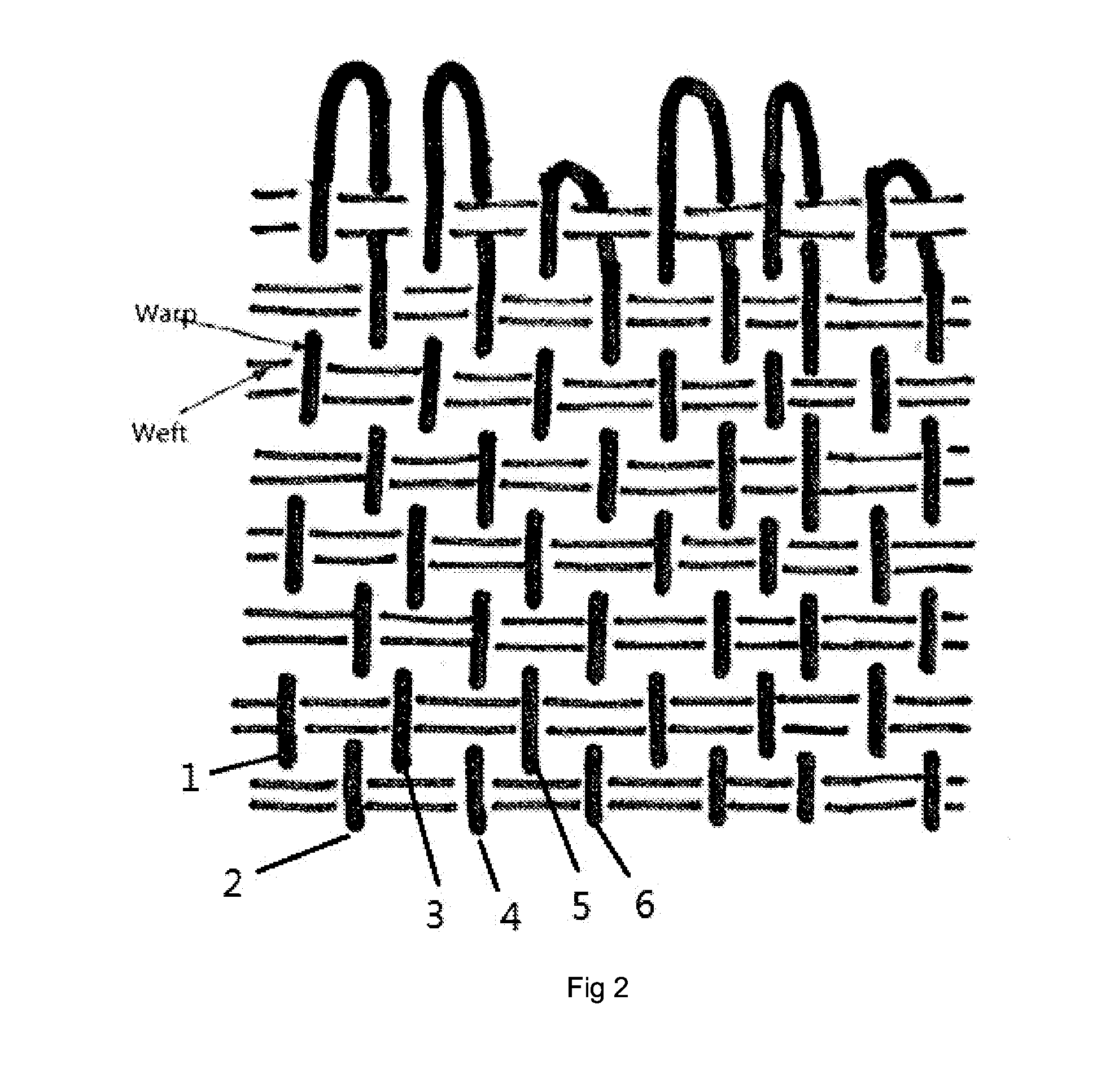

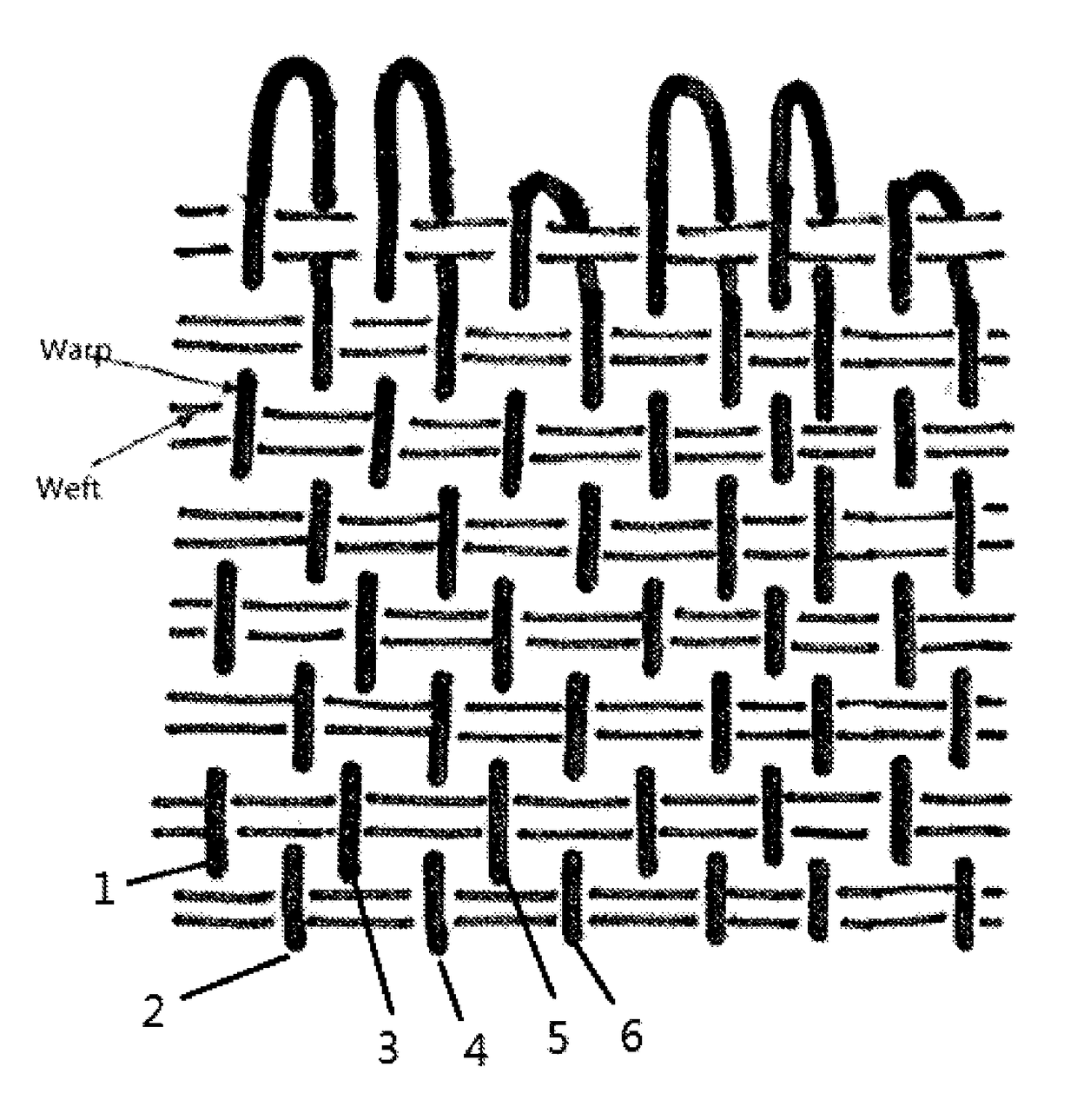

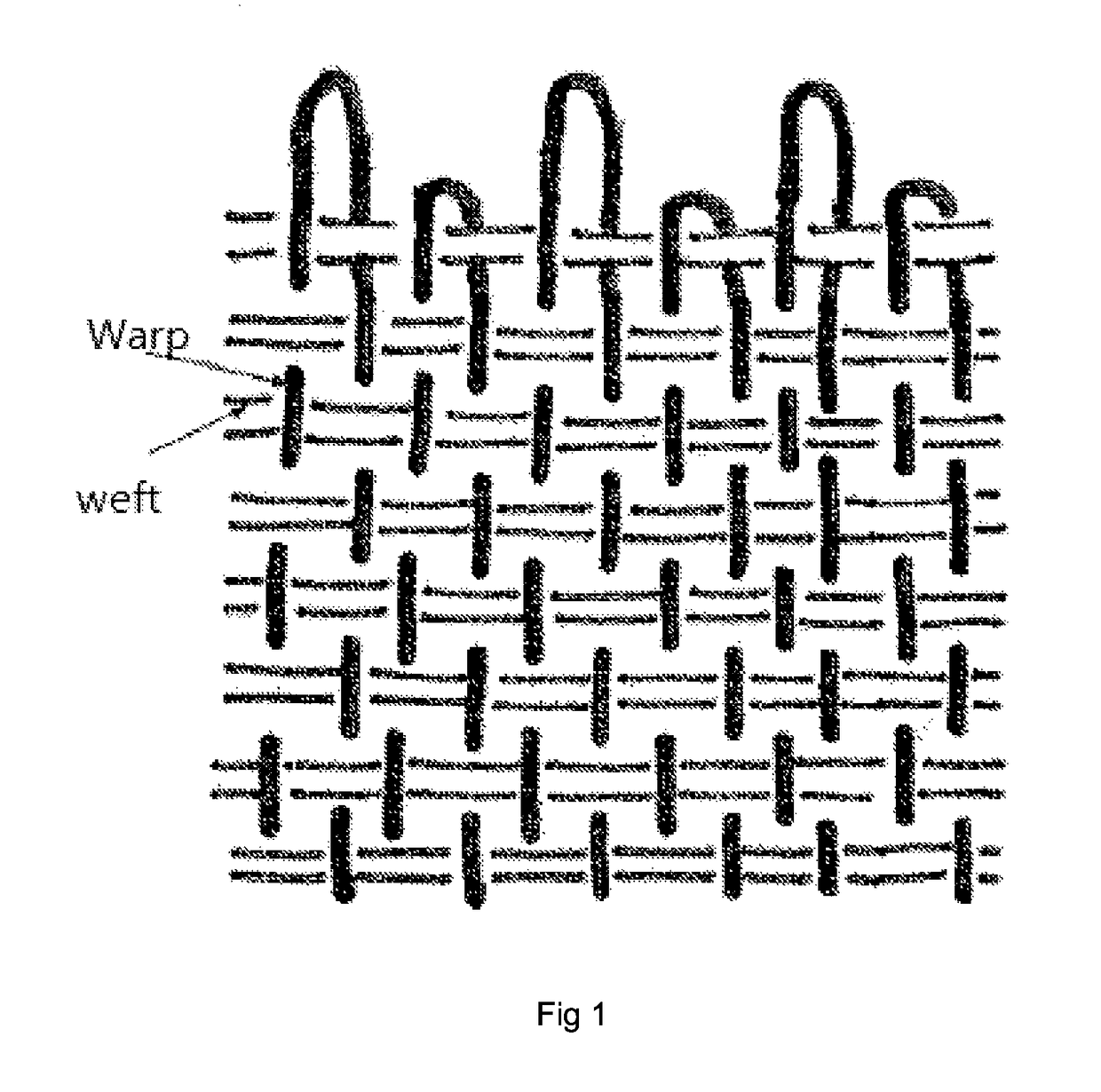

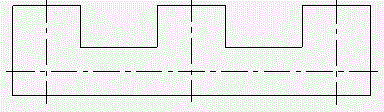

Multi-layer papermaker's fabrics with packing yarns

InactiveUS6902652B2Increasing caliperImproved seam strengthMachine wet endPaper/cardboardCotton materialLateral movement

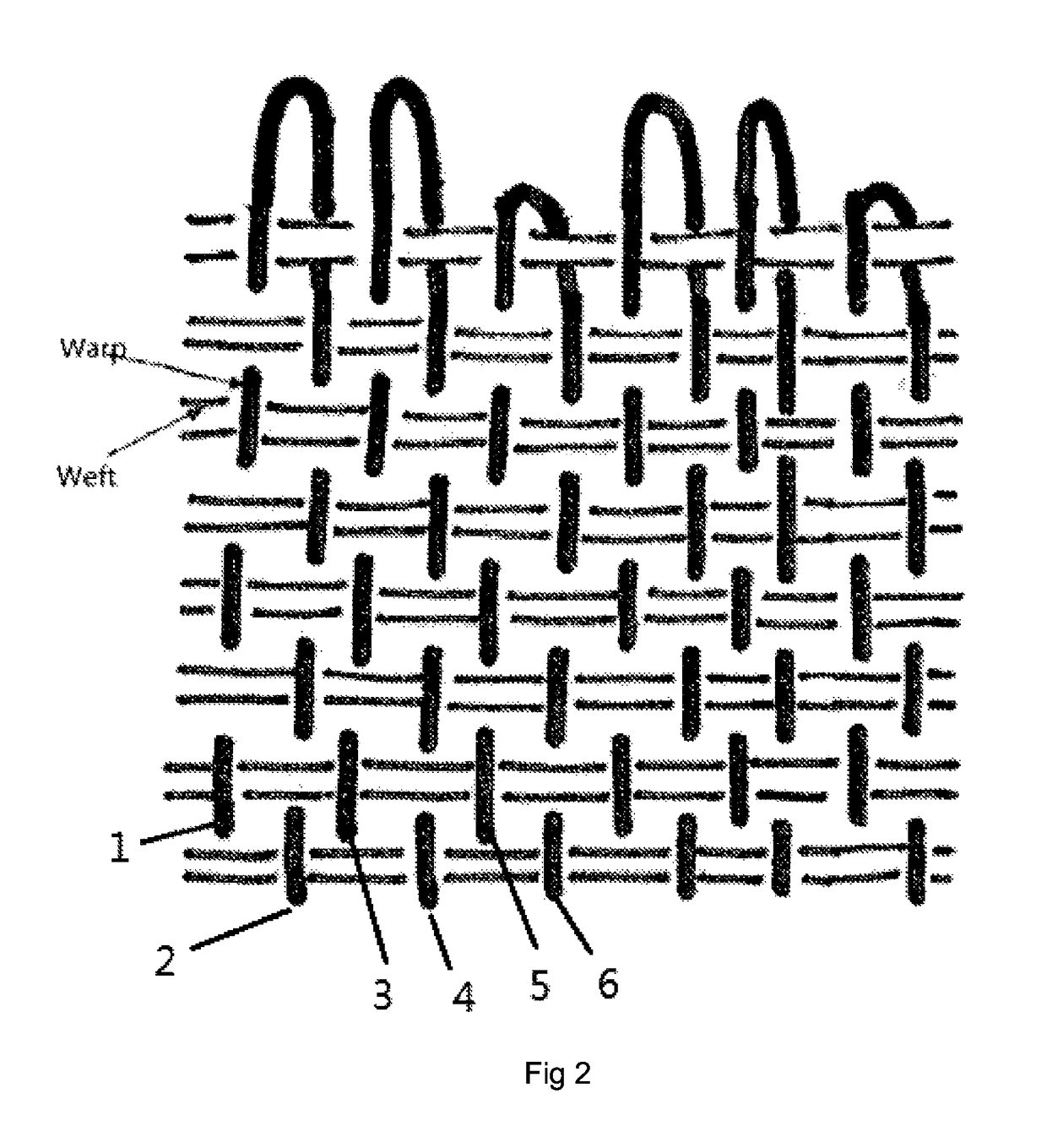

A papermaker's fabric, usable in the forming section of a paper machine, having a top layer and a bottom layer of cross-machine direction (CD) wefts. The top (forming) layer and bottom (wear side) layer are woven together to form a multi-layer fabric. CD packing yarns are inserted between adjacent wear side weft yarns. The packing yarns reduce the void volume on the wear side of the cloth without significantly disrupting the air permeability or increasing the caliper of the fabric. The placement of the packing yarns also adds to the CD stability and seam strength of the fabric and reduces the lateral movement of the wear side weft yarns.

Owner:ALBANY INT CORP

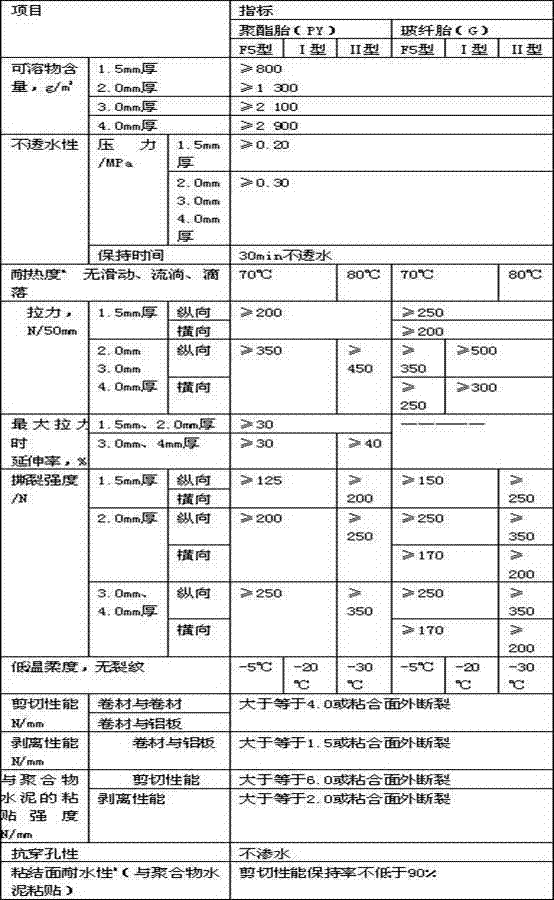

APF (advanced polarizer film) self-adhesive waterproof coiled material construction method

The invention discloses an APF (advanced polarizer film) self-adhesive waterproof coiled material construction method which includes a step of plane construction and a step of facade construction. The step of plane construction includes base layer cleaning, base face line snapping, polymer cement mortar preparing, node processing, reinforcing layer and internal and external corner adding, APF self-adhesive waterproof coiled material layer pre-paving, polymer cement mortar coating and scraping, APF self-adhesive waterproof coiled material layer paving, lapping, rolling, head recovering and organizing for acceptance testing, and the step of facade construction includes facade base layer cleaning, facade base face coiled material positioning and line snapping, base layer treating agent coating and scraping, node processing, APF self-adhesive waterproof coiled material layer paving, lapping, rolling, head recovering and organizing for acceptance testing. The polymer cement mortar is utilized as a bonding layer, so that the bonding layer can be quickly paved on a humid concrete base layer and can also be directly paved on a dry concrete face.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

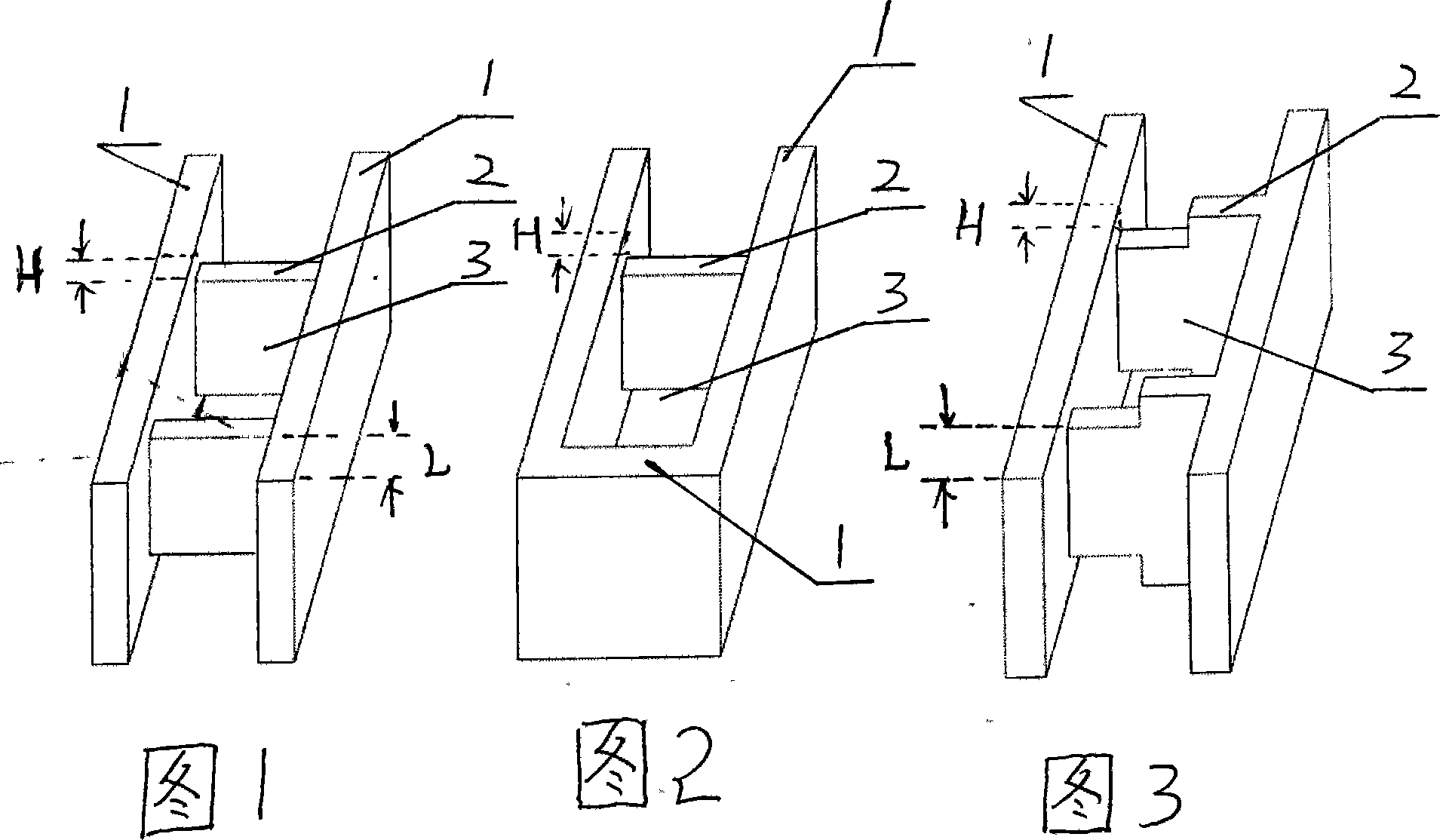

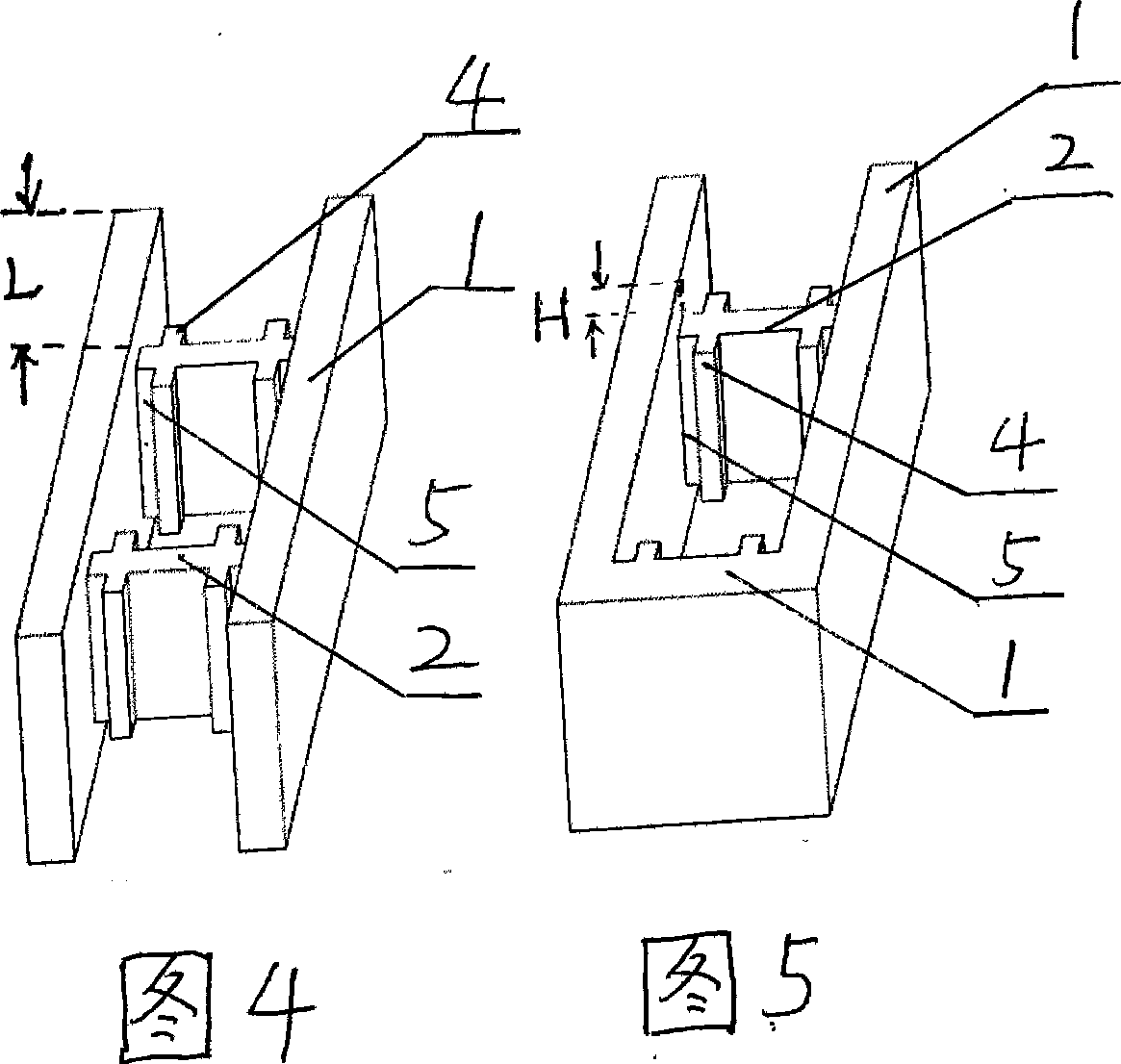

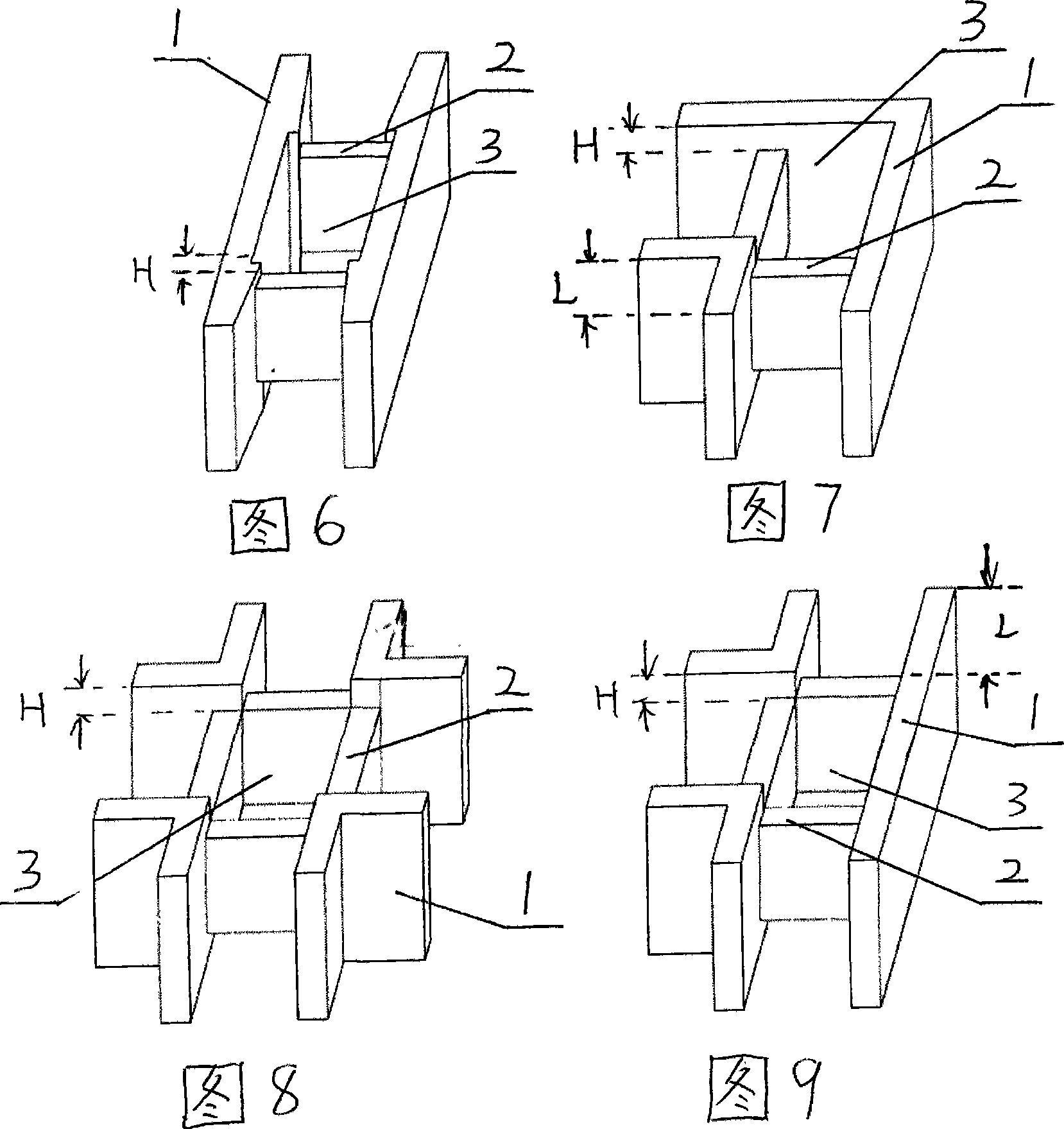

Building block

The building block consists of outer wall, and inner ribs in the height smaller than that of outer walls and connected to the outer walls, with the connection point being located in the place apart from the side ends of the outer wall by distance L. The said height difference forms transverse interval, into which concrete may be poured for connecting adjacent blocks, and the distance L forms space between blocks for pouring concrete. The building block has high connection strength, and may have reinforcing bar set inside the transverse space conveniently.

Owner:吴方伯

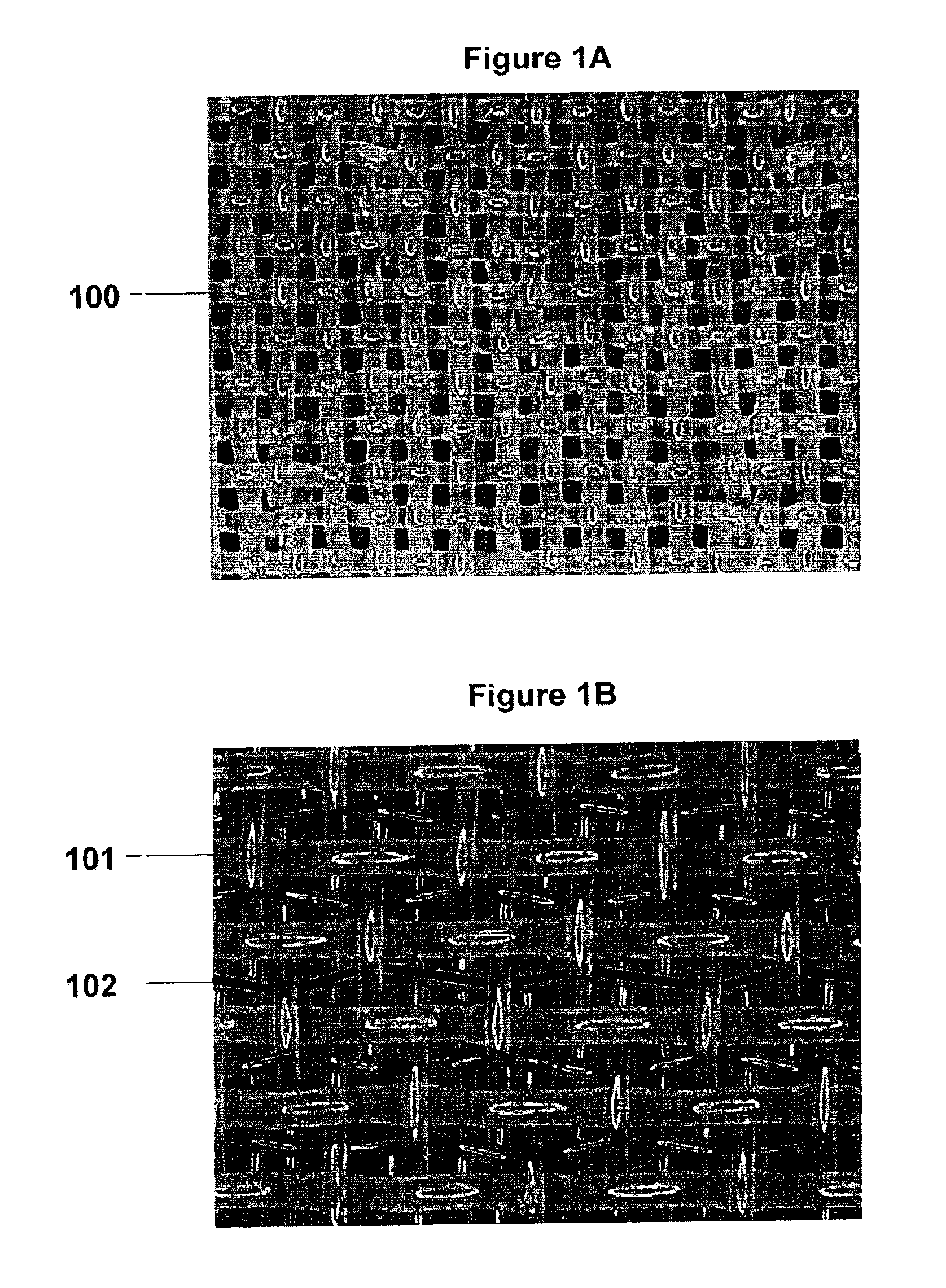

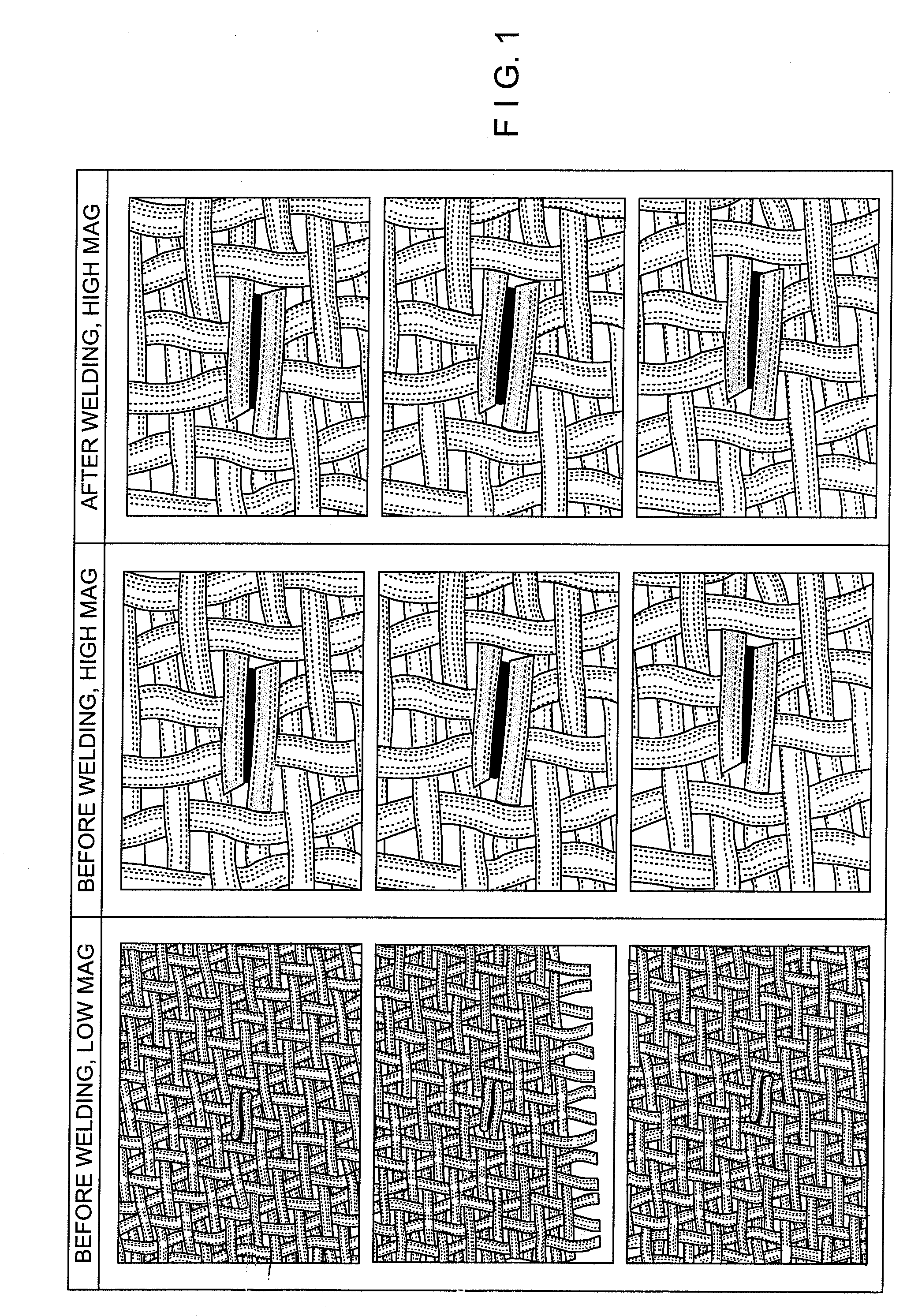

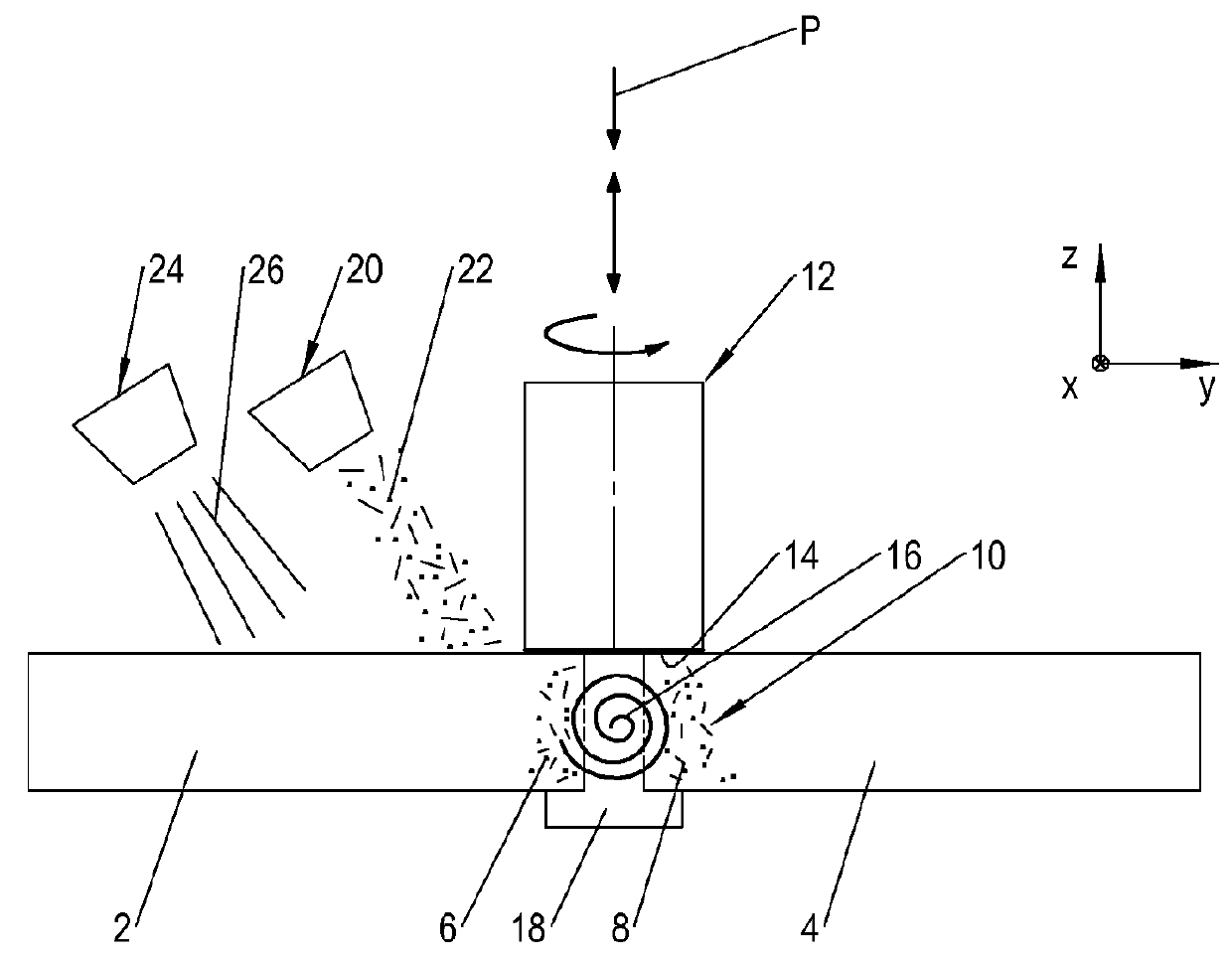

Process for producing papermaker's and industrial fabrics

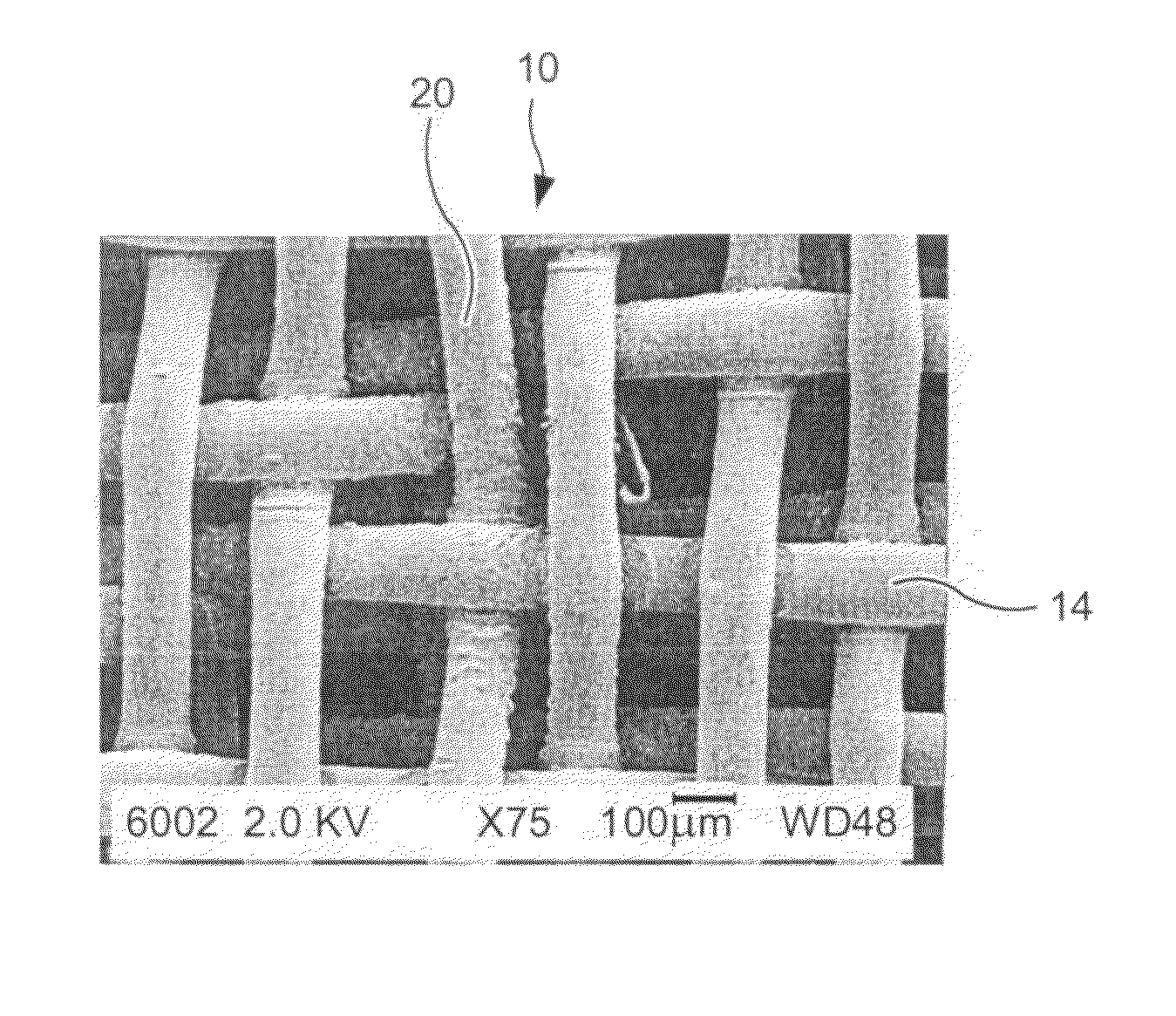

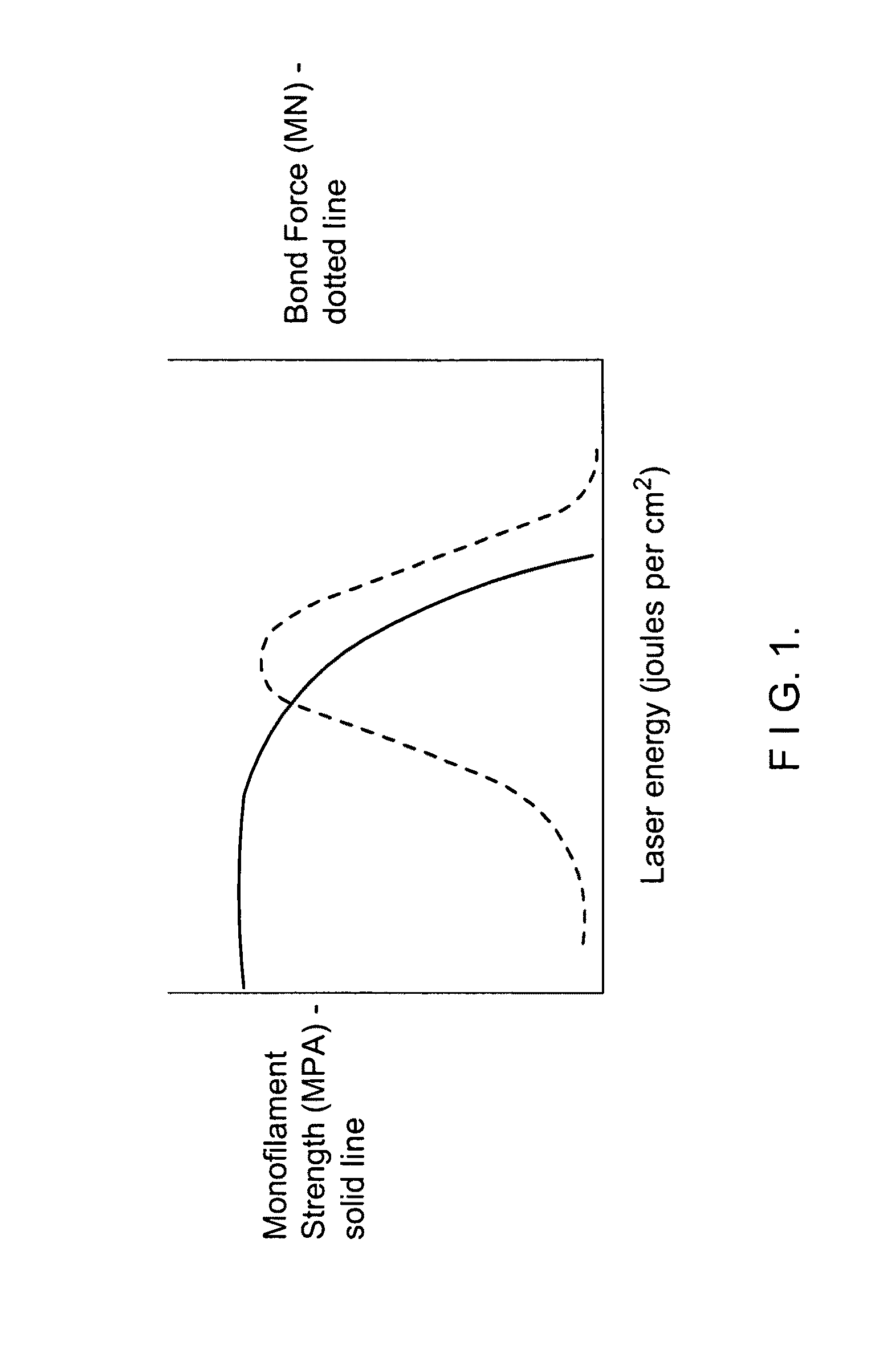

ActiveUS20090056900A1High strengthEasy to useLamination ancillary operationsPretreated surfacesYarnSurface pattern

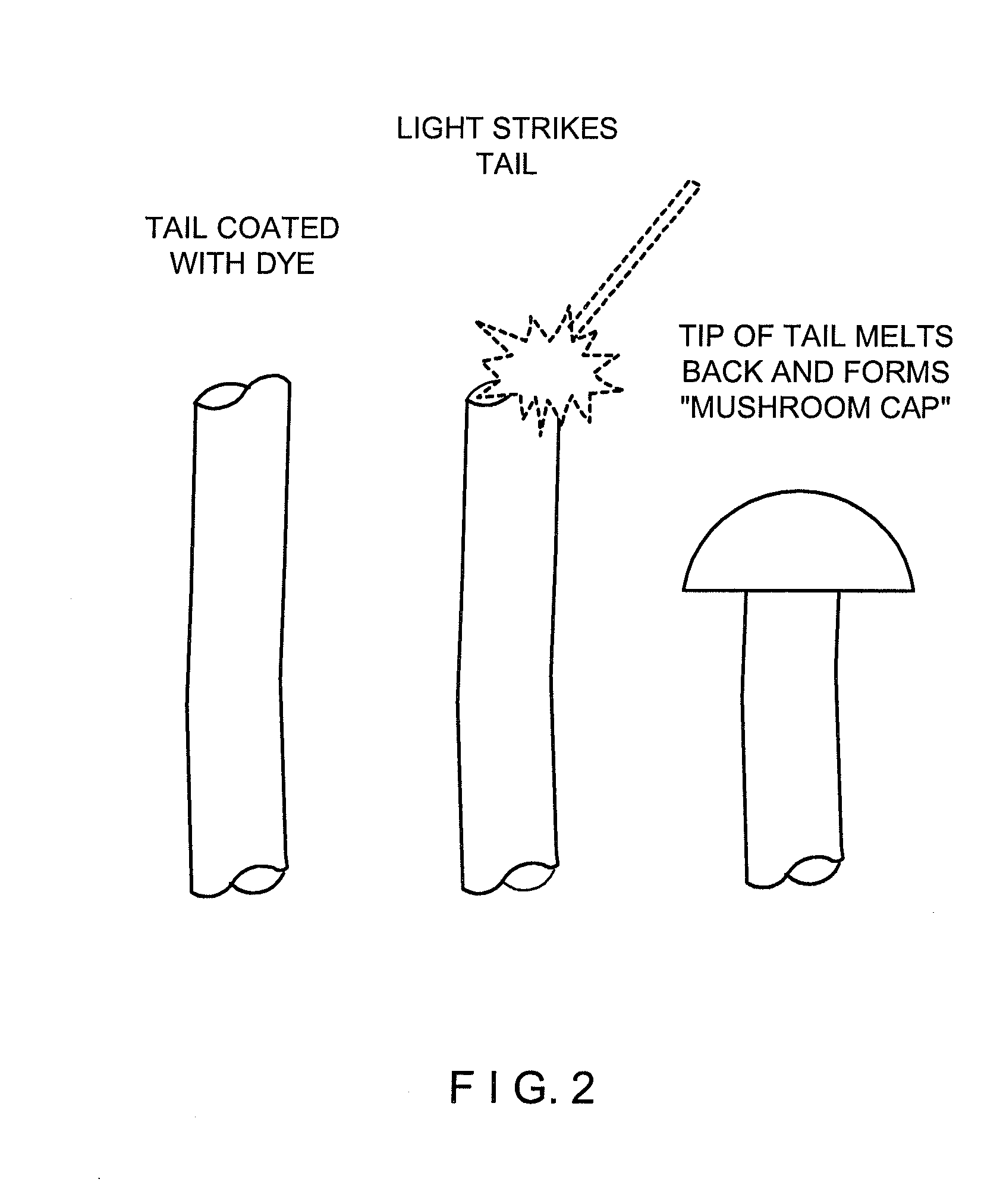

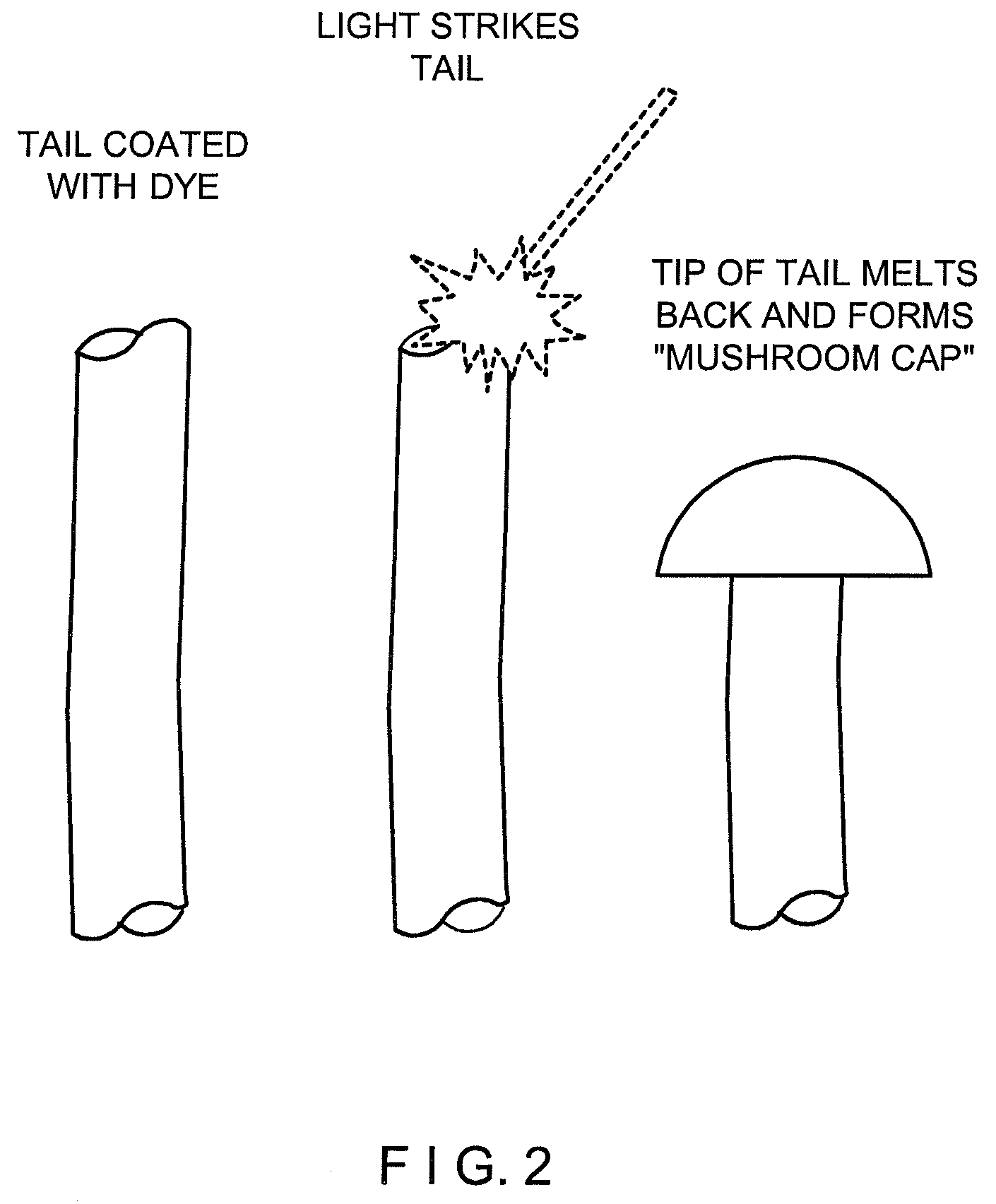

The invention discloses herein the use of short wavelength infrared energy to selectively control the locations where thermal fusing or bonding takes place or does not take place in an industrial fabric. Also, the method involves forming a mushroom cap on the tail of a fiber / yarn or monofilament and also creating a surface pattern formation.

Owner:ALBANY INT CORP

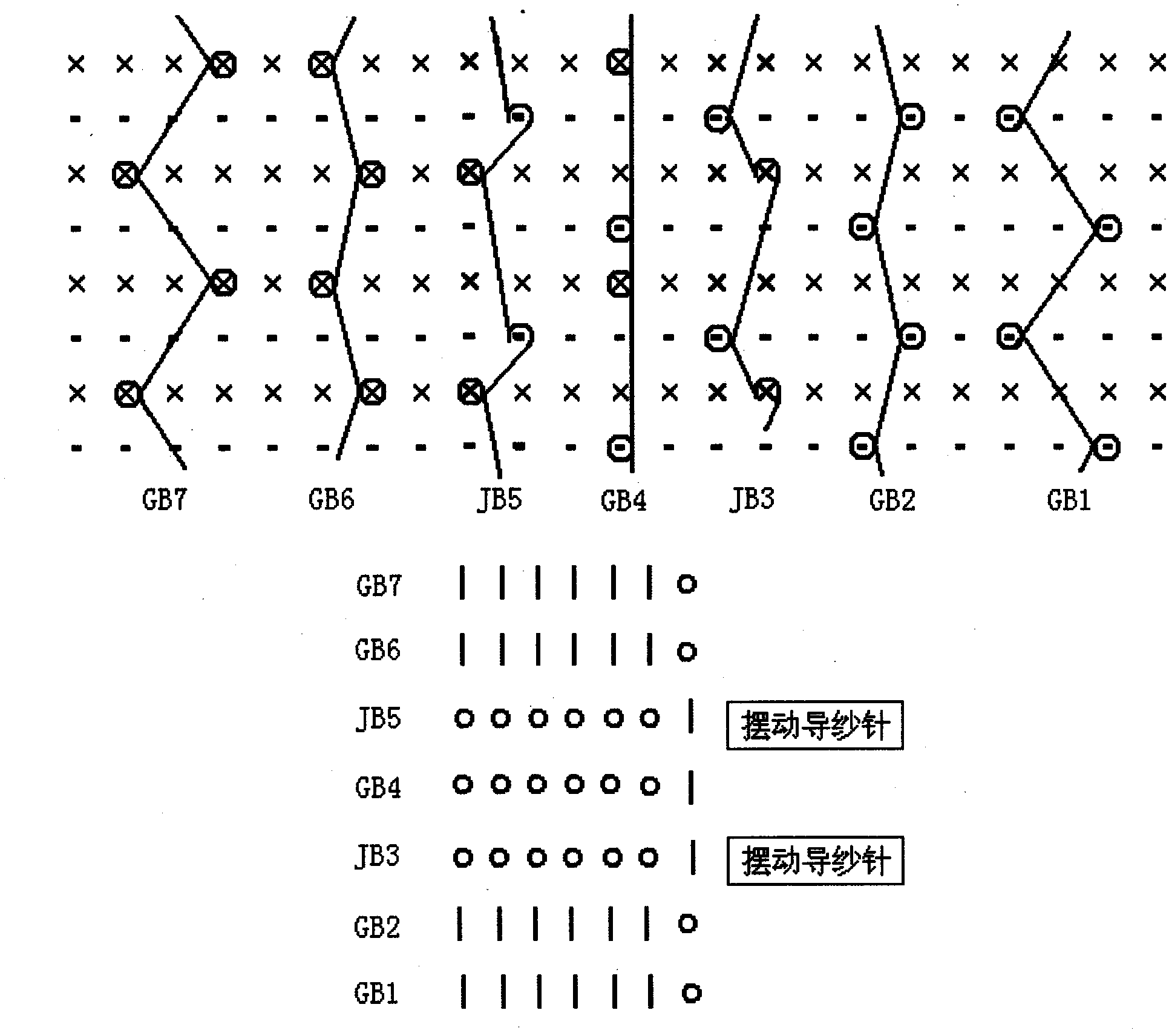

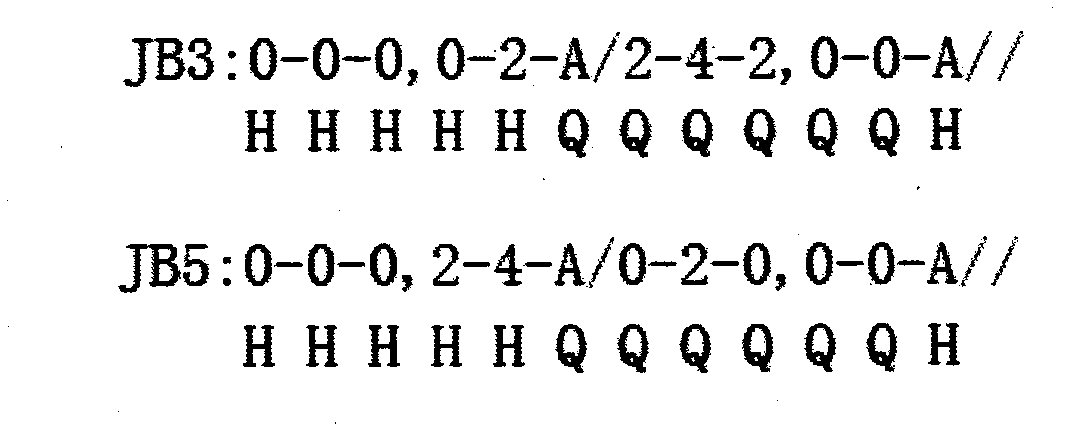

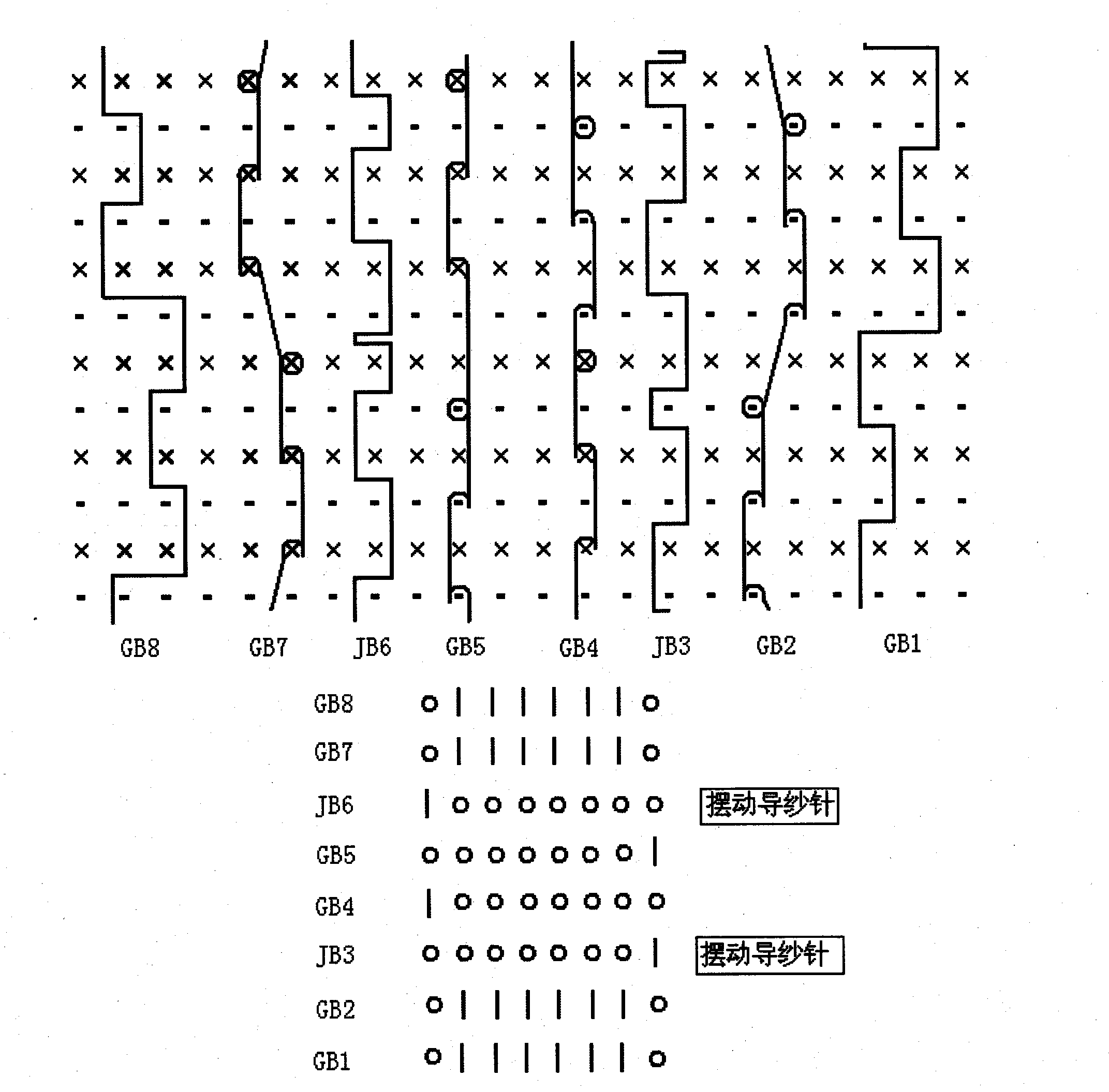

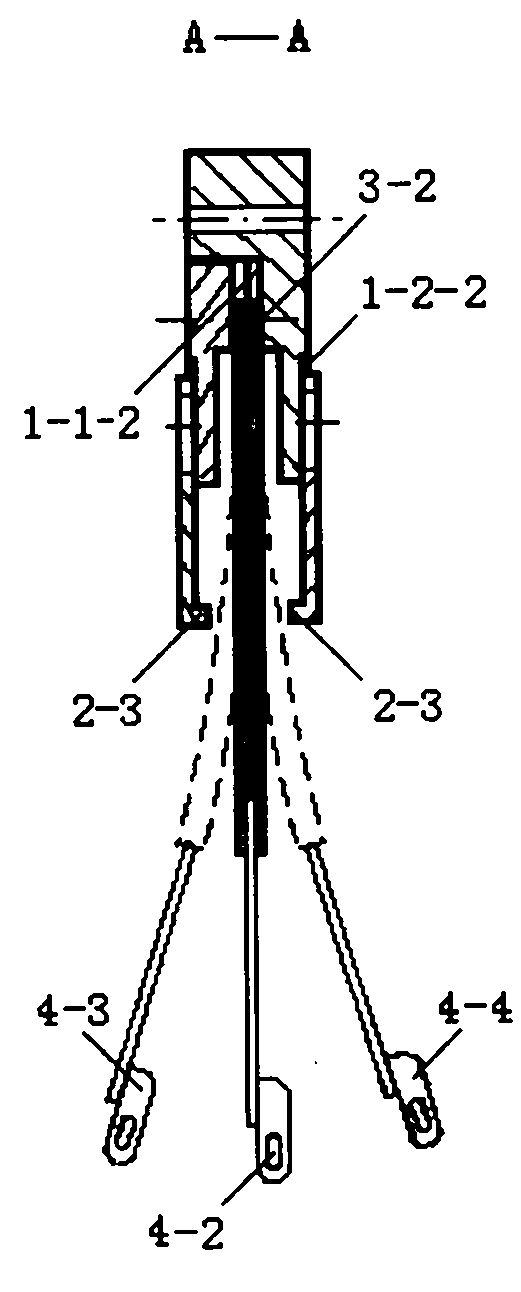

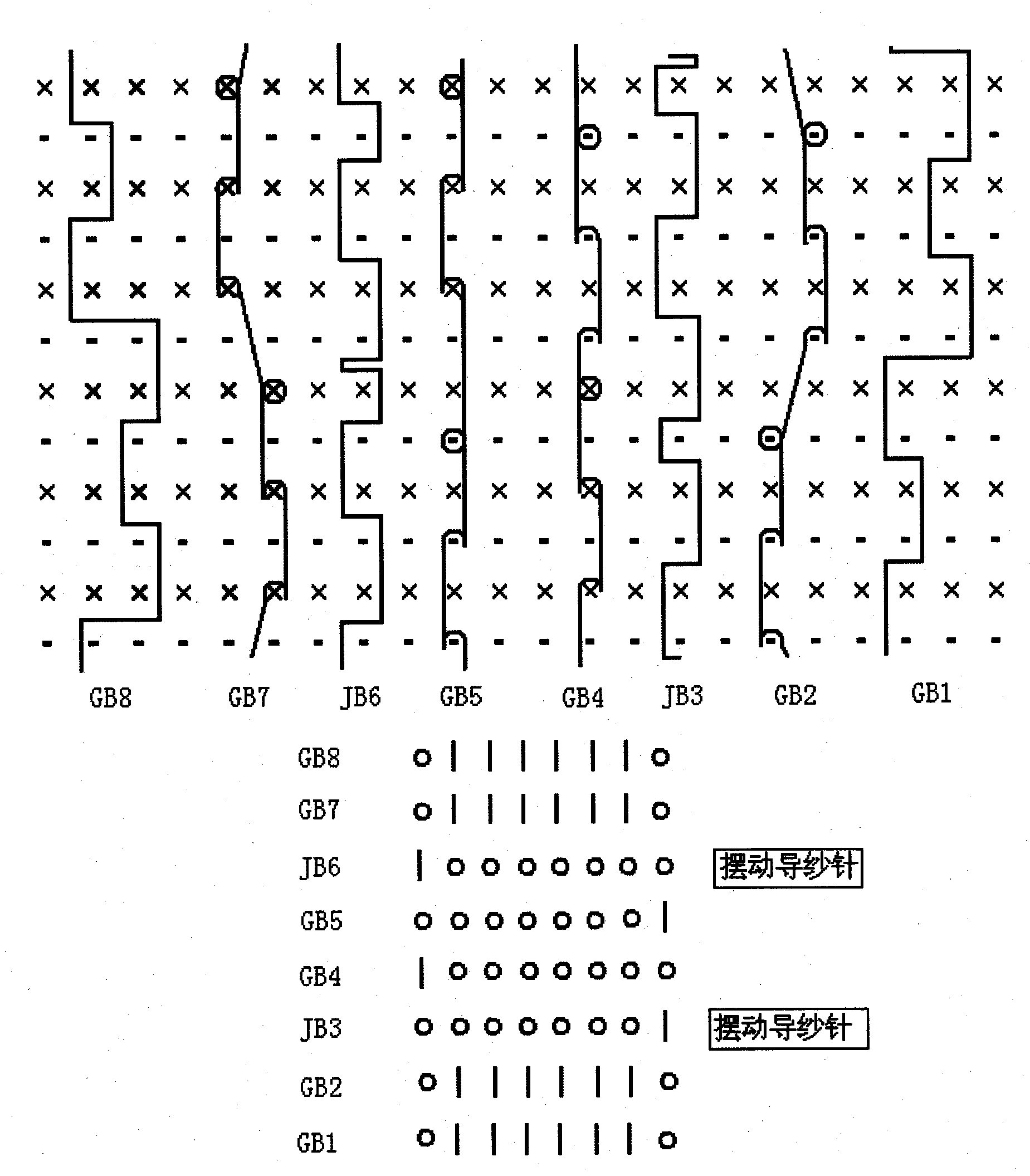

Traceless joint fabric knitting method of double-needle-bed warp knitting machine

InactiveCN102587023AEasy to prepareSuitable for industrial productionWarp knittingEngineeringTextile composite

The invention provides a traceless joint fabric knitting method of a double-needle-bed warp knitting machine, which is characterized by including the following steps of selecting warps materials, setting yarn laying motions of guide bars and utilizing yarn threading and aligning process; beaming warps; mounting the guide bars with swing yarn guide needles in a needle bed working area, performance traceless jointing at the edges of fabrics of a front needle bed and a rear needle bed; making up information of the yarn guide needles; performing machine-boarding processing adjustment and knitting; and arranging the fabrics. By the traceless joint fabric knitting method of the double-needle-bed warp knitting machine, the technical problem of cylindrical knitting by twice or more guiding on the double-needle-bed warp knitting machine can be solved, joint wrinkles of preformed parts of various cylindrical warp knitting composite materials are eliminated, mechanic performance of the spinning composite materials are improved, ultra-wide products can be provided for cloth used in shed cover industry. In addition, perfect traceless jointing can be provided for warp-knitted fully-formed clothes and appearance and comfortableness of the clothes can be improved.

Owner:DONGHUA UNIV

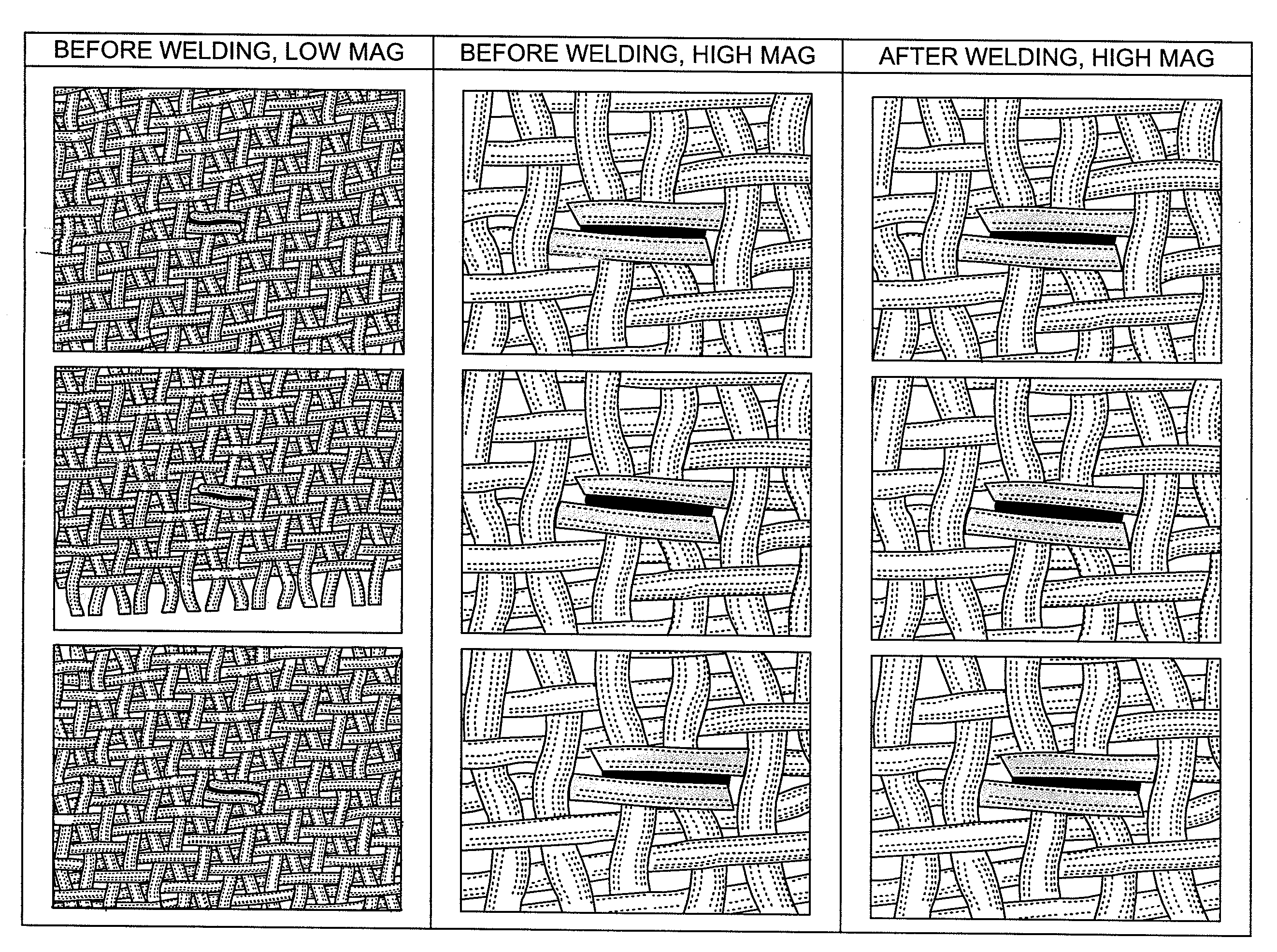

Process for producing papermaker's and industrial fabric seam and seam produced by that method

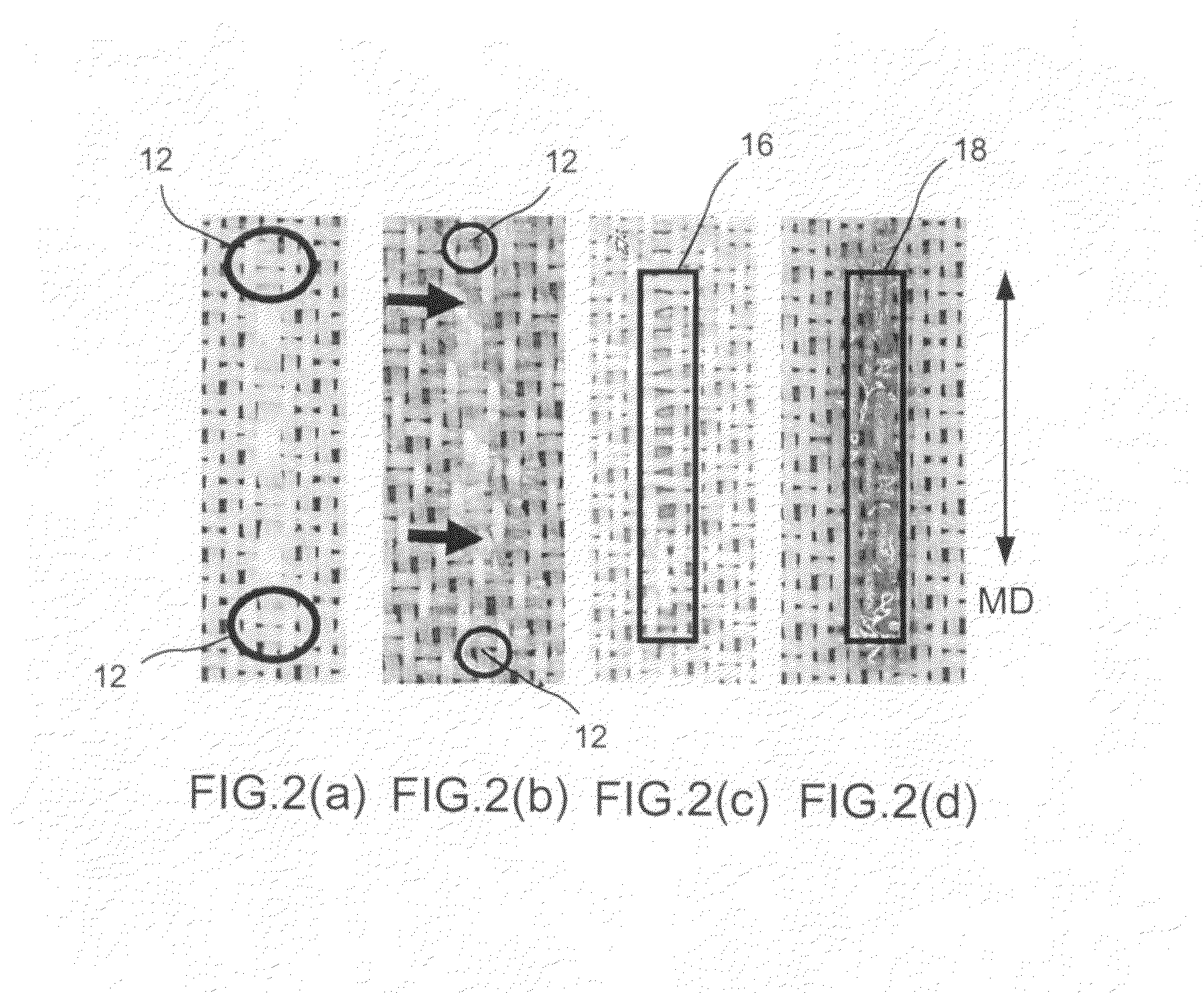

ActiveUS8062480B2Good seamsImprove fusion/bondingLamination ancillary operationsLaminationFiberEngineering

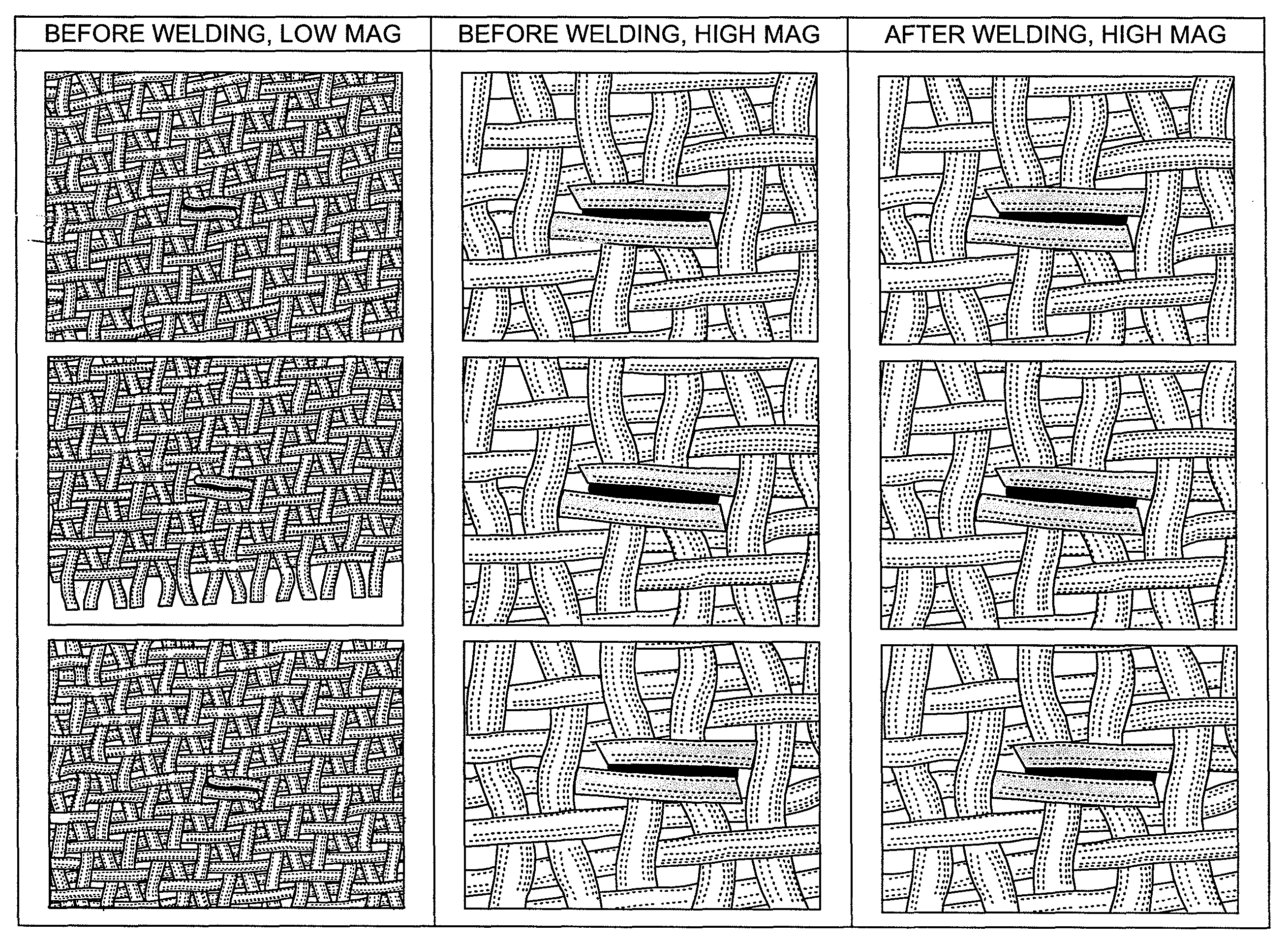

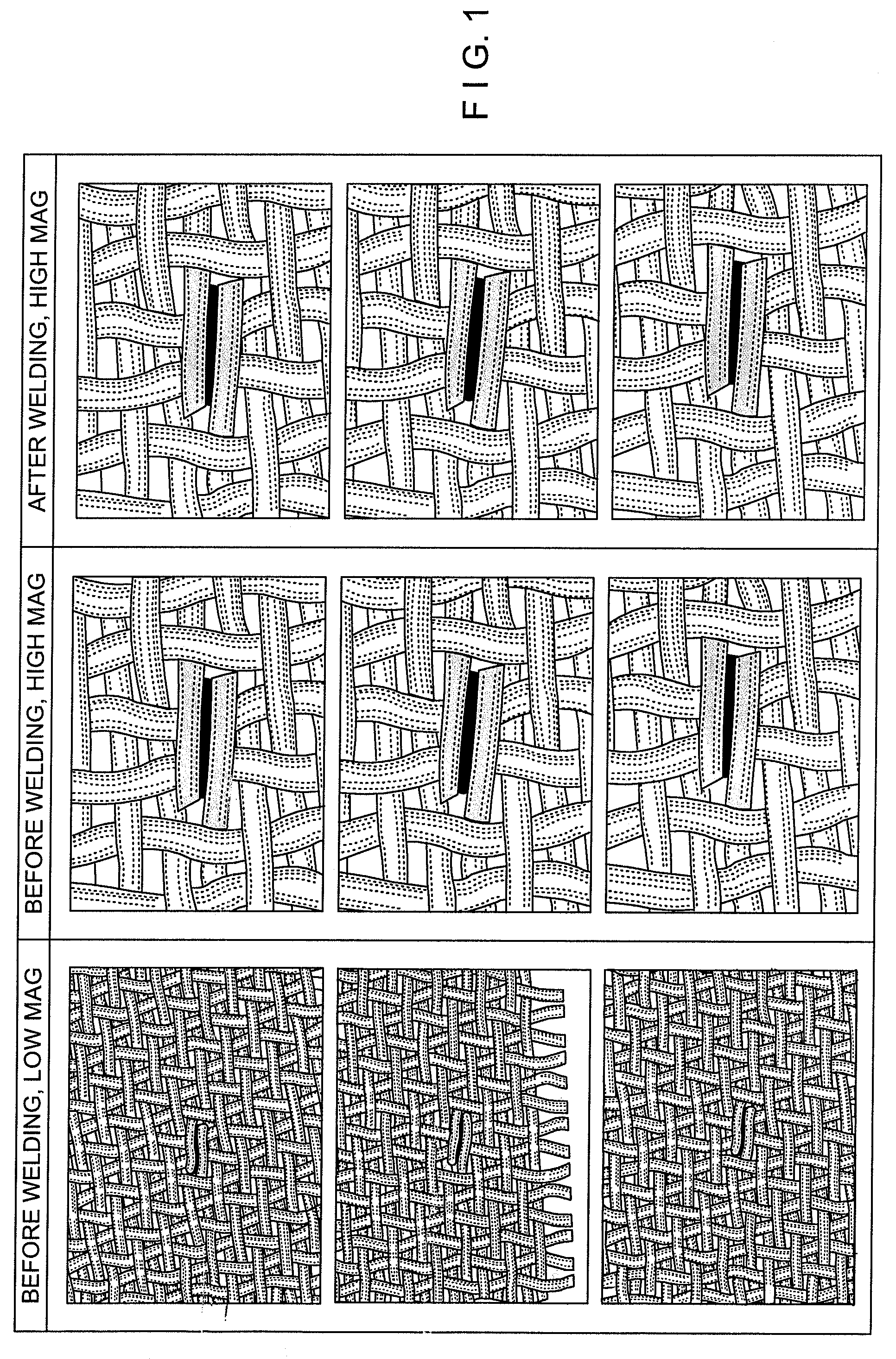

The invention disclosed herein relates to the use of laser energy to weld or melt selected locations in papermachine clothing (“PMC”) and other industrial and engineered fabrics. The invention also relates to an improved seam for a papermaker or other industrial fabric that has properties such as strength, durability, openness, adequate number of support points, and fiber support index (FSI) essentially the same as the fabric body. The invention also relates to a fabric having a durable seam, wherein the seam width as measured in the MD is a fraction of the width of a normal seam or a seam that is formed using a conventional technique of equal strength.

Owner:ALBANY INT CORP

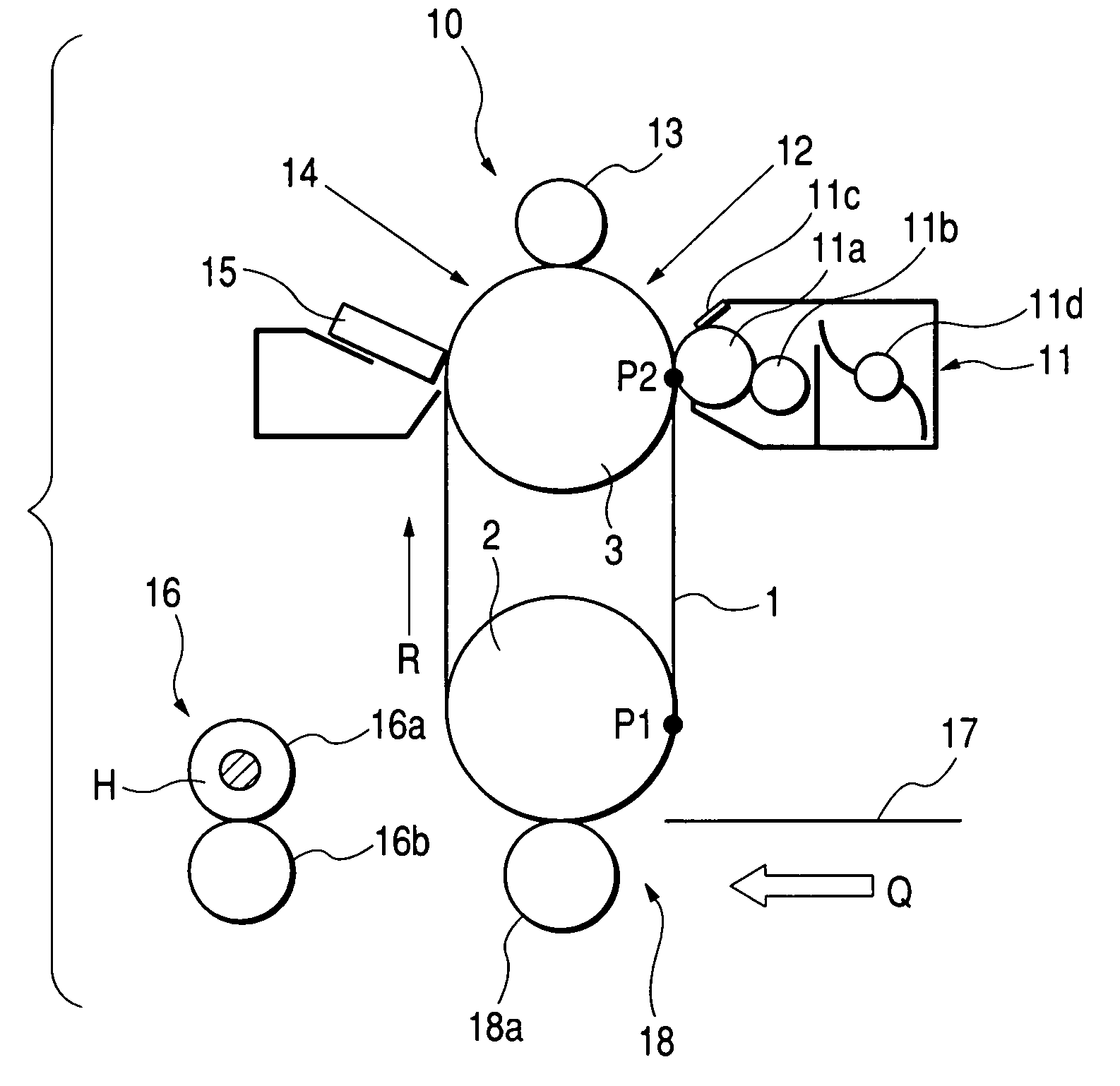

Belt member incorporated in image forming apparatus

InactiveUS6993270B2Avoid damageImproved seam strengthV-belt fasteningsLayered productsImage formationEngineering

Owner:SEIKO EPSON CORP

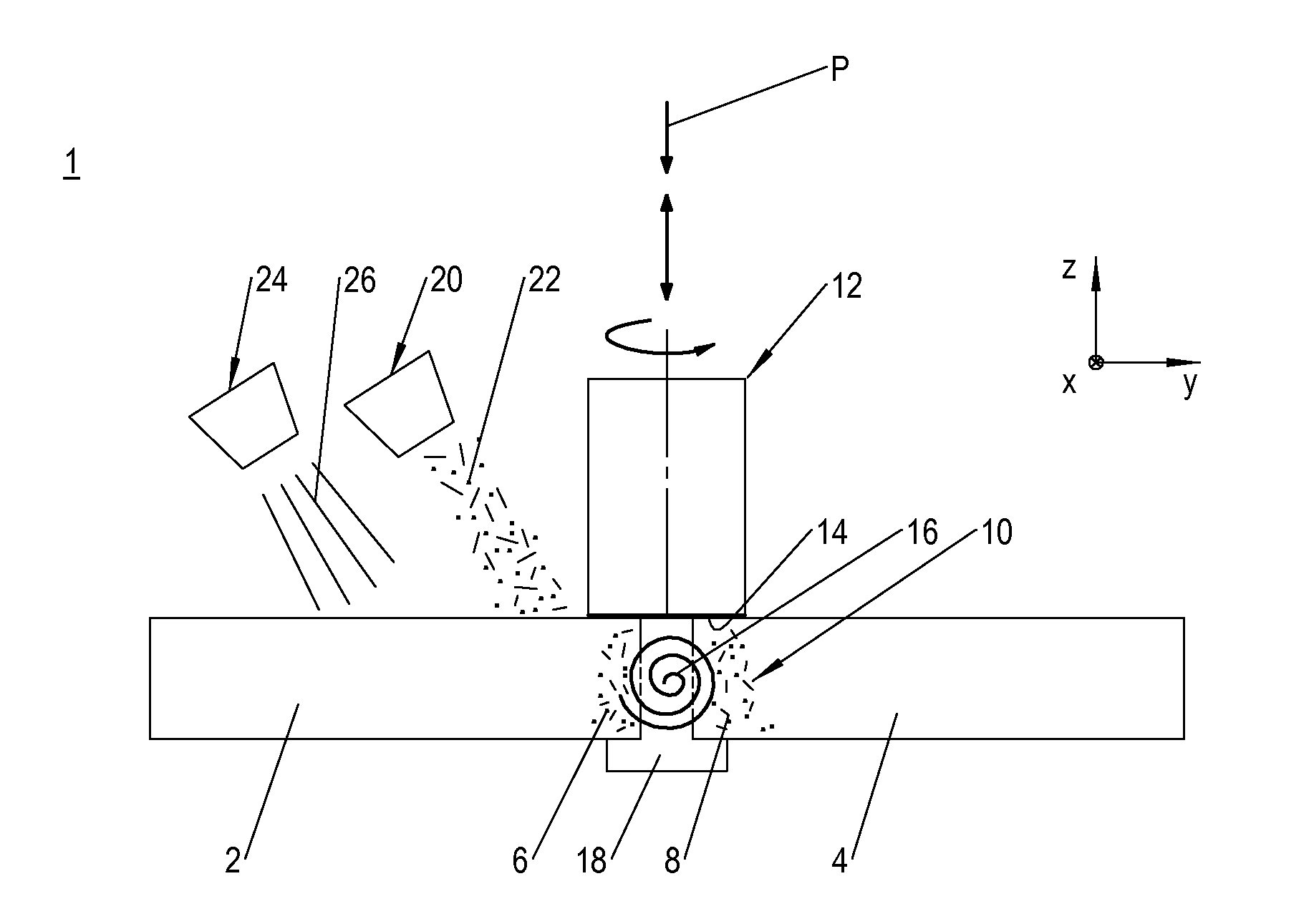

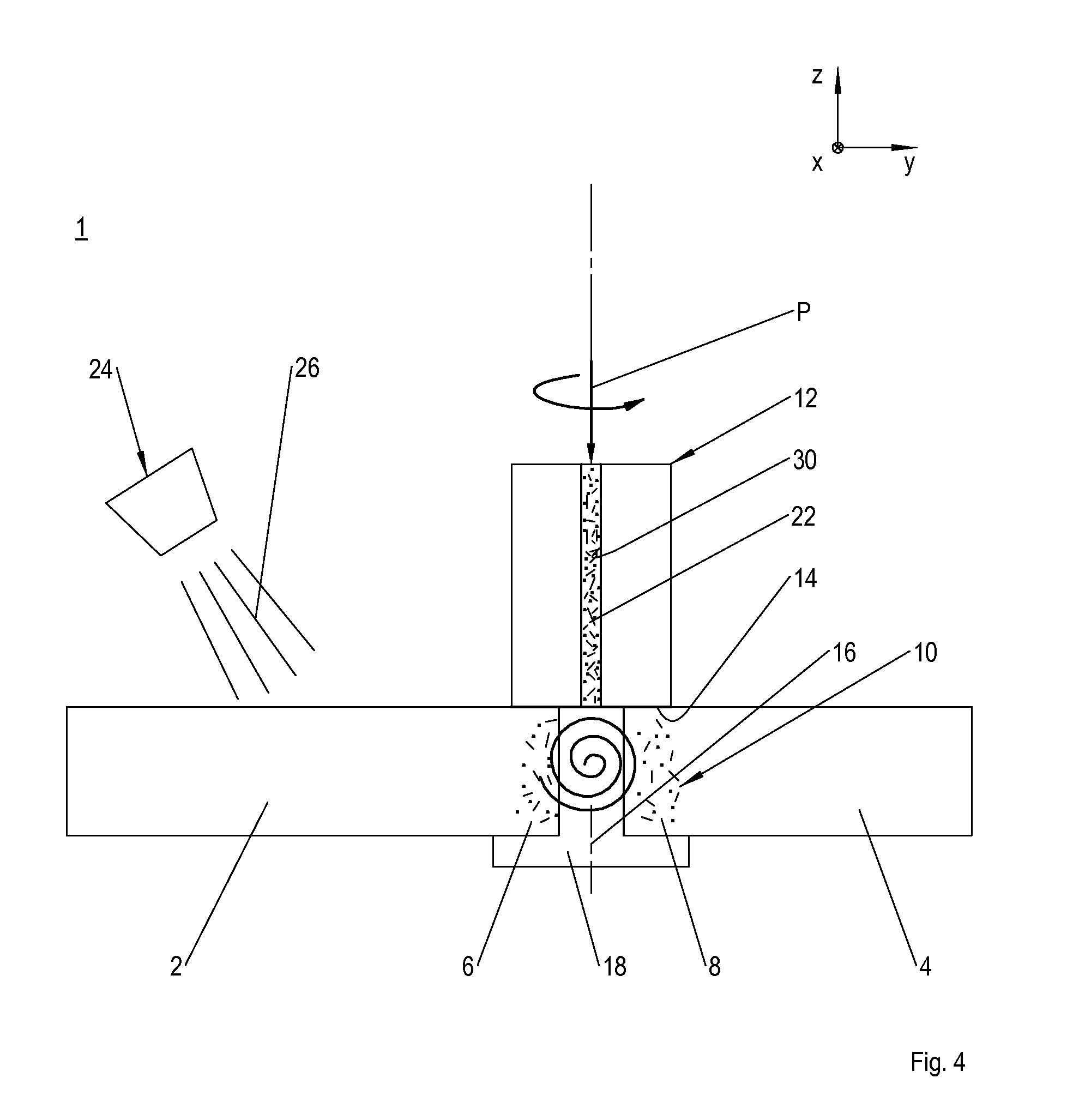

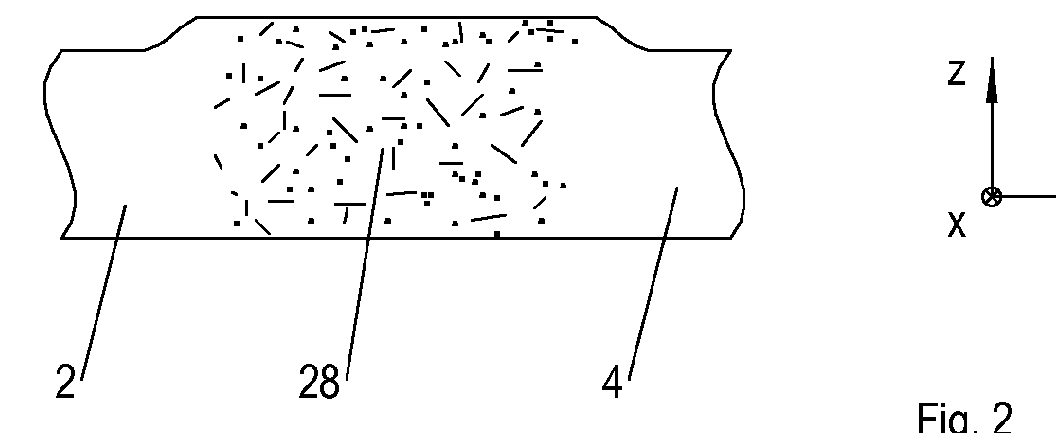

Method and device for bonding parts to be joined, as well as component

ActiveUS20120328837A1Short cycleWeight optimizationLayered productsDomestic articlesButt jointEngineering

A method is provided for producing a bonded joint between fiber-reinforced thermoplastic parts to be joined, in which fiber-containing plastic material is mixed into the joining zone while friction stir welding the parts to be joined in the form of a butt joint. A device for carrying out such a method for a joined component is also provided.

Owner:AIRBUS OPERATIONS GMBH

Papermaking machine wire, the running side of which has cross threads with different lengths

Owner:ANDRITZ KUFFERATH

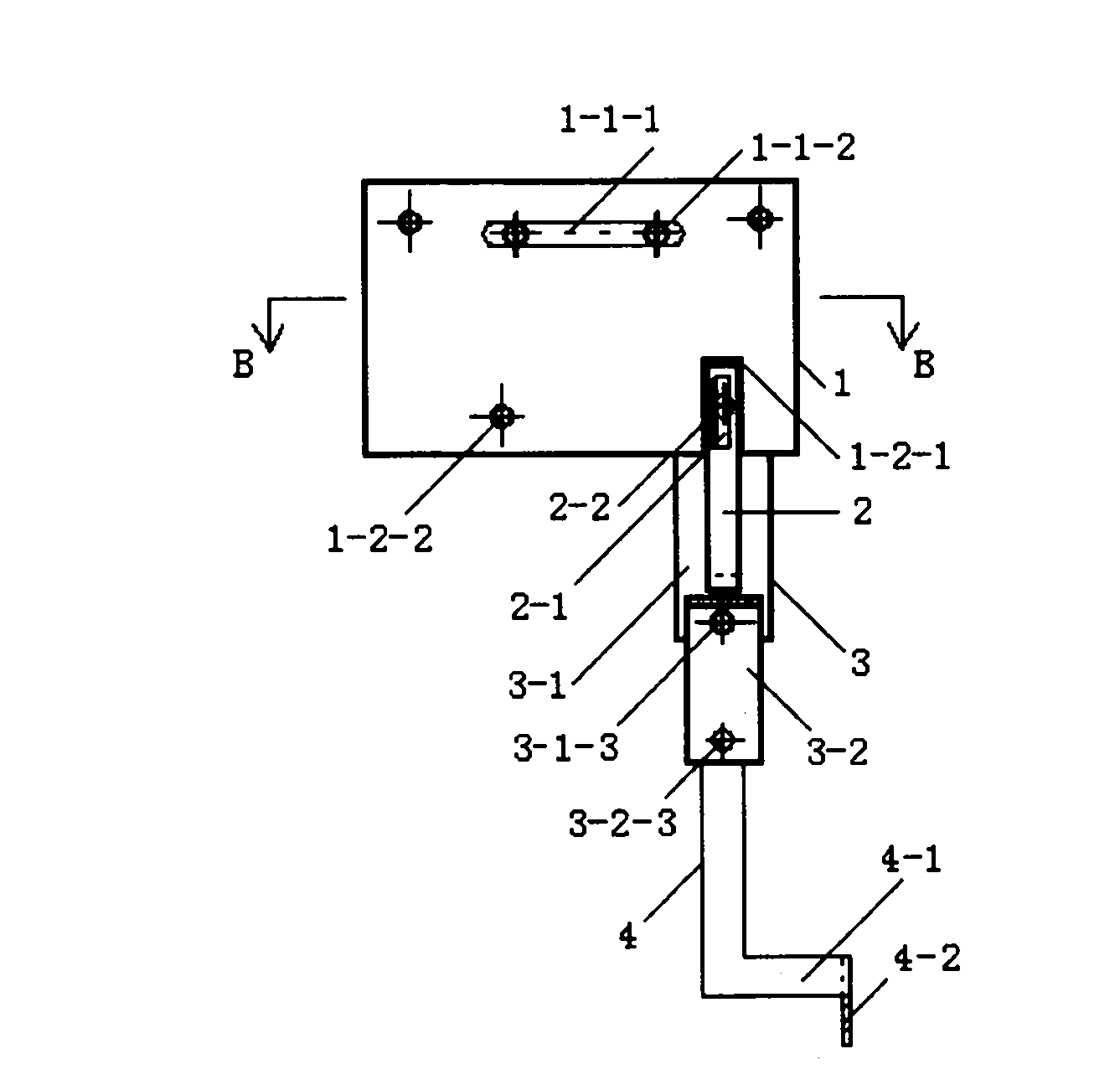

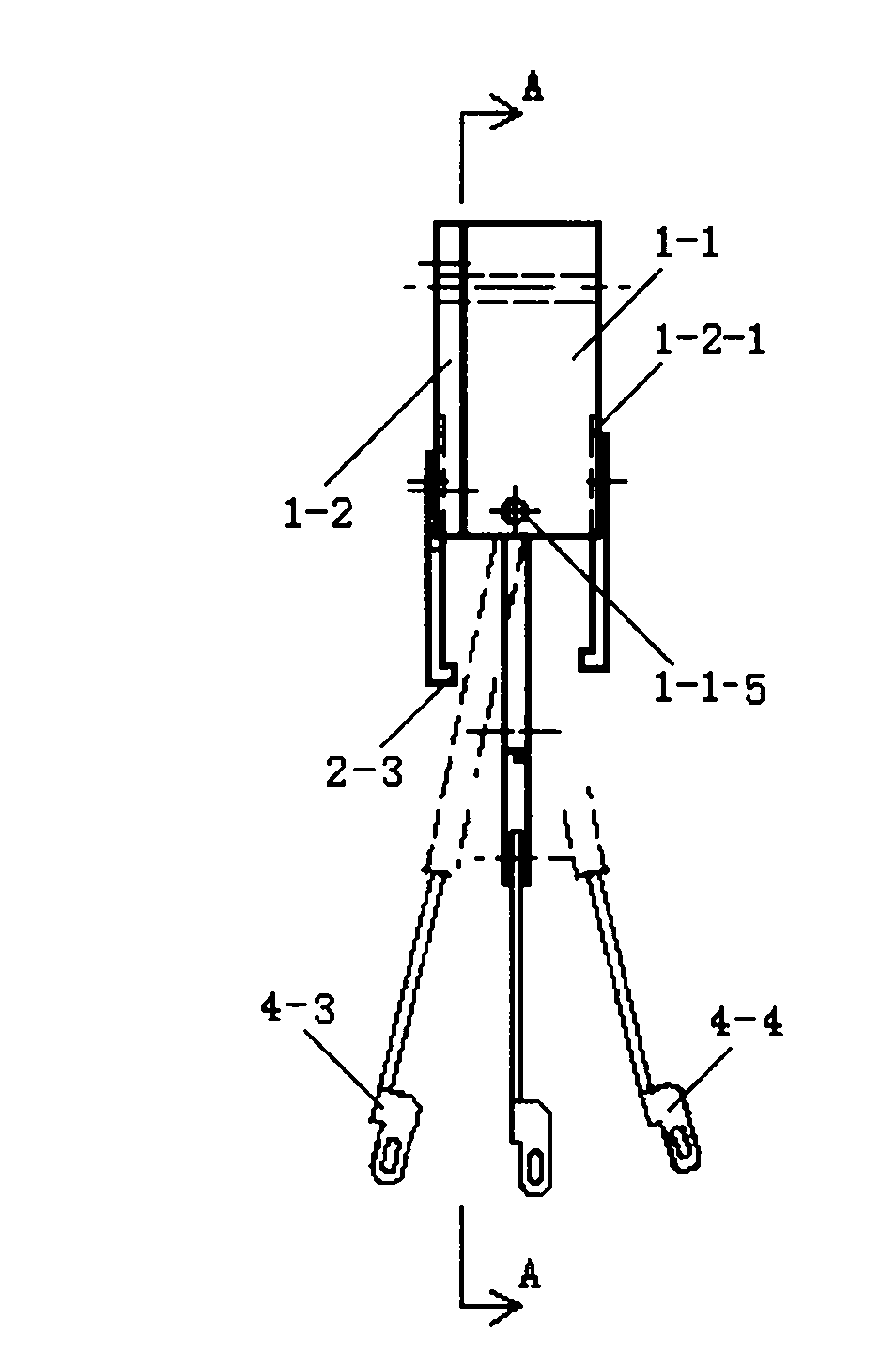

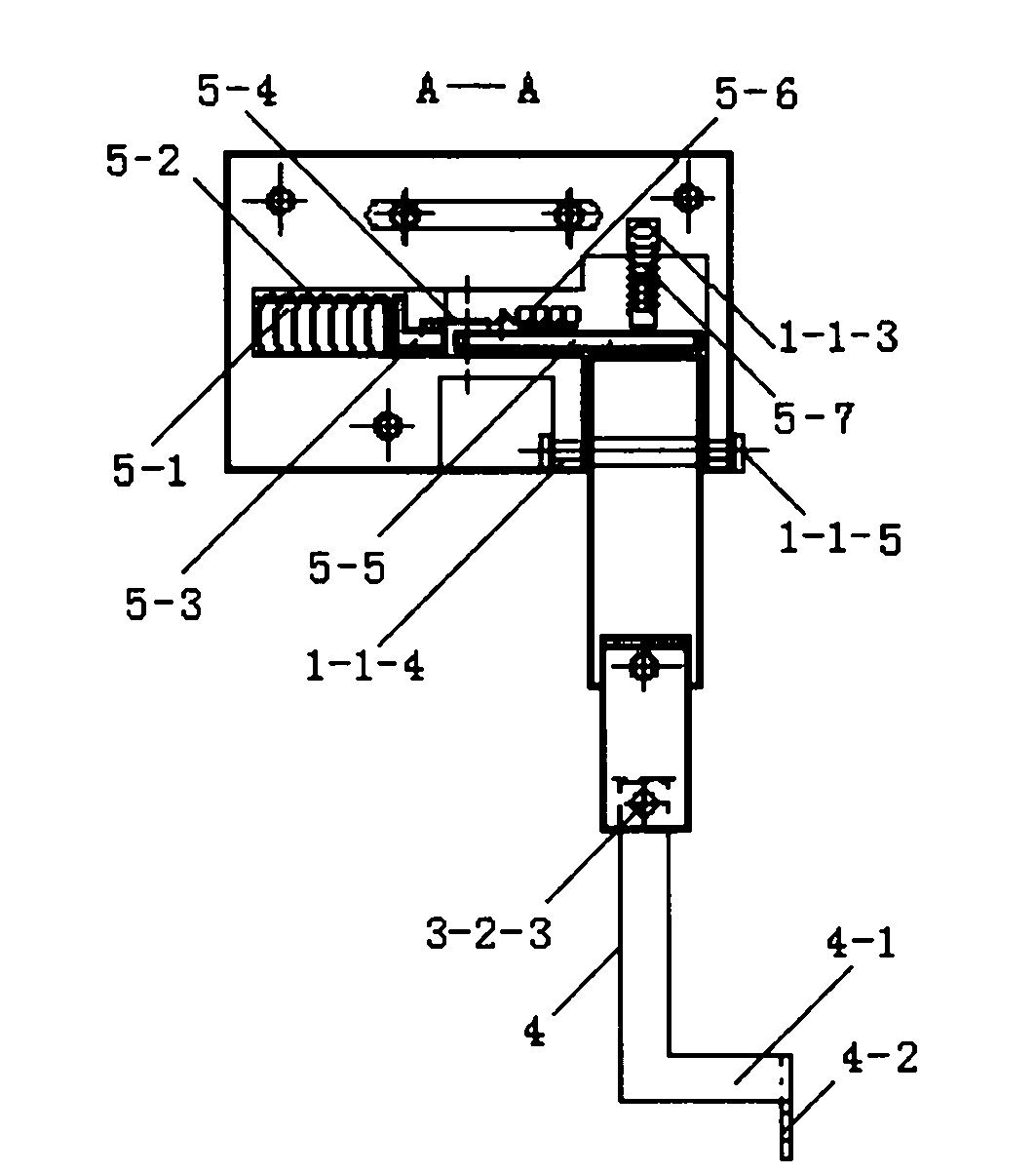

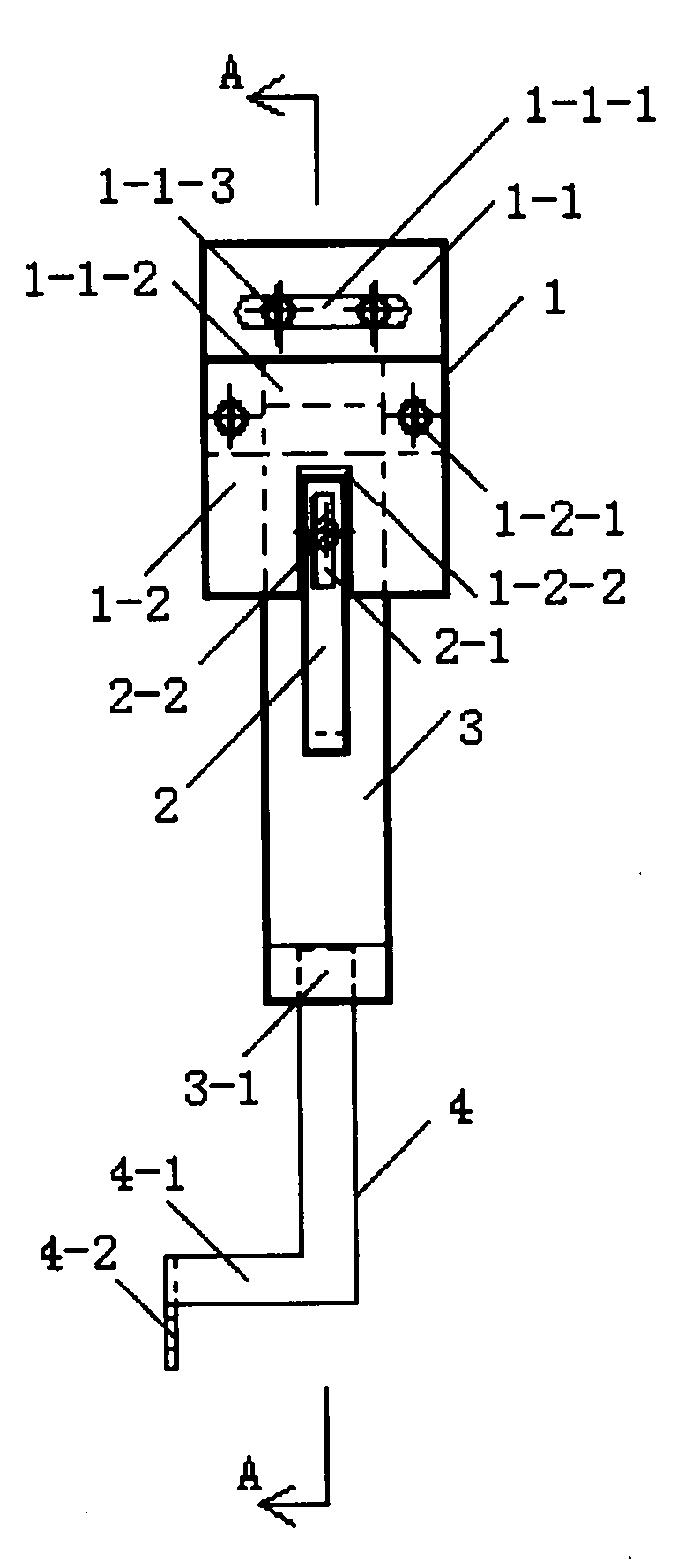

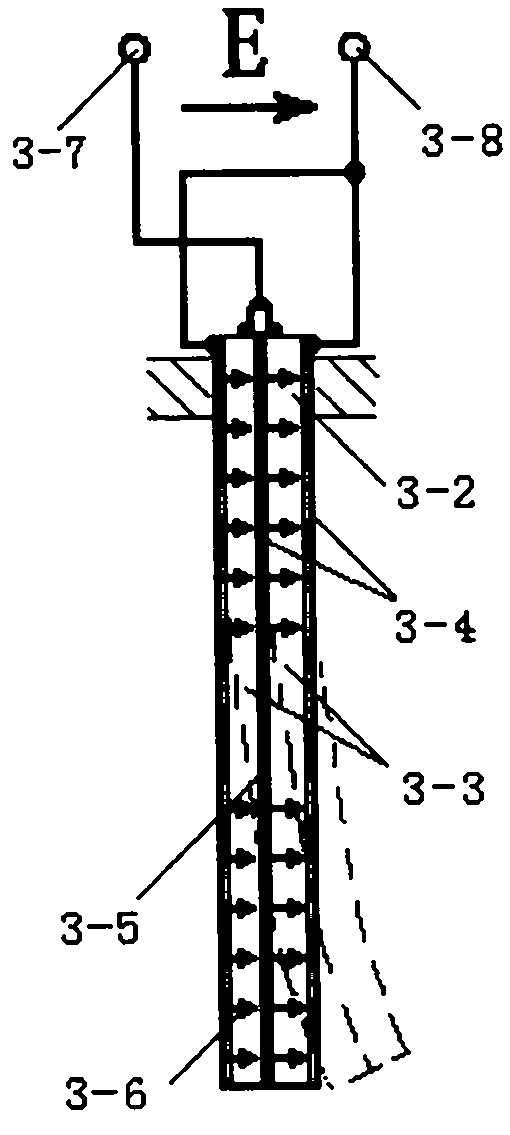

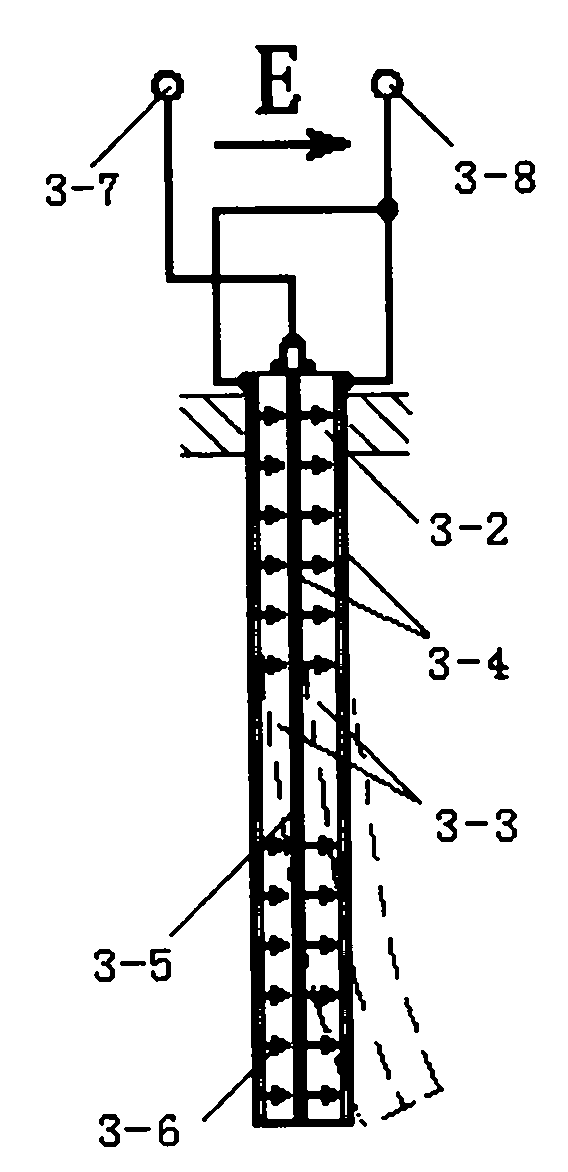

Electromagnetic swing yarn guide needle device used for double-needle-bed warp knitting machine

InactiveCN102587026AOvercome the technical bottleneck of warp knittingSolve technical bottlenecksWarp knittingFull widthBraid

The invention provides an electromagnetic swing yarn guide needle device used for a double-needle-bed warp knitting machine, which is characterized by comprising a bearing seat, a swing piece, an L-shaped yarn guide needle and an electromagnetic control part. The bearing seat is fixed on a guide bar plate of the double-needle-bed warp knitting machine, the electromagnetic control part is arranged in a cavity of the bearing seat, the top end of the swing piece is connected with the electromagnetic control part, the upper portion of the swing piece is rotationally connected with the bearing seat, and the bottom end of the swing piece is connected with the L-shaped yarn guide needle. Connecting yarns can be inlaid on edge knitting needles in a front needle bed working area and a rear needle bed working area alternatively by the electromagnetic swing yarn guide needle device according to knitting process, so that seamless cylindrical warp-knitted fabrics or seamless ultra-wide full-width fabrics are formed after fabrics are taken off the machine. Connecting seams of a front fabric and a rear fabric are in weaving structures identical with twice or more guiding fabrics, and the bottleneck problem of existing double-needle-bed warp knitting process is solved.

Owner:DONGHUA UNIV

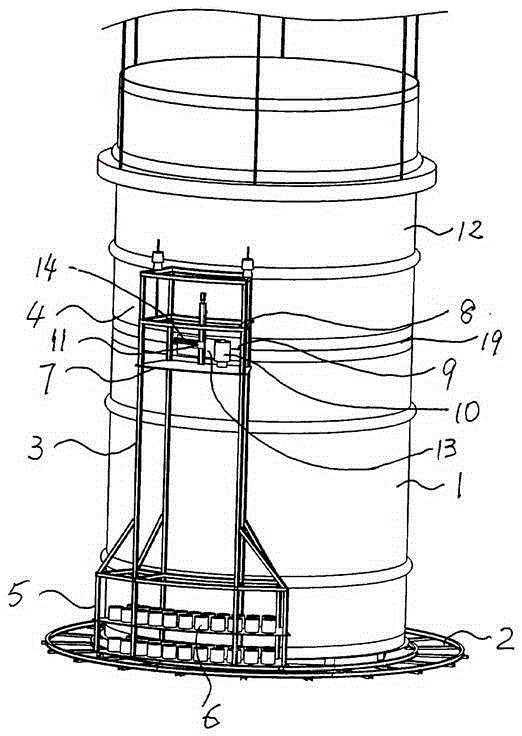

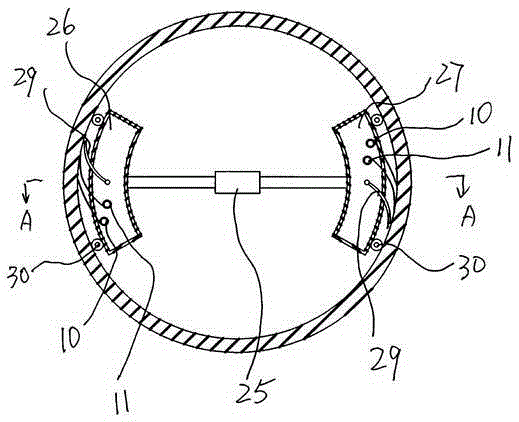

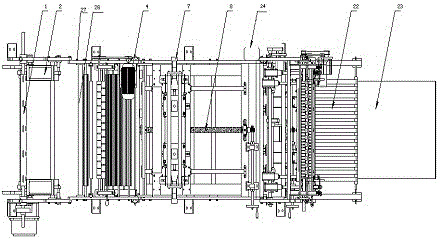

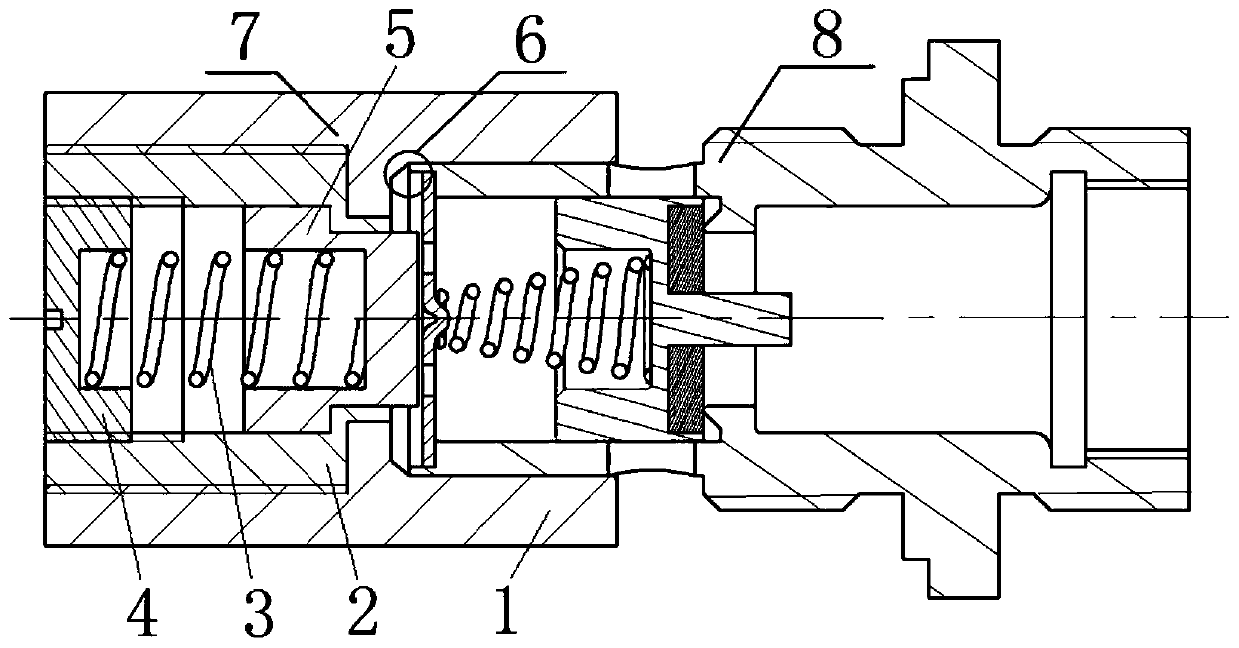

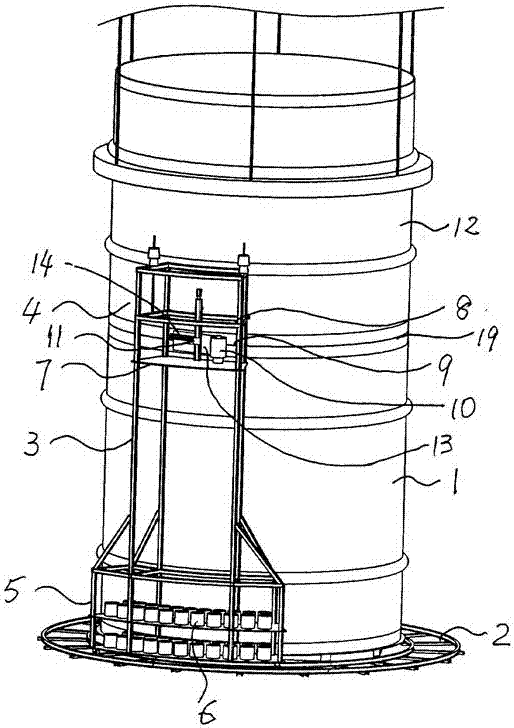

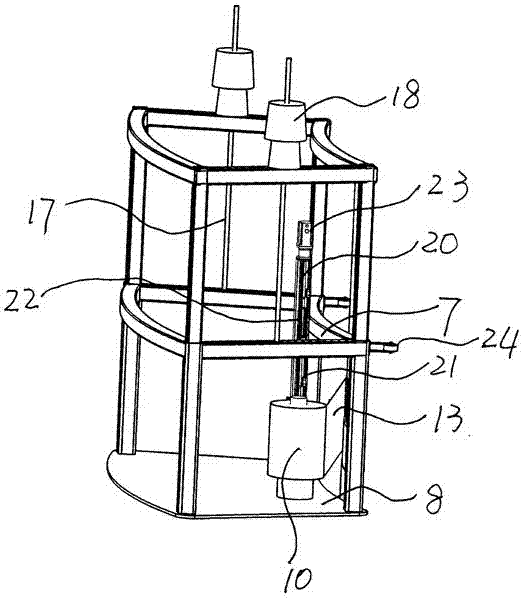

Glass fiber reinforced plastic chimney butt seam assembling and winding apparatus

ActiveCN105401735AIncrease productivityImproved seam strengthTowersBuilding material handlingFiberGlass fiber

The invention belongs to the technical field of glass fiber reinforced plastic pipe cylinders and concretely discloses. The technical scheme of the apparatus is that the apparatus comprises a surrounding track arranged on the external side of a lower-segment glass fiber reinforced plastic cylinder body and a walking trolley arranged on the track and formed by an upper rack body and a lower rack body connected via connection rods, wherein a resin fiber yarn mechanism is arranged on the walking trolley; the upper rack body is formed by a sector-shaped framework in an arc-shaped correspondence to the external side surface of the glass fiber reinforced plastic cylinder body; a unidirection cloth winding mechanism and a resin fiber yarn winding mechanism are mounted in the sector-shaped framework. And / or the apparatus comprises a left and right walking trolleys connected via a telescopic mechanism; each walking trolley is formed by an upper rack body and a lower rack body connected via connection rods; a resin fiber yarn mechanism is arranged on the left or / and right walking trolley; the upper and lower rack bodies on the left and right sides are respectively formed a sector-shaped framework in an arc-shaped correspondence to the inner side surface of the glass fiber reinforced plastic cylinder body; and a unidirection cloth winding mechanism and a resin fiber yarn winding mechanism are mounted in the sector-shaped framework. By the use of the apparatus, the inner and outer side walls of upper and lower glass fiber reinforced plastic cylinder bodies can be assembled, abutted and winded.

Owner:JIZHOU ZHONGYI FRP

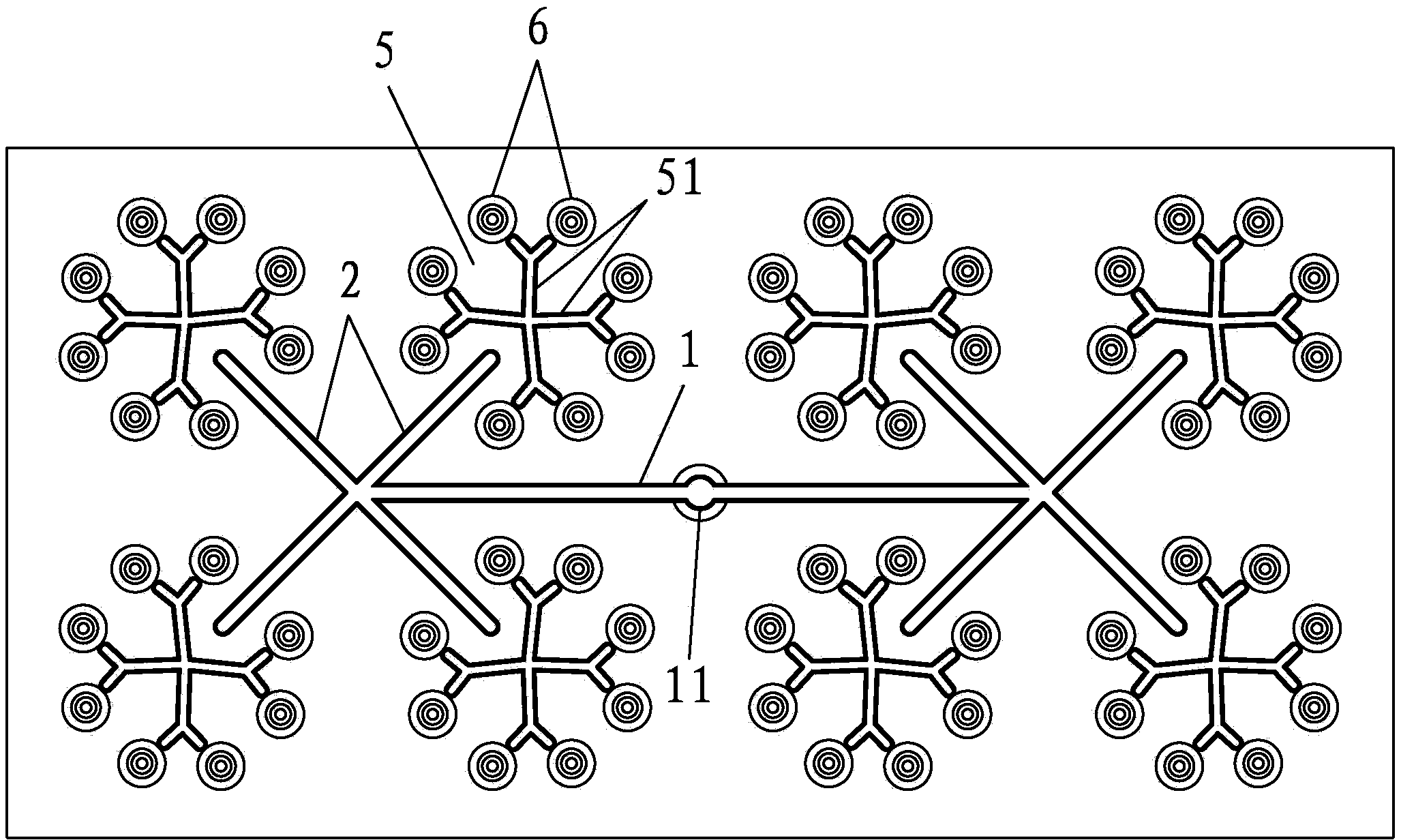

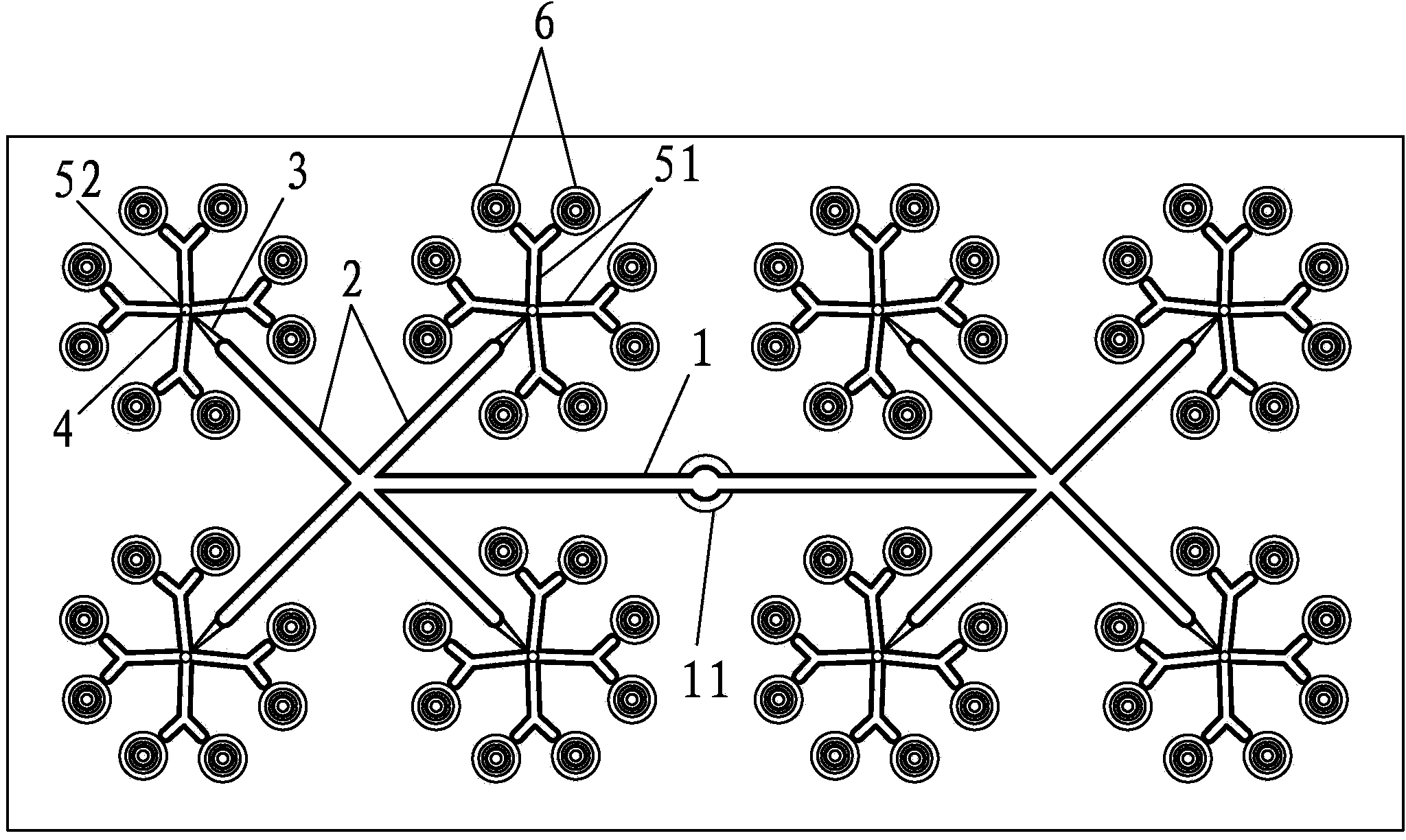

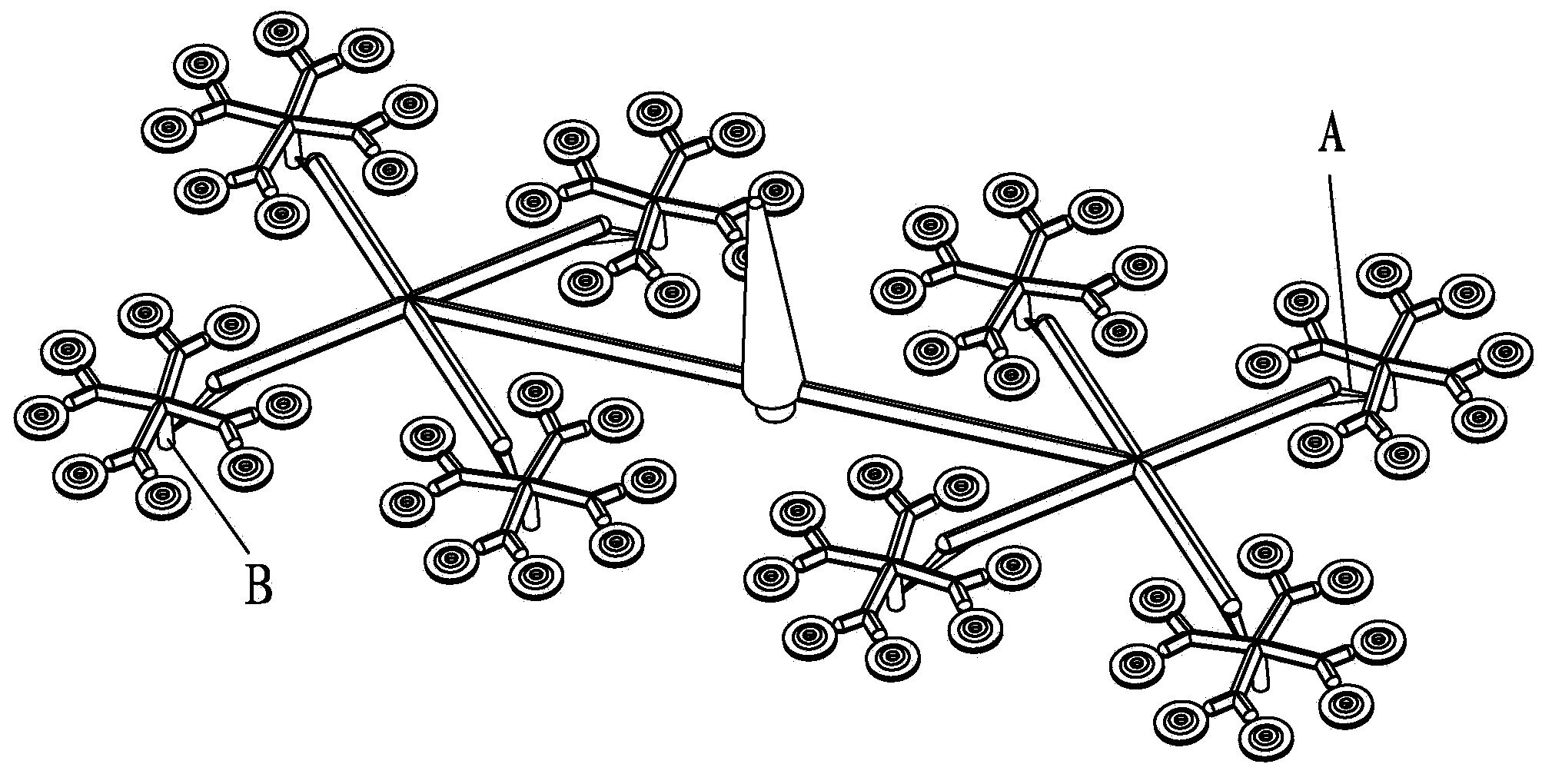

Injection moulding process and mould for precision and minitype plastic piece

The invention discloses an injection moulding process and mould for a precision and minitype plastic piece. The technological process adopting the mould comprises the following steps: firstly, a material flow flows into a main channel from a main pouring gate, then flows into sub channels, flows from the end part of each sub channel through a secondary pouring gate in a perpendicular manner to a center confluence opening corresponding to sub channel group, and then flows into a cavity of each plastic piece. During injecting moulding, the material flow flows through the sub channel, particularly passes through the secondary pouring gates and flows into the center confluence opening of the sub channel group in a perpendicular manner, so that the material flow which flows into the center confluence opening can spread out uniformly and flows into the sub channel groups uniformly; the material flows can finally reach and fill every cavity of the plastic pieces uniformly and simultaneously, so that the cavity of each plastic piece has excellent welding trace jointing strength, the impact resistance of the plastic piece is improved, the uniformity of the product size is improved, the product yield is high, and the product performance is better.

Owner:HUA LIAN GARMENT COMPONENT ENTERPRISE

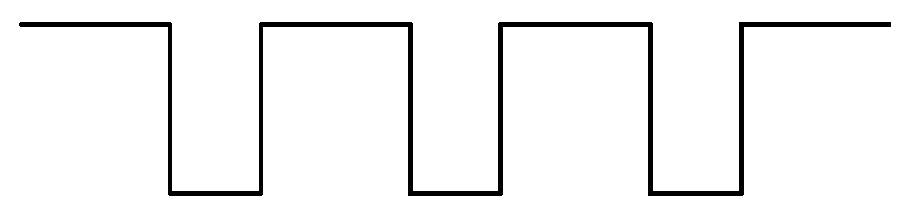

Papermaking fabric with double loop seam

ActiveUS20160145799A1Improved seam strengthIncrease the number ofMachine wet endPress sectionWoven fabricYarn

A seam for joining together the ends of woven fabric to form an endless belt is particularly suitable for joining the ends of woven synthetic dryer fabrics as used in the dryer section of paper making machines and is particularly applicable to joining the ends of those dryer fabrics in at least the machine direction of the fabric. A papermaking fabric comprising a woven fabric body having opposing ends, said fabric body having a system of MD-yarns interwoven with a system of CD yarns. The MD-yarns include first pairs of MD-yarns, second pairs of MD-yarns and third pairs of MD-yarns and the first and the second pairs of MD-yarns form two seam loops, while the third MD-yarns forms the binder. The loops are at identical length to each other over the whole fabric width. Such seam construction reduces marking and increases the seam strength and seam abrasion resistance.

Owner:VOITH PATENT GMBH

Low-noise dry-type iron core reactor assembling process

ActiveCN103594240AOvercome Adhesion DeficienciesAchieve vacuum pouringInductances/transformers/magnets manufactureInductance with magnetic coreLow noiseEngineering

Discloses is a low-noise dry-type iron core reactor assembling process. The assembling process includes the steps: S5-1, taking a flexible pouring guide pipe, blocking one end of the flexible pouring guide pipe, and uniformly drilling small holes in a section equal to the perimeter of an iron core column along a same side of the pouring guide pipe; S5-2, moving the iron core column down to enable a seam on the upper portion to be exposed; S5-3, enabling the pouring guide pipe to surround the seam by one circle, keeping the small holes to face the seam, and using a rubber belt to tension, wind and fix the pouring guide pipe; S5-4, hanging a coil up to enable a seam on the lower portion to be exposed; S5-5, burying the pouring guide pipe at the seam on the lower portion by referring to S5-3, and resetting an upper cushion block and a lower cushion block; S6, transferring a reactor into vacuum pouring equipment, and connecting the guide pipe; S7, vacuumizing to complete vacuum pouring of a seam of the iron core column and an iron yoke; S8, releasing vacuum, and transferring a reactor product into a curing furnace to complete resin curing of the seam. By the low-noise dry-type iron core reactor assembling process, vacuum pouring of the seam of the iron core column and the iron yoke of a dry-type iron core reactor can be realized, firmness in bonding and less proneness to loosening are realized, and seam noise is effectively inhibited.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Method and device for bonding parts to be joined, as well as component

A method is provided for producing a bonded joint between fiber-reinforced thermoplastic parts to be joined, in which fiber-containing plastic material is mixed into the joining zone while friction stir welding the parts to be joined in the form of a butt joint. A device for carrying out such a method for a joined component is also provided.

Owner:AIRBUS OPERATIONS GMBH

Piezoelectric swing yarn guide needle device for double-needle-bed tricot machine

InactiveCN102587025AOvercome the technical bottleneck of warp knittingSolve technical bottlenecksWarp knittingEngineeringMechanical engineering

The invention provides a piezoelectric swing yarn guide needle device for a double-needle-bed tricot machine. The piezoelectric swing yarn guide needle device comprises a support seat, a swing plate and an L-shaped yarn guide needle, wherein the support seat is fixedly connected with a combing plate of the double-needle-bed tricot machine, the upper end of the swing plate is fixed in the support seat, and the lower end of the swing plate is connected with the L-shaped yarn guide needle. With the piezoelectric swing yarn guide needle device, connecting yarns can be padded on edge knitting needles alternatively in front and rear needle bed working areas according to the needs of the knitting technology, so that a seamless cylindrical warp knitting fabric or a seamless superwide flat fabric is formed after the fabric is off the machine. The connection seams of the front and rear fabrics has a textile structure completely consistent with fabrics with two combs or more than two combs, and the bottleneck problem of the existing double-needle-bed warp knitting process is overcome. Warp knitting fabric knitted by adopting the piezoelectric swing yarn guide needle device disclosed by the invention can be used as tubular warp knitting composite materials for decoration, garment and various industries.

Owner:DONGHUA UNIV

Papermaking fabric with double loop seam

ActiveUS9976254B2Reduce marksImproved seam strengthMachine wet endWoven fabricsPulp and paper industry

A seam for joining together the ends of woven fabric to form an endless belt is particularly suitable for joining the ends of woven synthetic dryer fabrics as used in the dryer section of paper making machines and is particularly applicable to joining the ends of those dryer fabrics in at least the machine direction of the fabric. A papermaking fabric comprising a woven fabric body having opposing ends, said fabric body having a system of MD-yarns interwoven with a system of CD yarns. The MD-yarns include first pairs of MD-yarns, second pairs of MD-yarns and third pairs of MD-yarns and the first and the second pairs of MD-yarns form two seam loops, while the third MD-yarns forms the binder. The loops are at identical length to each other over the whole fabric width. Such seam construction reduces marking and increases the seam strength and seam abrasion resistance.

Owner:VOITH PATENT GMBH

Process for producing papermaker's and industrial fabrics

ActiveUS7897018B2Easy to useImproved seam strengthLamination ancillary operationsLaminationFiberYarn

Owner:ALBANY INT CORP

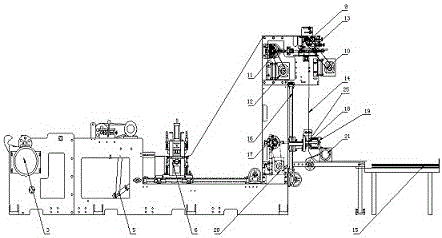

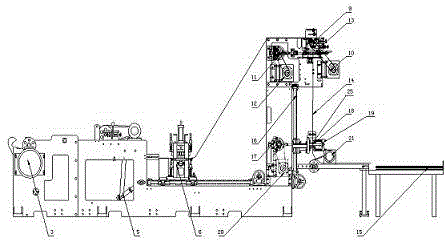

A high-speed thick packaging film bag making machine

ActiveCN104416952BIncrease productivityImproved seam strengthBox making operationsPaper-makingMotor driveProgrammable logic controller

The invention discloses a high-speed thick package film bag making machine, which comprises an air expansion shaft, a clamping motor, an ironing corner mechanism, a cooling air mechanism, an ironing cutter mechanism, a cutter mechanism, a water circulating cooling mechanism, a conveying motor, a conveying mechanism and a programmable logic control mechanism, wherein the ironing corner mechanism, the cooling air mechanism, the ironing cutter mechanism, the cutter mechanism and the water circulating cooling mechanism are sequentially connected with the working surface of the bag making machine. The high-speed thick package film bag making machine is characterized in that the working surface of the ironing cutter machine is higher than the working surface of the ironing corner mechanism, a rubber roll servo motor is arranged at the right side of the working surface of the ironing cutter mechanism, and is used for driving a pressing rubber roll to convey a to-be-processed film bag to the fixing position of the ironing cutter mechanism for seam ironing, the film bag after the seam ironing by an ironing cutter vertically falls onto the water circulating cooling mechanism and the working surface of the cutter mechanism along the tail end of the right side of the ironing cutter mechanism under the action of gravity, and the conveying motor drives the conveying mechanism to continuously work when the package film bag making machine starts to work. The package film bag making machine has the advantages that the production efficiency is improved by two times, and the seam ironing strength of the film bag is improved by five times.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

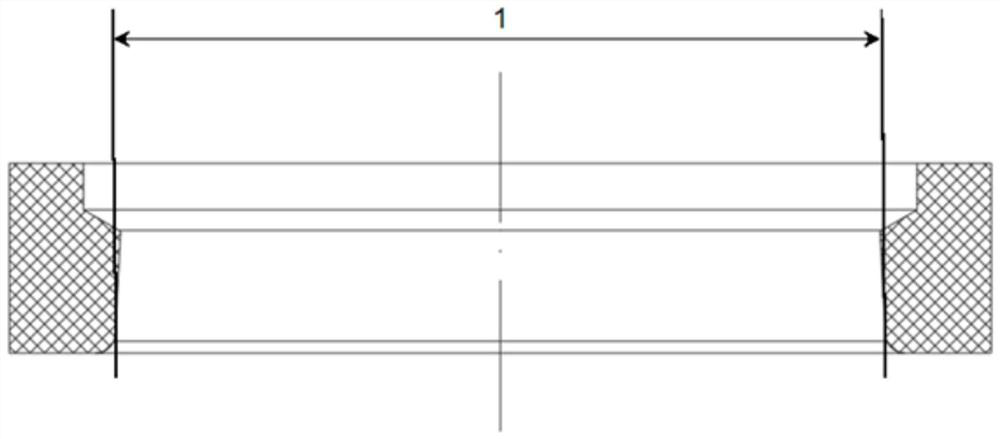

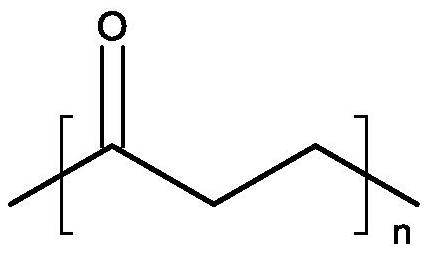

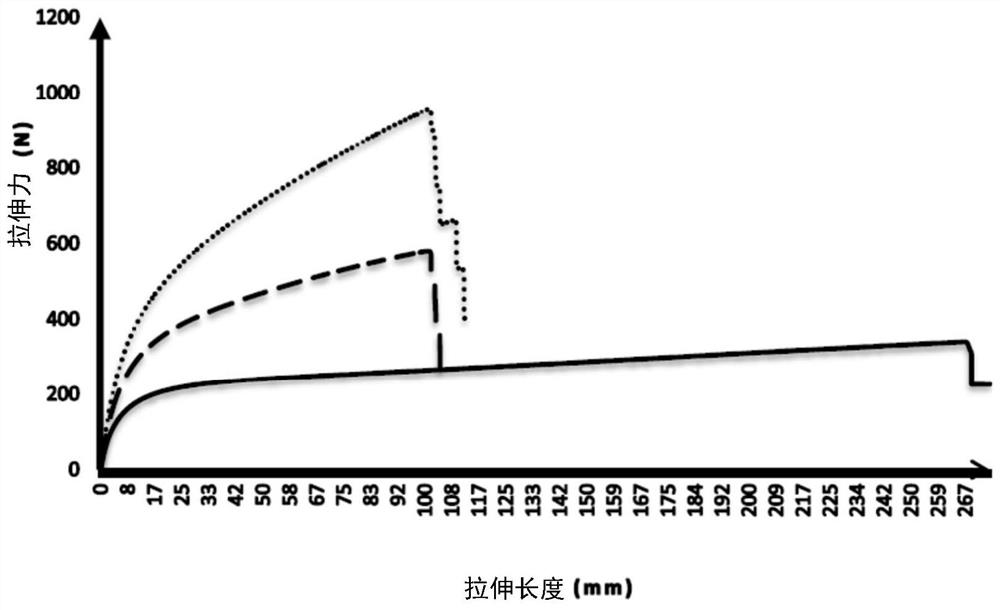

Polyketone compound

ActiveCN112839980AImproved seam strengthImprove tribological propertiesEngine sealsPiston ringsPolymer sciencePolyketone

The invention relates to an aliphatic polyketone compound comprising 85.0 wt. % to 99.5 wt.% aliphatic polyketone and 0.5 wt. % to 15.0 wt.% ultra-high molecular weight polyethylene.

Owner:CARL FREUDENBERG KG

High-speed thick package film bag making machine

ActiveCN104416952AIncrease productivityImproved seam strengthBox making operationsPaper-makingMotor driveProgrammable logic controller

The invention discloses a high-speed thick package film bag making machine, which comprises an air expansion shaft, a clamping motor, an ironing corner mechanism, a cooling air mechanism, an ironing cutter mechanism, a cutter mechanism, a water circulating cooling mechanism, a conveying motor, a conveying mechanism and a programmable logic control mechanism, wherein the ironing corner mechanism, the cooling air mechanism, the ironing cutter mechanism, the cutter mechanism and the water circulating cooling mechanism are sequentially connected with the working surface of the bag making machine. The high-speed thick package film bag making machine is characterized in that the working surface of the ironing cutter machine is higher than the working surface of the ironing corner mechanism, a rubber roll servo motor is arranged at the right side of the working surface of the ironing cutter mechanism, and is used for driving a pressing rubber roll to convey a to-be-processed film bag to the fixing position of the ironing cutter mechanism for seam ironing, the film bag after the seam ironing by an ironing cutter vertically falls onto the water circulating cooling mechanism and the working surface of the cutter mechanism along the tail end of the right side of the ironing cutter mechanism under the action of gravity, and the conveying motor drives the conveying mechanism to continuously work when the package film bag making machine starts to work. The package film bag making machine has the advantages that the production efficiency is improved by two times, and the seam ironing strength of the film bag is improved by five times.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

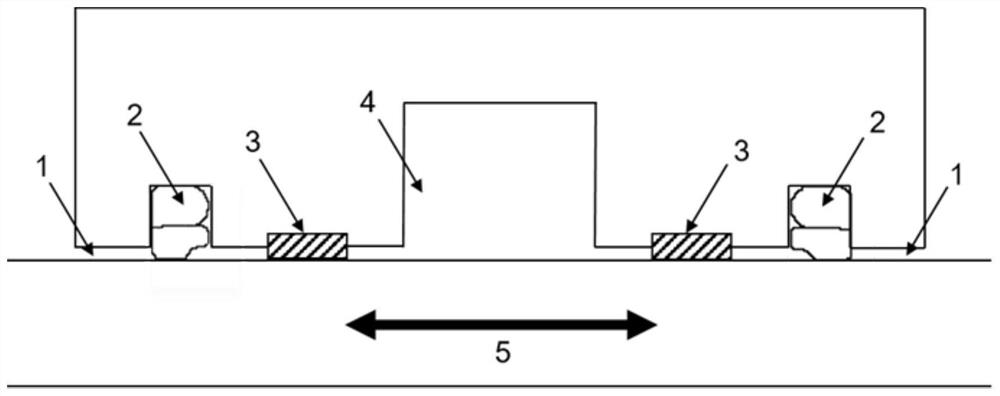

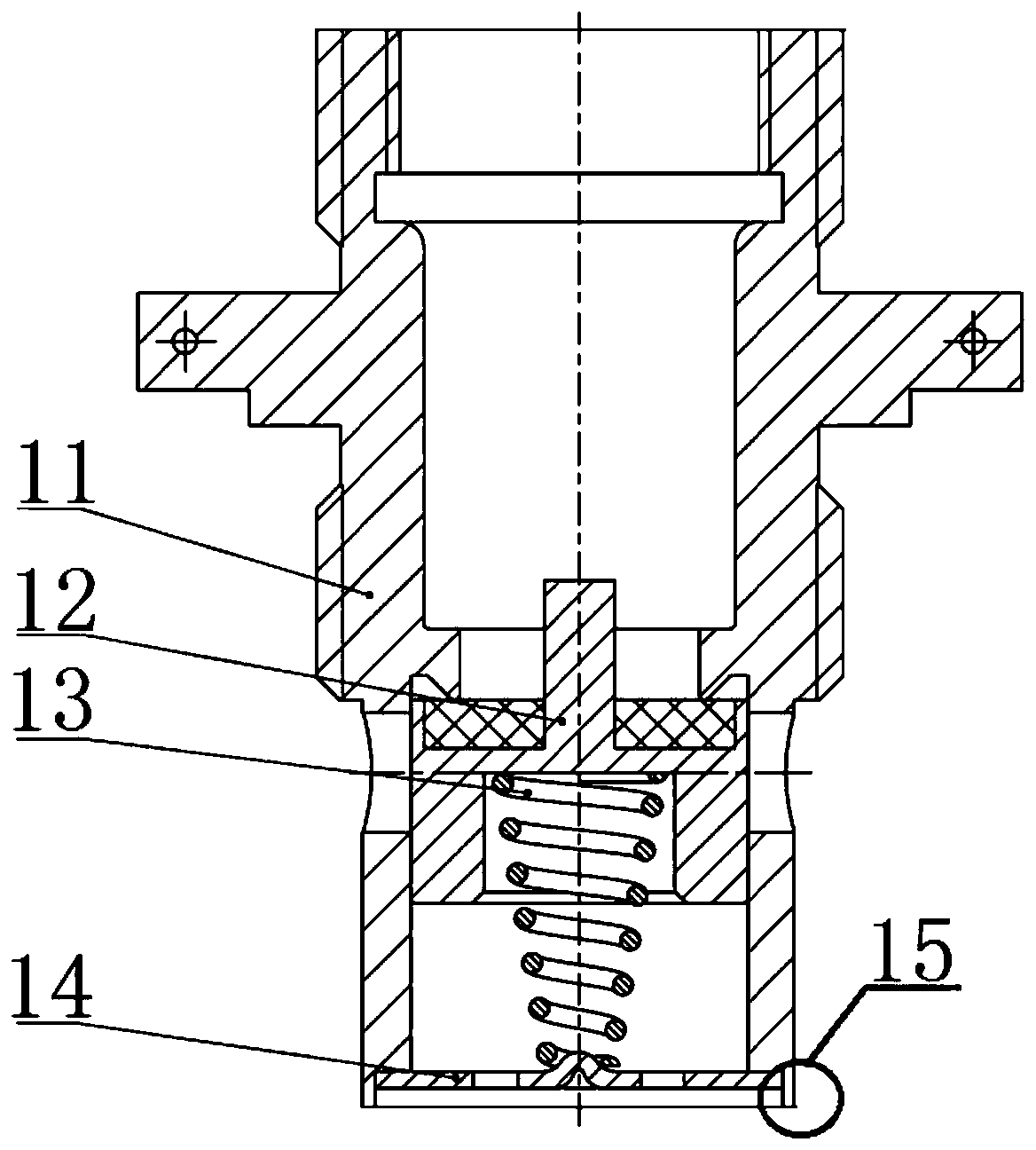

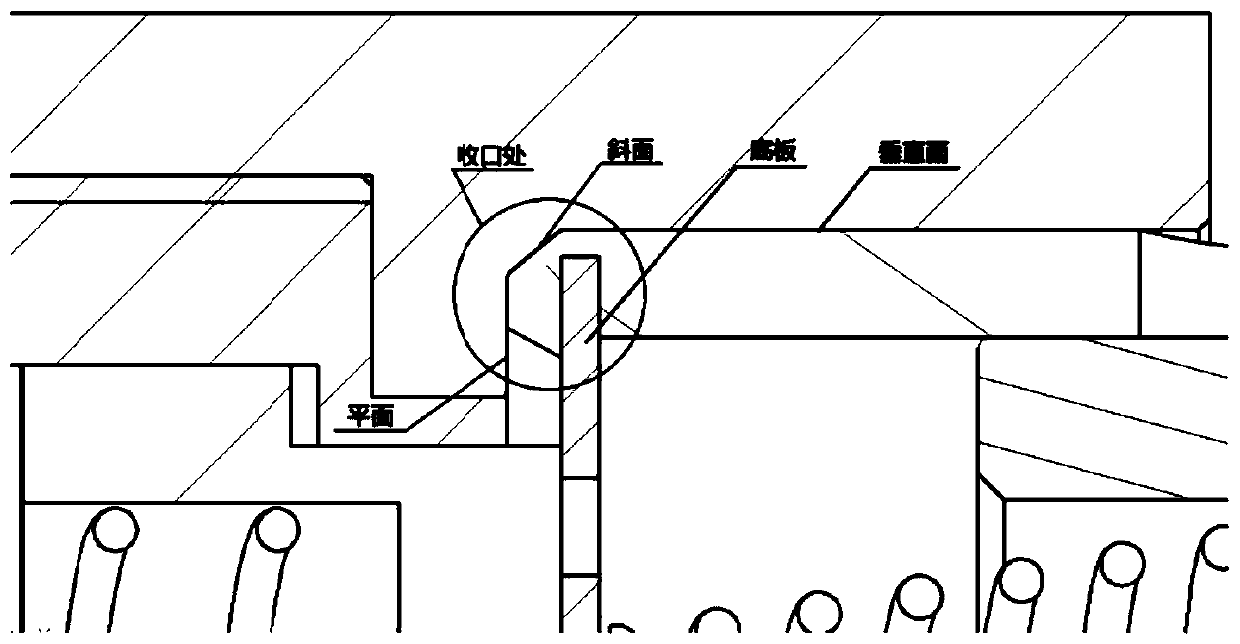

Necking tool and necking method of filling valve

ActiveCN110842516AImproved seam strengthImprove processing quality and efficiencyMetal working apparatusMachine pressScrew cap

The invention discloses a necking tool and necking method of a filling valve. The necking tool comprises a pressing sleeve, a screw sleeve, a spring, a screw cap and a top block, wherein the pressingsleeve is a rotary body, the screw sleeve is arranged on the left side of the pressing sleeve, the top block is arranged at the right end of the screw sleeve, the screw cap is arranged at the left endof the screw sleeve, the spring is arranged between the screw cap and the top block, and an inclined edge and a plane are arranged on the right side of the pressing sleeve and used for being matchedwith the necking end of a shell of the filling valve. Compared with the prior art, the necking tool and necking method have the positive effects that in the using process of the necking tool, and thedisposable necking of the shell of the valve is realized by using a press machine through the inclined plane and the plane matching the shell in the inner cavity of the pressing sleeve. Compared withthe necking tool in the prior art, the necking tool is obviously improved in the outer shape, the necking mode and the necking strength, the machining quality and efficiency are greatly improved, andthe labor intensity of an operator is reduced.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

A fiberglass chimney assembly butt joint winding device

ActiveCN105401735BIncrease productivityImproved seam strengthTowersBuilding material handlingGlass fiberYarn

The invention belongs to the technical field of glass fiber reinforced plastic pipe cylinders and concretely discloses. The technical scheme of the apparatus is that the apparatus comprises a surrounding track arranged on the external side of a lower-segment glass fiber reinforced plastic cylinder body and a walking trolley arranged on the track and formed by an upper rack body and a lower rack body connected via connection rods, wherein a resin fiber yarn mechanism is arranged on the walking trolley; the upper rack body is formed by a sector-shaped framework in an arc-shaped correspondence to the external side surface of the glass fiber reinforced plastic cylinder body; a unidirection cloth winding mechanism and a resin fiber yarn winding mechanism are mounted in the sector-shaped framework. And / or the apparatus comprises a left and right walking trolleys connected via a telescopic mechanism; each walking trolley is formed by an upper rack body and a lower rack body connected via connection rods; a resin fiber yarn mechanism is arranged on the left or / and right walking trolley; the upper and lower rack bodies on the left and right sides are respectively formed a sector-shaped framework in an arc-shaped correspondence to the inner side surface of the glass fiber reinforced plastic cylinder body; and a unidirection cloth winding mechanism and a resin fiber yarn winding mechanism are mounted in the sector-shaped framework. By the use of the apparatus, the inner and outer side walls of upper and lower glass fiber reinforced plastic cylinder bodies can be assembled, abutted and winded.

Owner:JIZHOU ZHONGYI FRP

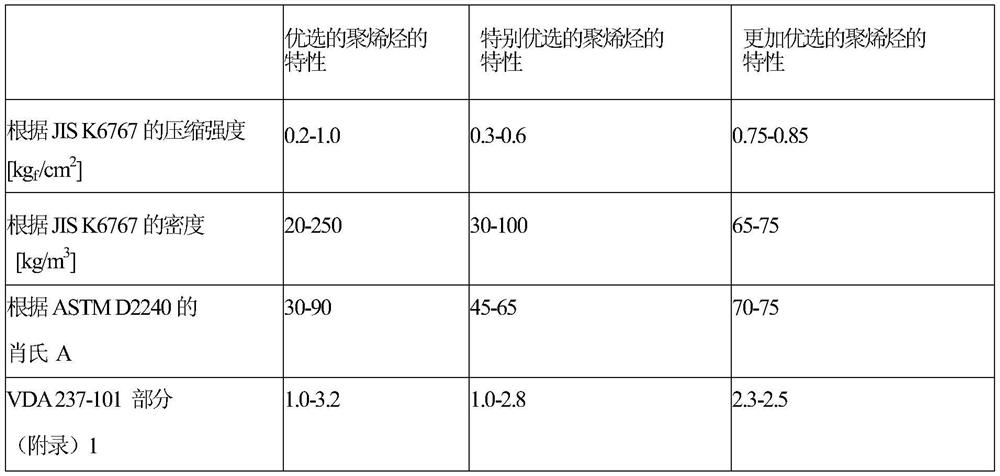

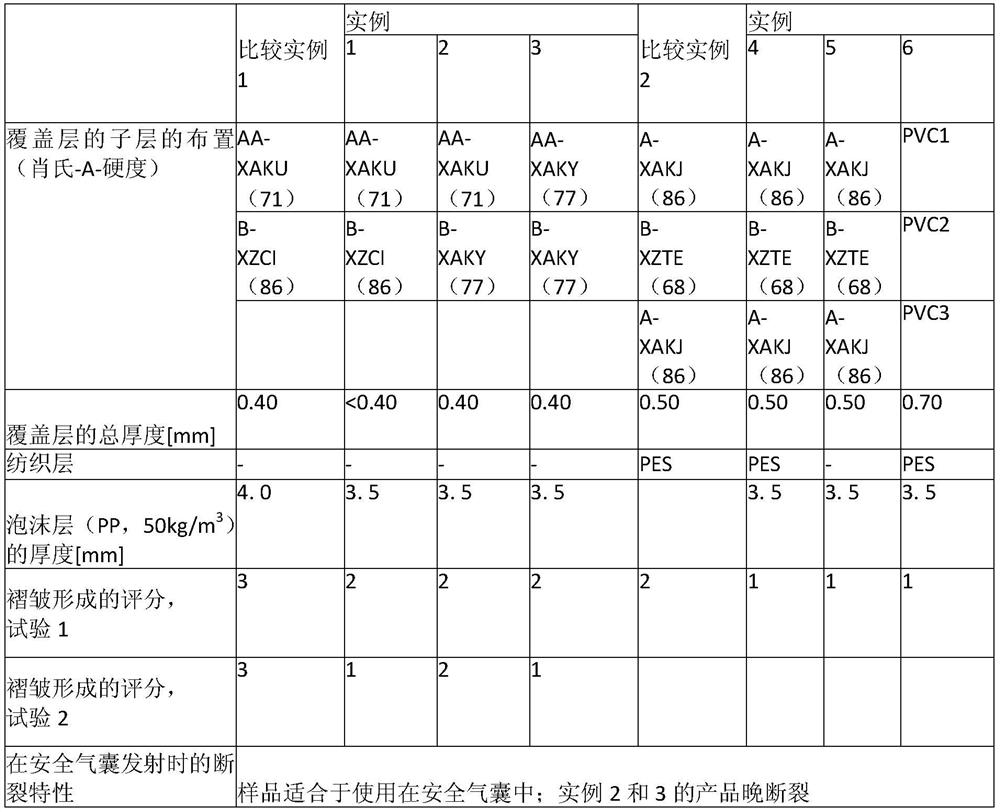

Composite structure for airbag cover, and sewn product of composite structure

ActiveCN113056367AReduce manufacturing costEasy to operateLamination ancillary operationsPedestrian/occupant safety arrangementThermoplasticPolymer science

The invention relates to a composite structure, to a method for producing the same, to a sewn product which contains the composite structure, and to a method for producing the sewn product. The composite structure has a Shore A hardness of 20 to 45 according to DIN 53505 and has a foam layer, a cover layer, and a lacquer layer in this order, wherein the foam layer has a density of 40 to 100 kg / m3 and a gel content of 20 to 80% and contains a polyolefin, and the cover layer has a gel content of 0 to 20%, is thermoplastic, and comprises at least two compact sub-layers, each of which contains at least one thermoplastic selected from polyolefin and polyvinyl chloride.

Owner:汽车工业用TMG塑化织物及其他涂料公司

Low-noise dry-type iron core reactor assembling process

ActiveCN103594240BOvercome Adhesion DeficienciesAchieve vacuum pouringInductances/transformers/magnets manufactureInductance with magnetic coreLow noiseEngineering

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

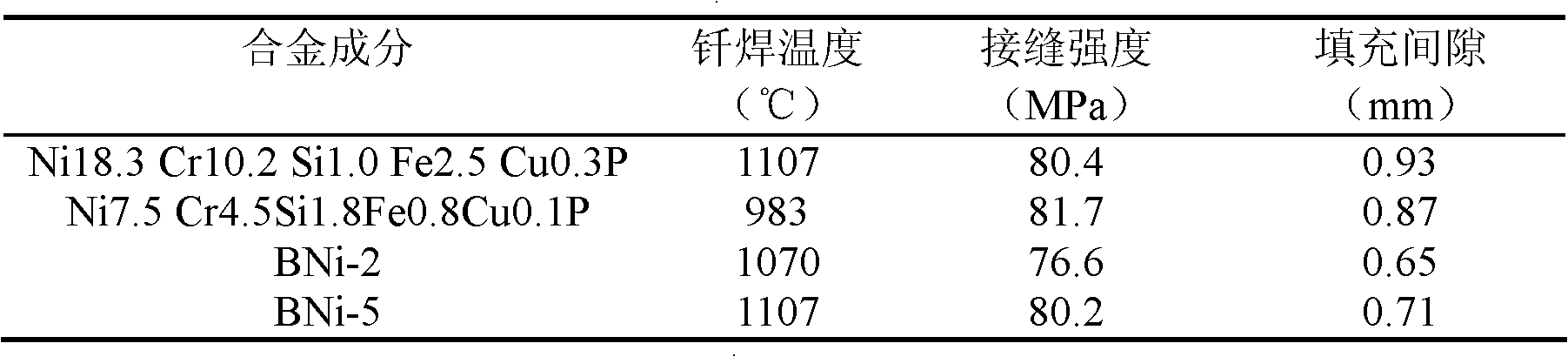

Nickelbase superalloy brazing filler metal and preparation method thereof

ActiveCN102500952BCurb flowStrong welded seamsWelding/cutting media/materialsSoldering mediaSS - Stainless steelWeld seam

The invention relates to a nickelbase superalloy brazing filler metal and a preparation method thereof. The nickelbase superalloy brazing filler metal comprises the following components in weight percentage: 5.0%-20% of Cr, 4.0%-10% of Si, 0.1%-3% of Fe, 0.1%-10% of Cu, 0.1%-3% of P and the rest of Ni. The preparation method comprises the following steps of: mixing the following components of Cr, Si, Fe, Cu, P and Ni according to proportion; preparing the brazing filler metal into 240-600mesh spherical powder by adopting vacuum smelting, gas atomization and ultrasonic sieving; and mixing the brazing filler metal into paste brazing filler metal by an organic binder. The invention has the advantages that the welding seam has high welding strength, the high temperature resistance is good due to a high melting point, and the flowing of the brazing filler metal can be effectively inhabited by added Cu and Fe; the brazing filler metal is suitable for brazing of stainless steel, and has excellent wettability and gap fallibility for the brazing of an automobile EGR (Exhaust Gas Recirulation) stainless steel cooler, and the tightness, corrosion resistance and welding seam strength of brazing members reach the technical requirements of an automobile EGR stainless steel cooler.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Traceless joint fabric knitting method of double-needle-bed warp knitting machine

InactiveCN102587023BEasy to prepareSuitable for industrial productionWarp knittingEngineeringTextile composite

The invention provides a traceless joint fabric knitting method of a double-needle-bed warp knitting machine, which is characterized by including the following steps of selecting warps materials, setting yarn laying motions of guide bars and utilizing yarn threading and aligning process; beaming warps; mounting the guide bars with swing yarn guide needles in a needle bed working area, performance traceless jointing at the edges of fabrics of a front needle bed and a rear needle bed; making up information of the yarn guide needles; performing machine-boarding processing adjustment and knitting; and arranging the fabrics. By the traceless joint fabric knitting method of the double-needle-bed warp knitting machine, the technical problem of cylindrical knitting by twice or more guiding on the double-needle-bed warp knitting machine can be solved, joint wrinkles of preformed parts of various cylindrical warp knitting composite materials are eliminated, mechanic performance of the spinning composite materials are improved, ultra-wide products can be provided for cloth used in shed cover industry. In addition, perfect traceless jointing can be provided for warp-knitted fully-formed clothes and appearance and comfortableness of the clothes can be improved.

Owner:DONGHUA UNIV

Piezoelectric swing yarn guide needle device for double-needle-bed tricot machine

InactiveCN102587025BOvercome the technical bottleneck of warp knittingSolve technical bottlenecksWarp knittingBraidWarp knitting

Owner:DONGHUA UNIV

Closing tool and method for filling valve

ActiveCN110842516BReduce labor intensityImproved seam strengthMetal working apparatusScrew capVALVE PORT

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Electromagnetic swing yarn guide needle device used for double-needle-bed warp knitting machine

InactiveCN102587026BOvercome the technical bottleneck of warp knittingSolve technical bottlenecksWarp knittingFull widthBraid

The invention provides an electromagnetic swing yarn guide needle device used for a double-needle-bed warp knitting machine, which is characterized by comprising a bearing seat, a swing piece, an L-shaped yarn guide needle and an electromagnetic control part. The bearing seat is fixed on a guide bar plate of the double-needle-bed warp knitting machine, the electromagnetic control part is arranged in a cavity of the bearing seat, the top end of the swing piece is connected with the electromagnetic control part, the upper portion of the swing piece is rotationally connected with the bearing seat, and the bottom end of the swing piece is connected with the L-shaped yarn guide needle. Connecting yarns can be inlaid on edge knitting needles in a front needle bed working area and a rear needle bed working area alternatively by the electromagnetic swing yarn guide needle device according to knitting process, so that seamless cylindrical warp-knitted fabrics or seamless ultra-wide full-width fabrics are formed after fabrics are taken off the machine. Connecting seams of a front fabric and a rear fabric are in weaving structures identical with twice or more guiding fabrics, and the bottleneck problem of existing double-needle-bed warp knitting process is solved.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com