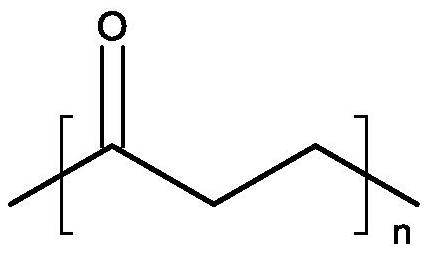

Polyketone compound

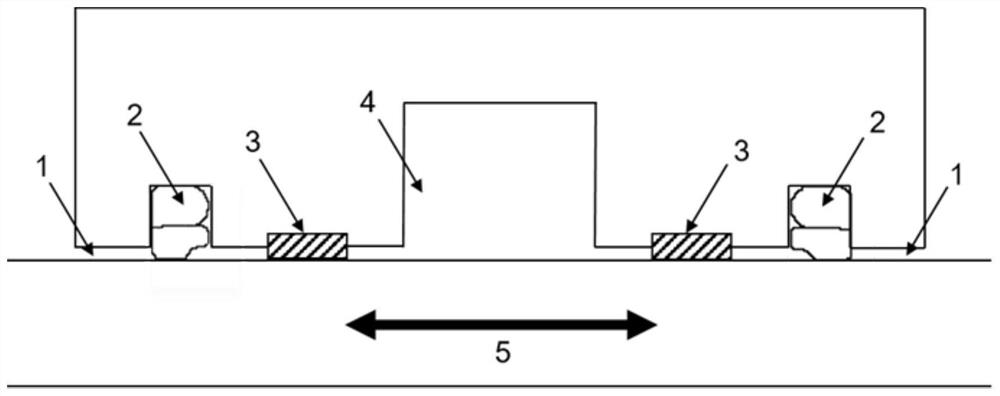

A compound, technology of aliphatic polyketone, applied in the direction of mechanical equipment, piston rings, engine components, etc., can solve problems such as cracks at seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: the preparation of polyketide compound of the present invention

[0061] Tribologically modified polyketide compound of the present invention is in the ZSE 27iMAXX type 27mm twin-screw extruder of Leistritz company (screw diameter: 28.3mm, channel depth: 5.6mm (no gap), D a / D i =1.66, maximum torque: 256Nm, screw speed: 600-1200U / min), the extruder is equipped with the BASIC 401 solid feeder of SCHOLZDosiertechnik GmbH company for feeding aliphatic polyketone, for feeding Solids feeder type BASIC 300 from SCHOLZ Dosiertechnik GmbH for UHMWPE, conveyor belts for strand deposition, water cooling system for cooling the deposited polymer strands, and Maag for crushing the deposited strands Downstream granulator PRIMO 60E from Automatik GmbH.

[0062] The aliphatic polyketones used are from AKRO-PLASTIC GmbH PK-VM natur (4774). PK-VM natur (4774) is a high flow non-reinforced polyketone type. Its melting point measured according to DINEN11357-1 method i...

Embodiment 2

[0066] Example 2: Mechanical and Tribological Tests of the Polyketides in Example 1

[0067] The specimens for the mechanical and tribological tests were produced on an injection molding machine type 320C 600-100 Allrounder from Arburg GmbH & Co. KG. Using Axicon Molds' AIM TM Quick change mold as injection mold. S1A tie bars for mechanical tests and Lewis specimens for tribological tests were prepared.

[0068] Mechanical tests showed the compound had a tensile modulus of elasticity of 1725 ± 10 MPa measured according to DIN EN ISO 527-2 / 1A / 50 and a tensile strength of 58.7 ± 0.2 MPa measured according to DIN EN ISO 527-2 / 1A / 50 , the elongation at break measured according to DIN ENISO527-2 / 1A / 50 was 28.2±7.1%.

[0069] The tribological tests were carried out on the LRI-1a Lewis test rig of Lewis Research Inc. Company. D2 steel / 52100 with chemical composition 100Cr6 was used as mating surface. The test was carried out without lubrication. The velocity is v=0.84m / s, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com