Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Textile composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blumea oil microcapsule textile composite finishing agent and use thereof

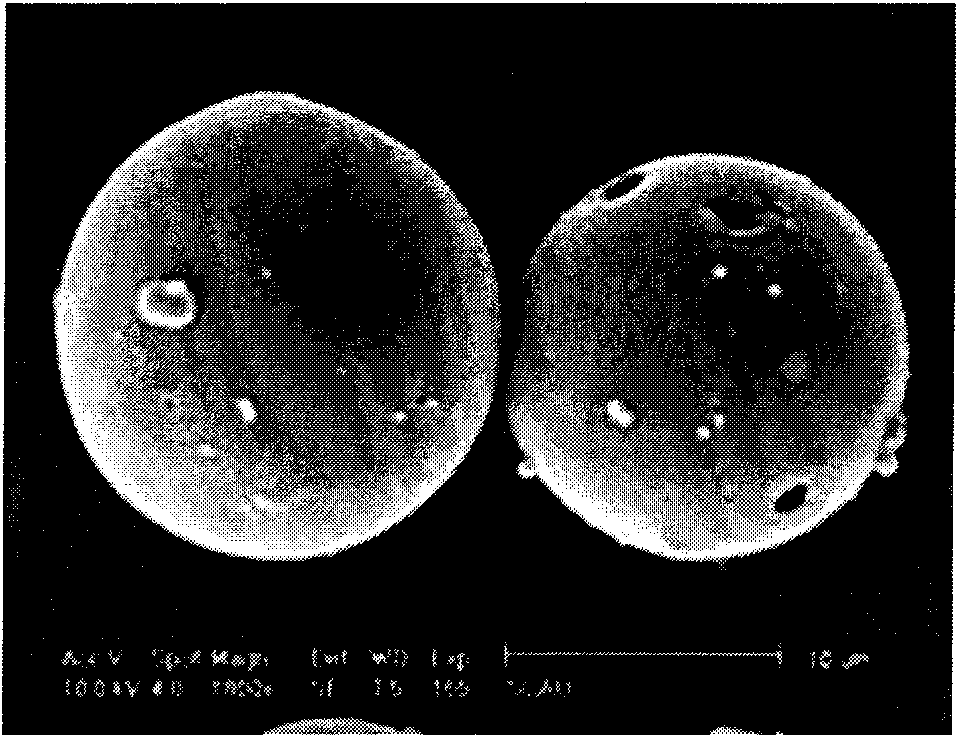

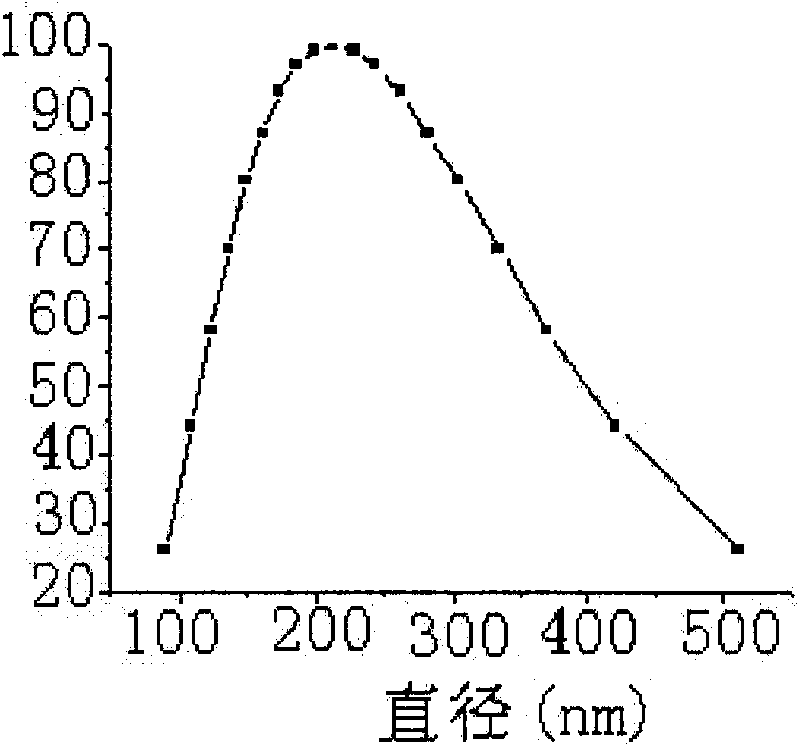

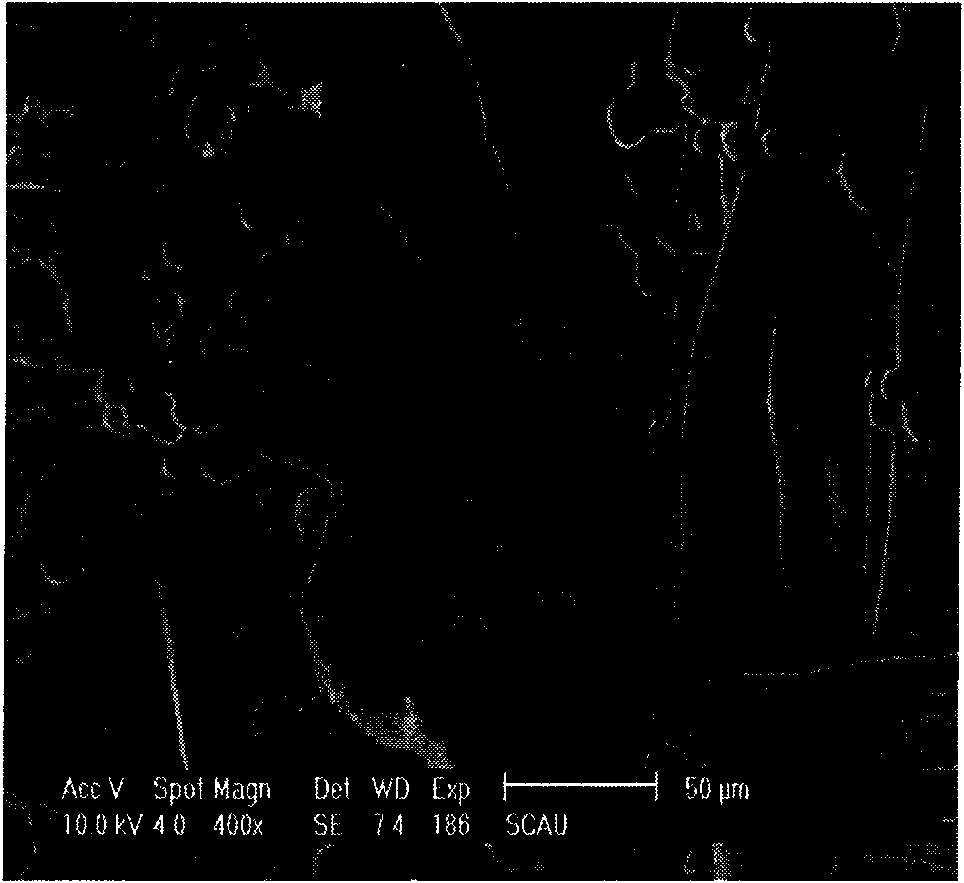

InactiveCN101591859AStir wellSmall particle sizeFibre treatmentMicroballoon preparationCross-linkChemical Linkage

The invention discloses a blumea oil microcapsule textile composite finishing agent and use thereof. Gelatin or acacia of natural polymers is used the main ingredient of a wall material, the blumea oil serving as a Chinese medicinal material is used as a core material, and complex coacervation is adopted to prepare an blumea oil microcapsule aqueous emulsion; a shrink-resistance crosslinker and a catalyst are added to be combined with the blumea oil microcapsule aqueous emulsion into a multifunctional blumea oil microcapsule textile composite finishing agent; researches on the use of blumea oil microcapsules in textile finishing are carried out; and a novel cross linked graft method is used to perform the microcapsule finishing of textiles to form chemical bonds between the microcapsules and the textiles though the shrink-resistance crosslinker and free formaldehyde molecules in 2D resin further participate in a cross-linking and curing reaction as a microcapsule curing agent, so the textiles achieve a long lasting antibacterial and health-care function, a shrink-resistance function and low formaldehyde release content performance.

Owner:SOUTH CHINA AGRI UNIV

Textile composite with iron oxide film

A colored textile composite is produced by forming an iron (III) oxide film on a textile surface. This is accomplished by contacting the textile with an aqueous solution having an iron (II) or iron (III) species present. The iron (II) ion resulting from the dissociated iron (II) salt, if an iron (II) salt is utilized, is first hydrolyzed within the aqueous solution and then oxidized under controlled conditions to form iron (III) oxide (hydroxide). The iron (III) ion resulting from the dissociated iron (III) salt, if an iron (III) salt is utilized, is only hydrolyzed under controlled condition to form iron (III) oxide (hydroxide). The iron (III) oxide is then nucleated and forms a smooth and coherent iron (III) oxide film or coating on the surface of the textile without forming an insoluble iron (III) hydroxide precipitate in the solution. This reaction occurs because the reaction conditions are controlled in such a manner as to form sub-colloidal sized iron oxide particles which, in turn, permits a faster rate of adsorption of the iron (III) oxides onto the substrate surface than the rate of formation of the same particles. The iron (III) oxide formed may be goethite, hematite, or magnetite or any mixture thereof. Varying the type of oxide formed allows control over the color shade and other properties of the treated textile composite.

Owner:MILLIKEN & CO

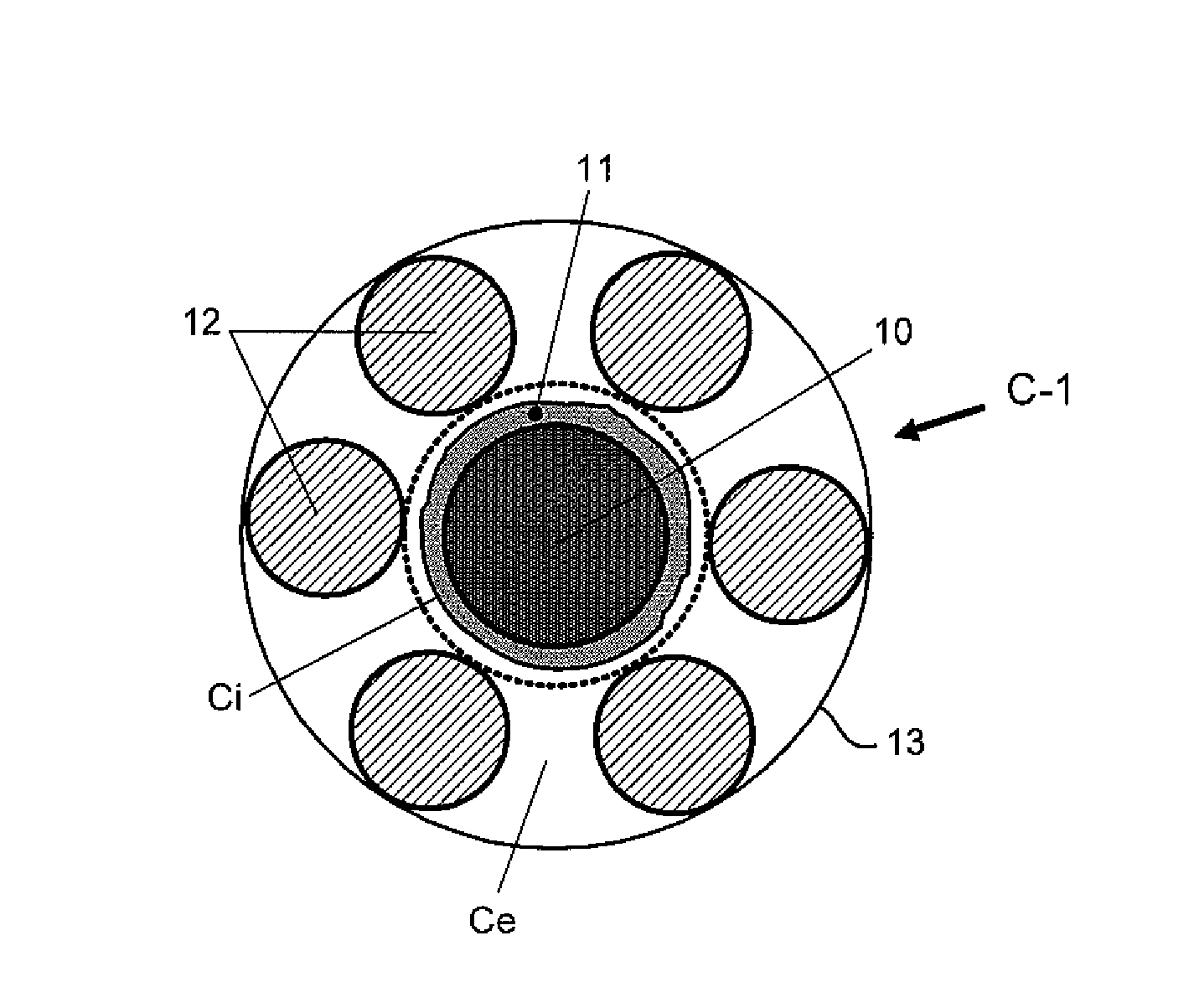

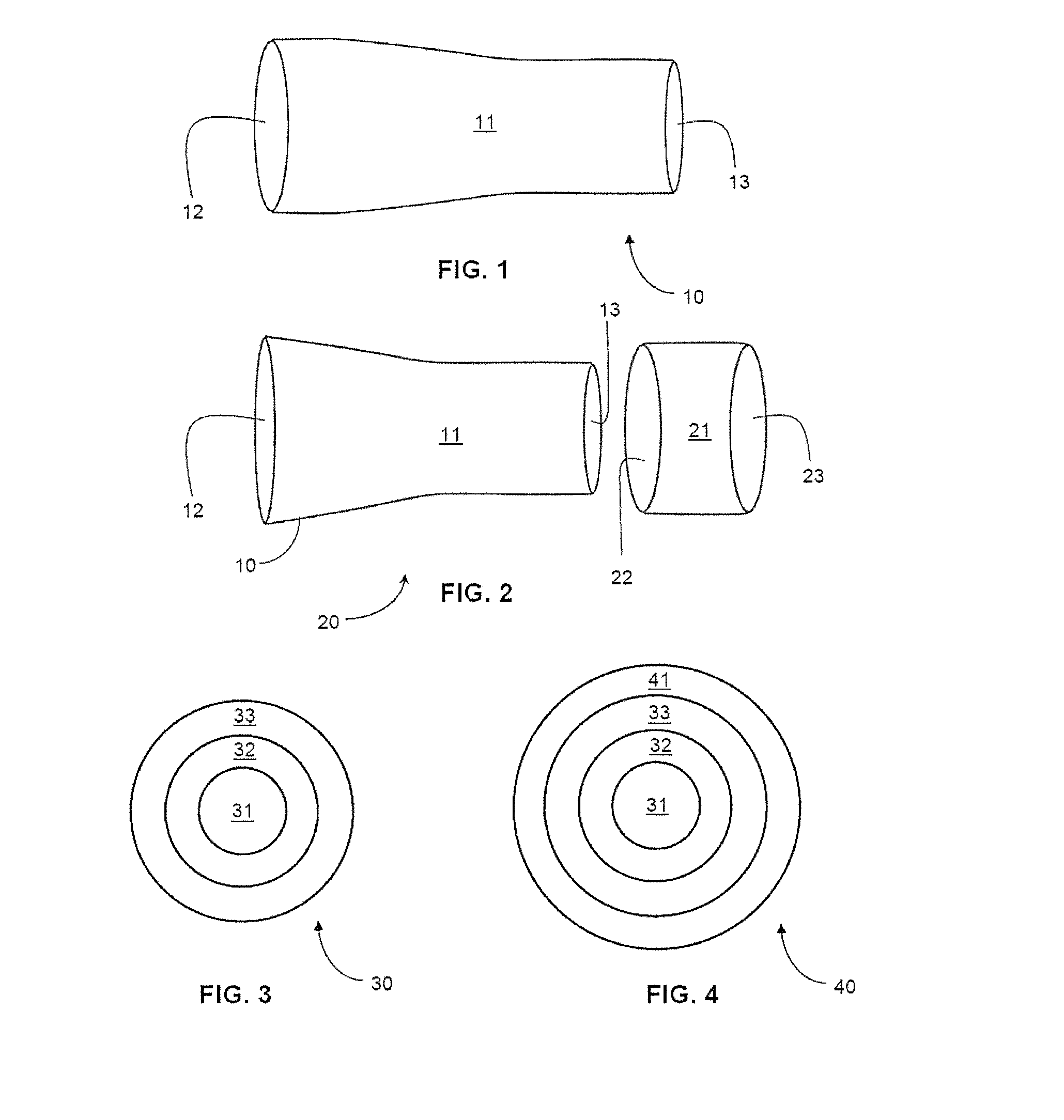

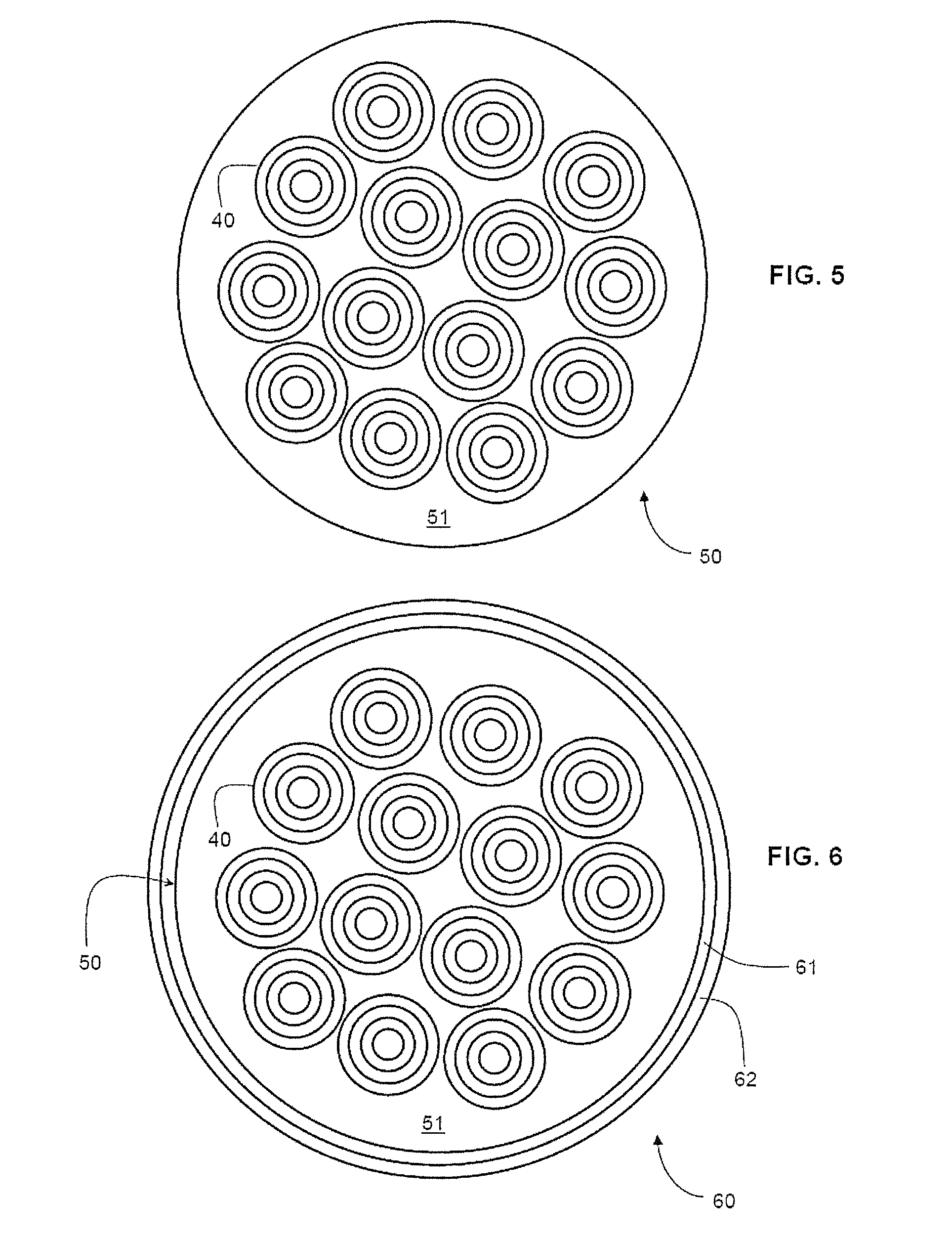

Resilient composite tire cord

ActiveUS8166741B2Improve compactnessImprove staminaPneumatic tyre reinforcementsAnimal housingFiberElastomer

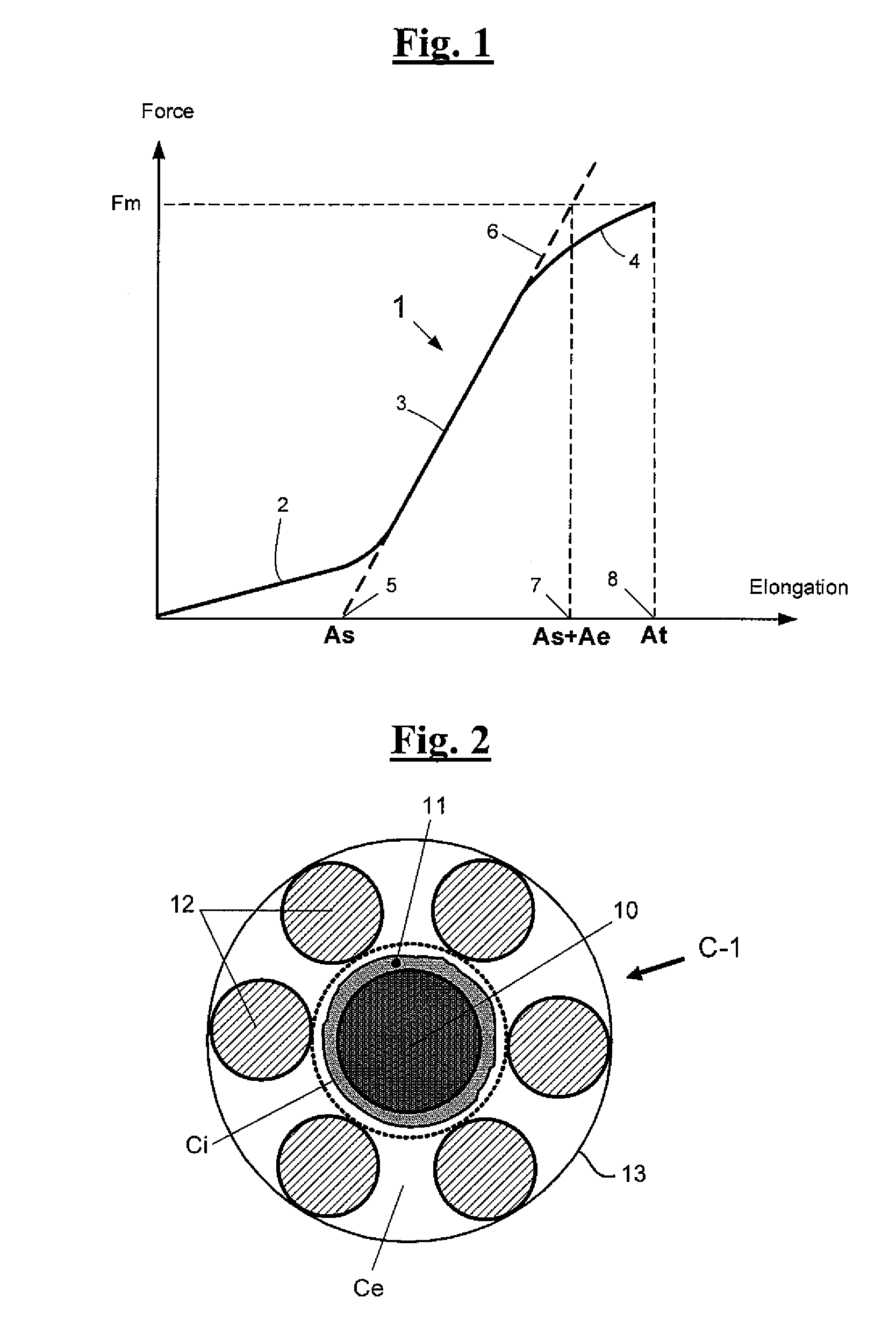

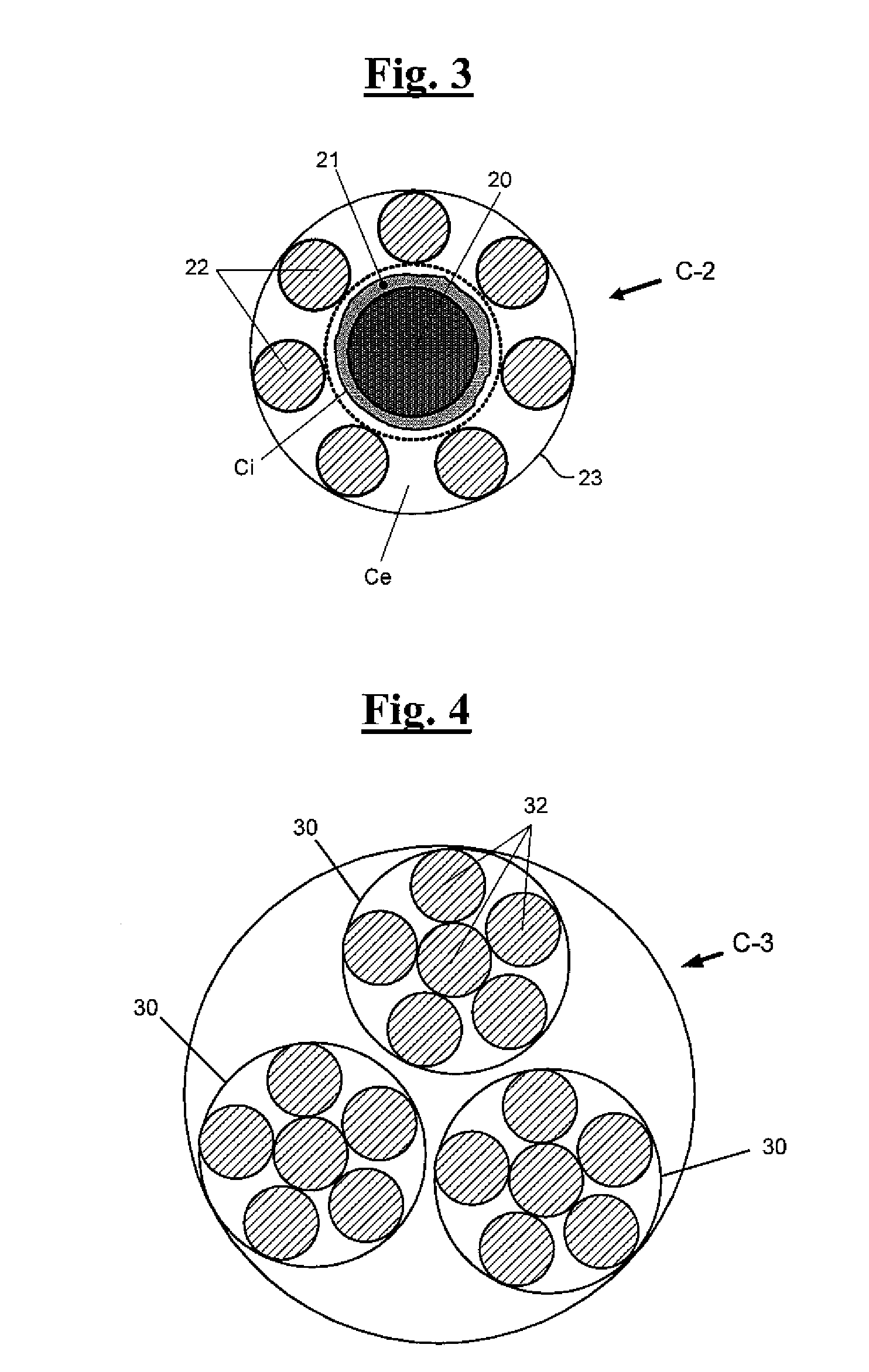

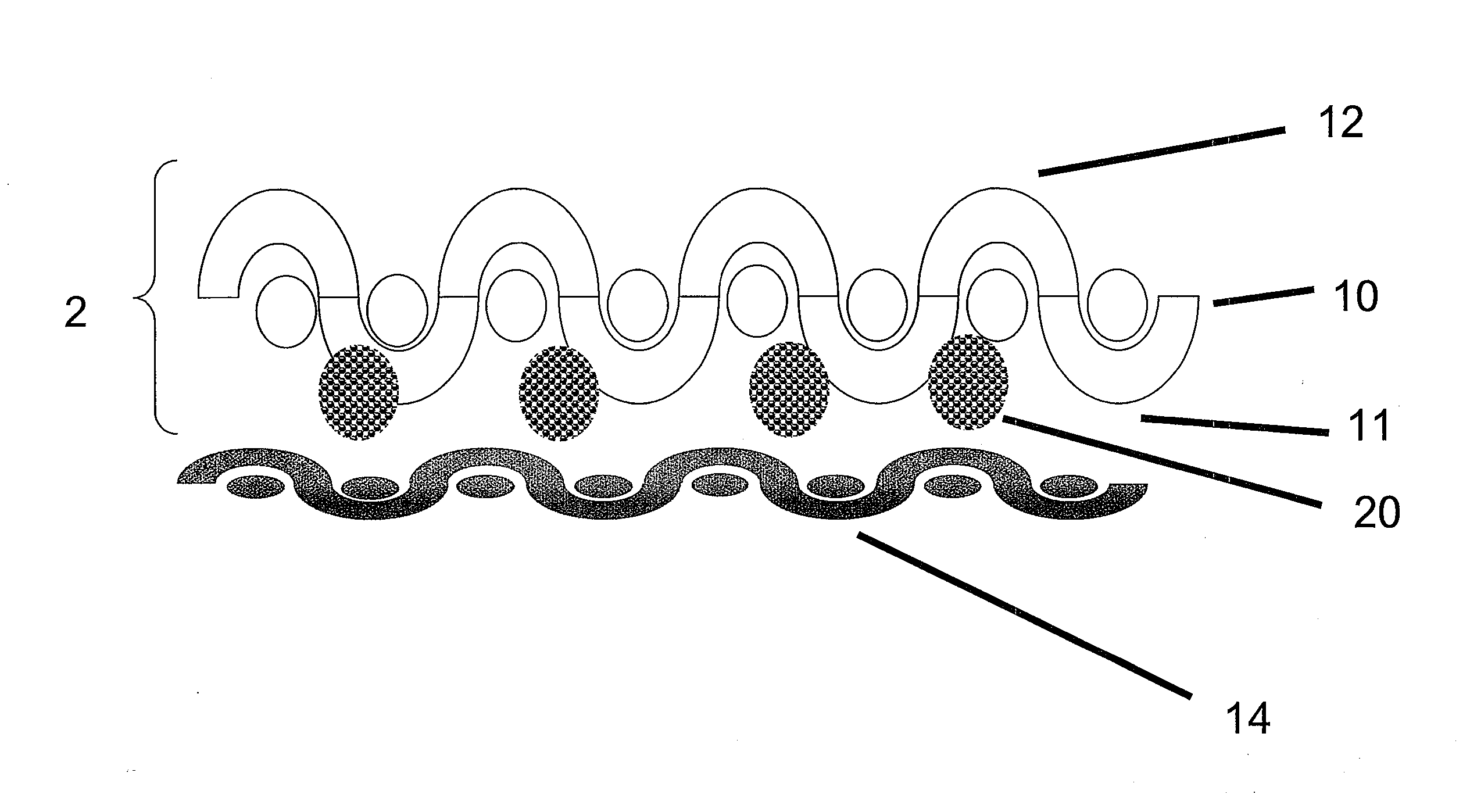

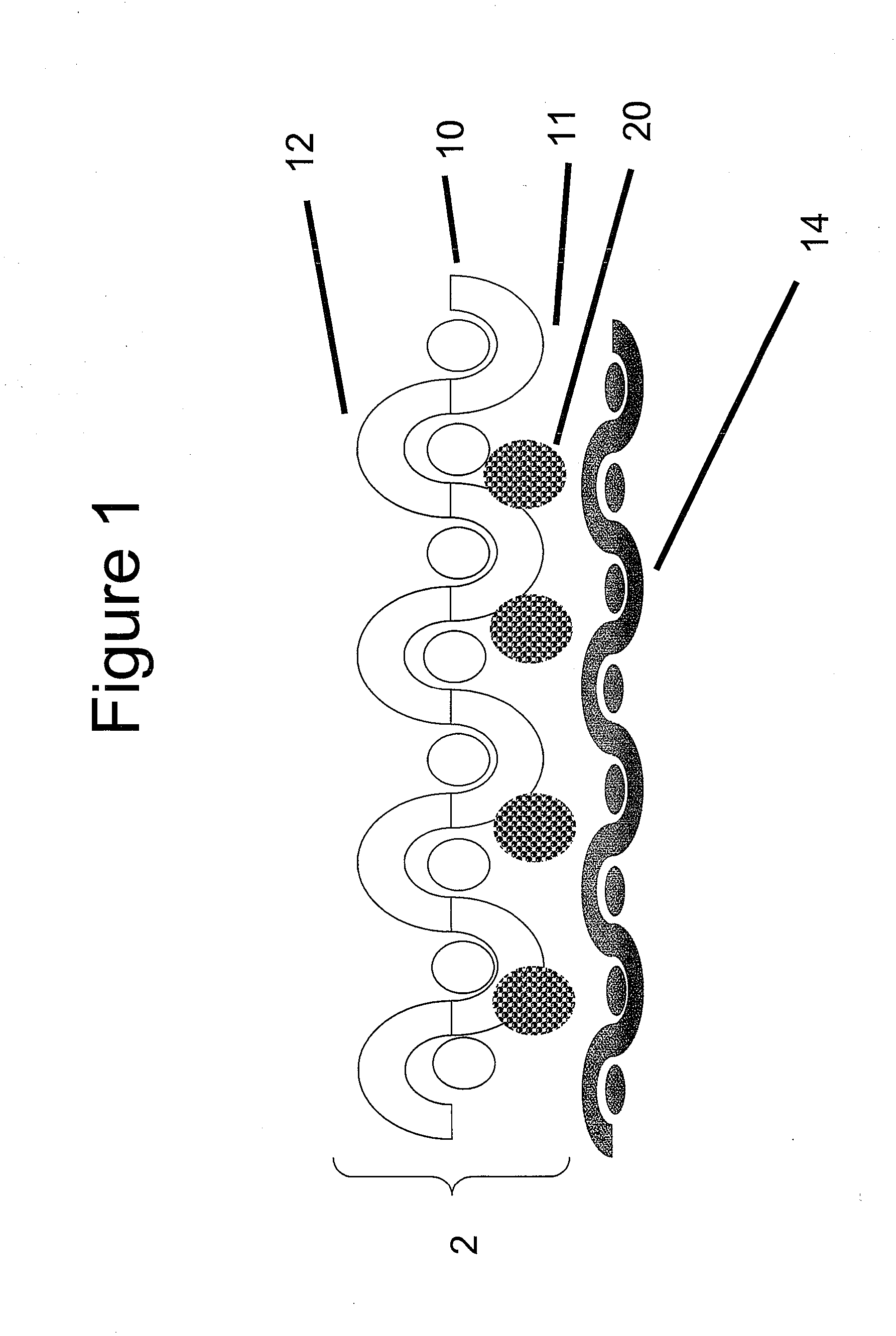

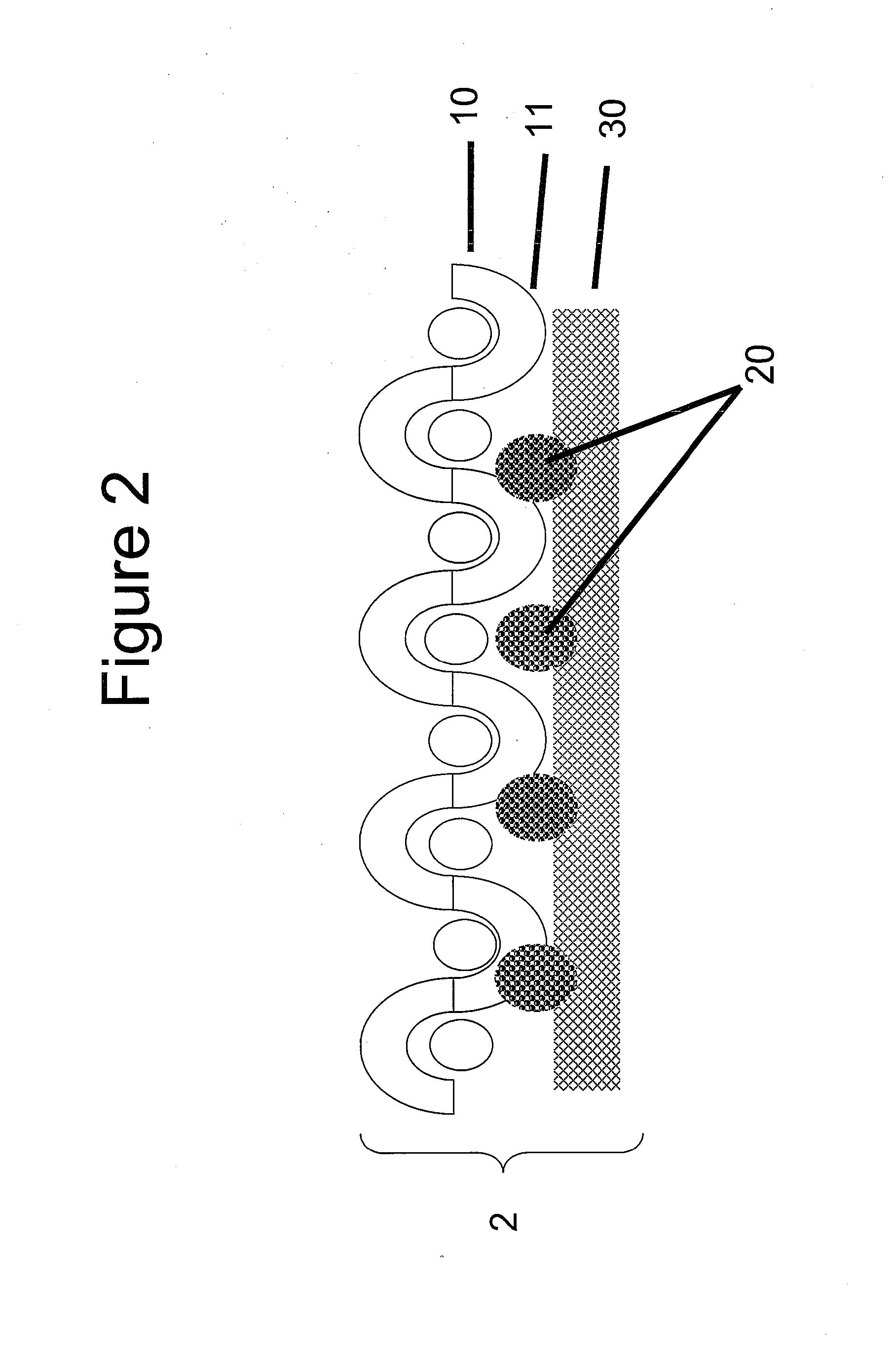

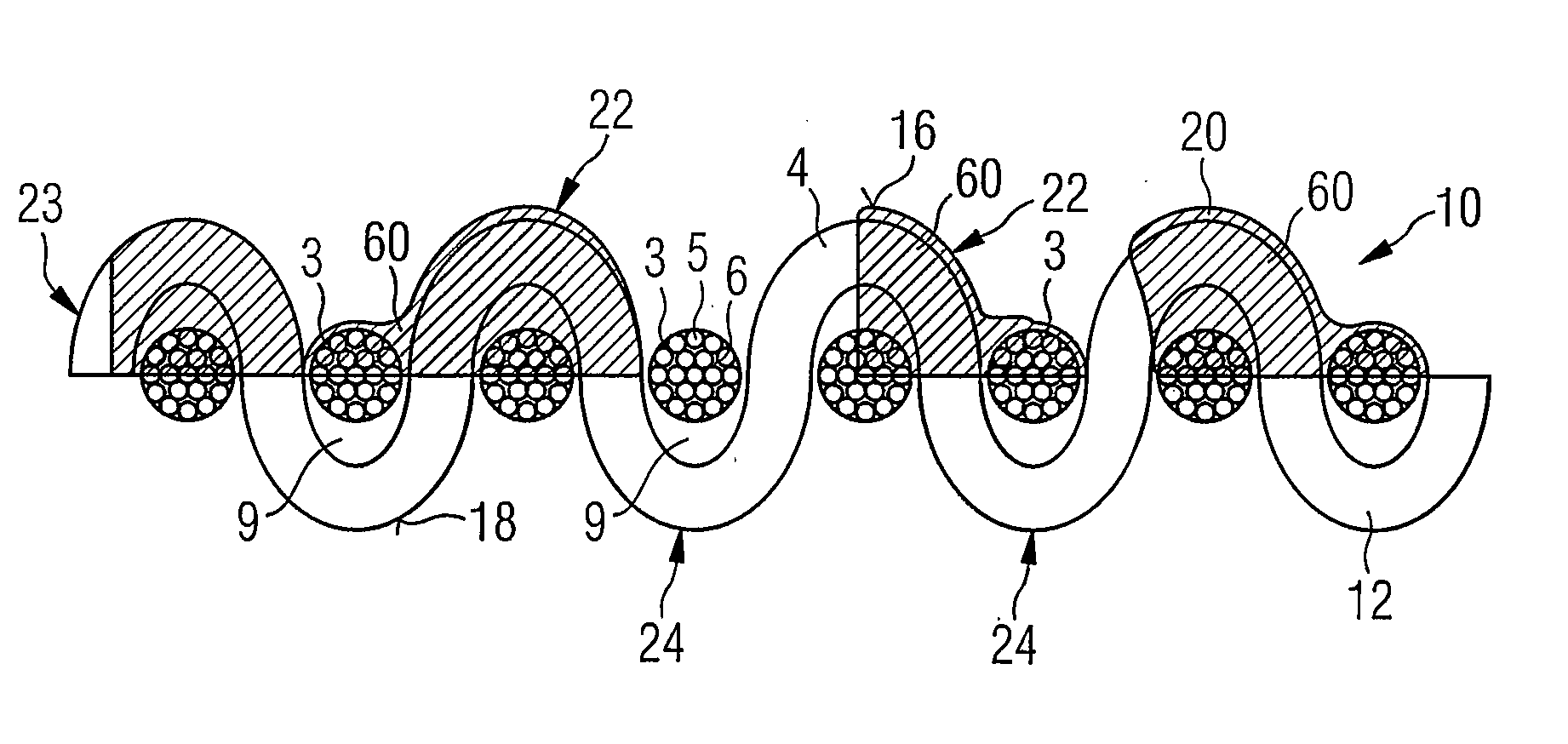

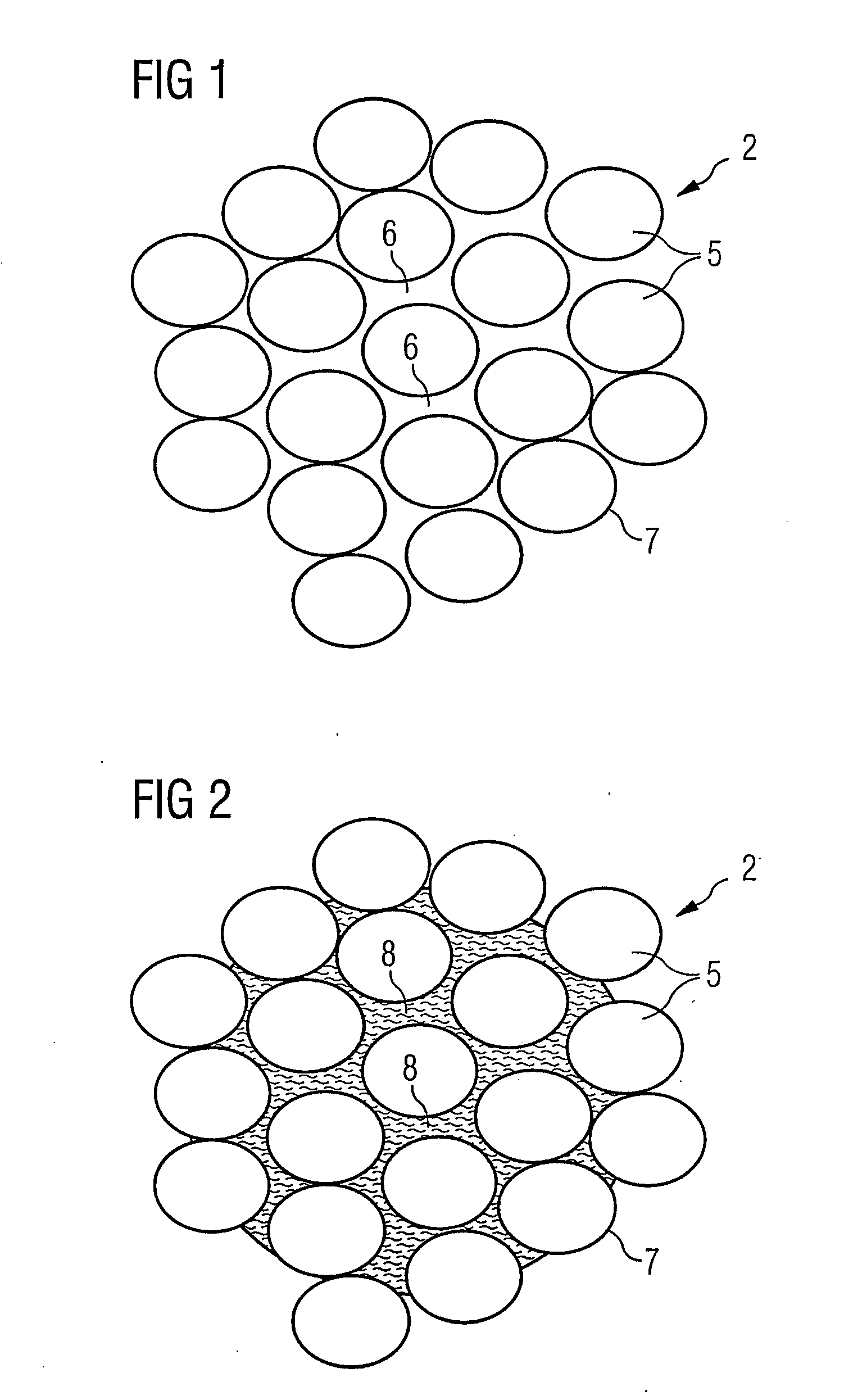

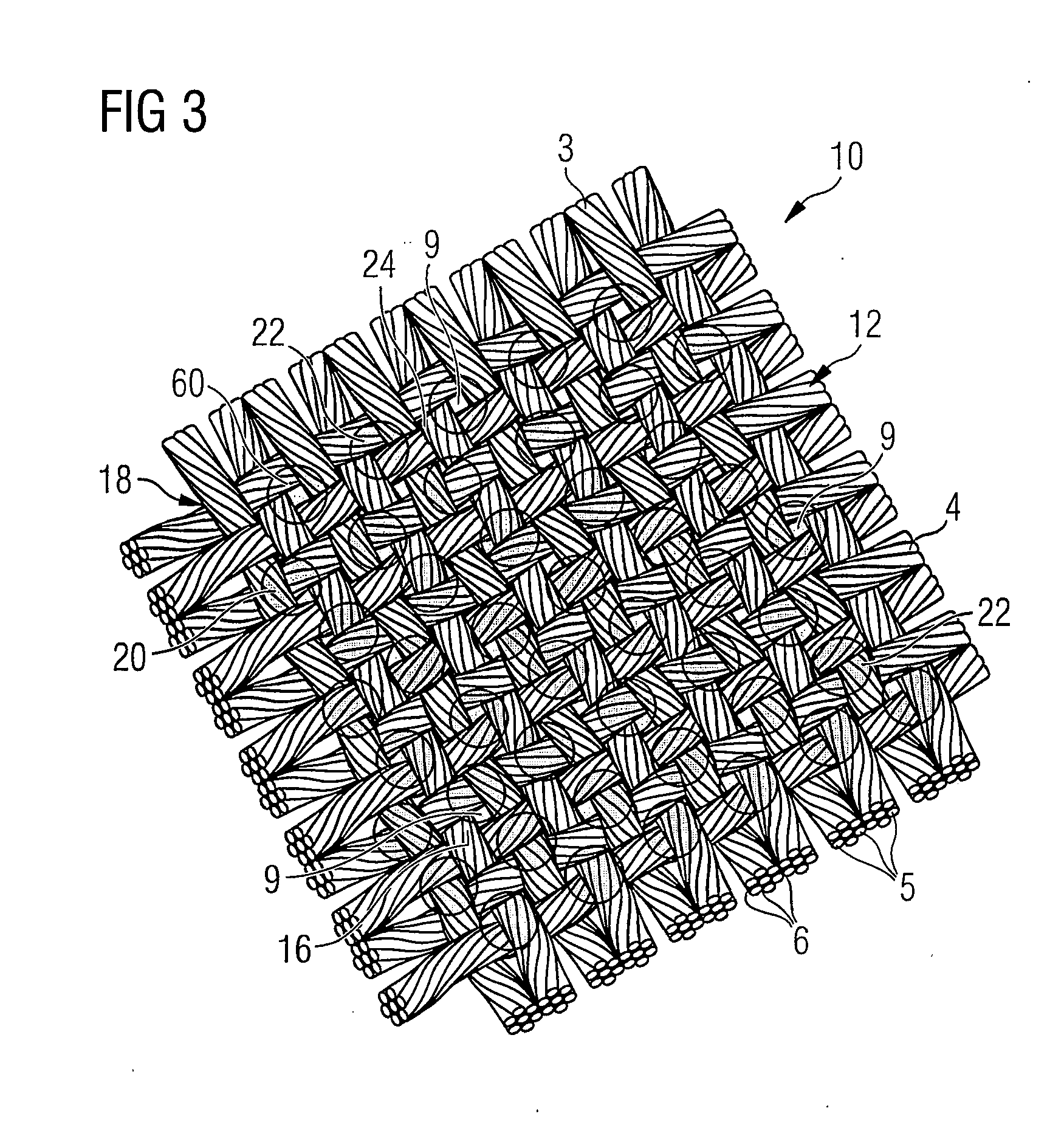

Elastic metal / textile composite cord (C-1) having two layers (Ci, Ce) of 1+N construction, formed from a core or inner layer (Ci) comprising a textile core thread (10) of diameter d1 and a metal outer layer (Ce) of N wires (12) of diameter d2 wound together in a helix with a pitch p2 around the layer Ci, said cord being characterized in that it has the following characteristics (p2 in mm): As>1.0%; At>4.0%; Af>6.0%; d1>1.1d2; 4<p2<14; and the core thread (10) is a textile fibre and is embedded in a sheath (11) of diene elastomer composition, As being the structural elongation of the composite cord, At its total elongation at break, and Af being the elongation at break of the textile fibre. Use of such a cord for the reinforcement of tires, for example in the belt of these tires.

Owner:MICHELIN RECH & TECH SA

Burn protective materials

InactiveUS20090110919A1Comfortable to wearPretreated surfacesHeat resistant fibresPolymer resinGraphite

A method is described for reducing the afterflame of a flammable, meltable material. A textile composite is described comprising an outer textile comprising a flammable, meltable material, and a heat reactive material comprising a polymer resin-expandable graphite mixture.

Owner:WL GORE & ASSOC INC

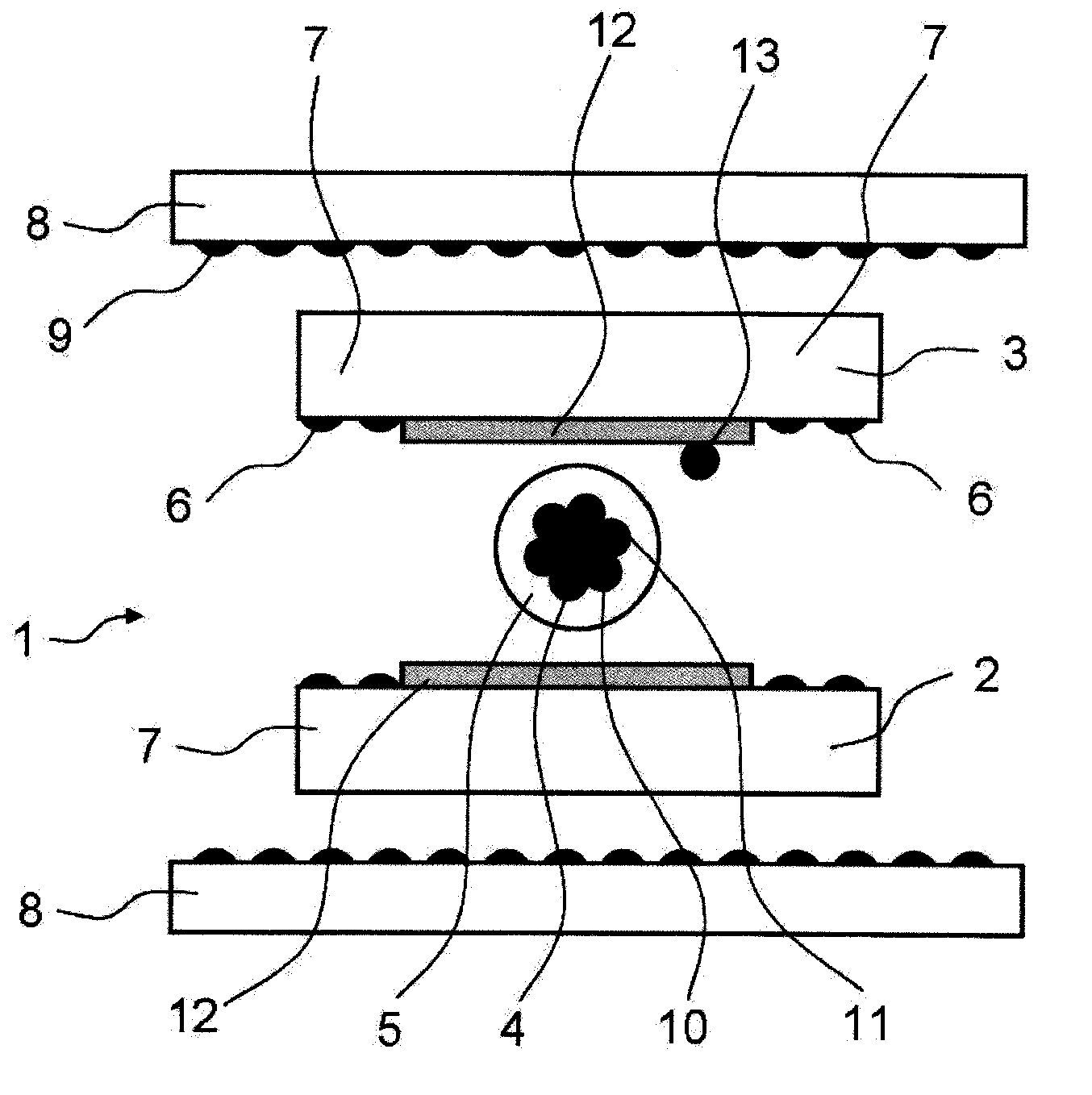

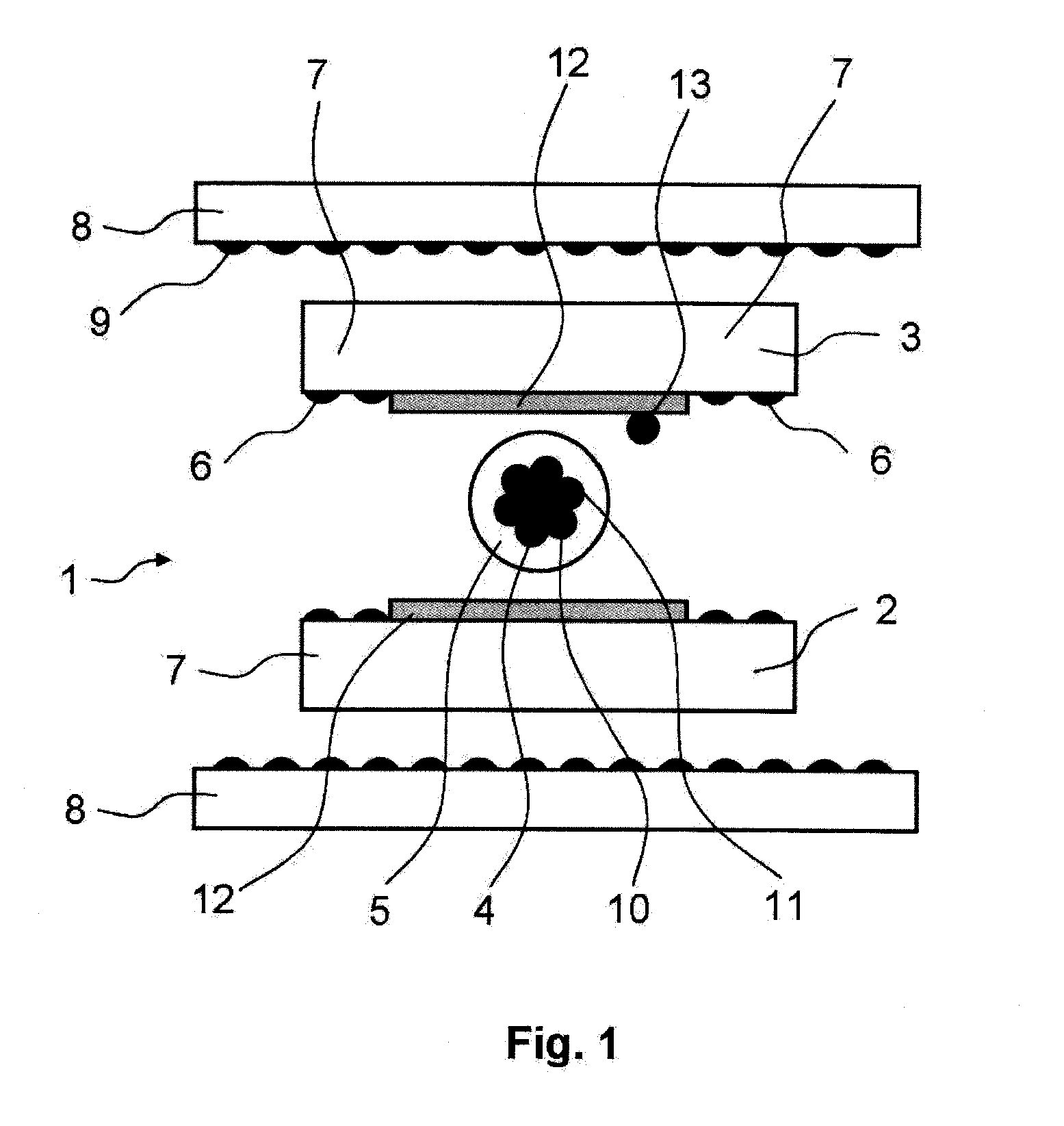

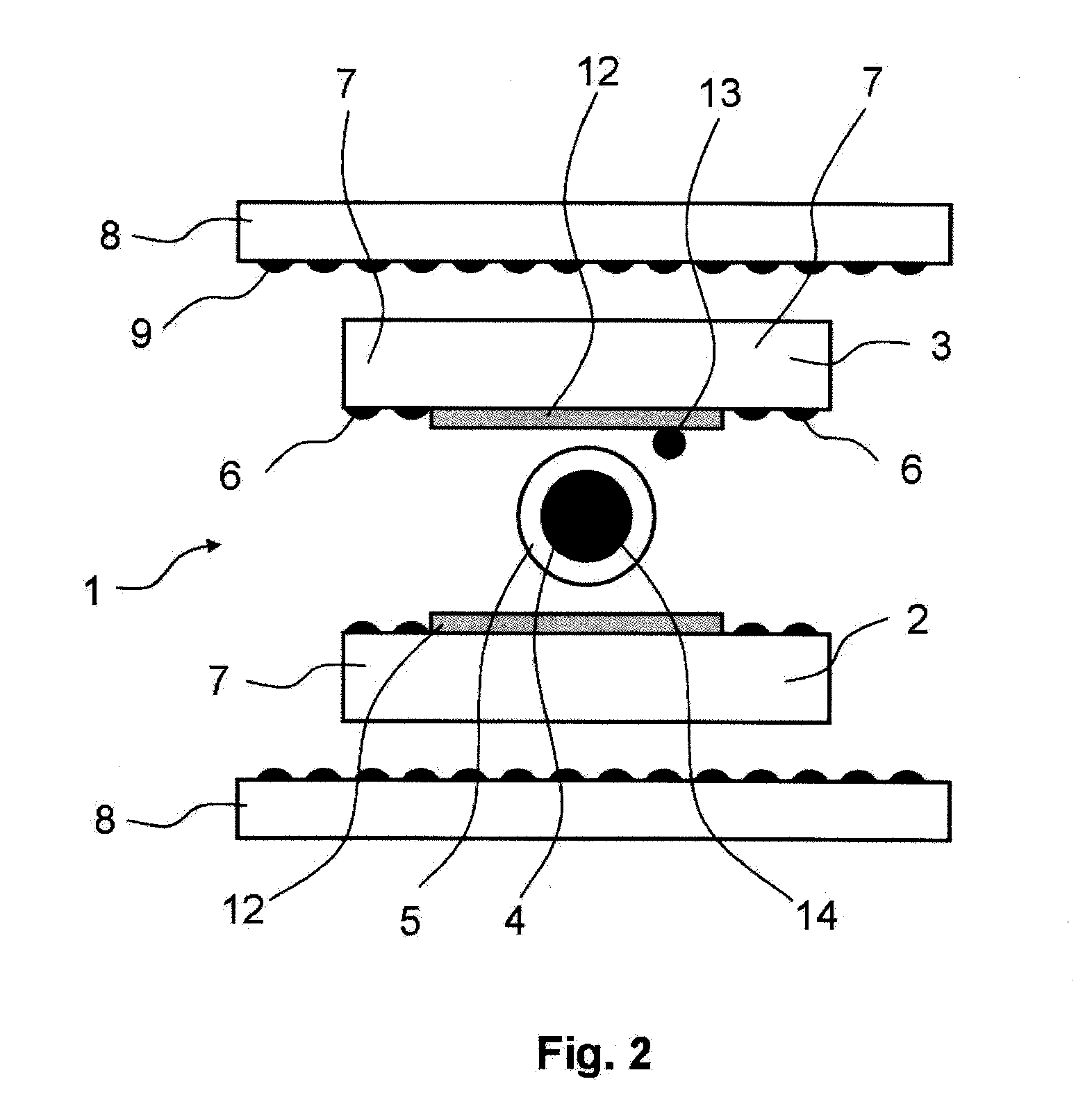

Capacitive sensing arrangement

InactiveUS20060198080A1Water retentionRetain its shapeFixed capacitor dielectricForce measurementElectrical conductorEngineering

A capacitive sensing arrangement includes a body formed of a textile composite material. Both a first electrical conductor and a second electrical conductor are attached to the body such that the conductors are oriented substantially parallel to one another. A capacitance measuring device is coupled to at least one of the conductors.

Owner:DELPHI TECH INC

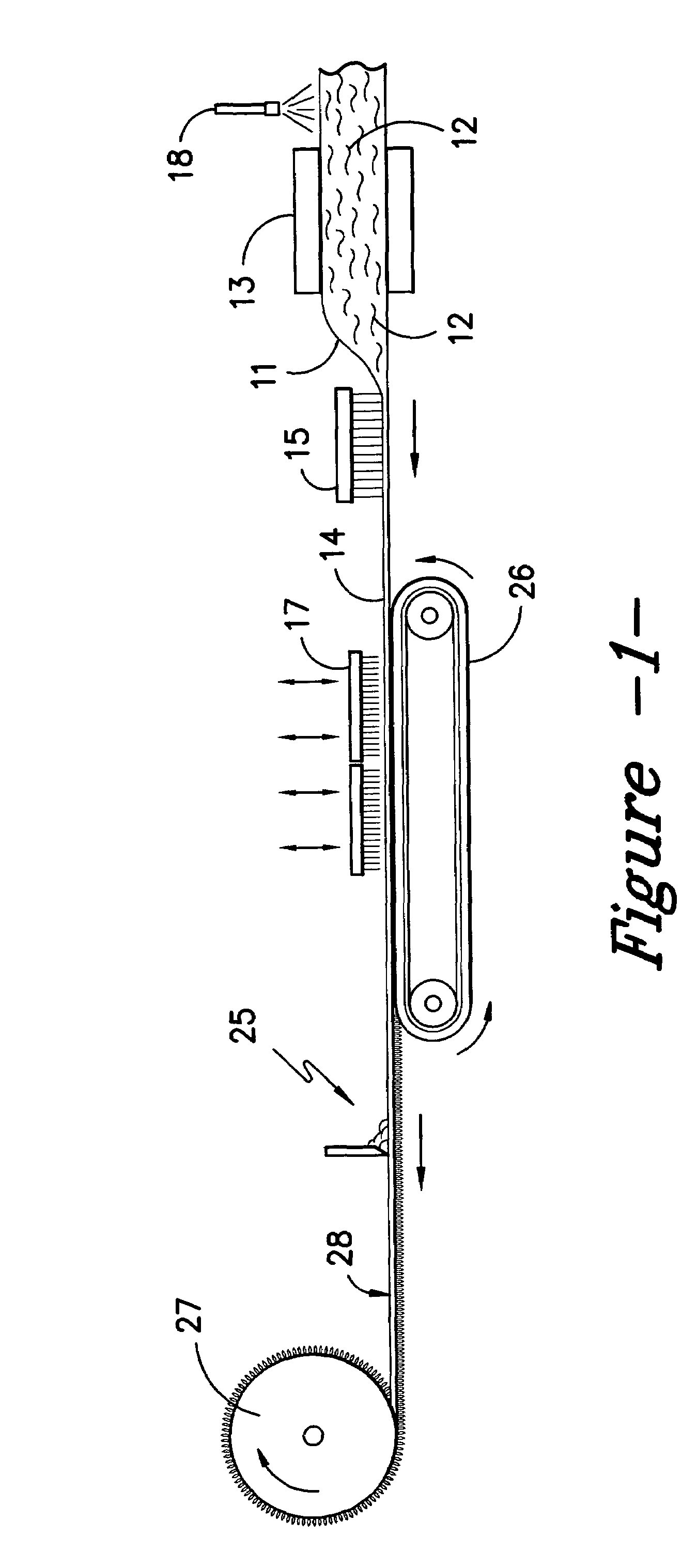

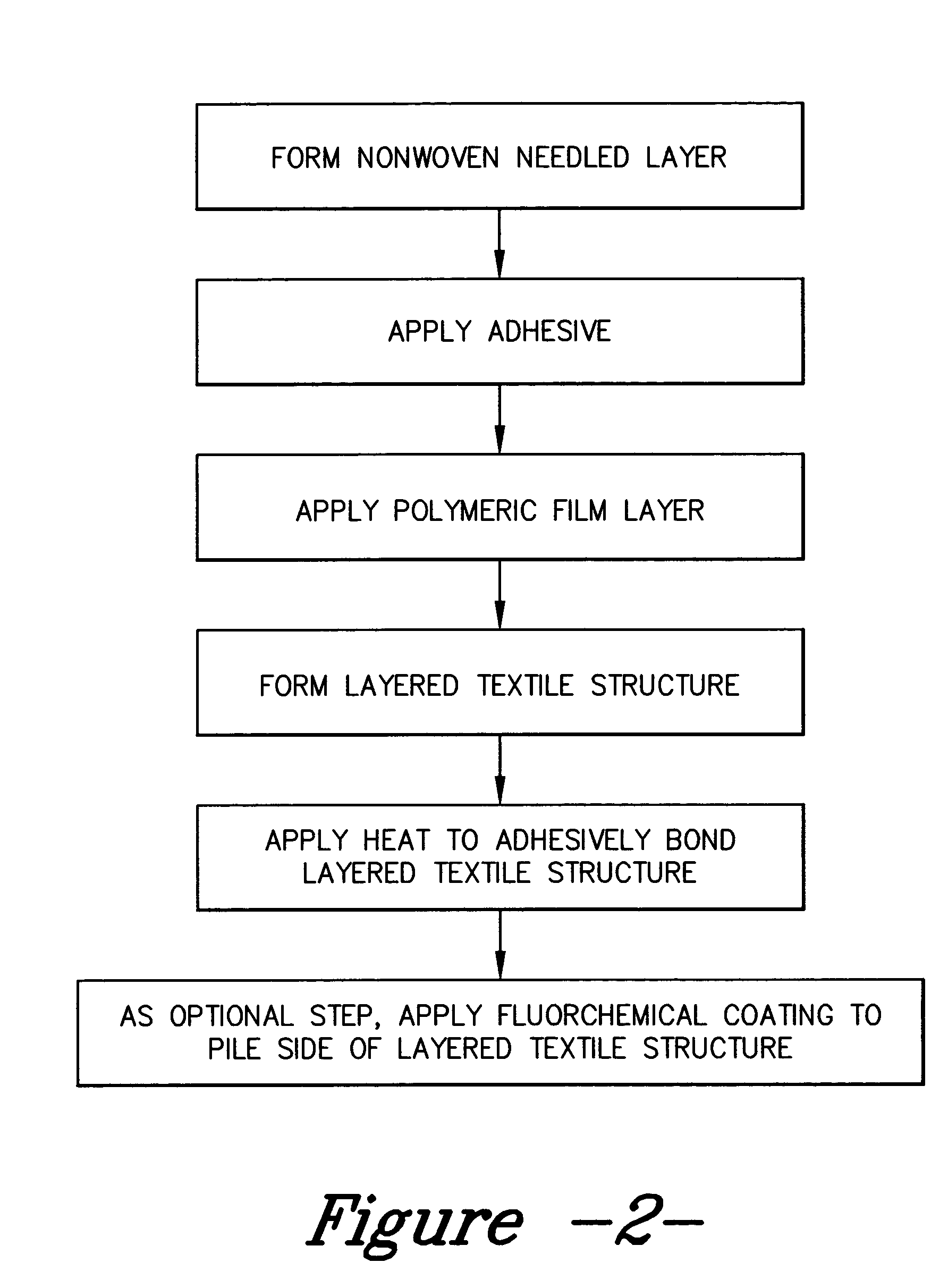

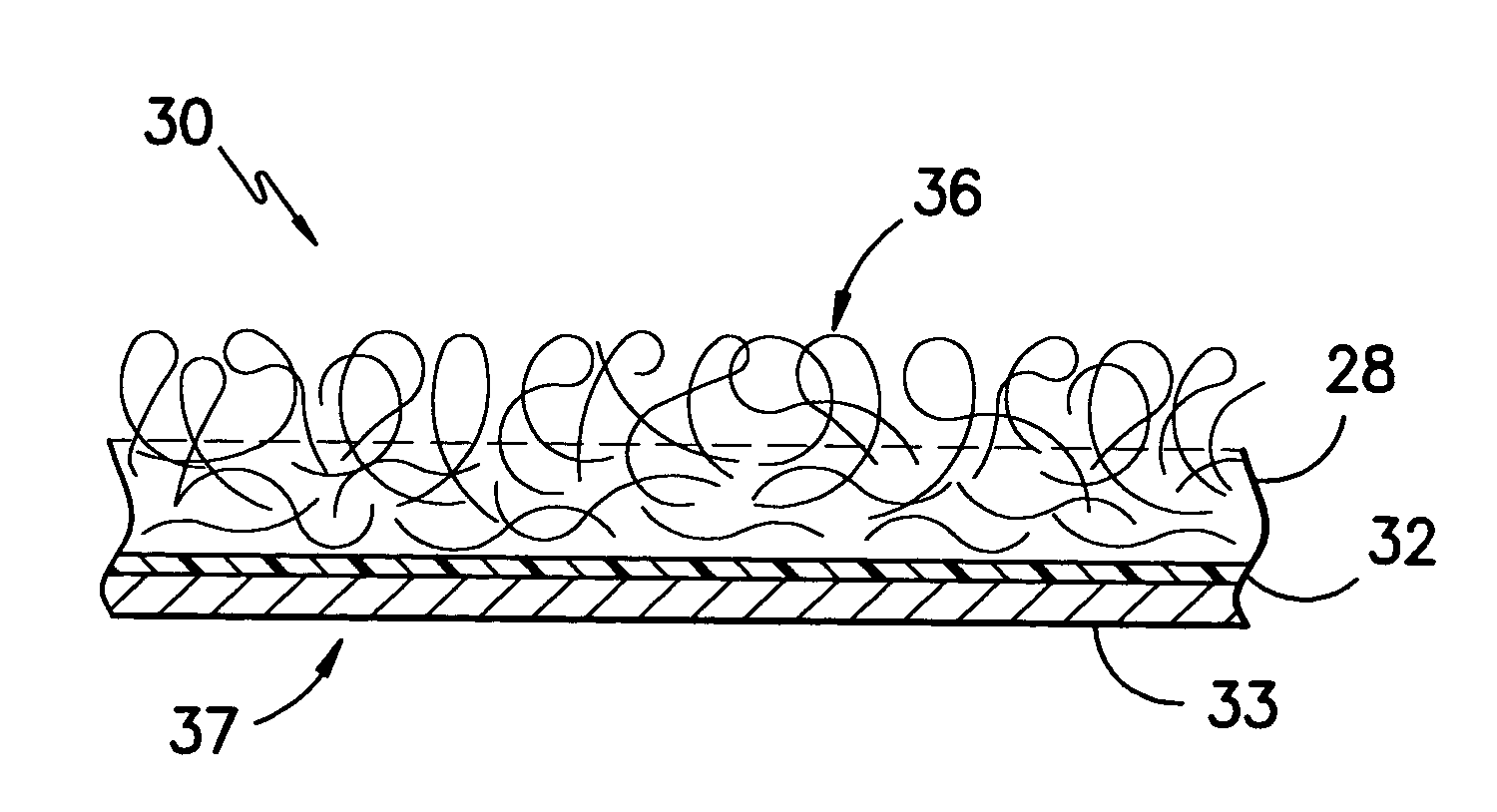

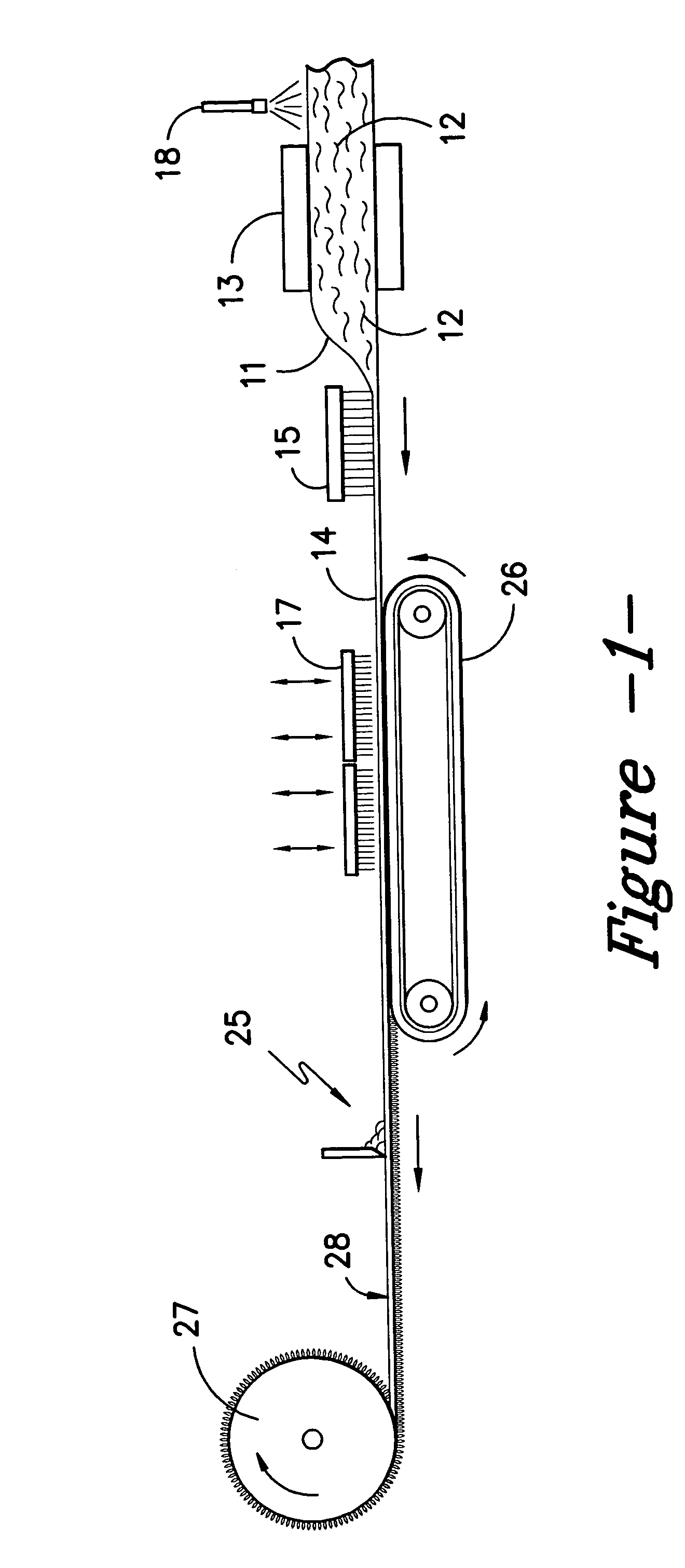

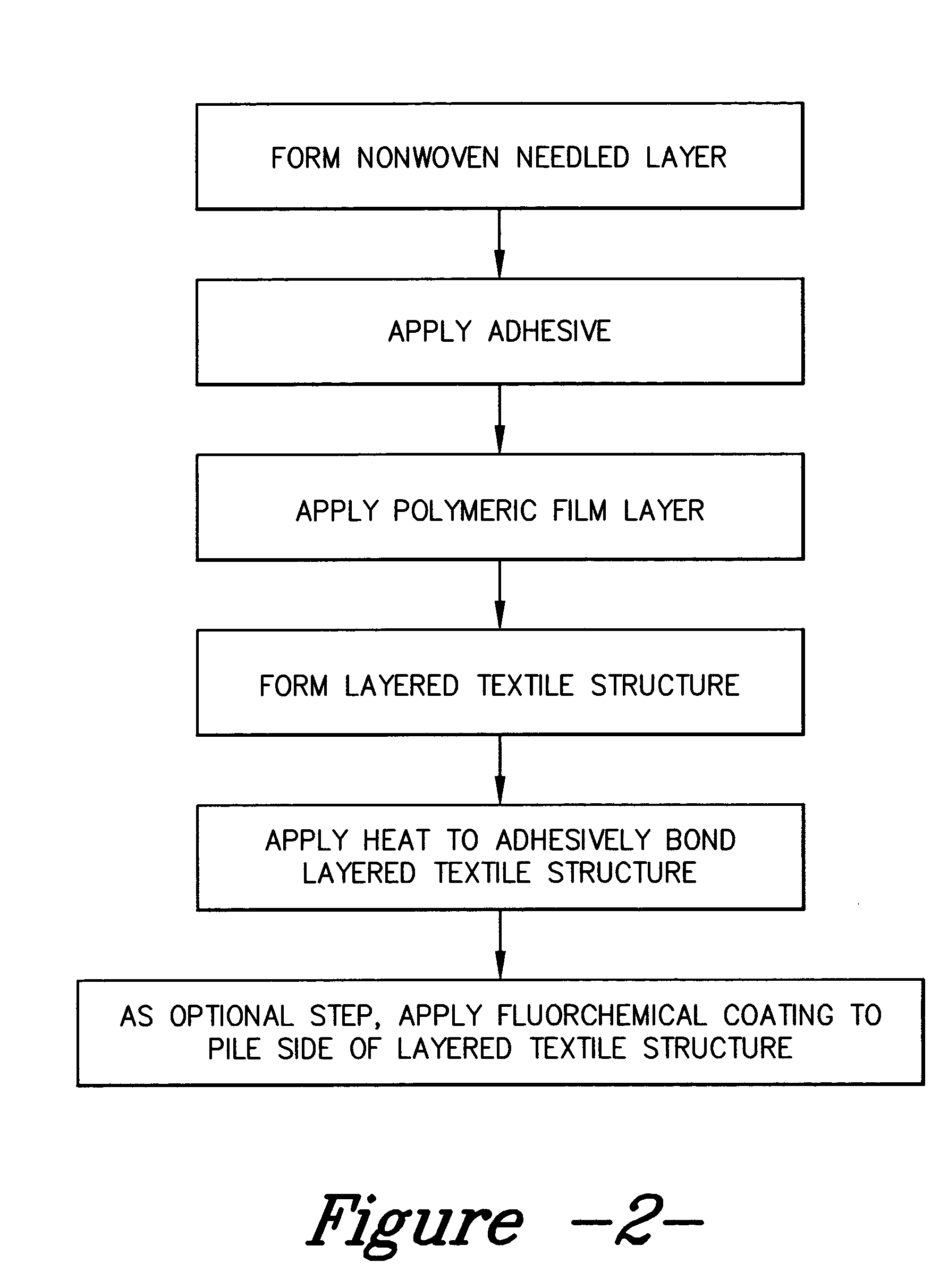

Needled nonwoven textile composite

A layered textile composite product is disclosed which may include a nonwoven needled layer. The nonwoven needled layer is comprised of mechanically interlocked staple fibers which are needled together on a needle punch machine and then bonded with an adhesive layer to a polymeric or polyolefin film layer. The overall layered textile product may be used in several different applications, including for example in automobiles for seating, load floor, trunk linings, floor carpeting, door panel trim, and other interior trim applications.

Owner:MILLIKEN & CO

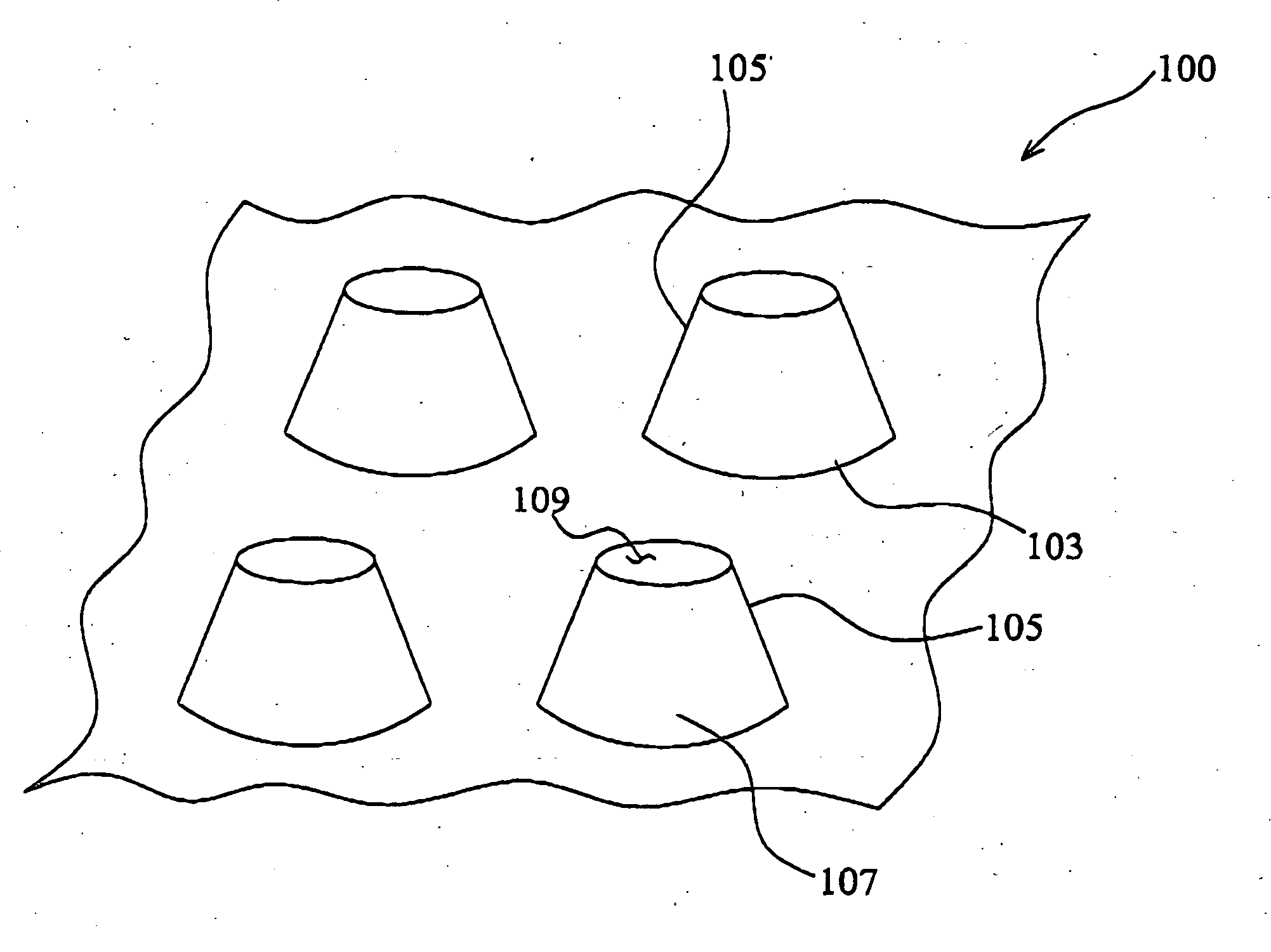

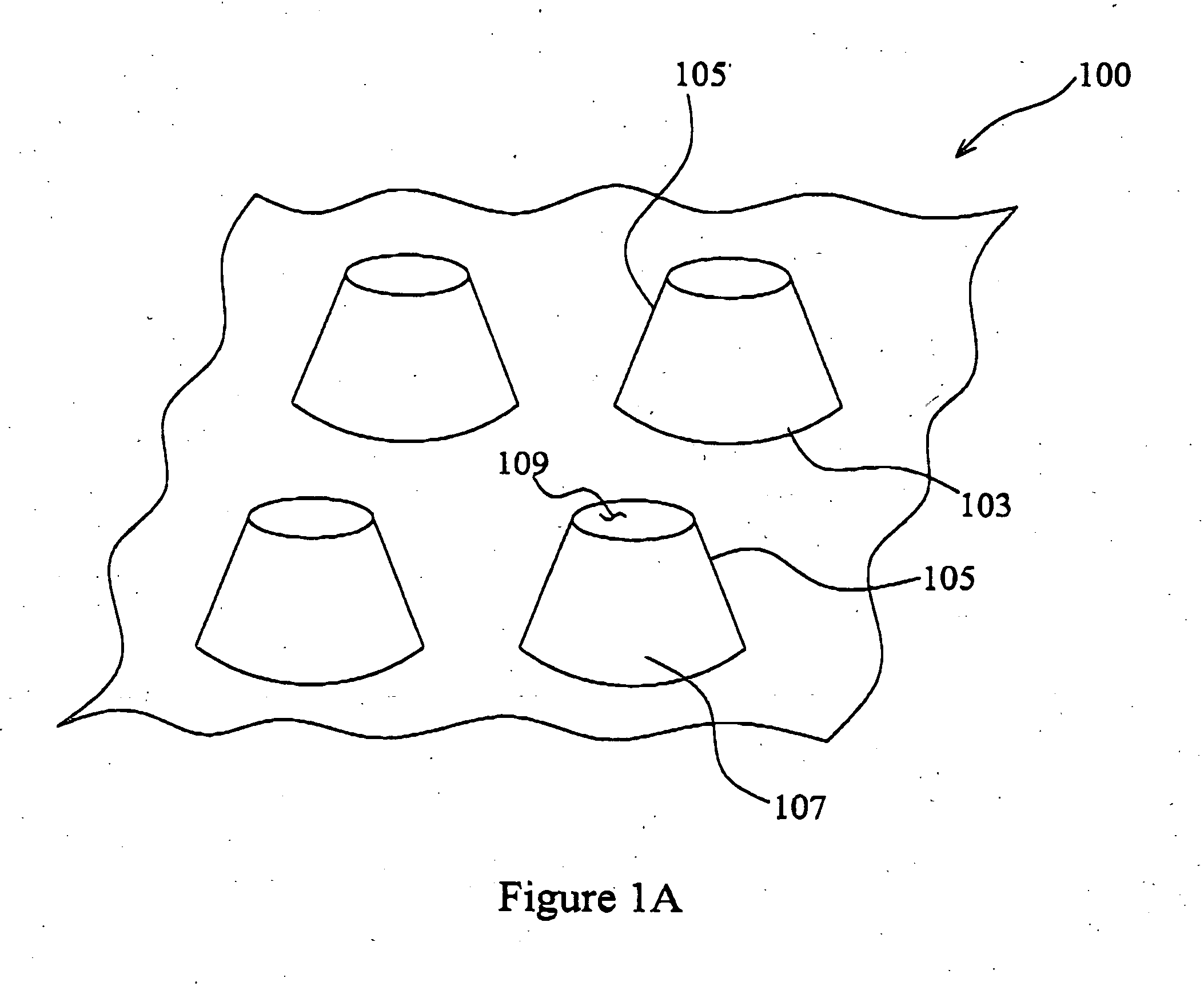

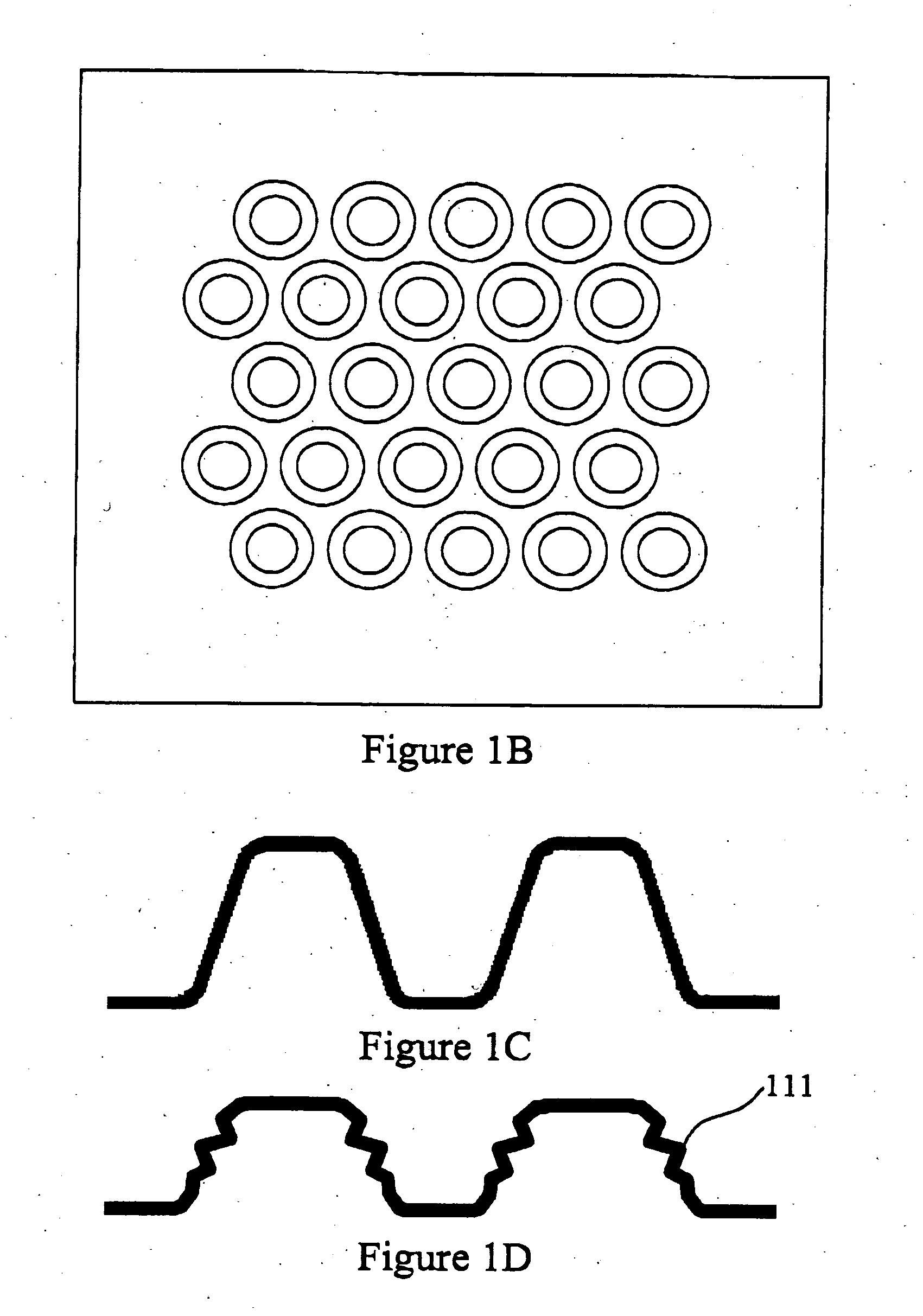

Three-dimensional textile composite structure and manufacture and use thereof

InactiveUS20050196592A1The process is convenient and fastCapacity retentionDomestic containersWood layered productsComposite constructionEnergy absorption

A three-dimensional cellular textile composite structure with energy-absorbing capacities under multiple impacts is provided. The cellular textile composite structure includes a base, and at least one progressively collapsible projection extending from the base for absorbing energies under the multiple impacts. The projection includes a non-woven textile material supported in a thermoplastic matrix material such that the projection is capable of retaining energy-absorption capacity at least after the first impact of the multiple impacts.

Owner:THE HONG KONG POLYTECHNIC UNIV +1

Collagen - Na-MMT complex fiber, and spinning technological process thereof

InactiveCN101503834AStrong interactionImprove mechanical propertiesMonocomponent protein artificial filamentArtificial filament washing/dryingInorganic saltsFiber

The invention discloses novel collagen composite fiber mainly comprising collagen and a small amount of Na-MMT, and a spinning technical method thereof. The proportion of collagen and Na-MMT in the composite fiber counted in portion by dry weight is 10,000:1-100. The main preparation method of the composite fiber comprises: stirring and mixing 15 to 50 weight percent collagen solution and 0.1 to 2 weight percent Na-MMT solution according to a set proportion under a water bath condition between 50 and 80 DEG C; carrying out hot filtration at a temperature between 50 and 80 DEG C after the solutions are evenly mixed; obtaining spinning solution used to imitate collagen-Na-MMT composite fiber after defoaming; extruding the spinning solution through a spinneret under the action of gas pressure at a temperature between 50 and 80 DEG C; and entering inorganic salt coagulation bath to prepare the collagen-Na-MMT composite fiber through solidification. In addition, the intensity, swelling capacity, water absorption, and the like of textile composite fiber can be improved through post treatments such as acetalation and oiling. The collagen-Na-MMT composite fiber can be used for textile materials and biomedical materials.

Owner:SICHUAN UNIV

Textile Composite Article

The application relates to a textile composite article comprising at least one textile made of fibers / filaments, especially in the form of yarns, having a partially internal discontinuous pattern of an impregnating material which penetrates at least partially a cross section of said first textile leading to impregnated areas and non-impregnated areas in accordance with the discontinuous pattern. The non-impregnated areas are air permeable and may comprise a functional coating.Such a treated textile composite is air-permeable and water vapor permeable and has reduced water absorption and re-dry time. In one embodiment the textile composite article shows an additional enhanced flame protection.

Owner:W L GORE & ASSOC GMBH

High voltage transmission line cable based on textile composite material

An electric transmission cable having a current conductive element comprising a braided core formed of a plurality of high modulus synthetic armored yarns, each yarn being of at least 53.6 tex and having a tensile strength of at least 200 cN / tex (centiNewton / tex), and the core being of a diameter in the range of 0.7 mm to 4.5 mm and being surrounded by a quartz sleeve covered on an outer surface thereof by a carbon layer.

Owner:SIMENHAUS ZIDKIYAHU +1

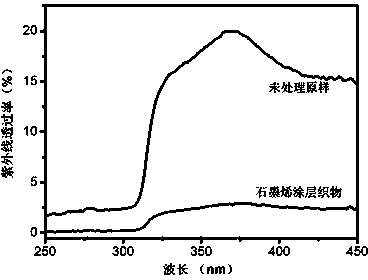

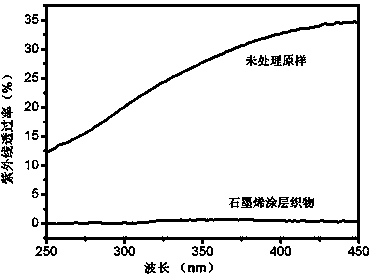

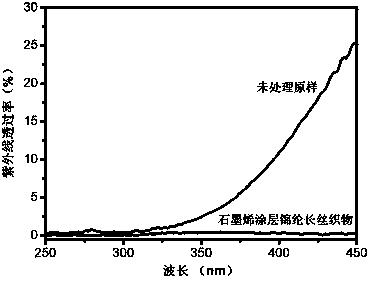

Method for preparing ultraviolet shielding textile composite fabric with graphene nanoplatelets

The invention provides a method for preparing an ultraviolet shielding textile composite fabric with graphene nanoplatelets. The method is characterized by comprising the following steps: performing shock dispersion on a graphene nanoplatelet solution and a nano titanium dioxide solution and adding into a certain quantity of adhesive solution, and fully stirring the mixed solution, wherein the composite fabric is prepared from the following raw materials in percentage by weight: 30-60 percent of graphene solution, 10-30 percent of nano titanium dioxide solution and 30-60 percent of adhesive solution; performing coating with a transfer coating method; performing high-temperature ultraviolet curing on a graphene coating fabric for 5-30 minutes and drying at 75-95 DEG C; and after the fabric is cooled, stripping the graphene coating fabric from transfer coating paper, thereby obtaining the composite material with the ultraviolet shielding function. The method is simple and reasonable in process, easy to operate and high in yield; the using amount of the graphene nanoplatelets is less, and the composite fabric has the high ultraviolet shielding function and can be used in functional textile products such as ultraviolet shielding sun umbrellas and protective clothing.

Owner:QINGDAO UNIV

Rubber oil pipe with efficient heat protection structure and preparation method of rubber oil pipe

InactiveCN104553089AThe preparation method is simple and efficientLow costThermal insulationFlexible pipesInsulation layerComposite film

The invention discloses a rubber oil pipe with an efficient heat protection structure and a preparation method of the rubber oil pipe. The preparation method comprises the following steps: preparing an inner rubber pipe, adhering a heat insulation layer and adhering a high-reflection metal / textile composite film. The high-reflection metal / textile composite film can be used for reflecting heat radiation; the heat insulation layer can be used for effectively reducing heat transferring and heat convection; the heat insulation material layer meeting the size requirements is compounded and fixed on the rubber oil pipe; and the high-reflection composite film is paved on the surface of a heat insulation felt and is combined with the heat insulation felt very well by using an adhesive. The rubber oil pipe has high heat protection efficiency, low cost and good reliability; and the prepared rubber oil pipe with the efficient heat protection structure has excellent mechanical property and heat insulation property and can be widely applied to industries including steel, chemical engineering, petroleum, ship building, automobile manufacturing and the like.

Owner:HEBEI SIBERIA SPECIAL RUBBER

Needled nonwoven textile composite

A layered textile composite product is disclosed which may include a nonwoven needled layer. The nonwoven needled layer is comprised of mechanically interlocked staple fibers which are needled together on a needle punch machine and then bonded with an adhesive layer to a polymeric or polyolefin film layer. The overall layered textile product may be used in several different applications, including for example in automobiles for seating, load floor, trunk linings, floor carpeting, door panel trim, and other interior trim applications.

Owner:MILLIKEN & CO

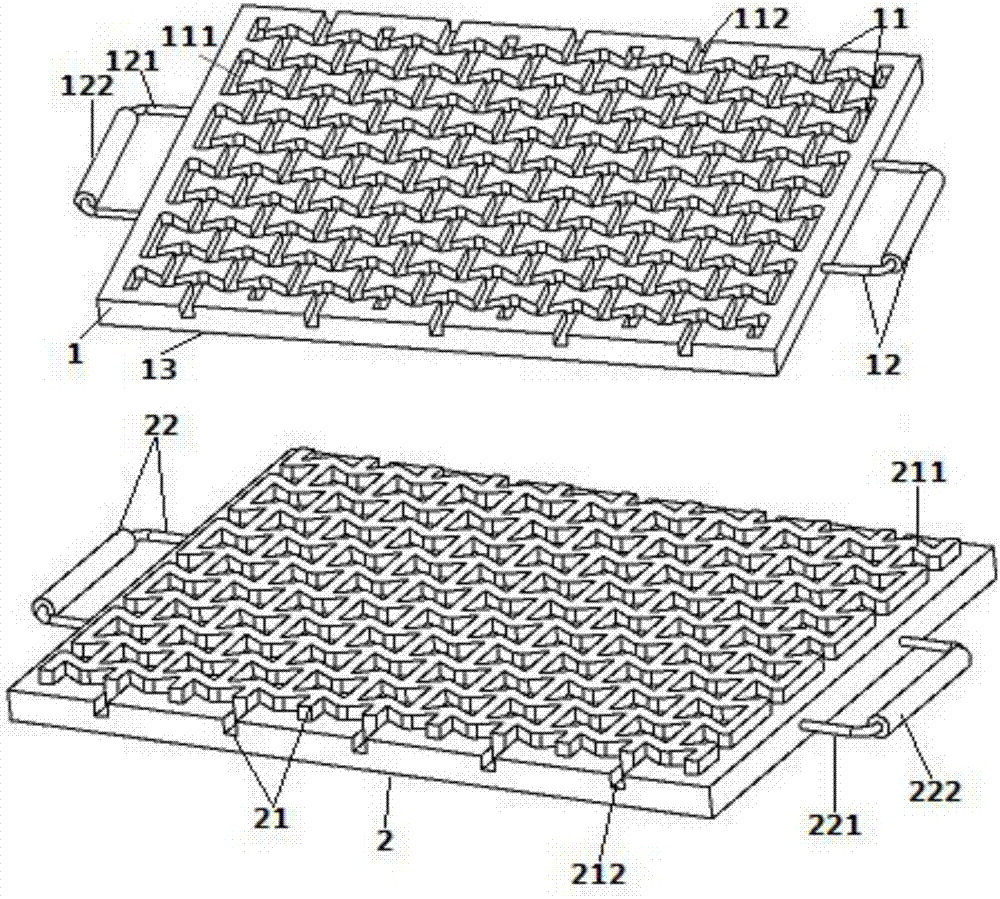

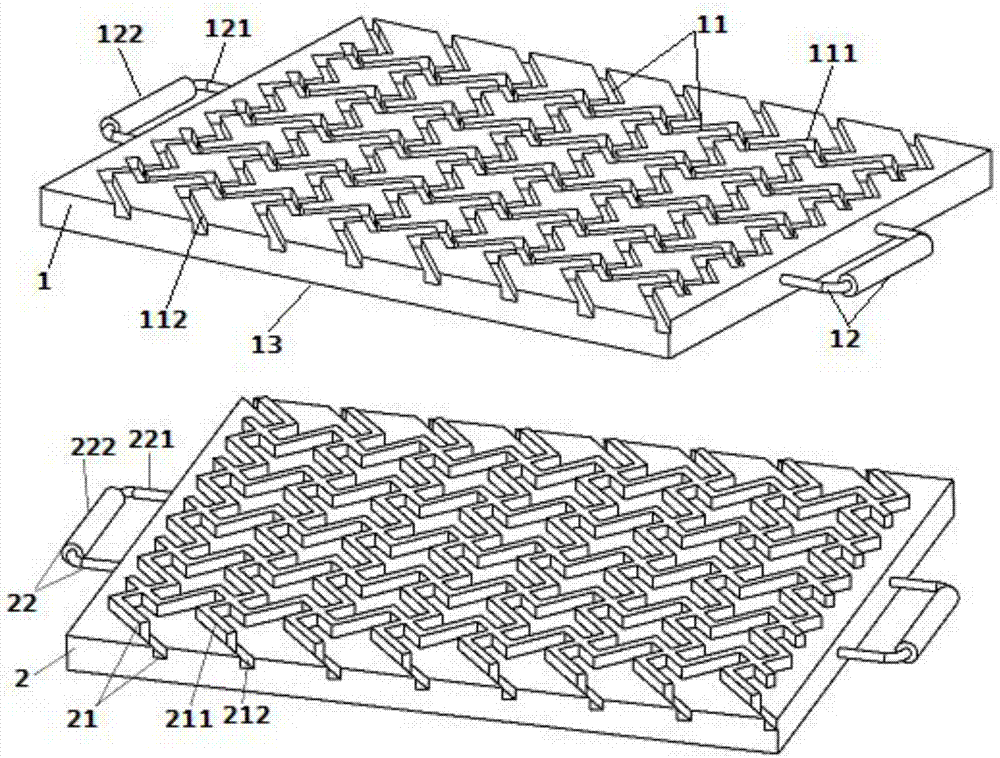

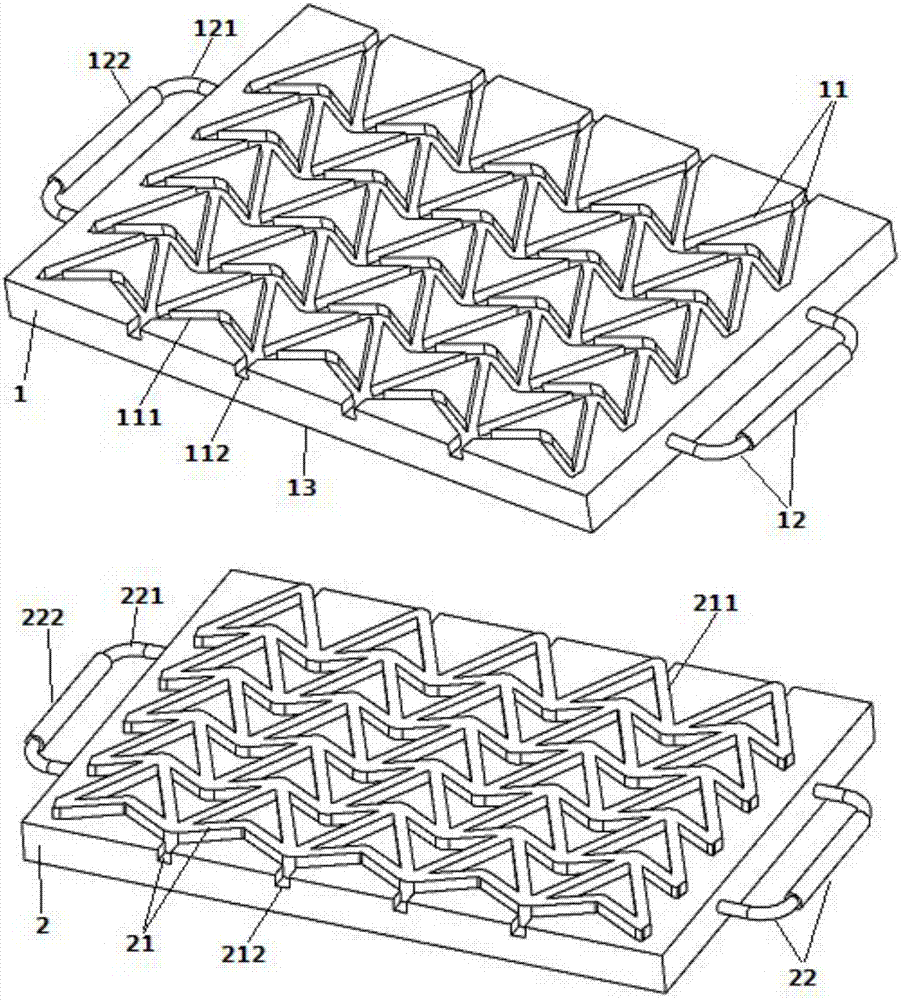

Negative poisson ratio textile composite material forming mold and method

The invention relates to a negative poisson ratio textile composite material forming mold. The negative poisson ratio textile composite material forming mold comprises a female mold and a male mold. The female mold comprises a forming groove and a heating plate. The forming groove comprises a structure groove and a first drainage groove, wherein the structure groove is provided with a negative poisson ratio structure. The heating plate is located on the back surface of the forming groove and used for heating melting of a base material. The male mold comprises an extrusion mold. The extrusion mold comprises a convex groove and a second drainage groove. The size and the shape of the convex groove are matched with those of the structure groove, and thus the convex groove and the structure groove can be coupled to each other. The first drainage groove and the second drainage groove are used for controlling viscous liquid to flow into and flow out of the structure groove. The invention further relates to an application method of the negative poisson ratio textile composite material forming mold. According to the negative poisson ratio textile composite material forming mold and the application method thereof, a two-dimensional textile composite material or three-dimensional textile composite material with the negative poisson ratio effect can be conveniently and rapidly made.

Owner:DONGHUA UNIV

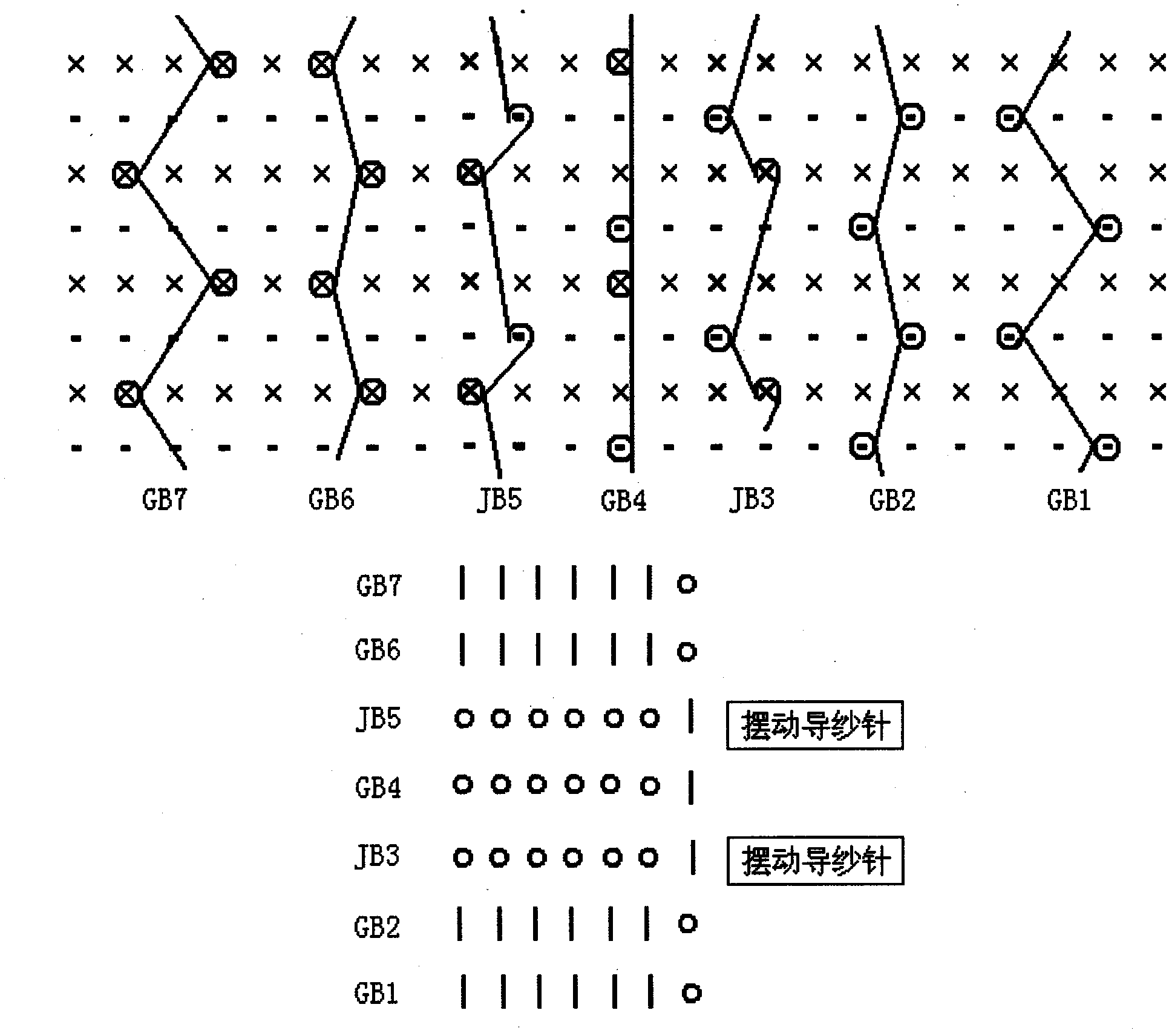

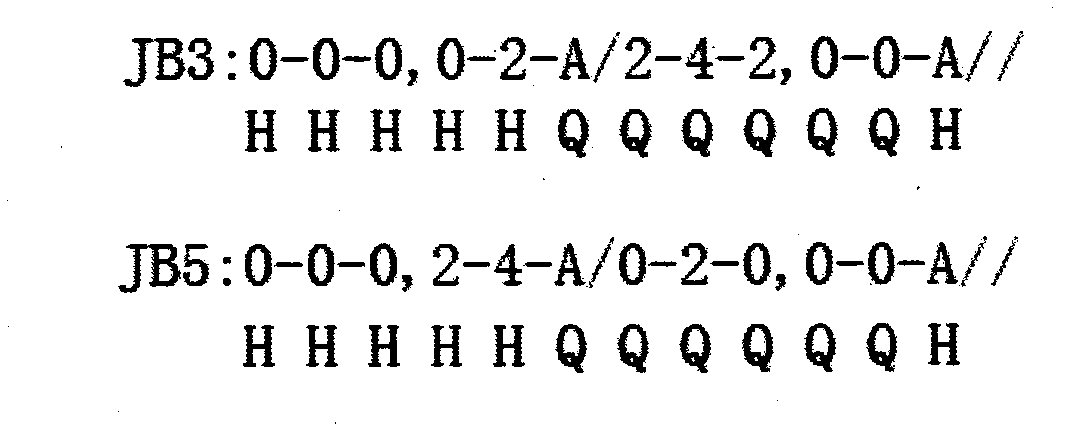

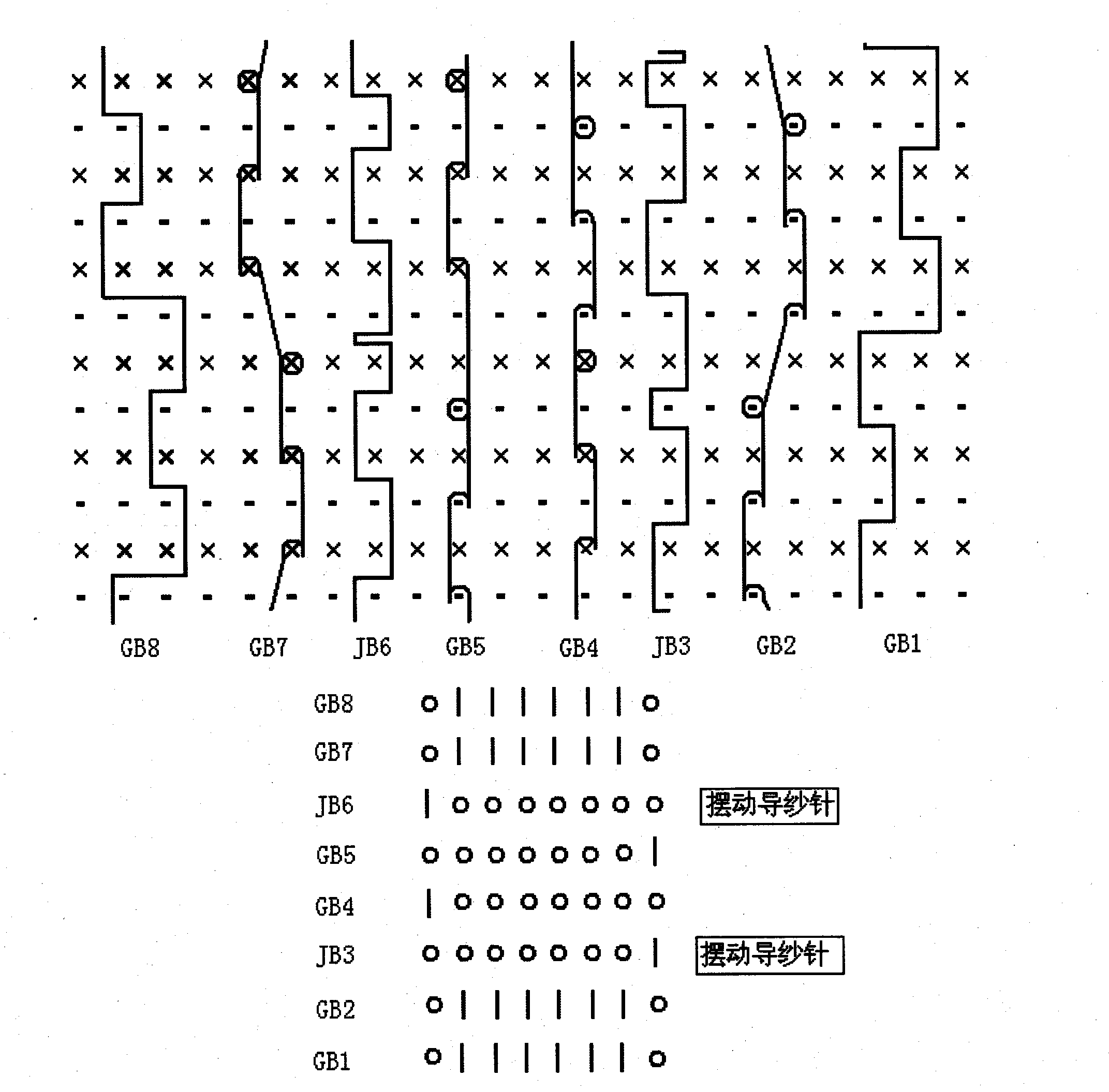

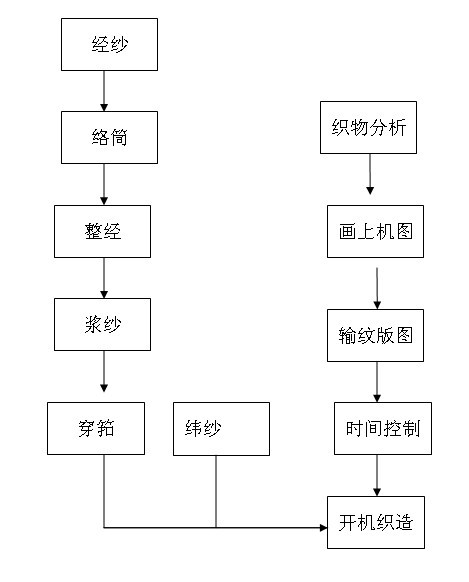

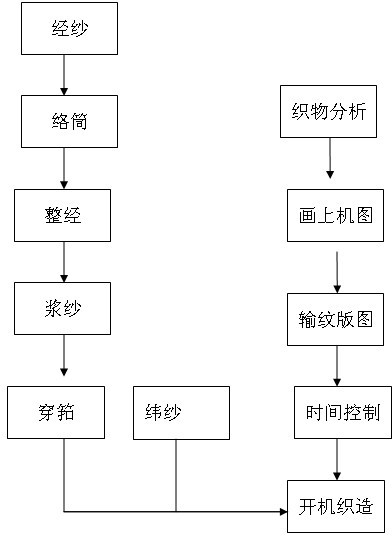

Traceless joint fabric knitting method of double-needle-bed warp knitting machine

InactiveCN102587023AEasy to prepareSuitable for industrial productionWarp knittingEngineeringTextile composite

The invention provides a traceless joint fabric knitting method of a double-needle-bed warp knitting machine, which is characterized by including the following steps of selecting warps materials, setting yarn laying motions of guide bars and utilizing yarn threading and aligning process; beaming warps; mounting the guide bars with swing yarn guide needles in a needle bed working area, performance traceless jointing at the edges of fabrics of a front needle bed and a rear needle bed; making up information of the yarn guide needles; performing machine-boarding processing adjustment and knitting; and arranging the fabrics. By the traceless joint fabric knitting method of the double-needle-bed warp knitting machine, the technical problem of cylindrical knitting by twice or more guiding on the double-needle-bed warp knitting machine can be solved, joint wrinkles of preformed parts of various cylindrical warp knitting composite materials are eliminated, mechanic performance of the spinning composite materials are improved, ultra-wide products can be provided for cloth used in shed cover industry. In addition, perfect traceless jointing can be provided for warp-knitted fully-formed clothes and appearance and comfortableness of the clothes can be improved.

Owner:DONGHUA UNIV

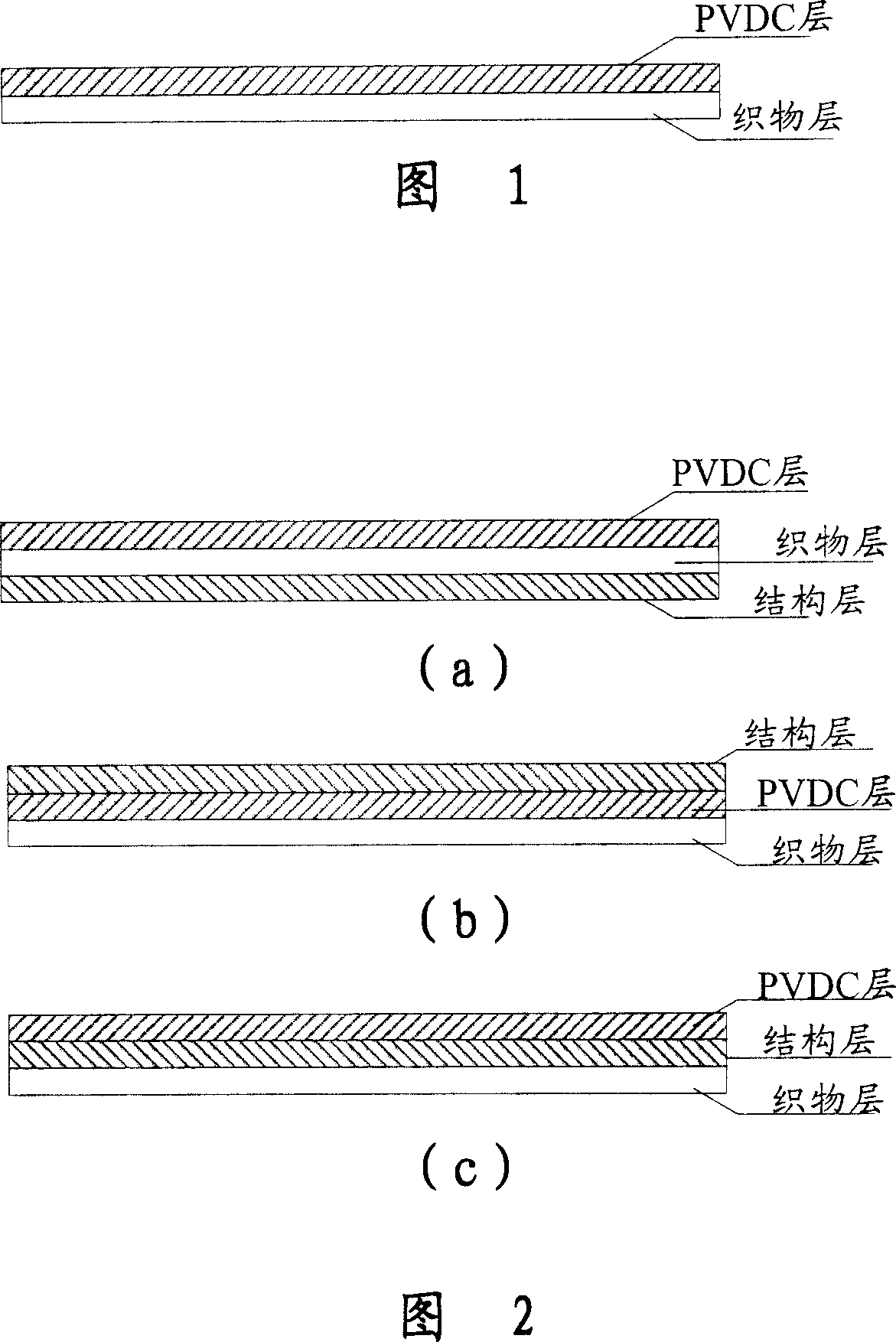

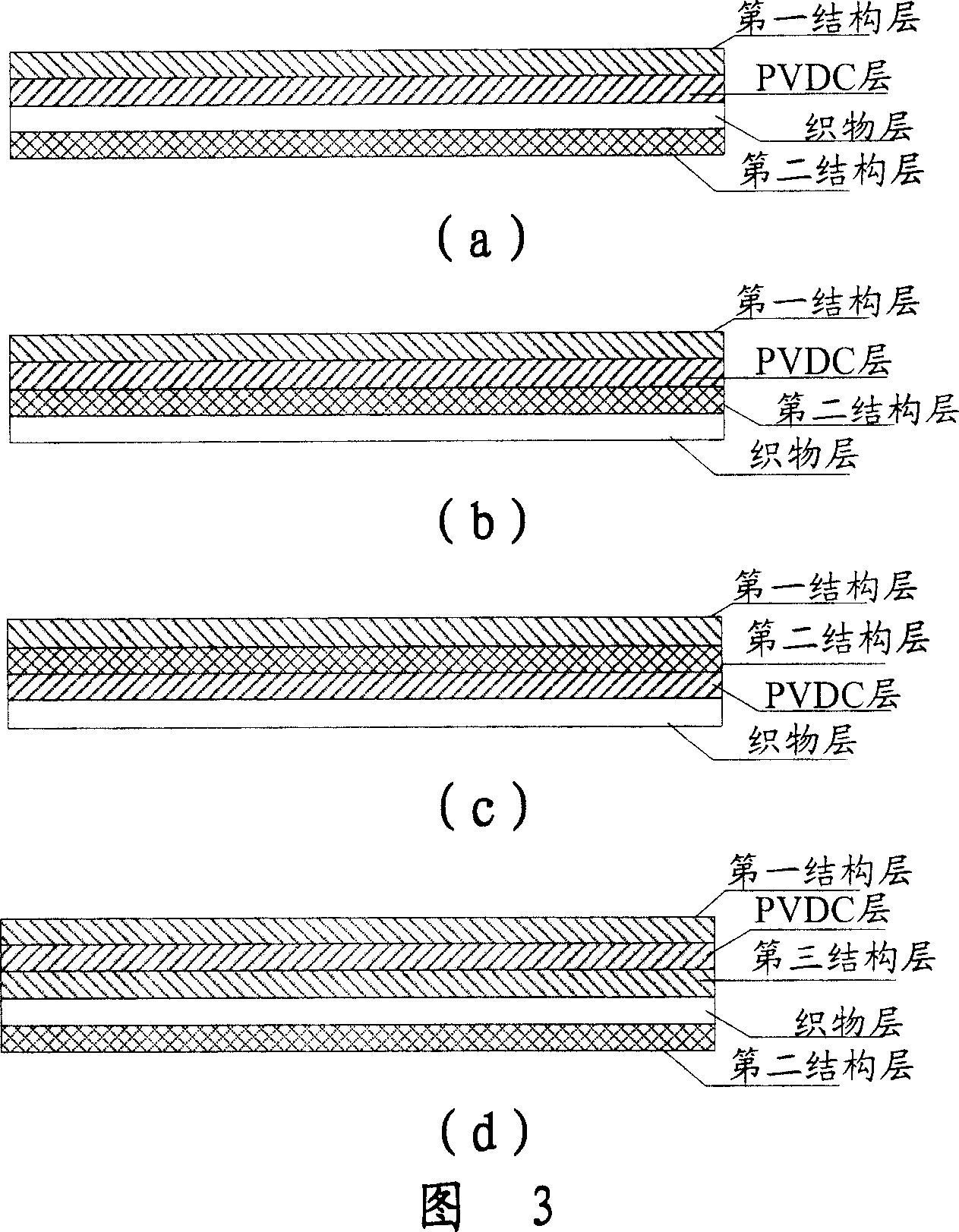

Composite material for weaving

InactiveCN101112805ALight in massImprove the protective effectSynthetic resin layered productsProtective garmentEngineeringProtection layer

The invention provides a spinning composite material which comprises a protection layer and a fabric layer; wherein, the protection layer comprises a PVDC layer. The protection layer further comprises one layer or more than one structure layer; the structure layer can be arranged between the fabric layer and the PVDC layer or between the fabric layer and any external side of the PVDC layer. The structure layer comprises a PVDC layer, a fabric layer, a thermal synthesis layer, a framework layer, a camouflage layer, an agglutination layer and a protection layer. By the invention, the fabric composite material has high gas defense performance, physical and mechanical performance and anti-aging and weatherability, and light weight. The invention is especially suitable for making the safety protection of tents, blindages and protection clothes, etc.

Owner:中国人民解放军62026部队 +2

Textile Composite Material Comprising Nanofiber Nonwoven

InactiveUS20110172507A1Good removal effectUpper layerPlastersPharmaceutical delivery mechanismNanofiberEngineering

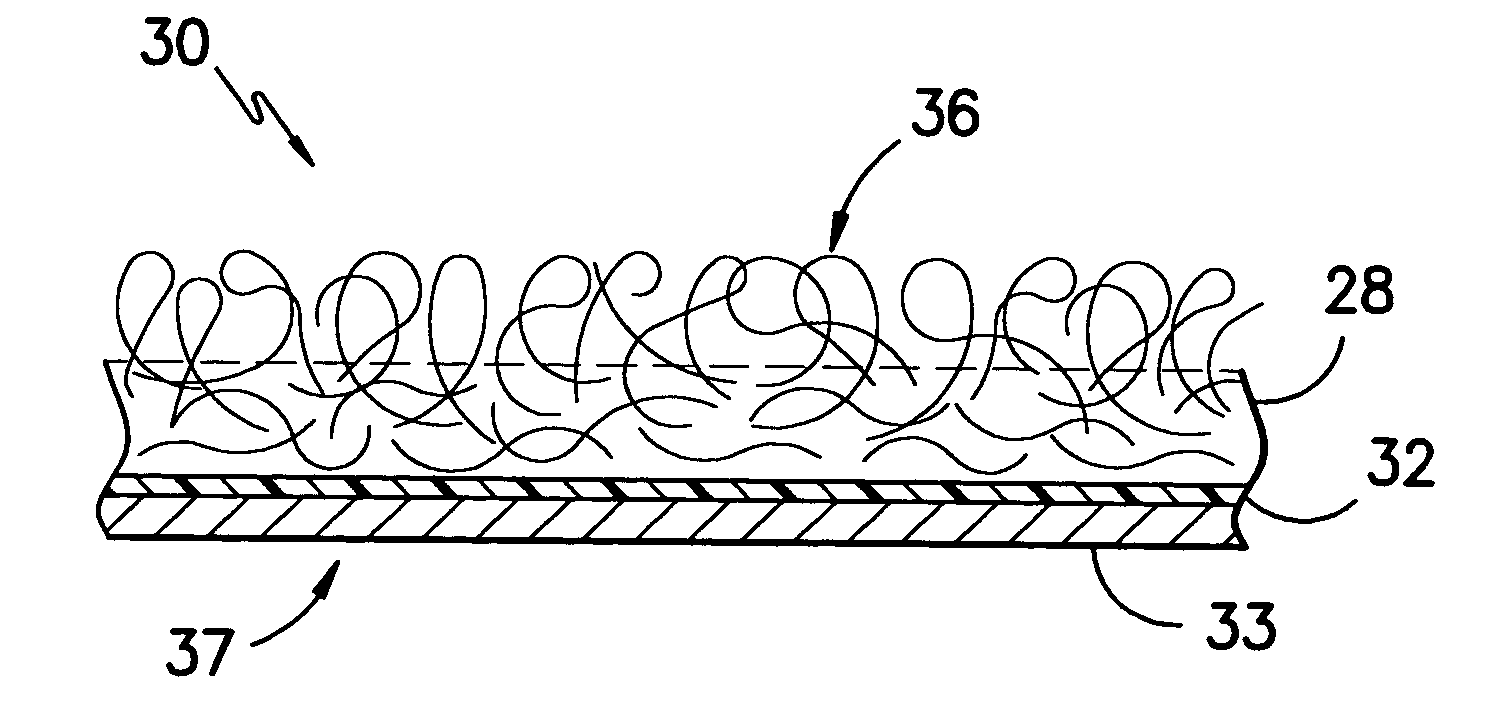

Among others, the present invention provides an absorbent textile composite material which comprises a flexible carrier layer and an active layer connected with the carrier layer, wherein the active layer comprises a nanofiber nonwoven optionally filled with a superabsorbent.

Owner:SNS NANO FIBER TECH

Weaving method for same-width and different-thickness three-dimensional woven fabric

The invention belongs to the field of textile composites and particularly discloses a method for producing a same-width and different-thickness three-dimensional woven fabric on a general shuttleless loom. According to the method, the problem that the thickness of textile on the same fabric width can be variably designed under the condition that the machine is not stopped. The invention has the technical scheme that the weaving method comprises the following steps of: firstly, respectively designing a plurality of weave diagrams for the required textile thickness; secondly, sequentially sorting the weave diagrams and designing to change the weave diagram every a period of time; and then simultaneously lifting residual warp yarns on a heald frame and warp yarns of an adjacent system when the thickness of the textile is reduced by one layer. The subsequent operation is finished in the manner and textiles with variable thicknesses can be woven on the general shuttleless loom without stopping, and thus the production efficiency is increased. According to the weaving method disclosed by the invention, the field of products woven by the shuttleless loom is enlarged and the same-width and different-thickness fabrics suitably prepared from composite material are developed.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

Textile Composite Material Comprising Nanofiber Nonwoven

Among others, the present invention provides an absorbent textile composite material which comprises a flexible carrier layer and an active layer connected with the carrier layer, wherein the active layer comprises a nanofiber nonwoven optionally filled with a superabsorbent.

Owner:SNS NANO FIBER TECH

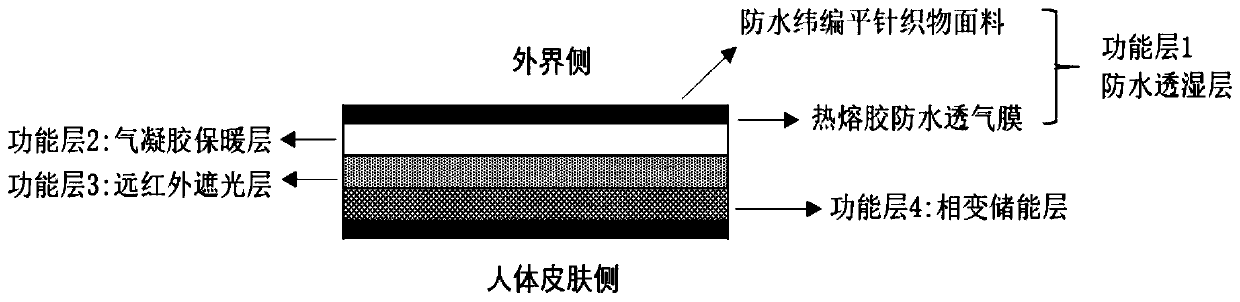

Aerogel based high-heat retention textile composite and preparation method thereof

InactiveCN110077063ASolve the problem of falling powderAvoid destructionMaterial nanotechnologySynthetic resin layered productsInsulation layerThree-dimensional space

The invention relates to an aerogel based high-heat retention textile composite and a preparation method of the aerogel based high-heat retention textile composite, and the aerogel based high-heat retention textile composite sequentially comprises a waterproof and moisture permeable layer, an aerogel heat insulation layer, a far infrared light shielding layer, a phase change energy storage layer and a waterproof and moisture permeable layer from outside to inside. The aerogel based high-heat retention textile composite solves the problem that a powder of an aerogel falls off when the aerogel is used as a heat insulation material, the aerogel is prevented from being dried again in the application process of the aerogel to break the three-dimensional space structure, the advantage of the heat conductivity coefficient is protected against damages, the defect of high loss of the thermal radiation heat of the aerogel, as a main body of the heat insulation material, is improved, the serviceability and the heat retention of the material are further improved, the material achieves the self-temperature regulation function, and the aerogel based high-heat retention textile composite has an excellent market application prospect.

Owner:上海驰纺材料科技有限公司

Production process of parallel composite yarn and fabric thereof

InactiveCN108823715AGood moisture absorption and air permeabilityFunction increaseWeft knittingWarp knittingYarnFiber

The invention belongs to the field of textile composite fiber, and discloses a production process of a parallel composite yarn, which comprises the following steps: a prior water-soluble vinylon plying and untwisting process is utilized for spinning to obtain an untwisted yarn, the untwisted yarn and a skeleton yarn are combined through a doubler winder, then, a two-for-one twister is used for twisting so as to obtain the parallel composite yarn, wherein the inner part is the untwisted yarn and the outer part is the skeleton yarn, according to the production process, the prior textile processtechnology is used to process and prepare the novel parallel composite yarn and fabric, so that the investment risk at the early stage of a project can be avoided, and the consumption demand of the market and consumers on the bionic functional fabric can be met as soon as possible.

Owner:王武英

Process for producing laser simulated jacquard-imitated textile composite fabric

ActiveCN103882649AHigh pattern finenessIncrease the level of detailPattern makingTextile decorationLaser engravingEngineering

The invention relates to a process for producing a laser simulated jacquard-imitated textile composite fabric. The process comprises the following steps: arranging a base fabric on a fabric rolling rack of an open width dynamic continuous laser carving machine in open width, wherein the temperature of a processing environment is 22-26 DEG C, the humidity is 60-80 percent, the width of fabric is less than or equal to 1.8m, and the vehicle speed is 0.01-5.4m / min; designing a 8-bit grey-scale map in an BMP format needing to be subjected to laser ablation in a computer; setting process parameters on the open width dynamic continuous laser carving machine, wherein the laser speed V is set to be 1000-1500m / min; the distance Y of the laser in the vertical direction is 0.45-0.60mm; the whiteness W is 0-100 percent; the blackness B is 0-100 percent; and the width of fabric is less than or equal to 1.8m; and operating the carving machine for carving. The problems that inside and outside carving of the laser carving machine is non-uniform, the light spots are large, the production efficiency is low and the carving breadth is limited and the like are solved, and the effects that fabric patterns are high in elaborate degree and the gradient three-dimensional concave-convex perspective visual impression is strong are achieved under the condition that the strength is guaranteed.

Owner:GUANGDONG XINFENG TECH

Preparation method of moisture-curing polyurethane hot melt adhesive for textile composite

ActiveCN104804697ALower Shore HardnessGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method of a moisture-curing polyurethane hot melt adhesive for textile composite. A diethylene glycol phthalic anhydride polymer is introduced into a polyhydric alcohol raw material, a benzene ring in polyhydric alcohol has higher stiffness and can provide higher peel strength, and the crystallinity is greatly reduced under the benzene ring steric effect, so that the product softness is substantially improved. The softness of a PUR (polyurethane) product which is synthesized with the technical scheme and is mainly applied to the textile composite field is improved while the peel strength of the PUR product is substantially improved.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Robust pre-impregnated yarn for manufacturing textile composites

ActiveUS20130302604A1Reduce viscosityHigh level of abrasion resistanceEngine sealsLayered productsYarnFiber

A composite prepreg yarn designed and constructed is a very large, strong yarn with resin infused throughout, which can be used to prepare composite preforms via conventional Maypole braiding or other textile processes. The invention increases the loads that can be transmitted by the cured yarn in a composite structure, decreases the stickiness that can prevent their use in braiding and other textile processes, provides protection to the high-strength fibers from abrasion that is encountered during and after composite preform manufacturing via braiding.

Owner:AUBURN UNIV

Biological reactive phosphate based continuous glass fiber textile composite and application thereof

The invention discloses a biological reactive phosphate based continuous glass fiber textile composite and application thereof. The composite comprises biological reactive phosphate based continuous glass fiber fabric and biocompatible polymers or comprises blended fabric and biocompatible polymers, wherein the blended fabric is prepared from biological reactive phosphate based continuous glass fiber and polylactic acid fiber. The mechanical performance of the composite reaches the level of human bones, the mechanical property is matched with that of bone tissue, and meanwhile the composite has excellent biocompatibility, degradability and absorbability, can be compatible with natural bones and is good in processing performance.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

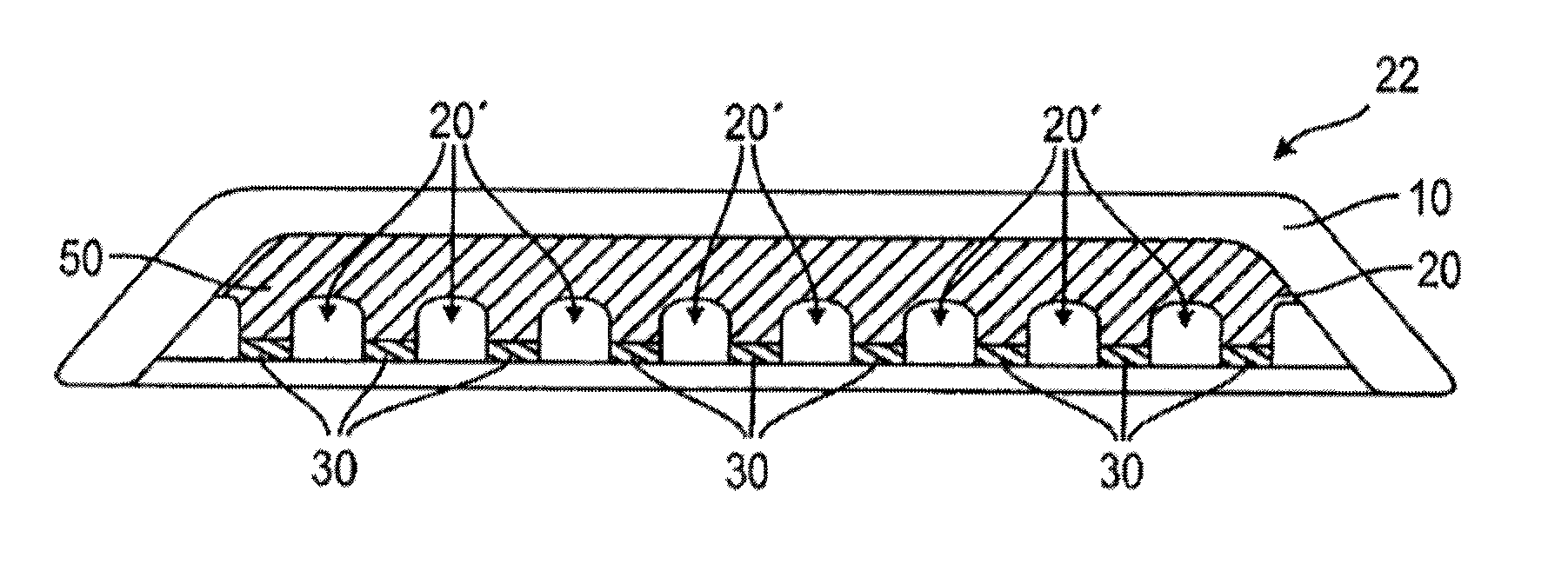

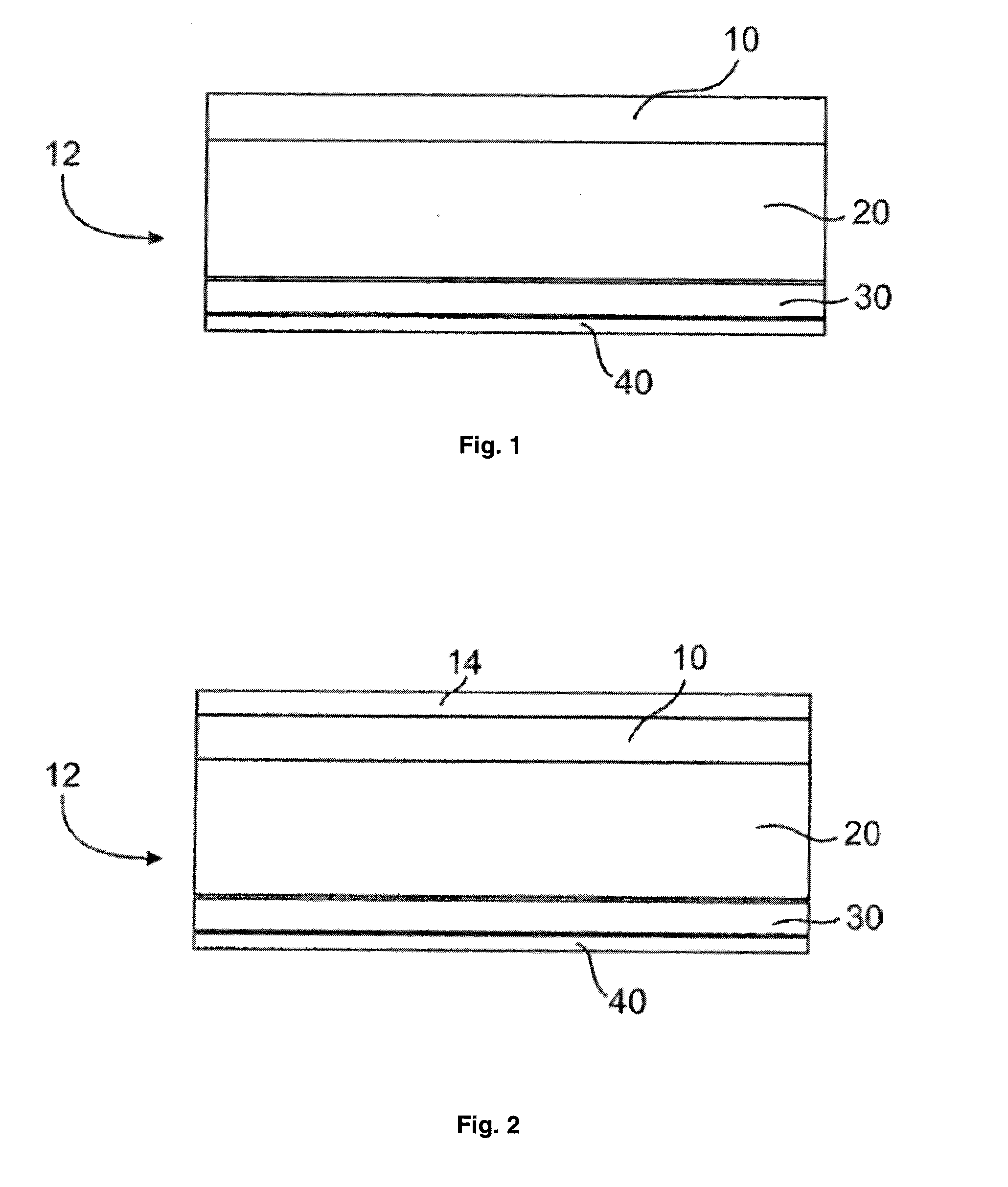

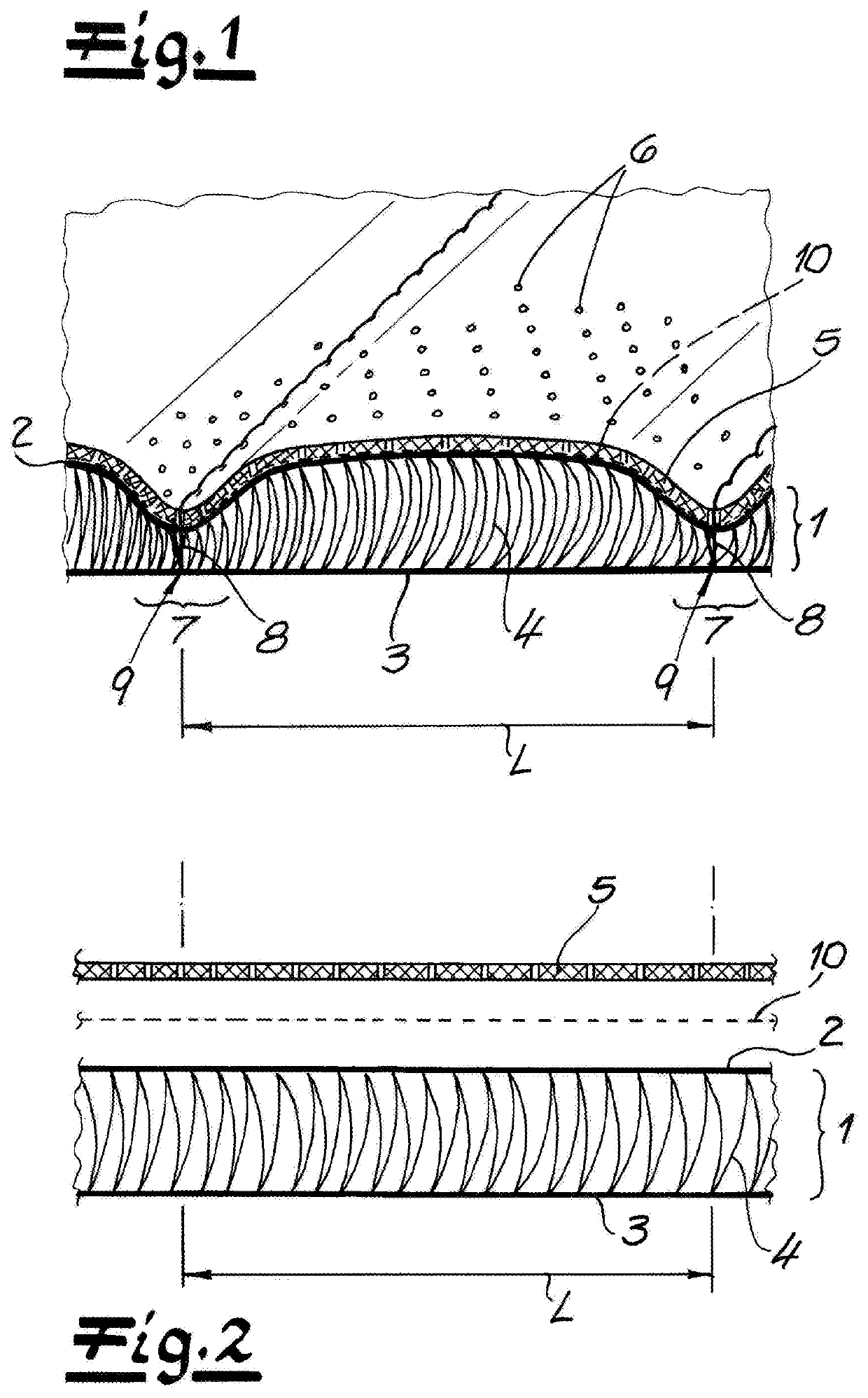

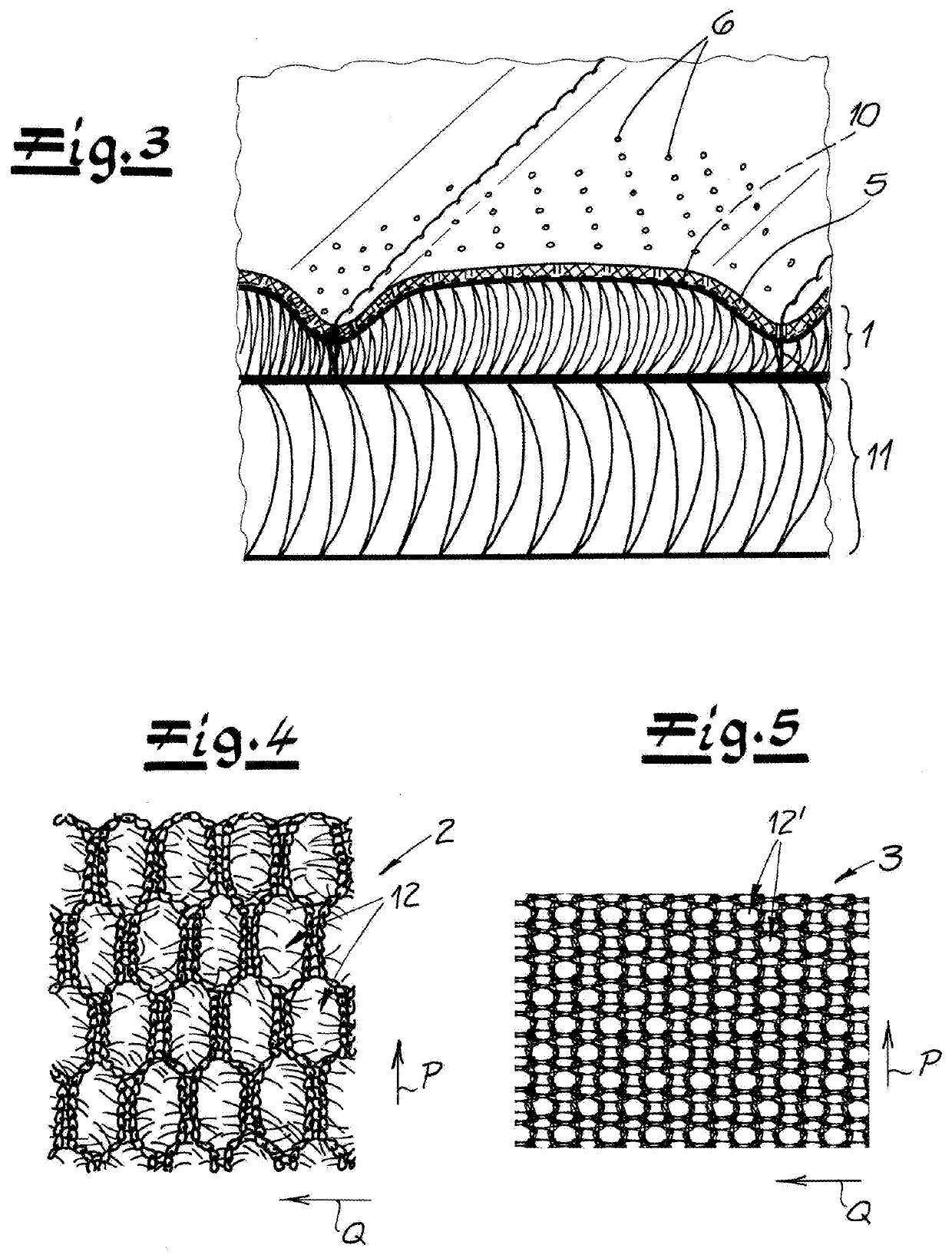

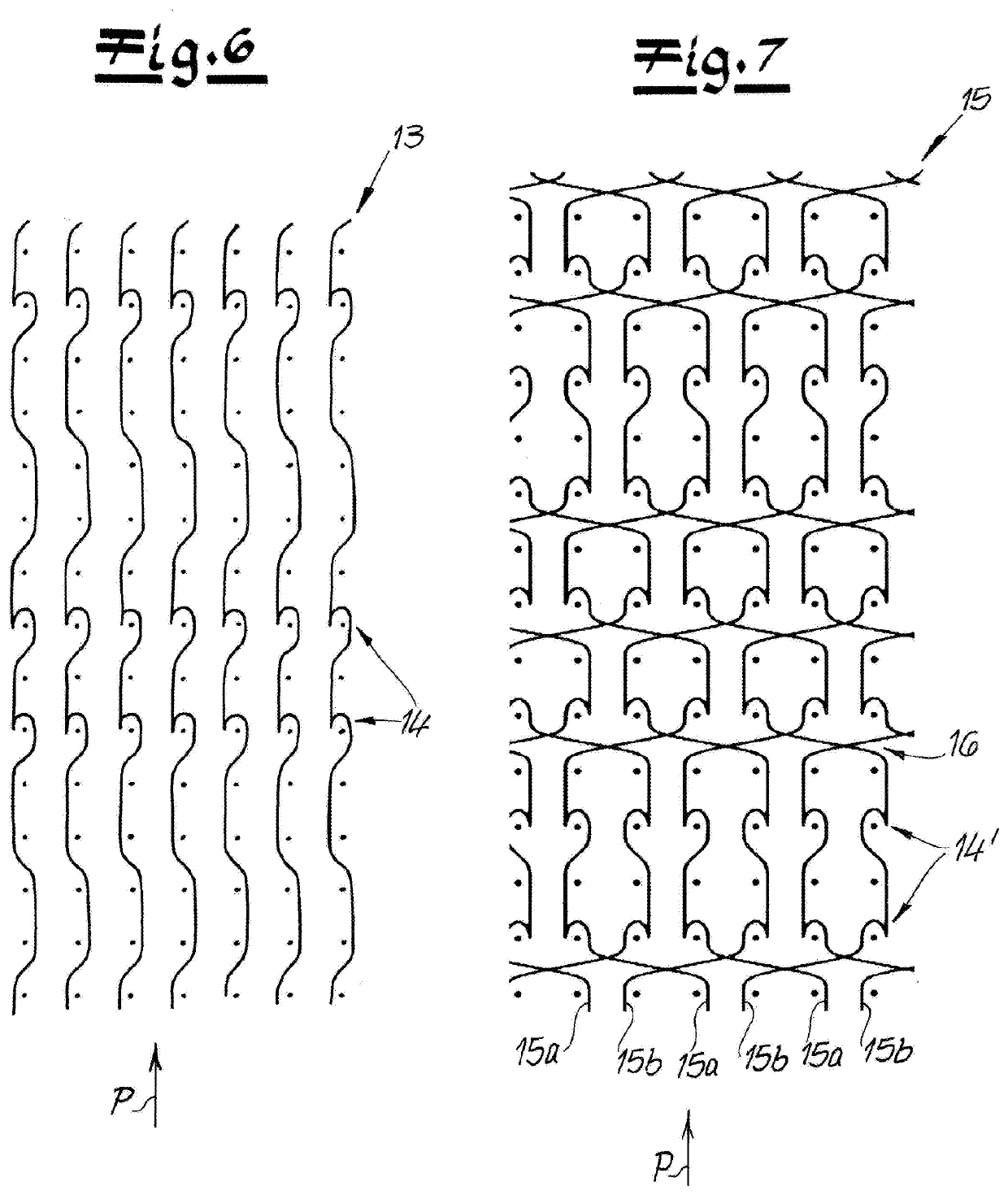

Composite spacer fabric

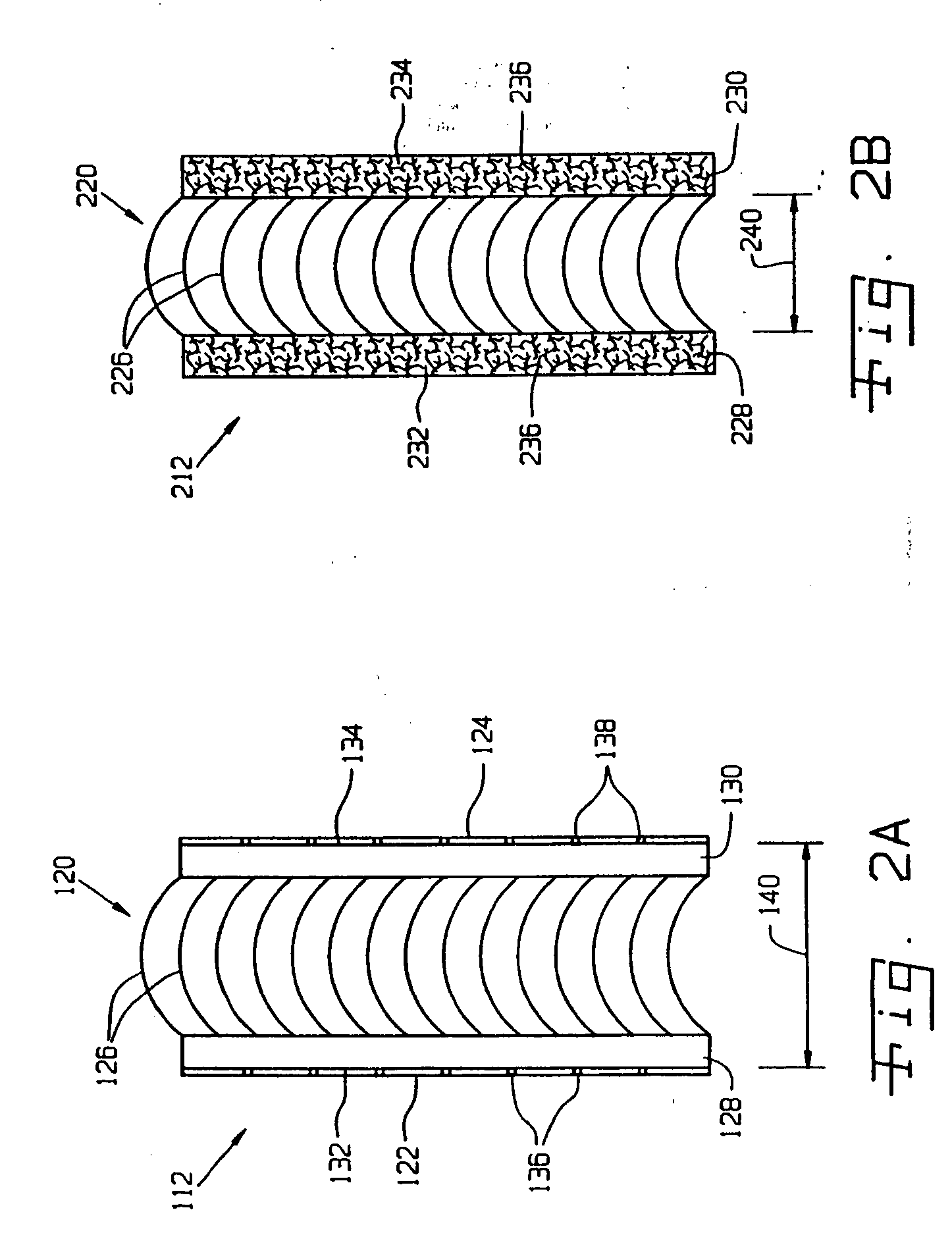

PendingUS20200338853A1Improve ventilationSmall stretchSeat coveringsOrnamental textile articlesPolymer sciencePolymer chemistry

A warp-knitted textile composite has a spacer fabric that extends in a production direction and a transverse direction and has an outer flat warp-knitted fabric layer of predetermined stretchability, an inner flat warp-knitted fabric layer of lesser stretchability in the production and transverse directions than the outer layer, and spacer threads interconnecting the warp-knitted fabric layers. A decorative cover layer is attached to the outer flat warp-knitted fabric layer and is formed with compressed areas where the spacer fabric is permanently at least partially compressed for structuring the decorative cover layer.

Owner:MULLER TEXTIL

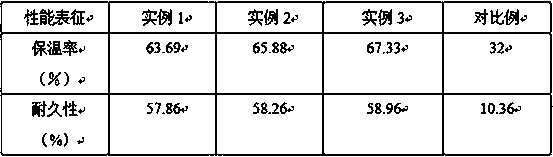

Preparation method of aerogel heat-insulation textile composite material

InactiveCN109023941AHigh densityLow densityConjugated cellulose/protein artificial filamentsVegetal fibresNetwork structureRefractive index

The invention relates to a preparation method of an aerogel heat-insulation textile composite material and belongs to the technical field of textile materials. According to the preparation method provided by the invention, silicon dioxide aerogel is utilized to prepare the aerogel heat-insulation textile composite material by adopting a gel spinning method; the silicon dioxide aerogel is a nano light-weight porous material which takes air as a main component, amorphous-state silicon dioxide as a basic framework and has a complicated three-dimensional network structure; the silicon dioxide aerogel has the characteristics of nano-hole structure, low heat conductivity, low density, low refractive index, low sound velocity and the like; the silicon dioxide aerogel has a unique nano-hole structure so that the aerogel has heat-preservation and heat-insulation properties; the prepared composite material has good heat preservation performance and is not easy to age; natural fibers are immersedinto wet gel so that the gel permeates into the natural fibers, a gel network is completed and a fiber-gel compound is formed, and furthermore, the strength is improved; the prepared aerogel heat-insulation textile composite material has good heat insulation performance and excellent durability.

Owner:黄勇

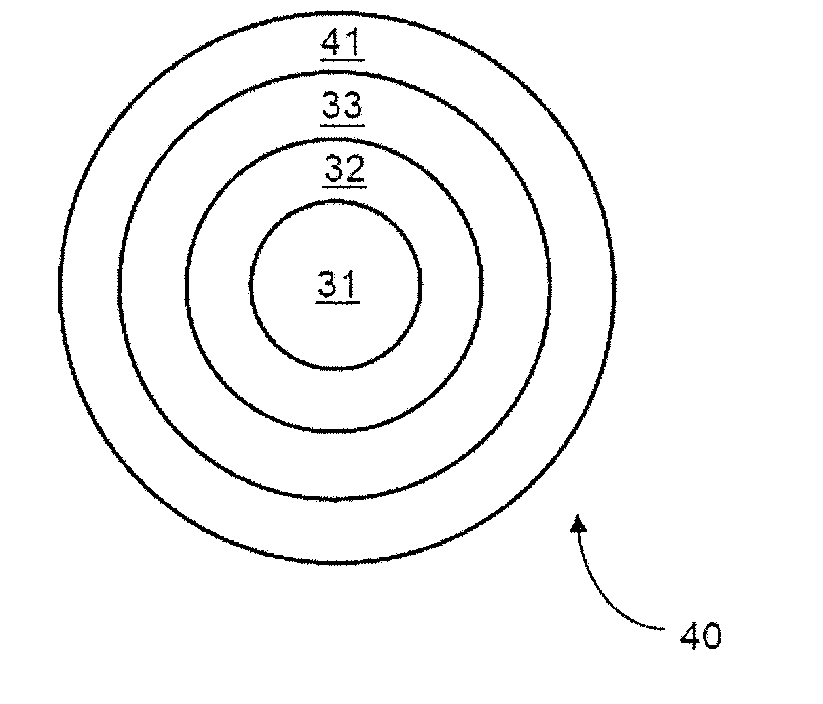

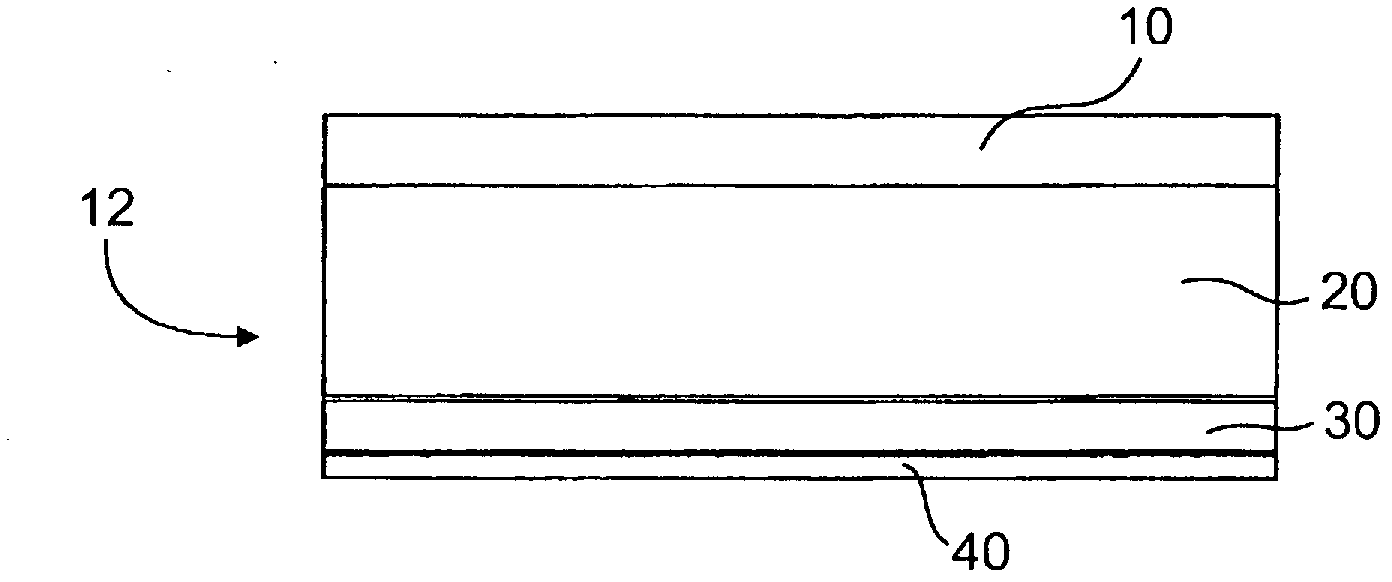

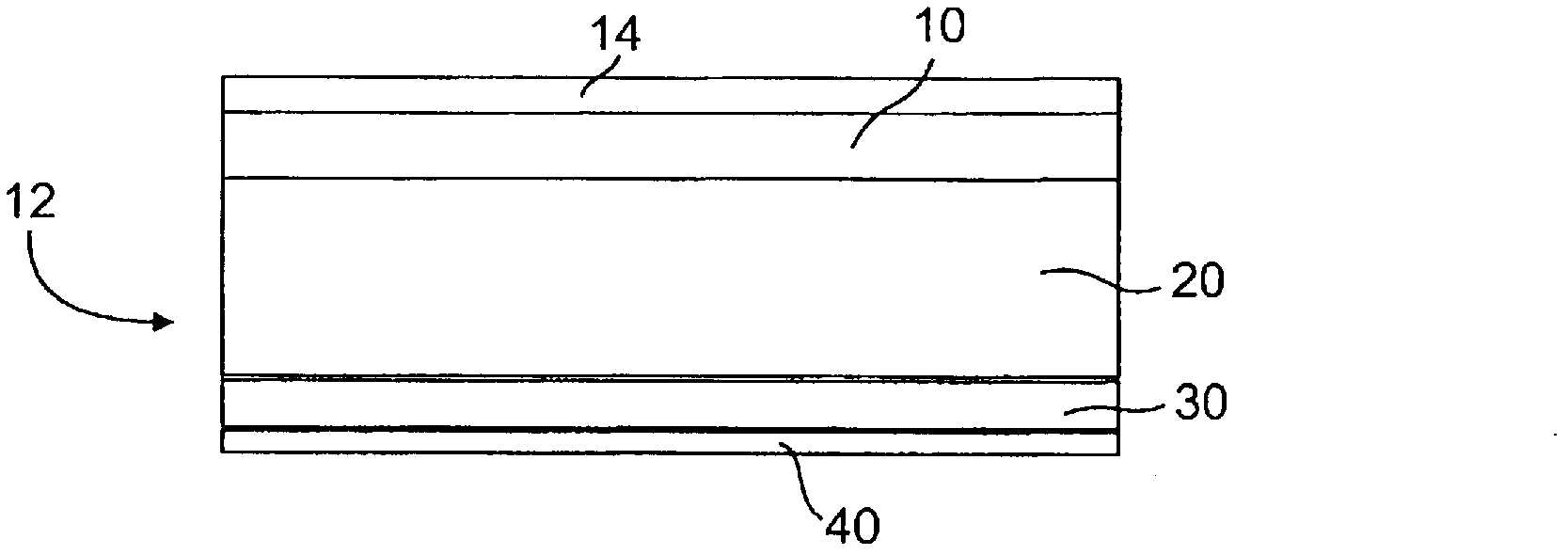

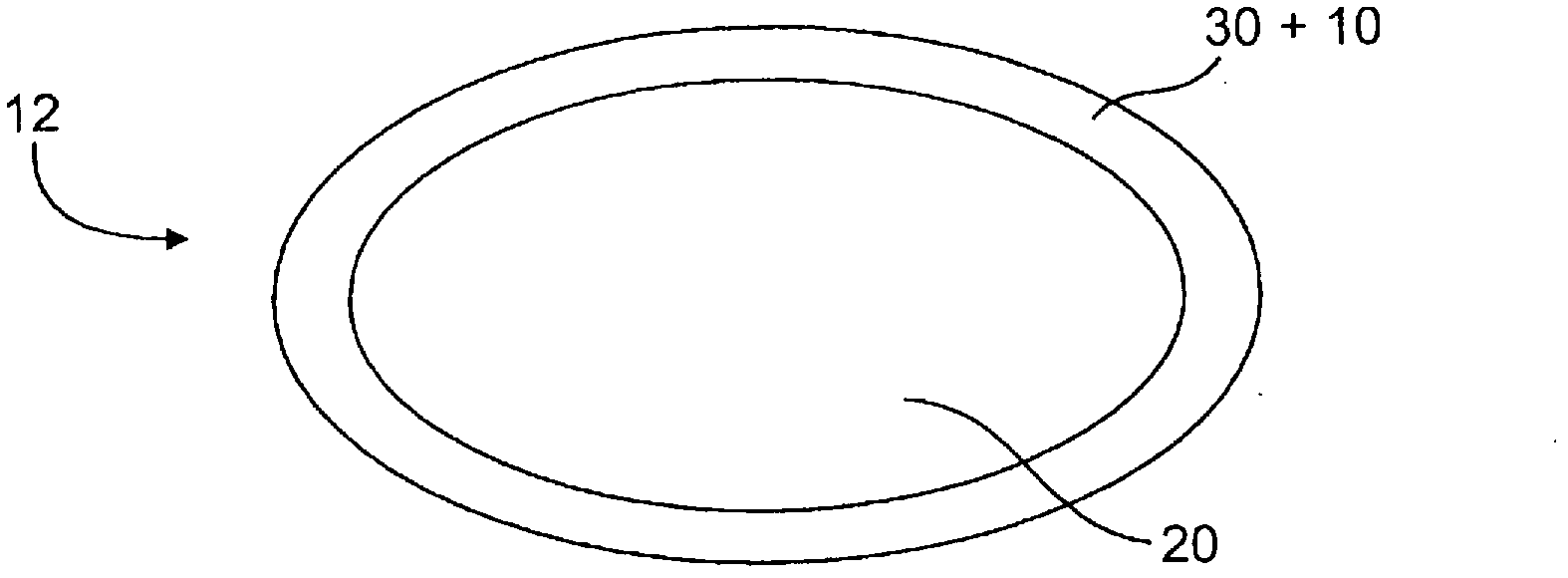

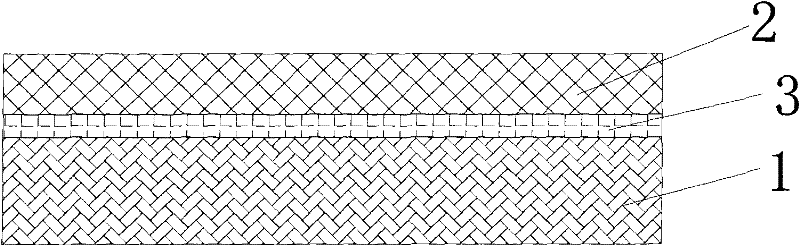

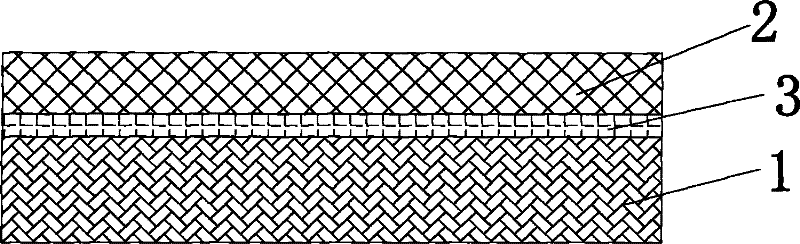

Flexibly deformable cable with textile composite for electromedical applications

InactiveUS20100185107A1Sufficient protection against short-circuitsSufficient protectionPlastic/resin/waxes insulatorsPower cables with screens/conductive layersBody shapeElectric light

A cable for electromedical application and especially for recording the ECG of patients of different body shapes and body sizes is provided including a textile composite (1) formed of a carrier layer (2) and a cover layer (3). At least one electric line (4) is accommodated between the carrier layer (2) and the cover layer (3). After manufacture in a cost-effective manner, the cable offers sufficient protection against short circuits in case of penetration of moisture, on the one hand, and adapts to curved and irregularly shaped structures without problems, on the other hand. The cable textile composite (1) is flexibly deformable without destruction, wherein at least one electric line (4) is electrically insulated by an insulation (5) against the carrier layer (2) and the cover layer (3).

Owner:DRAGERWERK AG

Self-repair structures and methods for making the same

ActiveUS20170057668A1Organic-compounds/hydrides/coordination-complexes catalystsFuselage bulkheadsStationary objectTextile composite

Methods and apparatuses are disclosed relating to multilayer 3D textile composite materials containing self-healing resins for use as protective structures on stationary objects, and moving objects including, without limitation, vehicles including spacecraft and aircraft.

Owner:THE BOEING CO

Cashmere textile composite fabric

InactiveCN102476476ASoft touchNot easy to looseSynthetic resin layered productsEngineeringTextile composite

The invention discloses a cashmere textile composite fabric, which comprises a fabric base layer and a cashmere fabric layer, a film layer being arranged between the fabric base layer and the cashmere fabric layer. The inventive cashmere textile composite fabric is water-proof and air-permeable, has soft and smooth hand-feeling and good warm-keeping effects as well as characteristics of no loosening or deformation of texture, and is especially suitable for underwear or top-grade dress.

Owner:CHANGSHU ZHUOHUI TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com