Burn protective materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fabric example 1

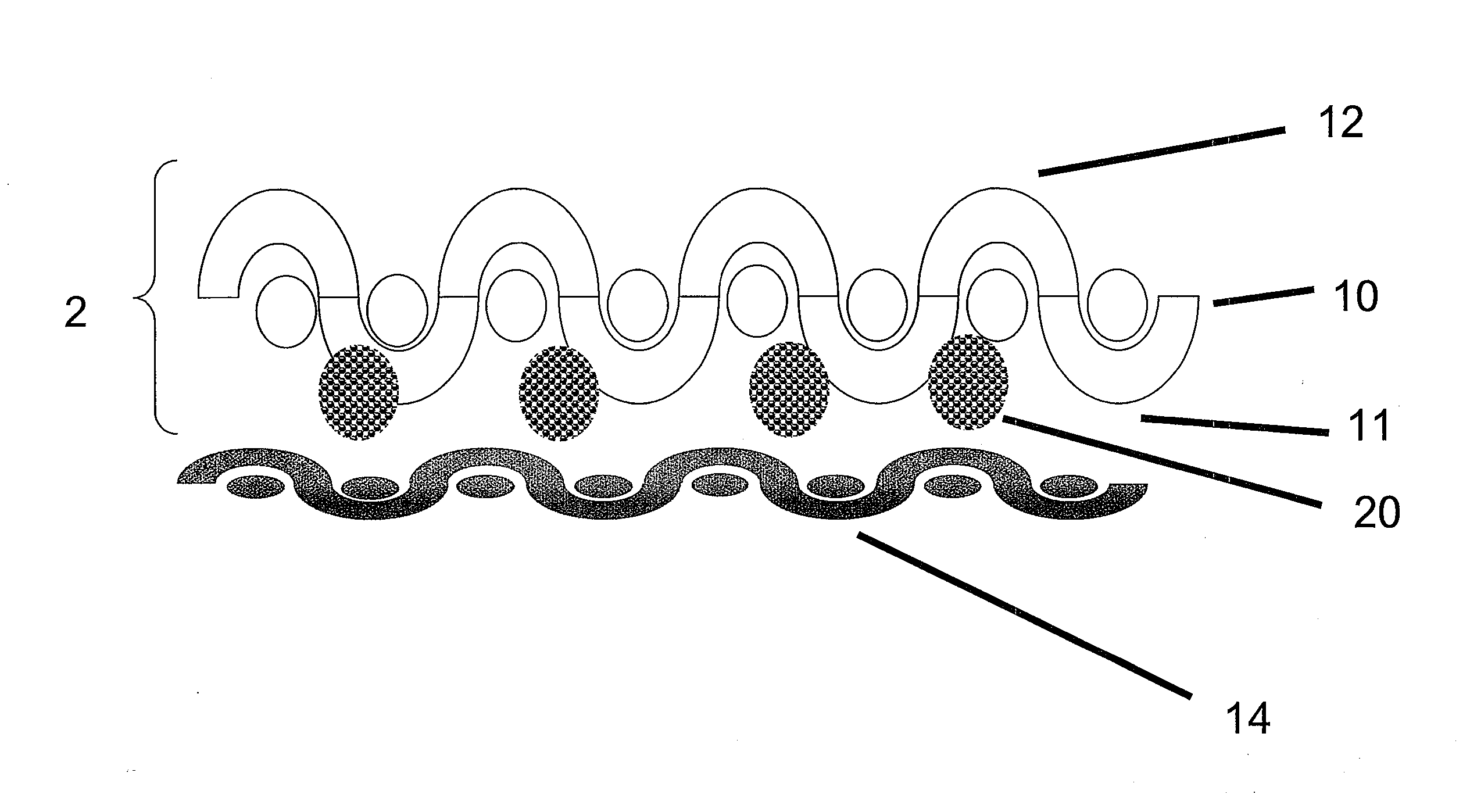

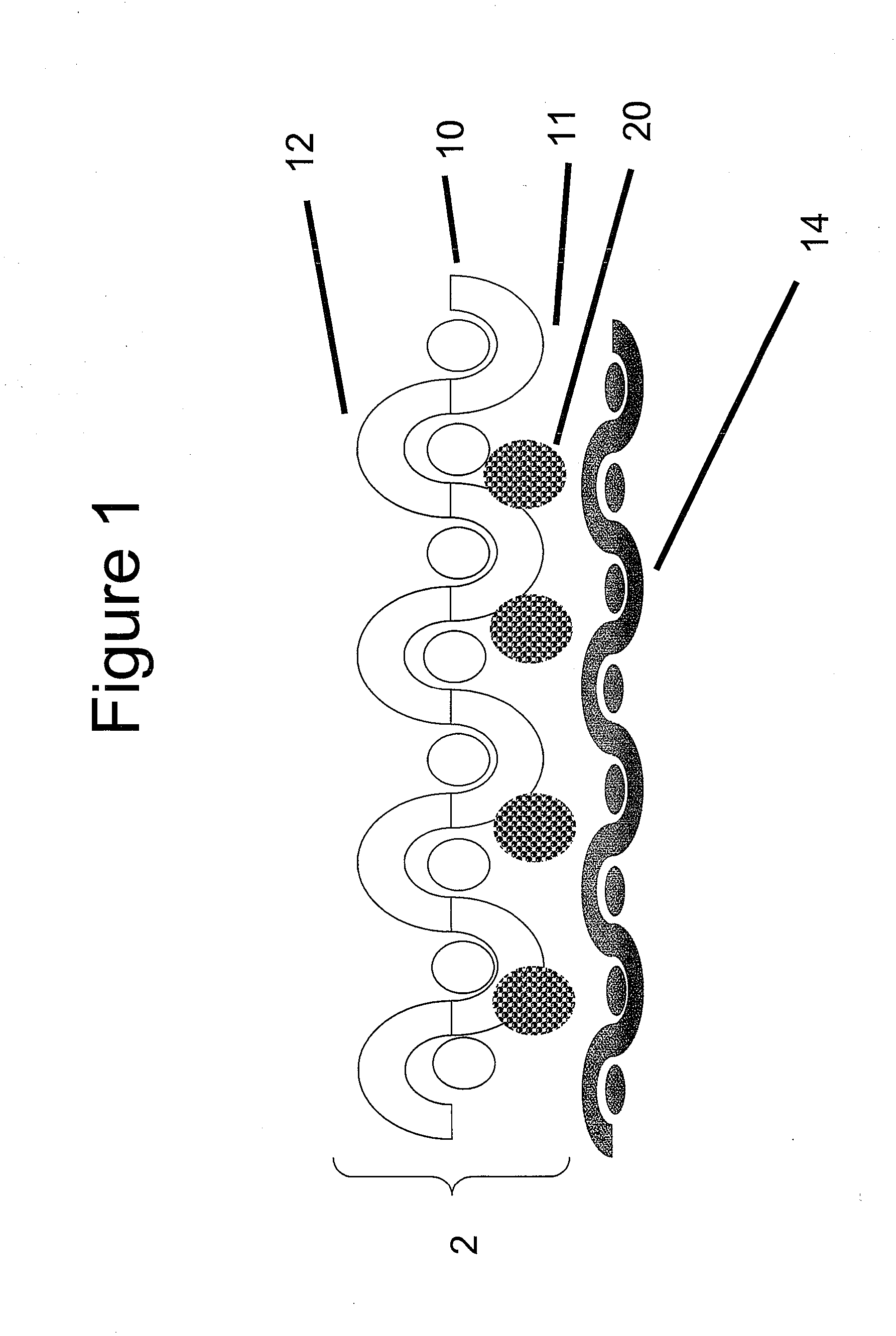

[0070]A textile comprising heat reactive material was prepared as follows. A 130 gsm nylon 6,6 knit outer textile (10) from Milliken Corporation, Spartanburg, S.C. (STYLE 755133) was coated with discrete dots of the polymer resin-expandable graphite mixture 1 by a gravure roller (at about 100° C. with a pressure of about 40 psi) in such a manner as to provide coverage of approximately 32 percent on the surface of the fabric, with a laydown of about 35 grams per square meter (gsm). The gravure roll had a round dot pattern with a cell depth about 1200 um, cell opening of about 2500 um, and a spacing of about 2500 um.

[0071]The coated fabric was allowed to cure at 50% RH and 23° C. for 48 hours. Samples of the textile coated with the polymer resin-graphite mixture 1 were tested as per self extinguishing test described herein recorded an afterflame of less than 5 seconds.

example 1

Laminate Example 1

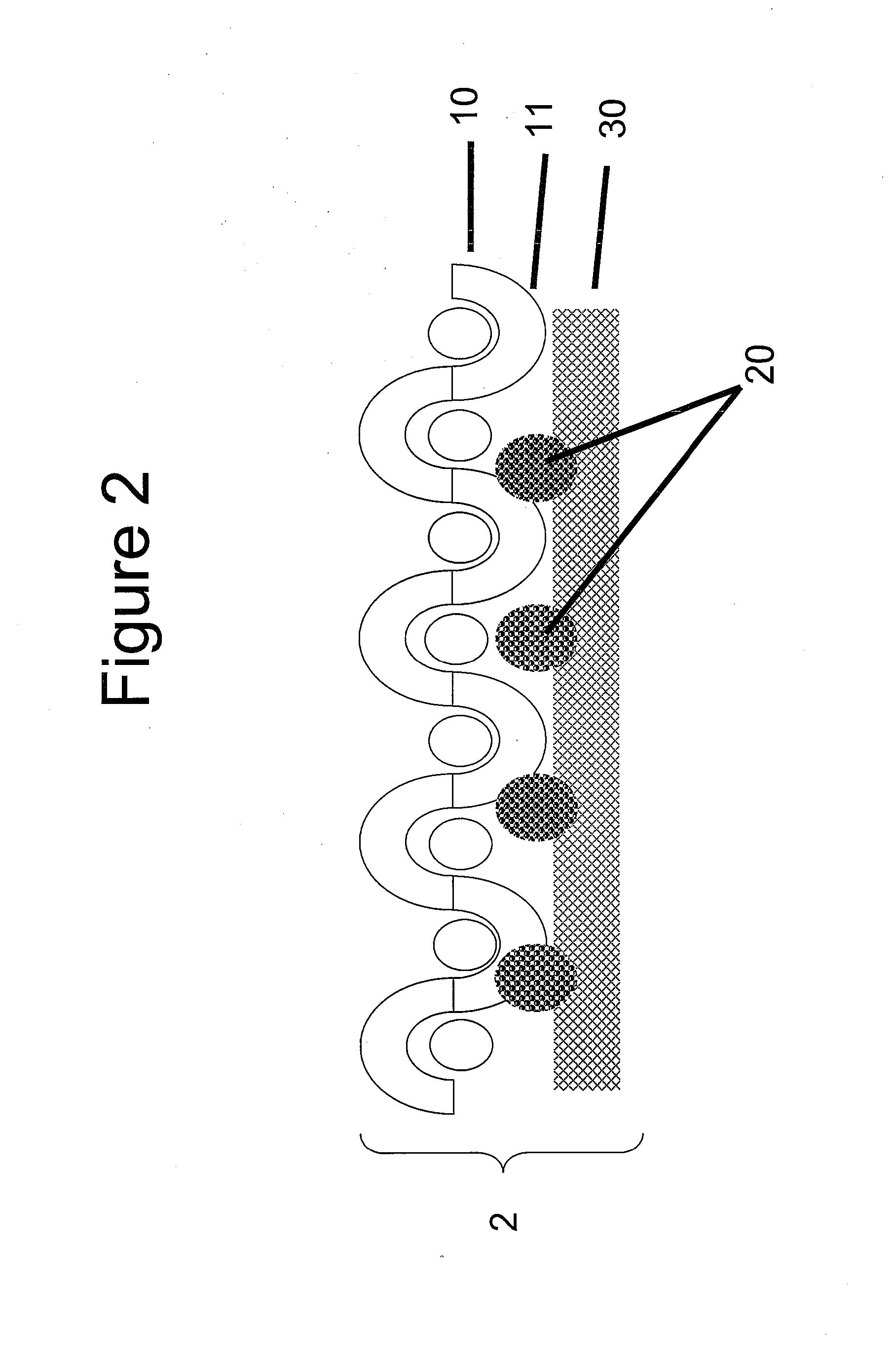

[0072]A laminate was made using a 95 gsm nylon 6,6 plain weave outer textile from Milliken (part number 131967) and thermally stable convective barrier 1, substantially as depicted in FIG. 2. The laminate was constructed by printing discrete dots of the Polymer Resin-Expandable Graphite Mixture 1 onto thermally stable convective barrier 1 and then adhering the 95 gsm nylon woven outer textile to the thermally stable convective barrier using a nip pressure of about 30 psi. The discrete dots of heat reactive material (20) were printed by a gravure roller as described above.

[0073]The resultant laminate was a two layer laminate of a thermally stable convective barrier and a nylon woven meltable outer textile layer bonded by dots of polymer resin-expandable graphite mixture 1. The laminate was taken up onto a steel drum under tension and allowed to cure for about 48 hours at greater than about 50% relative humidity.

[0074]Samples were tested according to MVTR, Horizontal...

example 2

Laminate Example 2

[0075]A two layer laminate was made substantially according to Example 1, except that thermally stable convective barrier 2, described above, was used in place of thermally stable convective barrier 1

[0076]Samples were tested according to the Horizontal Flame Test and Self-Extinguishing Test methods, described herein and reported in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com