Three-dimensional textile composite structure and manufacture and use thereof

a textile composite and three-dimensional technology, applied in the direction of pedestrian/occupant safety arrangement, packaging foodstuffs, packaged goods, etc., can solve the problems of time-consuming process of spraying and curing thermoset resin onto fabrics, unsatisfactory energy absorption performance, etc., to achieve a faster and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

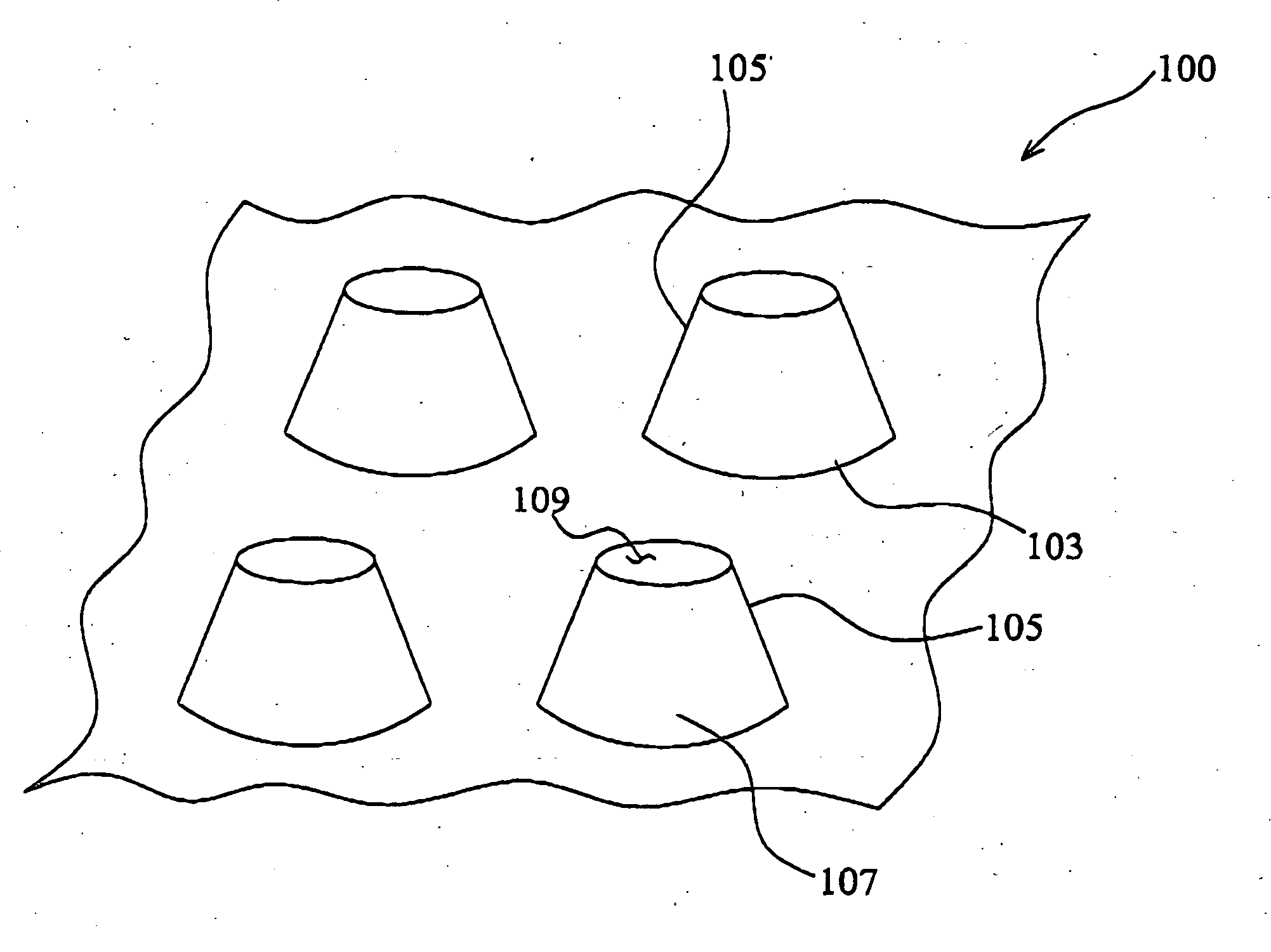

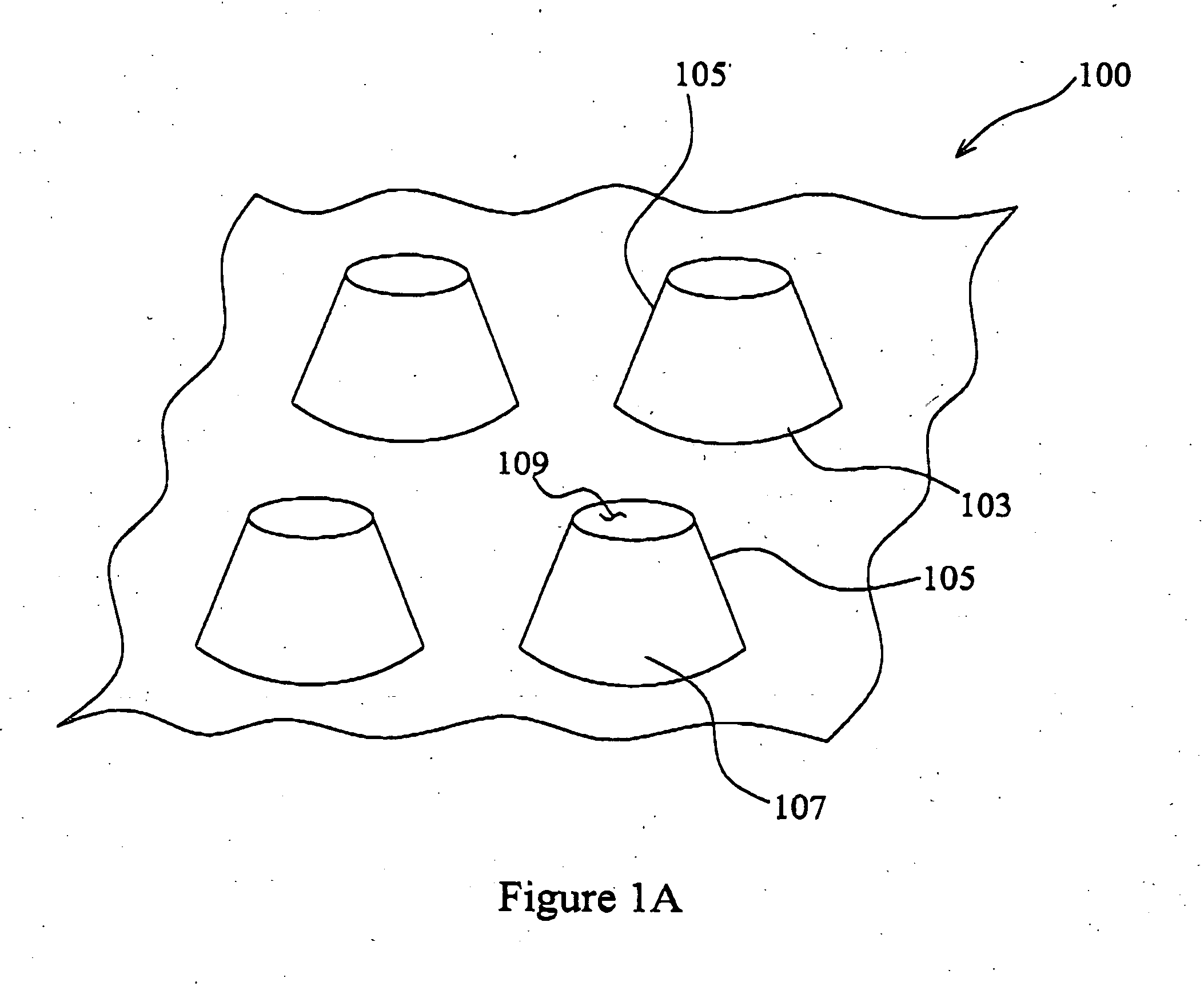

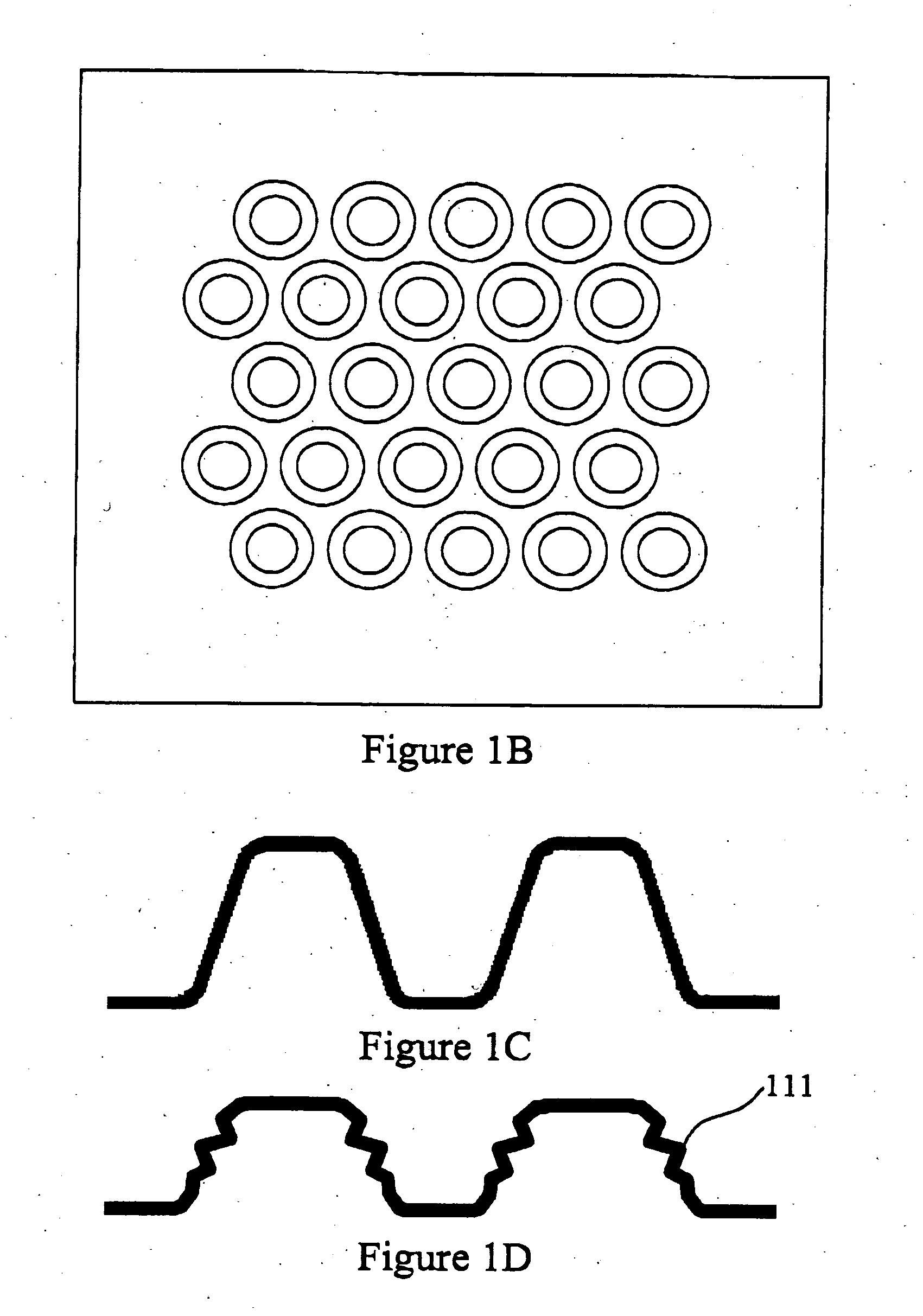

[0045]FIG. 1 illustrates an exemplary three-dimensional sheet-like textile composite structure 100 with energy-absorbing capacities under multiple impacts. The textile composite structure 100 has a generally planar base 103 and a plurality of projections 105 extending from the base 103. In the exemplary embodiment, each projection 105 has a grid-domed shape with a conical sidewall 107 and a generally flat top 109. Furthermore, each projection 105 defines a space (not shown) where the sidewall 107 and / or the top 109 may collapse under impacts. FIGS. 1B and 1C are respective top plan view and cross sectional view of the textile composite structure of FIG. 1A.

[0046] The textile composite structure 100, at least the projections 105, includes a textile and a matrix material. More specifically, in the exemplary embodiment, the textile structure 100 is made from non-woven fabric materials impregnated with thermoplastic matrix materials.

[0047] Materials for producing the non-woven fabric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| energy-absorbing capacities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com