Weaving method for same-width and different-thickness three-dimensional woven fabric

A three-dimensional machine and fabric technology, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of poor interlayer shear capacity, weak rings of strength, and low life, and achieve adjustable and controllable thickness, easy operation, and anti-corrosion. Excellent effect on fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

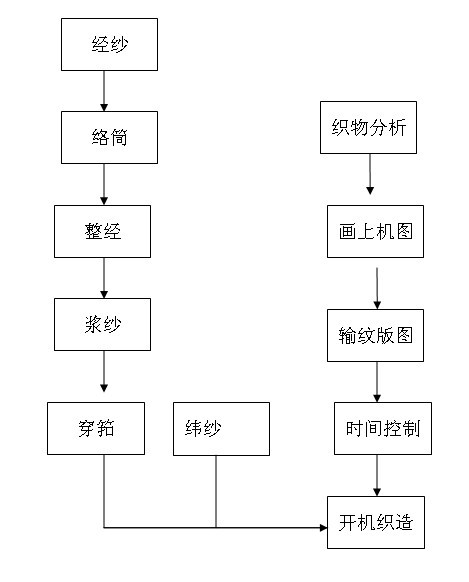

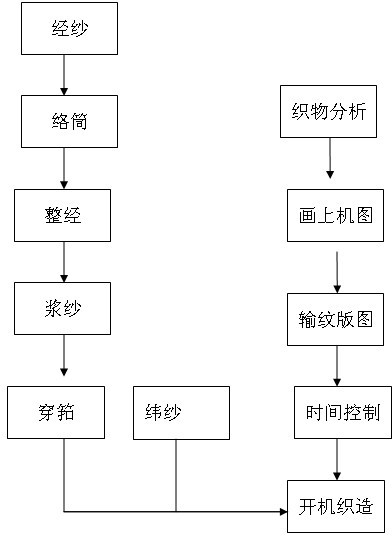

Image

Examples

Embodiment Construction

[0028] The three-dimensional fabric of the same width and different thickness according to the present invention will be further described below in conjunction with a specific example.

[0029] The material is composite yarn. Firstly, nine layers of angle interlocking fabrics are designed, the warp density is designed to be 180 threads / 10cm, and the weft density is 18 threads / 10cm per layer. The number of fabric layers is 9 layers, the number of required heald frames is 10, and the warp is threaded according to the straight-through method. Then design the weave diagram of the 8-layer warp angle interlocking fabric, the required heald frame is 9 pages, the warp density remains the same, the total weft density is reduced by 18, and then design the 7-layer warp angle interlocking fabric, and finally input the pattern pattern in turn, the 8-layer weave Compared with the 9th floor pattern, one heald frame is used less, and a double warp will appear when the sutra is lifted. Compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com