Manufacturing method of water and oxygen barrier layer

A technology of water-oxygen barrier layer and barrier layer, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as unfavorable industrialization development, increased difficulty in film preparation, and increased cost of OLED device preparation. Reduce the water oxygen transmission rate, improve the barrier effect, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

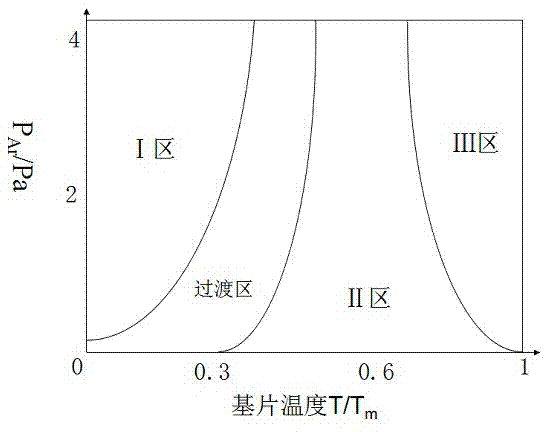

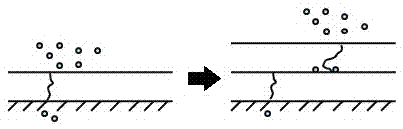

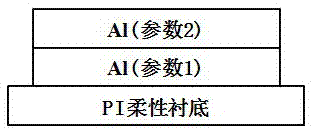

[0036] In this example, see Figure 1~3 , a method for preparing a water-oxygen barrier layer, adopting a magnetron sputtering method to sequentially sputter metal Al on a PI flexible substrate to prepare two layers of barrier material film layers to form a water-oxygen composite double-layer mismatch barrier layer. In the preparation process of the barrier material film layer, the first layer of barrier material film layer is prepared using the first set of parameters, and the second layer of barrier material film layer changes some parameters that affect the properties and structure of the film layer, and continues to deposit, thus preparing A double-mismatched barrier layer was developed.

[0037] In this embodiment, the substrate is a PI flexible substrate, and the sputtering material is pure Al. The specific method for preparing the double-layer mismatched barrier layer is as follows: first clean the PI flexible substrate, and then heat the PI flexible substrate on the su...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this example, see Figure 4 and Figure 5 , using the magnetron sputtering method to sequentially use three different parameters to sputter metal Al on the PI flexible substrate to prepare three layers of barrier material film layers to form a water-oxygen composite multilayer mismatch barrier layer. In the preparation process of the barrier material film layer, the first layer of barrier material film layer is prepared using the first set of parameters, and the second layer of barrier material film layer changes some parameters that affect the properties and structure of the film layer, and continues to deposit; the third layer The barrier material film layer changes some parameters that affect the properties and structure of the film layer, and continues to deposit, thus preparing a three-layer mismatched barrier layer;

[0042] In this embodiment, the substrate is a PI flexible s...

Embodiment 3

[0044] This embodiment is basically the same as the previous embodiment, and the special features are:

[0045] In this example, see Figure 6 , a method for preparing a water-oxygen barrier layer, using atomic layer deposition method, sequentially depositing Al on a PI flexible substrate 2 o 3 A multi-layer barrier material film layer is prepared to form a water-oxygen composite multi-layer mismatch barrier layer. This example is an expansion of the mismatch method in the preparation of barrier films, without destroying the vacuum environment. When changing the special parameters such as the reaction gas flow ratio and the type of precursor, the type of the product is not changed, but the product is significantly changed. The structural properties of the thin film layer, in this embodiment, use the same kind of material with the same type but different properties to form the film layer, so as to achieve the effect of water vapor passage mismatch, which is also one of the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com