Flexible transparent conductive film preparation method

A transparent conductive film, transparent conductive technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, conductor/cable insulation, etc. , high cost of photolithography, to achieve the effect of good water and oxygen barrier effect, high conductivity, prolong life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the flexible transparent conductive film of the present embodiment comprises the following steps:

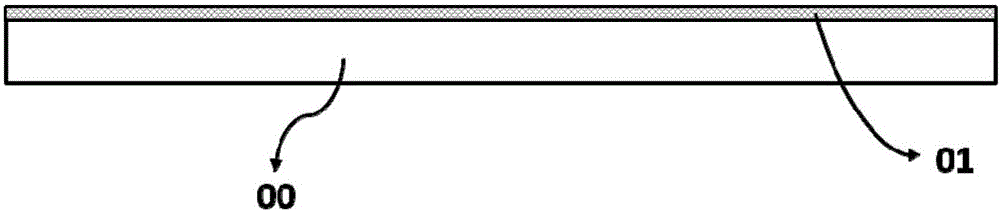

[0043] (1) On a clean glass substrate 00, first deposit a layer of SiN with a thickness of 100 nm by chemical vapor deposition (CVD) X Inorganic film as release layer 01, such as figure 1 shown;

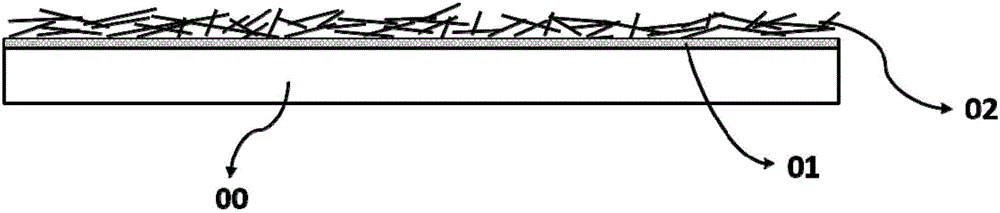

[0044] (2) Spin-coat the silver nanowire dispersion on the release layer 01 prepared in step (1) to obtain a uniform silver nanowire conductive layer 02, such as figure 2 shown;

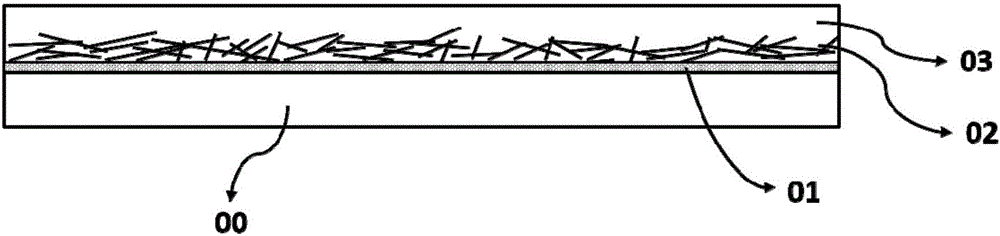

[0045] (3) On the silver nanowire conductive layer, prepare a layer of PDMS coating with a thickness of 20 μm as the polymer support layer 03 by spin coating, and leave it at room temperature for 1 hour, and then bake it in an oven at 120 ° C Roast for 1h, such as image 3 shown;

[0046] (4) Deposit a layer of Al with a thickness of 100nm on the PDMS film by atomic layer deposition (ALD) 2 o 3 The film acts as a water and oxygen barrier layer 04, such as Figure 4 sh...

Embodiment 2

[0054] The preparation method of the flexible transparent conductive film of the present embodiment comprises the following steps:

[0055] (1) On a clean glass substrate, first prepare a layer of polyimide film as a release layer by the method of slit coating;

[0056] (2) On the release layer, a layer of copper nanowire conductive layer is prepared by using a scraper coating method;

[0057] (3) Then on the copper nanowires, spin-coat a layer of CYTOP coating with a thickness of 10um as a polymer support layer, and bake in an oven at 80°C for 2h;

[0058] (4) Then use ALD on the CYTOP film to prepare a layer of Al with a thickness of 100nm 2 o 3 / MgO laminated film as water and oxygen barrier layer, in which Al 2 o 3 deposited alternately with MgO thin films, Al 2 o 3 The ratio of deposition cycles to MgO is 50 to 10;

[0059] (5) Then in Al 2 o 3 Lay a PSA lamination layer with a thickness of 50um on the film;

[0060] (6) Lay a PEN film with a thickness of 100um ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com