Quantum-dot optical film and backlight module

A quantum dot and optical film technology, applied in the field of backlight module and quantum dot optical film, can solve the problems of reduced luminous efficiency, poor stability of quantum dot film, small color gamut NTSC, etc., to improve luminous stability and improve water resistance. Oxygen barrier and stable luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the quantum dot capsule core is as follows:

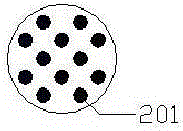

[0038] Firstly, the particles with micropores are added to the red quantum dot solution and the green quantum dot solution with a weight percentage of 5-20% respectively, and fully mixed and dispersed. According to the heterogeneous aggregation mechanism, the red quantum dots and green quantum dots will be adsorbed on the above-mentioned The surface of the particles is honeycombed and porous, and dried to evaporate the solvent. In the present invention, the diffusion particles that absorb a large amount of red quantum dots or green quantum dots are called red quantum dot capsule cores or green quantum dot capsule cores, respectively.

[0039] In order to improve the stability of the luminous efficiency of quantum dots, the present invention encapsulates the above-mentioned particles adsorbed with quantum dots—the quantum dot capsule core, and the packaging material is called capsule wall. The capsul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com