Quantum dot fluorescent composite material as well as preparation method and application thereof

A composite material and quantum dot technology, applied in the field of quantum dot fluorescent composite materials and their preparation, can solve problems such as quantum dot agglomeration and fluorescence quenching, and achieve the effects of uniform particle size, improved stability, and improved fluorescence stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

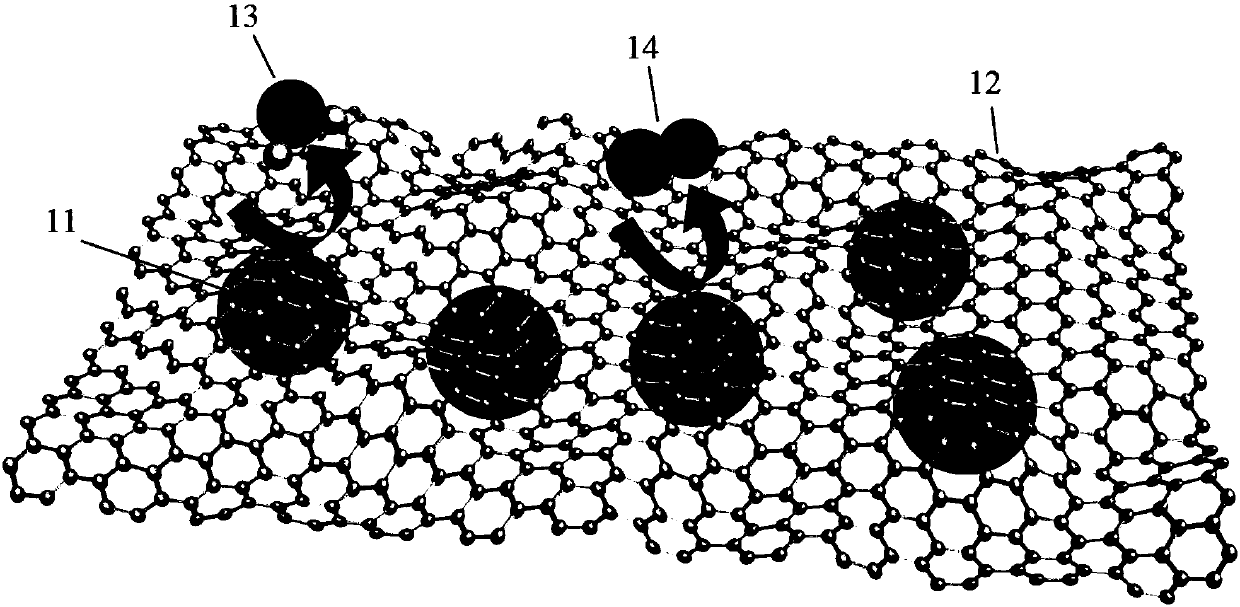

[0061] A quantum dot fluorescent composite material, which is composed of graphene and PS microspheres compounded on the graphene; the interior of the PS microspheres is embedded with cadmium selenide quantum dots; the particle size of the PS microspheres is 5 μm, and the surface of the PS microspheres is The surface of graphene is bonded by peptide bonds. The composite mass ratio of graphene to PS microspheres is 0.5:100.

[0062] The preparation steps of the quantum dot fluorescent composite material provided by embodiment 1 are as follows:

[0063] 1) Preparation of PS microspheres

[0064] Dissolve PVP in a mixed solvent composed of ethanol and water, put it into a 250mL four-necked bottle equipped with a thermometer, a stirrer and a condenser, protect it with nitrogen, pre-disperse at 70°C for 30min, and then add monomer styrene ( St) and the initiator AIBN were reacted at 70°C for 12h, and after the reaction was completed, PS microspheres were obtained;

[0065] 2) Sw...

Embodiment 2

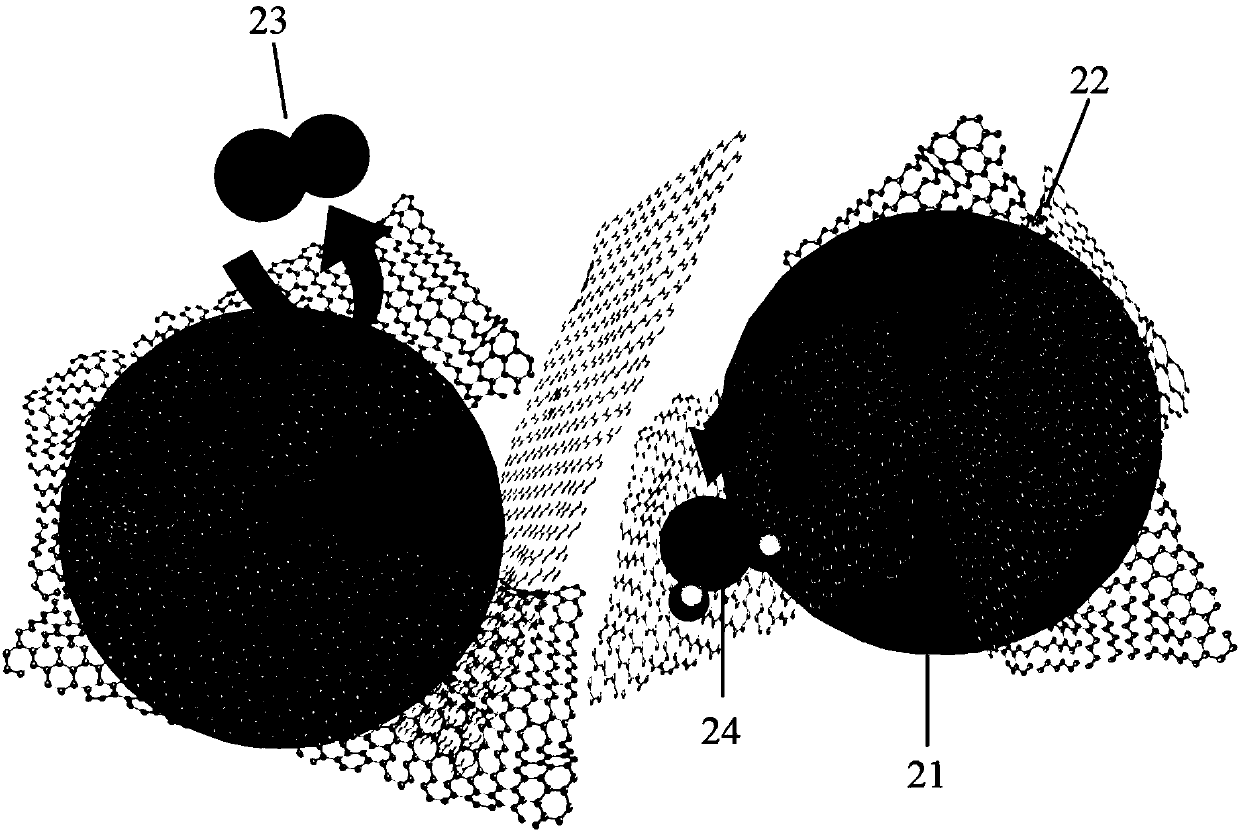

[0072] A quantum dot fluorescent composite material, which is composed of graphene and PS microspheres compounded on the graphene; wherein 10% zinc selenide quantum dots are embedded inside the PS microspheres; the particle size of the PS microspheres is 10 μm, and its The surface is bonded to the surface of the graphene through peptide bonds. The composite mass ratio of graphene to PS microspheres is 1:100.

[0073] The preparation steps of the quantum dot fluorescent composite material provided by embodiment 2 are as follows:

[0074] 1) Preparation of carboxylated PS microspheres

[0075]Similar to step 1) of Example 1, the difference is that, based on the quality of styrene, 1% acrylic acid is added to styrene, and 1% divinylbenzene is cross-linked to prepare carboxylated PS microspheres;

[0076] 2) Swelling of quantum dots + carboxylated PS microspheres:

[0077] Based on the mass of styrene, add 10 times of water, 15 times of ethanol, 10% of PVA, 10% of PVP, fully st...

Embodiment 3

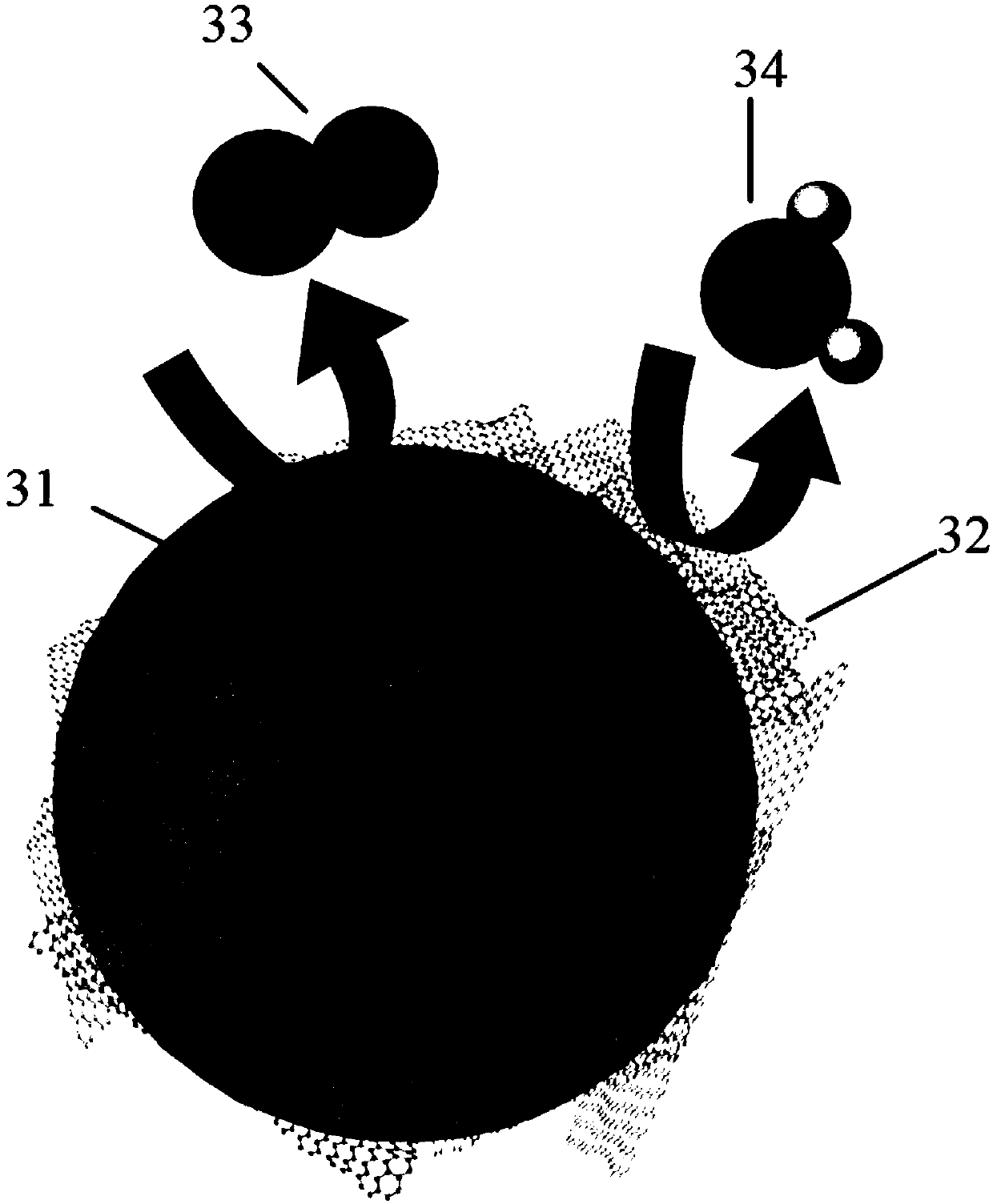

[0081] A quantum dot fluorescent composite material, which is composed of graphene and PS microspheres compounded on the graphene; wherein 10% cadmium sulfide quantum dots are embedded inside the PS microspheres; the particle size of the PS microspheres is 20 μm, and the surface of the PS microspheres is Bonded to the surface of graphene via peptide bonds. The composite mass ratio of graphene to PS microspheres is 1:100.

[0082] The preparation steps of the quantum dot fluorescent composite material provided by embodiment 3 are as follows:

[0083] 1) Preparation of PS microspheres

[0084] With the step 1) of embodiment 1

[0085] 2) Swelling of quantum dots + PS microspheres:

[0086] Based on the mass of styrene, add 10 times water, 15 times ethanol, 10% PVA and 10% PVP, stir and mix thoroughly, add 1% PS microspheres and 0.1% quantum dots, after mixing, at a rate of 2mL / min Add water to swell the quantum dot PS microspheres for 1 hour to obtain quantum dot-PS polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com