Microcapsule type additive for corrosion-resistant coating and preparation method thereof

An anti-corrosion coating and microcapsule technology, applied in the field of coatings, can solve the problems of not ensuring the uniform distribution of two kinds of microcapsules, reducing the uniform distribution of corrosion inhibitors, and unable to repair mechanical damage independently, saving manpower and material resources, and improving anti-corrosion. performance, the effect of extending the protection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Dissolve 1g of non-ionic emulsifier Tween80 in 150g of water and put it in a 500ml four-necked flask;

[0058] 2) Mix 30g of tung oil (containing 1 / 10,000 rare earth drier) and 0.5g of self-made rust inhibitor Yipsa evenly, and add slowly under high-speed stirring to form a stable dispersion;

[0059] 3) Adjust the pH of the dispersion to 4.5, add 100 g of an aqueous solution of melamine-formaldehyde prepolymer (wt%=30%) to it, maintain the temperature at 70° C., and react for 4 hours to form microcapsules;

[0060] 4) Filtering, washing and drying the prepared microcapsules to form a microcapsule additive.

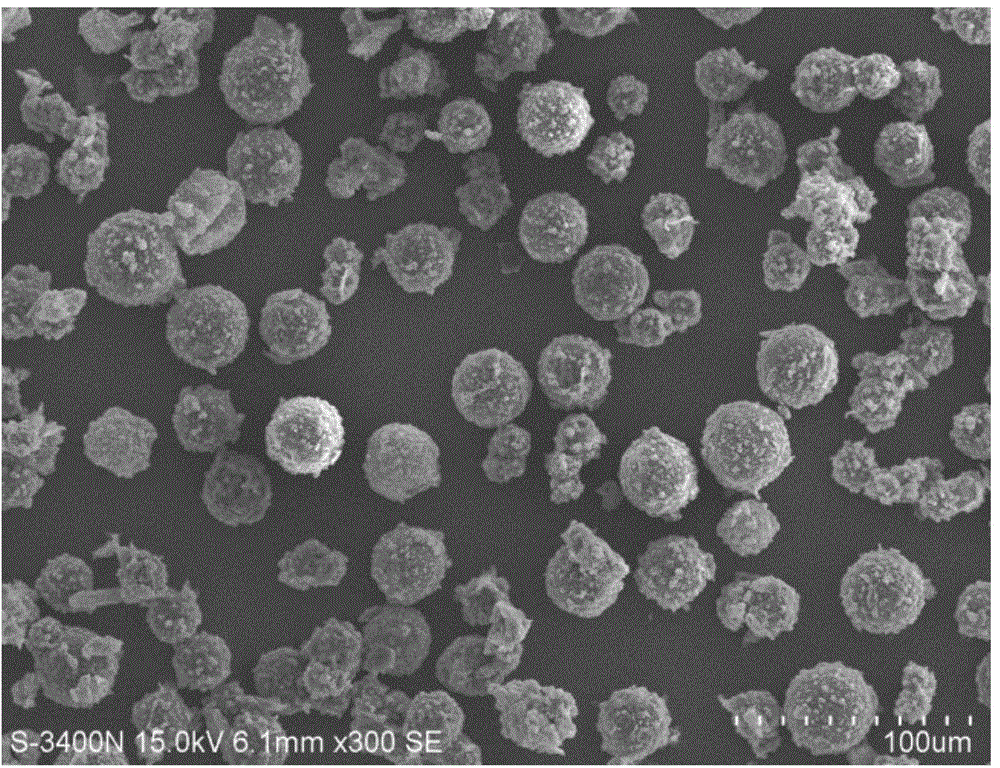

[0061] The SEM photo of the microcapsules that this embodiment prepares is as figure 1 shown. The particle size of the microcapsules prepared in this embodiment is almost all below 50 μm, which can be added to the coating more conveniently.

[0062] Paint blending, coating and paint film performance inspection experiments:

[0063] The present invention uses...

Embodiment 2

[0066] 1) Dissolve 1g of non-ionic emulsifier Tween80 in 150g of water and put it in a 500ml four-necked flask;

[0067] 2) Mix 30g of tung oil (containing 1 / 10,000 rare earth drier) and 1g of self-made rust inhibitor Yipsa evenly, and add slowly under high-speed stirring to form a stable dispersion;

[0068] 3) Adjust the pH of the dispersion to 4.5, add 100 g of an aqueous solution of melamine-formaldehyde prepolymer (wt%=30%) to it, maintain the temperature at 70° C., and react for 4 hours to form microcapsules;

[0069] 4) Filtering, washing and drying the prepared microcapsules to form a microcapsule additive.

Embodiment 3

[0071] 1) Dissolve 1g of non-ionic emulsifier Tween80 in 150g of water and put it in a 500ml four-necked flask;

[0072] 2) Mix 30g of tung oil (containing 1 / 10,000 rare earth drier) and 2g of self-made rust inhibitor Yipsa evenly, and add slowly under high-speed stirring to form a stable dispersion;

[0073] 3) Adjust the pH of the dispersion to 4.5, add 100 g of an aqueous solution of melamine-formaldehyde prepolymer (wt%=30%) to it, maintain the temperature at 70° C., and react for 4 hours to form microcapsules;

[0074] 4) Filtering, washing and drying the prepared microcapsules to form a microcapsule additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com