Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve the passing rate of one-time inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

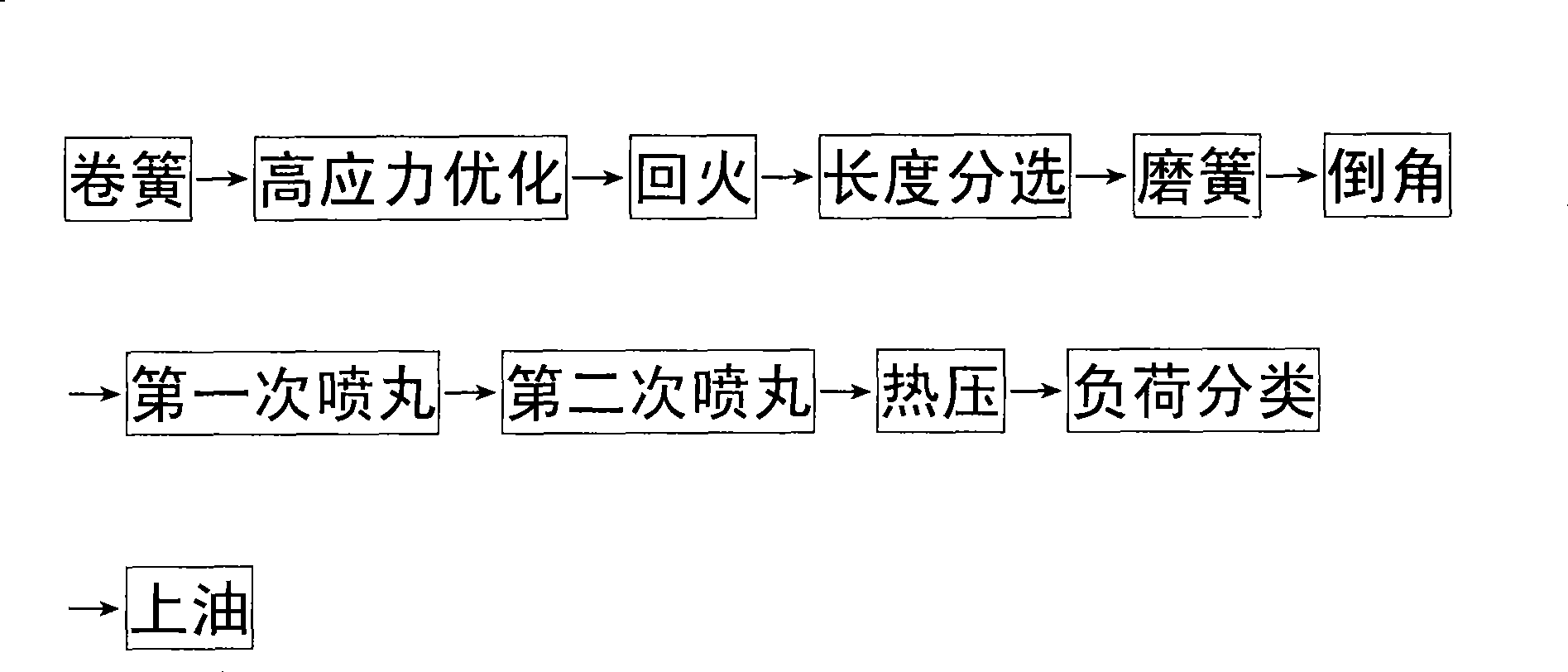

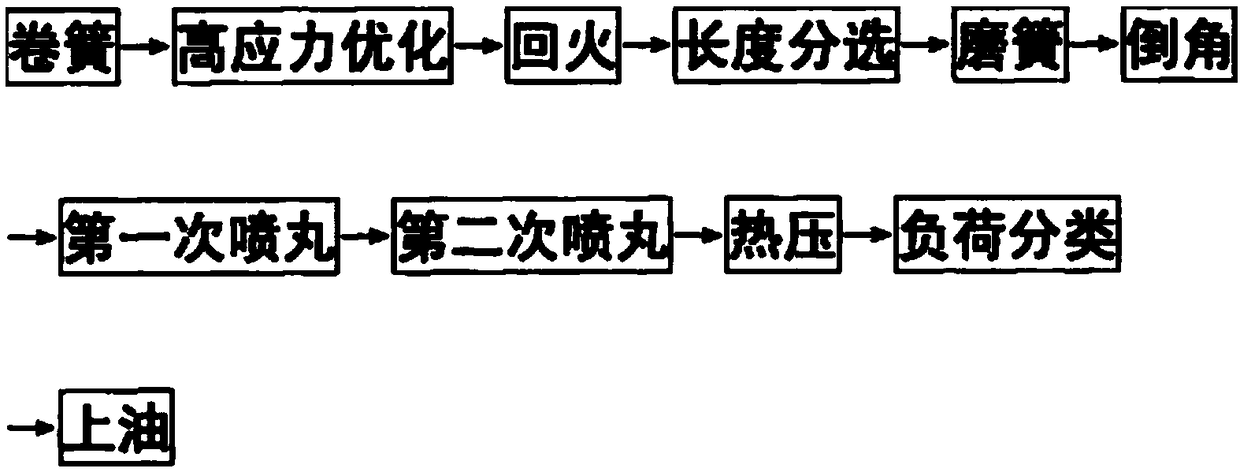

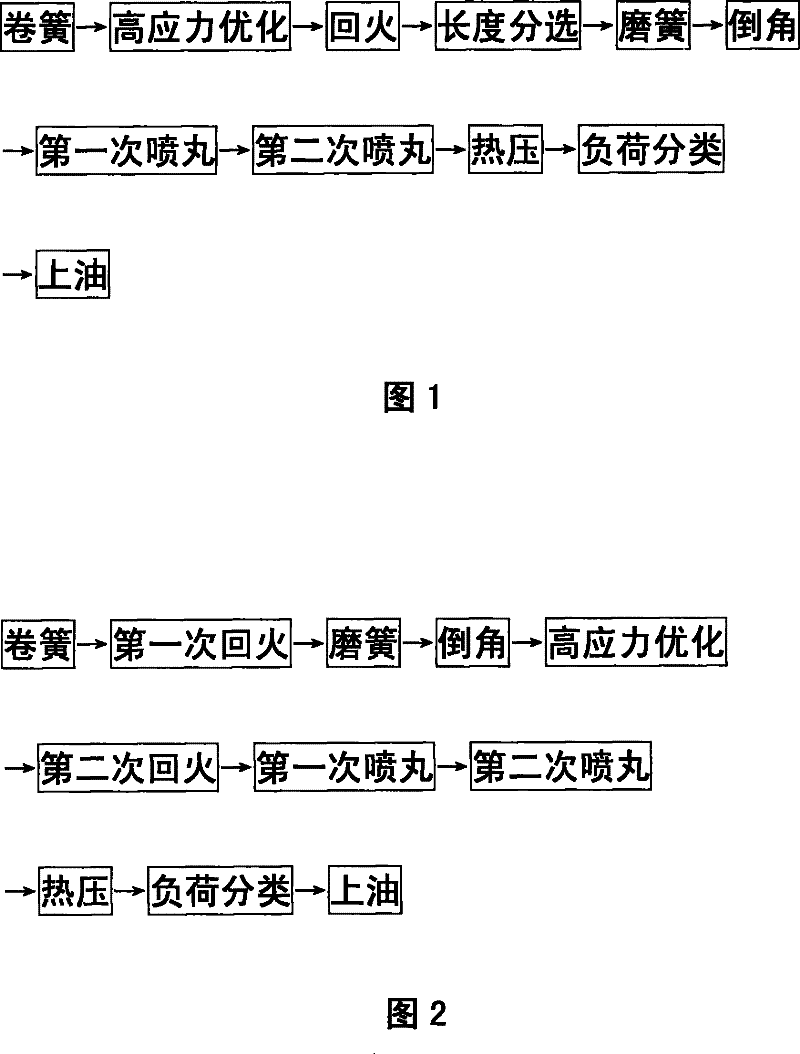

Process for manufacturing heavily stressed valve spring

The invention provides a manufacturing process used for a high-stress valve spring, which can improve the quality and product qualification ratio of the spring product, reduce the production cost of the spring and comprises the processes as follows: spring rolling: steel wire blanks are rolled and made into semi-finished springs; primary temper: the spring is tempered at low temperature so that the stress is removed; spring grinding: two end surfaces of the spring are grinded so as to achieve the required length; chamfering: the burrs of the grinded spring are removed; stress optimization: secondary temper: the spring is tempered again at low temperature so that the stress is removed; shot blasting which is used for prolonging the service life of the spring; hot-pressing; load classification: the spring with bad load is removed and the product with qualified load is used as the high-stress valve spring product; oiling: the high-stress valve spring is oiled; and is prepared for packaging. The process improves the quality and the qualification ratio of the spring product and reduces the production cost of the spring as the working procedure of length classification is saved and the stress optimization process is arranged after the process of spring grinding and chamfering in the traditional process.

Owner:SHANGHAI SPRING CORP

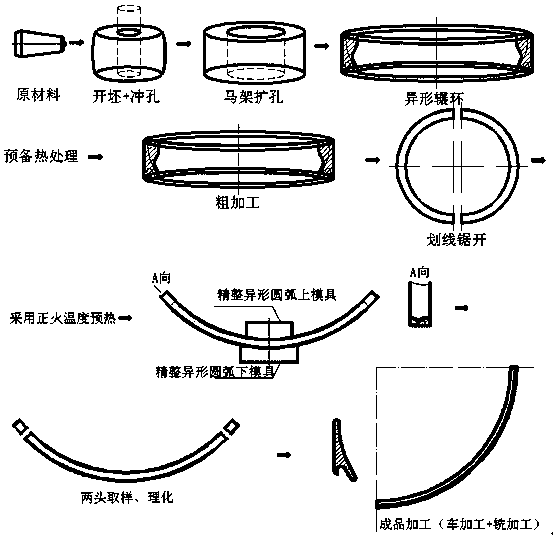

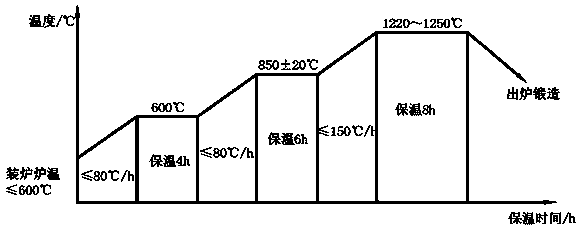

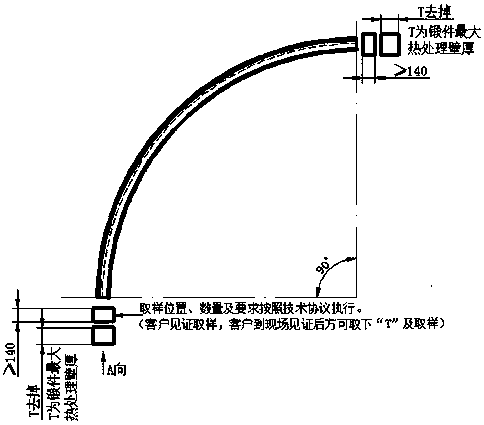

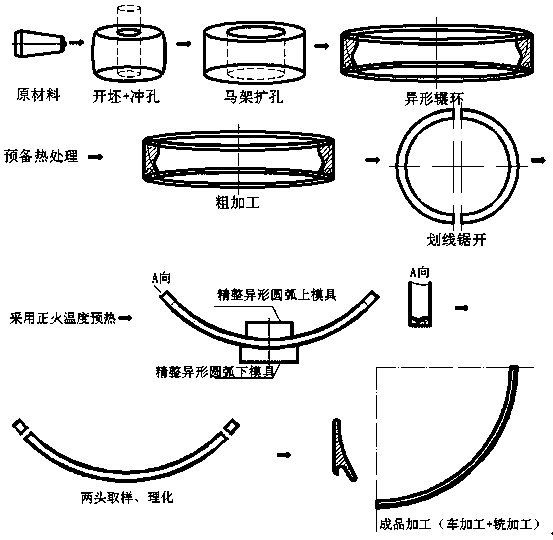

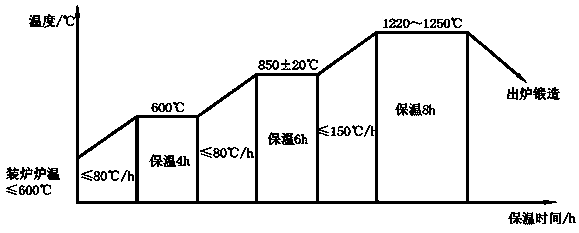

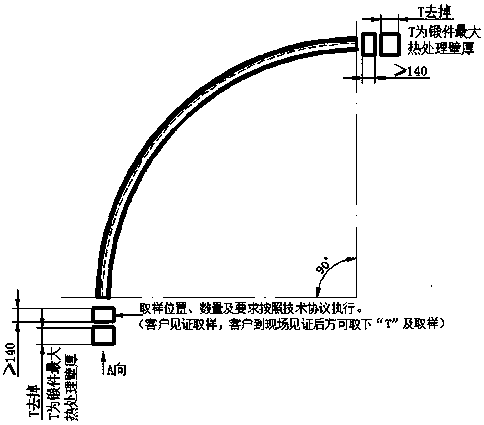

Low-alloy high-strength high-impact-energy extra-large special-shaped ring forging and forging method thereof

ActiveCN108914015AOptimize chemical compositionAvoid wastingMetal-working apparatusFurnace typesChemical compositionManufactured material

The invention discloses a low-alloy high-strength high-impact-energy extra-large special-shaped ring forging. Low-alloy high-strength steel comprises, by weight, 0.08-0.12% of C, 0.5-0.6% of Mn, lessthan or equal to 0.006% of P, less than or equal to 0.006% of S, 0.5-0.65% of Si, 1.4-1.5% of Cr, 0. 55-0.65% of Mo, 0.1-0.2% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.04% of V, 0.03-0.04% of Nb, 0.02-0.04% of Al, less than or equal to 0.01% of Sn, less than or equal to 0.01% of As, less than or equal to 0.0012% of Sb and the balance Fe and impurities, then through nozzle cold sawing, riser collection, riser heat chopping, then three times of upsetting and two times drawing, broaching chambering, special-shaped ring rolling, preparatory heat treatment, rough turning, sawing, preheating and arc finishing. In this way, chemical compositions of raw materials are optimized, a reasonable matching heat treatment system is adopted, the stability of the impact work can be improved through maximum simulated post-weld heat treatment of the materials, the product once inspection pass rate is increased to 100%, energy waste caused by rework and repair is avoided, the production cycle is shortened, the manufacturing cost is reduced, and the competitiveness of enterprises is improved.

Owner:AVIC EXCELLENCE FORGING WUXI

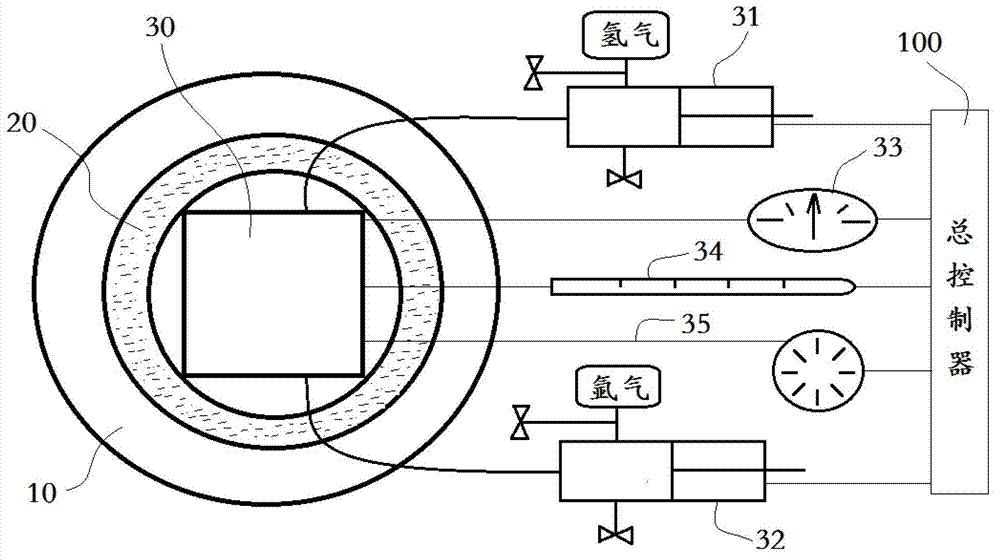

Sintering technology for cemented carbide extrusion bar

ActiveCN102921948AImprove the passing rate of one-time inspectionGuaranteed sintering atmosphereFurnace temperatureInternal pressure

The invention discloses a sintering technology for a cemented carbide extrusion bar. The sintering technology comprises four continuous processes of positive-pressure hydrogen dewaxing, partial-pressure sintering, high-pressure and high-temperature sintering, and cooling. At a normal temperature, hydrogen is filled into an empty sintering furnace, the furnace temperature is gradually boosted to 600 DEG C stage by stage in 490 minutes, the hydrogen is cut off, a mechanical pump is used for controlling the vacuum degree in the furnace to be about 10 pascals of the inner pressure of a sintering box, argon is then filled into the sintering box so as to ensure that the inner pressure of the sintering box is between 300 and 600 pascals, the furnace temperature is gradually increased to 1410 DEG C in 235 minutes stage by stage under the pressure of 300-600 pascals, the furnace is kept at the temperature of 1410 DEG C for 60 minutes, high-pressure argon of 60 bars is filled into the furnace for 20 minutes after the thermal insulation at 1410 DEG C is maintained for 30 minutes, the high pressure of the argon is maintained for 10 minutes, the pressure maintaining and temperature maintaining are finished at the same time, and then, the furnace begins to be cooled. Under the condition of fully filling the high-pressure argon in the furnace, the furnace is naturally cooled to 900 DEG C and is then quickly cooled to below 50 DEG C after about 300 minutes. The sintering technology can be used for effectively improving the bending percent of pass of the thin cemented carbide extrusion bars with the diameter of no more than phi 6 millimeters.

Owner:江西江钨硬质合金有限公司

Machining process of propeller shell

The invention discloses a machining process of a propeller shell, comprising the following steps of: A, taking a steel plate and cutting the steel plate by a straight-line cutter or a cutting machine, so as to guarantee that the error degree of the cut steel plate is less than 2 mm; B, rolling the cut steel plate by using a rolling machine; C, butting and welding two ends of the rolled steel plate to form a cylinder, and carrying out nondestructive testing on a welding part; D, grinding a welding seam by using a grinding machine; and E, pressing and molding the grinded cylinder by using a mould to prepare the propeller shell. The machining process of the propeller shell has the advantages of improving the working efficiency and further improving the quality of products.

Owner:NANTONG HONGBO MACHINERY

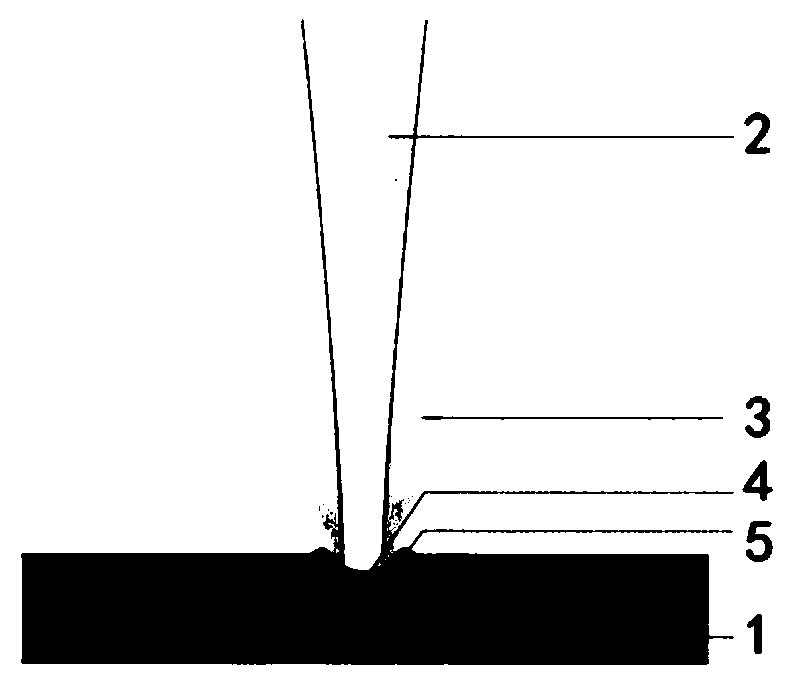

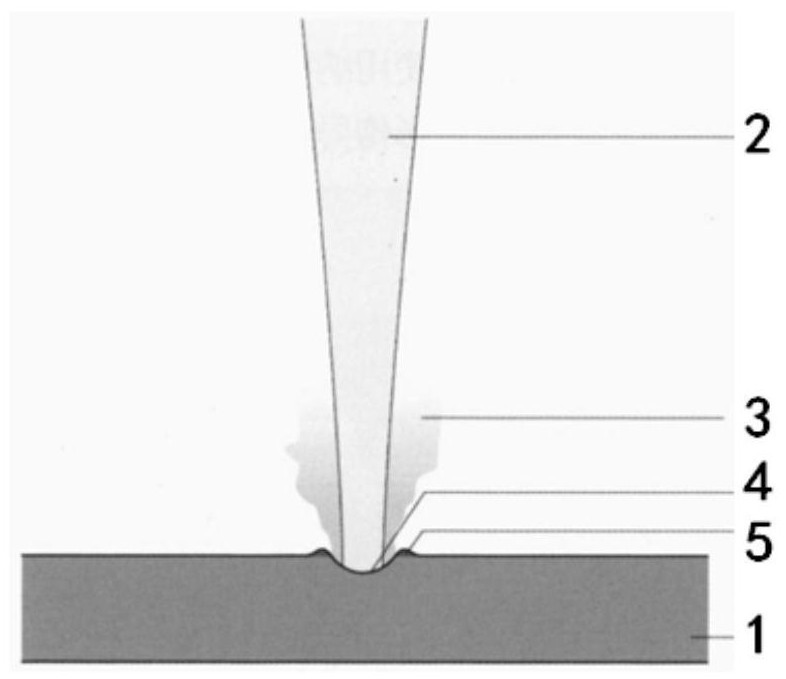

Technique for preventing defects of surfacing wear-resistant layer of part

InactiveCN104308327AImprove the passing rate of one-time inspectionAvoid scratchesArc welding apparatusIsosceles trapezoidWear resistant

The invention discloses a technique for preventing defects of a surfacing wear-resistant layer of a part. By the technique, the surfacing quality of parts such as pistons is improved, the number of rework is reduced, the one-step delivery-check qualified rate of the parts is improved, and the production cost is reduced. According to the technical scheme, the technique comprises the following steps of (1) roughly turning outlines of a piston part to obtain a part with a cylindrical boss structure and forming an annular groove with the inverted-isosceles-trapezoid-shaped section in a cambered surface of a large end of the part; (2) surfacing a nickel-base superalloy auxiliary layer in the annular groove, performing crossing symmetrical welding, transversely welding the annular groove along the axial direction, sequentially welding the annular groove until surfacing on the whole annular groove of the part is finished and machining the auxiliary layer; (3) surfacing an aluminum bronze layer on the auxiliary layer and performing crossing symmetric welding; and (4) sequentially performing destressing treatment and finish machining on the piston part after the piston part is subjected to surfacing so as to obtain a finished product of a piston.

Owner:AECC AVIATION POWER CO LTD

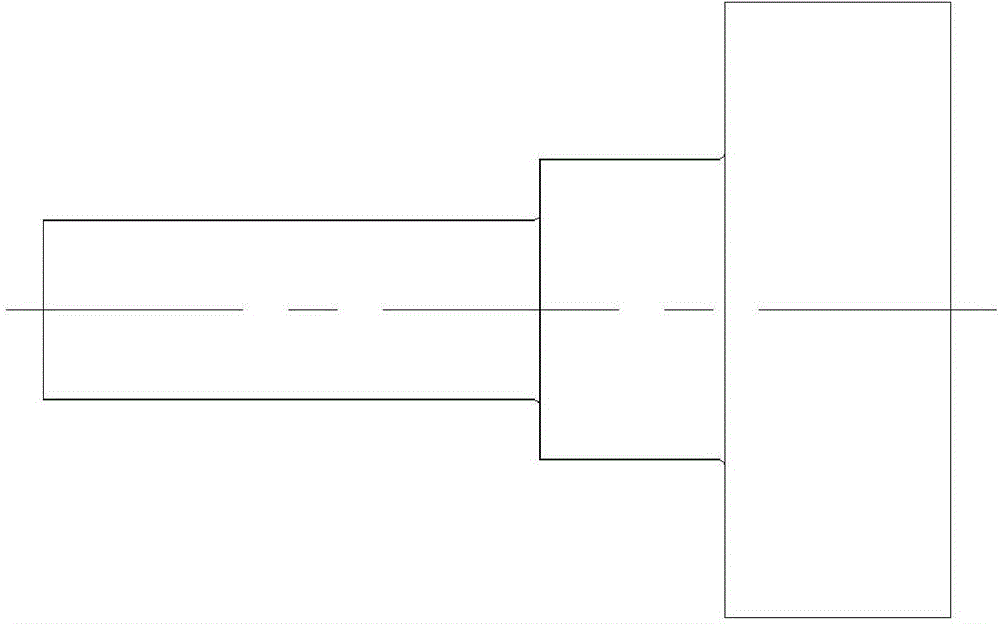

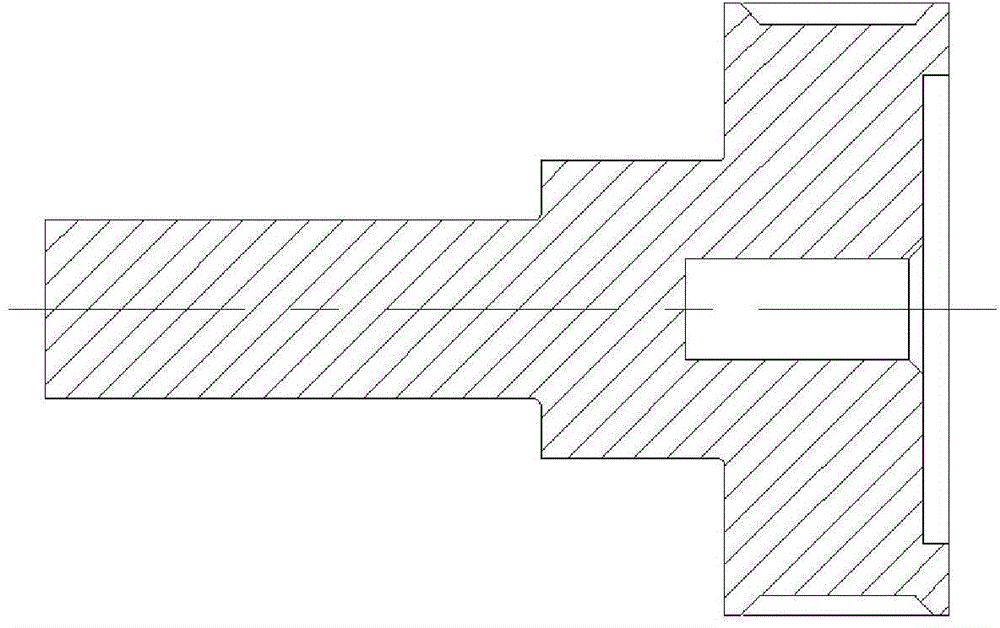

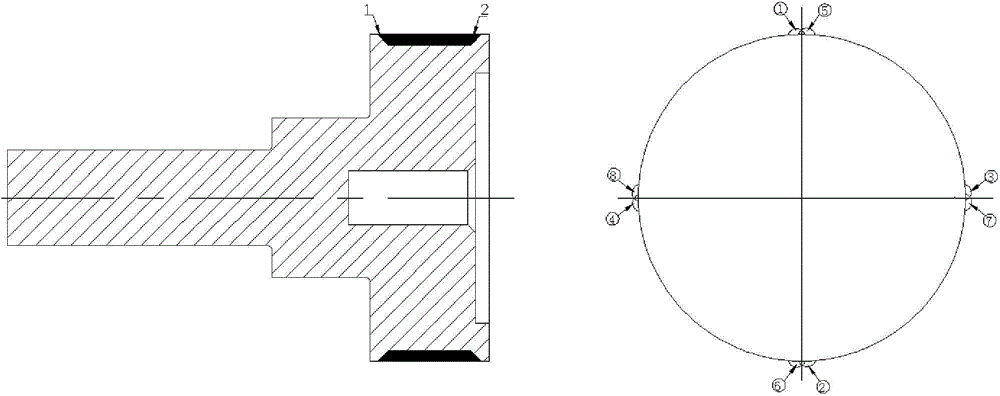

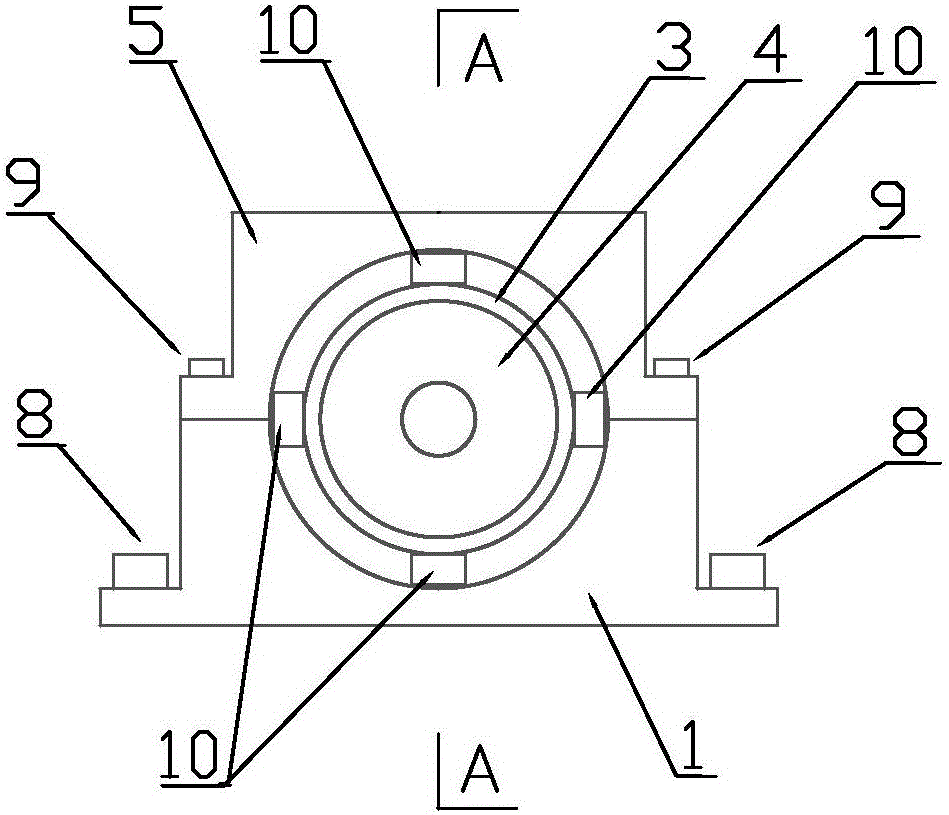

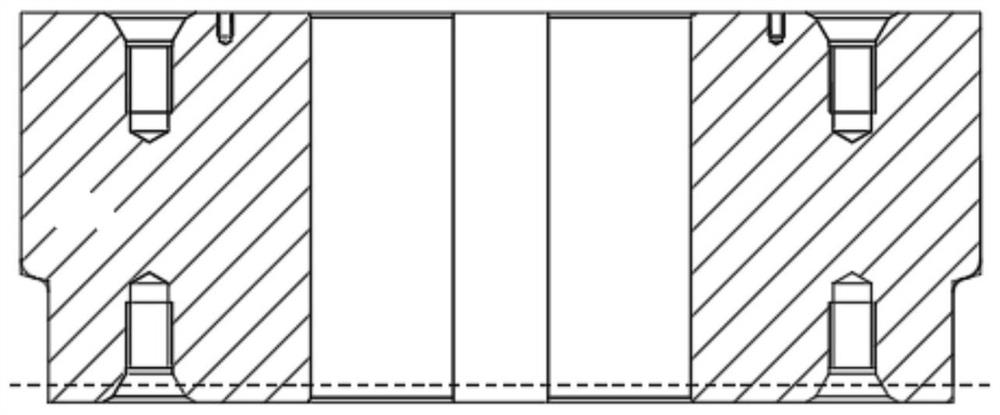

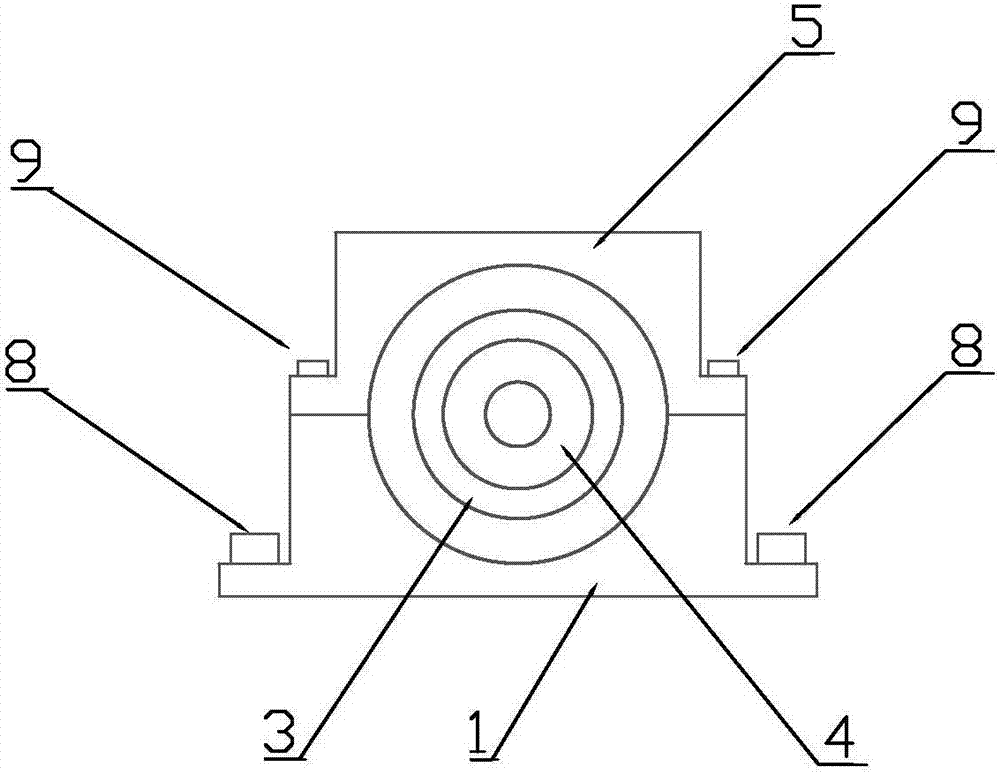

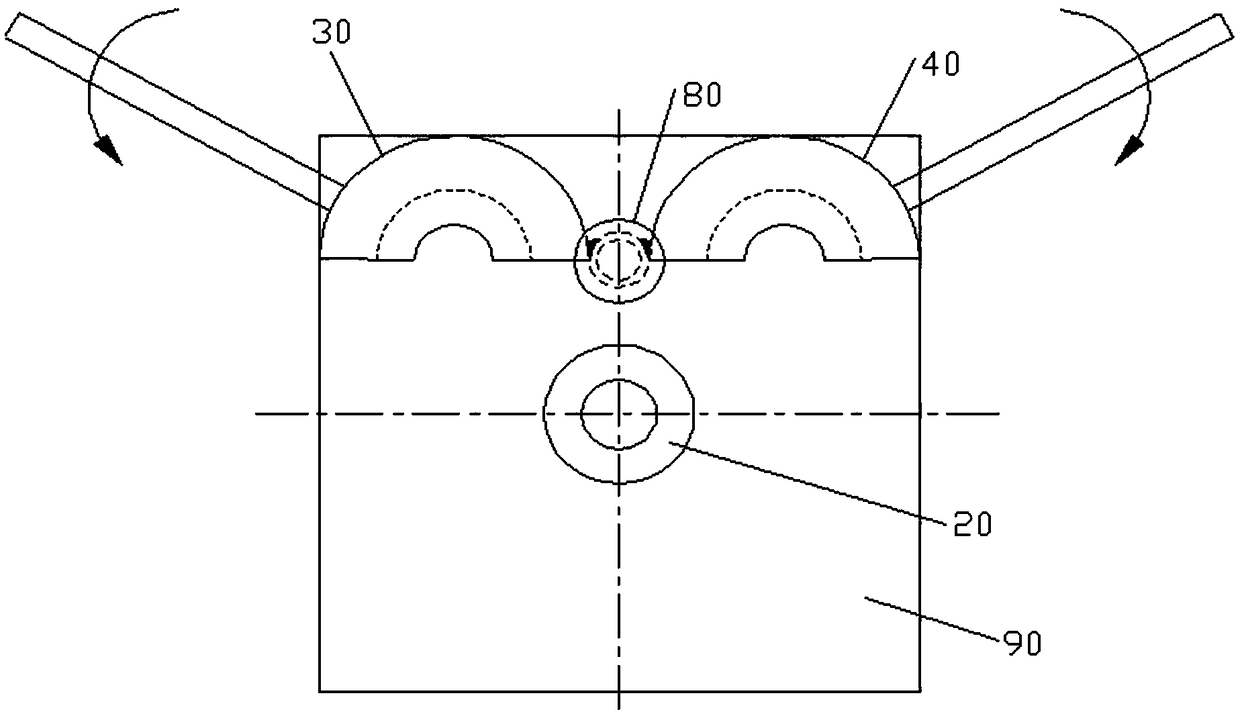

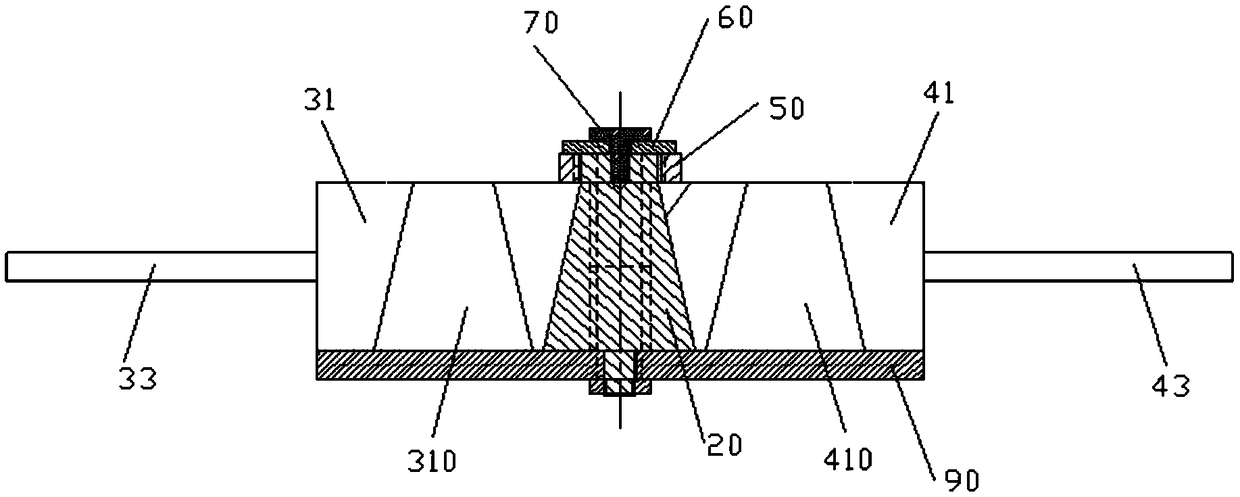

Wire/cable spinning mould

ActiveCN105869784AReduce volumeReduce manufacturing costCable/conductor manufactureInterference fitGear wheel

The invention discloses a wire / cable spinning mould, comprising a base, a thrust self-aligning roller bearing, a gear sleeve, a stranding die, an upper pressing cover, a signal pick-up device, a controller and a servo motor, wherein the thrust self-aligning roller bearing is arranged in each of the base and the upper pressing cover, the thrust self-aligning roller bearing is in interference fit with the gear sleeve, an external gear is arranged at one end of the gear sleeve, fastening antiskid bolts are arranged at the other end of the gear sleeve, the stranding die is in fixed connection with the gear sleeve by means of the fastening antiskid bolt, an in-die hole, a stranding tapered hole and a die exit are formed in the stranding die, and base fastening bolts are arranged at the lower part of the base. According to the wire / cable spinning mould disclosed by the invention, as the controller and the signal pick-up device are employed to acquire a spinning speed of an equipment stranding body, and a frictional force that is exerted by the stranding die in a tangential direction is eliminated by means of a synchronous and homodromous rotation of the servo motor and the spinning mould; the spinning mould has the advantages of small volume, low cost and long service life; material wastage is reduced by 15-20%; the one-time delivery qualification rate can reach 98-100%; and the product quality is improved greatly.

Owner:ECHU SPECIAL WIRE & CABLE KUNSHAN CO LTD

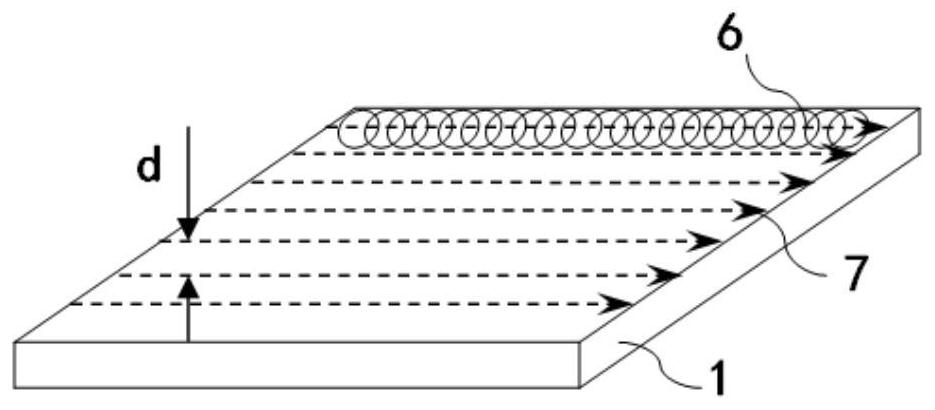

Method for improving adhesive force between metal film layer and high-dielectric-constant ceramic substrate

ActiveCN110729173AImprove uniformityReduce defectsSemiconductor/solid-state device manufacturingThin membraneIntegrated circuit

The invention relates to a method for improving an adhesive force between a metal film layer and a high-dielectric-constant ceramic substrate and belongs to the technical field of fine processing of microwave integrated circuits. According to the method, array scribing type etching roughening treatment is performed on the surface layer of a substrate by adopting ultraviolet laser with specific performance; high-temperature calcination is performed on the coarsened substrate under a high-temperature condition on the basis of a specific temperature curve, so that the roughness Ra value of the surface of the substrate is stabilized within the range of 0.25-0.3 mm, and good roughening uniformity is achieved; and the adhesive force between the metal film layer and the high-dielectric-constant substrate which serves as a base material in the process of manufacturing a microwave integrated thin film circuit.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

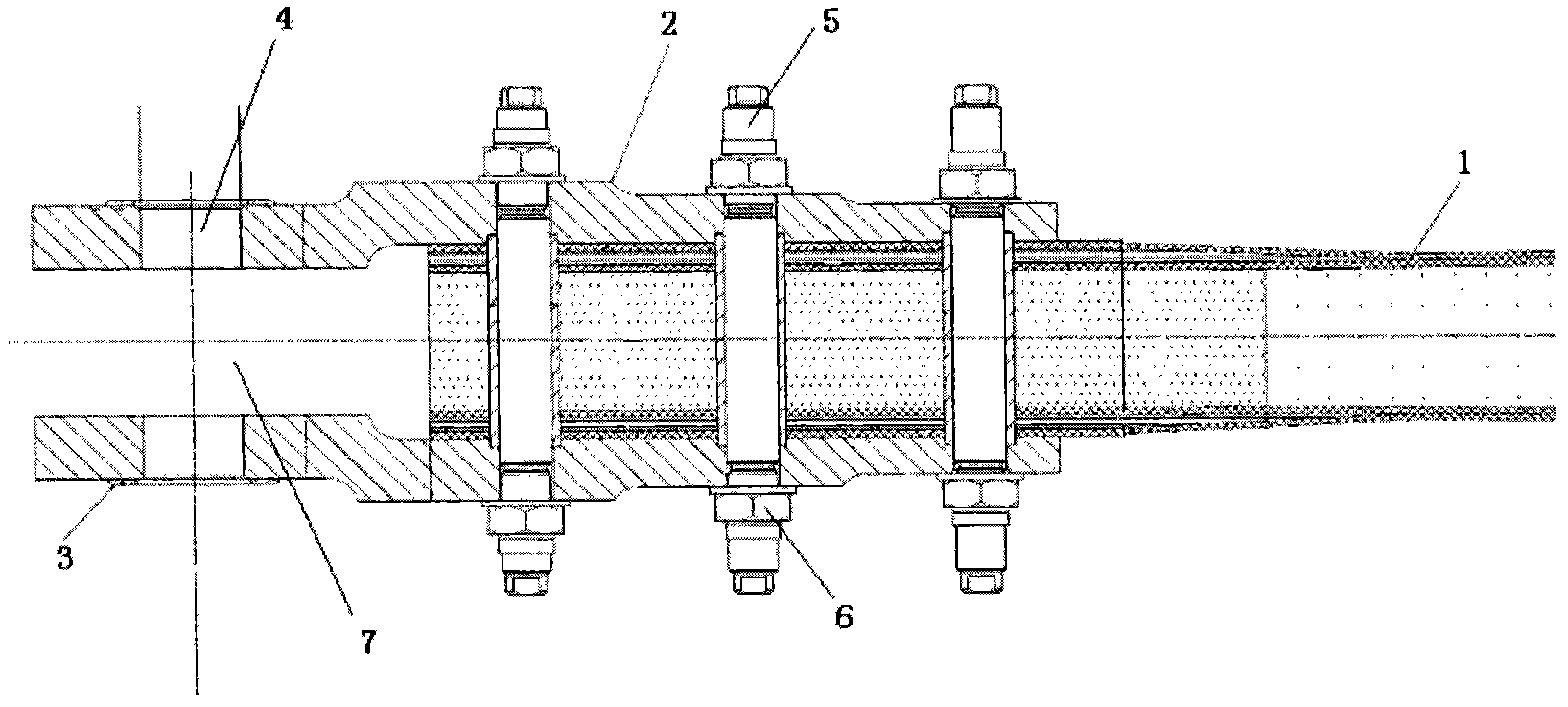

Manufacturing method of iron-based friction plate

ActiveCN101776123AReduce distortionImprove the passing rate of one-time inspectionFriction liningCopper platingDecomposition

A manufacturing method of iron-based friction plates comprises the following processes: 1. furnishing, 2. mixing, 3. profiling, 4. sintering friction layer, 5. plating copper on core boards, 6. pressuring and compositing at intermediate temperature, and 7. processing an oil groove; the friction layer is added with a process of sintering the friction layer after the profiling, i.e. the friction layer after the profiling is sintered into the powder base of the friction layer in a bell-type pressure sintering furnace or an iron-based through continuous sintering furnace, the sintering temperature is 1050 DEG C-1100 DEG C, heat preserving for 2.5-3.5 hours, the atmosphere is ammonia decomposition gas; the core board plating is formed by the steps that copper plating the core board by electroplating to be prepared into the core board plated copper, the core board is hung at a cathode, a copper board is hung at an anode, electroplate liquid with copper ion is added into a plating tank, direct current is conducted into the plating tank, and electroplating time is adjusted according to the thickness of plating; the thickness of the plating is 0.005-0.01mm; and the invention is characterized in that the core board has high strength, the deformation is small, the yield at one step of checking is high, and the cost is low, the method is suitable for mass production, and the like.

Owner:HANGZHOU ADVANCE GEARBOX GRP

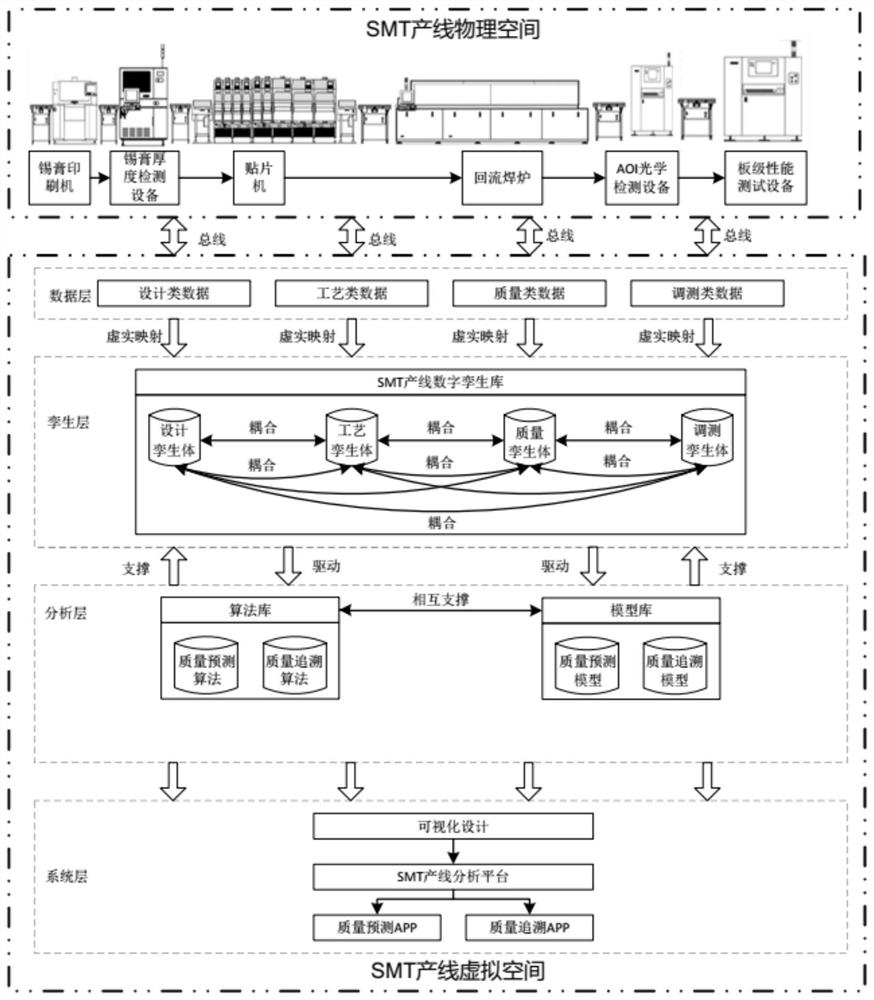

SMT production line quality analysis platform based on digital twinning

ActiveCN112288168AImprove the passing rate of one-time inspectionThe result is accurateForecastingResourcesProduction linePrediction algorithms

The invention discloses an SMT production line analysis platform based on digital twinning which is accurate in result and visual in process. According to the technical scheme, transmission of information and data is achieved between an SMT production line physical space and an SMT production line virtual space through a data bus, and a data layer divides the data into a design class, a process class, a quality class and an adjustment and measurement class according to data types and maps the data to a twinning layer in a virtual-real mode; the twinning layer organizes and couples the digitaltwinning bodies according to the functional relationship among the twinning bodies; wherein the analysis layer drives a quality prediction algorithm and a quality tracing algorithm through twinning bodies to perform tracing and quality prediction on the printing and welding quality of a production line, the system layer performs visual design based on the SMT production line digital twinborn library, the deep learning algorithm library and the quality prediction model and the quality tracing model in the model library; through an industrial prediction and quality tracing APP, the quality of the production line is visually displayed in real time in a three-dimensional space, and quality early warning is carried out in the product production process.

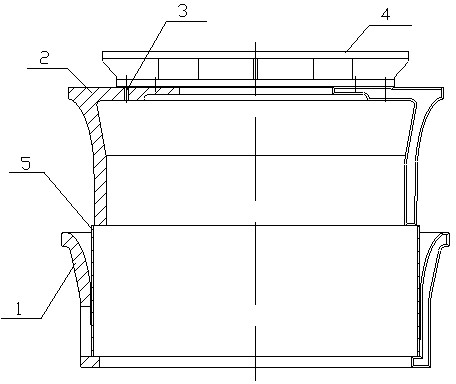

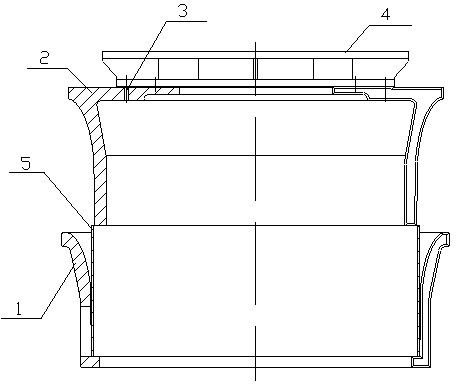

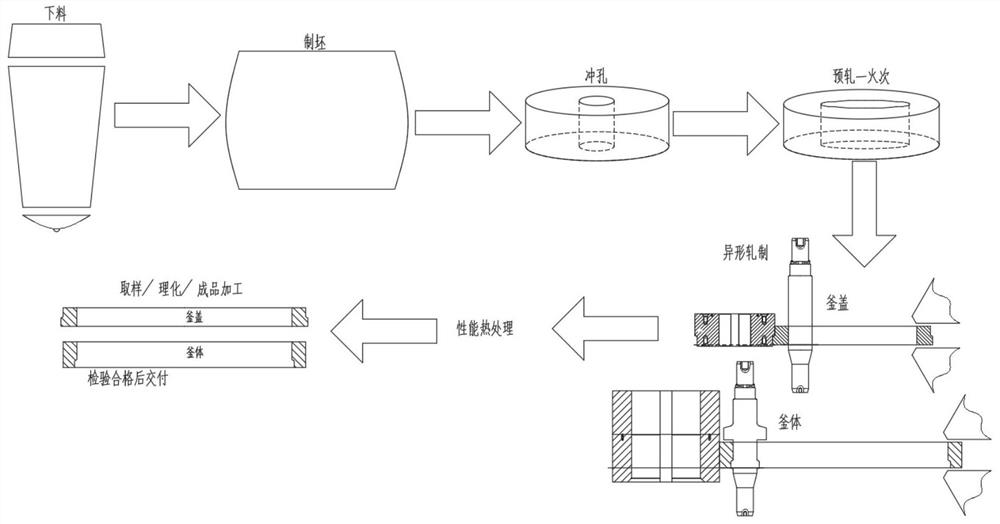

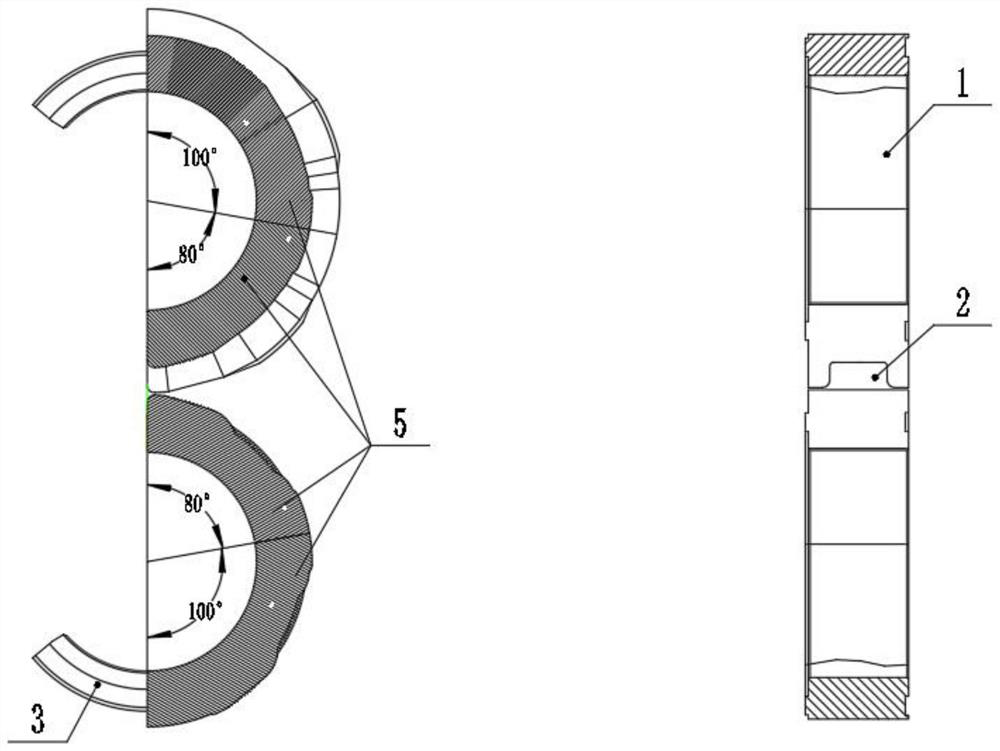

Manufacturing method of special-shaped ring forge piece of booster kettle flange

PendingCN114289650ASimple structureEasy to operateForging/hammering/pressing machinesMetal rollingMaximum diameterForge

The invention discloses a method for manufacturing a special-shaped ring forge piece of a pressurizing kettle flange, which comprises the following operation steps of: forming a kettle cover, pre-rolling a blank, replacing a special-shaped integrated main roller, rolling and forming, forming a kettle body, pre-rolling until an inner hole of the blank is larger than the maximum diameter of an integrated core roller, replacing the special-shaped integrated core roller, and forming the special-shaped ring forge piece of the pressurizing kettle flange. And then rolling and forming. According to the manufacturing method for the special-shaped ring forge piece of the pressurizing kettle flange, the core roller and the main roller are designed, a near-net forming mode is adopted, a kettle body and a kettle cover are rolled through a horizontal ring rolling machine, special-shaped rolling forming is adopted according to the product structure, a forming die is reasonably designed, and a performance heat treatment system is optimized; according to the special-shaped rolling production mode, the utilization rate of raw materials is increased, the production cycle is shortened, the manufacturing cost is reduced, the metal flow direction state of the product is guaranteed to the maximum extent, the comprehensive mechanical property of the product is further improved, and the market competitiveness of enterprises is further improved.

Owner:AVIC EXCELLENCE FORGING WUXI

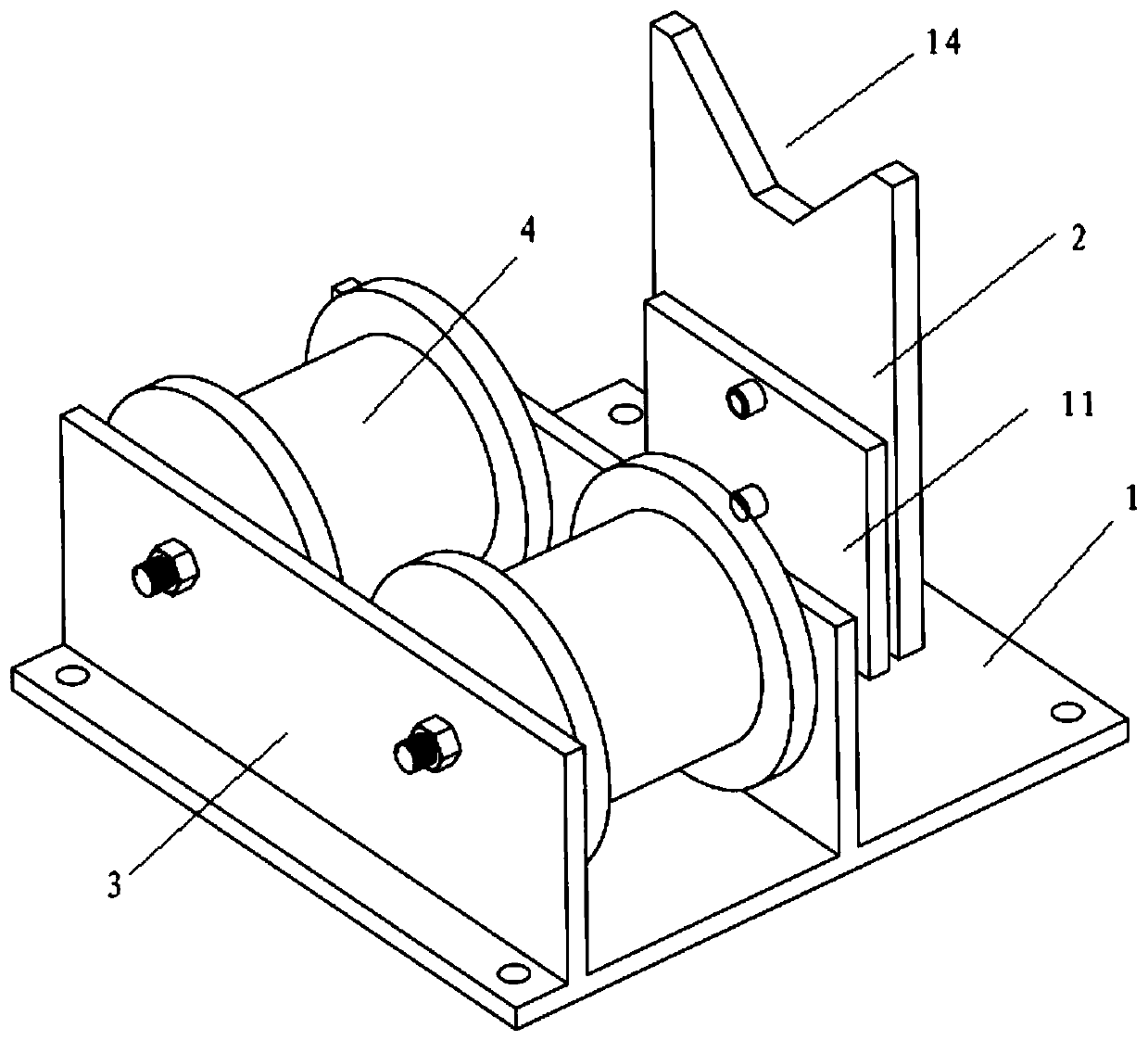

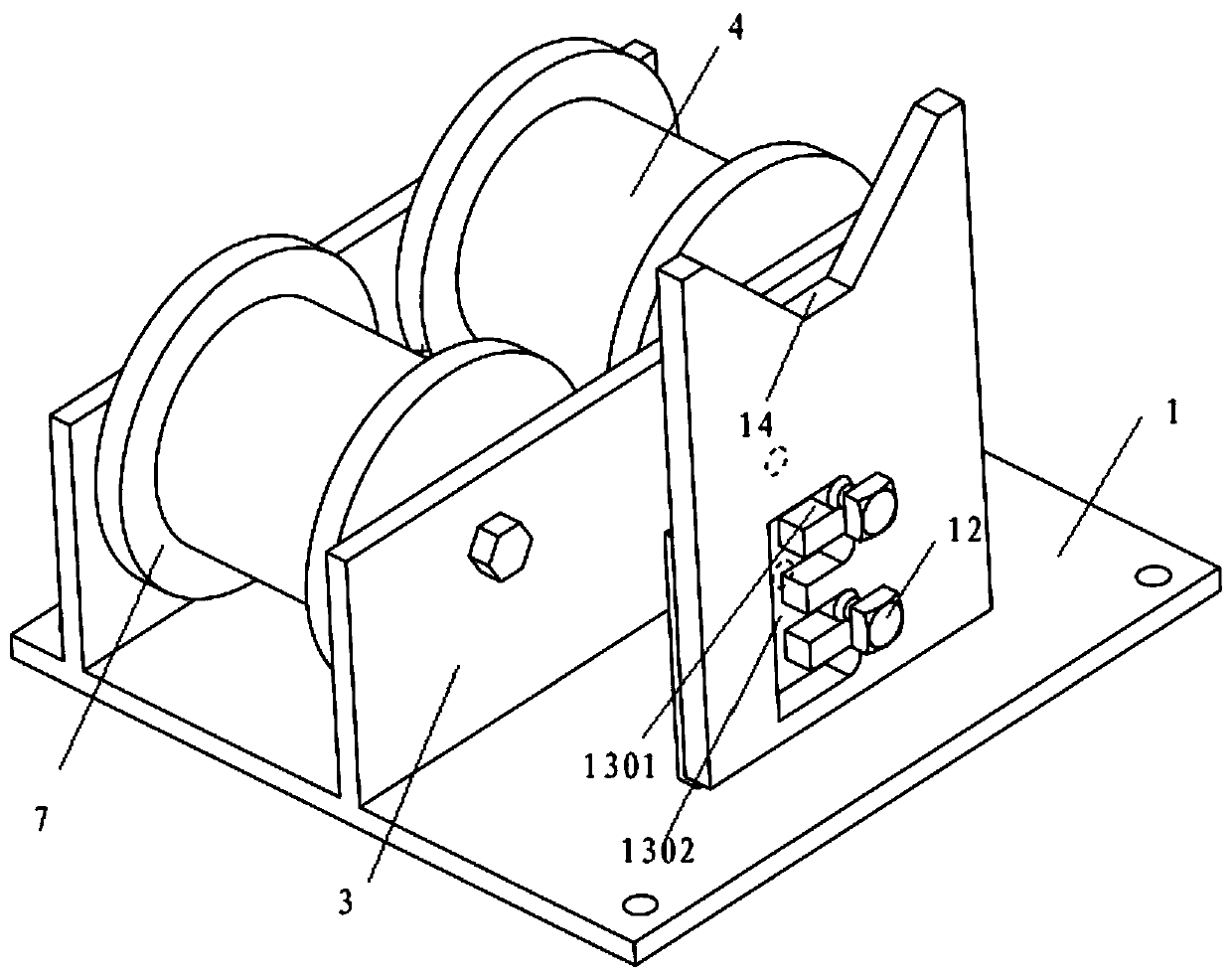

Detection device of wheel shaft

ActiveCN110186672AImprove the passing rate of one-time inspectionCheck carefullyMachine part testingVisual inspectionEngineering

The invention relates to the technical field of wheel shafts, and provides a detection device of a wheel shaft. The detection device comprises: a base; a plurality of rollers installed on the base andcapable of rotating around the axle of the rollers themselves, wherein a mounting space of a wheel component is formed between the rollers; and a support piece arranged at least one side of the rollers in the axial direction of the rollers, wherein a limiting groove / limiting hole of a shaft component is formed on the support piece. When the detection device of the wheel shaft is used for detecting the wheel shaft, the rollers are rotated to expose the portion of visual inspection to the maximum extent to ensure the more comprehensive and careful inspection by inspectors. The different portions of the wheel shaft are inspected, the rollers only need to rotate with no need for carrying the wheel shaft, so that the inspection efficiency is improved, the labor intensity of the personnel is reduced, and the workers are avoided to be damaged. Besides, the detection device of the wheel shaft reduces the problem incidence of product quality, such as the rework rate and the rework rate that the shaft caused because of unexpected bumping, and the one-time handing-over and inspection qualification rate of wheel shaft is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

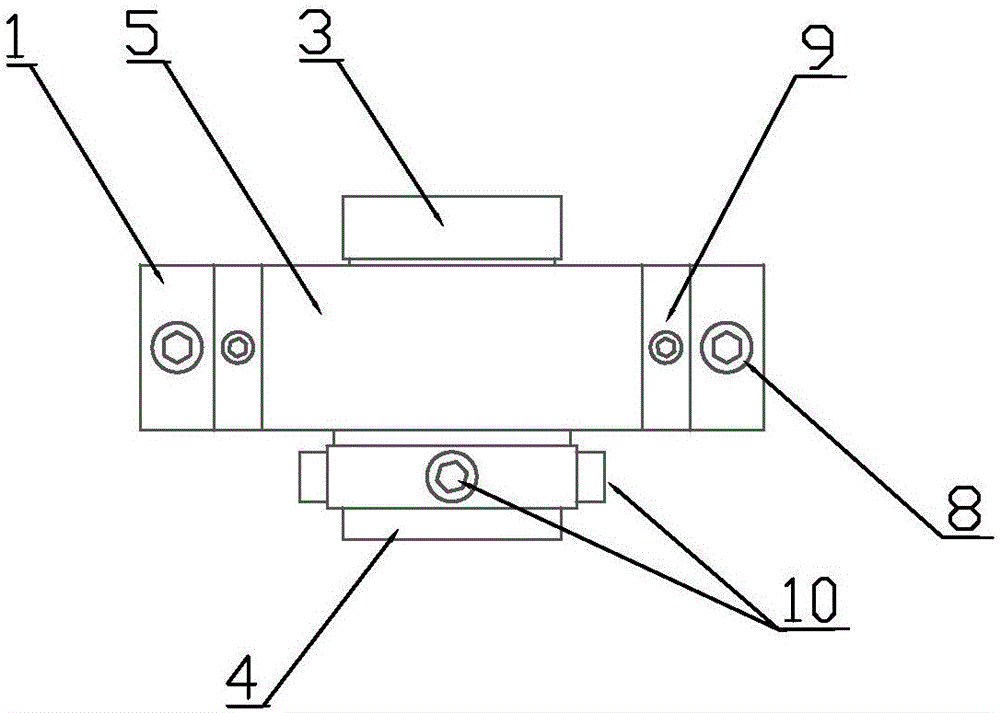

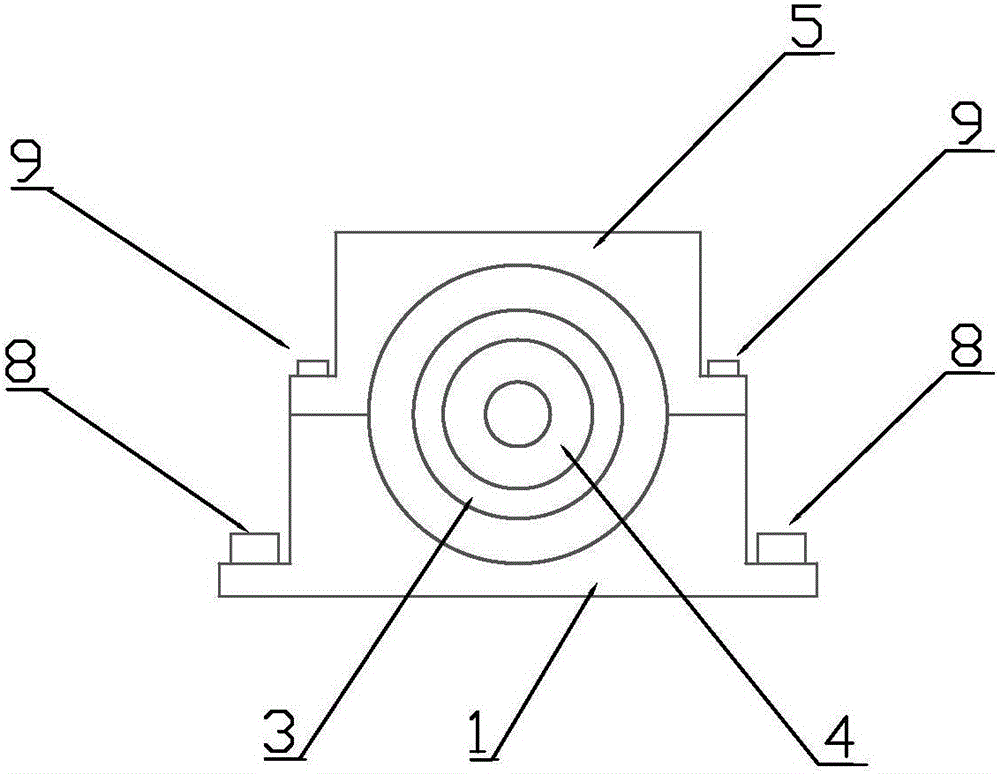

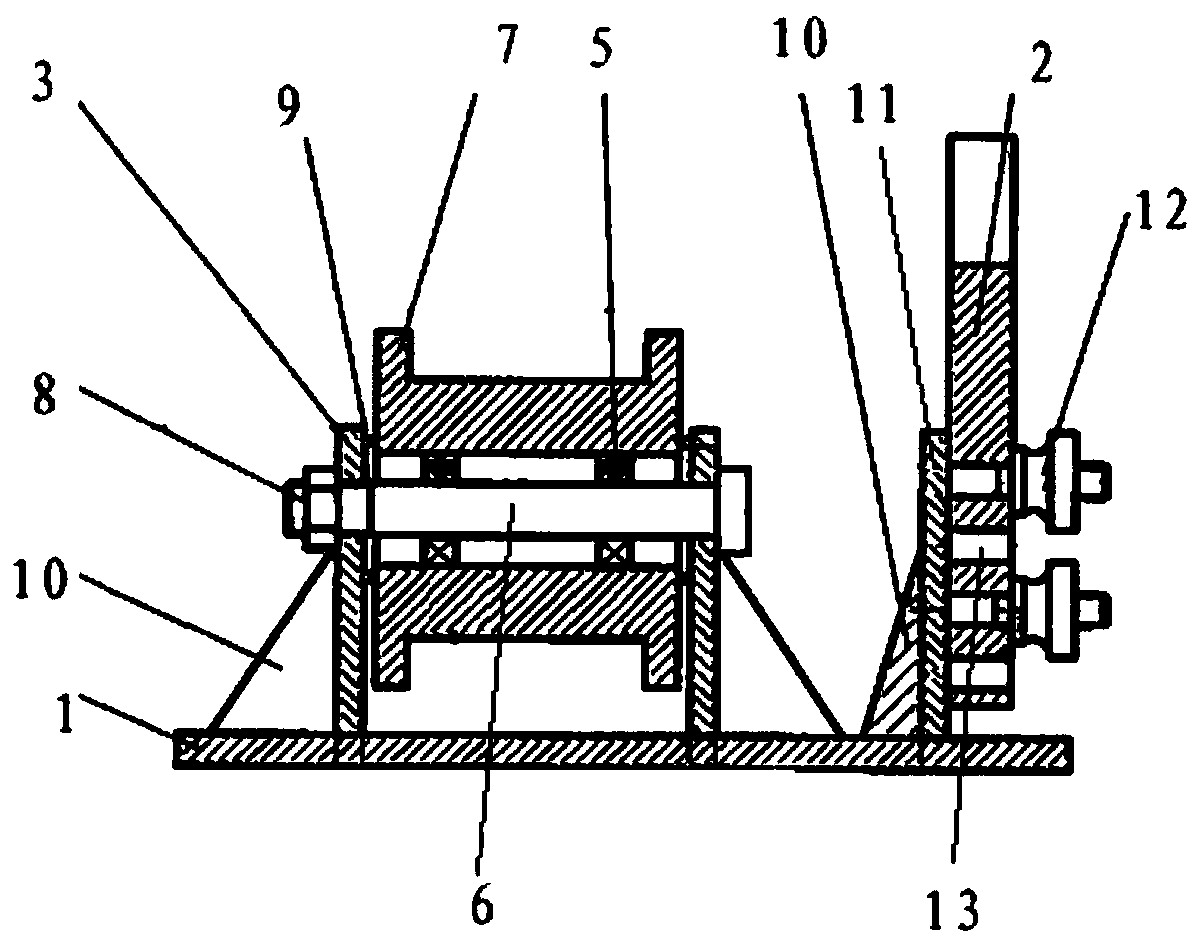

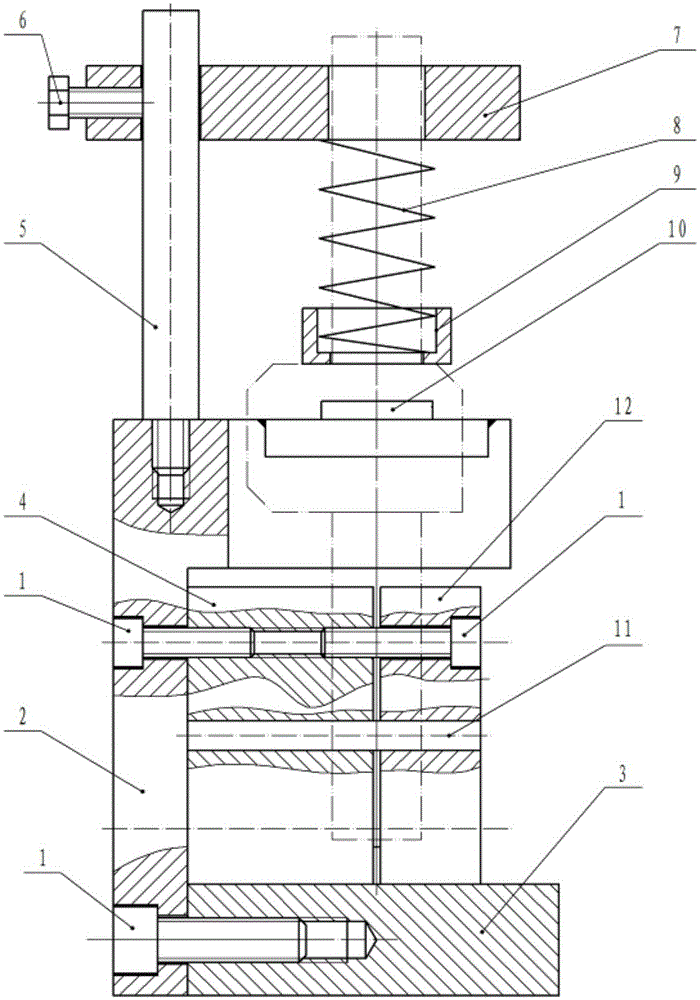

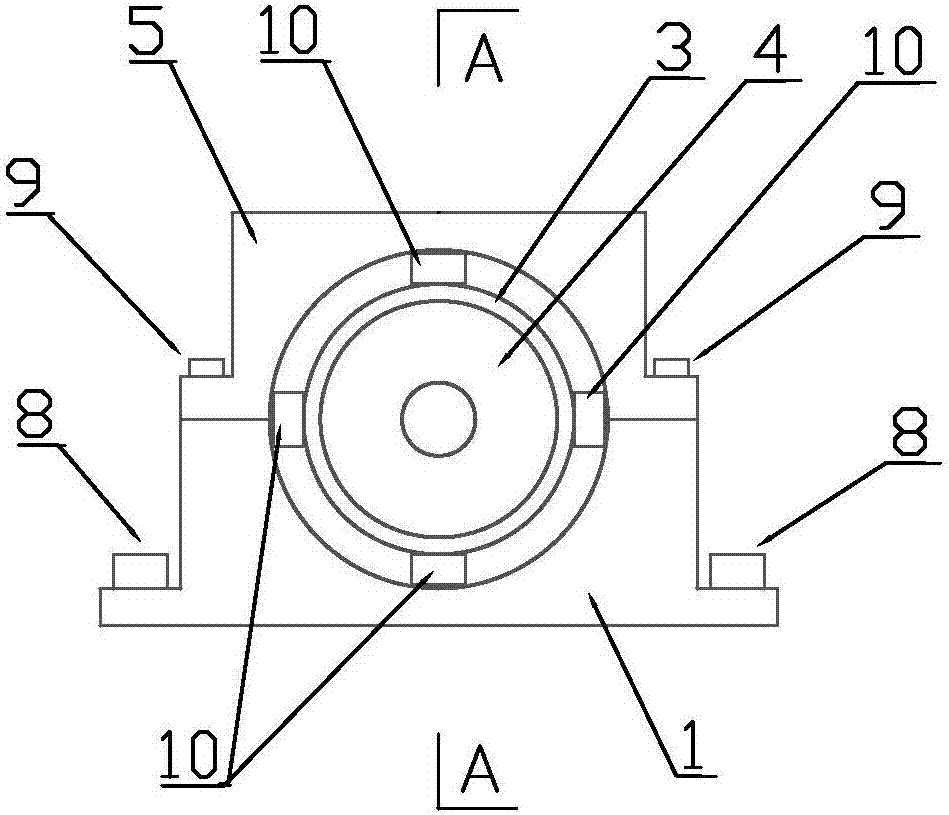

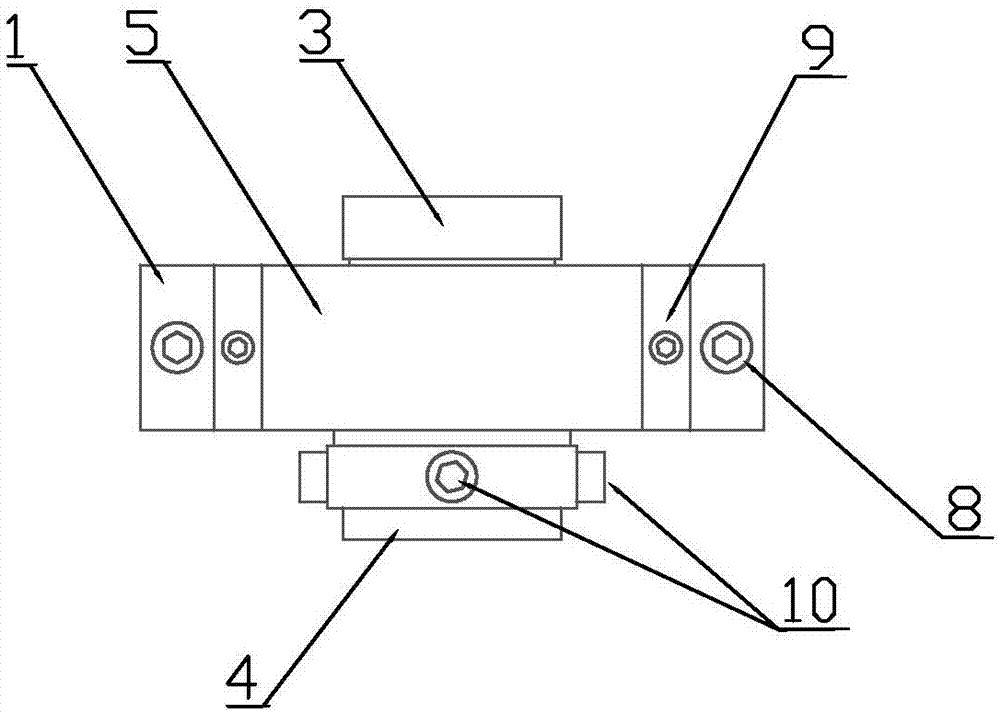

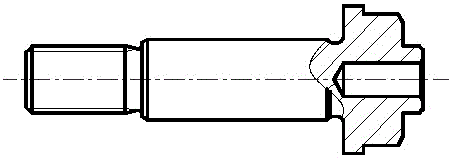

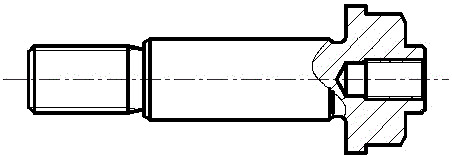

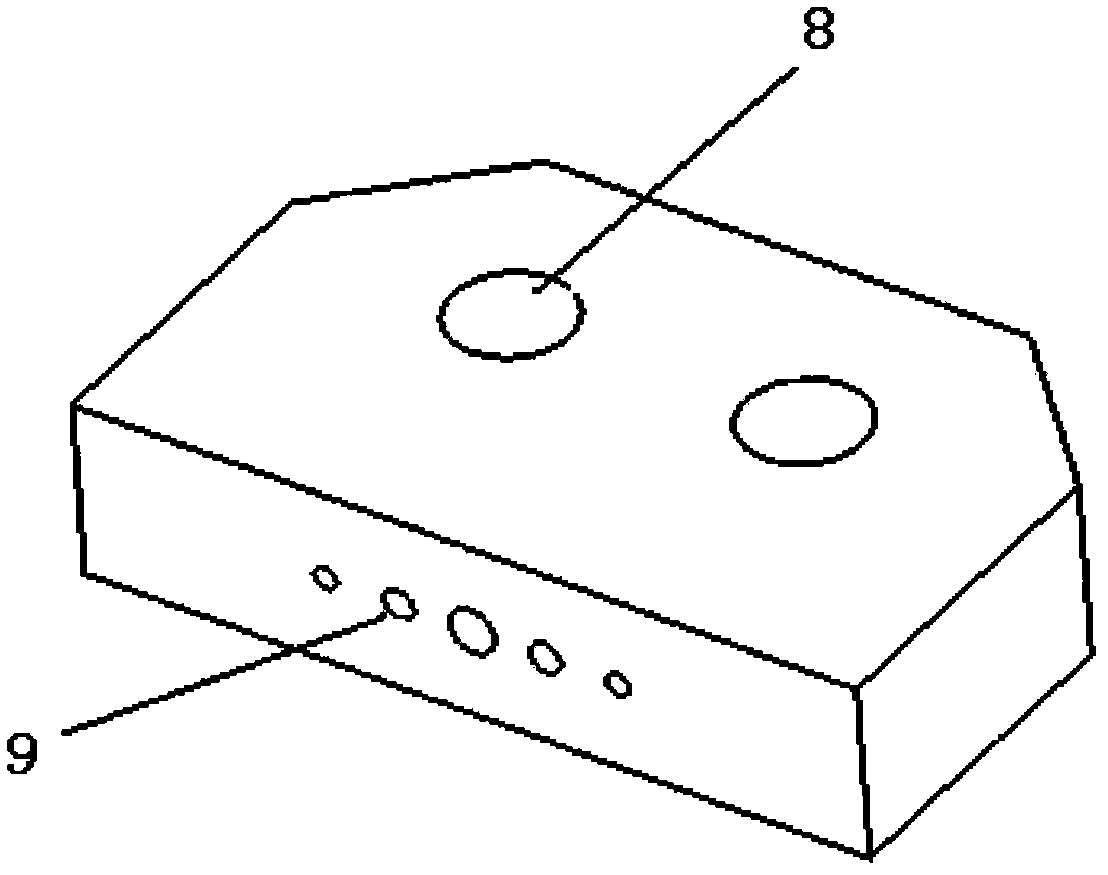

Grinding tool and method for square hole of servo mechanism roller transmission piston rod

ActiveCN106625205AEliminate the phenomenon of "collapse"Improve the passing rate of one-time inspectionLapping machinesWork carriersEngineeringPiston rod

The invention belongs to the technical field of precision grinding technologies and particularly relates to a grinding tool and method for a square hole of a servo mechanism roller transmission piston rod. The tool comprises a base, a support assembly fixed on the base, a fixed block fixed on the side surface of the support assembly and located at the upper part of the base, a sliding block fixed on the side surface of the fixed block and located at the upper part of the base, a vertical rod fixed at the upper part of the support assembly, a press plate fixed on the vertical rod and capable of moving up and down, a spring with one end fixed at the lower end of a middle hole of the press plate as well as a spring fixing seat fixed at the other end of the spring; and opposite V-shaped grooves are formed in the fixed block and the sliding block. With the precision grinding technology for the square hole of the servo mechanism roller transmission piston rod, the edge collapsing phenomenon is eliminated, the first-time yield is substantially increased to be 95% or higher, machining procedures are reduced, the workload of surface treatment and grinding procedures is also reduced, and the production quality and efficiency are substantially improved.

Owner:北京实验工厂有限责任公司 +1

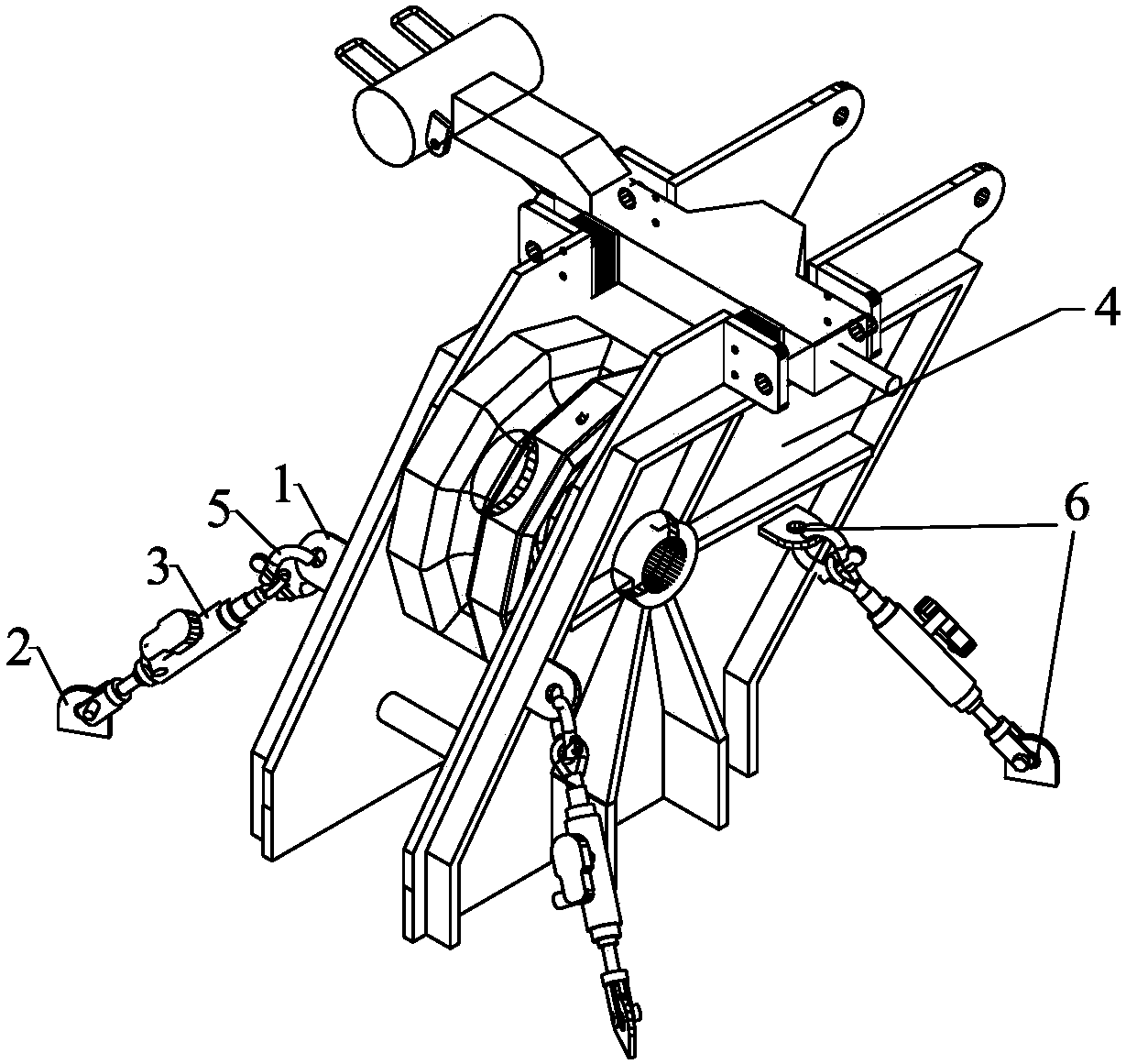

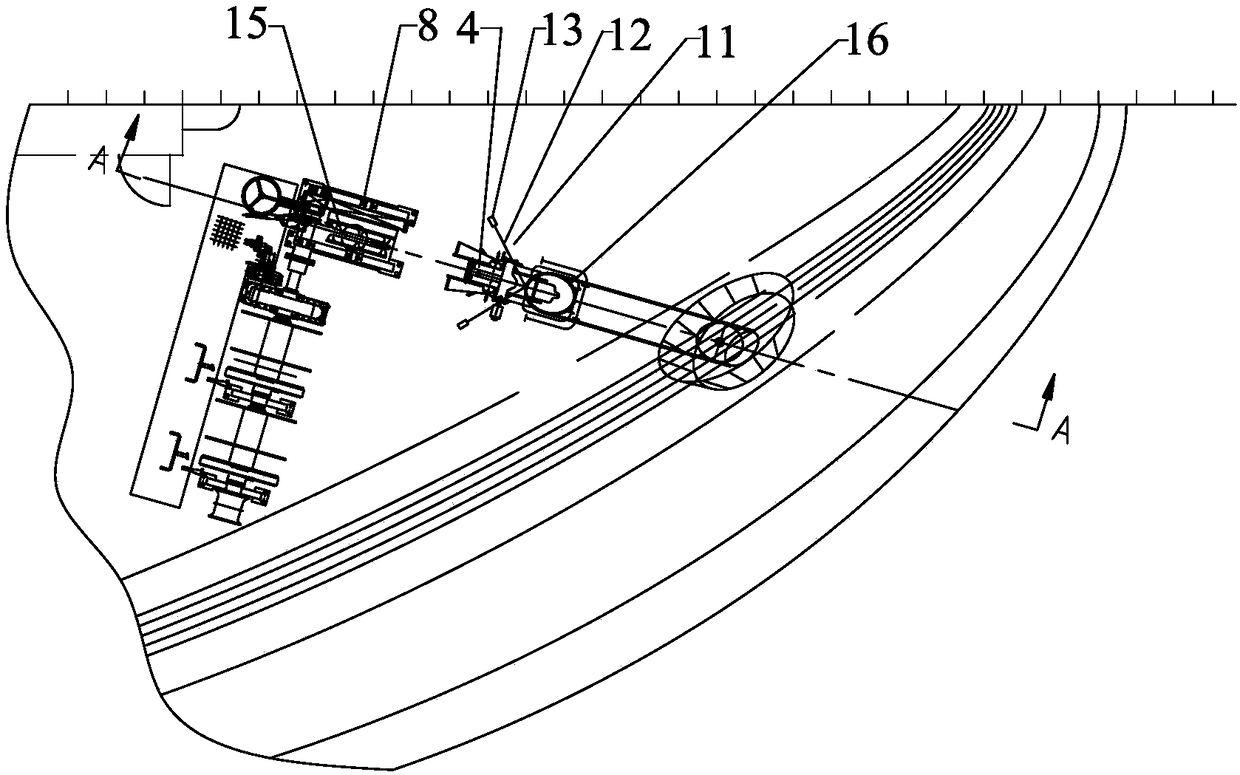

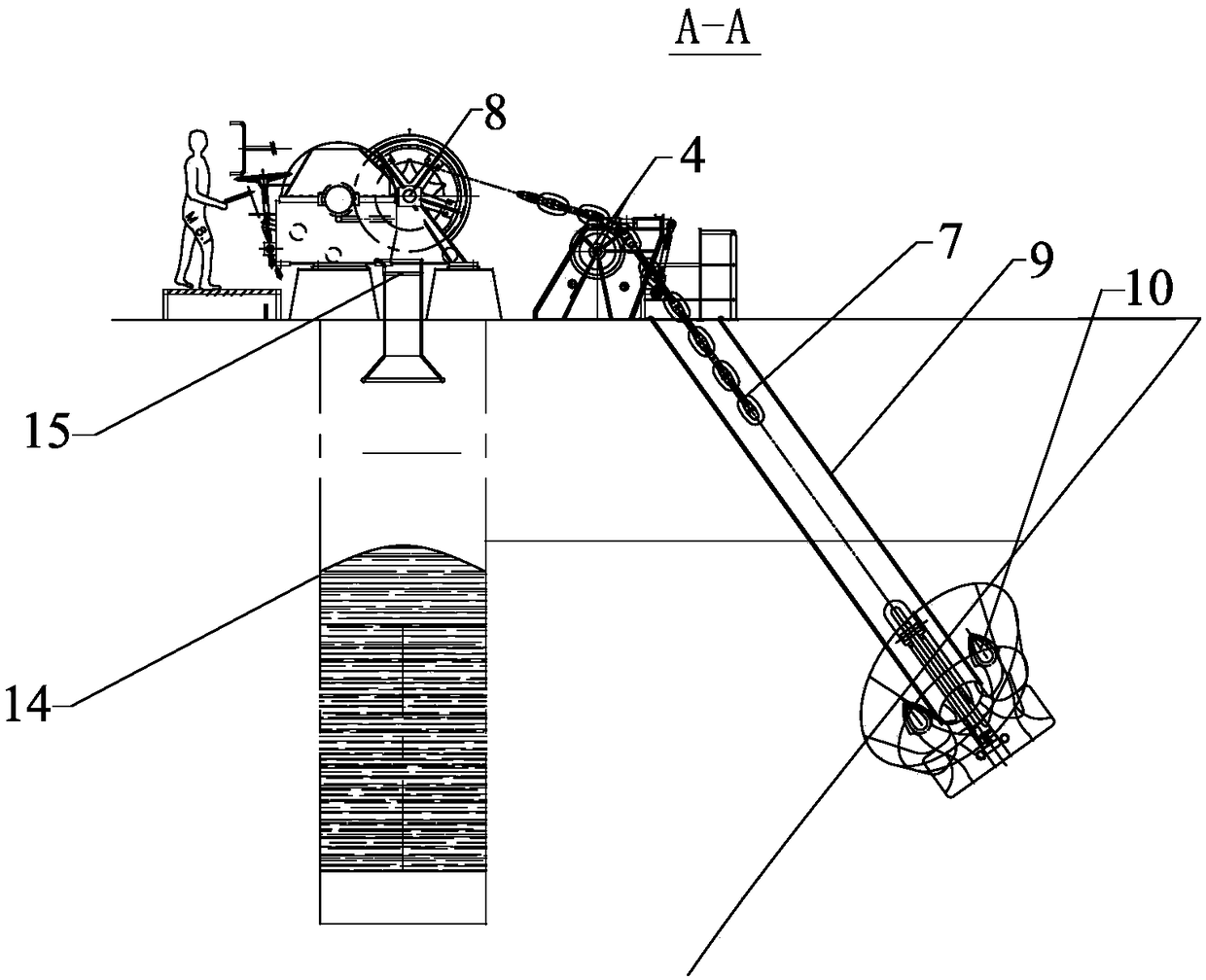

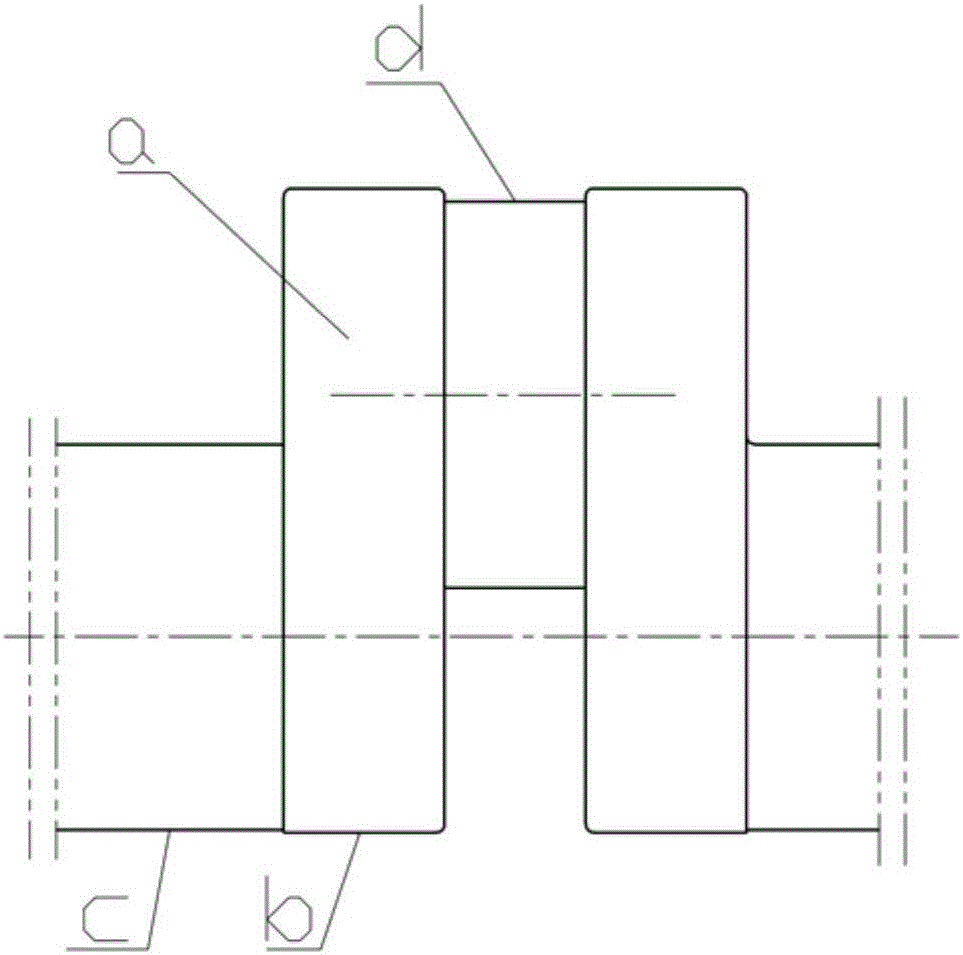

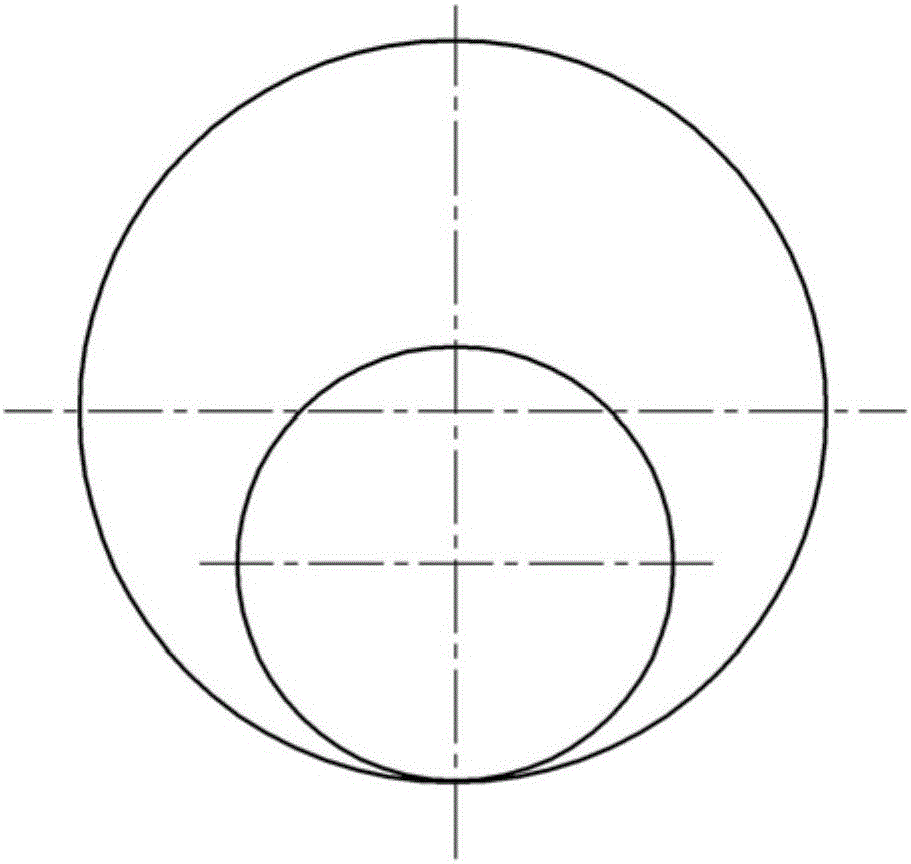

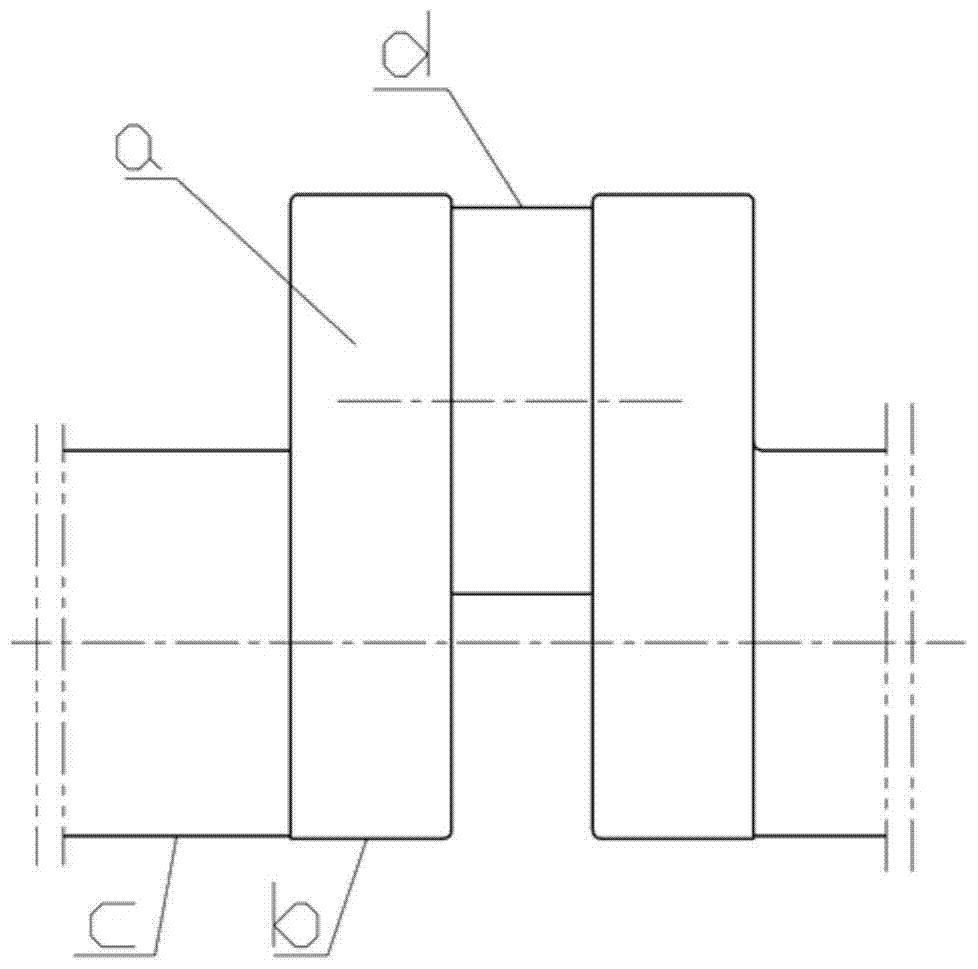

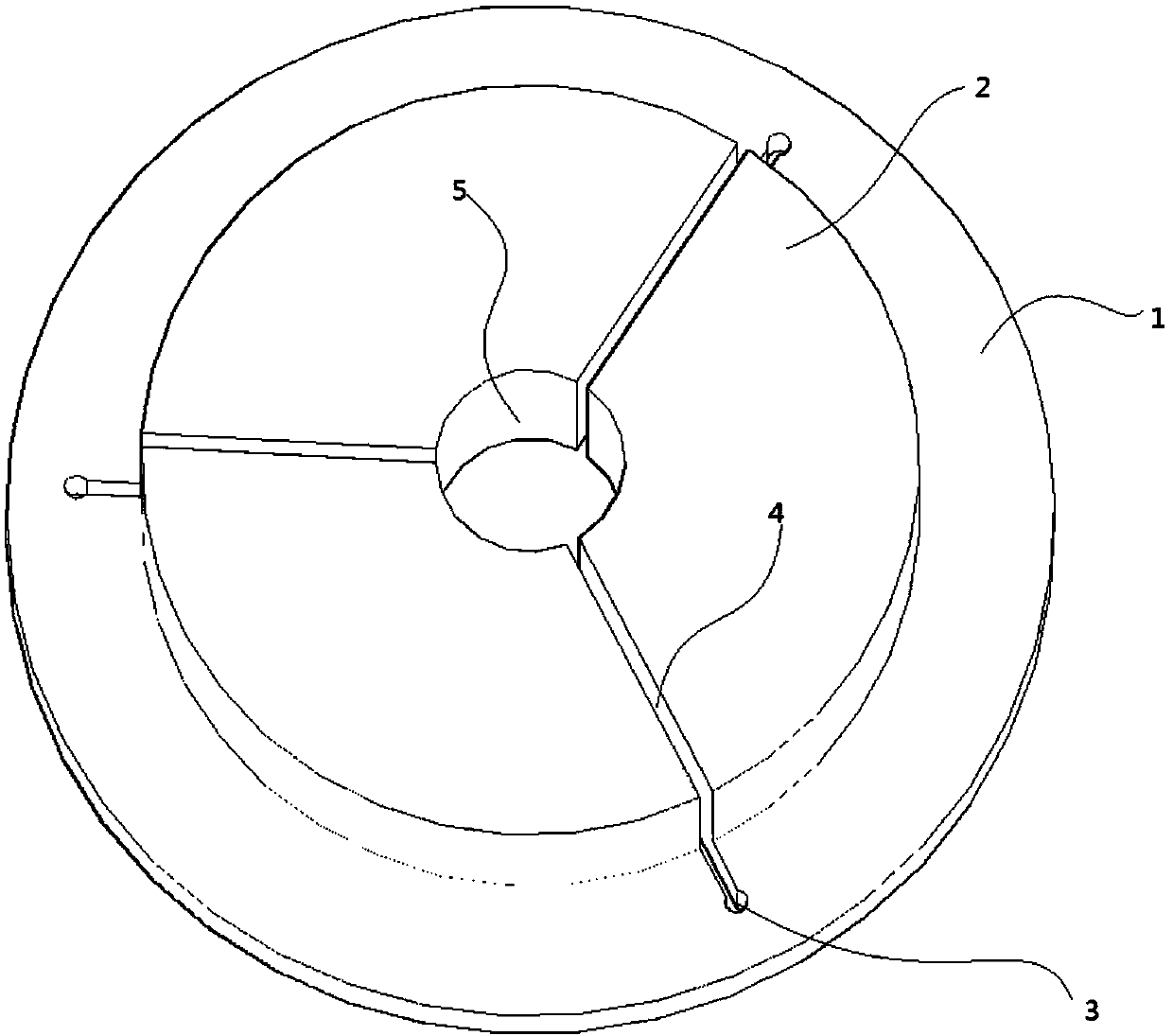

Quick positioning and installation tooling and positioning and installation method of a chain stopper

The invention provides a rapid positioning and mounting tool for a chain stopper and a positioning and mounting method. The rapid positioning and mounting tool for the chain stopper at least comprises a plurality of groups of positioning and mounting parts. Each group of positioning and mounting parts at least comprises a first fixing part (1), a second fixing part (2) and a length adjusting part (3), wherein one end of the length adjusting part (3) is connected with the first fixing part (1); the other end of the length adjusting part (3) is connected with the second fixing part (2); and the length of the length adjusting part (3) can be adjusted. During positioning and mounting, the first fixing parts (1) are fixedly connected to the chain stopper (4); the second fixing parts (2) are fixedly connected to surfaces, to be mounted, of the chain stopper (4); the plurality of positioning and mounting parts are distributed along the periphery of the chain stopper (4); and the mounting position of the chain stopper (4) is adjusted by adjusting the lengths of the length adjusting part (3). The rapid positioning and mounting tool for the chain stopper is advantaged in that the rapid positioning and mounting tool is easy to operate, a plurality of adjusting operations can be realized within a short time, autonomy, controllability and mobility can be enhanced and the cost can be reduced.

Owner:JIANGNAN SHIPYARD GRP CO LTD

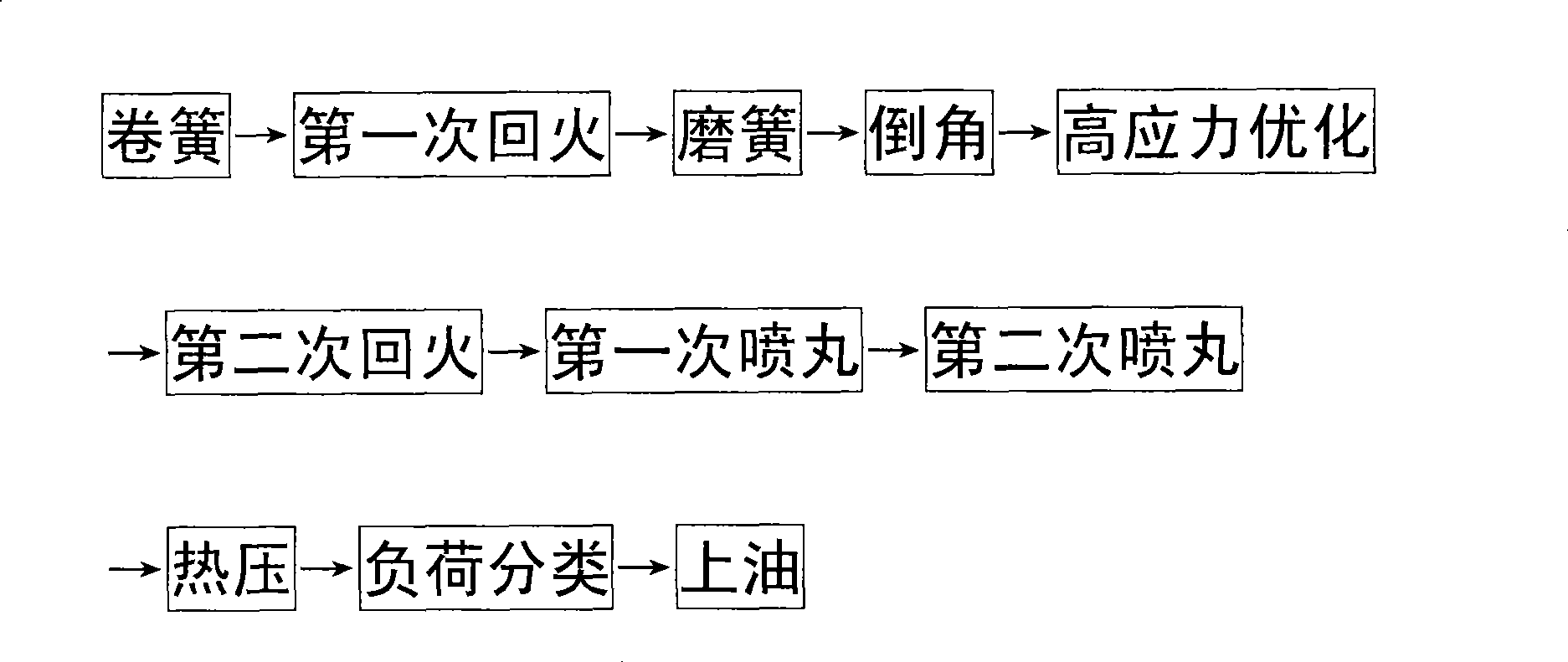

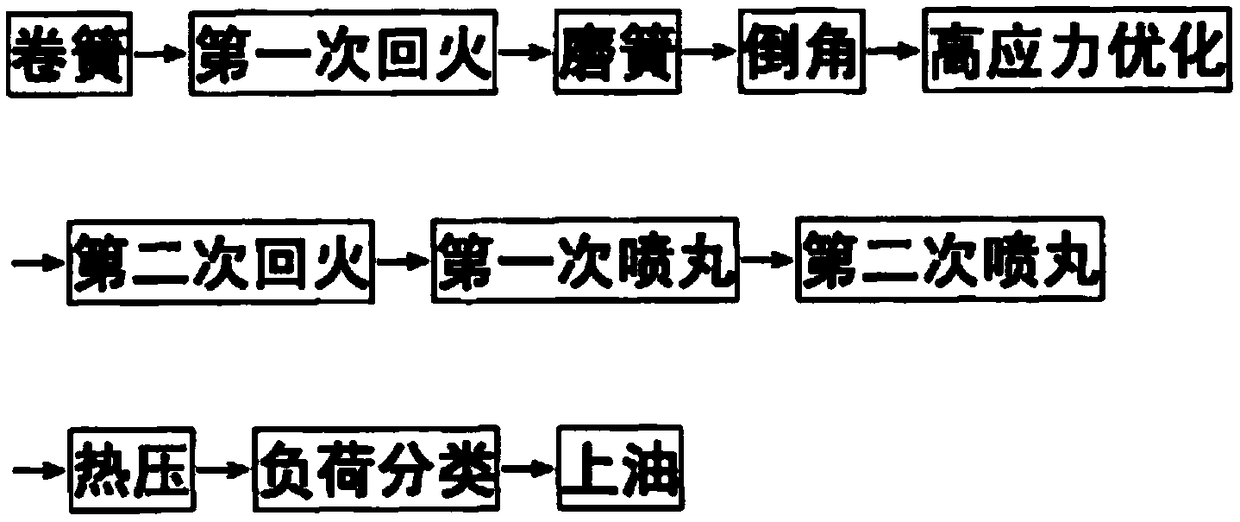

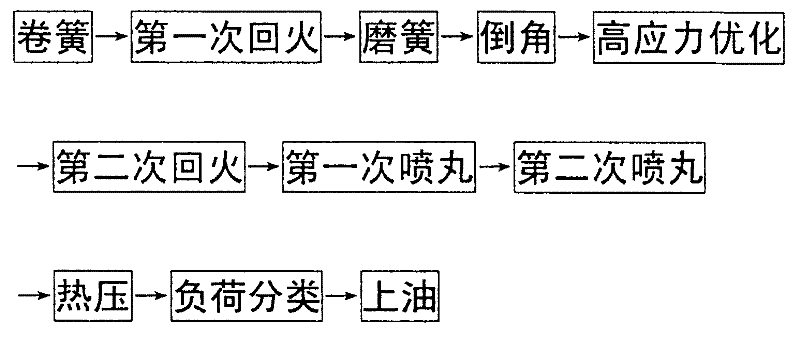

Manufacturing technology of high-stress valve spring

InactiveCN108723719AReduce length sorting processHigh concentricityManufacturing technologyWork in process

A manufacturing technology of a high-stress valve spring is a manufacturing technology which improves the spring product quality and qualification rate and decreases the spring production cost. The manufacturing technology comprises the following processes: spring coiling, namely, coiling a steel wire blank into a semi-finished spring; first annealing, namely, annealing the spring under low temperature to remove stress; spring grinding, namely, grinding two end surfaces of the spring to reach the required length; chamfering, namely, removing burrs on the spring after grinding; stress optimizing; secondary annealing, namely, annealing the spring under low temperature to remove stress again; shot blasting, namely, prolonging the fatigue life of the spring; thermal pressing; load classifying,namely, removing the spring with ultralow load, and treating the product with qualified load as the high-stress valve spring product; and oil coating, namely, coating the high-pressure valve spring product with oil, and preparing for packing. According to the manufacturing technology of the high-stress valve spring, the process of sorting based on length is saved and the process of optimizing stress is performed after the ball grinding process and the chamfering process in a traditional technology, so that the spring product quality and qualification rate can be improved; and the spring production cost is decreased.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

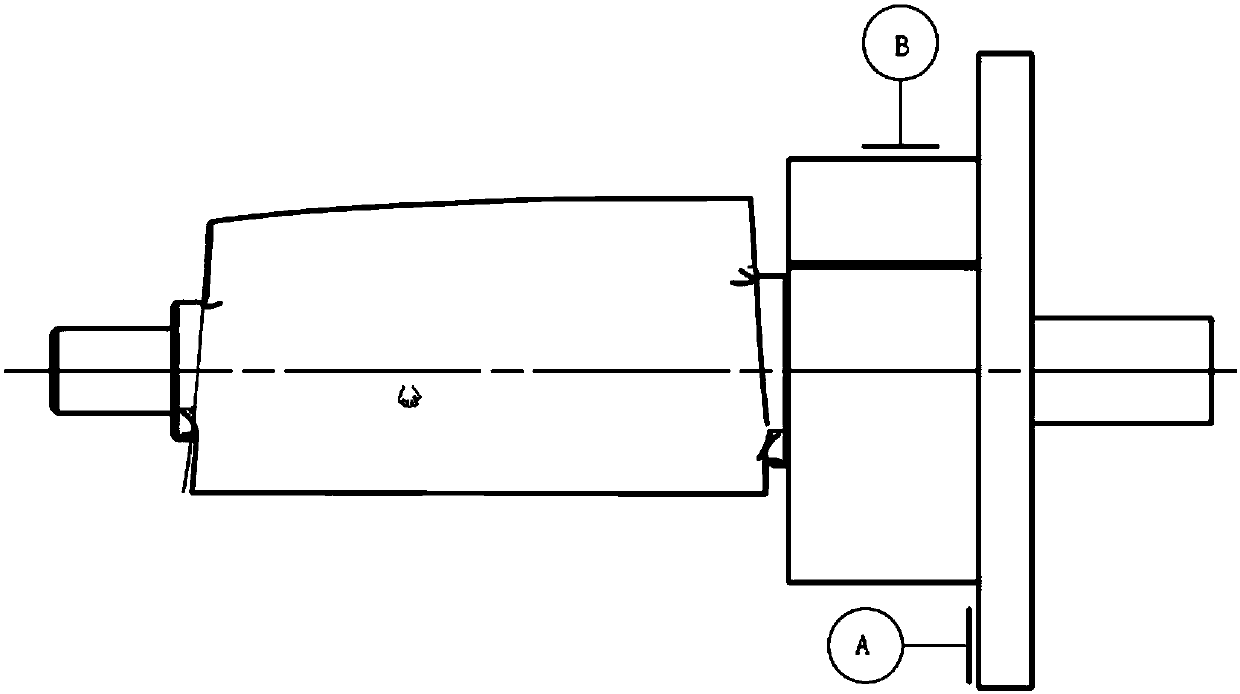

A wire and cable rotary mold

ActiveCN105869784BReduce volumeReduce manufacturing costCable/conductor manufactureInterference fitGear wheel

The invention discloses a wire / cable spinning mould, comprising a base, a thrust self-aligning roller bearing, a gear sleeve, a stranding die, an upper pressing cover, a signal pick-up device, a controller and a servo motor, wherein the thrust self-aligning roller bearing is arranged in each of the base and the upper pressing cover, the thrust self-aligning roller bearing is in interference fit with the gear sleeve, an external gear is arranged at one end of the gear sleeve, fastening antiskid bolts are arranged at the other end of the gear sleeve, the stranding die is in fixed connection with the gear sleeve by means of the fastening antiskid bolt, an in-die hole, a stranding tapered hole and a die exit are formed in the stranding die, and base fastening bolts are arranged at the lower part of the base. According to the wire / cable spinning mould disclosed by the invention, as the controller and the signal pick-up device are employed to acquire a spinning speed of an equipment stranding body, and a frictional force that is exerted by the stranding die in a tangential direction is eliminated by means of a synchronous and homodromous rotation of the servo motor and the spinning mould; the spinning mould has the advantages of small volume, low cost and long service life; material wastage is reduced by 15-20%; the one-time delivery qualification rate can reach 98-100%; and the product quality is improved greatly.

Owner:ECHU SPECIAL WIRE & CABLE KUNSHAN CO LTD

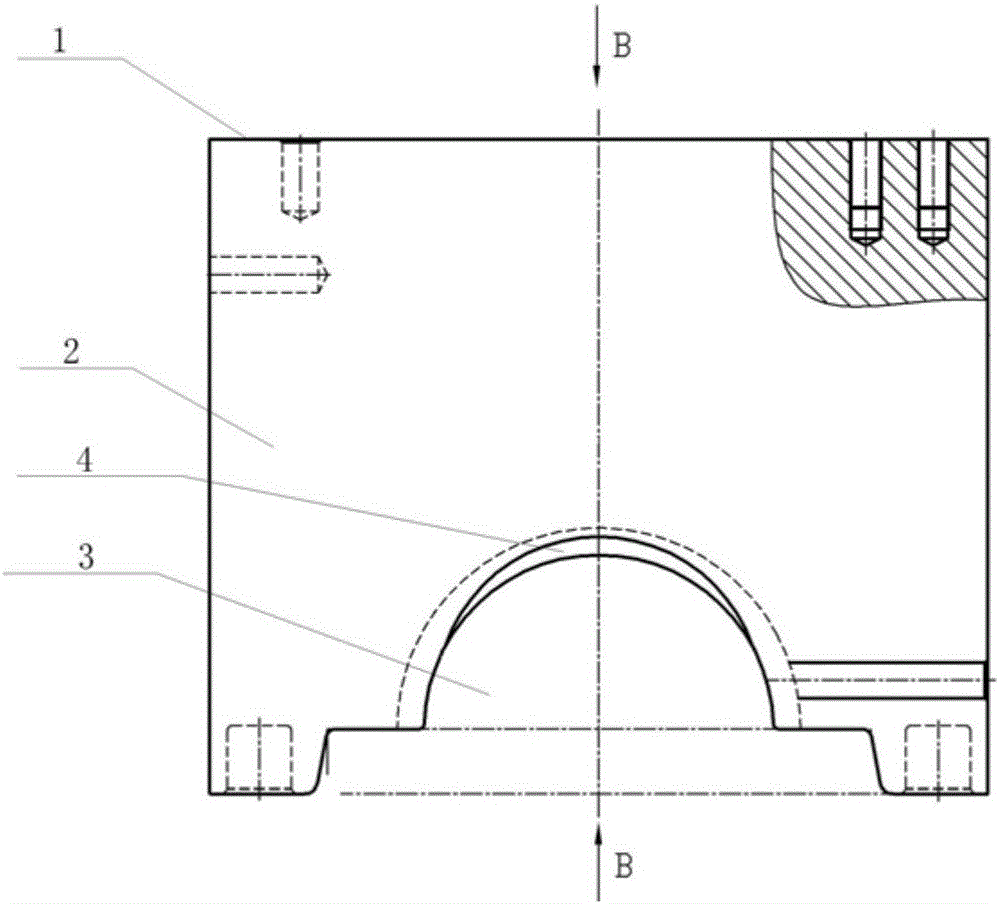

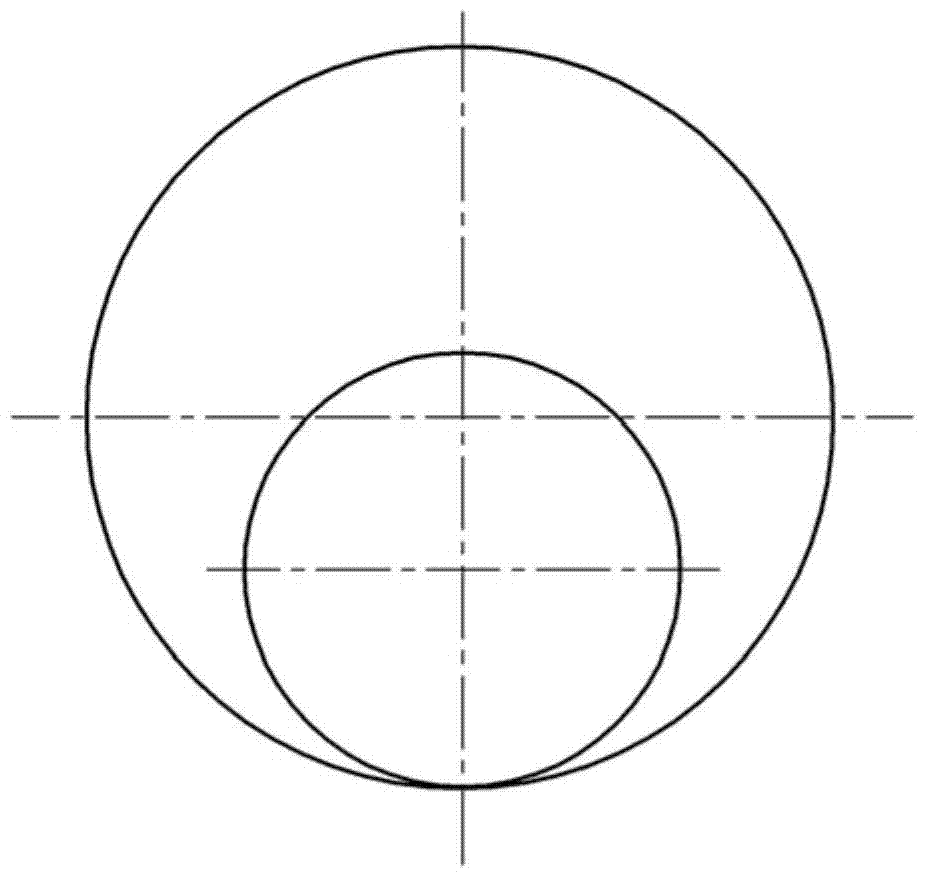

A method for protecting pictographic protection areas with spray paint

ActiveCN103272746BAchieve neatPrevent movementLiquid surface applicatorsCoatingsPaper adhesive tapeAlloy

Disclosed is a method for protecting a paint spraying figurative protected zone. According to the method, before a part is sprayed with paint, protection is quickly and accurately carried out on a circular protected zone by using paper adhesive tape and two types of tools, namely two concentric-circle punches made of high-temperature alloy or stainless steel, and a circular punch made of high-temperature alloy or stainless steel; a bottom lamp is arranged at the bottom of a worktable, the surface of the worktable is made of transparent resin or transparent glass, and the bottom lamp irradiates on the part on the surface of the worktable through the worktable. The method includes the following specific technological processes: adhering the paper adhesive tape to rubber or plastic, punching a paper bag by using the concentric-circle punches and the circular punch to remove the rest surface adhesive tape, taking down the punched figurative adhesive tape, adhering the concentric-circle adhesive tape to the surface of the part, aligning small holes by using the bottom lamp, and covering the concentric-circle adhesive tape with the circular adhesive tape. The method for protecting the paint spraying figurative protected zone has the advantages that a protected zone on the periphery of a part hole can be made neat, circular shapes are regular, moving is prevented, and the qualification ratio under one-time acceptance check of products is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

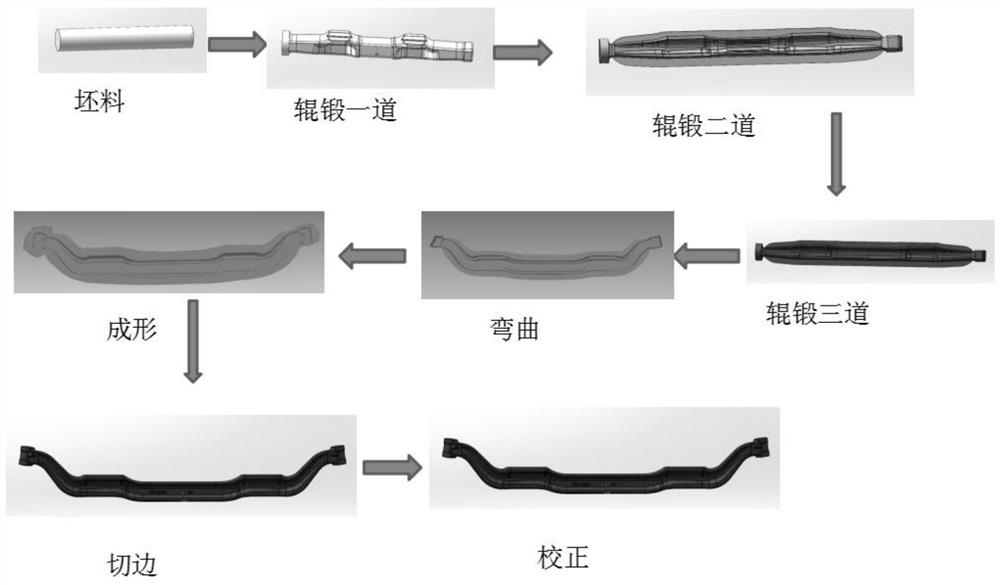

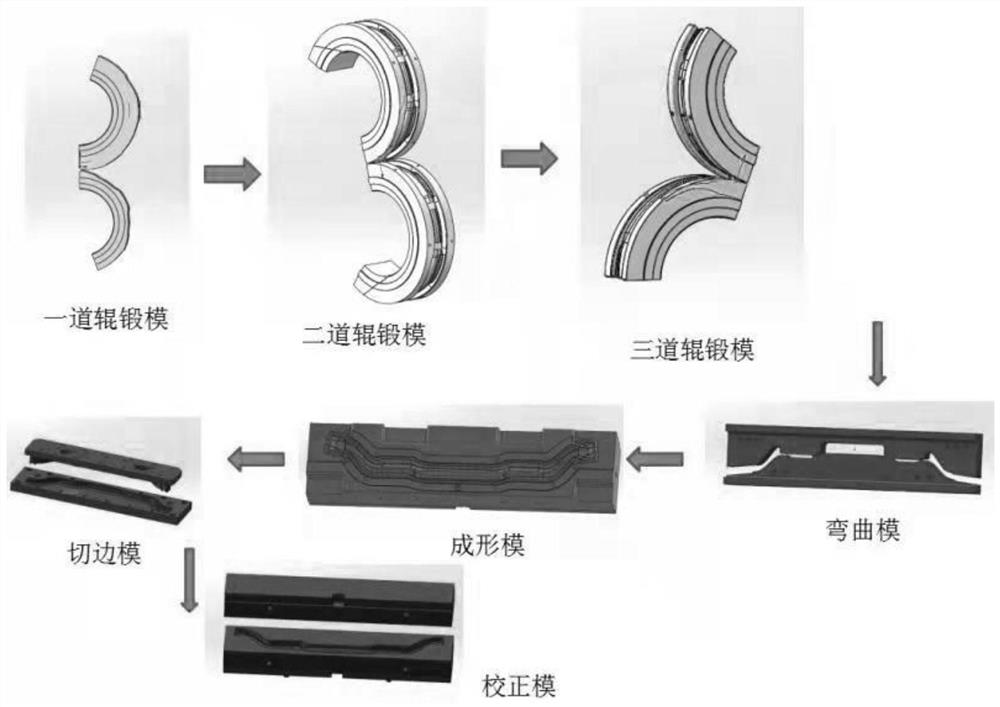

Forming Technology of Front Axle Seamless Segment Roll Forging Front Axle Beam

ActiveCN113926968BExtended service lifeLess grinding workIncreasing energy efficiencyForging/hammering/pressing machinesLeaf springManufacturing engineering

The invention discloses a front axle seamless segment roll forging front axle beam forming process, which includes the following process steps: S1, blank: using a sawing machine to cut the material, and intercepting the round steel that meets the requirements of the process size; S2, heating: using 1500kW intermediate frequency induction Heating to make the temperature of the round steel reach 1200±20℃; S3, one roll forging: through the top hat-shaped hole system on one roll forging die, the forced widening of the two spring plate positions of the front axle beam is realized, and at the same time, one roll forging is carried out. The rectangular hole pattern system on the die deforms other parts except the position of the leaf spring, so that the width and height meet the requirements of the second roll forging process; S4, roll forging second pass: after the first roll forging, the front The axle beam is rotated 90° into the second pass, and the roll forging forming of the two spring plates of the front axle beam and the transition position of the spring plate to the fist and the pre-forming of the middle I-shape are realized through the two roll forging dies. The present invention has strong practicability. and features that eliminate roll forging and forming defects.

Owner:CHONGQING KAIEN MACHINERY MFG CO LTD

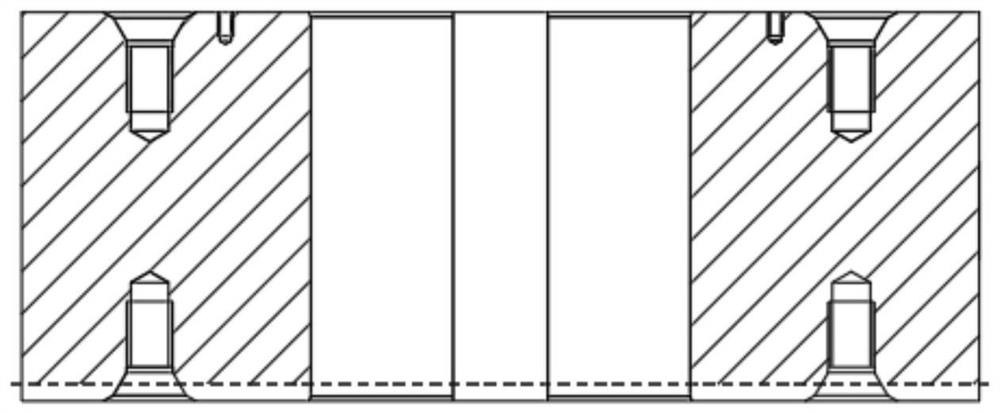

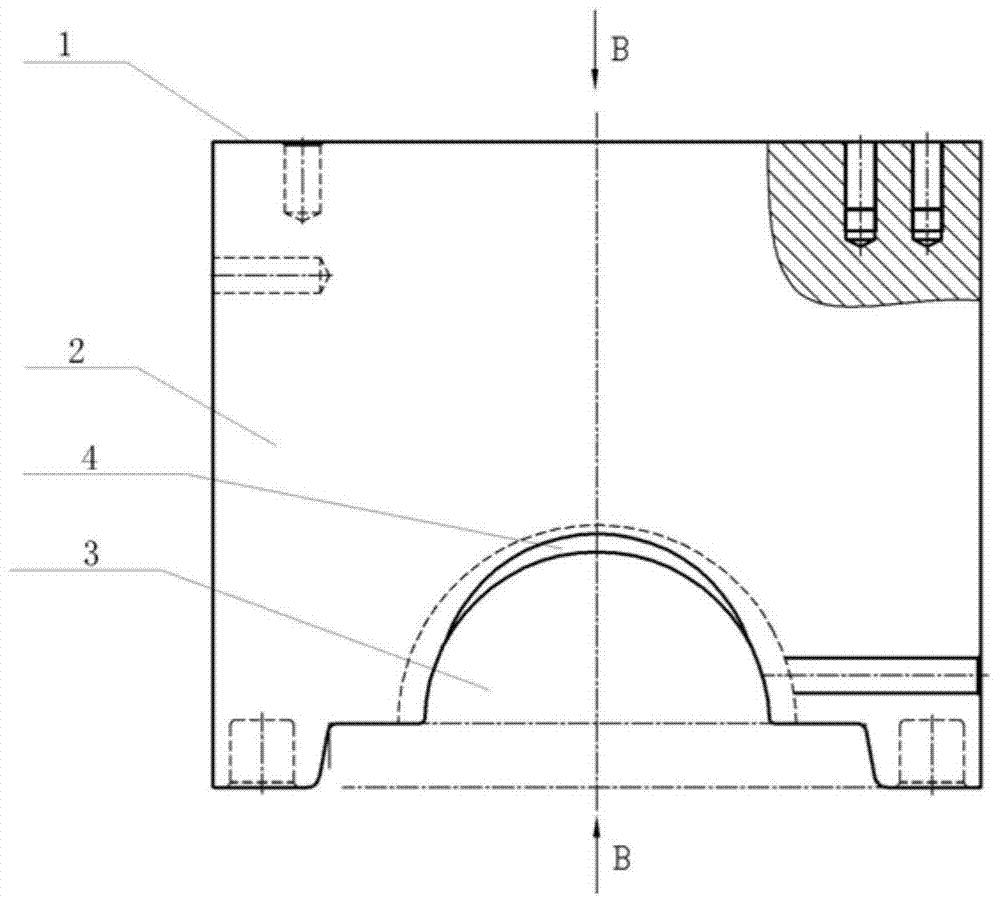

Upper bending die for forging round crank shaft

ActiveCN105127351AImprove the passing rate of one-time inspectionEasy to controlForging/hammering/pressing machinesEngine componentsEngineeringCrankshaft

The invention discloses an upper bending die for forging a round crank shaft. The upper bending die is provided with a die cavity for forging a crank throw in the round crank shaft, wherein the crank throw comprises two round cranks and a connecting rod neck located between the two round cranks. The upper bending die is also provided with a flash groove communicated with the die cavity and used for containing forging flashes of the mounting surfaces of the round cranks. By using the upper bending die for forging the round crank shaft, the forging flashes easily generated in extrusion molding of forging can exactly enter the flash groove, so that each crank throw can be extruded in place when being forged, the single-throw forging size can be controlled and conform to a design size, the length of the whole shaft is favorably controlled, the disposable delivery-check qualified rate of rough forgings is increased, and the quality of each forging is improved.

Owner:CRRC ZIYANG CO LTD

A method of increasing the force value of tension spring

ActiveCN103949856BIncrease force valueImprove the passing rate of one-time inspectionManufacturing technologyEngineering

The invention belongs to a spring manufacturing technology, and relates to a method for increasing the force value of an extension spring. The method adopts a twice winding technology; a certain stress is generated during the first winding; a pre-tightening force is effectively increased for the second winding because of the principle that the greater the acting force is, the greater the counter-acting force is during the second winding; thus, the force value of the spring is increased, unnecessary trial-manufacture and waste are avoided, and the rolled throughput yield of the elastic part is increased. The method is not only applicable to springs at key parts of a helicopter but also applicable to processing and production of all major parts requiring higher stress.

Owner:HARBIN

Low-alloy, high-strength, high-impact energy extra-large special-shaped ring forging and its forging method

ActiveCN108914015BOptimize chemical compositionAvoid wastingMetal-working apparatusFurnace typesChemical compositionManufactured material

The invention discloses a low-alloy high-strength high-impact-energy extra-large special-shaped ring forging. Low-alloy high-strength steel comprises, by weight, 0.08-0.12% of C, 0.5-0.6% of Mn, lessthan or equal to 0.006% of P, less than or equal to 0.006% of S, 0.5-0.65% of Si, 1.4-1.5% of Cr, 0. 55-0.65% of Mo, 0.1-0.2% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.04% of V, 0.03-0.04% of Nb, 0.02-0.04% of Al, less than or equal to 0.01% of Sn, less than or equal to 0.01% of As, less than or equal to 0.0012% of Sb and the balance Fe and impurities, then through nozzle cold sawing, riser collection, riser heat chopping, then three times of upsetting and two times drawing, broaching chambering, special-shaped ring rolling, preparatory heat treatment, rough turning, sawing, preheating and arc finishing. In this way, chemical compositions of raw materials are optimized, a reasonable matching heat treatment system is adopted, the stability of the impact work can be improved through maximum simulated post-weld heat treatment of the materials, the product once inspection pass rate is increased to 100%, energy waste caused by rework and repair is avoided, the production cycle is shortened, the manufacturing cost is reduced, and the competitiveness of enterprises is improved.

Owner:AVIC EXCELLENCE FORGING WUXI

Cone forming mold

ActiveCN107116145BPrevent removalReduce processing timeShaping toolsHollow articlesAxial displacementEngineering

The invention discloses a taper tube molding die. The taper tube molding die comprises a vertically-arranged inner die column, a first molding outer die and a second molding outer die, the first molding outer die and the second molding outer die are folded to be used for clamping the inner die column, and the first molding outer die and the second molding outer die are arranged around a vertical fixed shaft in an opening and closing manner; and when the first molding outer die and the second molding outer die are folded to be used for clamping the inner die column, a molding ring cavity used for molding a taper tube is formed amount the outer ring face of the inner die column and the first molding outer die and the second molding outer die. A molding pressing block is further installed on the inner die column to be used for abutting against a top arc line of a fan-shaped material in the process that the fan-shaped material is molded into the taper tube so as to limit axial displacement of the fan-shaped material along the inner die column, and the fan-shaped material is prevented from moving out of the molding ring cavity. According to the taper tube molding die, the part machining time can be greatly shortened, the part molding efficiency is improved, the quality of molded parts is stable, the surface quality is obviously improved, the part roundness is good, the one-time submitting and checking yield is high, the part molding process is simple in operation, and the requirement for the technical ability of an operator is low.

Owner:CHINA HANGFA SOUTH IND CO LTD

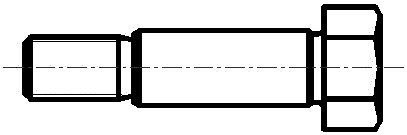

Hanging method during hard chromium electroplating of bolt product

InactiveCN105154946AReduce usageImprove the passing rate of one-time inspectionJewelleryEngineeringCopper

The invention discloses a hanging method during hard chromium electroplating of a bolt product. The hanging method comprises the following steps: adding process sections at the head parts of bolts; processing the process sections into threaded holes with internal threads; mounting the tail part of a bolt into the head part of another bolt with the treaded hole containing the internal thread; connecting the head parts and tail parts of five or more parts in series, and suspending on a cooper hook tooling; then, hanging a plurality of bunches of parts on the tooling. According to the hanging method, large amounts of toolings, jigs and insulating adhesive tapes are saved used during the surface treatment and electroplating procedures of hard chrome, the one-time delivery-check qualified rate is increased, and the production efficiency is improved.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

A Bending Upper Die for Forging a Round Crankshaft

ActiveCN105127351BImprove the passing rate of one-time inspectionEasy to controlForging/hammering/pressing machinesEngine componentsEngineeringCrankshaft

The invention discloses an upper bending die for forging a round crank shaft. The upper bending die is provided with a die cavity for forging a crank throw in the round crank shaft, wherein the crank throw comprises two round cranks and a connecting rod neck located between the two round cranks. The upper bending die is also provided with a flash groove communicated with the die cavity and used for containing forging flashes of the mounting surfaces of the round cranks. By using the upper bending die for forging the round crank shaft, the forging flashes easily generated in extrusion molding of forging can exactly enter the flash groove, so that each crank throw can be extruded in place when being forged, the single-throw forging size can be controlled and conform to a design size, the length of the whole shaft is favorably controlled, the disposable delivery-check qualified rate of rough forgings is increased, and the quality of each forging is improved.

Owner:CRRC ZIYANG CO LTD

Process for manufacturing heavily stressed valve spring

The invention provides a manufacturing process used for a high-stress valve spring, which can improve the quality and product qualification ratio of the spring product, reduce the production cost of the spring and comprises the processes as follows: spring rolling: steel wire blanks are rolled and made into semi-finished springs; primary temper: the spring is tempered at low temperature so that the stress is removed; spring grinding: two end surfaces of the spring are grinded so as to achieve the required length; chamfering: the burrs of the grinded spring are removed; stress optimization: secondary temper: the spring is tempered again at low temperature so that the stress is removed; shot blasting which is used for prolonging the service life of the spring; hot-pressing; load classification: the spring with bad load is removed and the product with qualified load is used as the high-stress valve spring product; oiling: the high-stress valve spring is oiled; and is prepared for packaging. The process improves the quality and the qualification ratio of the spring product and reduces the production cost of the spring as the working procedure of length classification is saved and the stress optimization process is arranged after the process of spring grinding and chamfering in the traditional process.

Owner:SHANGHAI SPRING CORP

Manufacturing method of iron-based friction plate

ActiveCN101776123BReduce distortionImprove the passing rate of one-time inspectionFriction liningCopper platingDecomposition

A manufacturing method of iron-based friction plates comprises the following processes: 1. furnishing, 2. mixing, 3. profiling, 4. sintering friction layer, 5. plating copper on core boards, 6. pressuring and compositing at intermediate temperature, and 7. processing an oil groove; the friction layer is added with a process of sintering the friction layer after the profiling, i.e. the friction layer after the profiling is sintered into the powder base of the friction layer in a bell-type pressure sintering furnace or an iron-based through continuous sintering furnace, the sintering temperature is 1050 DEG C-1100 DEG C, heat preserving for 2.5-3.5 hours, the atmosphere is ammonia decomposition gas; the core board plating is formed by the steps that copper plating the core board by electroplating to be prepared into the core board plated copper, the core board is hung at a cathode, a copper board is hung at an anode, electroplate liquid with copper ion is added into a plating tank, direct current is conducted into the plating tank, and electroplating time is adjusted according to the thickness of plating; the thickness of the plating is 0.005-0.01mm; and the invention is characterized in that the core board has high strength, the deformation is small, the yield at one step of checking is high, and the cost is low, the method is suitable for mass production, and the like.

Owner:HANGZHOU ADVANCE GEARBOX GRP

A method for improving the adhesion of metal film layer on high dielectric constant ceramic substrate

ActiveCN110729173BReduce difficultyImprove coarsening stateSemiconductor/solid-state device manufacturingHigh dielectric constant substrateHemt circuits

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Helicopter composite material paddle fatigue test piece molding method

InactiveCN102507275BImprove the passing rate of one-time inspectionZero scrap rateMachine part testingPreparing sample for investigationNumerical controlRejection rate

The invention belongs to a composite material molding technology, and relates to helicopter composite material paddle fatigue test piece molding technological process which is suitable for helicopter composite material technological process molding. According to the invention, a platform thickness spacing tool is adopted, an interval between two splints of a paddle fatigue test piece is effectively ensured, and simultaneously the positioning of the spacing tool can insure symmetry of the two splints; and a working procedure of numerical control processing is directly omitted from a technical process, furthermore a manufacturing cycle is also shortened, once alternating detection qualification rate of the paddle fatigue test piece is improved, the rejection rate of the paddle fatigue test piece is zero, and the stability and the smoothness of the assembly process of the paddle fatigue test piece are ensured.

Owner:中航直升机股份有限公司

Journal conversion clamping head for double-journal blades

InactiveCN108032121AReduce in quantitySimple and stable clamping and positioningWork clamping meansPositioning apparatusEngineeringUltimate tensile strength

The invention provides a journal conversion clamping head for double-journal blades. The journal conversion clamping head comprises a limit plate and a clamping sleeve and is characterized in that thelimit plate is fixedly connected to one end of the clamping sleeve, a plurality of rotation holes are formed in the end face of the limit plate, a clamping hole is machined in the center of openings,and each rotation hole is connected with the clamping hole through one opening. The journal conversion clamping head has the advantages that simple and stable clamping positioning is achieved, X-direction alignment needed in each clamping is omitted, unqualified products caused by tool alignment errors and upper-journal length conversion errors are avoided, first time yield (the number of reworkparts is reduced greatly) and part yield are increased, machining labor intensity is lowered, and machining efficiency is increased.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

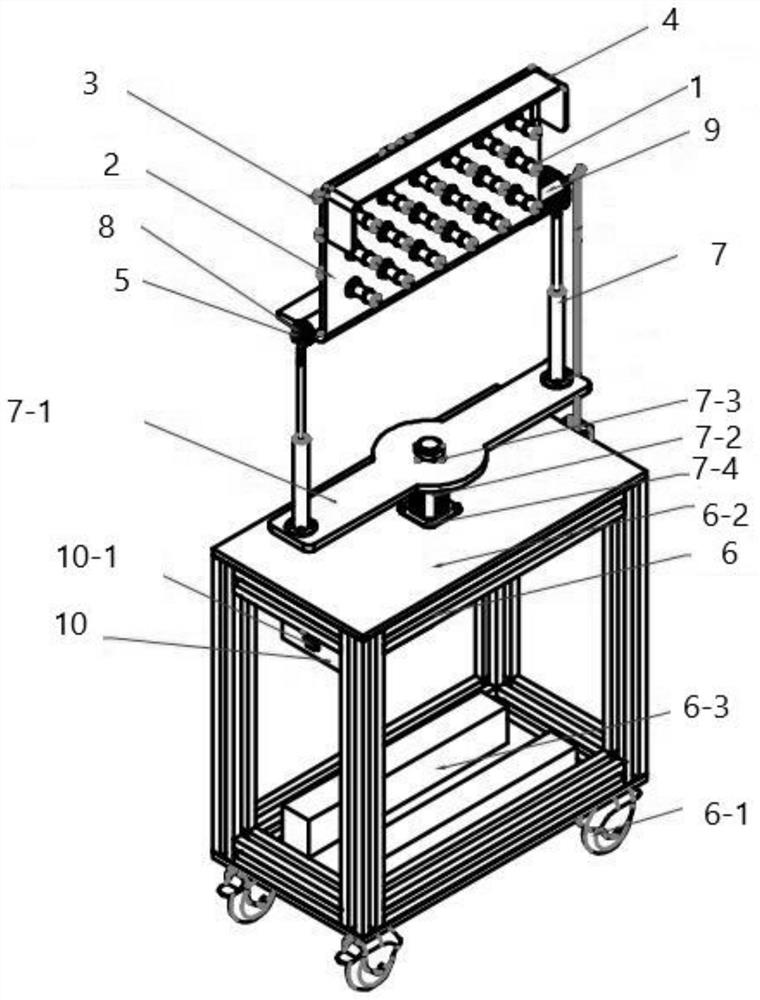

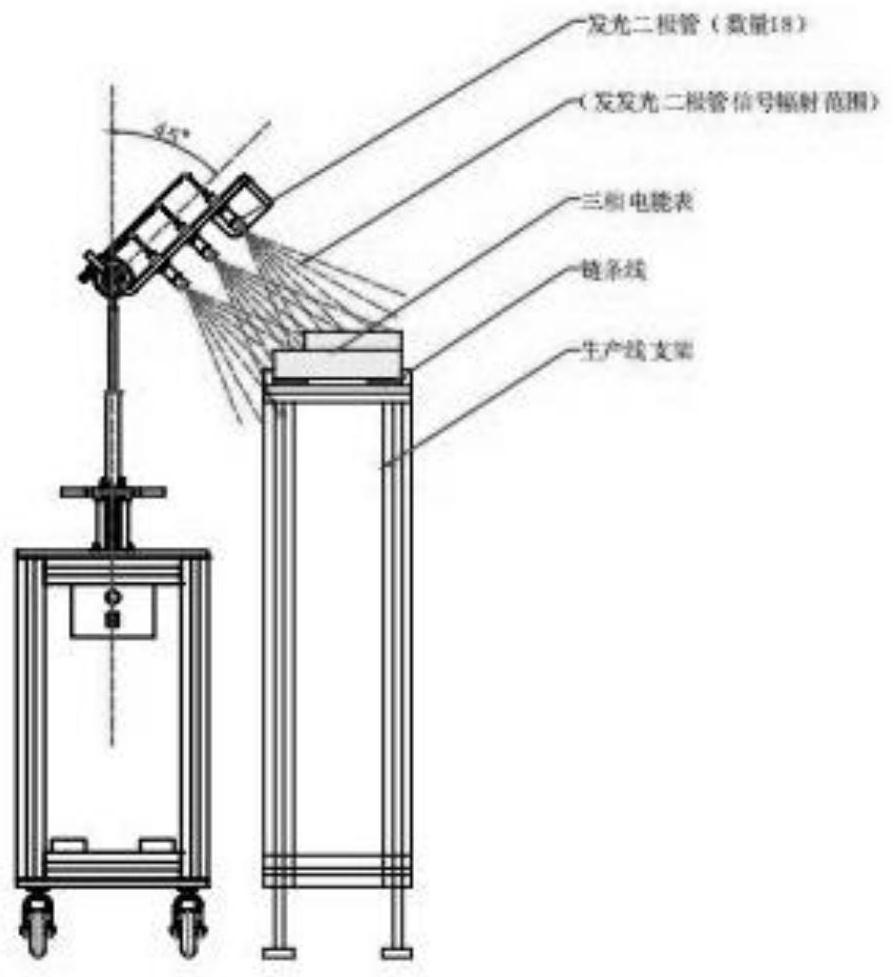

Device for infrared awakening automatic detection of three-phase electric energy meter

PendingCN111913149AMan-made instabilityImprove the passing rate of one-time inspectionNon-electrical signal transmission systemsElectrical measurementsEngineeringComputational physics

The invention relates to a device for automatically detecting infrared awakening of a three-phase electric energy meter, which is characterized in that an infrared light emitting module is used for emitting infrared light, and a detection module is used for detecting optical signals emitted after awakening of the three-phase electric energy meter, converting the optical signals into electric signals and sending the electric signals to a control module; the control module controls the inclination angle and the rotation angle of the infrared light-emitting module, so that the emitted infrared light covers the awakening unit of the to-be-detected three-phase electric energy meter, and the to-be-detected three-phase electric energy meter can be awakened; the electric signal sent by the detection module is received, and whether the awakening function of the three-phase electric energy meter is normal or not is judged. According to the invention, the automatic detection process of infrared awakening in the three-phase electric energy meter production process is achieved for the first time, the automation degree of electric energy meter production is improved, the labor cost is saved, thehuman unstable factors of the electric energy meter in the detection process are controlled, and the one-time inspection qualification rate of the electric energy meter is improved.

Owner:中电装备山东电子有限公司

Method for finely adjusting glossiness of water-based matte finish paint by improving spraying process

InactiveCN111001550ASolve the problem of gloss deviationResolve glossSpraying apparatusPretreated surfacesSpray paintingCoating

The invention particularly relates to a method for finely adjusting the glossiness of a water-based matte finish paint by improving a spraying process, and belongs to the technical field of water-based coating spraying construction. The technical problem to be solved is paint film glossiness deviation caused by construction factors. The method for finely adjusting the glossiness of the water-basedmatte finish paint by improving the spraying process comprises the following process conditions: (1) the paint viscosity of the water-based epoxy finish paint spraying process is improved to be 20-23s; 2) the flash-drying time of the water-based epoxy finish paint is canceled, and 3) the finish paint is baked at 45-53 DEG C for 2-2.5 h. The problem of paint film glossiness deviation caused by construction factors is effectively solved by investigating the factors such as the drying mode, the flash-drying time and the paint viscosity, and the one-time delivery qualification rate of products is improved.

Owner:永济优耐特绝缘材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com