SMT production line quality analysis platform based on digital twinning

A twin and digital technology, applied in the field of SMT production line quality analysis platform based on digital twin, can solve the problems of extensive quality management of SMT production line, limited product quality improvement effect, and lack of attention to digital twin, so as to improve product quality, The effect of shortening the time of diagnosis and remediation, and improving the pass rate of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

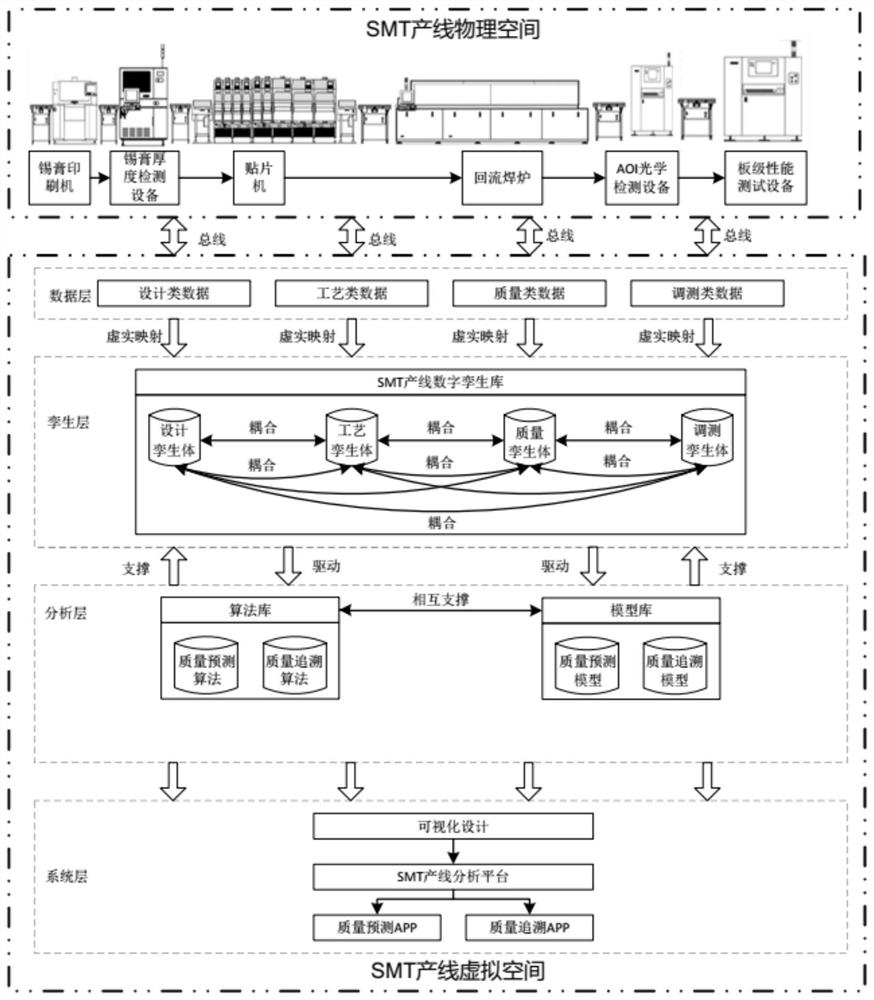

[0013] refer to figure 1 . In the preferred embodiment described below, a digital twin-based SMT production line analysis platform includes: printing machines, solder paste thickness detection equipment, placement machines, reflow ovens, AOI optical detection equipment and board-level performance testing The physical space of the SMT production line composed of equipment, and the virtual space of the SMT production line composed of the data layer, the twin layer, the analysis layer and the system layer. For the transmission of information and data, the data layer divides the data into design data, process data, quality data, and commissioning data according to the data type, and maps the data to the twin layer. The twin layer is divided into design, process, quality, and commissioning etc. The functional relationship between different twins organizes and couples each digital twin, and drives the analysis layer to realize the information binding between different twins and var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com