Manufacturing method of special-shaped ring forge piece of booster kettle flange

A manufacturing method and technology of special-shaped rings, applied in the direction of manufacturing tools, forging/pressing/hammering machinery, metal rolling, etc., can solve the problems of corresponding to a set of moulds, no market competitiveness, and increasing the size of the kettle, so as to achieve the guarantee The effect of metal flow state, shortening manufacturing cost, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

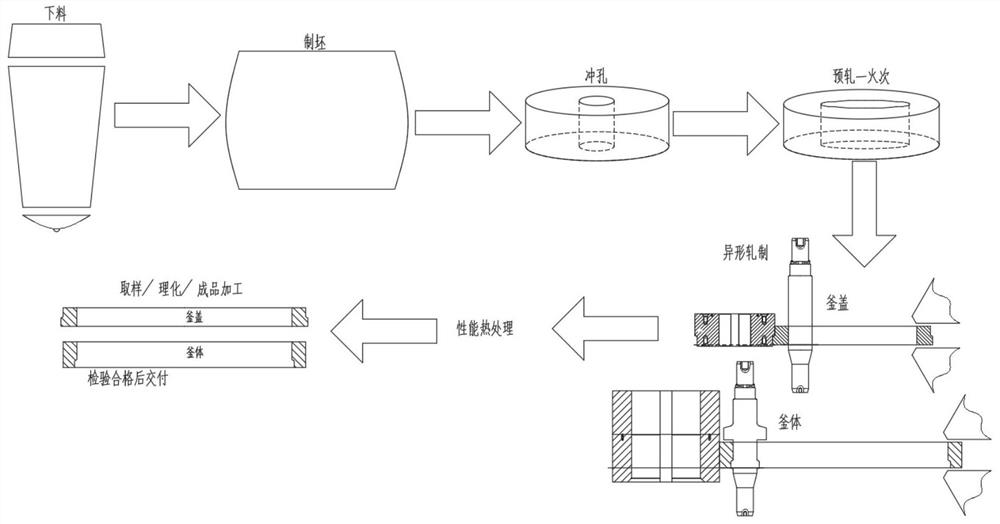

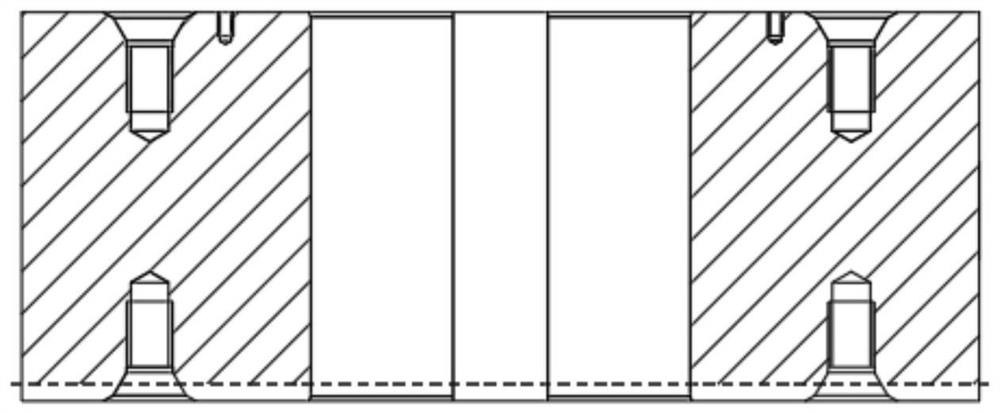

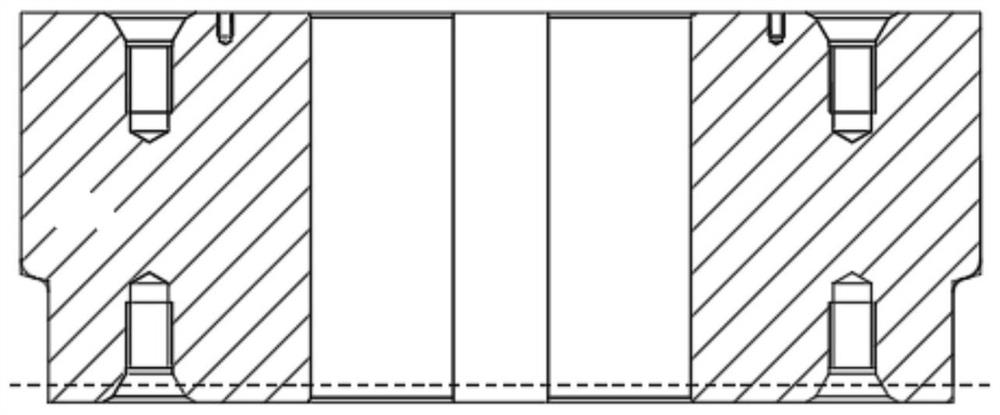

[0031] Such as Figure 1-5 Shown, a kind of manufacturing method of booster kettle flange special-shaped ring forging, comprises the following operation steps:

[0032] S1: Prepare the materials and tools needed to prepare the special-shaped ring forgings of the pressurized kettle flange, including forging blanks, automatic blanking devices, punching devices, pre-rolling devices, rolling devices, heat treatment devices and processing devices;

[0033] S2: Lead the forging billet into the inner position of the automatic blanking device, and feed the material through the automatic blanking device. After feeding, first perform the billet making operation, and then perform punching processing after the billet making is completed, and then pre-rolling processing;

[0034] S3: Carry out forming processing on the lid of the kettle, first pre-roll the billet, then replace the special-shaped one-piece main roll, and then roll into shape, the rolling amount does not exceed 1000mm;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com