Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

300results about How to "Reduce welding defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soldering process

ActiveCN1986133AFast heat conductionSufficient mechanical bond strengthWelding/cutting media/materialsSoldering mediaCopperUltimate tensile strength

The brazing process includes the following steps: preparing the copper back board, pre-heating the copper back board and soldering tin, pre-heating the aluminum target and soldering tin, combining copper back board and the aluminum target, and maintaining pressure and circular cooling water. Thus brazed hetero metal assembly has excellent heat transferring performance and sufficient mechanical binding strength, and the brazing process is simple, practical and reliable.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

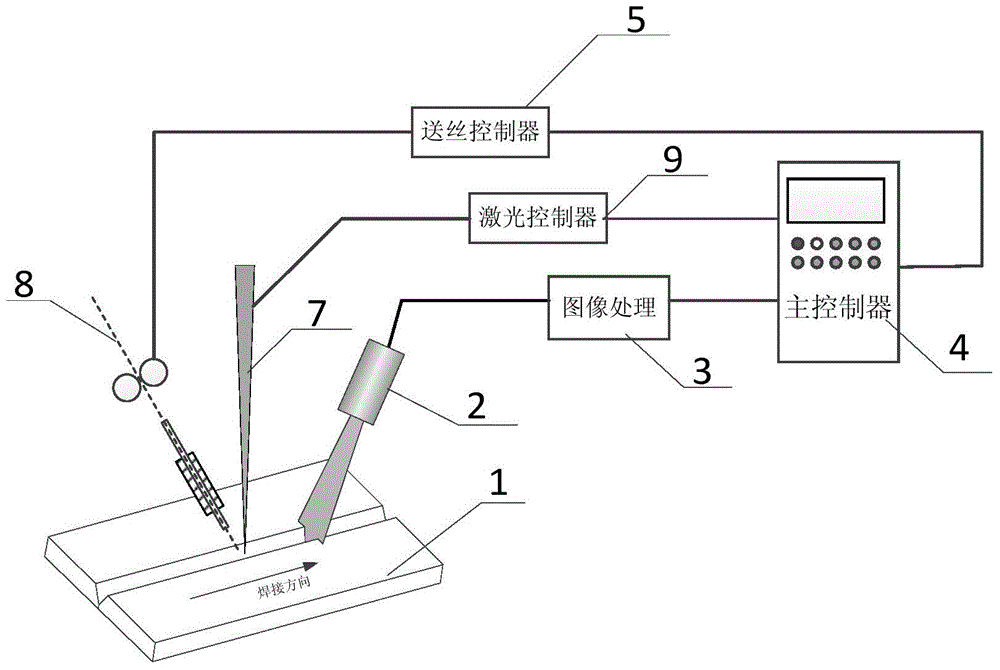

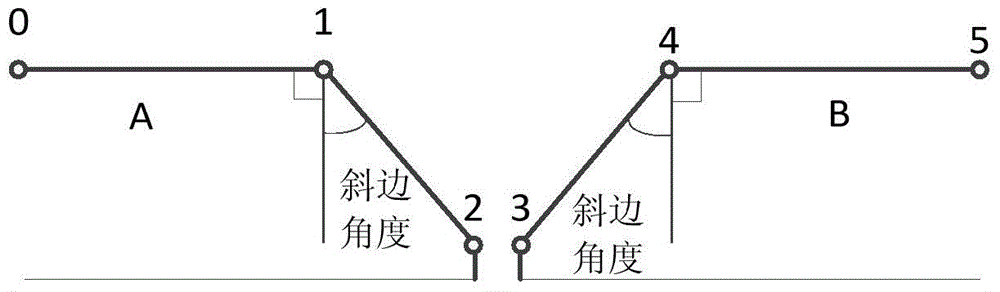

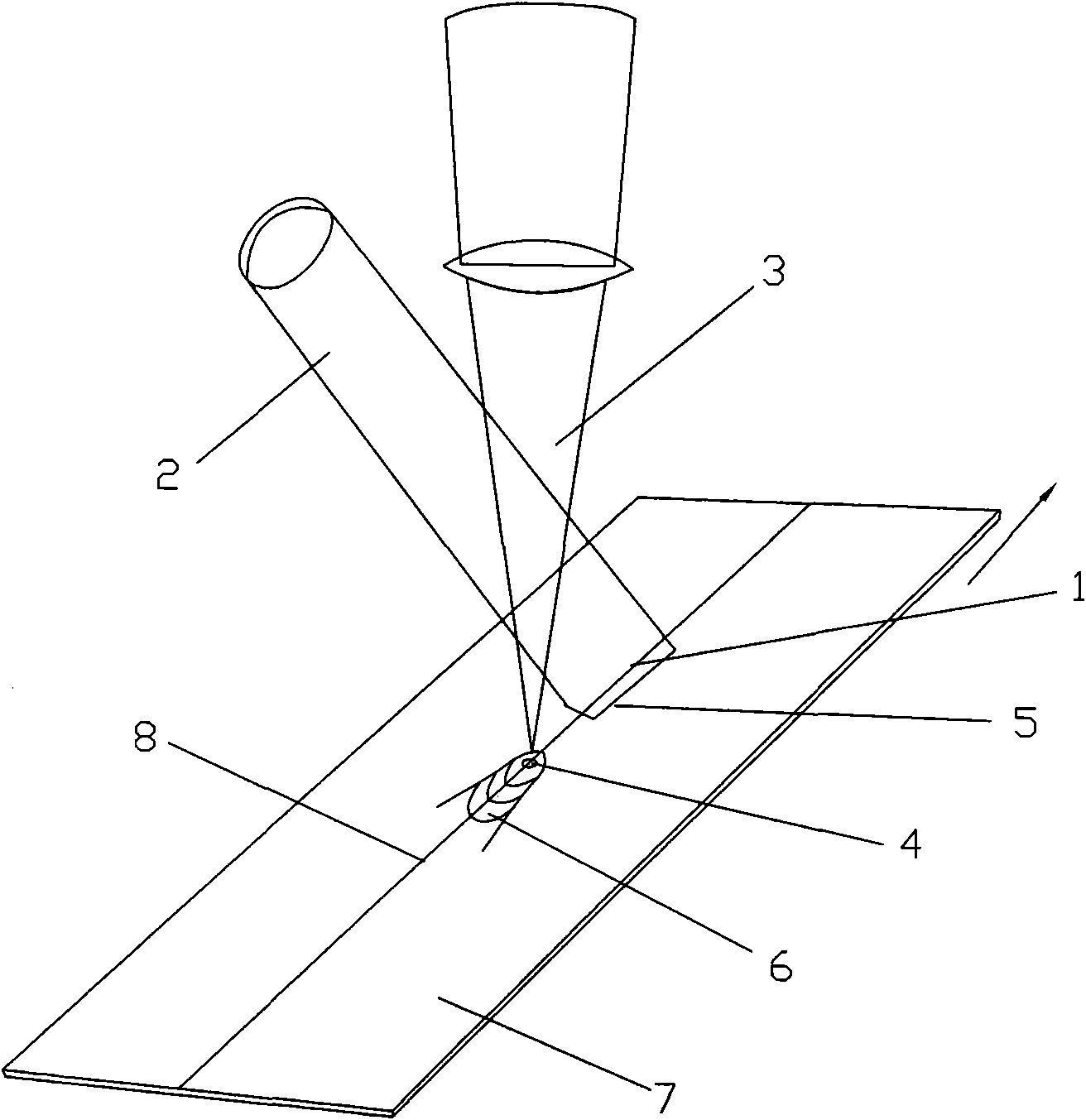

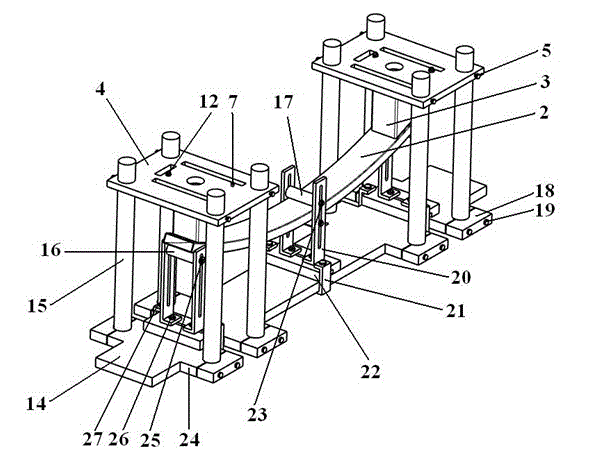

Adaptive welding method for laser filler wire welding of high-strength steel sheet

ActiveCN104057204ARealize adaptive adjustmentGuaranteed stabilityMetal working apparatusLaser beam welding apparatusNuclear powerMathematical model

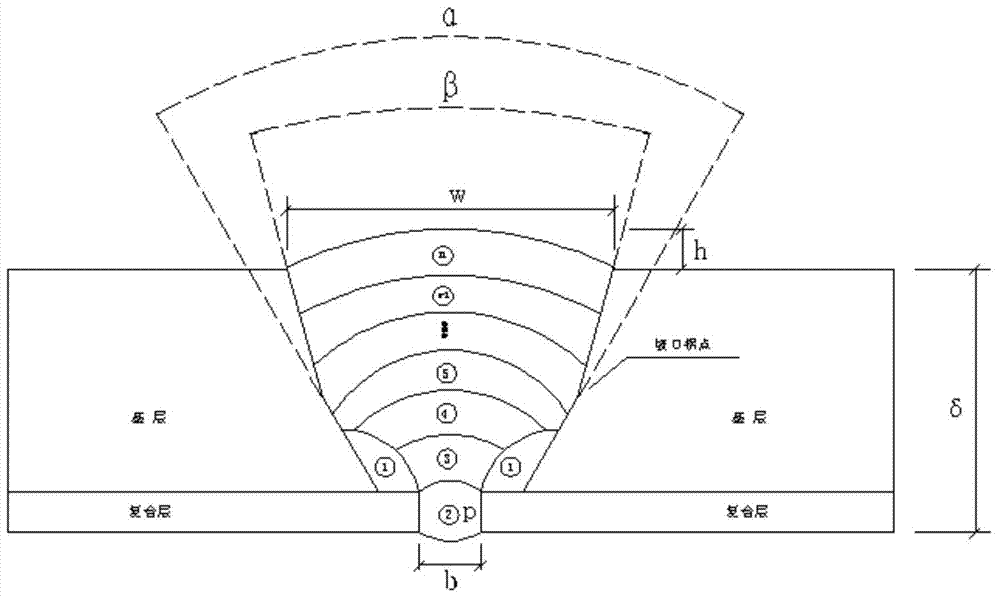

The invention provides an adaptive welding method for laser filler wire welding of a high-strength steel sheet. The method comprises: step 1, performing process experiment on the high-strength steel sheet, and building a process parameter model of welding wire filling area and upper-groove width; step 2, during welding, acquiring the welding wire filling area and the groove width of a current groove in real time based on a laser vision sensor; step 3, according to the filling area and the groove width of the current groove and the process parameter model, adjusting process parameters in real time, so as to realize adaptive control during welding. Through an expert database or a process mathematical model built in specific materials and groove forms, and the groove filling area acquired in real time based on the laser vision sensor, adaptive adjustment on the process parameters during welding is realized, the stability and uniformity of the welding quality are ensured, the welding efficiency is improved, welding defects are reduced, and the method has very high practical values during welding large sheet elements in the fields such as aviation, spaceflight and nuclear power.

Owner:SHANGHAI JIAO TONG UNIV +1

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

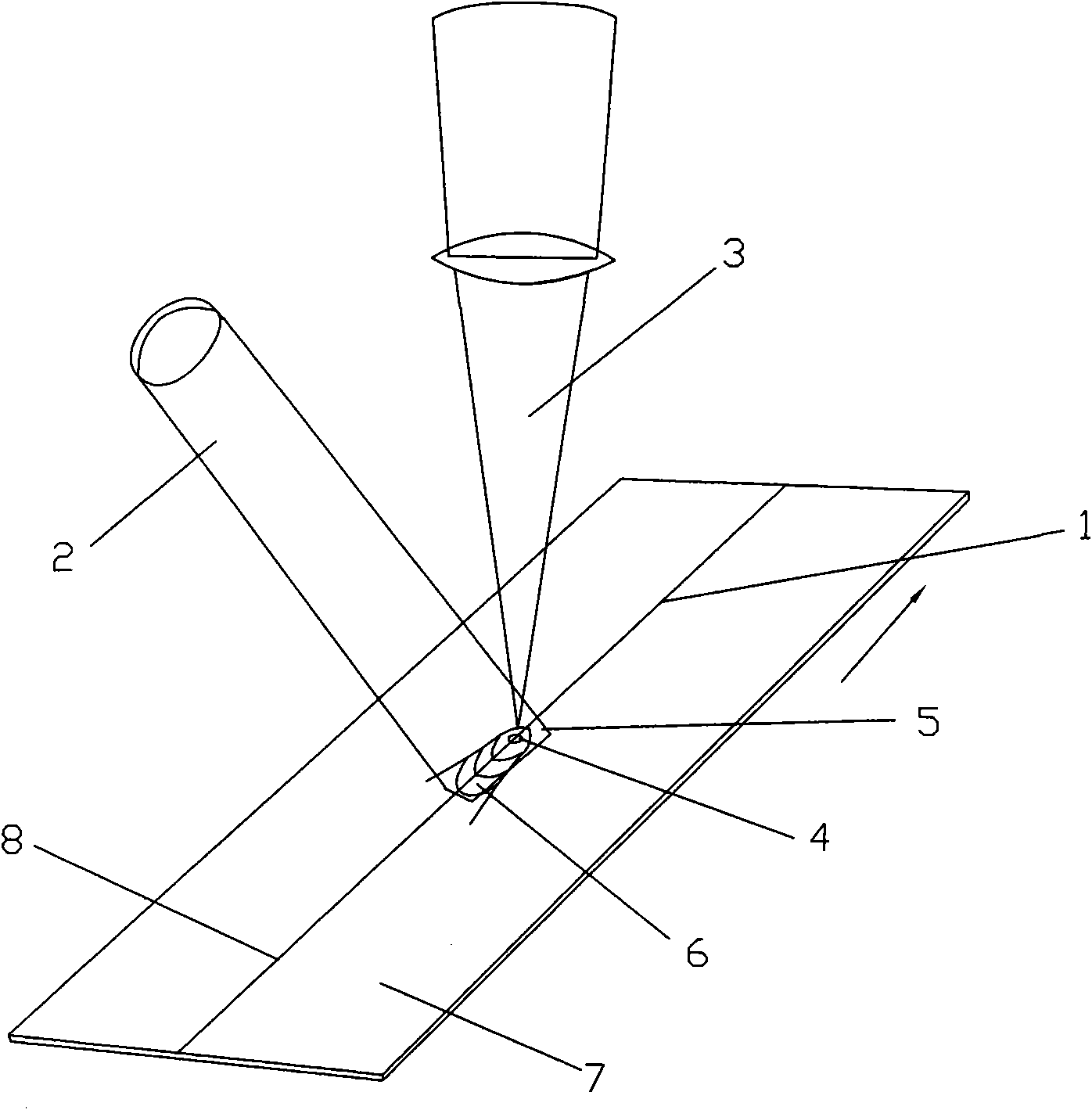

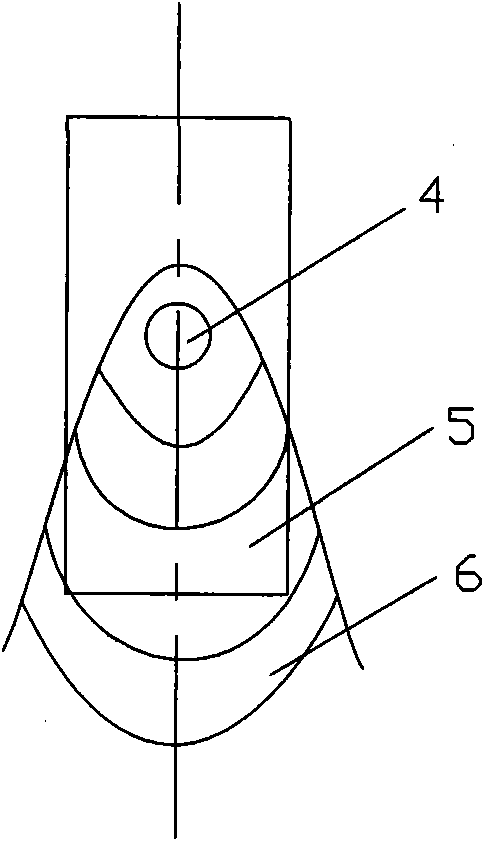

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

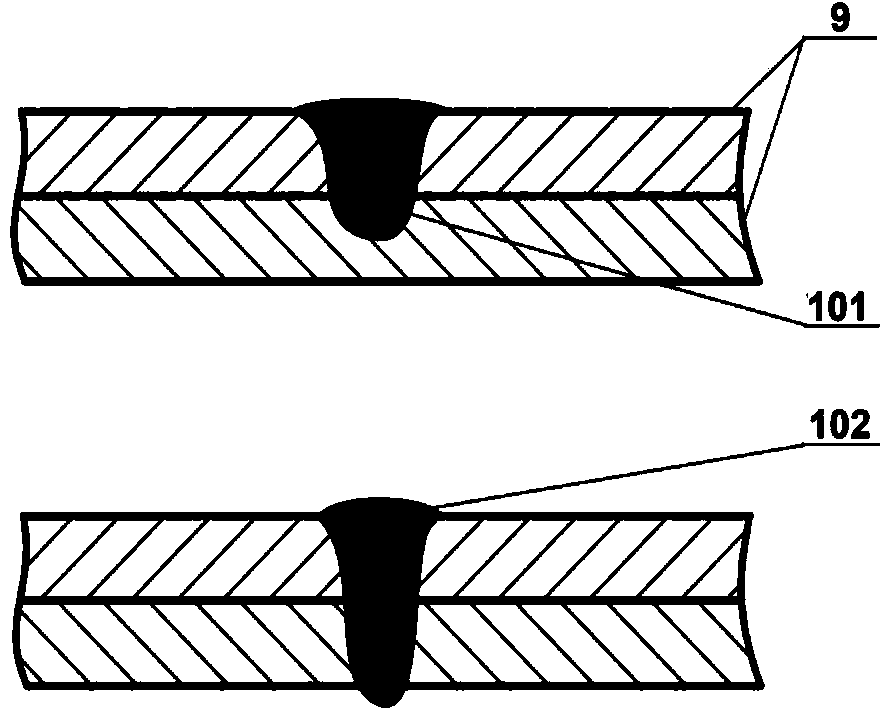

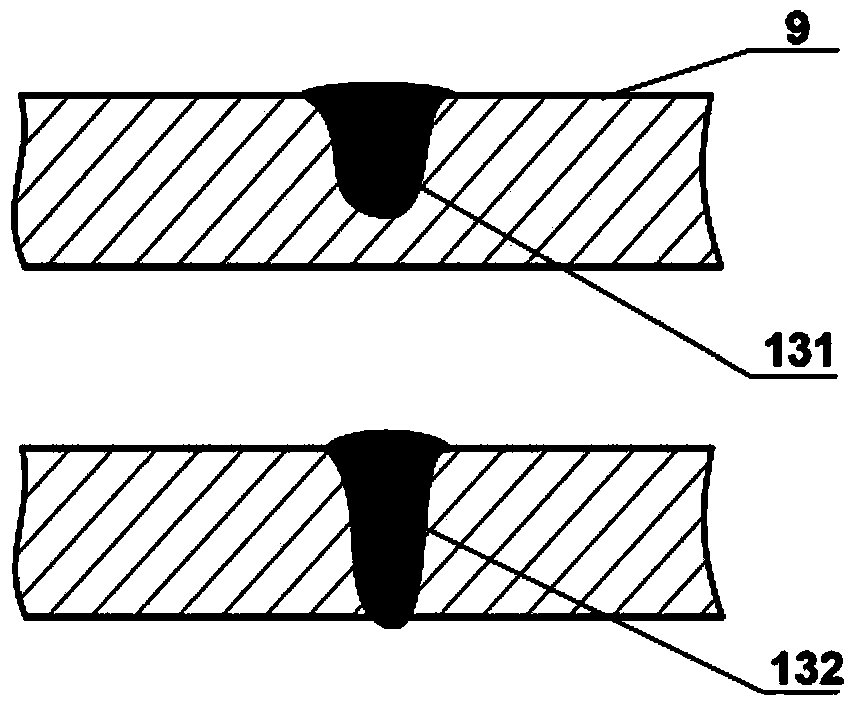

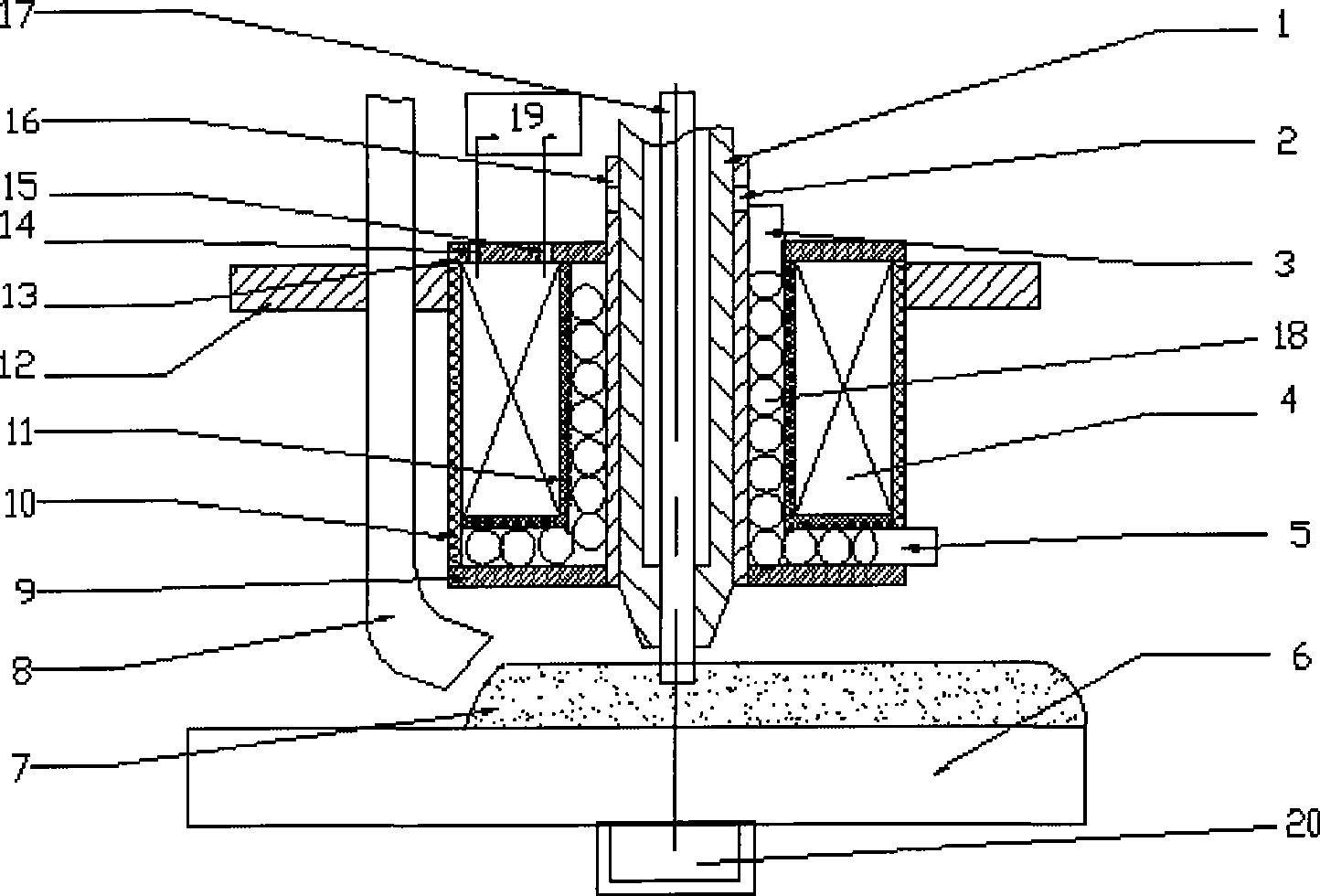

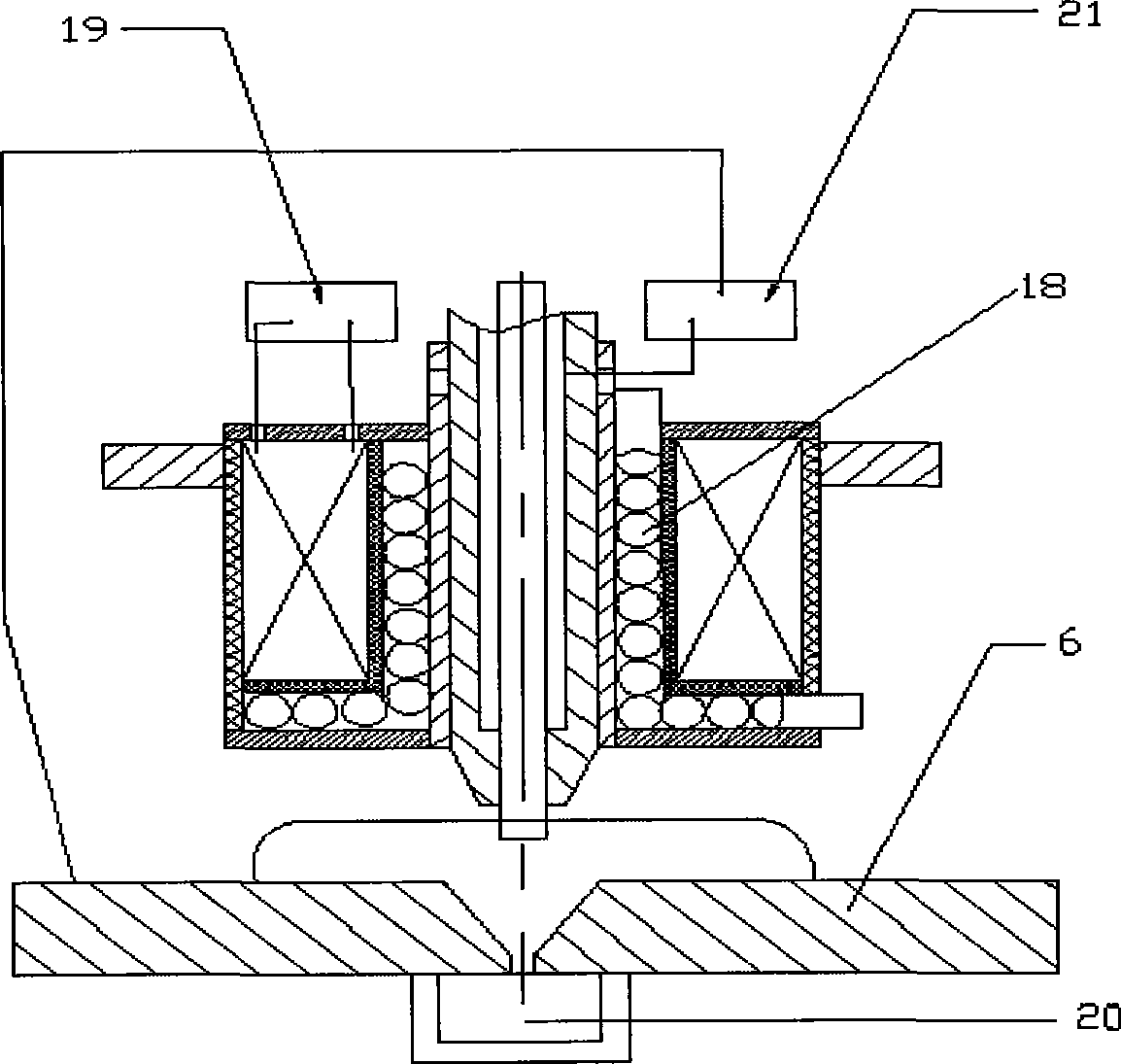

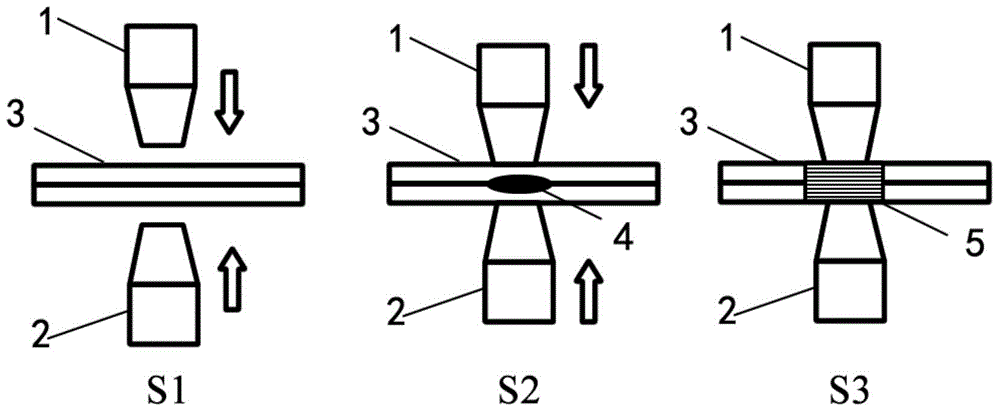

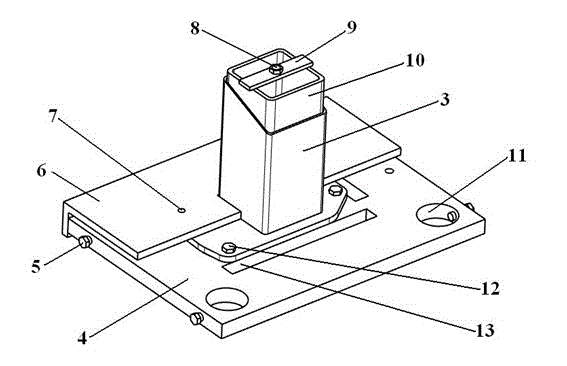

Method for deep penetration laser welding of plate under assistance of ultrasound

ActiveCN105583523AWide range of process parametersReduce crater depthWelding/soldering/cutting articlesMetal working apparatusSmall holeWeld bead

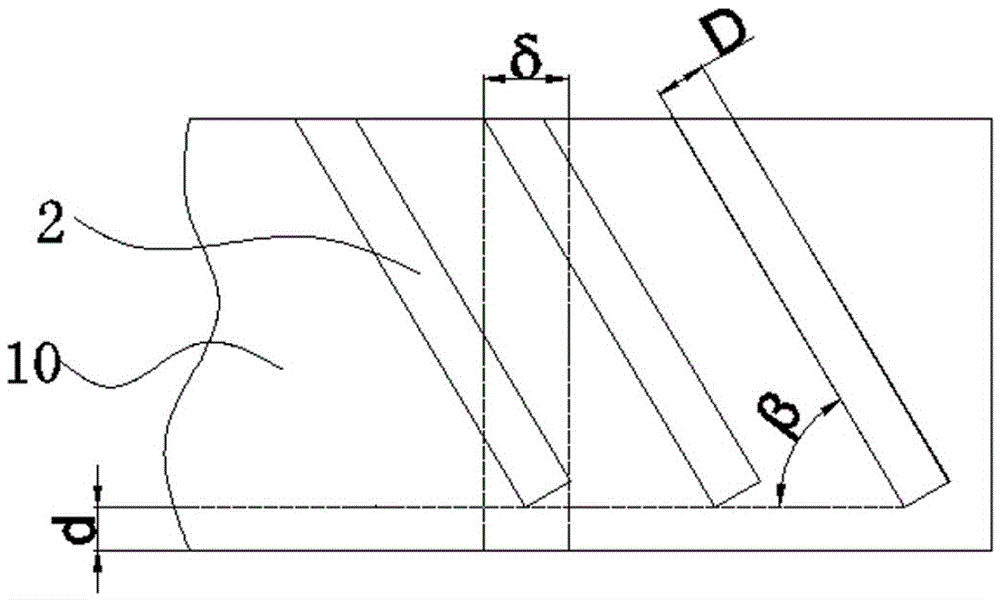

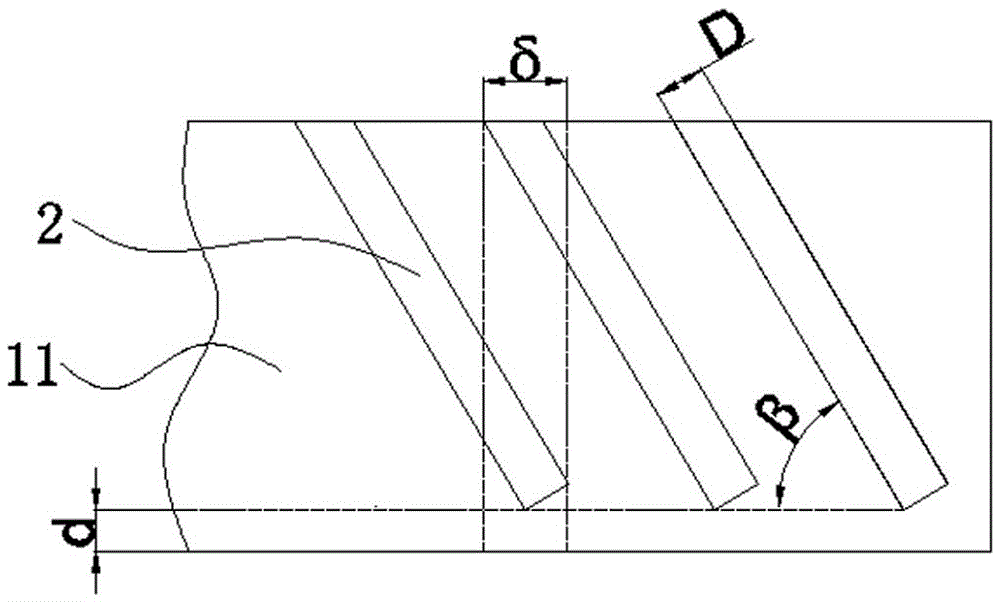

The invention relates to a method for deep penetration laser welding of a plate under the assistance of ultrasound. The method is characterized by comprising the following steps that firstly, first base metal (10) and second base metal (11) are machined to form butt joint end faces, and a series of inclined semicircular grooves are machined; secondly, the first base metal (10) and the second base metal (11) are in butt joint and are clamped, and a series of inclined blind holes are formed in a weld bead; thirdly, a first ultrasonic amplitude-changing rod (3) is pressed to the upper surface of a workpiece to be welded; fourthly, a second ultrasonic amplitude-changing rod (4) is fixed to one side of a laser welding head; fifthly, an ultrasonic generation device is started, the ultrasonic frequency is adjusted; sixthly, a laser beam (5) perpendicularly irradiates the upper surface of the workpiece, and the welding process is completed under continuous ultrasonic vibration; and seventhly, after welding is completed, ultrasonic vibration is maintained for 1-2 minutes. In the method, due to the pre-formed inclined blind holes and ultrasonic vibration, weld joint root leakage caused by molten pool downward flowing driven by local evaporation back flushing pressure of the front edge walls of the small holes is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

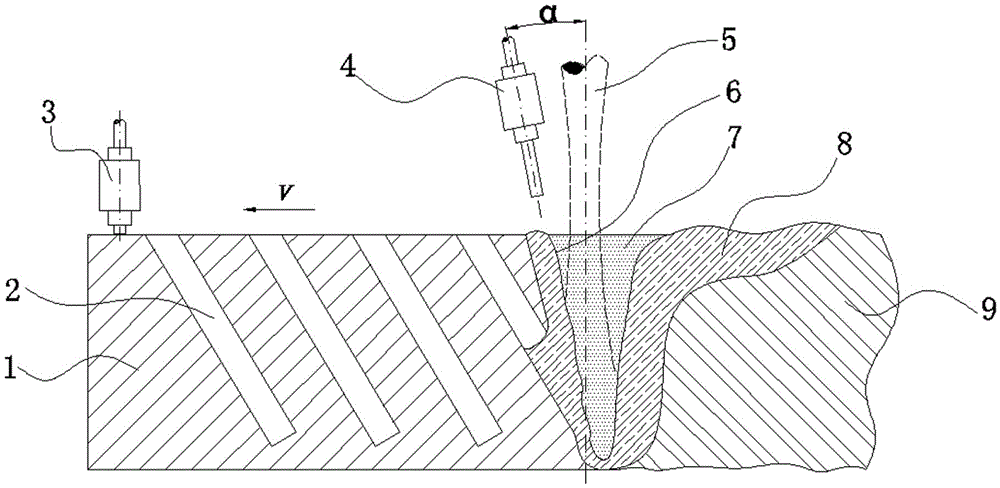

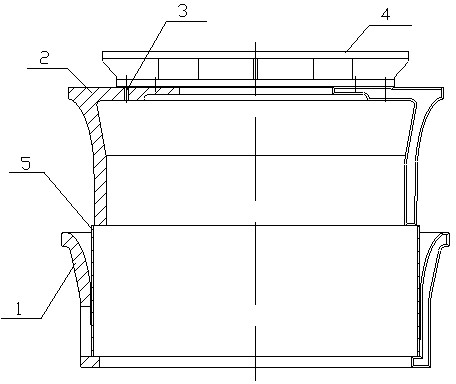

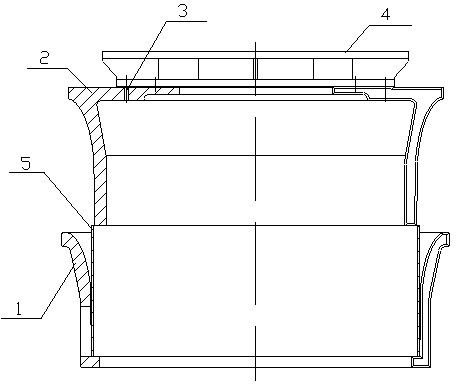

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

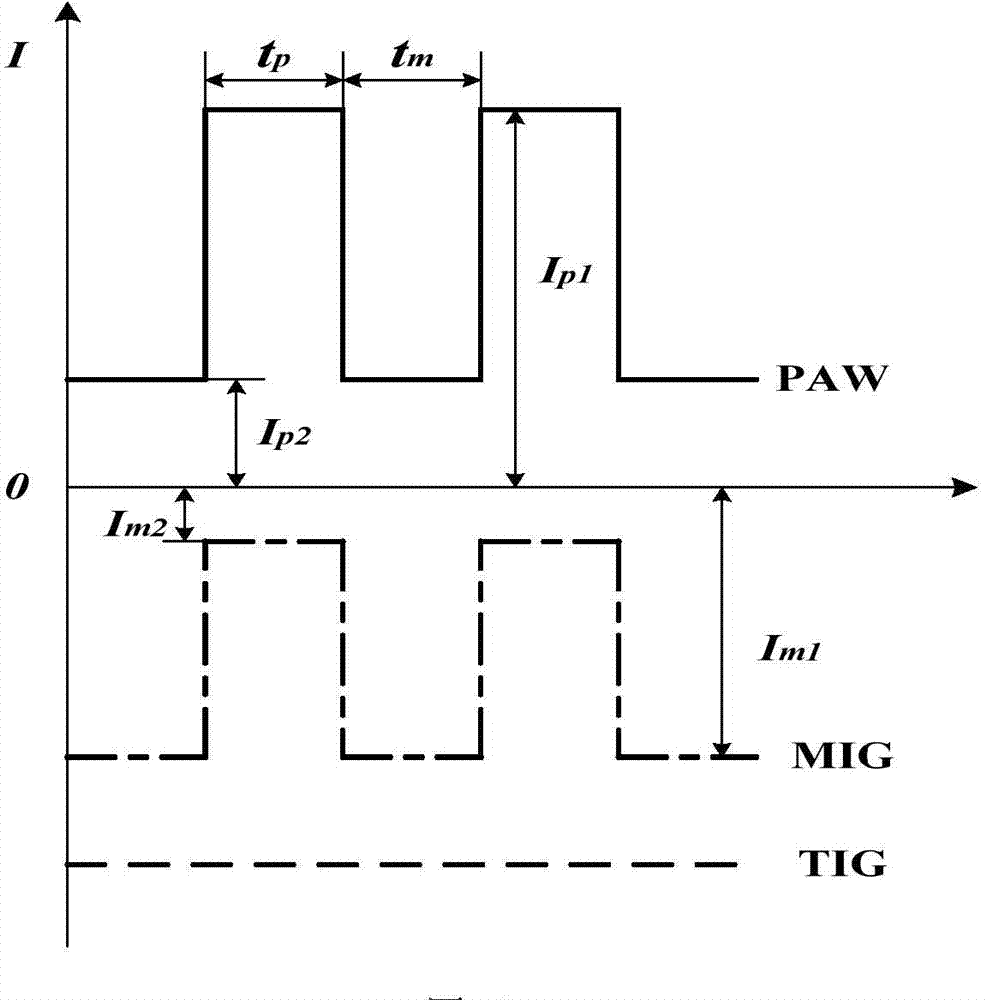

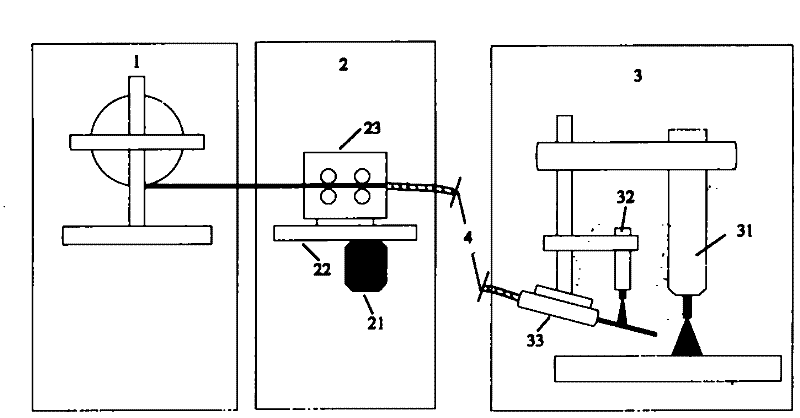

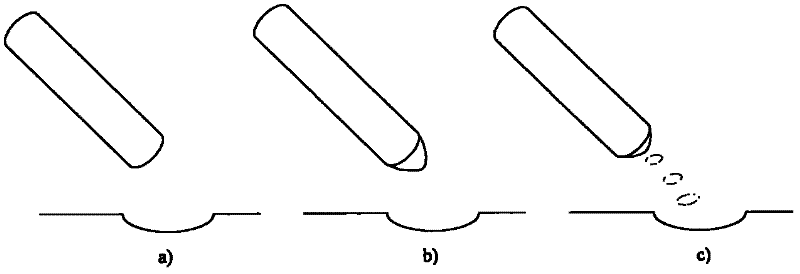

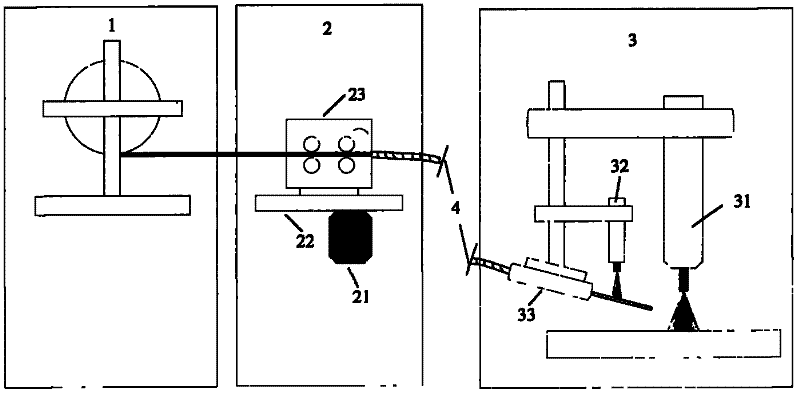

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

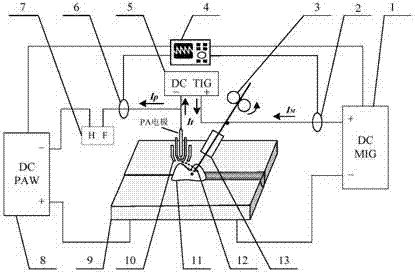

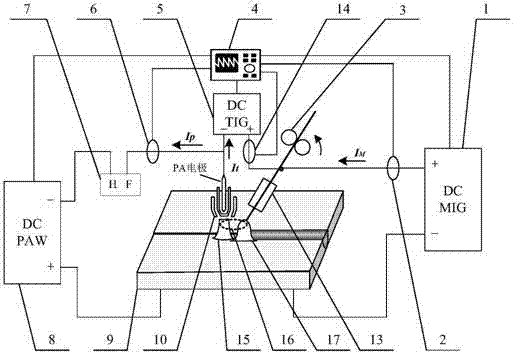

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

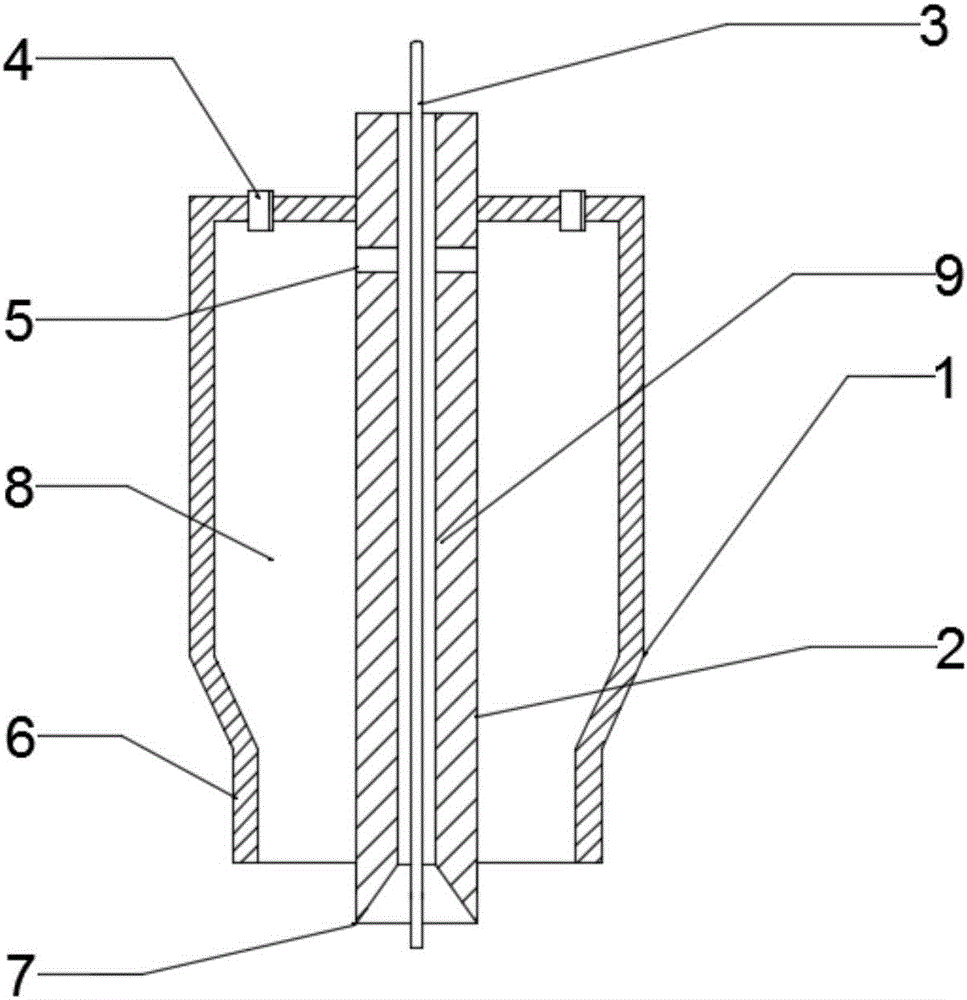

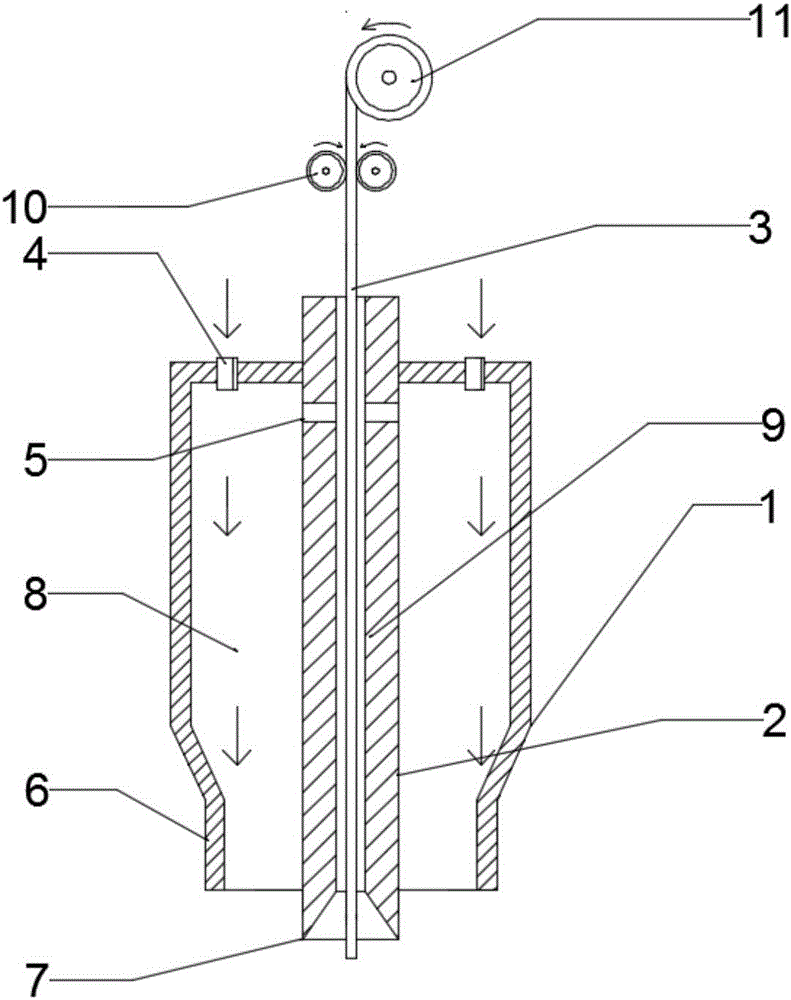

Cold metal transition welding method and device thereof

The invention aims at providing a cold metal transition welding method and a device thereof. The device consists of an MAG (Metal Active Gas) welding wire automatic feeding unit, a vibration wire feeding unit and an argon arc hot wire welding gun unit; the MAG welding wire automatic feeding unit is connected with the vibration wire feeding unit; the vibration wire feeding unit is connected with the argon arc hot wire welding gun unit through a hose; the argon arc hot wire welding gun unit comprises a straightener, an auxiliary arc welding gun and a main TIG (Tungsten Inert Gas) arc welding gun; and the auxiliary arc welding gun and the main TIG arc welding gun compose a heating source of the argon arc hot wire welding gun unit. The welding method comprises the following steps of: switching on a welding main circuit, and initiating a main TIG arc to heat a welding workpiece; and starting the MAG welding wire automatic feeding unit and a vibrating motor after the arcing of an auxiliary arc is stable. According to the cold metal transition welding method and the device thereof, the welding process is stable, the welding quality is even, the wire-feeding speed and the welding current are independently adjusted, the device is simple, and the cost is low. Based on the ordinary MAG welding wire feeding and arc wire-heating equipment, the vibration wire feeding unit is introduced, thewire heating manner is changed, thus, the cold metal transition welding is realized.

Owner:LIAONING SUPOR SHOWER EQUIP

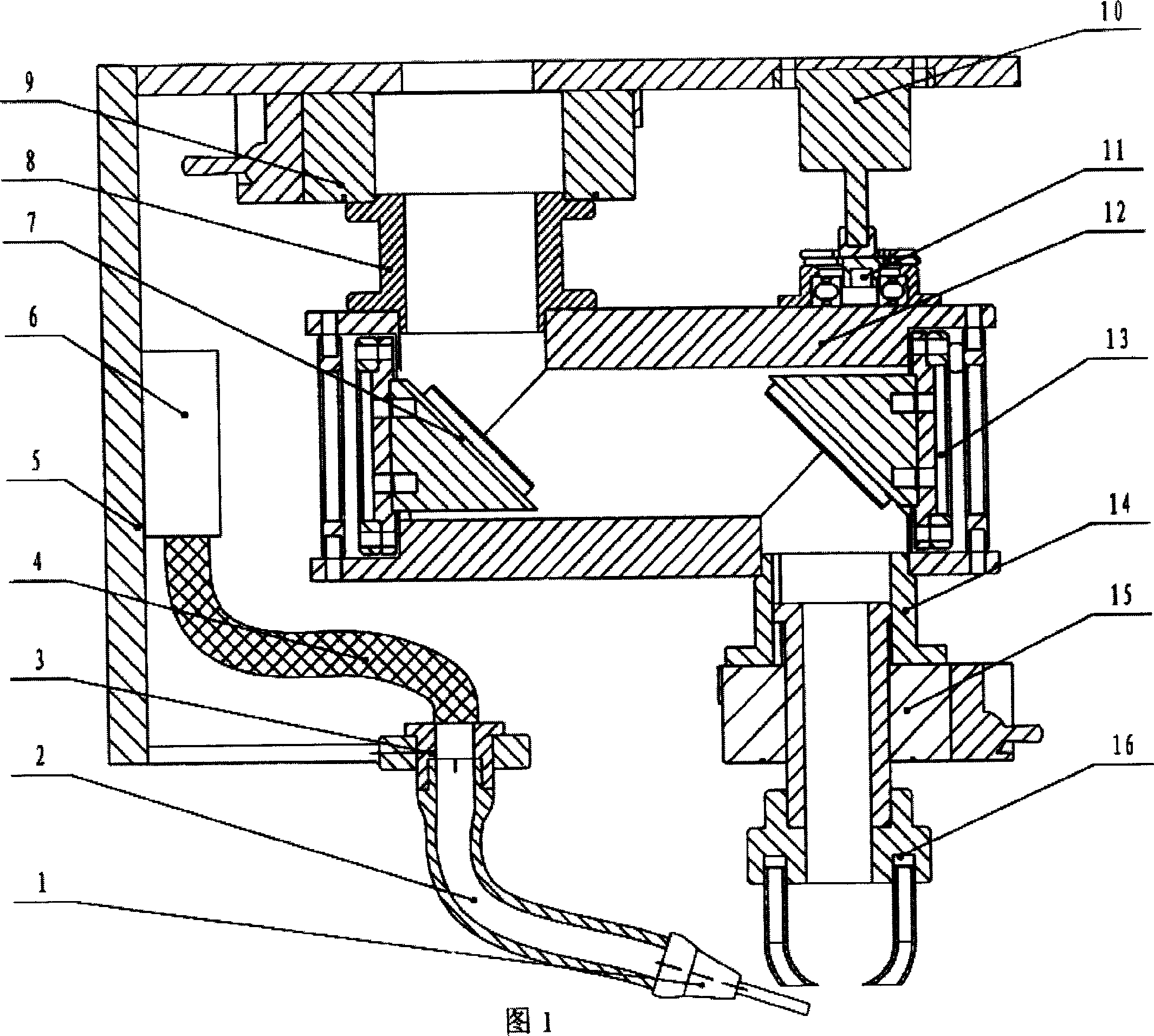

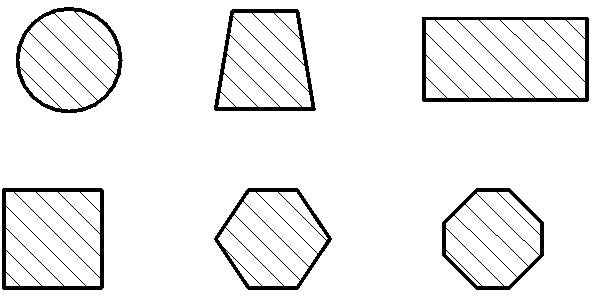

Rotary double focus laser-MIG electric arc composite welding head

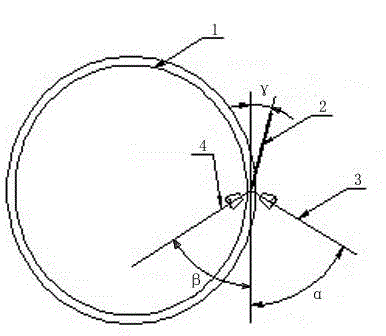

InactiveCN1586788APromote absorptionImproving Laser Welding Process PerformanceArc welding apparatusLaser beam welding apparatusWide areaLaser

The composite rotary double focus laser-MIG electric arc welding head includes mainly two parts, the rotary double focus laser welding head and the MIG electric arc welding wire feeding welding gun, connected via a connecting plate. It has welding wire feeder fixed on the connecting plate, welding wire feeding hose connected to the feeder, conducting nozzle and goose neck for welding wire to pass through; protecting nozzle in the end of the goose neck; and rotating table with reflecting cavity, regulating frame, reflector, connecting barrel and welding laser head. The present invention combines the rotary double focus laser welding and the MIG electric arc welding, and has greatly raised welding performance and lowered assembling precision requirement for even wide application.

Owner:BEIHANG UNIV +1

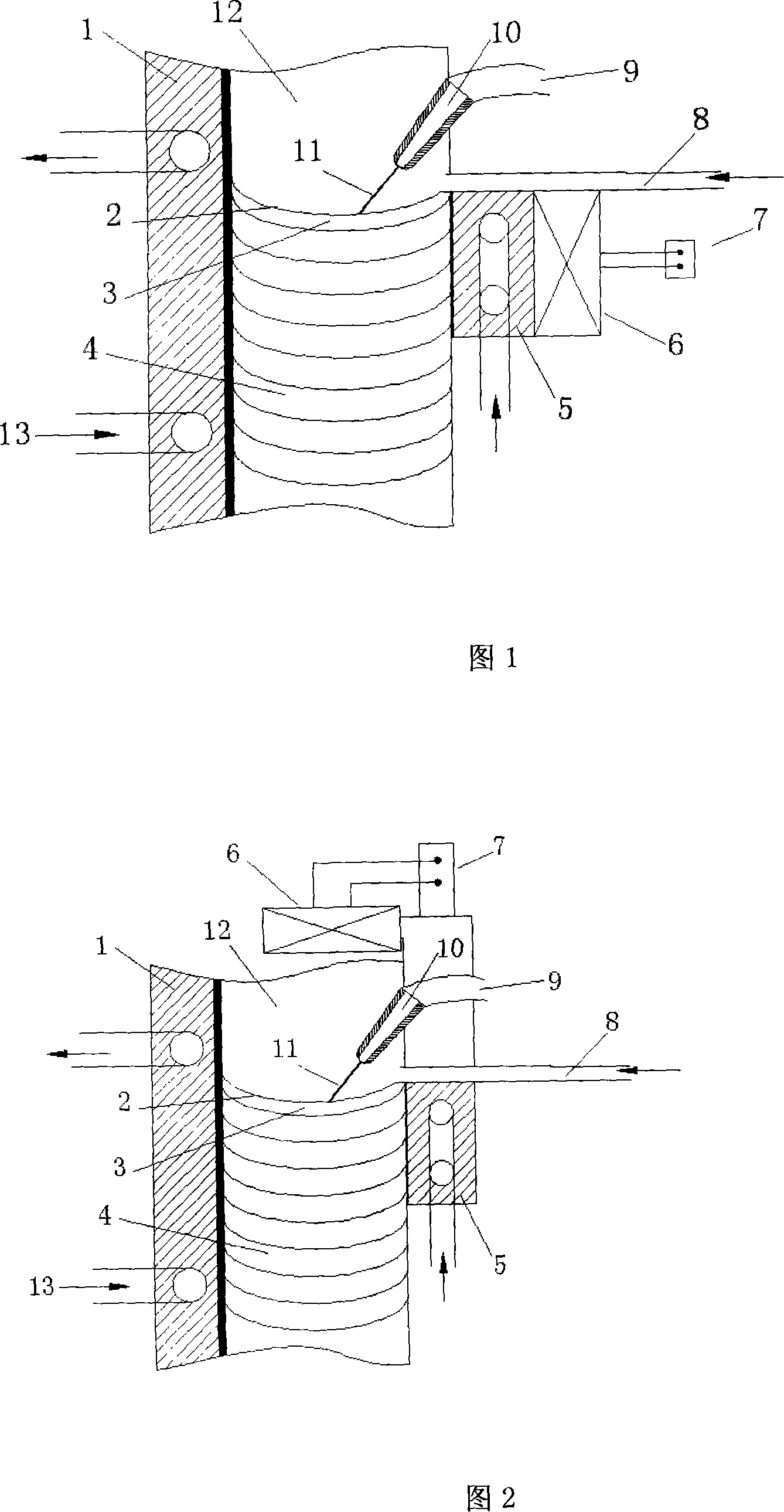

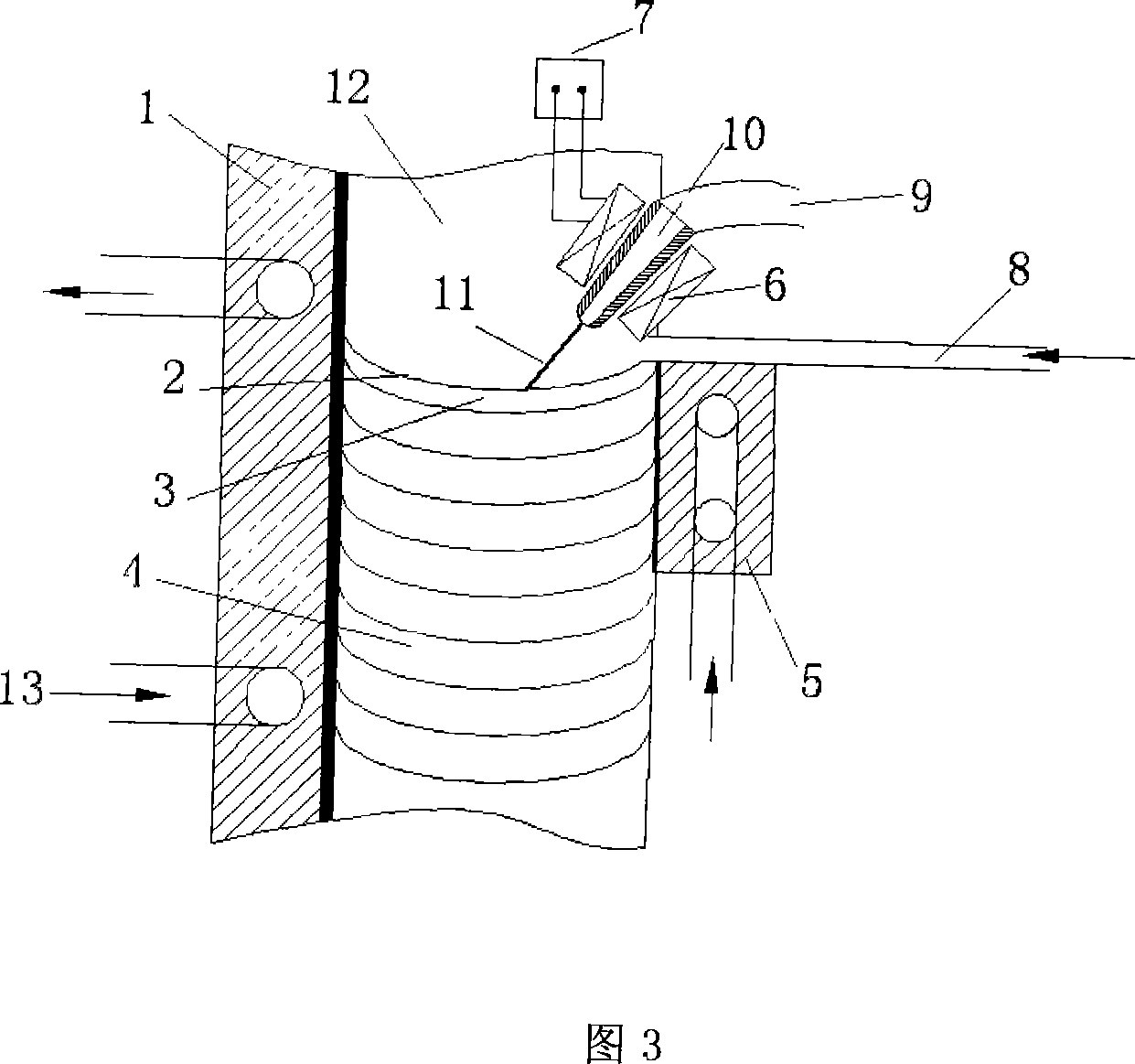

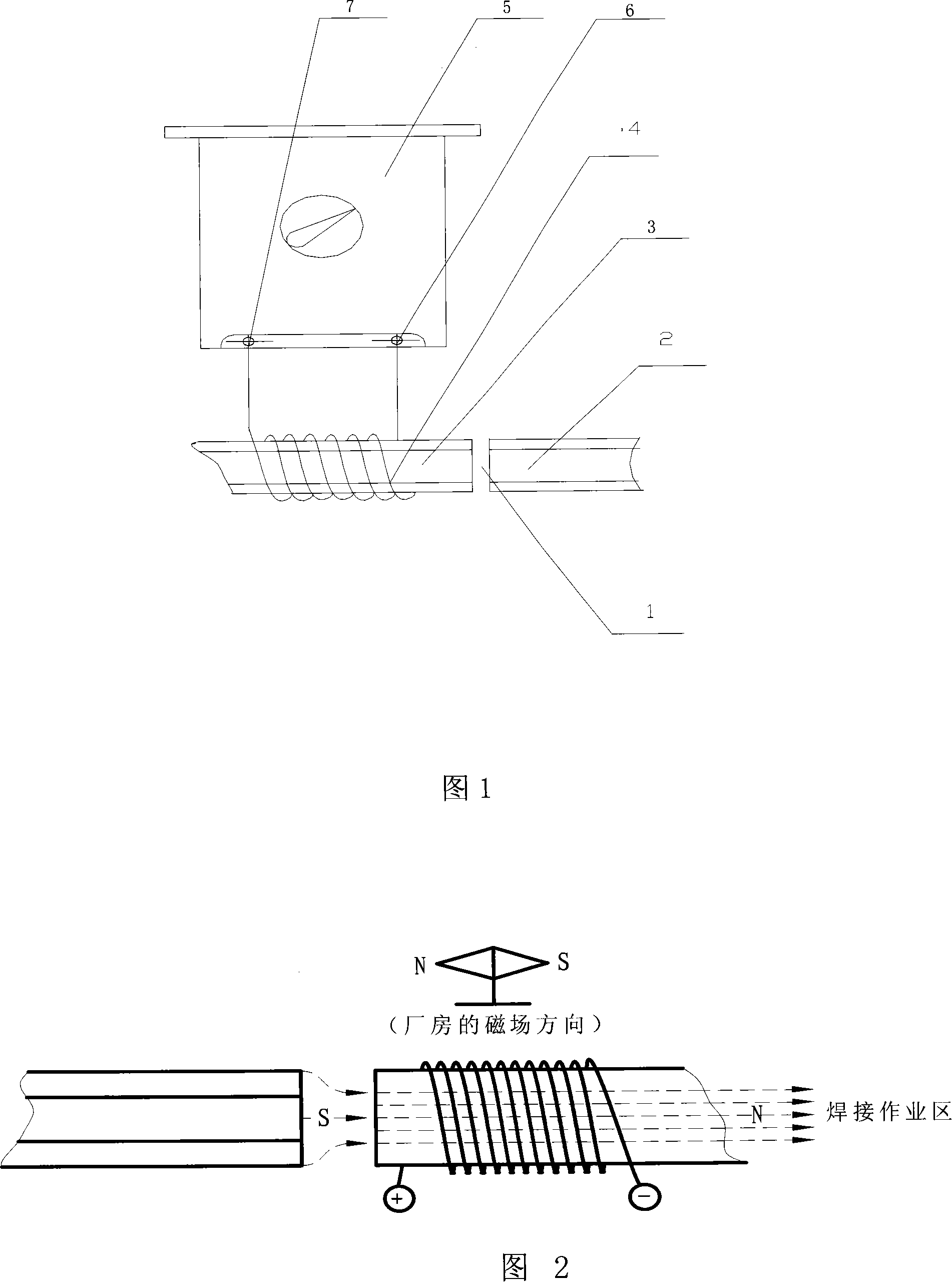

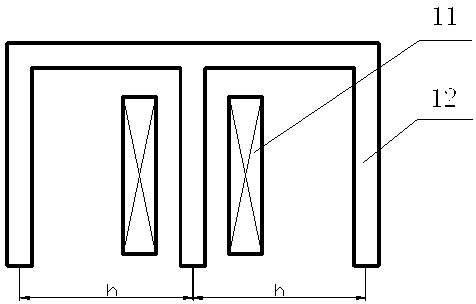

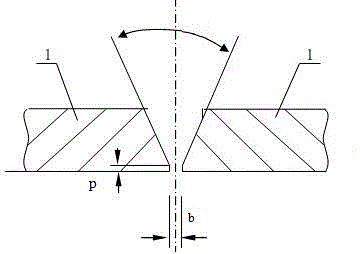

Method and equipment for electromagnetic composite double-face submerged arc welding of diphase stainless steel thick plate

InactiveCN101462196AImprove crystallizationReduce sensitivityArc welding apparatusChemical industryWelding power supply

The invention discloses a method for welding a dual-phase stainless steel and a device thereof. The method comprises: dual-side surfacing of heavy current submerged arc is controlled by an electromagnetic-composite field of the dual phase stainless steel of heavy plates without a grooveb; excitation current is provided by an excitation power supply to generate an additional longitudinal electromagnetic field; and a submerged arc welding process of the dual-phase stainless steel of the heavy plates without the groove is comprehensively controlled and realized by the electromagnetic field. The welding device is provided with the excitation power supply, a welding power supply, an excitation welding device, a device of an auxiliary electric field and a water cooling system. The excitation device consists of excitation coils, is fixed on a welding torch, and generates the additional longitudinal electromagnetic field which is coaxial with the welding torch, and the water cooling system is arranged in a bracket of the excitation coils. The device can realize the submerged arc welding of the dual-phase stainless steel of the heavy plates without the groove, with high efficiency, high quality and low cost through the electromagnetic-complex submerged arc welding; meanwhile, the device can be used for welding the dual-phase stainless steel of the heavy plates in industries, such as shipbuilding, chemical industry and so on.

Owner:CHONGQING UNIV

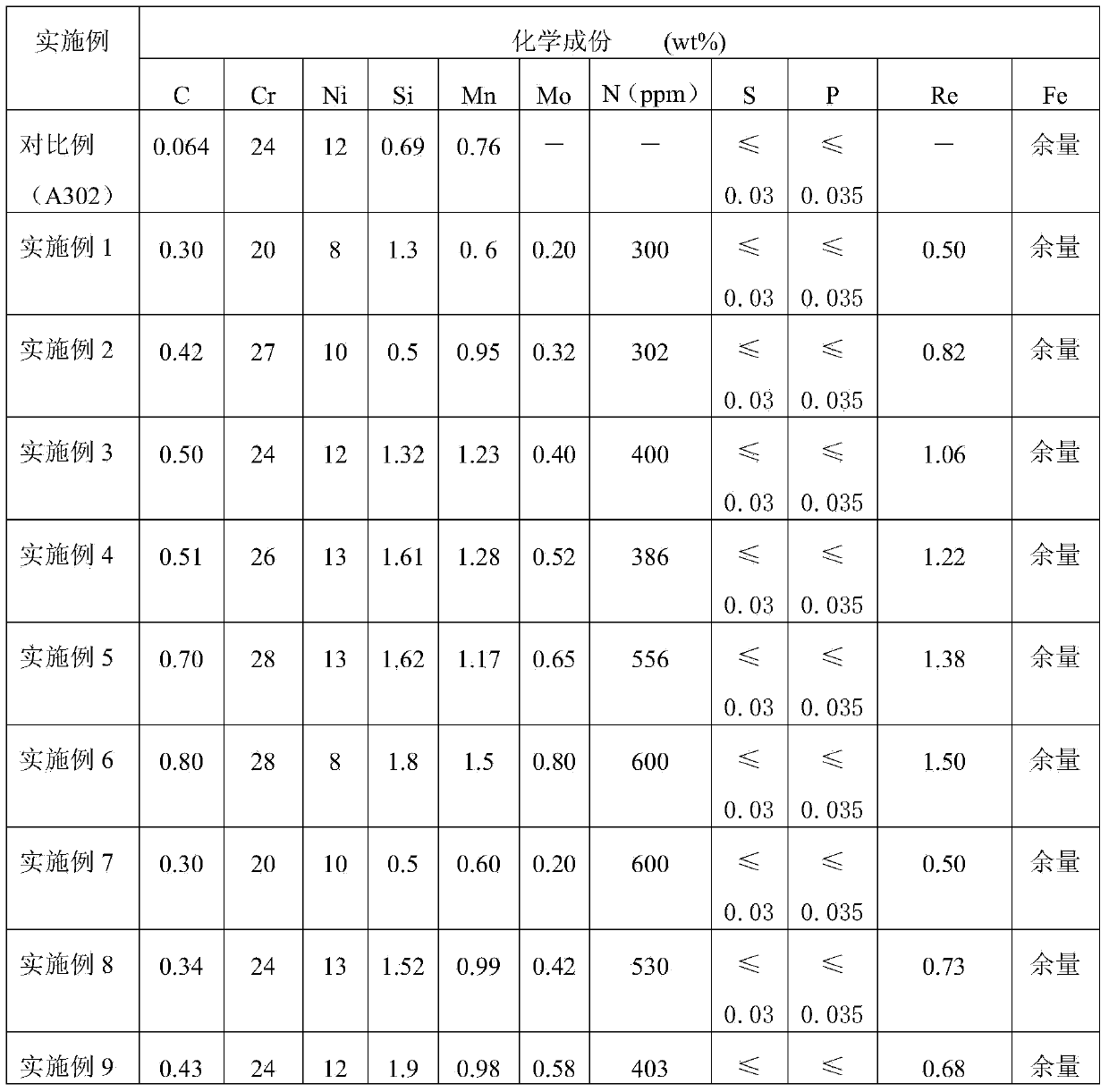

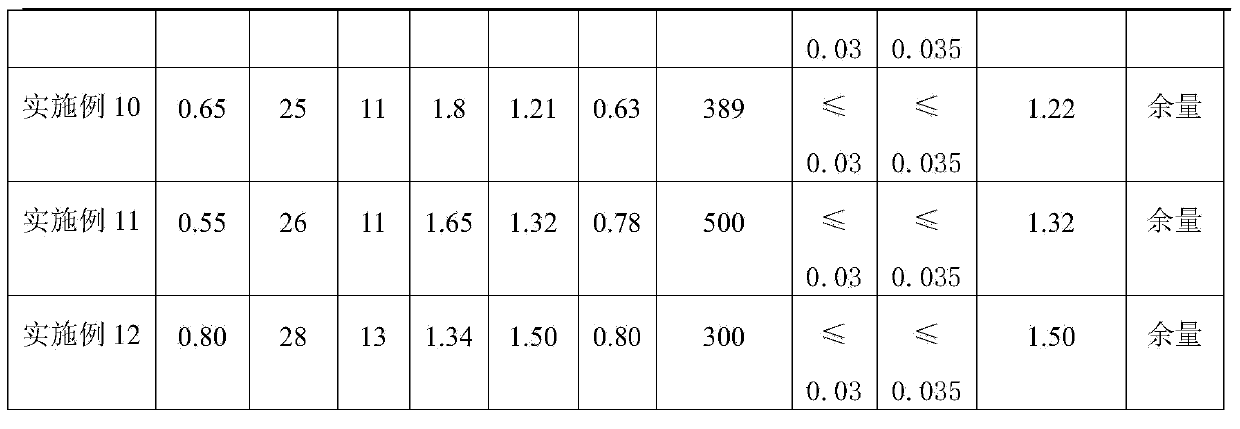

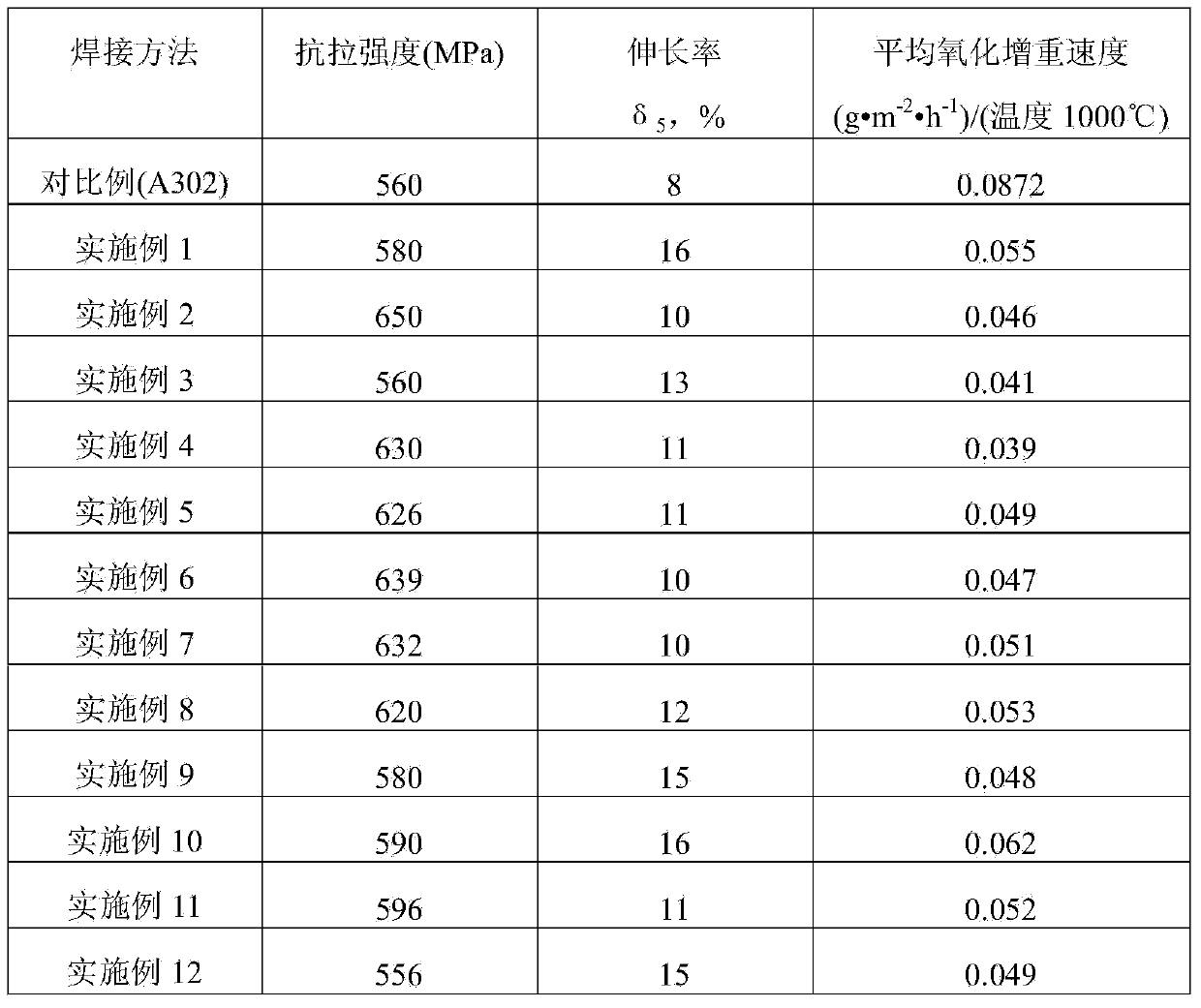

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

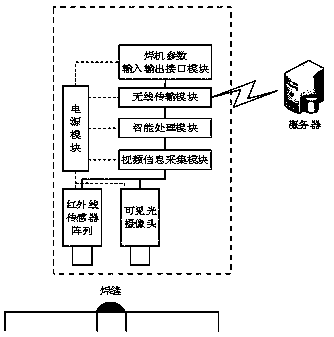

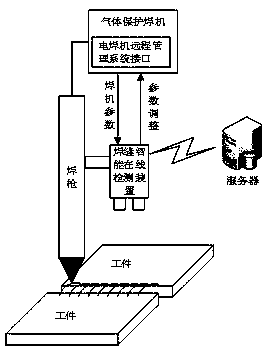

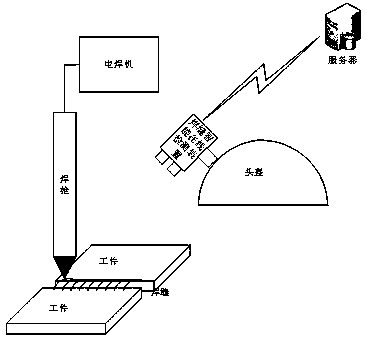

Intelligent online detection device based on multi-source information fusion for welded joint

PendingCN109483107AReduce welding defectsImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesComputer visionWireless data transmission

The invention discloses an intelligent online detection device based on multi-source information fusion for a welded joint. High-quality and time-varying infrared imaging information is acquired according to the welding residue temperature, an infrared light video and a visible light video of a real-time welded joint during the welding process are acquired through an infrared ray array sensor anda visible light camera, the fusion and the intelligent identification of two video information are realized through a video information acquisition module and an intelligent processing module, information such as the weld width, the center path, the welded joint texture and the surface temperature field distribution of the welded joint is acquired, and the quality of the welded joint is evaluatedby utilizing a deep learning algorithm; and the video information and a processing result are sent to a server through a wireless data transmission module, the image splicing and the matched fusing ofthe whole welded joint are carried out through the server according to the obtained infrared and visible light images of the welded joint, and a whole welding process quality evaluation database is built, so that a decision support is provided for welding process evaluation.

Owner:朱清

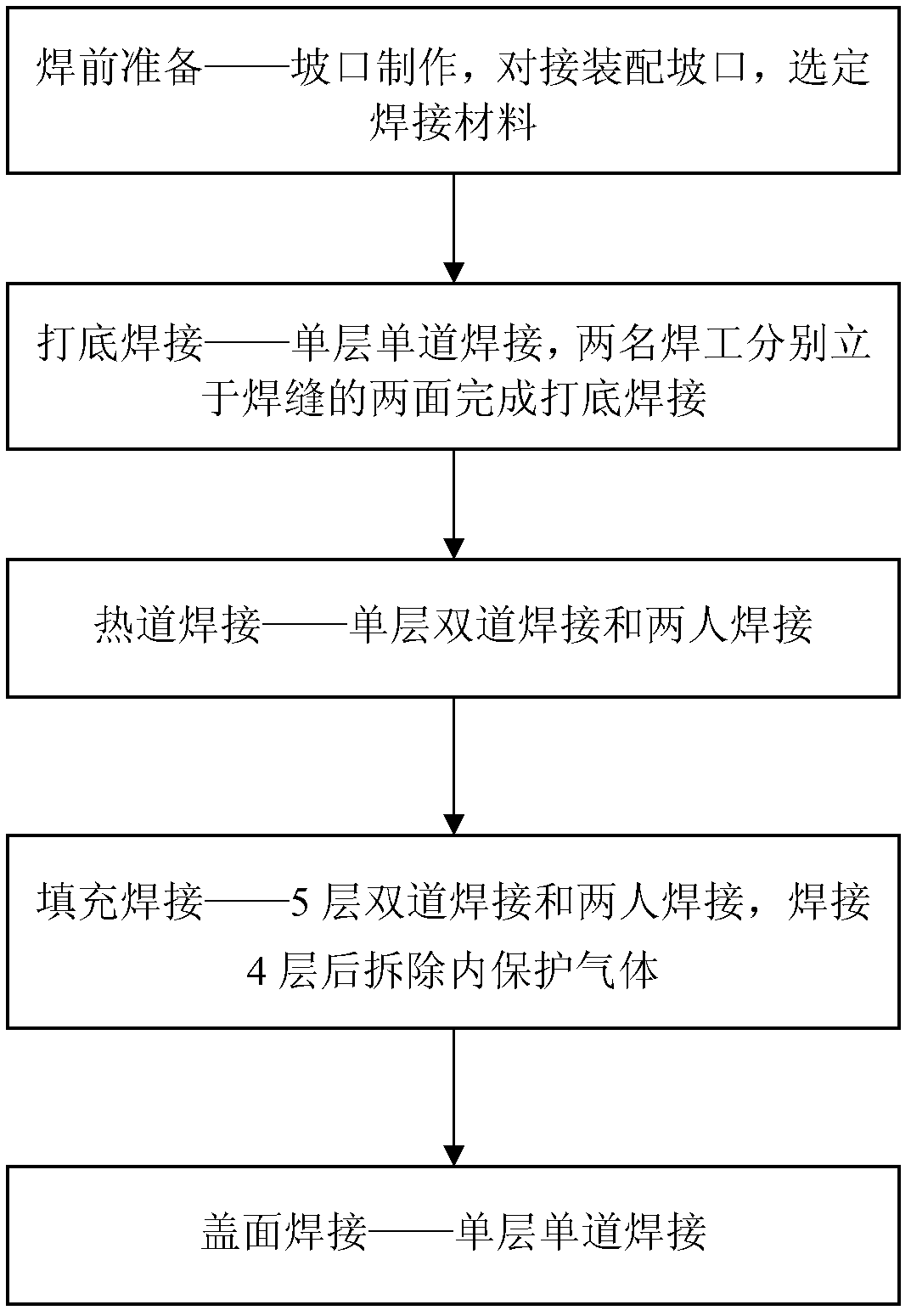

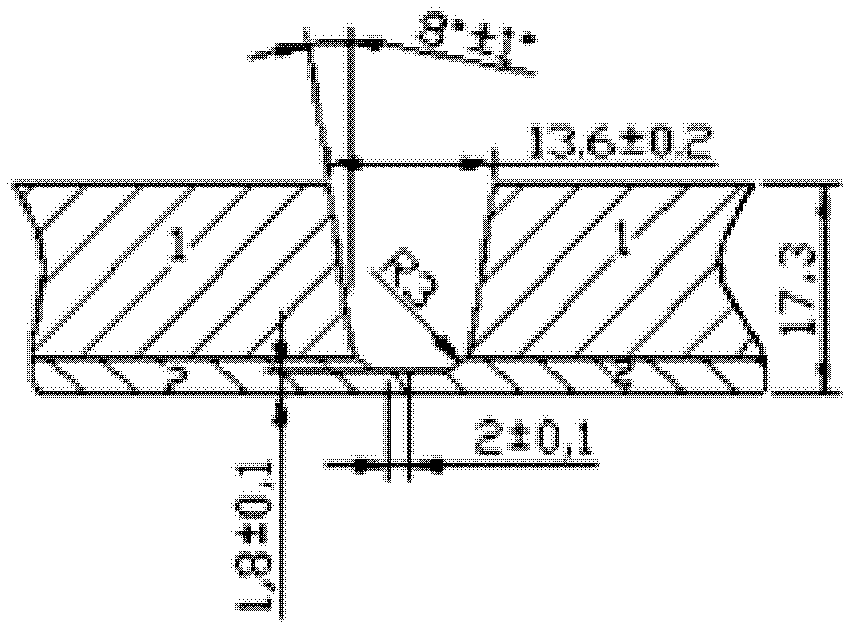

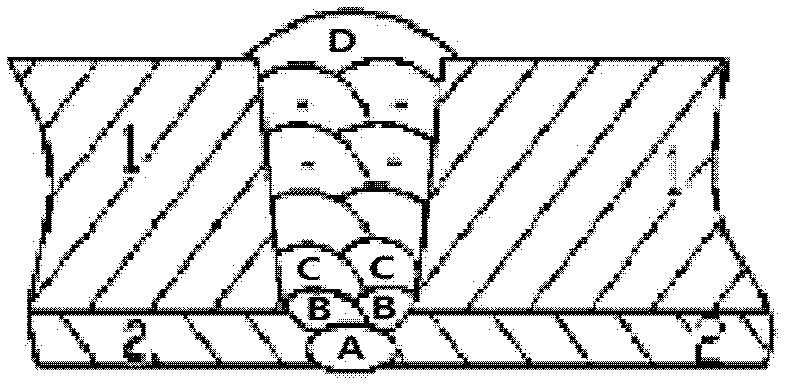

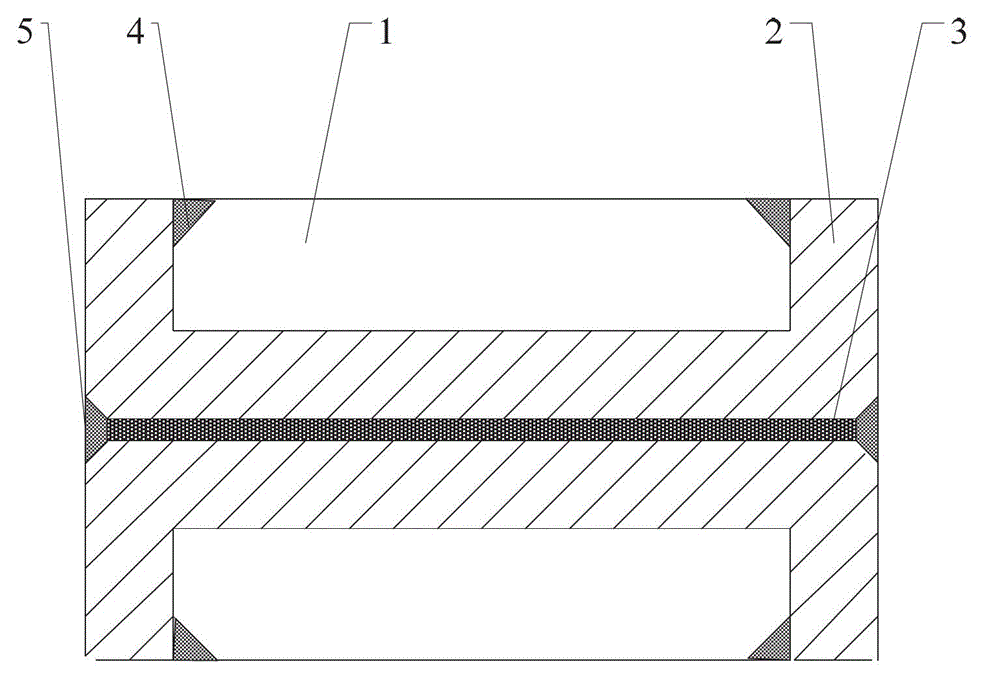

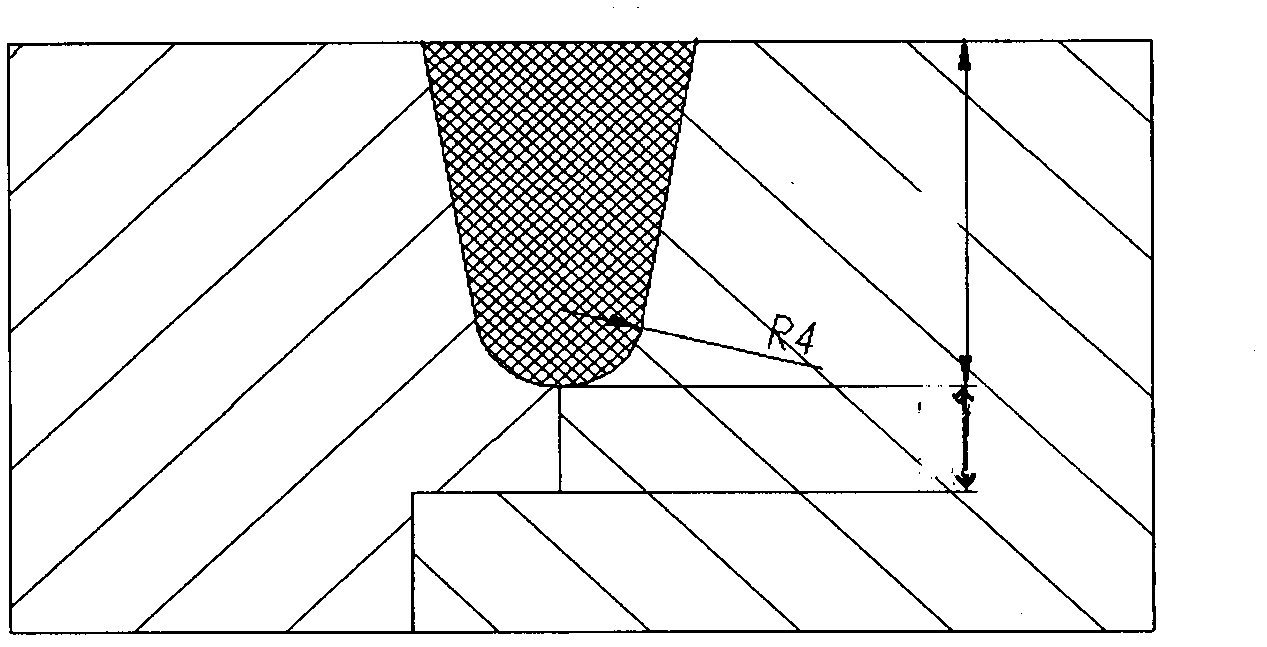

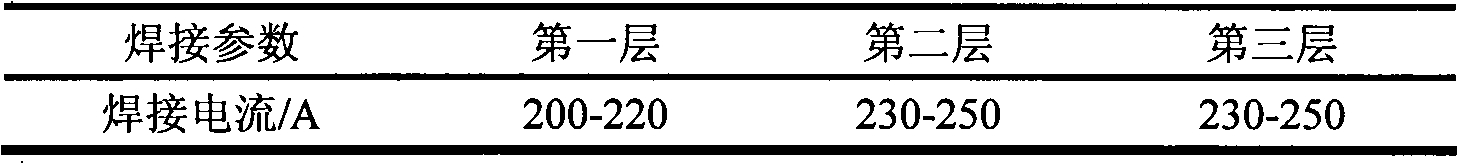

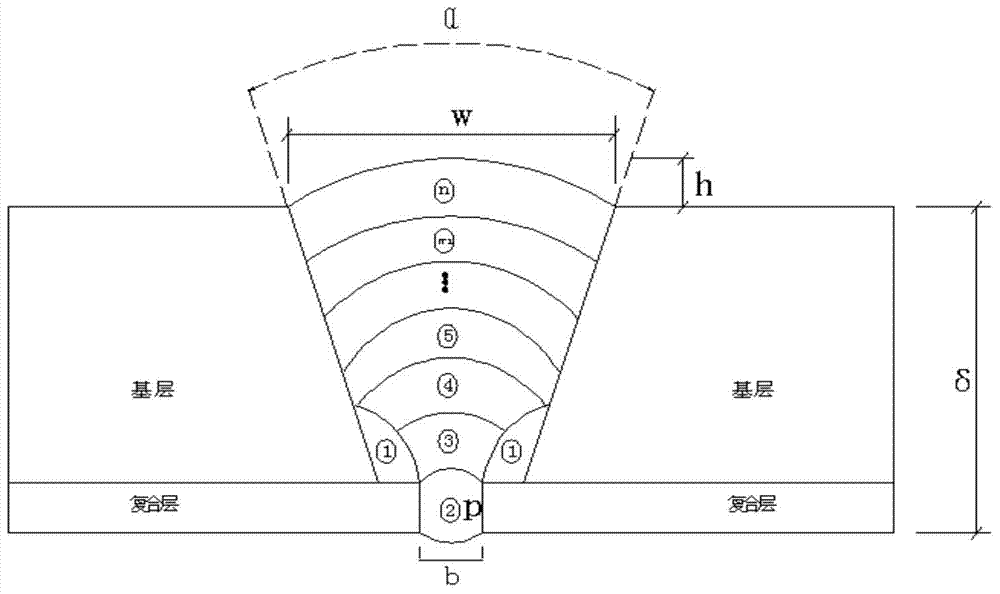

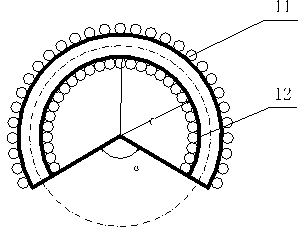

Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

The invention relates to a semiautomatic argon tungsten-arc welding technological process of a bimetal compounding sea pipe, a labour hand-held semi-automatic welding gun welding is adopted, a wire feeder continuously feeds wires, and argon gas is utilized as protective gas. The technological process comprises the following operation steps of: firstly, procedure preparation before welding: manufacturing a groove, picking up fitting the groove, and selecting a welding material; secondly, backing welding process: adopting single layer one-pass welding, wherein two welders respectively stand thetwo sides of a welding seam so as to finish the backing welding; thirdly, hot-runner welding procedure: adopting single layer two-way welding and two-person welding; fourthly, filling welding procedure: adopting five-layer two-way welding and the two-person welding, and dismantling the protective gas after welding four layers; and fifthly, a cover surface welding process: adopting the single layer one-pass welding. The technological process provided by the invention has the advantages of high welding quality, small labour intensity, low construction cost, and high production efficiency; and the technological process is suitable for a compounding submarine pipeline and welding procedure of a subsidiary vertical pipe of the compounding submarine pipeline, and is suitable for the welding of a deep water composite material pressure container and deep water pipe manifold nickel base alloy and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Preparation method for wear-resistant steel and carbon structural steel composite plates

InactiveCN102873091ALess chance of welding defectsReduce welding defectsTemperature control deviceWork treatment devicesSteel platesWear resistant

The invention discloses a preparation method for wear-resistant steel and carbon structural steel composite plates. The method includes the steps: processing a groove on each carbon structural steel plate according to the size of each wear-resistant steel plate, and cleaning the surfaces of the grooves and the wear-resistant steel plates; placing the wear-resistant steel plates into the grooves correspondingly, placing the wear-resistant steel plates and the carbon structural steel plates into a vacuum chamber in a clamping manner, performing seal welding for the bonding positions of the peripheries of the grooves with the wear-resistant steel plates to form wear-resistant steel plate blanks, and spraying high-temperature anti-adhesion coating on the bottom surfaces of the carbon structural steel plates; stacking the bottom surfaces of the carbon structural steel plates sprayed with the high-temperature anti-adhesion coating in two composite plate blank groups in a relative bonding manner, placing into the vacuum chamber in a clamping manner, and performing seal welding for the peripheries of the bonding surfaces of the two composite plate blank groups to form a combined blank; placing the combined blank into a heating furnace for heating prior to rolling; and conveying the rolled combined blank onto a roller type quenching machine for quenching prior to trimming so that the two wear-resistant steel and carbon structural steel composite plates are obtained. The method is capable of decreasing probability of welding defects and improving interfacial strength of the composite plates without changing performances of base plate layers, and is high in production efficiency.

Owner:武汉钢铁有限公司

Cylinder barrel of oil cylinder of crane and processing process thereof

ActiveCN102517491AReduce welding defectsImprove safety and reliabilityArc welding apparatusCylindersHydraulic cylinderWelding defect

The invention discloses a cylinder barrel of an oil cylinder of a crane and a processing process thereof. The invention belongs to the field of hydraulic cylinders. The material of a cylinder barrel body is Q345B. The material contains alloy elements, such as Cr, Nb, Ni, V and the like, and the mechanical property and the welding property are both better than those of 45# steel. The processing process comprises the following steps: (1) using a hot rolling steel pipe: selecting on a pipe blank, blanking, aligning, rough turning on an outer circle, welding on a flange, scraping on an inner hole, rough turning and finish turning; and (2) using a high-accuracy cold drawing steel pipe: cold drawing, aligning, blanking, welding on a flange, scraping on an inner hole, rough turning and finish turning; and the cylinder barrel of the oil cylinder of the crane and the processing process thereof are characterized by the technological parameter of welding, the technological parameter of cold-drawing processing and the technological parameter of scraping processing. The cylinder barrel of the oil cylinder of the crane and the processing process thereof have the beneficial effects that the welding defect of the oil cylinder is lowered by more than 50 percent; and moreover, the after-fracture elongation rate of the material of the cylinder barrel is enhanced, the toughness of the cylinder barrel is ensured, and the danger of the occurrence of brittle fracture of the cylinder barrel is decreased, so that the safety reliability of the oil cylinder is greatly enhanced.

Owner:XCMG HYDRAULICS CO LTD

Semi-automatic argon-arc welding method for bimetal composite pipes

ActiveCN103586566AReduce welding heatAvoid welding stress concentrationArc welding apparatusWelding/soldering/cutting articlesCorrosionEngineering

The invention discloses a semi-automatic argon-arc welding method for bimetal composite pipes. The semi-automatic argon-arc welding method includes preprocessing orifices of welded pipelines; sequentially welding root welding layers, transition layers, filling layers and capping layers. The semi-automatic argon-arc welding method for the bimetal composite pipes has the advantages that difficult problems of low welding speeds, high labor intensity of workers and welding heat input quantities, influence on corrosion resistance of stainless steel layers and the like due to the fact that bimetal composite pipes are only welded and constructed manually can be solved, the problem of welding stress concentration at seal welding positions due to high welding head input for conventional cosmetic welding can be solved, the welding quality can be improved, and the welding speed can be increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

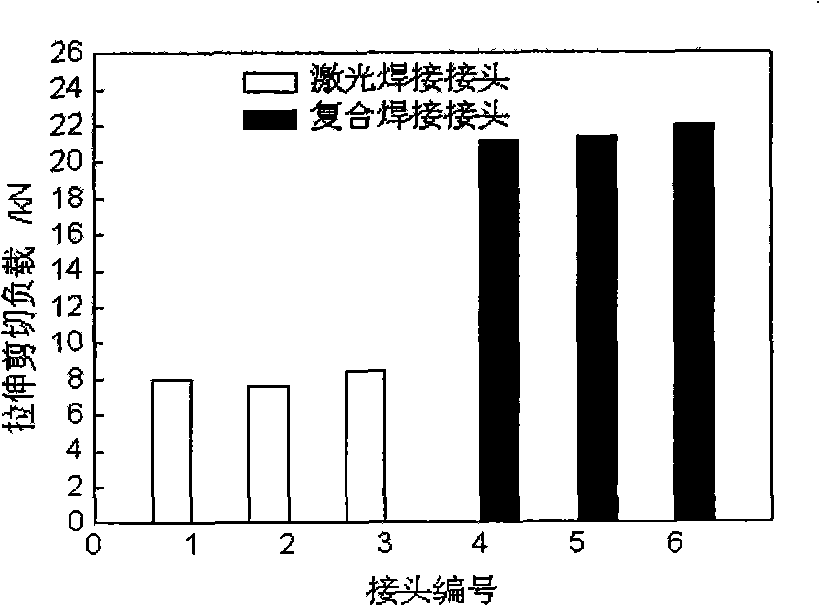

Laser-electric resistance seam welding in-phase compound welding method of frame-covering structure

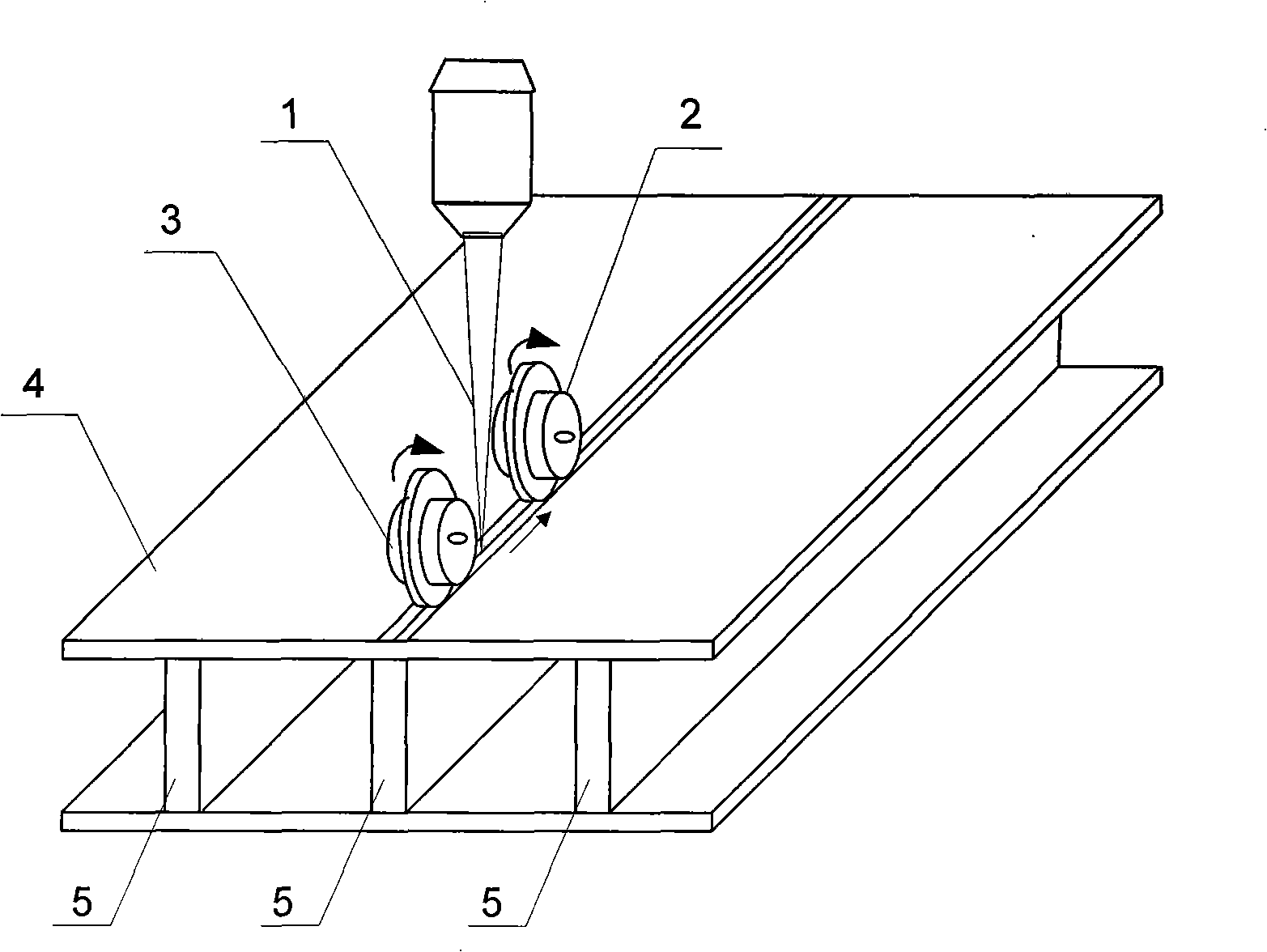

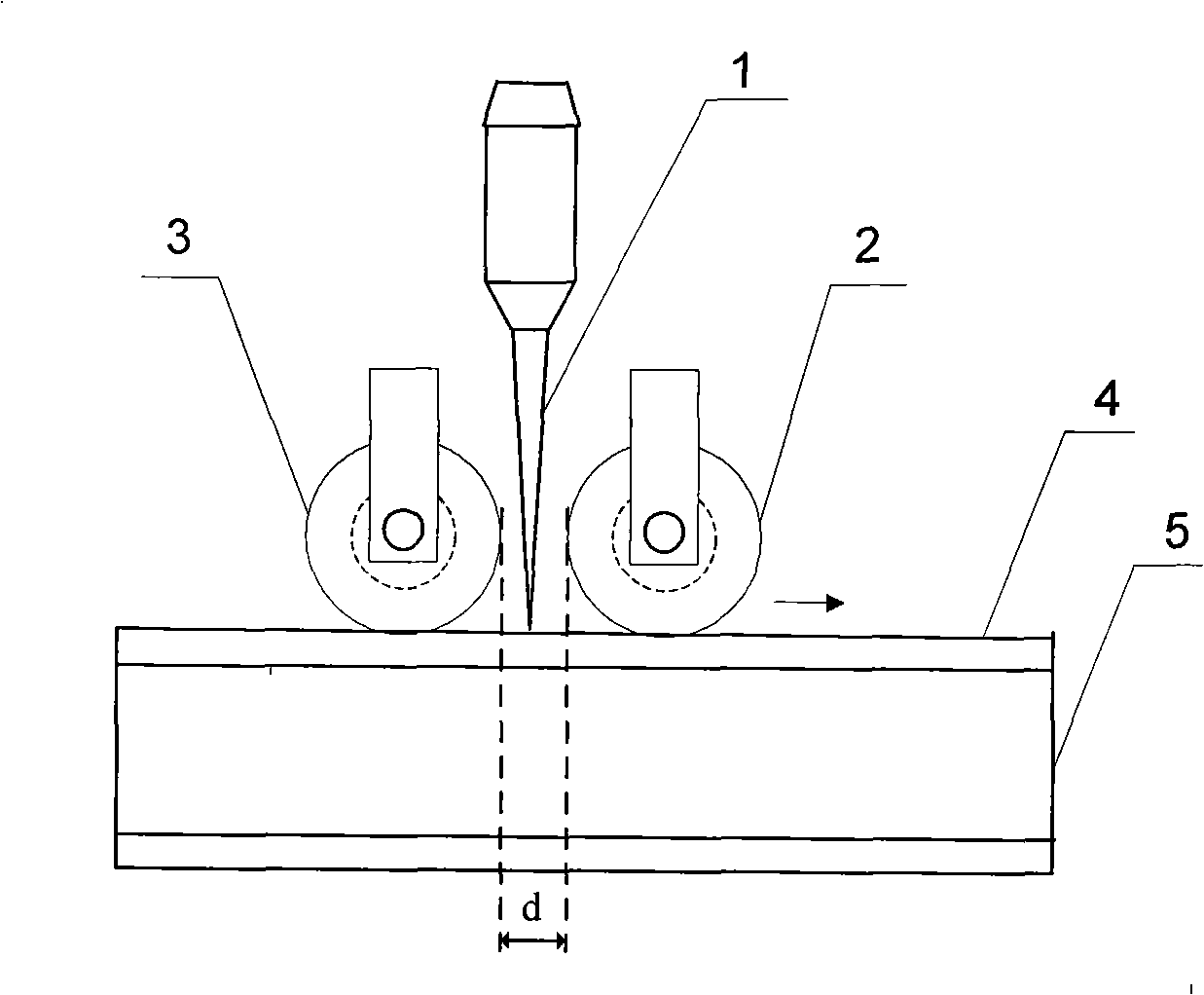

InactiveCN101306491AFit tightlyImprove welding qualityWelding with roller electrodesLaser beam welding apparatusLight beamElectric resistance welding

A laser and electric-resistance seam-welding synchronous composite welding method for an envelope-framework structure relates to a novel laser and electric-resistance seam-welding synchronous composite welding method, belongs to the welding field, and aims to solve the problems in welding the envelope-framework structure by the single laser, such as narrow seam, low shear strength of the seam, a plurality of air vents on the faying surface of the envelope and the framework. The invention aims at the workpiece with the envelope-framework structure to be welded, and adopts the laser and the electric-resistance seam-welding synchronous composite welding; the electric-resistance seam-welding adopts double-roller single-side welding, two roller electrodes are disposed on the front and the back sides of the upper top surface of the envelope along the seam formed by the contact of the envelope and the framework, so that the envelope is pressed to the lower framework in the travel forward, and the laser beam is always positioned in the middle position of the two roller electrodes during the welding process. The seam formed by the welding method can improve the shear strength more than twice in comparison with the base material, and the air vent amount per area can be reduced from about 10% to about 2% of the laser welding.

Owner:HARBIN INST OF TECH

Coaxial hollow tungsten electrode TIG device and welding gun thereof, using method and application

InactiveCN106312270AThe structural design is exquisite, reasonable and creativeSave energyWelding electrode featuresManufacturing technologyEngineering

The invention discloses a coaxial hollow tungsten electrode TIG device and a welding gun thereof, a using method and application and belongs to the technical field of electric arc additive manufacturing. The welding gun of the TIG device comprises a gun body and a hollow tungsten electrode, wherein the front end of the gun body is provided with a ceramic nozzle. The gun body is internally provided with a protective air cavity, and an air inlet hole communicated with the protective air cavity is formed in the gun body and used for being connected with an air source. The hollow tungsten electrode is arranged in the gun body, the front end of the hollow tungsten electrode extends out of the ceramic nozzle, and the middle of the hollow tungsten electrode is provided with a hollow wire feeding cavity. The side wall of the hollow tungsten electrode is provided with an air hole, and the air hole enables the wire feeding cavity of the hollow tungsten electrode to be communicated with the protective air cavity of the gun body. The welding gun is good in welding wire preheating effect, an additive manufacturing cracking phenomenon is avoided, the deposition efficiency is high, the welding speed is quick, weld defects are fewer, and the welding quality is high. According to the device, superspeed and high-quality electric arc additive manufacturing can be performed, and the device is particularly suitable for additive manufacturing of active metals such as copper and aluminum as well as alloy thereof. According to the using method, high quality weld joints can be obtained, and the welding quality is improved.

Owner:JIANGSU ASWEMET PRECISION TECH CO LTD

Spot welding method and application thereof in aluminum alloy and steel

InactiveCN103350276ALow heat inputImprove welding qualityResistance welding apparatusSpot weldingUltimate tensile strength

The invention discloses a spot welding method. Aiming at aluminum alloy plates, aluminum alloy and various steel dissimilar materials, the method adds a solid adding material which is generally a rivet in a welded plate and then carries out spot welding at the riveting place. The tensile strength of a spot-welding lap joint which is welded with the method is higher than that of a spot-welding test piece which is welded under same parameters, meanwhile the welding quality of the spot-welding lap joint is good, and the spot-welding lap joint does not have obvious cracks or gas holes.

Owner:TIANJIN UNIV

Metal inert gas (MIG) welding method of aluminum alloy thin plate for high speed train

InactiveCN103537784AReduce processIncrease productivityArc welding apparatusVehicle componentsSurface oxidationThin slab

The invention discloses a metal inert gas (MIG) welding method of an aluminum alloy thin plate for a high speed train. The method is characterized in that an ER5356 welding wire and 99.9% argon protective gas are selected to conduct single pass welding. The method includes the following steps: 1) surface machining of a workpiece to be welded; 2) MIG welding; 3) welding gap defect checking. The step 1) includes that the workpiece to be welded is not preheated, an organic solvent is directly adopted to remove grease dirt and dust on the surface of the workpiece to be welded, and a mechanical method is adopted to remove an oxidation film on the surface of the workpiece in a washing mode. The step 2) includes that weld heat input is controlled between 4.0KJ / cm and 5.0KJ / cm during MIG welding, and environment humidity is controlled to be smaller than or equal to 70%. The step 3) includes that pore defects of a welded workpiece are removed through a steel wire brush or an air chipper. The method has the advantage that thin plate aluminum alloy welding connector pore welding hot crack number can be greatly reduced, welding gap forming is good, welding deformation is small, welding connector strength is higher, the MIG welding quality of the aluminum alloy thin plate for the high speed train is effectively improved, and welding quality stability is ensured.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Electromagnetic control electro-gas welding method and equipment thereof

InactiveCN101172312AStir wellImprove crystallizationArc welding apparatusEngineeringElectromagnetic shielding

The invention relates to an electromagnetically controlled gas-electric vertical welding (EMS-EGW) method, which is to set an external magnetic field above or / and near the side of the gas-electric vertical welding (EGW) molten pool (3), such as an excitation coil that provides an excitation current by an excitation power supply , produce time-varying or constant electromagnetic stirring and external magnetic field to produce electromagnetic stirring effect; the electromagnetic field promotes the forced movement of the metal fluid in the gas-electric vertical welding pool, and comprehensively controls the solidification process of the weld metal. With the cooperation of gas protection, the method of electromagnetically controlled gas-electric vertical welding (EMS-EGW) is realized on the workpiece. The electromagnetic control gas-electric vertical welding (EMS-EGW) device of the present invention adds excitation equipment on the existing basis, and the excitation equipment is composed of an excitation coil and an excitation power supply that provides excitation current for the excitation coil. The invention breaks through the traditional gas-electric vertical welding method, and provides a new idea for improving gas-electric vertical welding; reduces welding defects, reduces welding costs, improves welding quality and production efficiency, and ensures product reliability; The appearance is well formed; the equipment is simple and easy to popularize and apply.

Owner:CHONGQING UNIV

Stirring friction welding method for improving aluminum copper dissimilar metal connection intensity

ActiveCN101758329AOvercoming plastic deformation inhomogeneityReduce welding defectsWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingCopper

The invention provides a stirring friction welding method for improving the aluminum copper dissimilar metal connection intensity. The stirring friction welding is carried out on aluminum copper dissimilar metal plates under the condition of bias placement of welding tools, the flowability of the materials can be improved, and the aluminum copper connection intensity can be improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

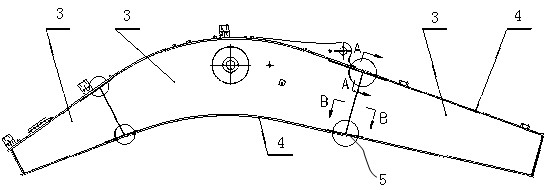

Method for welding metal under strong magnetic field circumstance

InactiveCN101148009ASolve welding difficultiesReduce welding defectsMagnetic bodiesWelding/cutting auxillary devicesElectricityWeld seam

The present invention relates to welding technology, and is especially metal welding method in strong magnetic field environment. The metal welding method in strong magnetic field environment includes measuring the strength and direction of the environmental magnetic field with special instrument, forming one coil of certain turn number and winding direction and connecting the coil to one metal workpiece to be welded, connecting the coil to one DC welder to generate one magnetic field in the same strength as and reverse direction to the environmental magnetic field, and welding with one other welder in no or weak magnetic field condition. The method of the present invention can result in high welding quality, weld seam strength reaching 80 % of mother material strength and tensile strength of the weld seam up to 700 MPa.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

T-shaped joint welding method

InactiveCN101934417AReduce welding defectsImprove welding qualityArc welding apparatusSlagEngineering

The invention discloses a T-shaped joint welding method comprising the following steps of: (a) carrying out backing welding on the main weld of the groove of a side plate, wherein the arc starting position and the arc ending position of the weld are at the longitudinal weld position which is at least 20mm away from the top end of the main weld of the groove of the side plate; (b) cleaning interlayer welding slag, and carrying out intermediate layer welding and cosmetic welding on the main weld of the groove of the side plate, wherein the arc starting position and the arc ending position of the weld are the same as the backing welding in the step (a); (c) removing the arc starting and arc ending welds in the longitudinal weld by using carbon arc gouging at both ends of the main weld of the groove of the side plate, and polishing clean an angular grinding wheel for removing surfaces so as to make the groove ground out; and (d) carrying out the backing welding and the cosmetic welding on the longitudinal angular weld. The T-shaped joint welding method effectively reduces the welding defect of the weld at the T-shaped junction and improves the welding quality of a structure through controlling the arc staring position and the arc ending position of the main weld of the groove of the side plate and removing and polishing the arc starting and arc ending welds.

Owner:龙工(上海)挖掘机制造有限公司

Ultrasonic wave-electrical resistance composite welding method

InactiveCN104907715AImprove welding qualityIncrease solder joint sizeWelding/soldering/cutting articlesMetal working apparatusMolten stateLiquid metal

The invention discloses an ultrasonic wave-electrical resistance composite welding method, wherein the method comprises that, at the pre-pressing stage, a welding contact face of a workpiece to be welded is maintained to be contacted; upper and lower electrode welding heads are respectively set at two sides of the workpiece to be welded and the electrode welding heads are maintained at the same shaft; the electrode welding heads are shared by the electrical resistance welding and the ultrasonic wave welding for use; at the welding stage, current is communicated between the electrode welding heads while applying ultrasonic wave; the vibration and friction heat produced by the electrical resistance heat and ultrasonic wave are utilized to heat the workpiece to be welded to reach at a molten state to form a molten core; at the cooling crystallization stage, after the size of the molten core of the workpiece to be welded reaches at a preset size, the pressure of the electrode welding heads are maintained constantly; the electrical resistance welding current and the ultrasonic wave are stopped; or the electrical resistance welding current is cut off, after the ultrasonic wave works until the preset time; and until the liquid state metal is cooled to form a welding spot / a welding joint. According to the invention, the contact between workpieces to be welded is increased by utilizing the high frequency vibration produced by the ultrasonic wave; and the indentation welding defects are reduced, thus the mechanical property of a welding joint is improved.

Owner:DALIAN UNIV OF TECH

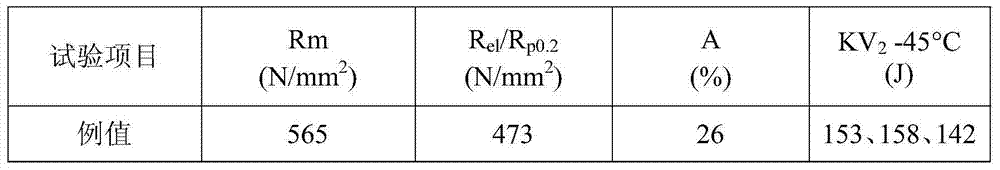

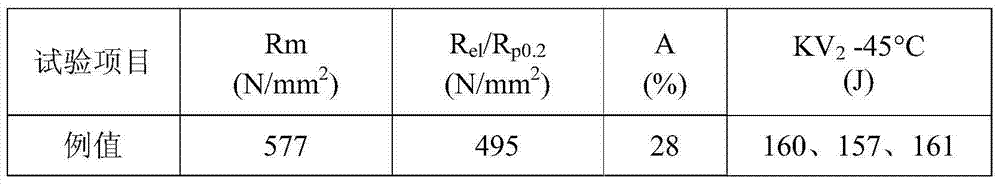

Metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel

ActiveCN104259687ALow diffusible hydrogen contentImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsFerrosiliconRare earth

The invention discloses a metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel. The metal powder-cored wire consists of a carbon steel strip and a metal powder core, wherein a formula of metal powder consists of low-carbon ferromanganese, ferrosilicon, ferrotitanium, nickel powder, ferromolybdenum, ferroboron, magnesium powder, rare earth fluoride and the balance of iron powder. The metal powder-cored wire is characterized by adopting an Ni-Mo-Ti-B alloy system to be applied to the root welding, filling and cover surface welding of the X80 high-strength low-alloy pipeline steel, in particular to the backing welding, so that the melting speed is fast, the melting efficiency is high, the all-position welding can be realized, the content of diffusible hydrogen is lower, and KV2(-45 DEG C) is higher than 100 J.

Owner:TIANJIN YONGCHANG WELDING WIRES

Method and device for refining weld joint structures by using pulsed magnet fields in welding process

ActiveCN102848058AStir wellImprove crystallizationWelding accessoriesWelding defectMaterials science

The invention relates to a processing technology for refining weld joint structures in a welding process, in particular to a method and a device for refining weld joint structures by using pulsed magnet fields in the welding process, and belongs to the technical field of welding. The method for refining weld joint structures by using pulsed magnet fields in the welding process includes that welding is performed by using an ordinary gas metal arc welding method, an applied magnetic field is added above a gas metal arc welding pool, mechanical movement and welding gun movement of the magnet fields are synchronous, electric arc and melt drip transition action is controlled by the magnet fields in a welding process, metal melt in the gas metal arc welding pool is forced to move, an electromagnetic stirring effect is produced, and weld joint structures are finally refined in the welding process. According to the method and the device, in the welding process, the weld joint structures are refined, welding defects are reduced, and further the cost is reduced, and the welding quality and the production efficiency are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

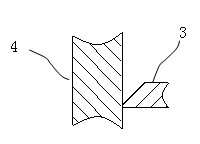

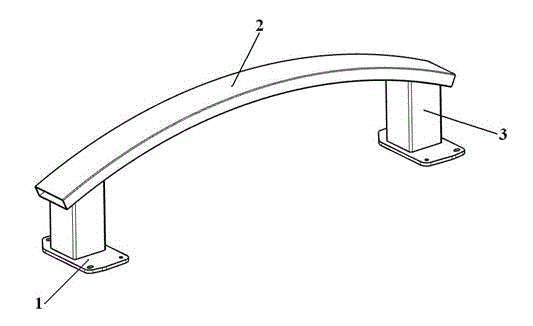

Method for welding automobile aluminium alloy bumper assembly

ActiveCN102941400AImprove welding qualityEasy to operateWelding accessoriesEnergy absorptionAC - Alternating current

A method for welding an automobile aluminium alloy bumper assembly belongs to the technical field of metal welding. The automobile aluminium alloy bumper assembly consists of a beam, an energy absorption box and a support, wherein two sets of welding tools are respectively adopted to weld the automobile aluminium alloy bumper assembly step by step, firstly, the energy absorption box and the support are welded with each other, and then, the energy absorption box and the support which are welded with each other are welded with the beam. A welding device can be adjusted and positioned according to the characteristics of weldments, and the weldments are fixed, so that deformation after the welding is avoided; and an alternating current electric welding machine is adopted for manual argon tungsten-arc TIG (tungsten insert gas) welding, the technological parameters of welding wire material, welding current, welding speed, wire feed speed and the like are adjusted so as to carry out optimal matching, and the welding defects can be avoided. The method has the characteristics of flexibility and simplicity in welding equipment, convenience in operation, stability in welding, quick welding speed, low production cost, less filler wires, less welding layers, small deformation, no correction for welding, attractiveness in appearance formation, high welding quality and the like.

Owner:CHINA AUTOMOTIVE ENG RES INST +1

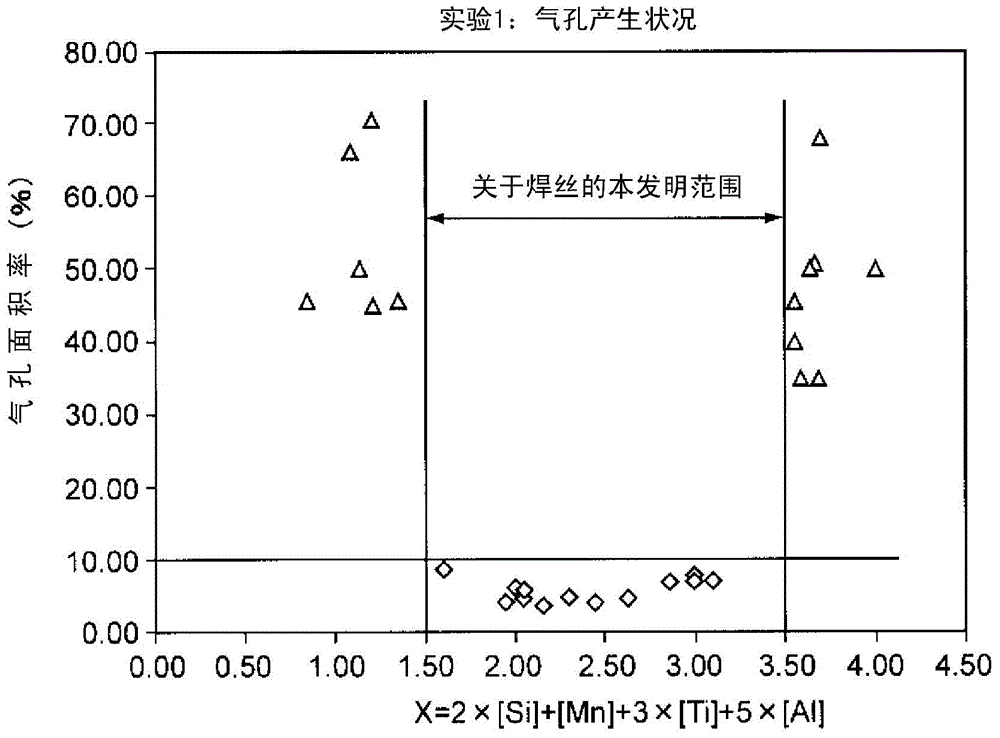

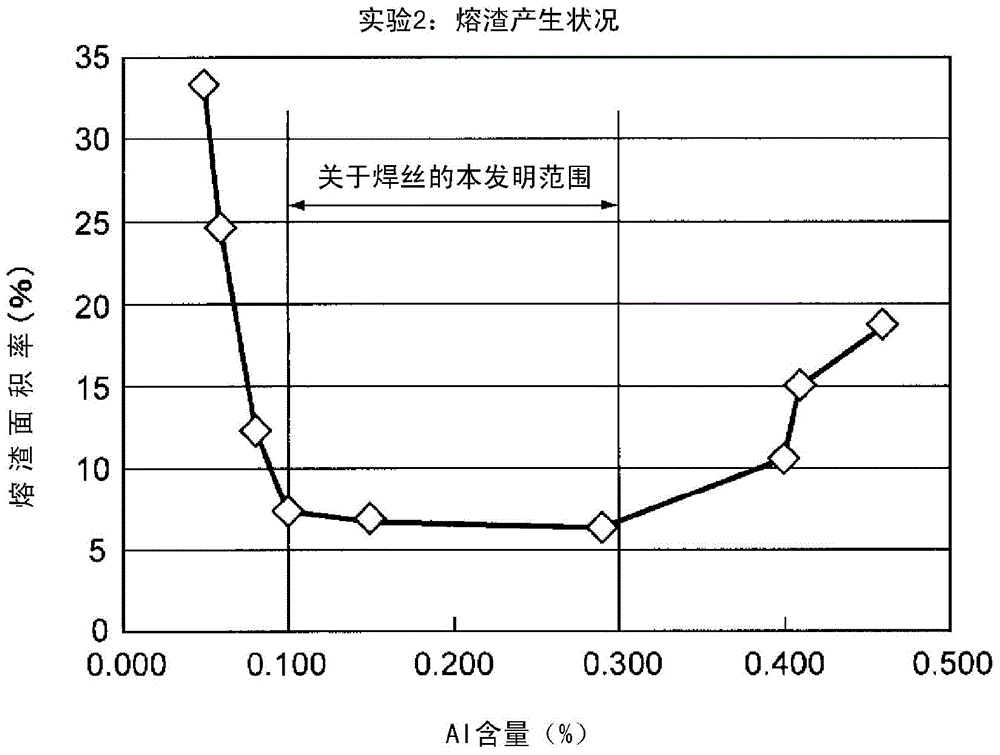

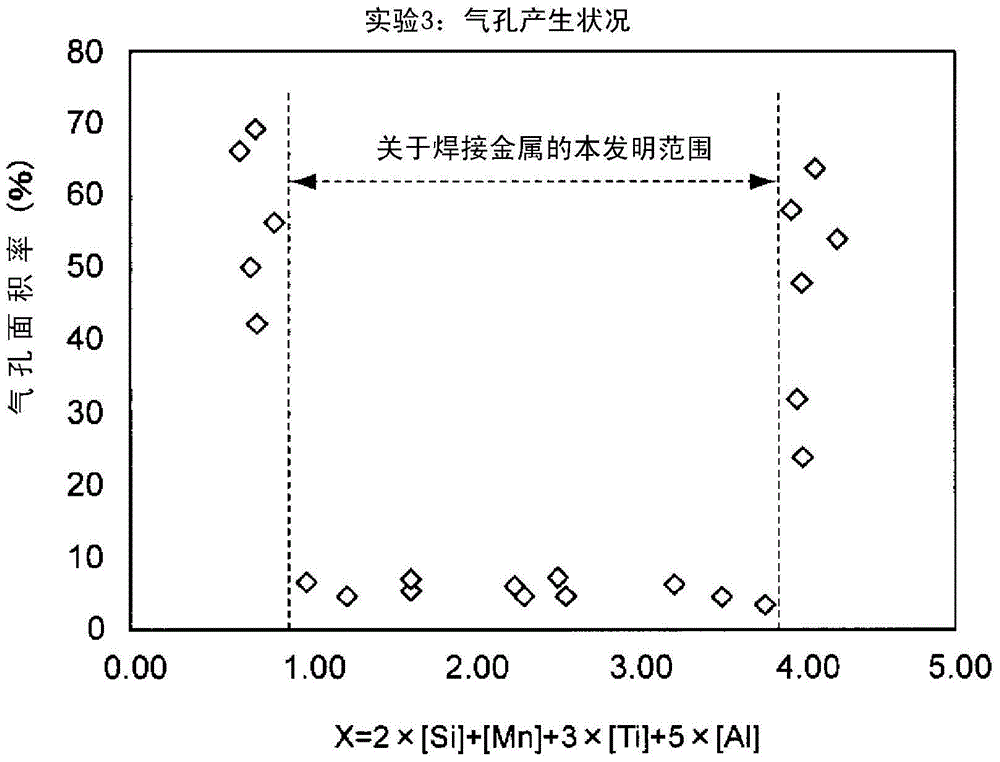

Solid wire for gas-shielded arc welding, gas-shielded arc welding metal, welding joint, welding member, welding method, and method for manufacturing welding joint

ActiveCN104981319AInhibitionGood lookingHot-dipping/immersion processesArc welding apparatusMetallurgyImpurity

The present invention comprises a solid wire for gas-shielded arc welding which contains, by mass% relative to the total mass of the wire including plating, C: 0.03-0.15%, Si: 0.2-0.5%, Mn: 0.3-0.8%, P: 0.02% or less, S: 0.02% or less, Al: 0.1-0.3%, Ti: 0.001-0.2%, Cu: 0-0.5%, Cr: 0-2.5%, Nb: 0-1.0%, V: 0-1.0%. The remainder thereof comprises Fe and impurities, and value X of formula (I) is, by mass%, within the range of 1.5-3.5%. Furthermore, the present invention comprises a welding metal wherein value X of formula (I) is within the range of 1.0-4.0%. Furthermore, the present invention comprises a welding joint, a welding member, a welding method, and a method for manufacturing the welding joint which use the solid wire or the welding metal. Formula (I): X=2×[Si]+[Mn]+3×[Ti]+5×[Al]

Owner:NIPPON STEEL CORP

Double-side double-arc welding process for root layer of pipeline

ActiveCN102744499AAvoid it happening againImprove liquidityArc welding apparatusEngineeringWeld seam

The invention discloses a double-side double-arc welding process for a root layer of a pipeline, and the process comprises preparation before welding and backing welding. By utilizing the backing welding process of the double-side double-arc welding for the root layer of a pipeline disclosed by the invention, the inside and outside welding seams of the pipeline can be formed once, and the both surfaces of a molten pool for the pipeline are always in the protection of argon, so that the generation of air vents is avoided, the formation for the inside and outside welding seams of the pipeline is good, the dimensional requirements are relatively decreased due to assembly, the welding difficulty of welders is decreased, welding deformations are reduced, welding speed is increased, welding efficiency is increased, welding defects are reduced, energy and welding materials are saved, and welding cost is reduced. Simultaneously, by virtue of the design for the process parameters of a welding gun for the inside and outside of the pipeline, and under the action of the blowing force of double arcs, the flowability of metals in the molten pool is improved, the heat energy of the double arcs is adequately exerted, the penetration capacity is improved, and the welding characteristics of stainless steel are adapted, thus improving the quality of welding joints, and guaranteeing the welding quality.

Owner:CHINA NAT CHEM ENG NO 7 CONSTR

Machining process of propeller shell

The invention discloses a machining process of a propeller shell, comprising the following steps of: A, taking a steel plate and cutting the steel plate by a straight-line cutter or a cutting machine, so as to guarantee that the error degree of the cut steel plate is less than 2 mm; B, rolling the cut steel plate by using a rolling machine; C, butting and welding two ends of the rolled steel plate to form a cylinder, and carrying out nondestructive testing on a welding part; D, grinding a welding seam by using a grinding machine; and E, pressing and molding the grinded cylinder by using a mould to prepare the propeller shell. The machining process of the propeller shell has the advantages of improving the working efficiency and further improving the quality of products.

Owner:NANTONG HONGBO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com