Preparation method for wear-resistant steel and carbon structural steel composite plates

A carbon structural steel and carbon structure technology, applied in metal rolling, manufacturing tools, temperature control and other directions, can solve the problems of high energy consumption, high labor intensity, environmental pollution and other problems in the composite method, so as to reduce welding defects and improve Productivity, the effect of improving surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

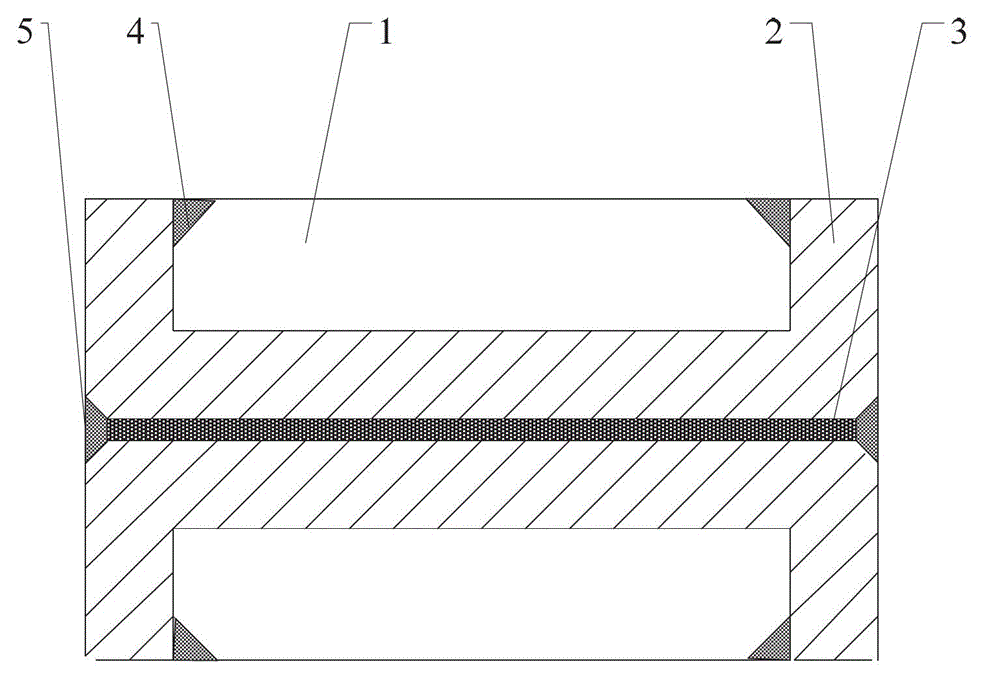

[0026] like figure 1 As shown, the preparation method of wear-resistant steel and carbon structural steel composite plate of the present invention comprises the following steps:

[0027] (1) Processed slab: process grooves on the upper part of the carbon structural steel plate 2 according to the size of the wear-resistant steel plate 1;

[0028] (2) Surface cleaning: the surface of the groove on the upper part of the carbon structural steel plate 2 and the wear-resistant steel plate 1 are sandblasted to remove surface rust and oxide layer, cleaned and dried;

[0029] (3) Making composite slabs: place the cleaned wear-resistant steel plate 1 in the groove on the upper part of the carbon structural steel plate 2, clamp it with a clamp and put it into a vacuum chamber, and evacuate until the air pressure is ≤1.0×10 -2MPa; then the groove periphery of the carbon structural steel plate 2 and the joint of the wear-resistant steel plate 1 are sealed and welded with an electron beam ...

Embodiment 1

[0036] In this embodiment, the model of wear-resistant steel plate 1 is NM360, the size (thickness×width×length) is 10mm×1000mm×3000mm, and the quantity is 2 pieces, the model of carbon structural steel plate 2 is Q345, and the size (thickness×width×length) Length) is 50 mm × 1100mm × 3100mm, and the quantity is 2 pieces. Firstly, a groove (thickness × width × length) of 10 mm × 1000mm × 3000mm is processed on the upper part of the carbon structural steel plate 2, and the distance between the edge of the groove and the carbon The same-side edge of the plain structural steel plate 2 is 50 mm. Sandblasting is used to remove the rust and oxide layers of the wear-resistant steel plate 1 and the carbon structural steel 2, and the grain size of the iron sand used for sandblasting is ≤1mm; then the two steel plates are cleaned and dried.

[0037] Put a piece of wear-resistant steel plate 1 in the groove of a piece of carbon structural steel 2, and clamp it with a clamp, put it into a...

Embodiment 2

[0043] In this embodiment, the model of wear-resistant steel plate 1 is NM360, the size (thickness×width×length) is 25mm×1000mm×2500mm, and the quantity is 2 pieces, the model of carbon structural steel plate 2 is Q235, and the size (thickness×width×length) Length) is 50 mm × 1080mm × 2580mm, the quantity is 2 pieces, first process a groove (thickness × width × length) of 25mm × 1000mm × 2500mm on the upper part of the carbon structural steel plate 2, the distance between the edge of the groove and the carbon The same-side edge portion of the structural steel plate 2 is 40 mm. Sandblasting is used to remove the rust and oxide layers of the wear-resistant steel plate 1 and the carbon structural steel 2, and the grain size of the iron sand used for sandblasting is ≤1mm; then the two steel plates are cleaned and dried.

[0044] Put a piece of wear-resistant steel plate 1 in the groove of a piece of carbon structural steel 2, clamp it with a clamp, put it into a vacuum chamber, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com