Ultrasonic wave-electrical resistance composite welding method

A hybrid welding and ultrasonic technology, applied in the field of welding manufacturing, can solve problems such as limited welding application range, and achieve the effects of reducing welding defects, eliminating pores, and reducing indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Adopt welding 6061 aluminum alloy structural part of the present invention, the plate thickness of workpiece 3 to be welded is 1mm, and preparation method comprises the following steps:

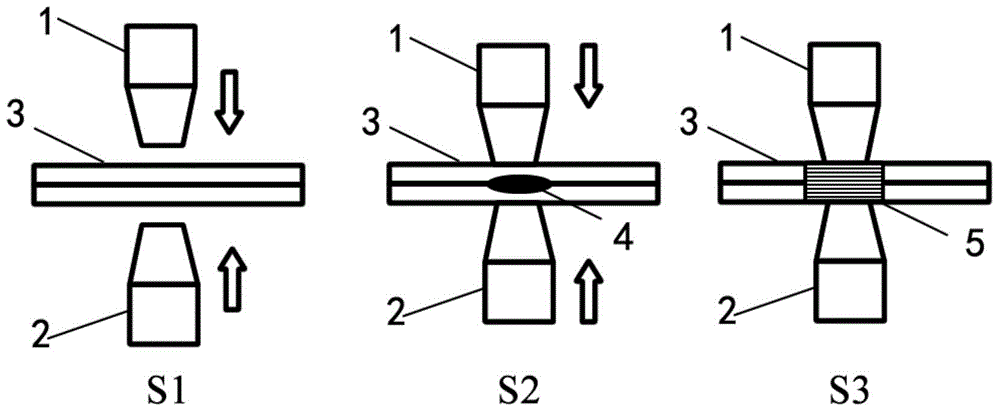

[0030] The upper electrode welding head 1 and the lower electrode welding head 2 shared by resistance / ultrasonic are used to keep the welding contact surface of the workpiece 3 to be welded in contact and ensure the contact resistance required by the welding process; the upper electrode welding head 1 and the lower electrode welding head The current is connected between 2, and the upper electrode welding head 1 and the lower electrode welding head 2 apply ultrasonic waves on the surface of the workpiece 3 to be welded. The welding parameters are: the pressure of the upper electrode welding head 1 and the lower electrode welding head 2 is 3kN, and the welding current DC 20kA, resistance welding maintenance time 1s, ultrasonic frequency 20kHz, amplitude 20μm; resistance welding pressure a...

Embodiment 2

[0032] Adopt the welding AZ31 magnesium alloy structural part of the present invention, the plate material thickness of workpiece 3 to be welded is 1.5mm, and preparation method comprises the following steps:

[0033] The upper electrode welding head 1 and the lower electrode welding head 2 shared by resistance / ultrasonic are used to keep the welding contact surface of the workpiece 3 to be welded in contact and ensure the contact resistance required by the welding process; the upper electrode welding head 1 and the lower electrode welding head Connect the current between 2, and at the same time, the upper electrode welding head 1 and the lower electrode welding head 2 apply ultrasonic waves on the surface of the workpiece 3 to be welded. The welding parameters are: the pressure of the upper electrode welding head 1 and the lower electrode welding head 2 is 3.5kN, and the welding The current is DC 15kA, the resistance welding duration is 1.5s, the ultrasonic frequency is 15kHz,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com