Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Wide range of process parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

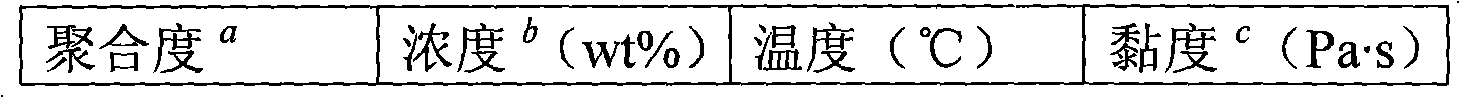

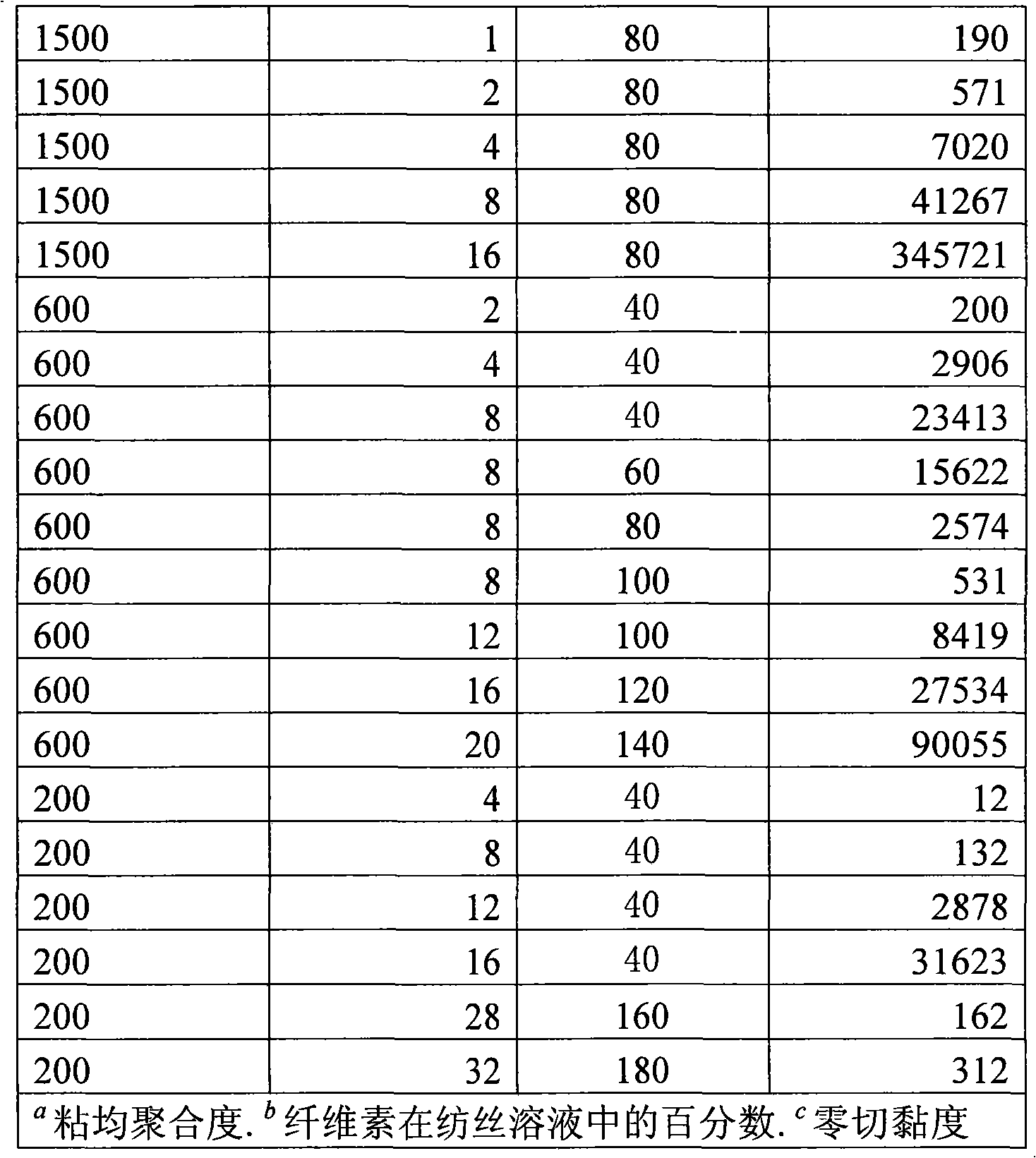

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

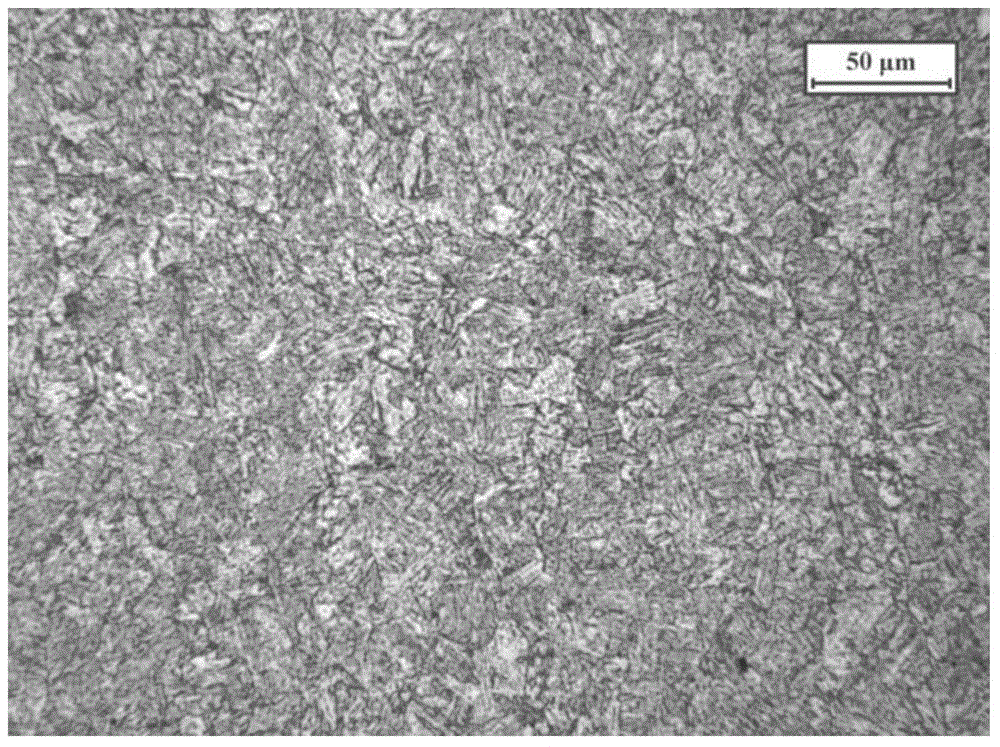

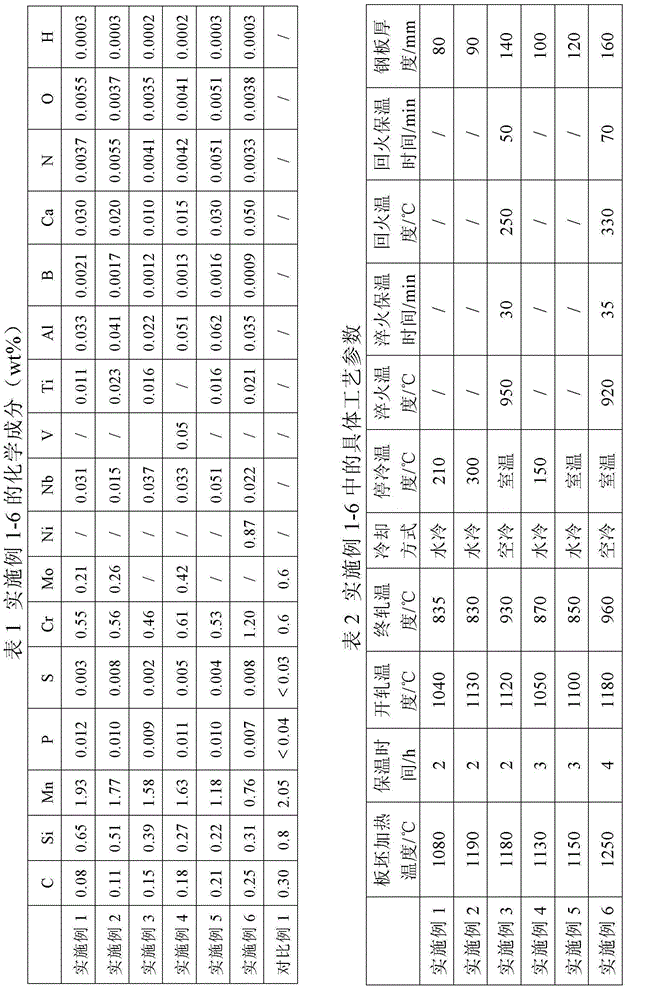

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

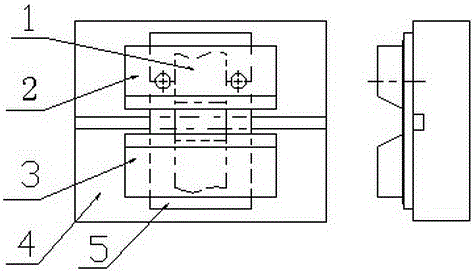

Method for deep penetration laser welding of plate under assistance of ultrasound

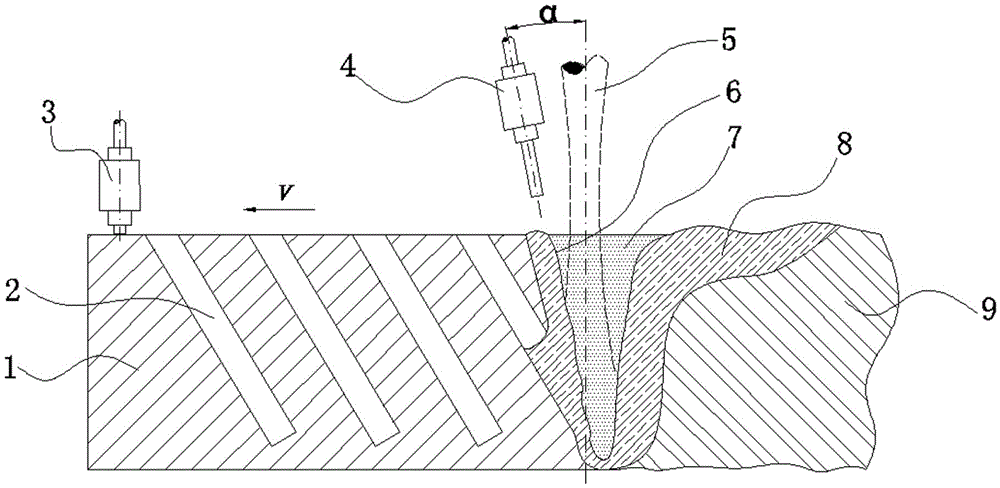

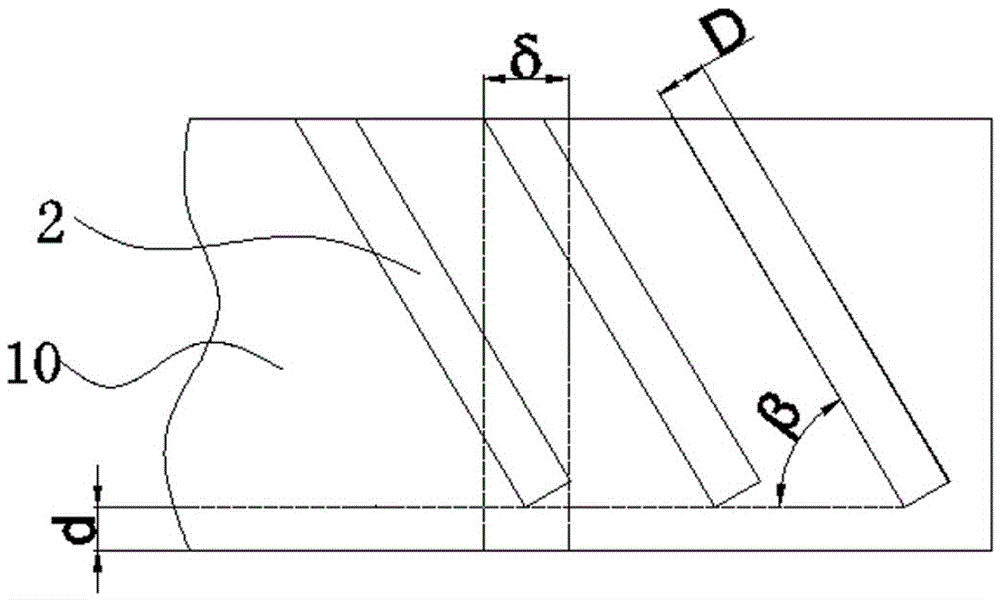

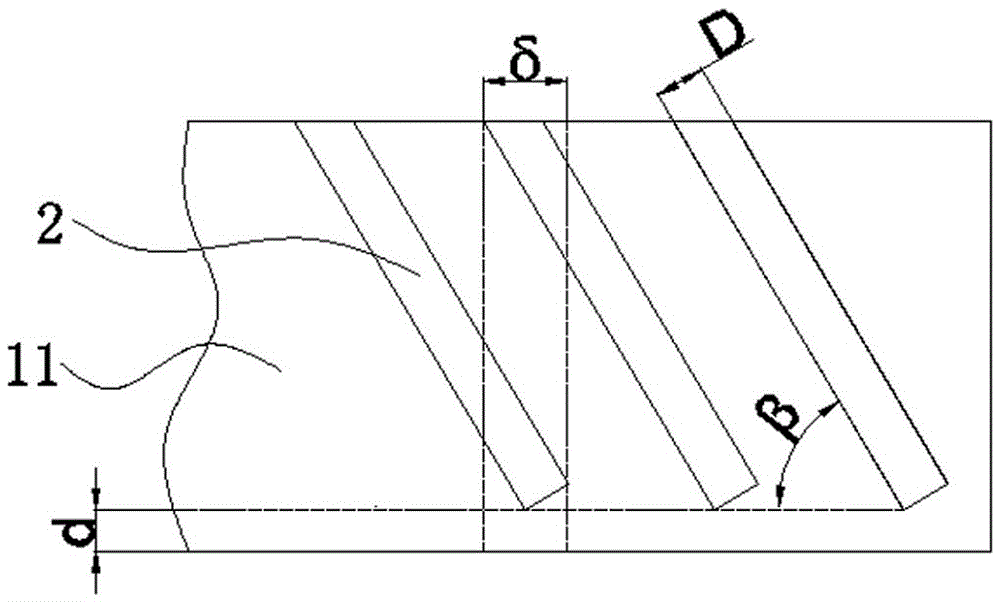

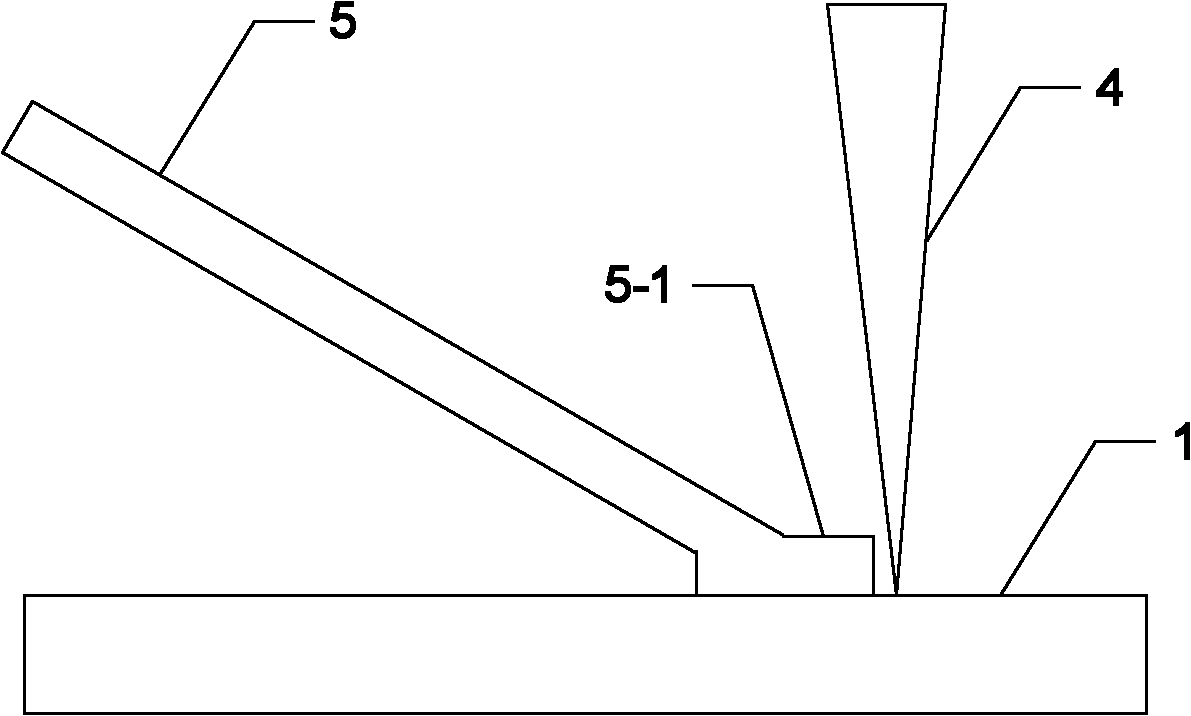

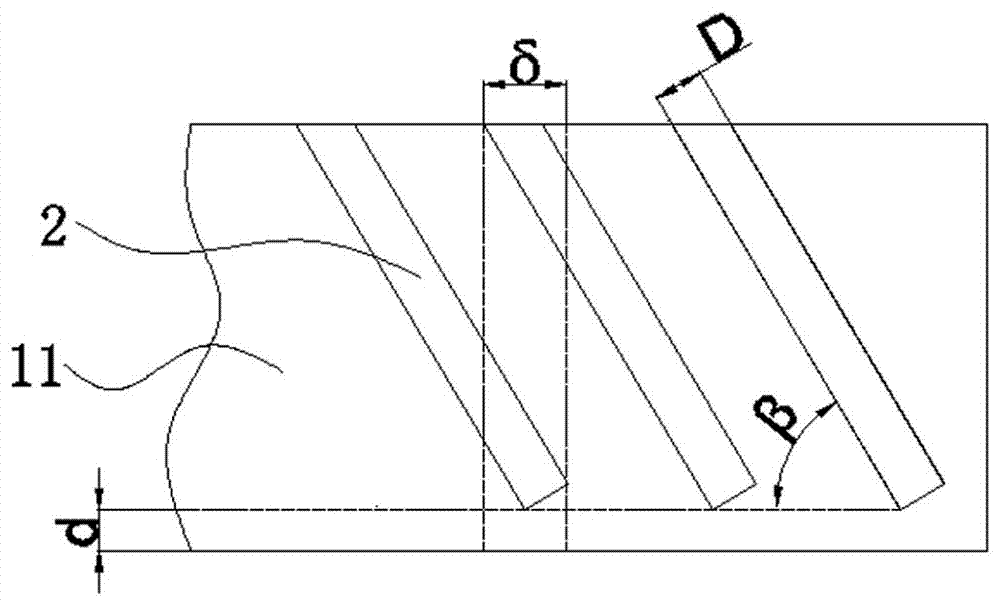

ActiveCN105583523AWide range of process parametersReduce crater depthWelding/soldering/cutting articlesMetal working apparatusSmall holeWeld bead

The invention relates to a method for deep penetration laser welding of a plate under the assistance of ultrasound. The method is characterized by comprising the following steps that firstly, first base metal (10) and second base metal (11) are machined to form butt joint end faces, and a series of inclined semicircular grooves are machined; secondly, the first base metal (10) and the second base metal (11) are in butt joint and are clamped, and a series of inclined blind holes are formed in a weld bead; thirdly, a first ultrasonic amplitude-changing rod (3) is pressed to the upper surface of a workpiece to be welded; fourthly, a second ultrasonic amplitude-changing rod (4) is fixed to one side of a laser welding head; fifthly, an ultrasonic generation device is started, the ultrasonic frequency is adjusted; sixthly, a laser beam (5) perpendicularly irradiates the upper surface of the workpiece, and the welding process is completed under continuous ultrasonic vibration; and seventhly, after welding is completed, ultrasonic vibration is maintained for 1-2 minutes. In the method, due to the pre-formed inclined blind holes and ultrasonic vibration, weld joint root leakage caused by molten pool downward flowing driven by local evaporation back flushing pressure of the front edge walls of the small holes is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Printed wiring board chemical copper plating solution

InactiveCN104152881AAchieve metallizationAchieve the effect of metallization in the hole of the printed circuit boardLiquid/solution decomposition chemical coatingPrinted circuit manufactureCopper platingChalcanthite

The invention discloses a printed wiring board chemical copper plating solution which is prepared from the following raw materials in parts by mass: 10-15 parts of chalcanthite, 30-35 parts of sodium hypophosphite, 10-15 parts of boric acid, 12-18 parts of complexing agent, 0.05-0.1 part of stabilizer, 0.5-1.5 parts of catalyst, 0.05-0.1 part of surfactant, 15-18 parts of sodium hydroxide and 300-320 parts of deionized water. By using the sodium hypophosphite as the main reducer, the chalcanthite, boric acid, complexing agent, stabilizer, catalyst, surfactant and sodium hydroxide are added to prepare the chemical copper plating solution; and the chemical copper plating solution is diluted to be used for chemical copper plating on the printed wiring board, thereby achieving the effects of the metallization of the non-conductor surface of the activated printed wiring board and the metallization in the printed wiring board holes. The printed wiring board chemical copper plating solution has the advantages of wide technological parameter range, long service life and no harmful formaldehyde vapor.

Owner:YANTAI HENGDIKE ENERGY TECH

Metal anti-rust phosphating solution

InactiveCN103397318AImprove corrosion resistanceShort film forming timeMetallic material coating processesIron sulfateO-Phosphoric Acid

The invention provides a metal anti-rust phosphating solution, comprising the following raw materials by concentration: 2 g / L of octylphenol polyoxyethylene ether, 2 g / L of sodium polyoxyethylenelauryl ether sulfate, 2 g / L of diethyl thiourea, 10 g / L of phosphoric acid, 5 g / L of citric acid, 15 g / L of nickel sulfate (NiSO4.6H2O), 10 g / L of ferric sulfate, 10 g / L of zinc dihydrogen phosphate, 5 g / L of ferrocene, 5.0 g / L of sodium perborate, 2 g / L of hydroxyethyl cellulose, 5 g / L of gelatin, 40 g / L of aluminium hydroxide and 5 g / L of graphite. Harmful substances such as nitrate, nitrite, chromate and the like are not adopted, so that the metal anti-rust phosphating solution is environment-friendly. Meanwhile, an anti-rust object of the metal surface can be achieved; and a phosphating film formed by the phosphating solution has good corrosion resistance, thereby completely reaching relevant standards.

Owner:石欣

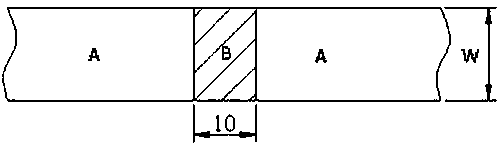

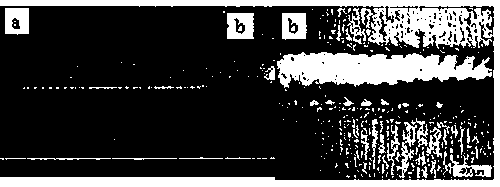

Welding method for obtaining amorphous connector for FeSiB amorphous strip

ActiveCN105364314ASimplify welding toolingWide range of process parametersLaser beam welding apparatusLaser technologyLap joint

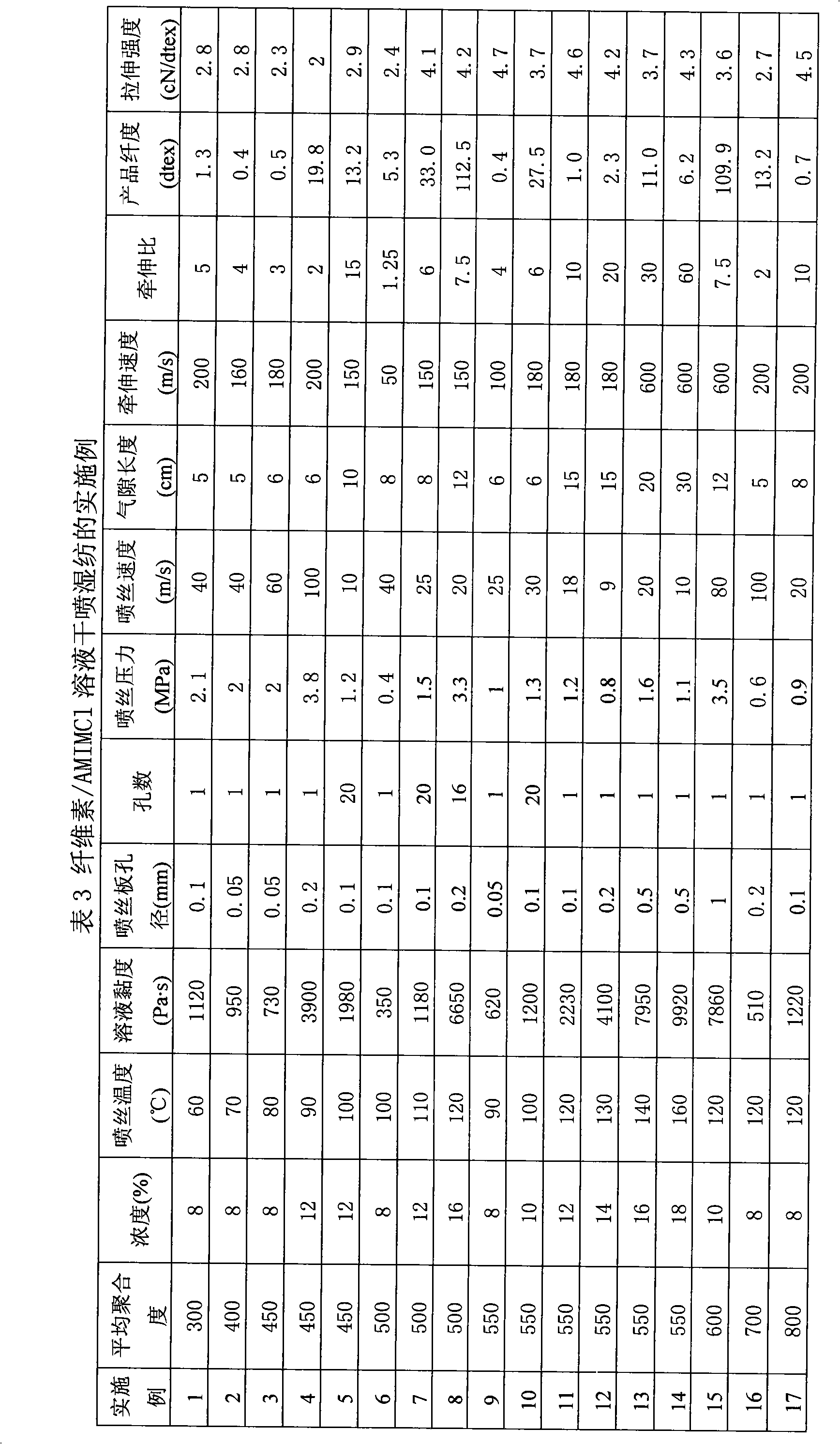

The invention relates to the technical field of amorphous materials and welding, in particular to a welding method for obtaining an amorphous connector for a FeSiB amorphous strip and belongs to the technology of amorphous material connection. The method is used for solving the problems that the size of a Fe-based amorphous alloy strip is limited, materials are crisp and extremely thin, and weldability is poor. The completely amorphous connector is obtained successfully through a micropulse laser technology. The welding method includes the steps that the surface of a FeSiB amorphous alloy strip sample is ground, cleaned and blown to be dried; a self-designed special clamp is clamped at one end, the other end of the special clamp is used for fixing base metal in a flattening manner, and gas Ar is laterally blown to protect a weld pool; and the micropulse laser technology is used for conducting lap joint welding, technological parameters such as the pulse power P, the pulse width T, the pulse frequency F and the like are optimized, and the completely amorphous connector is obtained. The welding method has the advantages that a welding tool is simple, welding efficiency is high, cost is low, connector quality is good, and the connector has the completely amorphous characteristic.

Owner:NANCHANG HANGKONG UNIVERSITY

Current-assisted laser brazing method or laser fusion brazing method

The invention relates to a current-assisted laser brazing method or laser fusion brazing method, and belongs to the field of welding. The invention aims to solve the problems of poor moistening and spreading capabilities of brazing materials, and space nonuniformity and low energy utilization efficiency of interface reaction in the traditional laser brazing and laser fusion brazing. In the welding process, two mother metals are connected to one output end of an auxiliary current power supply, the other output end of the auxiliary power supply is connected with a welding wire or a non-fusion electrode through a welding controller, a laser beam is vertically incident to a welding seam, and the welding wire or the non-fusion electrode is added along the front or back side of the welding direction of the laser beam. The method comprises the following steps of: 1. pretreating two mother metals to be welded; 2. fixing the two mother metals to be welded on a worktable, connecting the auxiliary current power supply to the two mother metals; 3. putting the welding wire or the non-fusion electrode at the front or rear side of the welding direction of the laser beam; 4. and starting the laser welding, switching on the auxiliary current power supply, and coordinating and controlling the matching relation between the laser beam and the auxiliary current so as to implement welding.

Owner:HARBIN INST OF TECH

Double-pulse cyanide-free alkali silver electroplating method

The invention discloses components of double-pulse cyanide-free alkali silver electroplating solution and a process. Silver nitrate is used as a main salt, sodium thiosulfate and ammonium thiosulfate are used as complexing agents, sodium metabisulfite is used as an auxiliary complexing agent, sodium sulfate is used as a conductive salt, boric acid is used as a pH value adjustor, and gelatin is added into the plating solution. The operation conditions comprise that the pH value of the plating solution is 4.0 to 4.5, the temperature of the plating solution is 20 to 30 DEG C, and the mechanical stirring speed is 100 to 150rpm. A silver plating layer with fine and compact crystallization can be obtained by adopting double-pulse electroplating, controlling the duty ratio, average current density and working time of the positive and negative pulses and electroplating on pure copper or copper alloy without silver immersion plating pretreatment. The plating solution of the invention has the advantages of simple formulation, easy control, strong even plating and covering capabilities, and high batch production stability. The plating layer has fine and compact crystallization and good appearance luster, and has no peeling, shedding and stripping; and the technology can replace a cyanide silver electroplating process, and can be used as a surface electroplating process for jewelries, artware and parts of electronic products.

Owner:KUNMING UNIV OF SCI & TECH

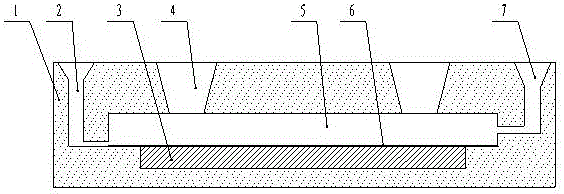

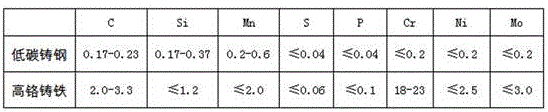

Double-fluid composite iron-based bimetal casting method

InactiveCN106623862AImprove yieldWide range of process parametersFoundry mouldsFoundry coresCarbon steelChiller

The invention discloses a double-fluid composite iron-based bimetal casting method. The melting point of metal of a first layer is not lower than that of metal of a second layer; after the metal of the first layer is poured, a low-carbon steel chiller is used for fast cooling; after cooling is conducted to obtain a certain temperature, the metal of the second layer is poured, and the pouring temperature of the metal of the second layer is not lower than the melting point of the metal of the first layer; and fusion of the metal of the two layers is ensured. Due to the fact that the chiller fast cooling method is adopted, the fusion amount of the metal of the first layer is reduced, components of the metal of the second layer are ensured, and a bimetal composite workpiece with metallurgical bonding is obtained. According to the technological method, the fusion amount of the metal of the first layer is reduced, the components obtained after fusion of the metal of the second layer are ensured, the double-fluid composite qualification rate is increased, and industrial mass production is facilitated.

Owner:邢振国

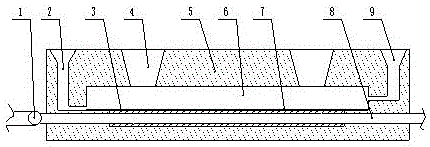

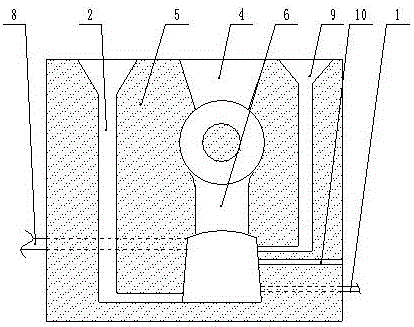

Method for manufacturing bi-metal composite material by pouring two layers of molten metal with cooling speed adjustable

The invention discloses a method for manufacturing a bi-metal composite material by pouring two layers of molten metal with the cooling speed adjustable. The method comprises the steps that after the first layer of molten metal is poured, water is introduced into a chiller for cooling, and the cooling speed of the first layer of molten metal is adjusted by adjusting the pressure and flow of the cooling water in the chiller or controlling the introduction time of the cooling water; and the second layer of molten metal is poured at the high temperature so that the first layer of molten metal can be fully fused by the second layer of molten metal, due to the fact that controlled cooling measures are taken for the first layer of molten metal, fusion of the first layer of metal achieved through the second layer of metal is guaranteed, superfusion is also prevented, constituents of the second layer of metal are guaranteed, and the bi-metal composite material acquired through metallurgical bonding is obtained. By means of the process method, the qualification rate of composting of the two layers of molten metal is greatly increased; process parameters are simplified; and industrialized production can be conducted conveniently.

Owner:邢振国

Low-temperature zinc-based phosphatization liquid

InactiveCN1952213ALower working temperatureWide range of process parametersMetallic material coating processesPhosphoric acidManganese

This invention involves a cryogenic phosphorization liquid of zinc, belonging to the field of phosphorization liquid for steel surface treatment. The phosphorization liquid of zinc of the invention is composed by the following composition as the raw materials, zinc oxide 100g / L, 80%phosphoric acid 230g / L,30% nitric acid 280g / L, nickel sulfate 2.67g / L, manganese carbonate 0.2g / L, ethylene dinitrilotetraacetic acid 0.66g / L, citric acid 5.0g / L, sodium perborate 1.0g / L, sodium carbonate 2.3g / L. The phosphorization liquid of zinc of the invention is characterized in low temperature; short time, low energy consumption, and can form an excellent dense phosphorization crystal film in the steel surface. The phosphorization liquid has broad process parameters range, is easy to adjust and improves the quality of coating products.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

Low-temperature zinc-based phosphatization liquid

InactiveCN100443632CLower working temperatureWide range of process parametersMetallic material coating processesPhosphoric acidManganese

This invention involves a cryogenic phosphorization liquid of zinc, belonging to the field of phosphorization liquid for steel surface treatment. The phosphorization liquid of zinc of the invention is composed by the following composition as the raw materials, zinc oxide 100g / L, 80%phosphoric acid 230g / L,30% nitric acid 280g / L, nickel sulfate 2.67g / L, manganese carbonate 0.2g / L, ethylene dinitrilotetraacetic acid 0.66g / L, citric acid 5.0g / L, sodium perborate 1.0g / L, sodium carbonate 2.3g / L. The phosphorization liquid of zinc of the invention is characterized in low temperature; short time, low energy consumption, and can form an excellent dense phosphorization crystal film in the steel surface. The phosphorization liquid has broad process parameters range, is easy to adjust and improves the quality of coating products.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

Cu-Zn-Sn ternary alloy electroplate liquid

The invention relates to Cu-Zn-Sn ternary alloy electroplate liquid. The Cu-Zn-Sn ternary alloy electroplate liquid comprises, by concentration, 15-25 g / L of copper sulfate, 10-20 g / L of tin methane sulfonate, 20-40 g / L of zinc sulfate, 100-120 g / L of sulfuric acid, 10-20 mL / L of citric acid and 20-35 g / L of potassium citrate. The pH value of the electroplate liquid is regulated to range from 8.0 to 10.0 through a pH value regulating agent. An existing cyanide gold imitation electroplate technology can be replaced with the electroplate liquid, and the electroplate liquid can be applied to utilization of imitated 9K or imitated 18K or imitated 24K gold on the surfaces of decorative objects such as jewelry, clocks, watches and crafts.

Owner:WUXI QIAOYANG MACHINERY MFG

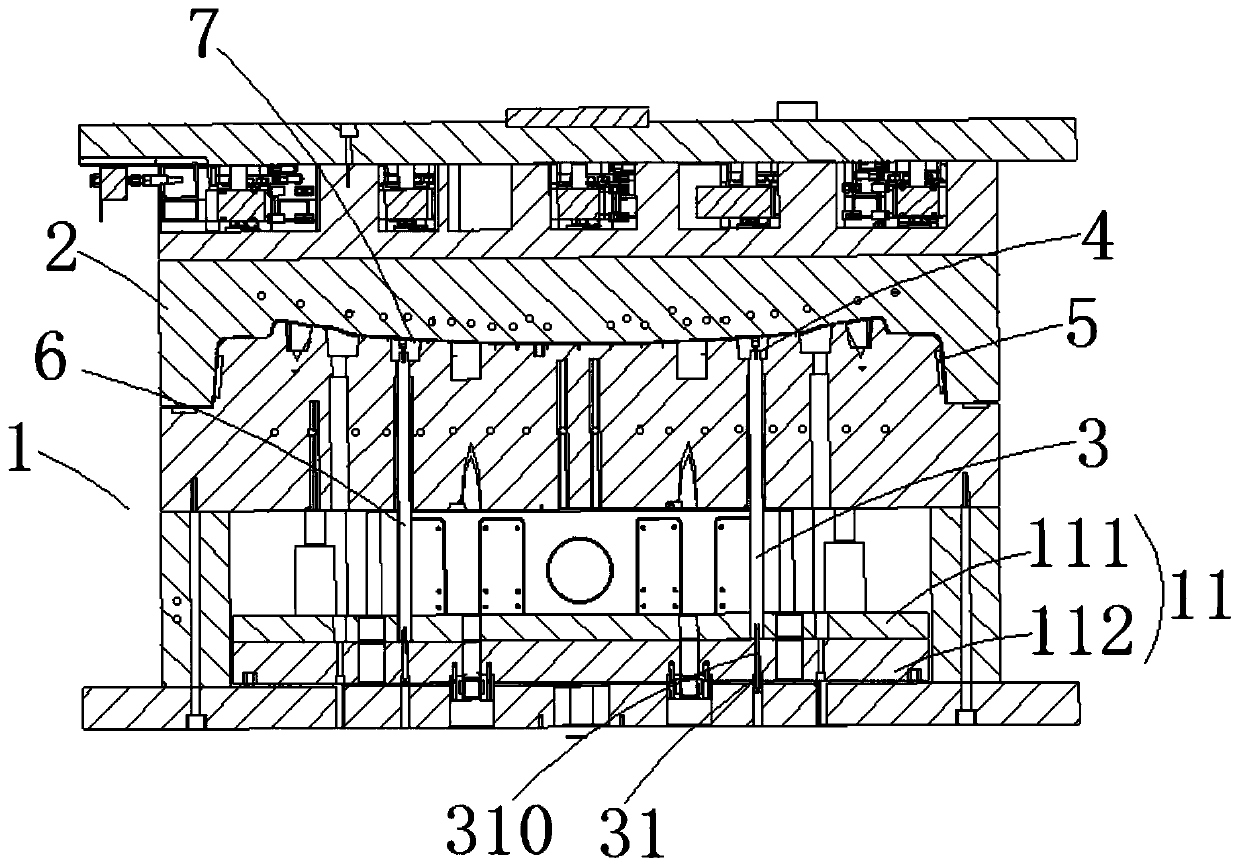

Injection mold capable of realizing local delayed ejection

PendingCN111152424ASolve the problem of top block printingSolve the long-term problem of top block printing in injection molding productionEngineeringMechanical engineering

Owner:CHONGQING PINGWEI AUTO PARTS CO LTD

Method for preparing inorganic binding material and inorganic binding material obtained through preparation method

ActiveCN104004454AImprove conductivityReduced dielectric strengthNon-conductive material with dispersed conductive materialInorganic adhesivesSolar cellMaterials science

The invention relates to a method for preparing an inorganic binding material for solar cell positive electrode paste and the inorganic binding material obtained through the preparation method. In particular, the method includes the following steps that (1) high temperature smelting powder is prepared, (2) high temperature sintering powder is prepared, and (3) the prepared high temperature smelting powder and the prepared high temperature sintering powder are mixed.

Owner:宁夏中色新材料有限公司

Electrolyte for preparing fine copper powder and use method thereof

The invention discloses an electrolyte for preparing fine copper powder and a use method thereof. The electrolyte comprises the following components: 5g / L of copper sulfate, 400-800g / L of phosphoric acid, 200-600g / L of distilled water, 1-2g / L of gelatin and 2g / L of benzotriazole. Operation conditions of electrolysis are as follows: the interelectrode distance is 10-30cm, the temperature of the electrolyte is 5-30 DEG C, the density of cathode current is 3-8A / dm2, and a powder scraping period is 10-25min. Cathode copper is used as an anode of electrolytic production, and a 316 stainless steel plate is used as a cathode for scraping powder. Compared with a sulfuric acid electrolysis method for preparing the fine copper powder, the invention has the advantages of simple electrolyte prescription, easy control, wide technological parameter range, long service life and high batch production stability, and the prepared fine copper powder has fine and uniform distribution granularity, high purity, good forming property and strong oxidation resistance.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting crude salamander oil from giant salamander tail fat by using papain

ActiveCN103666743AActive ingredients are stableHigh extraction rateFatty-oils/fats productionEmulsionAdditive ingredient

The invention provides a method for extracting crude salamander oil from giant salamander tail fat by using papain. The method comprises the following steps: separating tail subcutaneous fat from the skin of a giant salamander to obtain the giant salamander tail fat, then stirring the giant salamander tail fat into paste, blending the giant salamander tail fat and water at the ratio of 1:0.5-1:2.0, regulating the pH value of a material liquid to 6.0-7.0, adding the papain of which the weight is 0.1-0.5% of that of the giant salamander tail fat, shaking well, heating to 40-60 DEG C, stirring and shocking for reaction for 0.5-2.0h, centrifuging the obtained enzymatic hydrolysate for 5-15min by a centrifugal machine at 4000-5000r / min, acquiring three layers of the mixture after centrifuging, and absorbing the upper layer to obtain the crude salamander oil. According to the method provided by the invention, the constraint of protein on the fat is removed, meanwhile, the protein formed by combining emulsion and the fat in the process of enzymolysis is also degraded, and the reaction condition is mild, so that effective ingredients in the salamander oil are enabled to be stable. The reaction operation is simple, the extraction ratio of the crude salamander oil and the additional valve of the product are increased, the cost is low, and the method is environment-friendly and can be widely applied to industrial production.

Owner:张家界金鲵生物产品开发有限公司

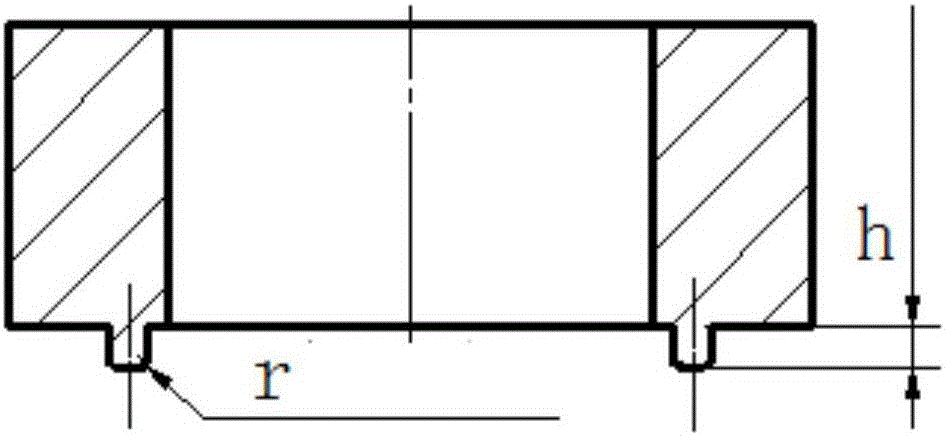

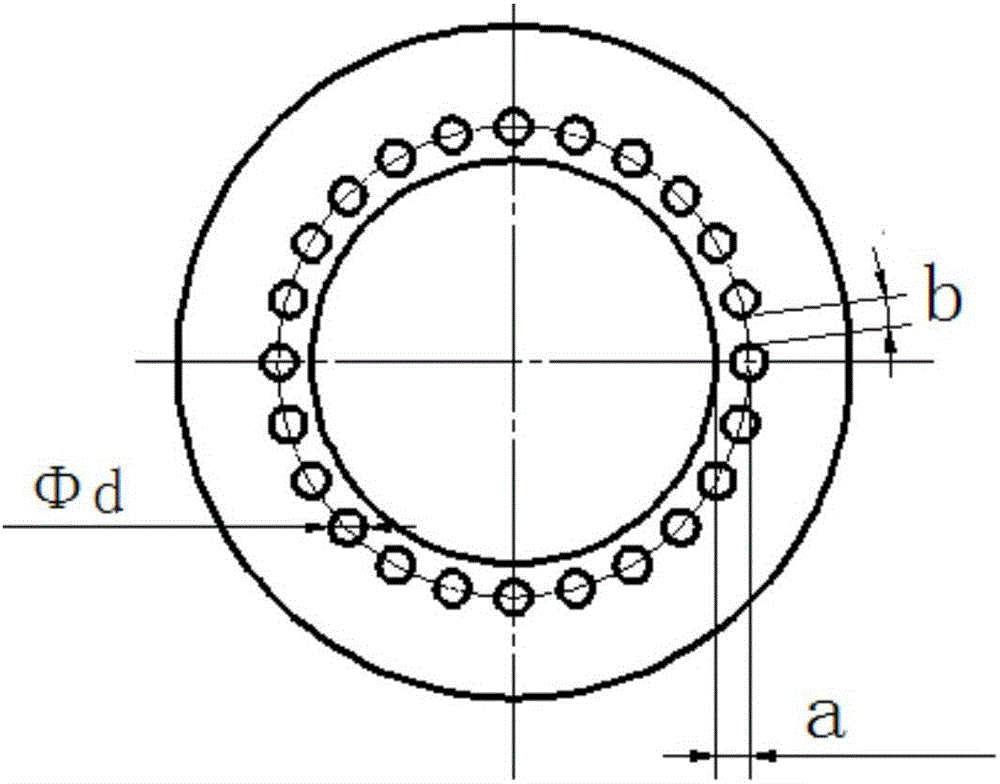

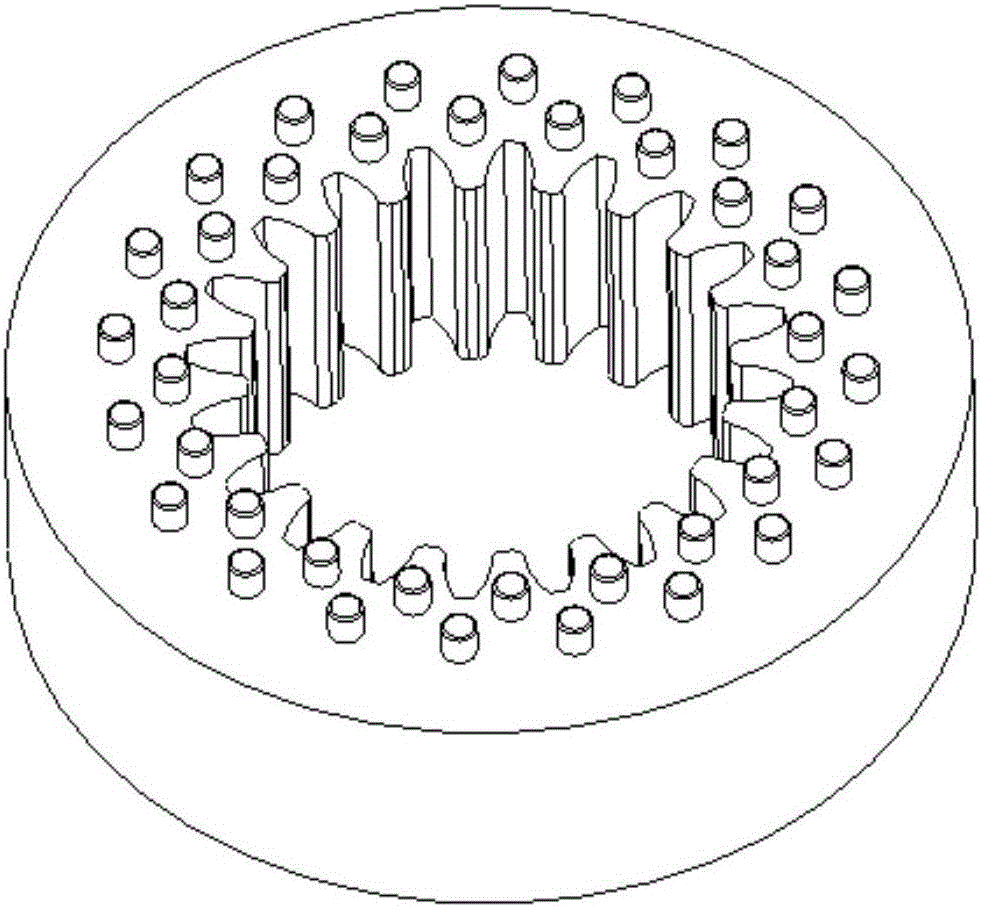

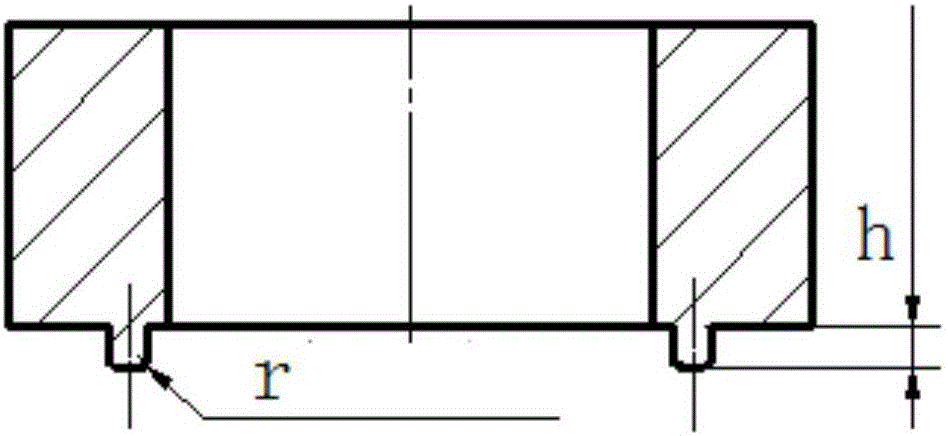

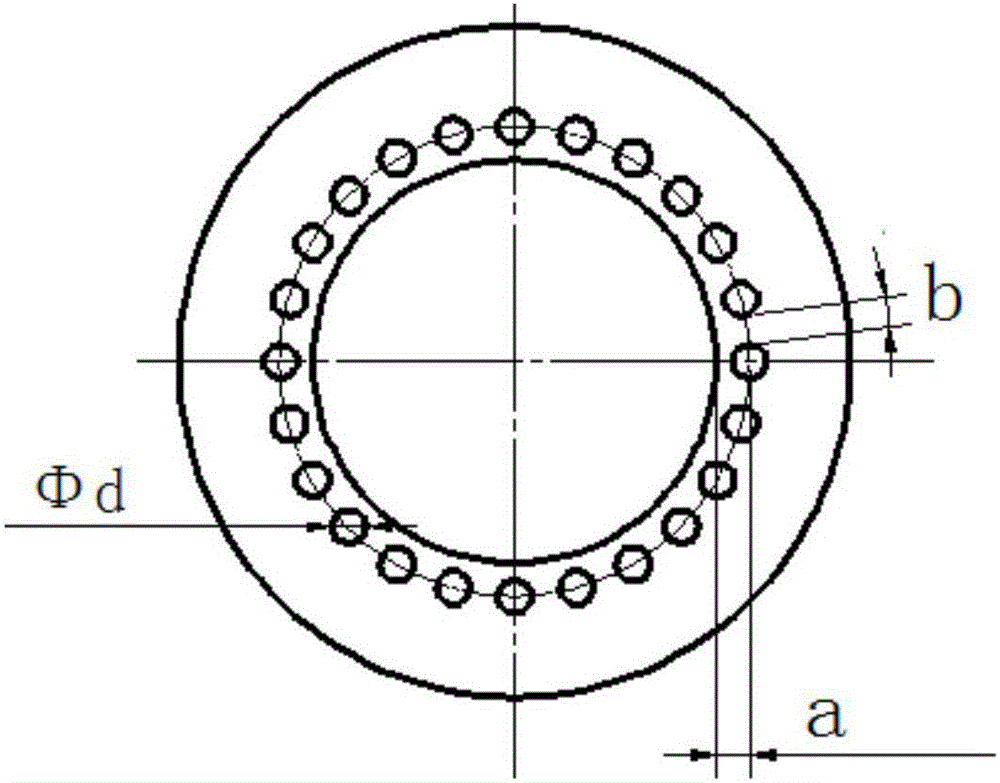

Discontinuous point type blank holder for fine blanking die and design method of technological parameters of discontinuous point type blank holder

ActiveCN105880350AIncreased hydrostatic stressImprove plastic deformation abilityMetal-working feeding devicesPositioning devicesEngineeringDesign methods

Owner:WUHAN UNIV OF TECH

Method for preparing Ti2PbC ceramic by powder metallurgy method

The invention relates to a method for preparing Ti2PbC ceramic by a powder metallurgy method. The method is as follows: proportioning ingredients according to the ratio of TiC: Ti: Pb= 1: 1: (1-1.3) (molar ratio), mixing for 1-50 hours, using a tube furnace to heat to 900 to1500 DEG C under a protective atmosphere in the heating rate of 1-50 DEG C / min, holding for 30-200Min, and cooling with the furnace to obtain the high-purity Ti2PbC ceramic. The synthesis method has many advantages: the synthesis time needed for the Ti2PbC ceramic is greatly shortened, a very high purity can be achieved, synthesis cost is low, equipment is simple, process parameters are large in range, and the method is suitable for industrial production. The obtained ceramic can be used in a transition layer of a lead acid battery, the cost of the ceramic is lower than that of a noble metal, and the ceramic has extremely excellent compatibility with graphite fiber and a lead-based active phase in the battery.

Owner:SOUTHEAST UNIV

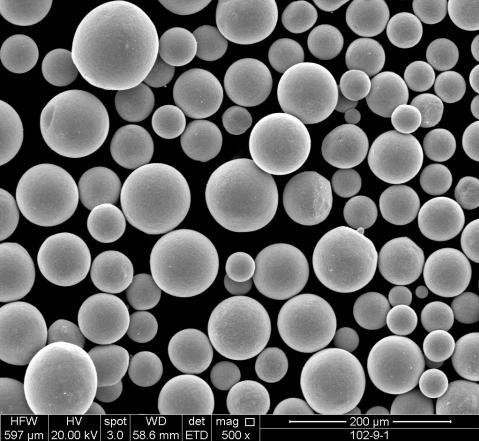

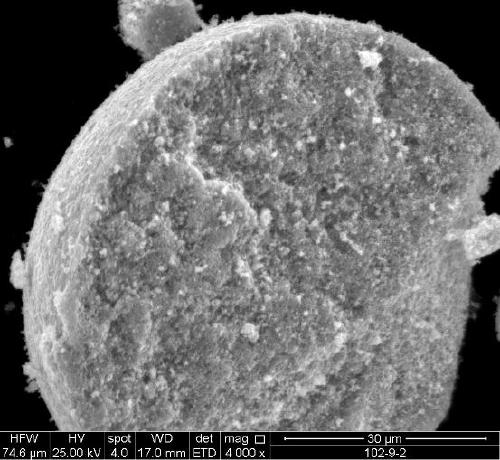

A method for preparing high-performance ito granulated powder

The invention provides a high-performance ITO granulation powder preparation method, which comprises: weighing indium oxide nanometer powder with a purity of more than 99.99% and tin oxide nanometer powder with a purity of more than 99.99% according to a mass ratio of 9:1, adding deionized water and a dispersing agent to prepare a slurry with a certain solid content, and carrying out ball milling with a sand mill to achieve a certain fineness; adding a binder and an antifoaming agent, and carrying out spray drying to obtain powder; adding cyclone powder, a certain amount of a dispersing agent and water to the powder to prepare a slurry with a certain solid content; and carrying out high speed dispersing, and carrying out spray drying to obtain the final granulation powder. According to the present invention, the prepare granulation powder has the solid sphere shape and the large bulk density, and the prepared indium tin oxide has the single-phase micro-particle dispersed state, has the characteristics superior to the agglomerated powder, has good fluidity and good gradation, and is beneficial for meeting the molding requirement of the high-end ITO target.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

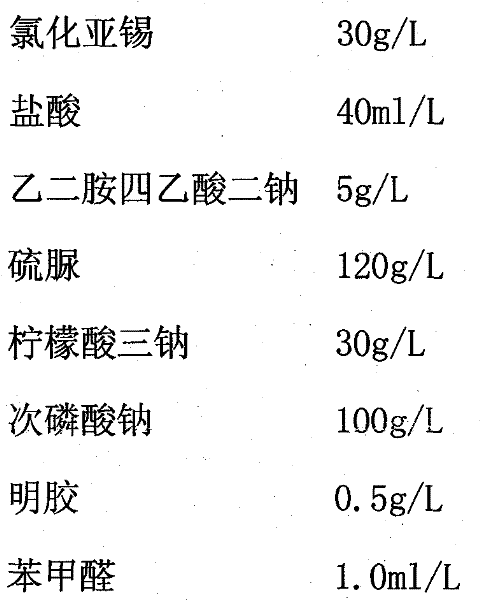

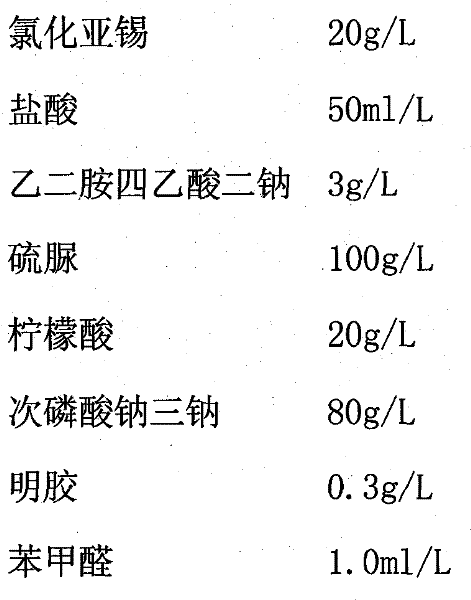

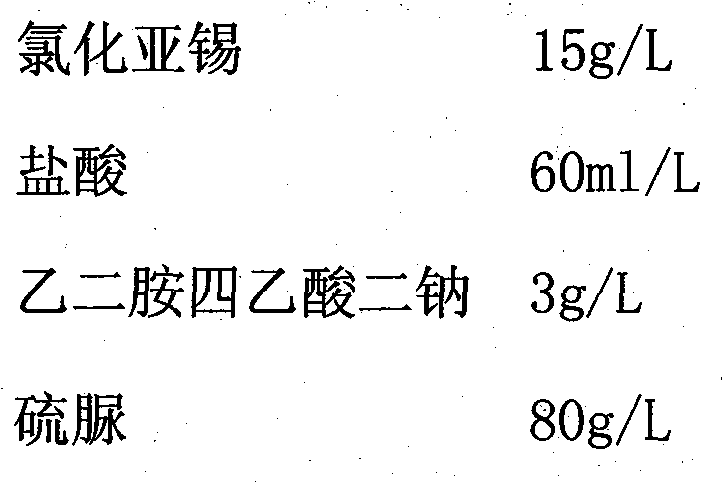

Semi-bright lead-free chemical tinning liquid and using method thereof

InactiveCN101717929BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingThioureaBenzaldehyde

The invention discloses new semi-bright lead-free chemical tinning liquid and a using method thereof. A semi-bright silver tin-copper alloy chemical plating layer is obtained on copper and copper alloy matrix. In the chemical plating liquid, tin sulfate is used as a main salt, thiourea is used as a main complexing agent, citric acid is used as an auxiliary complexing agent, sodium hypophosphite is used as a reducing agent, ethylene diamine tetraacetic acid is used as an antioxidant, sulfuric acid is used as a stabilizing agent, gelatin is used as a leveling agent, and benzaldehyde is used as an auxiliary brightening agent. The pH value of the plating liquid is 0.8 to 2.0, the temperature of the plating liquid is between 80 and 90 DEG C, the carrying capacity of the plating liquid is 0.8 to 1.5dm2 / L, and the mechanical stirring speed is 50 to 100 rpm. The continuous self-catalytic deposition of tin is implemented on the copper and copper alloy matrix, plating layers of different thicknesses can be obtained by controlling the chemical plating time, and the deposition speed is high; crystalline grains are obviously refined, the surface flatness of the plating layer is improved, and the plating surface area is large; the plating layer and the matrix are combined firmly; and after passivating treatment, the change resistance of the plating layer is high. The technology has broad application prospect in products such as deep hole pieces, blind hole pieces, small-sized electronic parts and components which are difficult to process, printed circuit boards (PCB) and the like.

Owner:KUNMING UNIV OF SCI & TECH

A preparation method of inorganic bonding material and inorganic bonding material obtained therefrom

ActiveCN104004454BImprove conductivityReduced dielectric strengthNon-conductive material with dispersed conductive materialInorganic adhesivesSolar cellMaterials science

The invention relates to a method for preparing an inorganic binding material for solar cell positive electrode paste and the inorganic binding material obtained through the preparation method. In particular, the method includes the following steps that (1) high temperature smelting powder is prepared, (2) high temperature sintering powder is prepared, and (3) the prepared high temperature smelting powder and the prepared high temperature sintering powder are mixed.

Owner:宁夏中色新材料有限公司

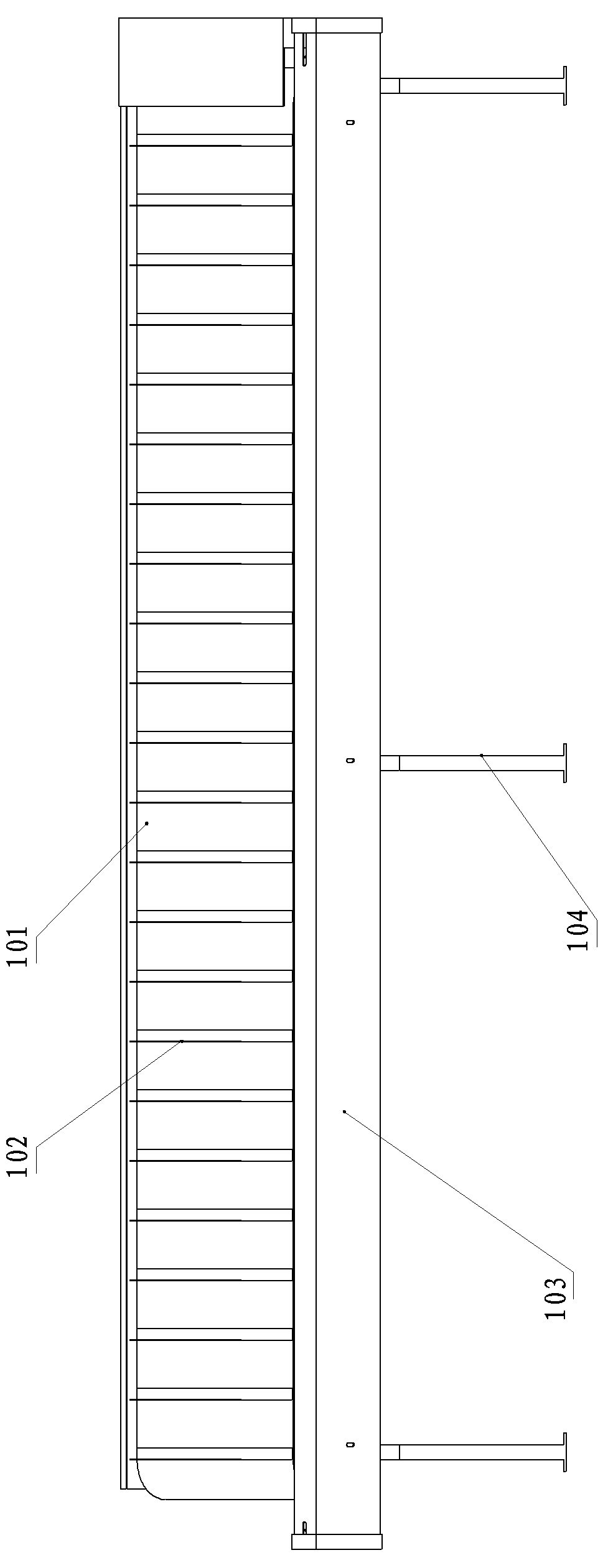

Slantwise type self-tidying integrated equipment with functions of handle cutting, handle releasing and cutting off

InactiveCN102631019BReduce labor inputImprove work efficiencyTobacco treatmentEngineeringSupport belt

Owner:BAOFENG REDRYING FACTORY OF TIANCHANG INT TOBACCO CO LTD +1

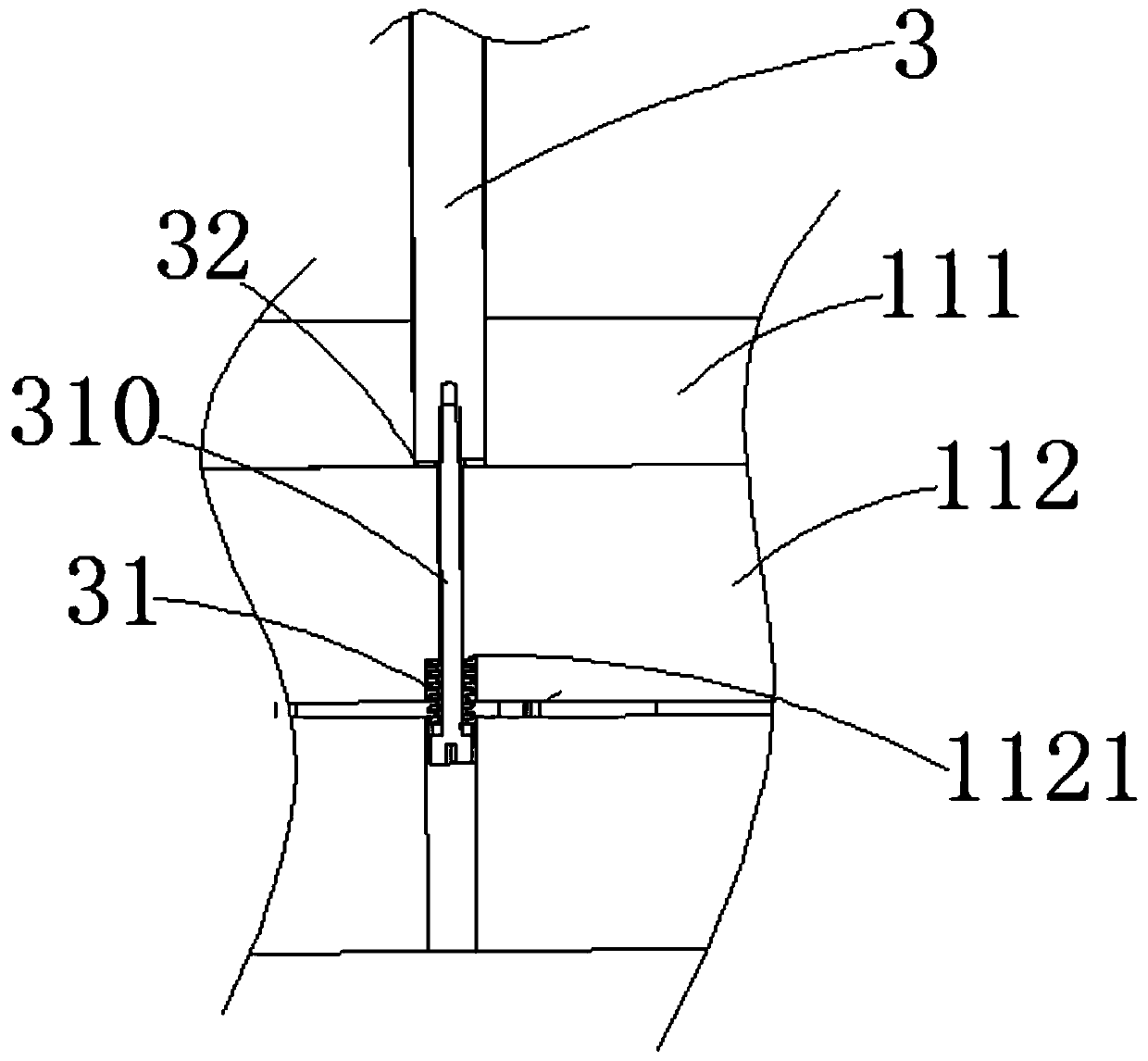

A method for ultrasonic-assisted laser deep penetration welding of plates

ActiveCN105583523BSpeed up the flowStable supportWelding/soldering/cutting articlesMetal working apparatusEvaporationEngineering

The invention relates to a method for deep penetration laser welding of a plate under the assistance of ultrasound. The method is characterized by comprising the following steps that firstly, first base metal (10) and second base metal (11) are machined to form butt joint end faces, and a series of inclined semicircular grooves are machined; secondly, the first base metal (10) and the second base metal (11) are in butt joint and are clamped, and a series of inclined blind holes are formed in a weld bead; thirdly, a first ultrasonic amplitude-changing rod (3) is pressed to the upper surface of a workpiece to be welded; fourthly, a second ultrasonic amplitude-changing rod (4) is fixed to one side of a laser welding head; fifthly, an ultrasonic generation device is started, the ultrasonic frequency is adjusted; sixthly, a laser beam (5) perpendicularly irradiates the upper surface of the workpiece, and the welding process is completed under continuous ultrasonic vibration; and seventhly, after welding is completed, ultrasonic vibration is maintained for 1-2 minutes. In the method, due to the pre-formed inclined blind holes and ultrasonic vibration, weld joint root leakage caused by molten pool downward flowing driven by local evaporation back flushing pressure of the front edge walls of the small holes is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Continuously self-catalyzed deposition chemical plating solution of tin and using method thereof

InactiveCN101724834BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingAntioxidantBenzaldehyde

The invention discloses continuously self-catalyzed deposition chemical plating solution of tin and a using method thereof. Half-bright and silvery-white tin-copper alloy deposition layers are obtained on pure copper and a copper alloy substrate. In the chemical plating solution, stannous chloride serves as a main salt, thiourea serves as a main complexing agent, trisodium citrate serves as an auxiliary complexing agent, sodium hypophosphite serves as a reducing agent, disodium ethylene diamine tetraacetate serves as an antioxidant, a hydrochloric acid serves as a stabilizing agent, gelatin serves as a leveling agent and benzaldehyde serves as an auxiliary brightening agent. The using method comprises the following operating conditions that: the pH value of the plating solution is 0.8 to 2.0; the temperature is 80 to 90 DEG C; the loading capacity is 0.8 to 1.5 dm2 / L; and the mechanical stirring speed is 50 to 100 rpm. The continuously self-catalyzed deposition chemical plating solution of the tin and the using method thereof have the advantages of capability of obtaining half-bright and silvery-while tin-copper alloy clad layers with different thicknesses by controlling chemical plating time, high deposition rate, remarkable grain refinement, improvement on surface evenness of the clad layer and batch production stability, secure interface combination, strong change resistance of the clad layer after being passivated, and broad application prospect in the products of deep hole elements, blind hole elements, difficult-to-handle miniature electronic components and parts, printed circuit boards PCBs and the like.

Owner:KUNMING UNIV OF SCI & TECH

A welding method for obtaining amorphous joints for fesib amorphous strips

ActiveCN105364314BSimplify welding toolingWide range of process parametersLaser beam welding apparatusLaser technologyLap joint

The invention relates to the technical fields of amorphous materials and welding, in particular to a welding method for obtaining amorphous joints for FeSiB amorphous strips, which belongs to the connection technology of amorphous materials. Aiming at the limited size of the Fe-based amorphous alloy strip, brittle material, extremely thin material, and poor weldability, the method uses micropulse laser technology to successfully obtain a completely amorphous joint. The steps are as follows: grind the surface of the FeSiB amorphous alloy strip sample, clean it, and dry it; fix the base metal by clamping one end and flattening the other end on a special fixture designed by ourselves, and then blow Ar gas protection welding on the side. Melt pool: micro-pulse laser technology is used for lap welding, and process parameters such as pulse power P, pulse width T, and pulse frequency F are optimized to obtain completely amorphous welded joints. The invention has the following advantages: simple welding tooling, high welding efficiency, low cost, good joint quality, and the joint is completely amorphous.

Owner:NANCHANG HANGKONG UNIVERSITY

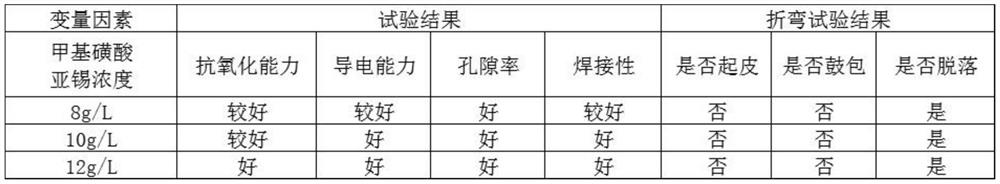

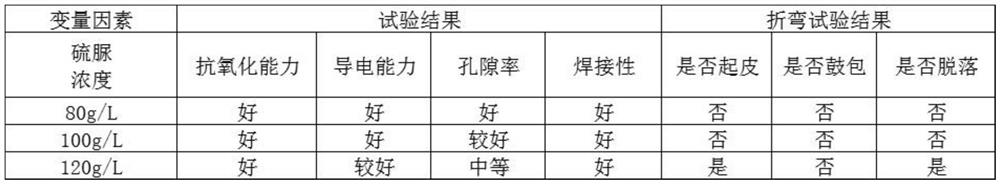

Tin plating solution for copper electronic material as well as preparation method and application method of tin plating solution

PendingCN114574840ATo preventEasy to degradeLiquid/solution decomposition chemical coatingPhosphorous acidMeth-

The invention discloses a copper electronic material tin plating solution, a preparation method and an application method, and the formula of an additive of the copper electronic material tin plating solution comprises the following components: main salt: stannous methanesulfonate with the concentration of 10-13g / L; a hydrolysis agent: 96 to 112 ml / L of methanesulfonic acid; the complexing agent is thiourea with the concentration of 75 g / L or 80 g / L; a tin whisker inhibitor: 0.8-1.2 g / L of silver methanesulfonate; the antioxidant is ethylenediamine tetraacetic acid with the concentration of 3-5g / L; the auxiliary brightening agent is benzaldehyde with the concentration of 0.2 g / L to 0.3 g / L; the reducing agent is at least one of hypophosphorous acid and sodium hypophosphite, and the concentration of the reducing agent is 50-82ml / L; gelatin is also added into the plating solution, and the concentration of the gelatin is 0.2-1.0 g / L; the complex solubilizer is polyalcohol with the concentration of 50 to 500g / L; and the crystal refiner is a polyoxyalkylene ether or amino acid type solution with the concentration of 0.1-10g / L.

Owner:深圳市虹喜科技发展有限公司

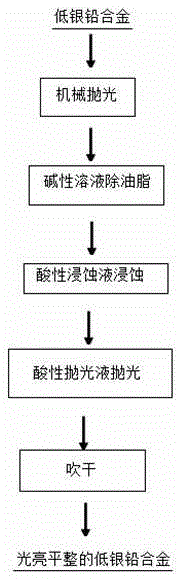

A kind of pretreatment method of low-silver-lead alloy surface

The invention relates to a pretreatment method for a low silver-lead alloy surface, and belongs to the technical field of metal surface treatment. The pretreatment method comprises the following steps: firstly, mechanically polishing the low silver-lead alloy surface, washing for twice by using deionized water after the polishing is accomplished, putting the low silver-lead alloy surface treated by the steps into an alkali solution, degreasing at the temperature of 60-80 DEG C, subsequently washing for twice by using the deionized water, putting the low silver-lead alloy surface treated by the steps into an acid etching liquid, etching for 5-10 minutes at the room temperature, subsequently washing for twice by using the deionized water, polishing and blowing to dry the low silver-lead alloy surface treated by the steps by using a low silver-lead alloy acid polishing liquid at the room temperature, so as to obtain a bright, flat and clean low silver-lead alloy surface which is necessary for composite electrodeposition. A pretreatment solution is simple in component, convenient to prepare, easy to control, wide in process parameter range, and free from over-corrosion.

Owner:KUNMING HENDERA SCI & TECH

Nd-YAG laser cladding method for preparing thickness adjustable biological ceramic composite coating adopting bone-like structure

InactiveCN103422089APermeableImprove performanceMetallic material coating processesCeramic compositeCeramic coating

The invention discloses an Nd-YAG laser cladding method for preparing a thickness adjustable biological ceramic composite coating adopting a bone-like structure. The method includes the following steps: 1, proportionally mixing rare earth, CaHPO4.2H2O and CaCO3 to prepare composite powder; 2, piling the composite powder obtained in step 1 on the surface of a titanium alloy basal body to form a precast coating; 3, performing Nd-YAG laser cladding to the composite powder; so as to obtain the biological ceramic composite coating with high binding force. According to the invention, the rare earth added in raw material improves the stability of an HAP phase structure; the obtained coating is high in bonding strength when bonded with the metal basal body, and is bonded with chemical metal to solve the problem that the biological ceramic coating is easy to fall off; in addition, the raw material is low in price, convenient to purchase and easy to store; the preparing technology is simple, the implementation is easy, and the metal has favorable market application prospect and commercial value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A non-continuous point blank holder for a fine blanking die and its process parameter design method

ActiveCN105880350BIncreased hydrostatic stressImprove plastic deformation abilityMetal-working feeding devicesPositioning devicesDesign methodsEngineering

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com