Method for welding automobile aluminium alloy bumper assembly

An assembly welding method, welding method technology, applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of welding deformation and incomplete application, and achieve the effects of improving productivity, reducing welding defects, and improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

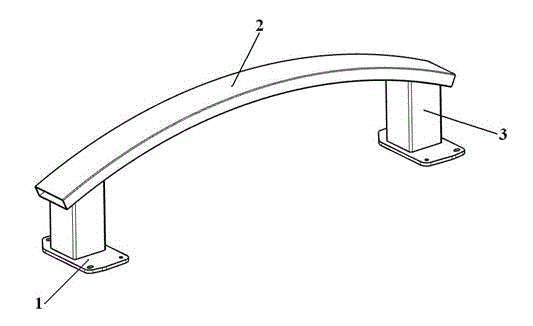

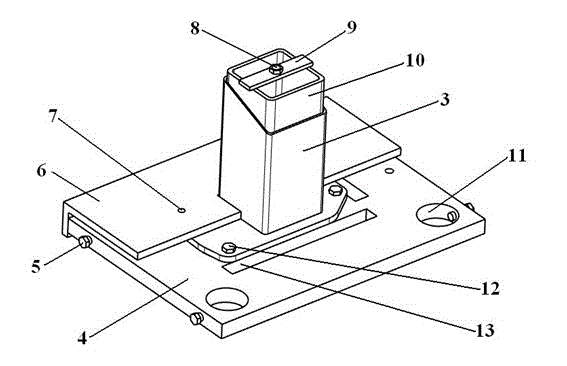

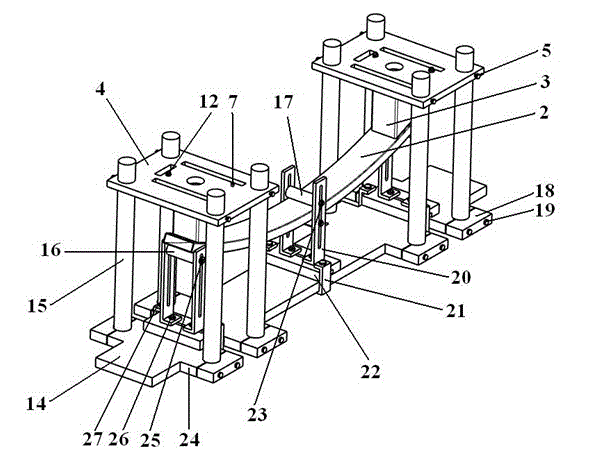

[0028] Combine below figure 1 , figure 2 , image 3 , Welding method embodiment and welding device further illustrate the present invention.

[0029] The present invention is composed of a beam 2, an energy-absorbing box 3 and a bracket 1, and the materials are 6061 aluminum alloy, 6063 aluminum alloy and 6005A aluminum alloy respectively, wherein the energy-absorbing box 3 and the bracket 1 are left and right respectively, and the energy-absorbing box needs to be welded 3 The contact surfaces between the beam 2 and the support 1 respectively, the joint form is a T-shaped joint, the energy-absorbing box 3 is a square tube, the cross-sectional shape is square, and the size is 90mm ╳ 90mm, the wall thickness is 2mm, its height is different, the high side is 174mm, the low side is 139mm, the outer dimension of bracket 1 is 125mm ╳ 218mm, the wall thickness is 5mm, the bending radius of beam 2 is 1332mm, the length of beam 2 is 1111mm, the cross-section is Japanese-shaped, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com