Cylinder barrel of oil cylinder of crane and processing process thereof

A crane oil and processing technology technology, applied in the field of oil cylinders and cylinders, can solve problems such as inability to meet heat treatment requirements, achieve the effects of reducing welding defects, reducing the risk of brittle fracture, and ensuring toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Directly use Q345B hot-rolled steel pipe for processing, raw material specification: Φ152*16, inner hole Φ120mm, inner hole size after processing: Φ125mm (+0.07~+0.03), processing equipment adopts 3-meter scraping roller burnisher of SIDRRA company in the United States. The products produced by this processing method do not have high requirements for strength, but have higher requirements for safety. After the outer circle of the steel pipe is machined, the inner hole is scraped after welding the flange.

[0016] The processing process is: select the tube blank → blanking → straightening → rough turning the outer circle → welding the cylinder body and flange → scraping the inner hole → rough turning → fine turning;

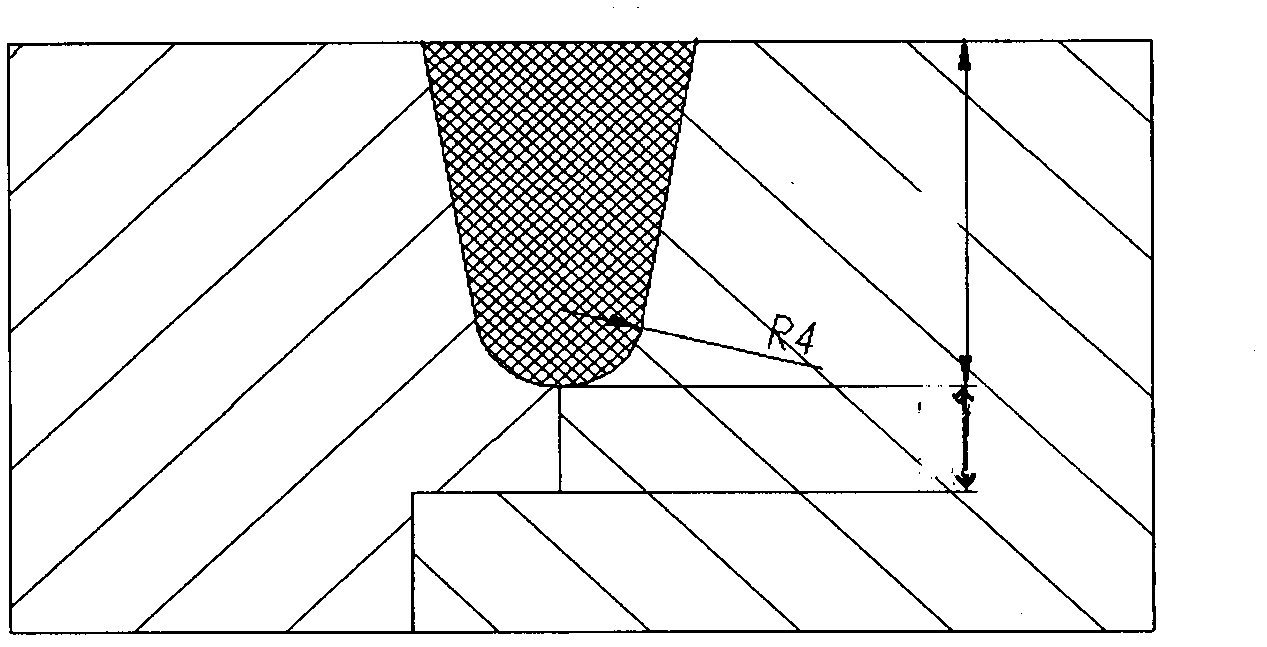

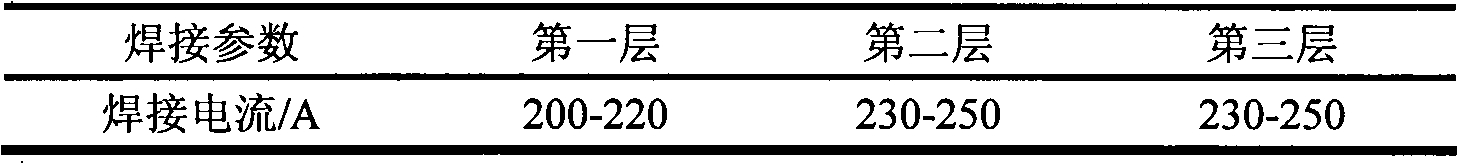

[0017] As shown in the attached figure, the welding groove form is U-shaped groove. The welding method is gas shielded welding, the shielding gas composition is 80% Ar+20% CO2, the welding wire is flux-cored wire ER50-6, the diameter of the welding wire is ...

Embodiment 2

[0025] Use Q345B cold-drawn steel pipe, raw material specification: Φ273*18, inner hole after cold drawing Φ229mm, inner hole size after processing: Φ230mm (+0.07~+0.03), processing equipment adopts 5-meter scraping and rolling machine from Italian TACCHI company. This processing method is mainly used in products that require higher strength. The strength performance of the steel pipe is improved by cold drawing processing. The outer circle of the steel pipe does not need to be machined, and the inner hole is directly welded and scraped.

[0026] The specific process flow is: cold drawing→straightening→cutting→welding flange→scraping inner hole→rough turning→finish turning.

[0027] The cold drawing process is: selection of tube blank → blank annealing → pickling → phosphating → saponification → cold drawing 1 (264 / 230) → phosphating → saponification → cold drawing 2 (260 / 229) → finished product tempering; the blank annealing Temperature: 850±10℃, finished product tempering te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com