Intelligent online detection device based on multi-source information fusion for welded joint

A multi-source information fusion and detection device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of large electromagnetic pollution, difficulty in welding structural parts, large ultrasonic transmitting and receiving devices, etc., to reduce welding defects , Improve the quality and efficiency of welding operations, and reduce the effect of duplication of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

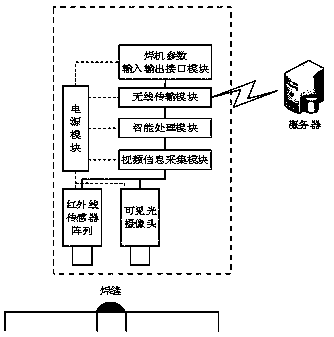

[0032] This embodiment provides an intelligent online detection device for welding seams based on multi-source information fusion, its structure is as follows figure 2 shown. The welding seam intelligent online detection device is connected with the welding torch. In order to avoid the high temperature splash in the welding process from affecting the detection effect of the camera, and considering the temperature change law of the welding pool, the device is installed at the rear of the welding torch 10mm.

[0033] Specifically, the infrared array sensor in this embodiment uses the MAG160Core thermal imaging chip, the visible light camera uses the OPT-C0620-2M, the video information acquisition module uses the TMS320DM6446 video processing module, and the intelligent processing module Tir-TX2S300 deep learning module, equipped with NVIDIA Jetson TX2 The module, video information acquisition module and intelligent processing module are connected by Ethernet interface, and the ...

Embodiment 2

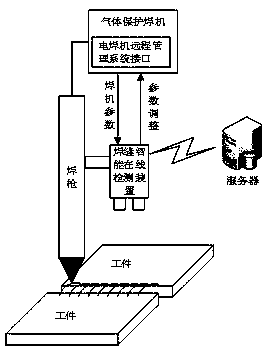

[0041] This embodiment provides an intelligent online detection device for welding seams based on multi-source information fusion, its structure is as follows image 3 shown. The online detection device is connected with the welding helmet. At the beginning of the welding operation, the administrator initializes the welding project through the system, and inputs the welding parameters into the welding parameter database through manual input or wireless transmission, and transmits them to the server.

[0042] In this embodiment, the infrared array sensor adopts MAG160Core thermal imaging chip, the visible light camera adopts OPT-C0620-2M, the video information acquisition module adopts TMS320DM6446 video processing module, the intelligent processing module Tir-TX2S300 deep learning module, equipped with NVIDIA Jetson TX2 module, video The information collection module and the intelligent processing module are connected by an Ethernet interface, and the wireless data transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com