Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

An electromagnetic pulse and hybrid welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as fatigue performance, fast solidification speed, and high-temperature evaporation of alloy elements, and achieve high-precision and high-quality manufacturing and upgrade Weld microstructure and properties, the effect of refining weld grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

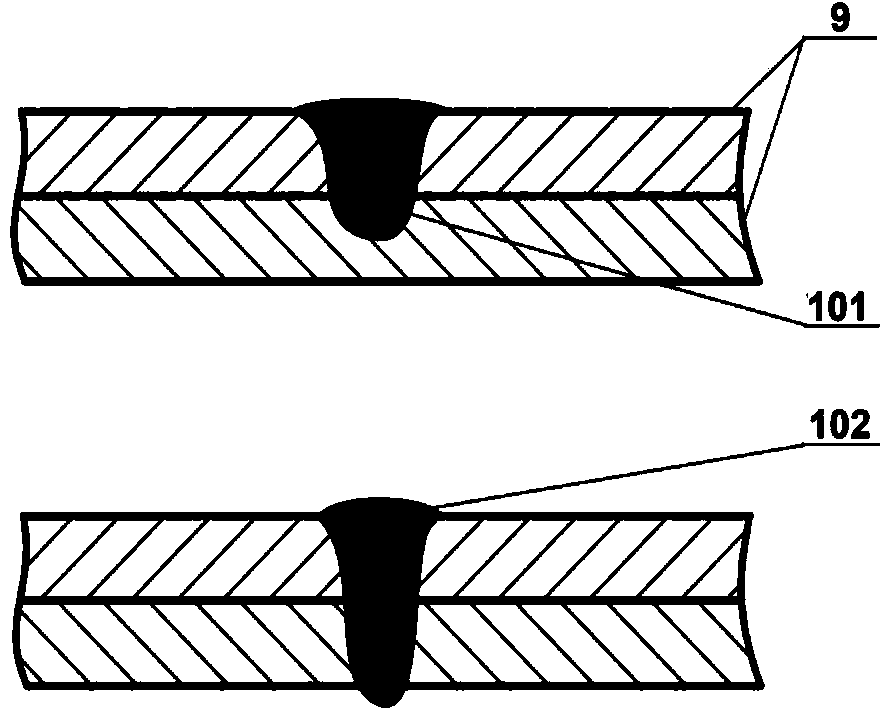

[0082] In this example, the welding workpiece 9 is a 2219 aluminum alloy cylindrical structure with a plate thickness of 2 mm, a diameter of 3.5 m and a height of 3 m. The welding requirements are upper and lower lap spot welding (the thickness of the welding point after lap is 4 mm). Figure 18 The laser electromagnetic pulse composite spot welding equipment shown is selected by the fiber laser and laser galvanometer scanning and focusing method (the shape and area of the welding spot can be controlled by the laser beam swing scanning), the laser focal length is 300mm, and the shape of the welding spot of the welding seam is a solid circle. shape, and the cross-sectional feature is an unpenetrated form.

[0083] The process parameters used in this example are: laser power 5000W, laser spot diameter 3mm, single point welding time 0.2s, laser beam swing along the radial direction 0.5mm, distance between electromagnetic conversion device and workpiece surface 10mm, pulse magnet...

Embodiment 2

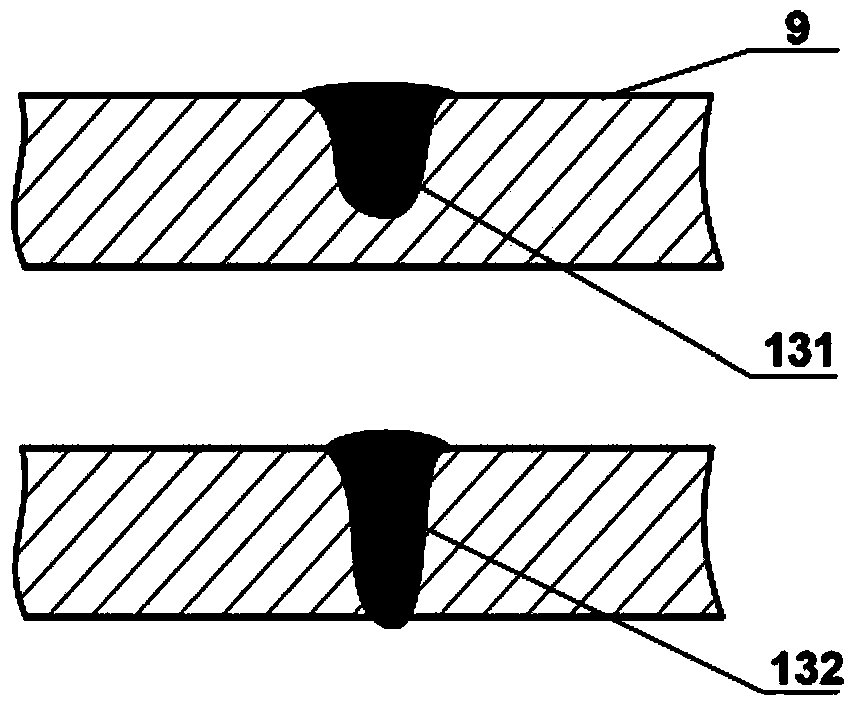

[0086] In this example, the welding workpiece is a 5A06 aluminum alloy flat plate structure with a plate thickness of 1mm, a length of 2m, and a width of 1m. The welding requirements are upper and lower lap spot welding (the thickness of the welding point after the lap is 2mm). The schematic diagram of the welding device is as follows Figure 19 As shown, the fiber laser and galvanometer scanning focusing method are selected, the laser focal length is 300mm, the shape of the welding spot of the welding seam is a solid circle, and the cross-sectional feature is the form of non-penetration.

[0087] The process parameters used in this example are: laser power 1500W, laser spot diameter 0.5mm, single point welding time 3s, laser beam swing along the radial direction 5mm, distance between electromagnetic conversion device and workpiece surface 2mm, pulse magnetic field induction intensity 300mT, Magnetic field pulse width 500ms.

[0088] After the welding is completed, the obtaine...

Embodiment 3

[0090] In this example, the welding workpiece 9 is a 6082 aluminum alloy flat plate structure with a plate thickness of 4 mm. The welding requirement is butt spot welding. The schematic diagram of the welding device is as follows: Figure 19 As shown in the figure, DISK solid-state laser and galvanometer scanning and focusing method are selected, the laser focal length is 350mm, the shape of the welding spot of the welding seam is a solid circle, and the cross-sectional feature is the form of full penetration.

[0091] The process parameters used in this example are: laser power 3500W, laser spot diameter 0.8mm, single point welding time 1s, laser beam swing along the radial direction 2mm, distance between electromagnetic conversion device and workpiece surface 4mm, pulse magnetic field induction intensity 120mT, Magnetic field pulse width 1s.

[0092] After the welding is completed, the obtained weld is beautiful in shape, free from defects such as center shrinkage, undercut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com