Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "High quality preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

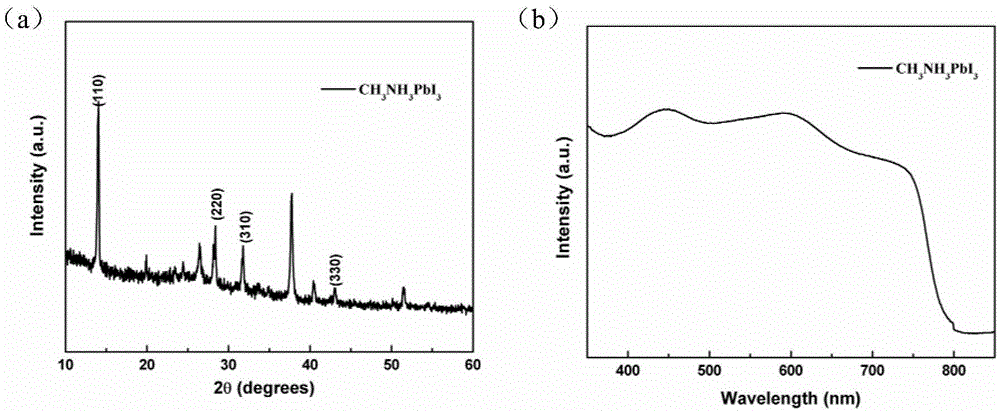

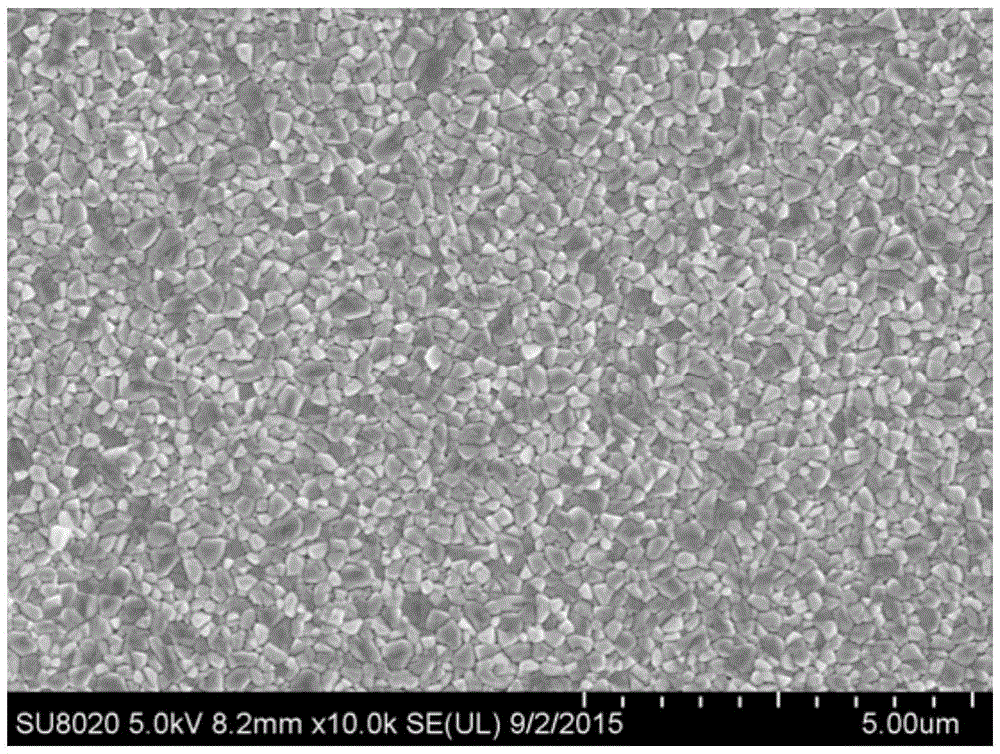

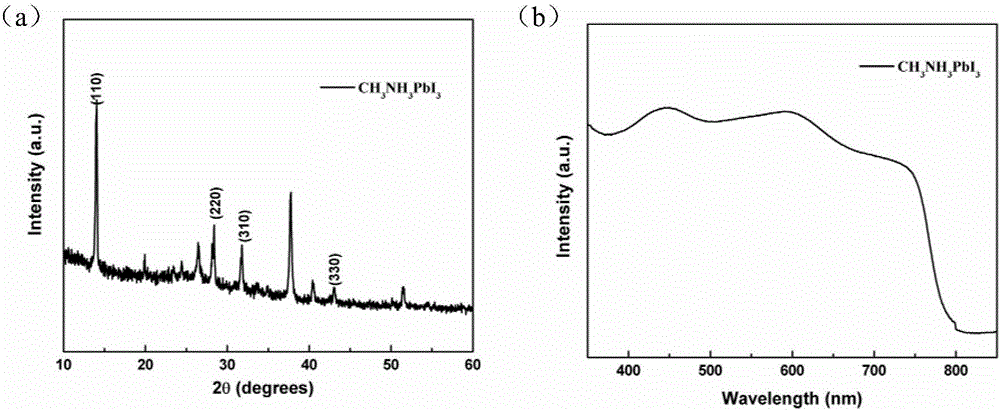

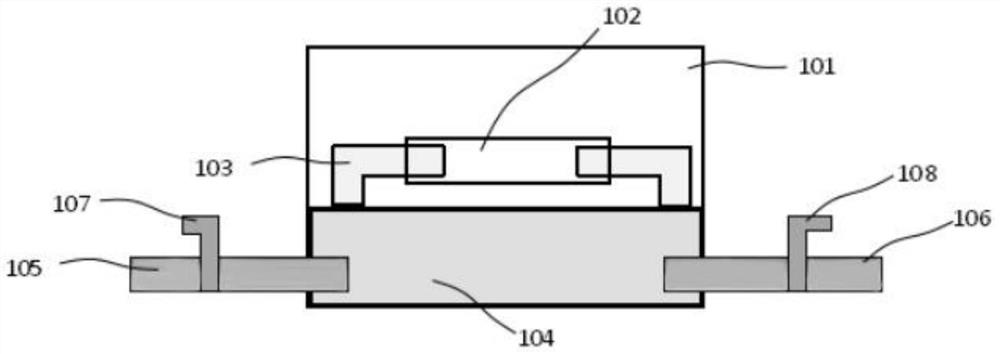

Chemical vapor deposition preparation method for perovskite solar cell

ActiveCN104393109AEasy to operateImprove film qualityFinal product manufactureChemical vapor deposition coatingHeterojunctionPerovskite solar cell

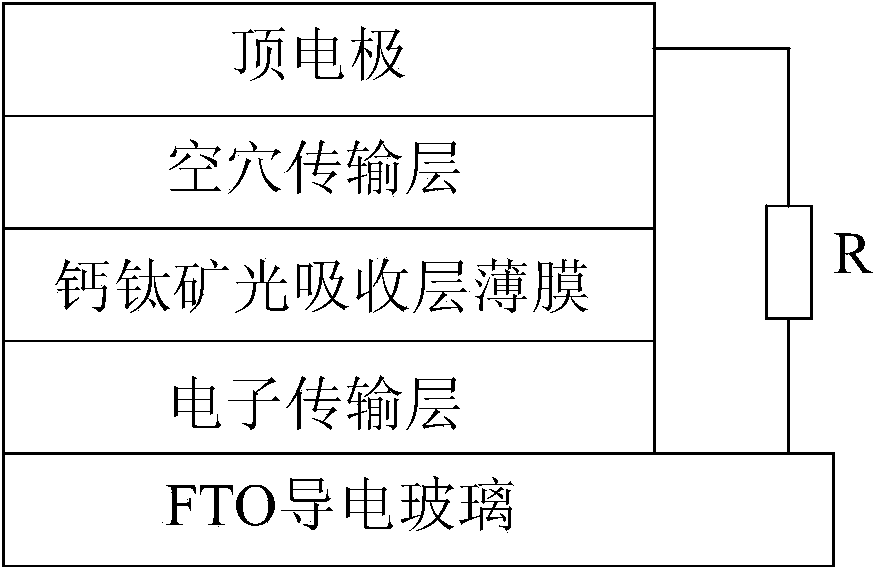

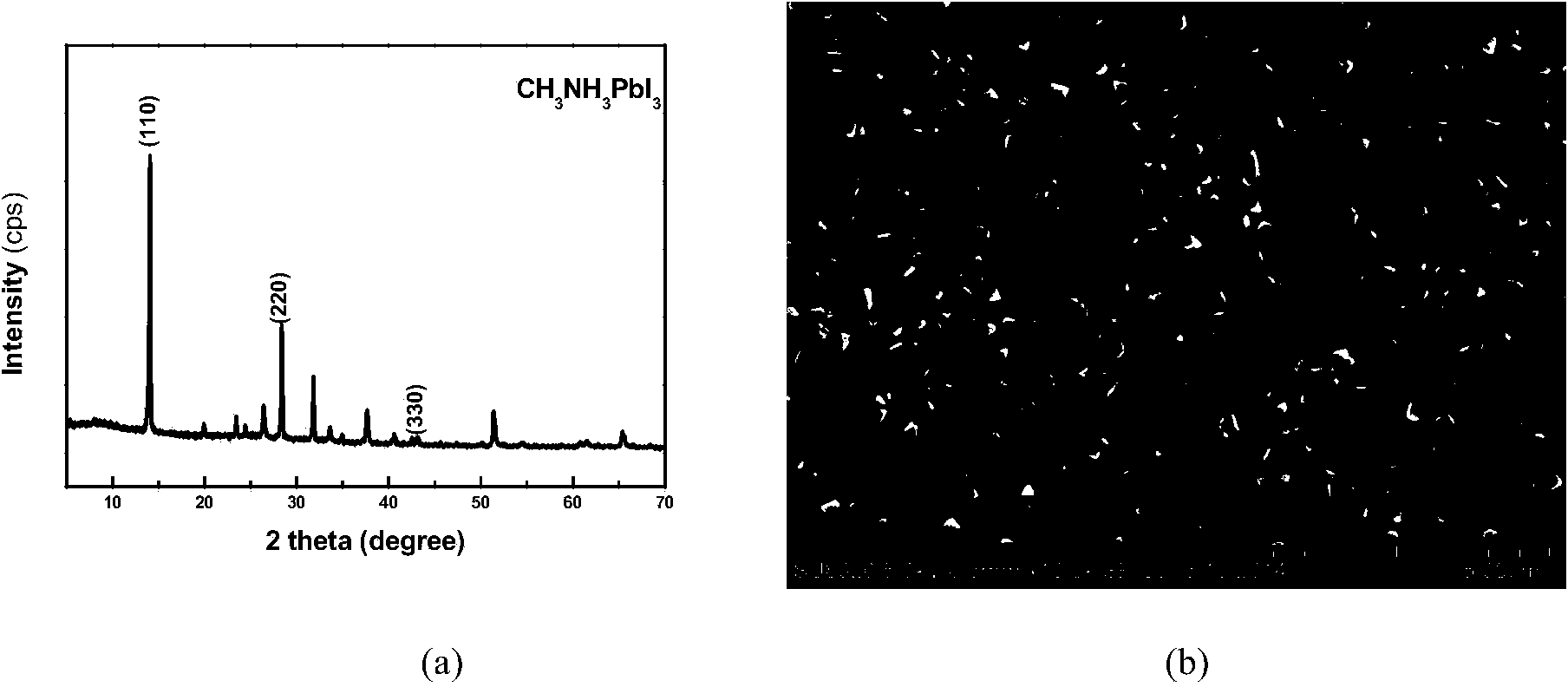

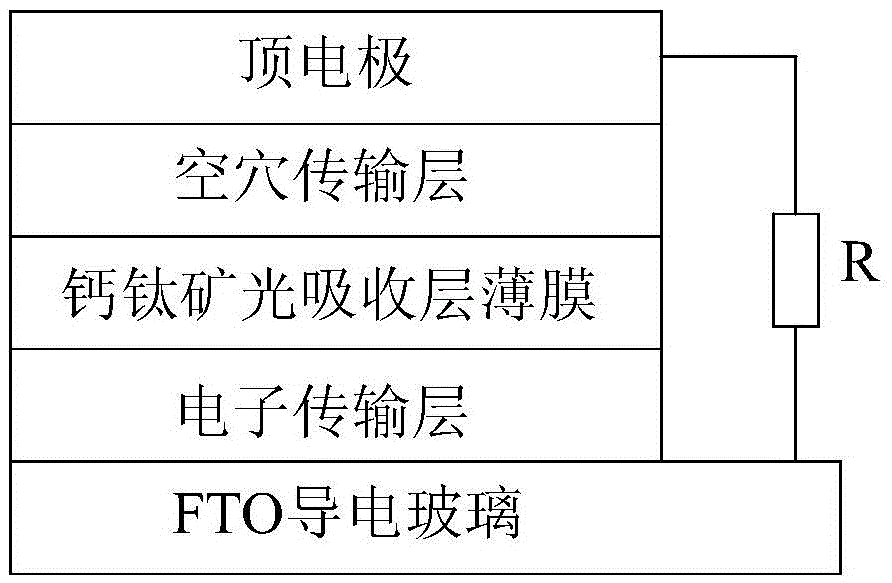

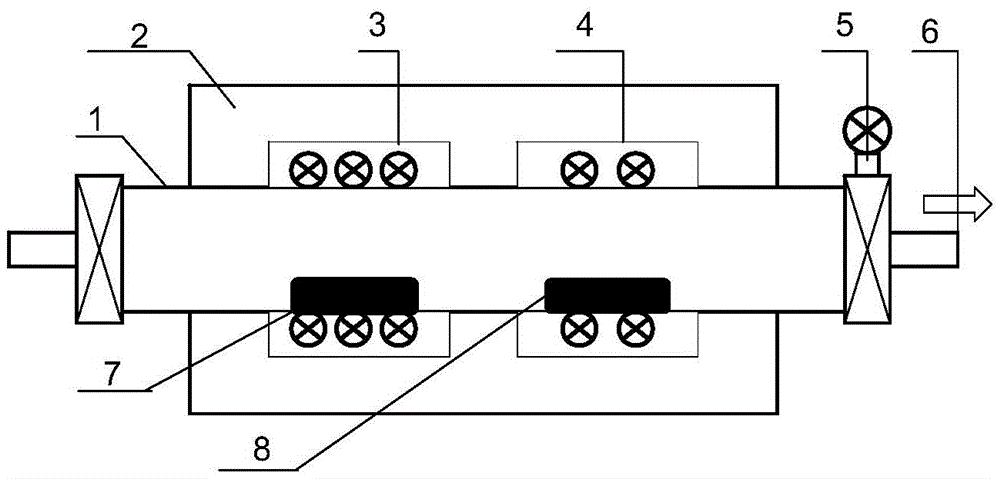

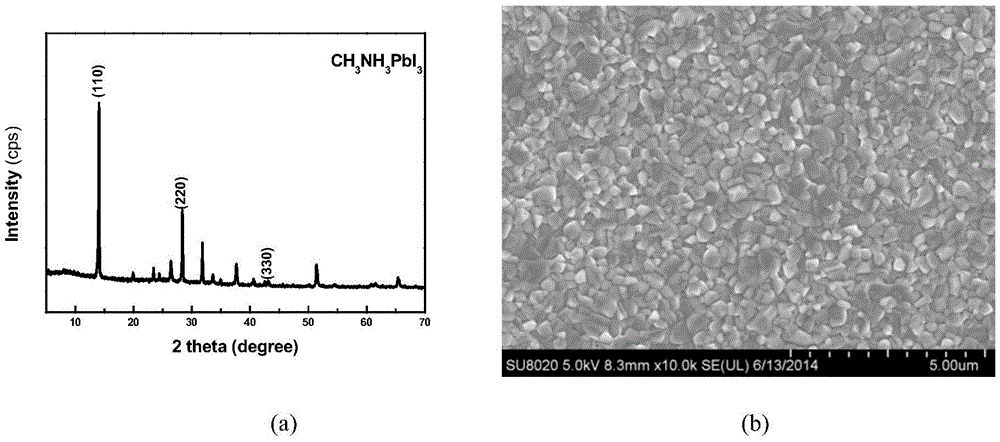

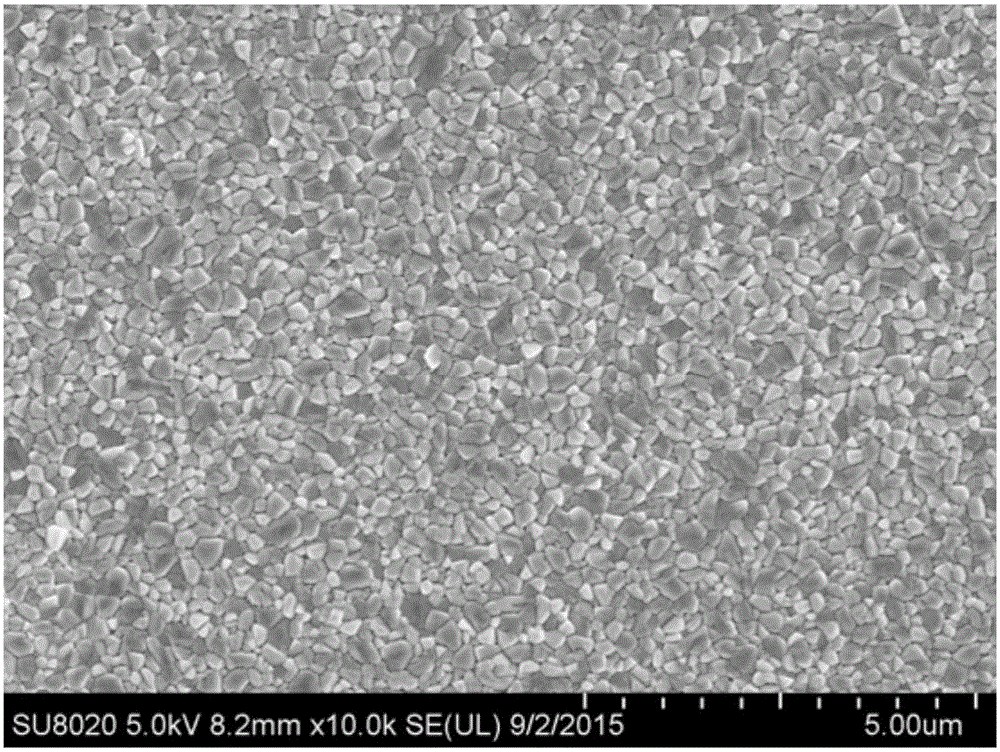

The invention discloses a chemical vapor deposition preparation method for a perovskite solar cell. The preparation method is characterized in that a compact layer TiO2 thin film is deposited on a surface on which the FTO thin film of FTO conductive glass is positioned so as to act as an electron transmission layer; a perovskite light absorption layer thin film is prepared on the electron transmission layer via a chemical vapor deposition method; a hole transmission layer is prepared on the perovskite light absorption layer thin film; and an Ag electrode or an Au electrode is vapor-deposited on the hole transmission layer to act as a top electrode so that the perovskite solar cell is obtained. The preparation method is simple and low in cost. The prepared perovskite light absorption layer thin film is high in quality, excellent in substrate coverage and great in stability and repeatability. Preliminary conversion efficiency of the prepared planar heterojunction perovskite solar cell can be 11%.

Owner:HEFEI UNIV OF TECH

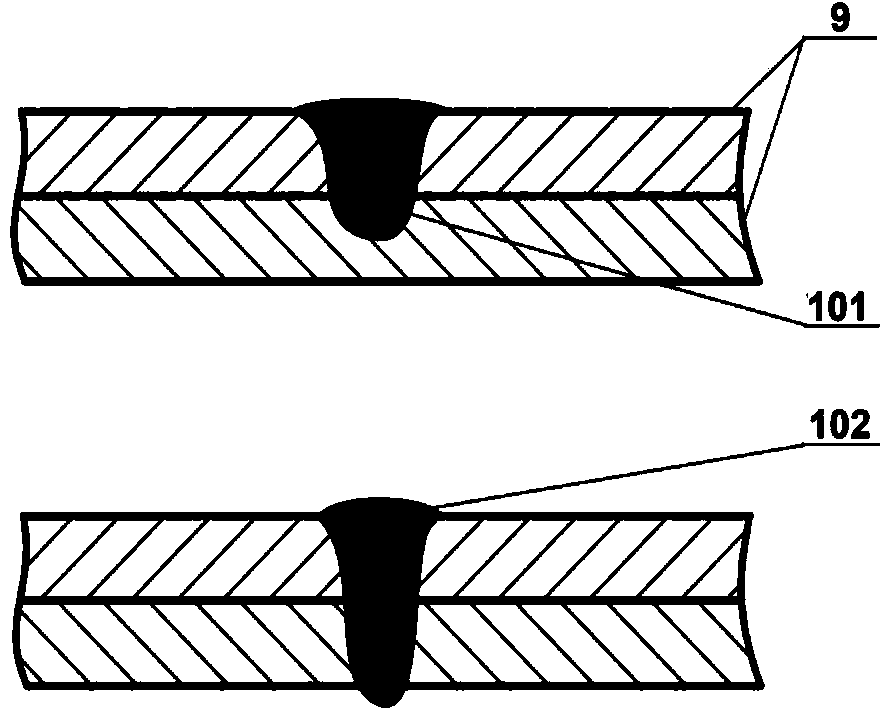

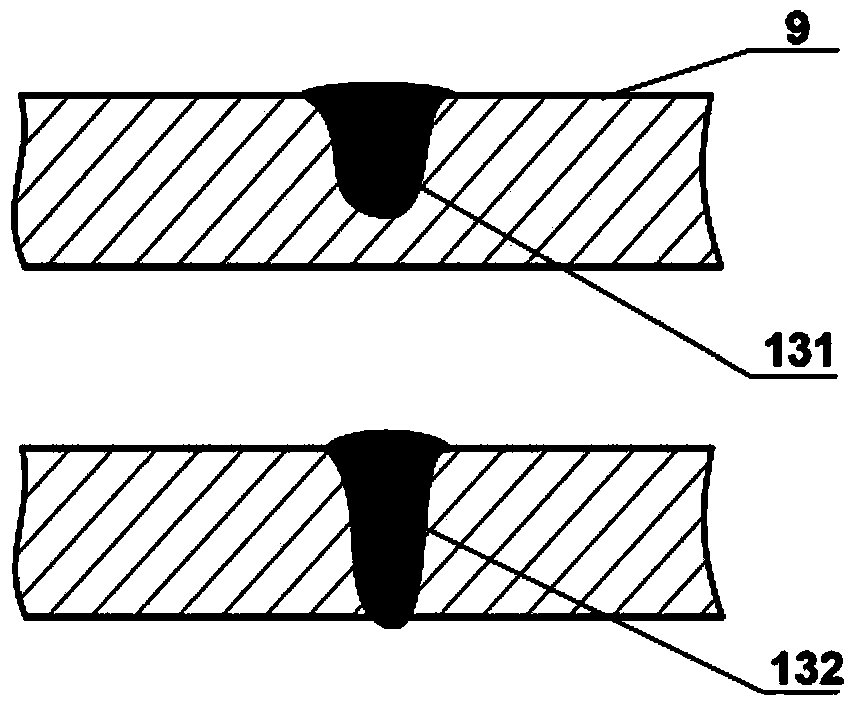

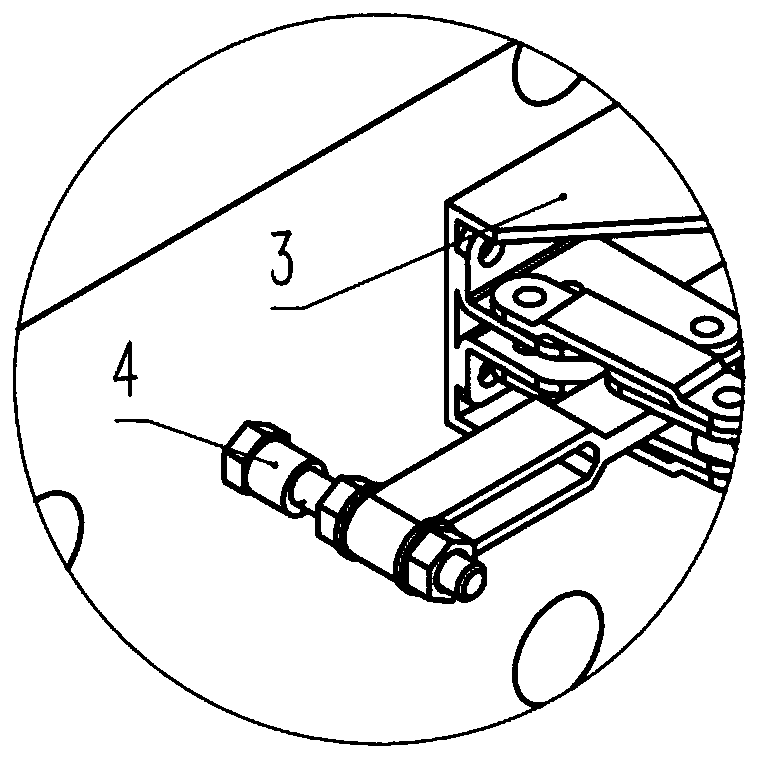

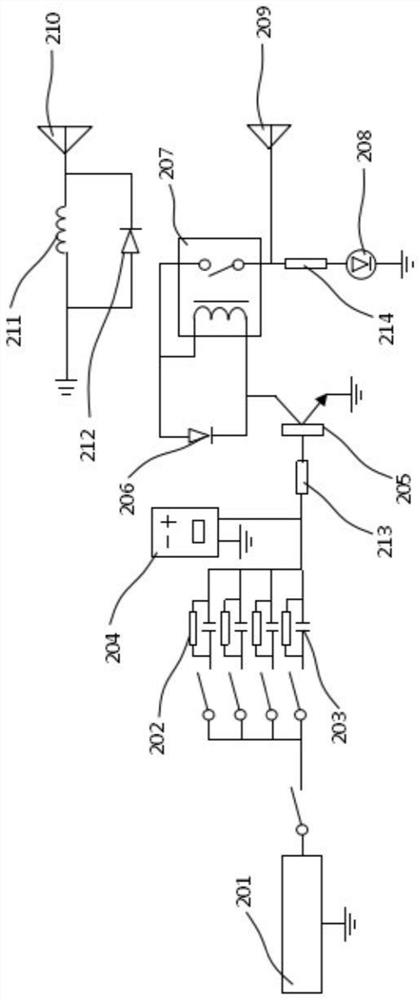

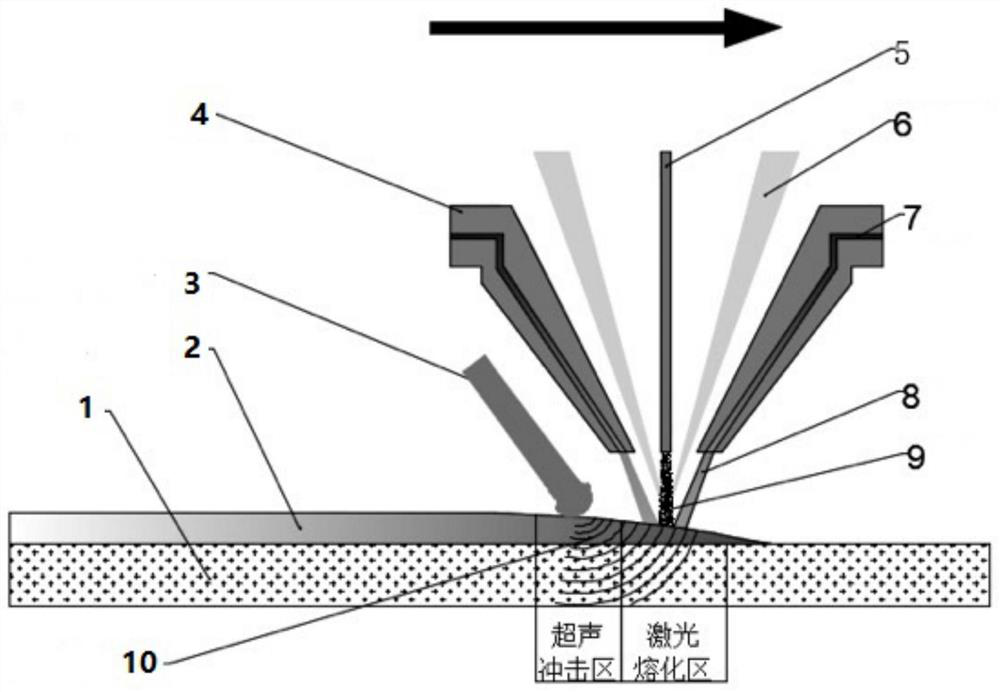

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

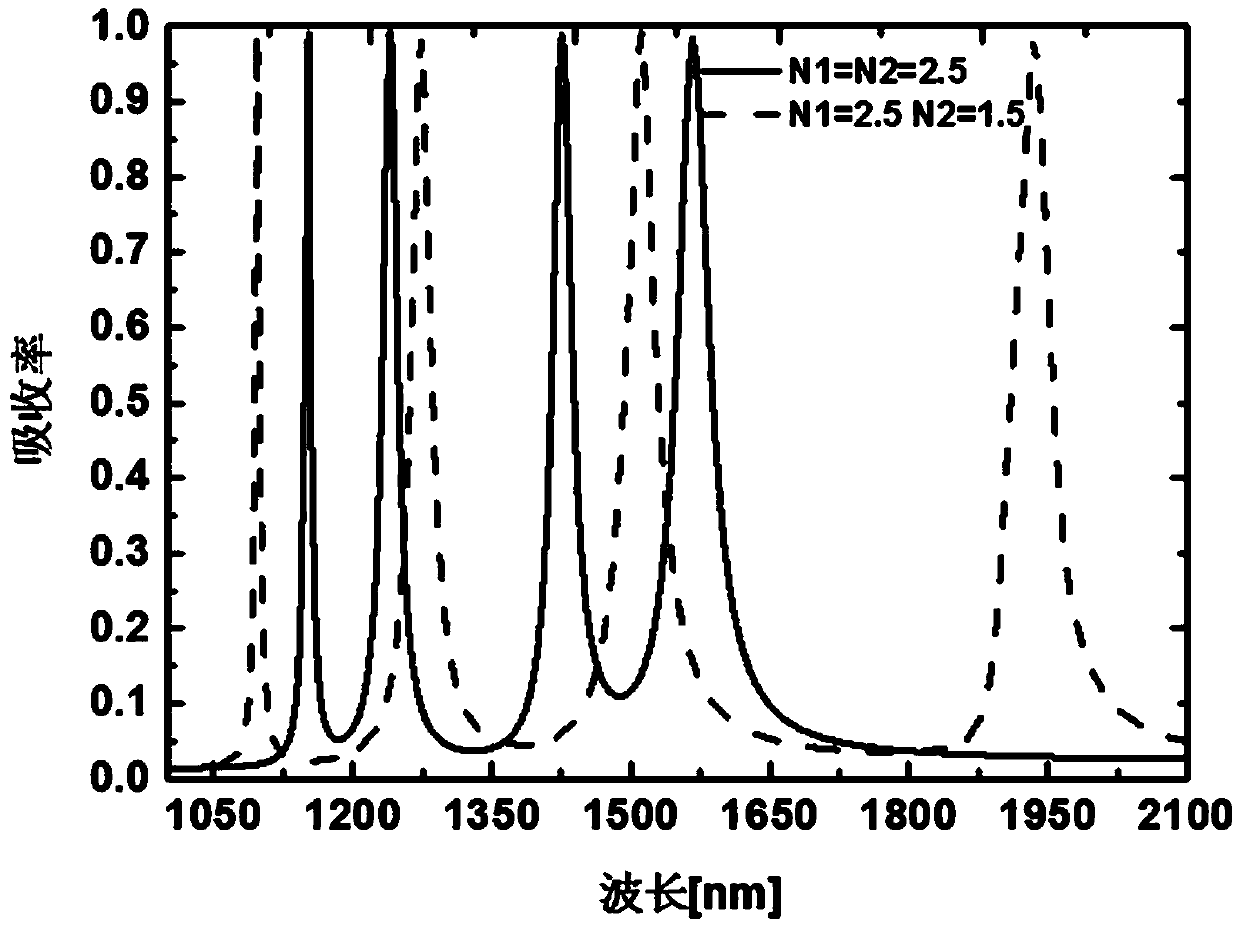

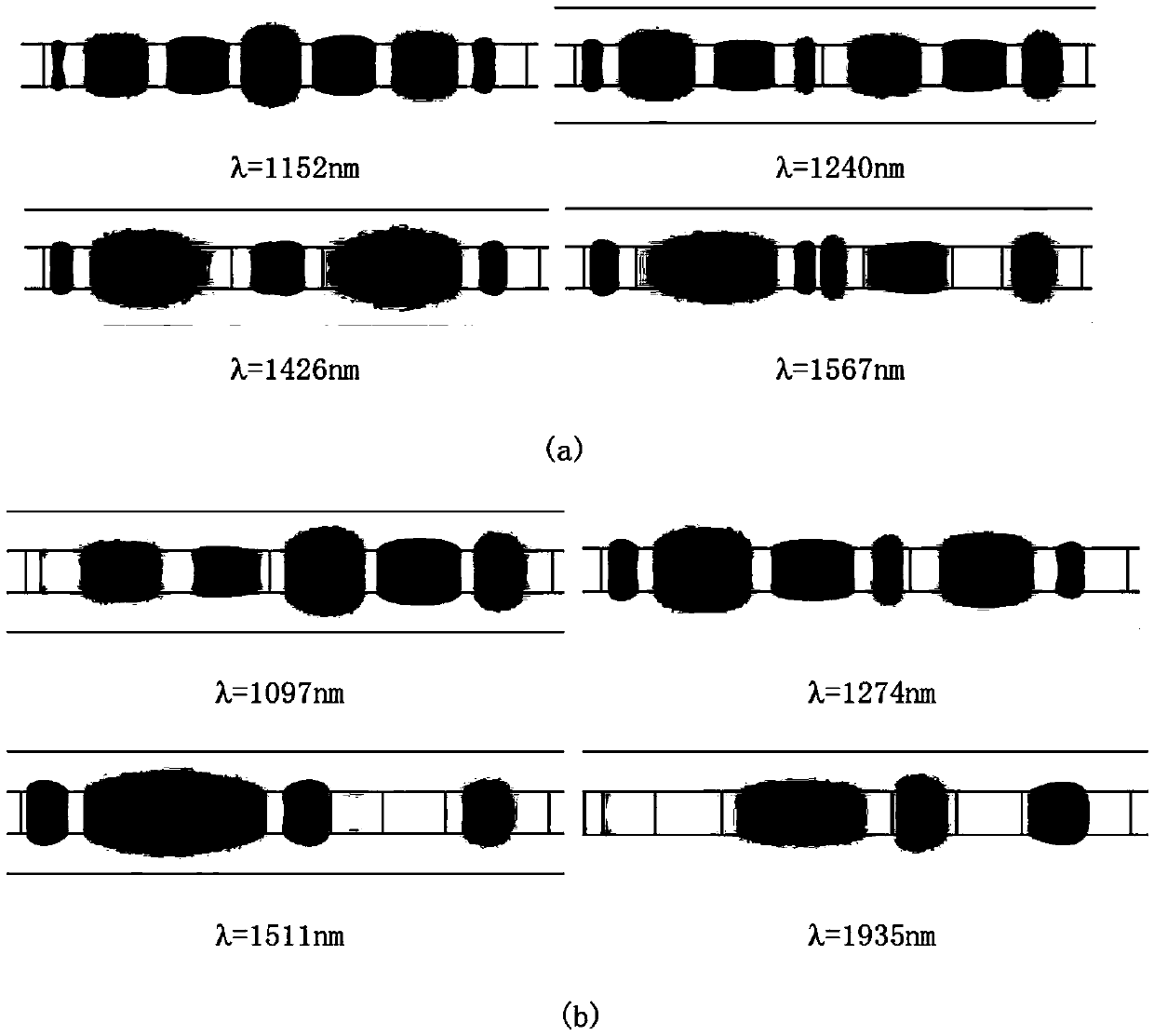

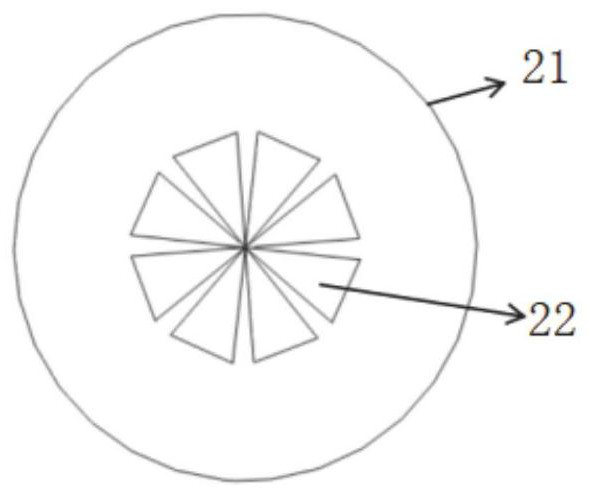

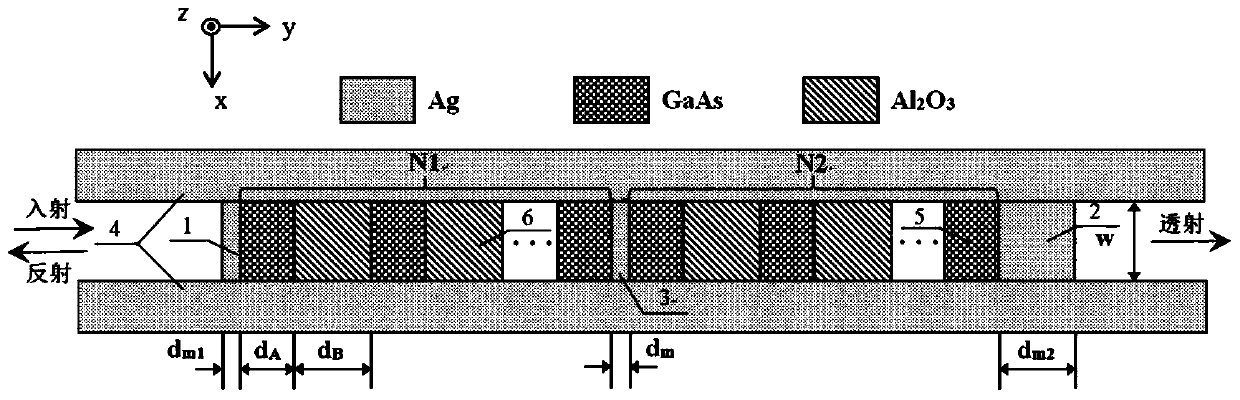

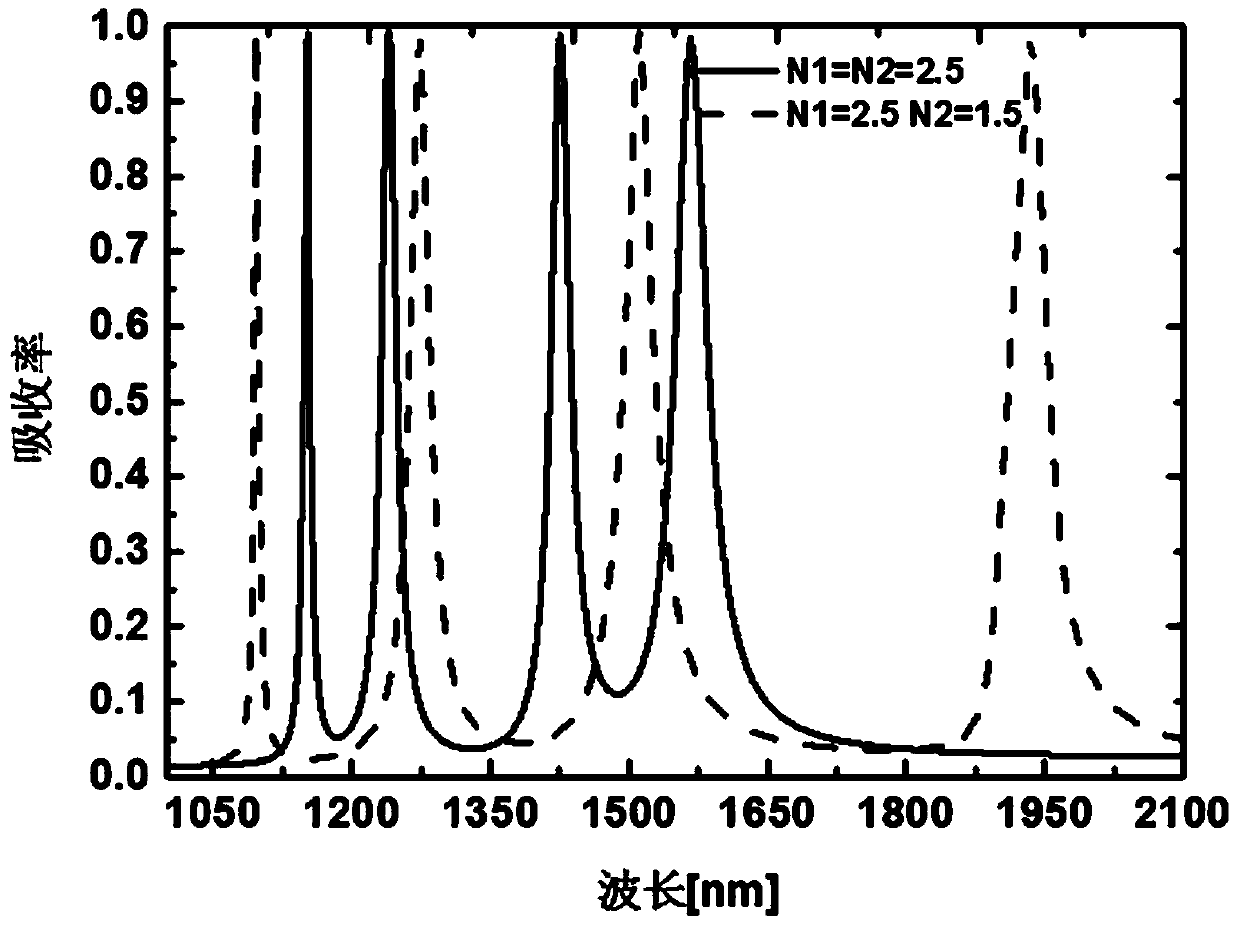

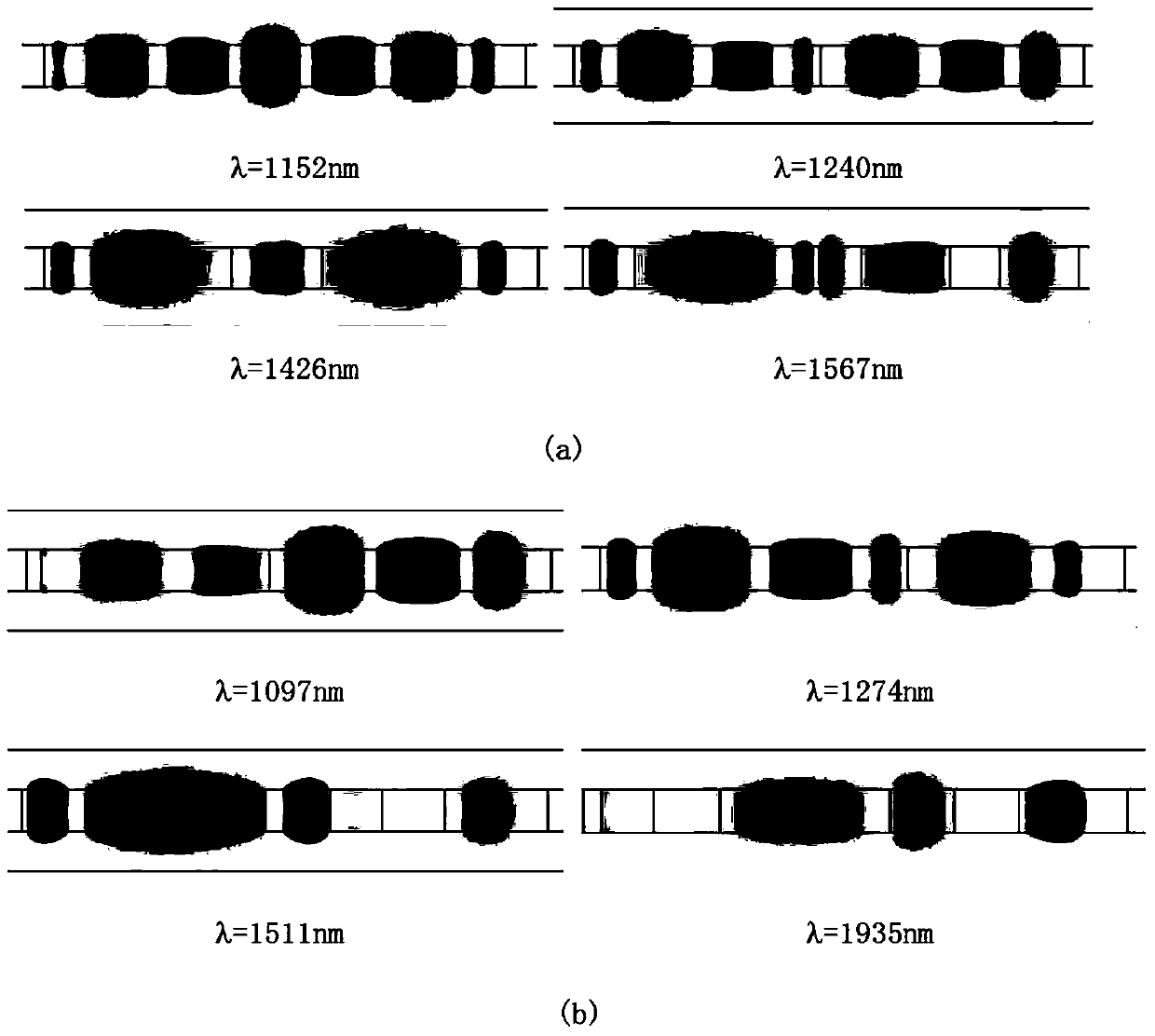

Multi-channel tunable Tamm plasma perfect absorber

The invention discloses a multi-channel tunable Tamm plasma perfect absorber, which comprises an MIM waveguide and a metal-DBR-metal intercalation-DBR-metal structure in the waveguide, wherein metals at two sides of the metal-DBR-metal intercalation-DBR-metal structure are different in thickness; and with the metal intercalation as the center, the cycle numbers of the DBRs at two sides are N1 and N2 respectively. The multi-channel tunable Tamm plasma perfect absorber is a novel multi-channel tunable Tamm plasma perfect absorber; a TM polarized light normally enters from the left side, passes through the MIM structure and can efficiently stimulate Gap-SPPs within the waveguide; the metal-DBR-metal intercalation-DBR-metal structure in the waveguide can stimulate multiple optical Tamm states; and the multiple optical Tamm states are coupled to one another to form multiple split absorption peaks, so that multi-channel narrow-band perfect absorption is achieved. The surface plasma resonance absorber disclosed by the invention is compact in structure and easy to process and prepare with high quality, and has a relatively good application prospect in the fields of dangerous substance detection, hyperspectral multi-frequency imaging, coherent thermal radiation, a stealth technology and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

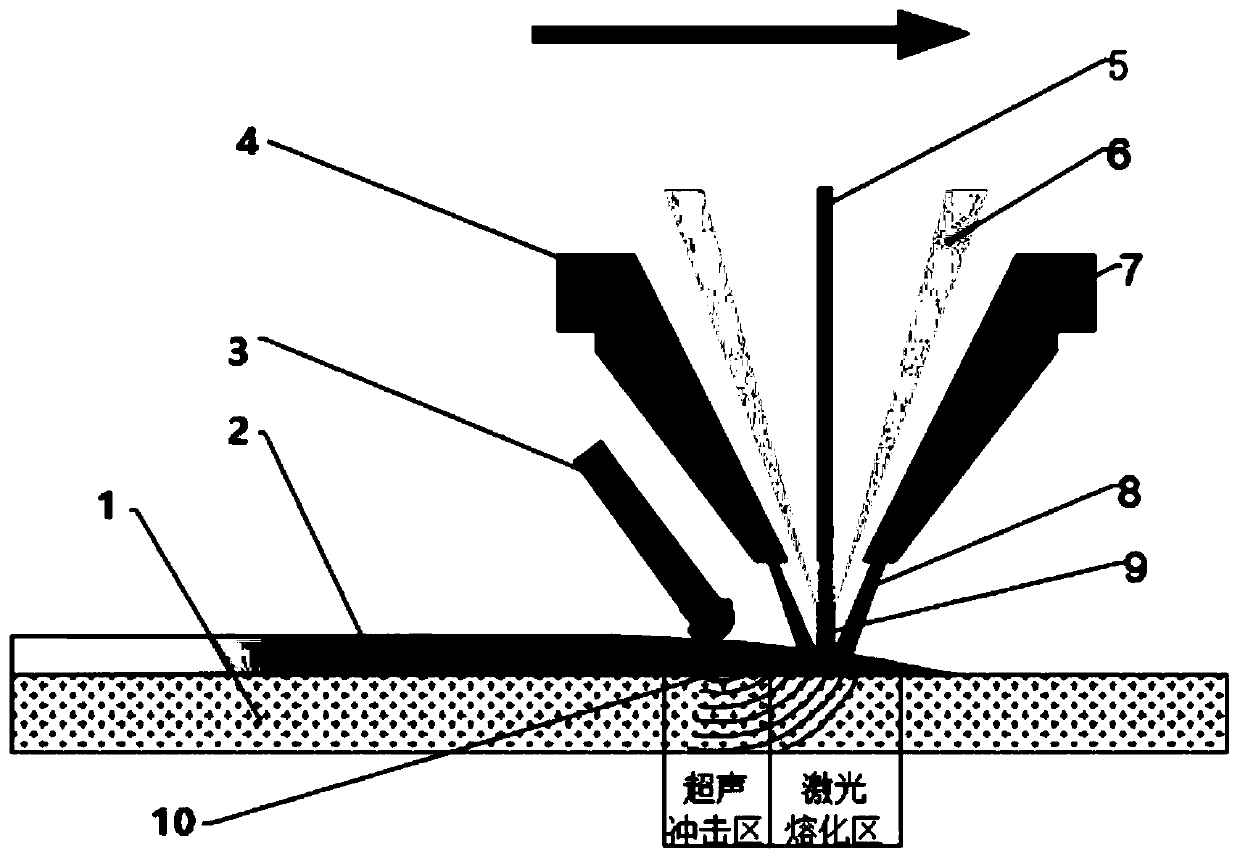

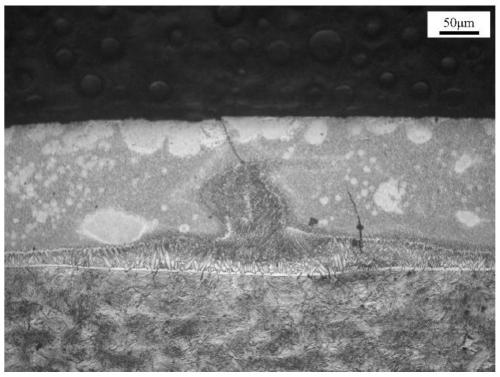

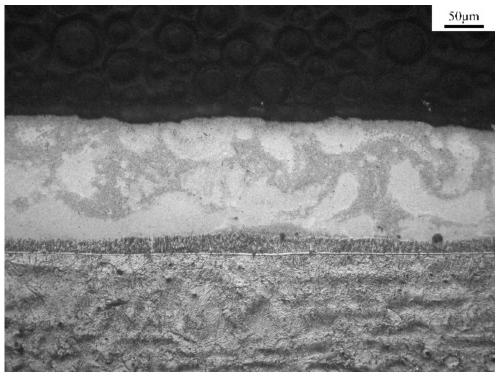

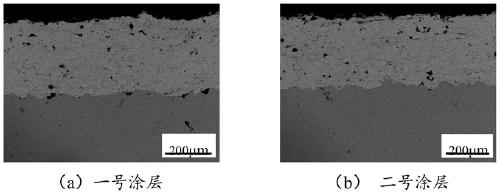

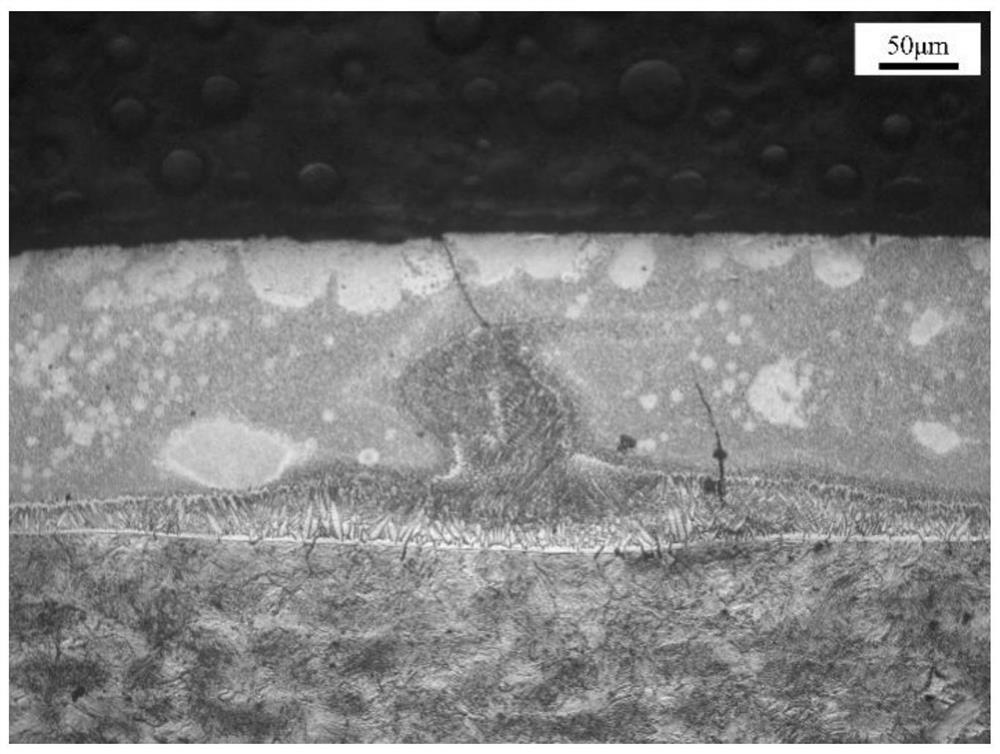

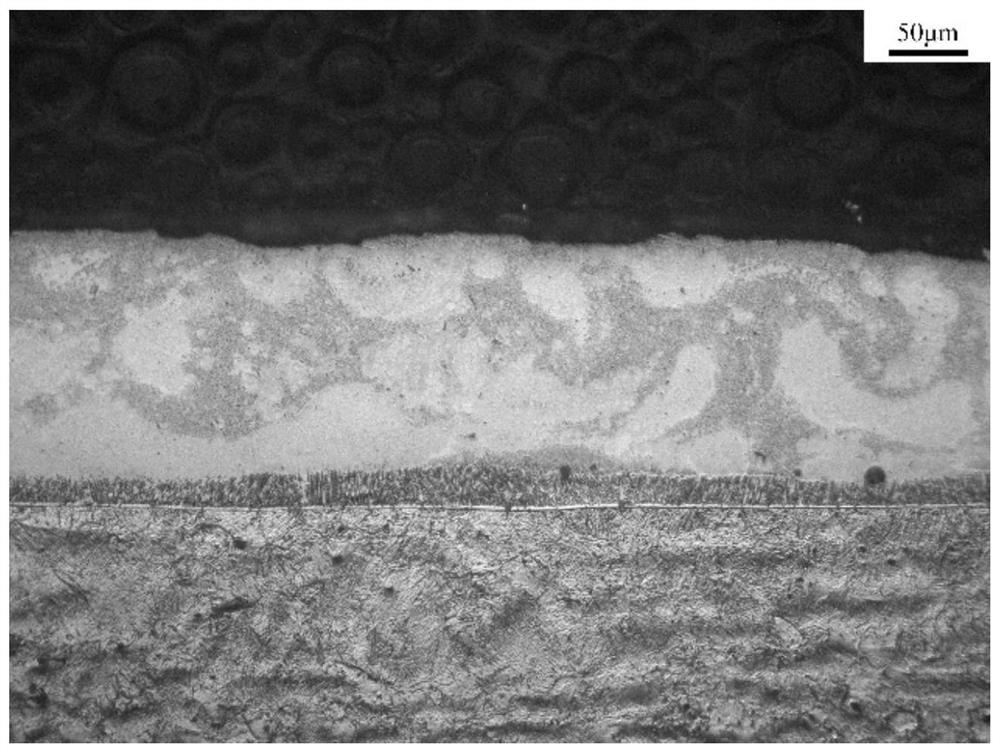

Method for preparing amorphous coating in manner of assisting in ultrahigh-speed laser cladding by ultrasonic peening

ActiveCN111286733ALow dilution rateHigh content of amorphous phaseMetallic material coating processesUltra high speedMetallurgy

The invention provides a method for preparing an amorphous coating in a manner of assisting in ultrahigh-speed laser cladding by ultrasonic peening. The ultrahigh-speed laser cladding technology and the ultrasonic peening micro forging technology are integrated and combined to be used, a workpiece is subjected to oil removal and rust removal, and the workpiece is mounted and located; amorphous metal powder is dried and is contained in a powder feeder; the laser power, the light spot diameter, the walking speed and the power feed speed are set, and ultrahigh-speed laser cladding equipment is started; the ultrasonic power and the ultrasonic frequency are set, ultrasonic peening equipment is started, and an ultrasonic peening head acts on the specific area of the solidified coating; claddingprocessing is finished, and the amorphous coating is naturally cooled to the room temperature; and the amorphous coating is cleaned by absolute ethyl alcohol, and the amorphous coating is aired afterbeing cleaned. By means of the method, the principles of rapid solidification of the ultrahigh-speed laser cladding technology, control solidification, stress elimination and micro defect eliminationof the ultrasonic peening micro forging technology and the like are fully utilized, and high-efficiency and high-quality preparation of the amorphous coating is achieved.

Owner:HARBIN ENG UNIV

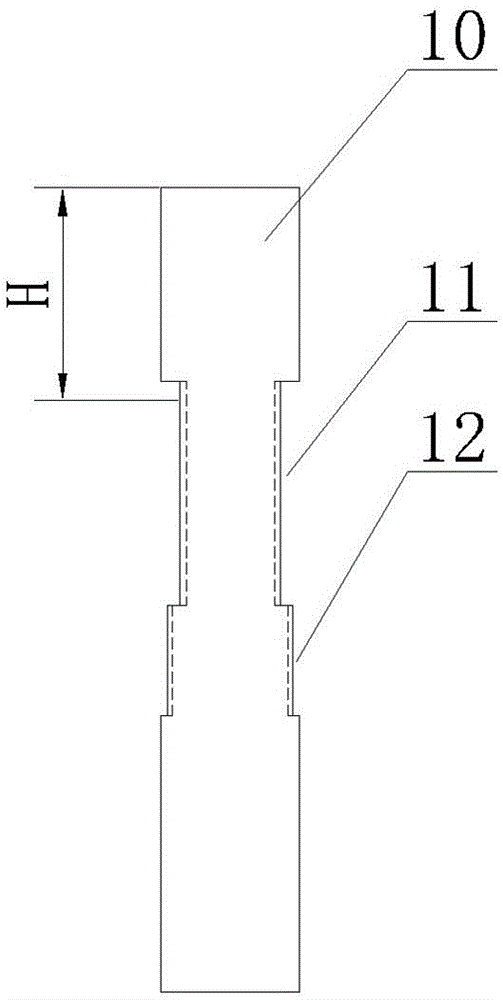

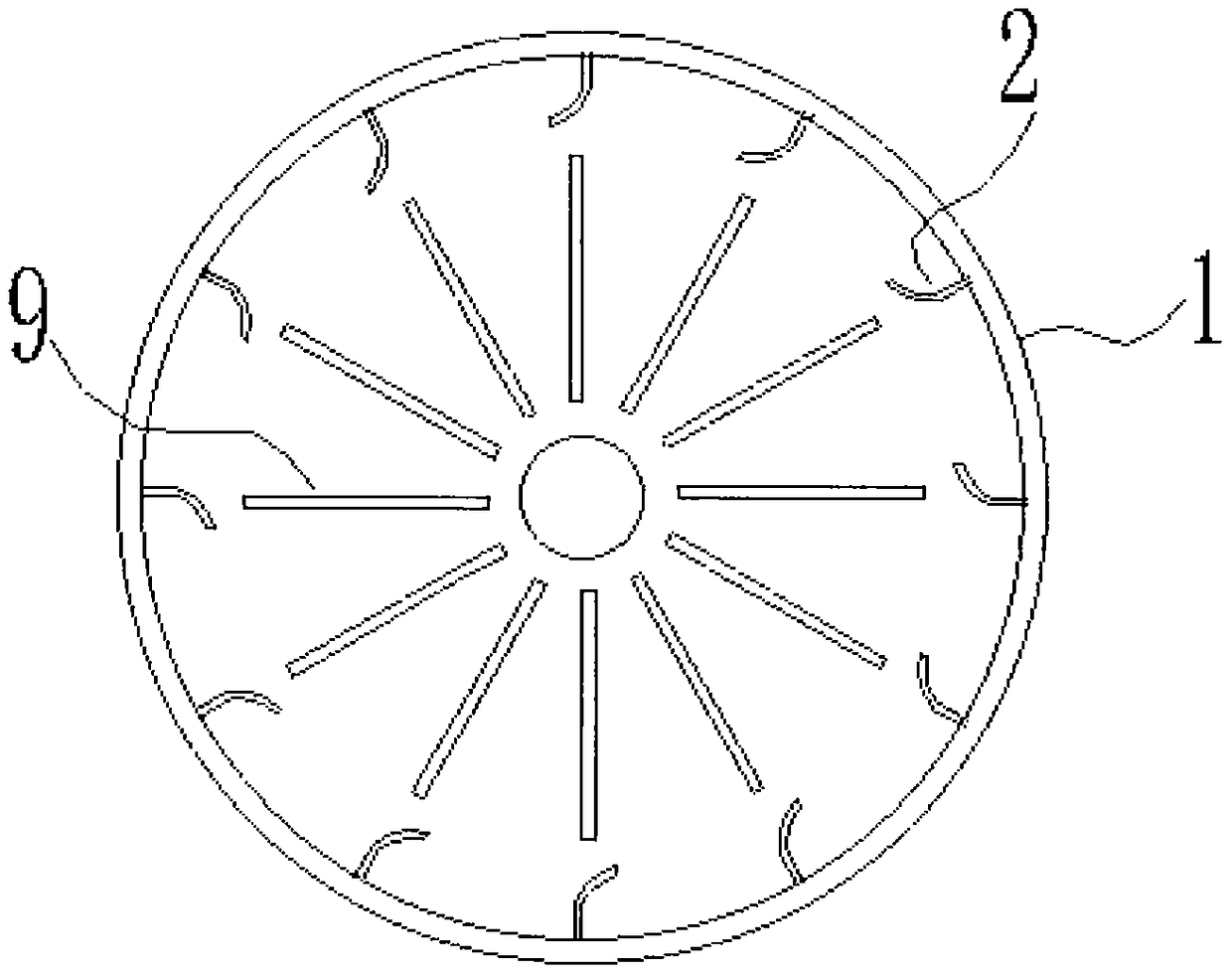

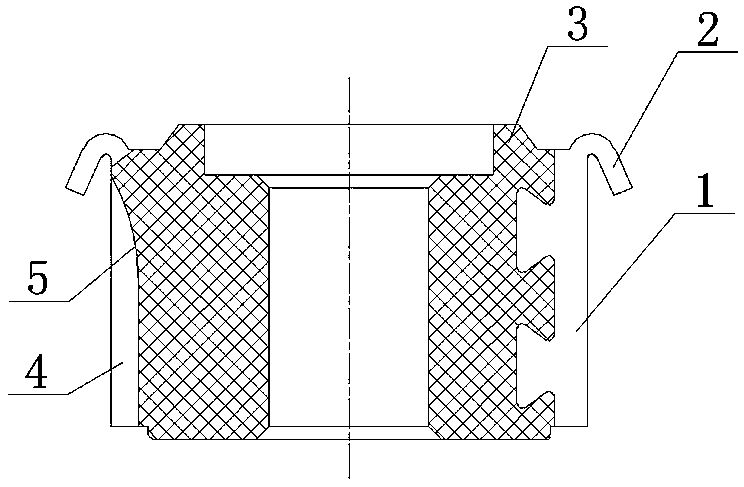

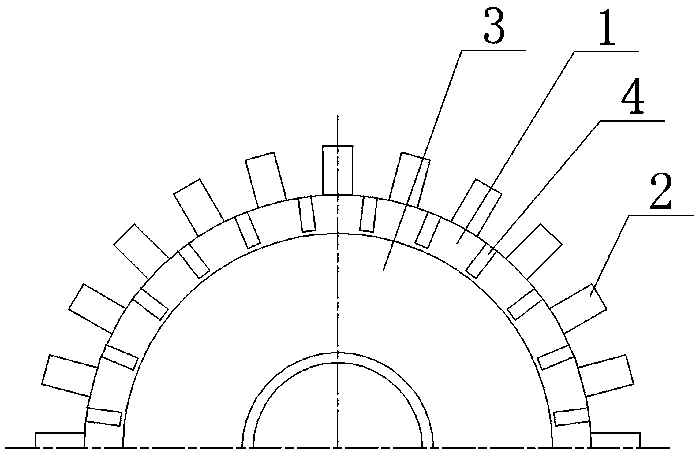

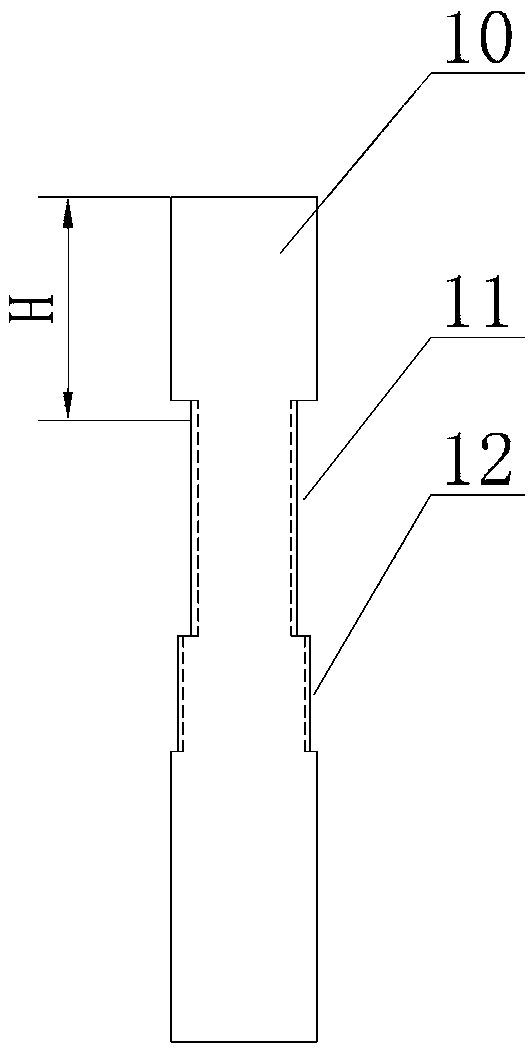

Hook-shaped commutator

ActiveCN106451001AJob impactImprove bonding fastnessRotary current collectorDynamoelectric machine connectorsPunchingMilling cutter

The invention discloses a hook-shaped commutator composed of a bakelite powder base and commutating copper sheets. The hook-shaped commutator is characterized in that insulation between the commutating copper sheets is carried out by milling insulating grooves with a circular milling cutter between, the tops of the insulating grooves is subjected to arc transition so as to be prevented from being pierced; the commutating copper sheets are elongated bodies before the insulating grooves are milled and hooks are formed; the outer side of each elongated body is an arc surface, the height of the top, where a hook is to be formed, of the elongated body is H; the middle positions of the left and right sides of the elongated body are provided with connected upper and lower punching notches respectively, the distance between the top of the upper punching notch and the top of the elongated body is less than H; the width of the lower punching notch is narrow; the width of the upper punching notch is wide; the upper punching notch has a punching slope in the radial direction, the punching slopes of adjacent elongated bodies define a tapered mouth with an inward large end. The hook-shaped commutator prevents glue from entering the insulating grooves, enables high-quality production and high mechanical strength, and facilitates automatic insertion and mass production.

Owner:ZHEJIANG SONGPU COMMUTATOR

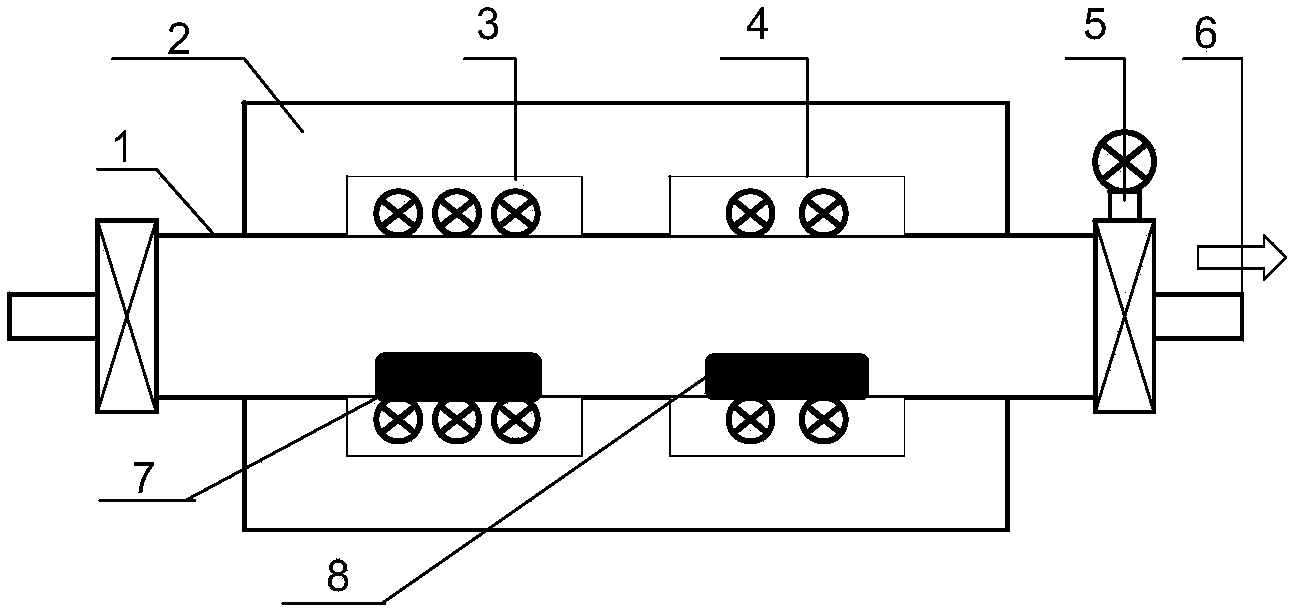

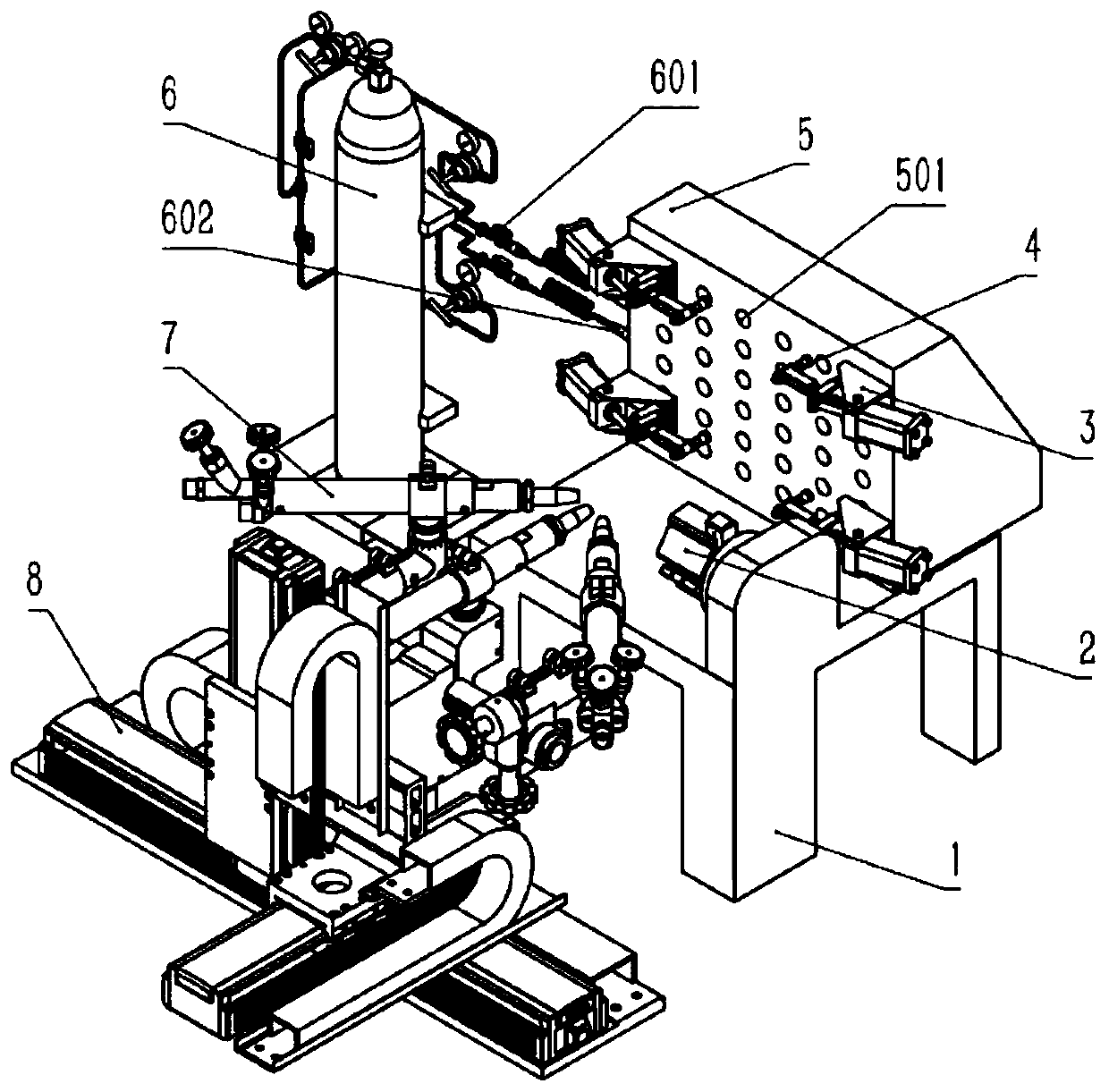

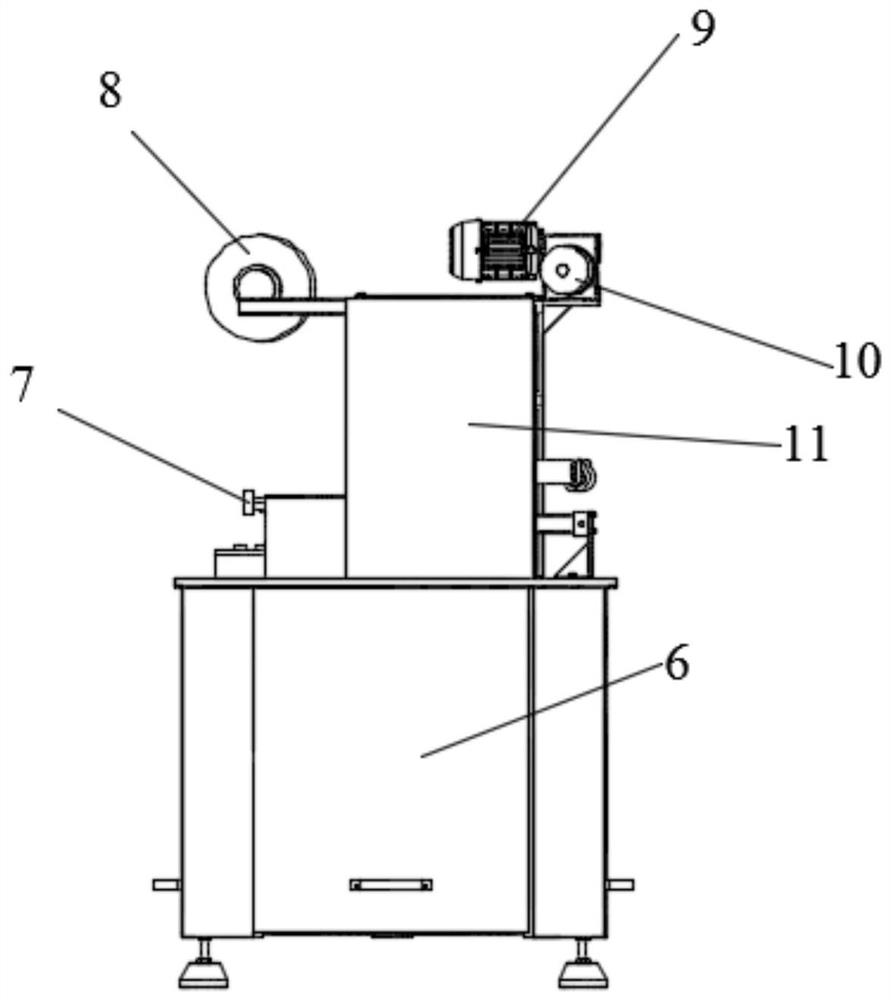

Ultrasonic flame painting system and manufacturing method of iron-based amorphous coating

ActiveCN110144542AImprove spraying efficiencyHigh quality preparationMolten spray coatingInternal cavityProduct gas

The invention discloses an ultrasonic flame painting system and a manufacturing method of a high-quality iron-based amorphous coating. The ultrasonic flame painting system comprises an ultrasonic flame spray gun and air cooling equipment; the air cooling equipment comprises a base, a cooling table and a storage cylinder; the cooling table is a hollow structure which is internally provided with a cavity; multiple air outlets which communicate with the internal cavity of the cooling table are formed in the cooling table; the storage cylinder communicates with the internal cavity of the cooling table; a solenoid valve is arranged on an air inlet pipe; a temperature sensor is further arranged on the cooling table; the temperature sensor is used for monitoring painting temperature; when the high-quality iron-based amorphous coating is manufactured, temperature of a base plate in the painting process is monitored by the temperature sensor in real time; the flow of cooling air entering the cooling table is controlled by the solenoid valve, so that the temperature of the base plate is precisely adjusted during the painting process; the amorphous coating with high density and high amorphouscontent is obtained; painting efficiency is greatly improved; and the high-quality iron-based amorphous coating can be effectively manufactured.

Owner:NANCHANG HANGKONG UNIVERSITY

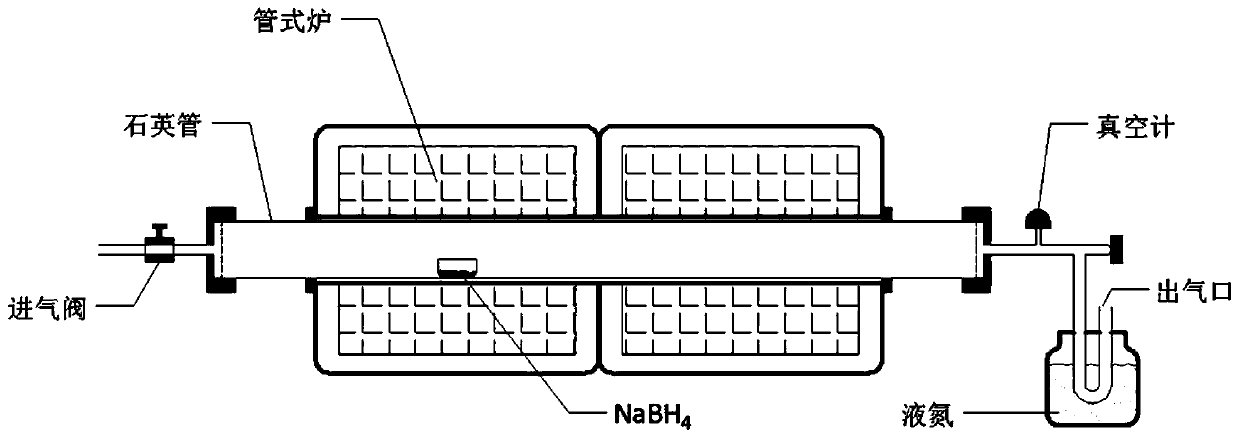

Method for preparing two-dimensional boron hydride nanosheet

The invention discloses a method for preparing a two-dimensional boron hydride nanosheet, and the method comprises the following steps of: placing a boron source in a vacuum reaction furnace, and obtaining the high-yield and super-stable two-dimensional boron hydride nanosheet in a quartz boat in a reducing atmosphere through a strict two-step or three-step sectional heating procedure under the condition of no metal substrate. According to the method, a step-by-step heating mode is adopted, under the condition that no metal substrate or other epitaxial substrates exist, the boron hydride nanosheet is obtained in the mode that the solid boron source is controllably decomposed through a two-step or three-step segmented heating method, and therefore the method for preparing the high-yield andsuper-stable two-dimensional boron hydride nanosheet is provided. The two-dimensional boron hydride nanosheet obtained by the method can be applied to multiple technical fields, including solar cells, energy storage and conversion devices, transistor devices, sensors and memristors.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

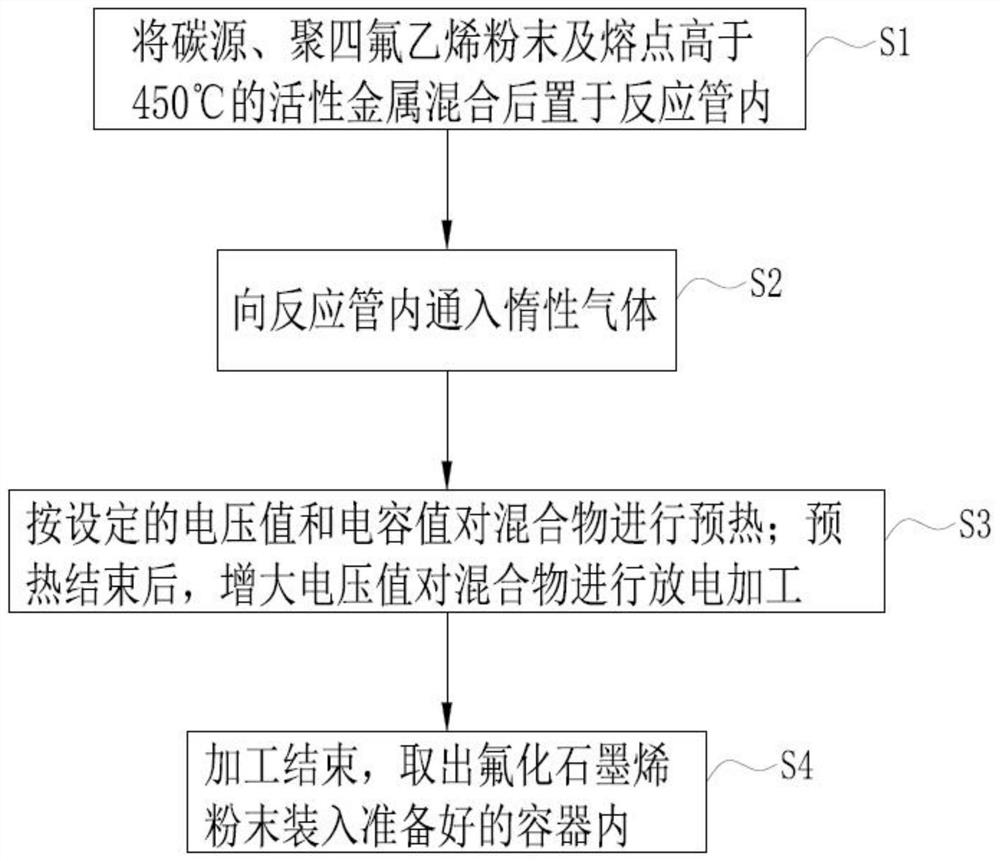

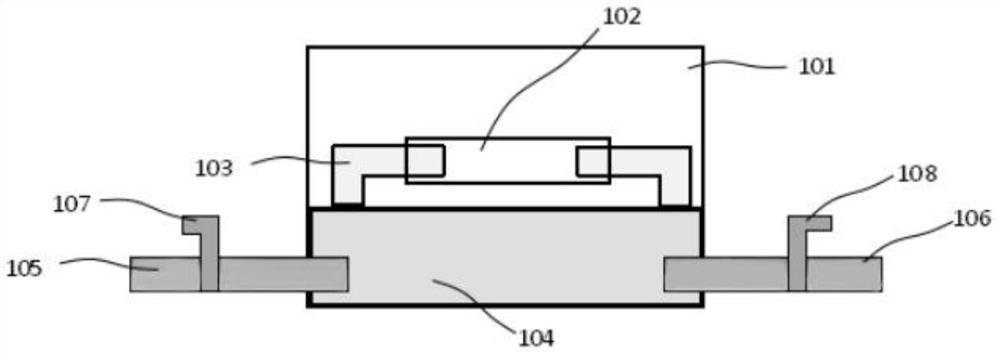

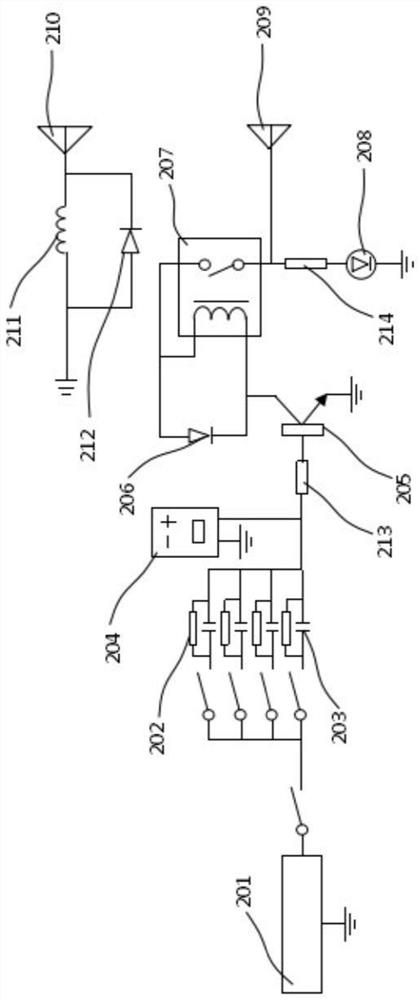

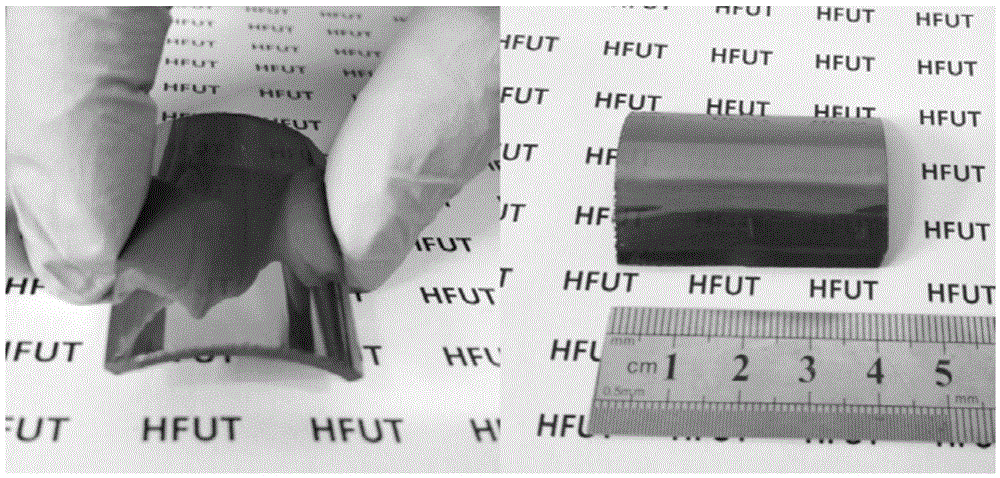

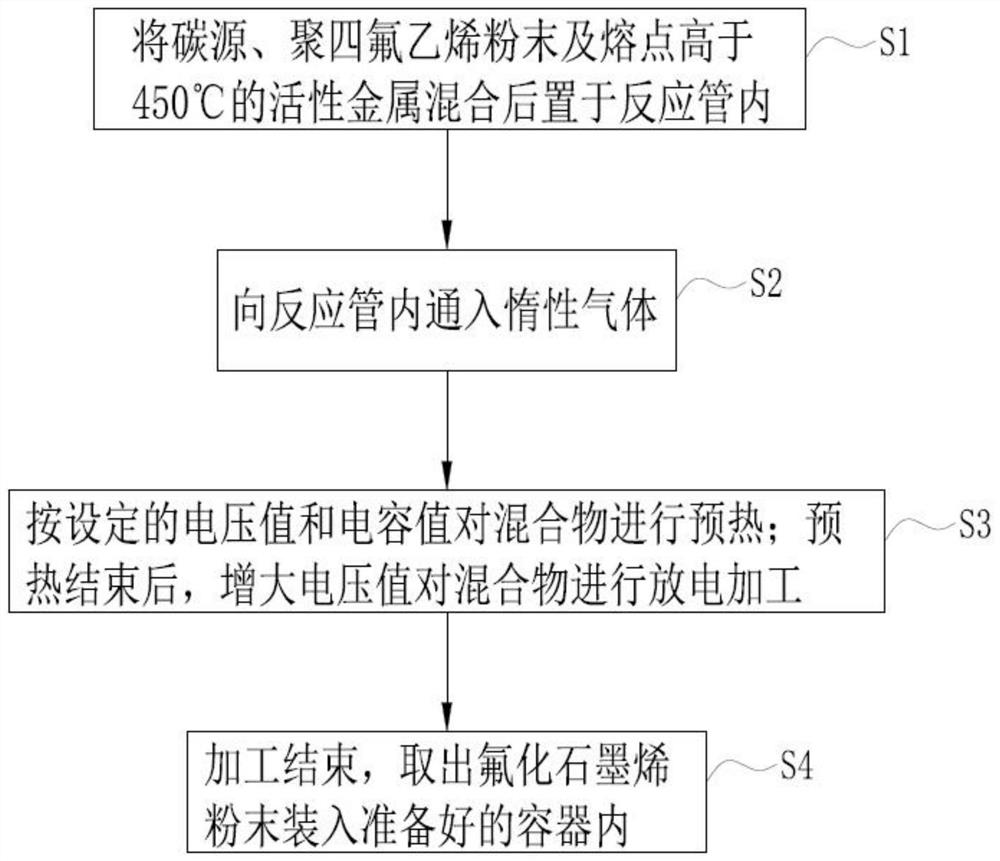

Mild discharge preparation method and device of fluorinated graphene

The invention discloses a mild discharge preparation method and device of fluorinated graphene, and relates to the technical field of graphene preparation. A chemical carbonization process and a physical stripping process are carried out by utilizing an electric field, so that the binding force of a graphite layer is overcome; the carbonized graphite carbon is successfully stripped into lamellas, so that the method can be suitable for almost all carbon-containing carbon sources, and the preparation raw materials are expanded to a carbon-based substance while high-efficiency and high-quality preparation of fluorinated graphene is ensured, namely, almost all carbon-containing substances can be used as raw materials of the process, so that the raw materials are wide in source and low in cost. The active metal is used as a catalyst and is electrified for preheating at first, so that the temperature of a carbon source and the temperature of the active metal are increased, and the metal activity is improved; then the voltage is increased, graphitization of the carbon source is achieved, reaction is rapid, reaction energy consumption is greatly reduced, the good conversion rate is achieved, the efficiency of preparing fluorinated graphene powder is high, and fluorinated graphene is prepared in a low-temperature environment. Therefore, low energy consumption is realized and the preparation cost is reduced.

Owner:GUANGDONG UNIV OF TECH

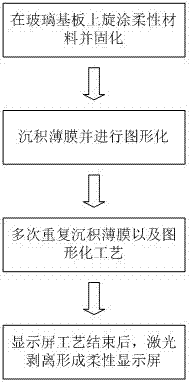

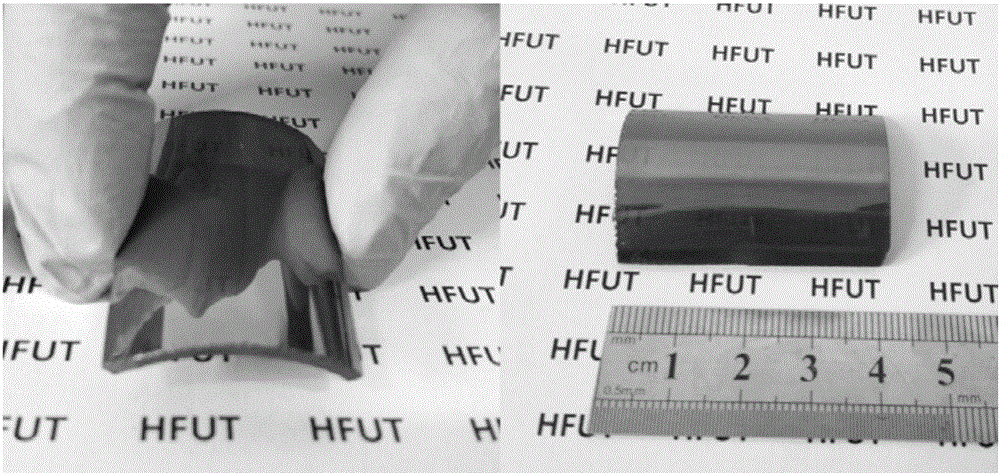

Large-area preparation method of perovskite films suitable for various substrate shapes

ActiveCN105655447AWide range of applicationsEasy to prepareFinal product manufactureSemiconductor devicesFilm materialNH3 compound

The invention discloses a large-area preparation method of perovskite films suitable for various substrate shapes. The method is characterized by comprising steps as follows: lead nitrate is used as a lead source, thiourea is used as a sulfur source, ammonia water is used as a complexing agent, the reaction speed and temperature are controlled, and lead sulfide films are produced on substrates in any shapes through chemical baths; then the lead sulfide films are converted into perovskite light absorption layer film materials with a solution immersion method or a chemical vapor deposition method. Perovskite light absorption layers are prepared through the chemical baths in combination with the solution immersion method or the chemical vapor deposition method, the method has the advantages of low cost, simplicity in operation, capability of realizing large-area amplification and the like, meanwhile, the prepared films are not affected by the substrate shapes and materials, and the high-quality perovskite films can be prepared on rigid or flexible substrates in various complex shapes such as curved surfaces, spherical surfaces and the like.

Owner:HEFEI UNIV OF TECH

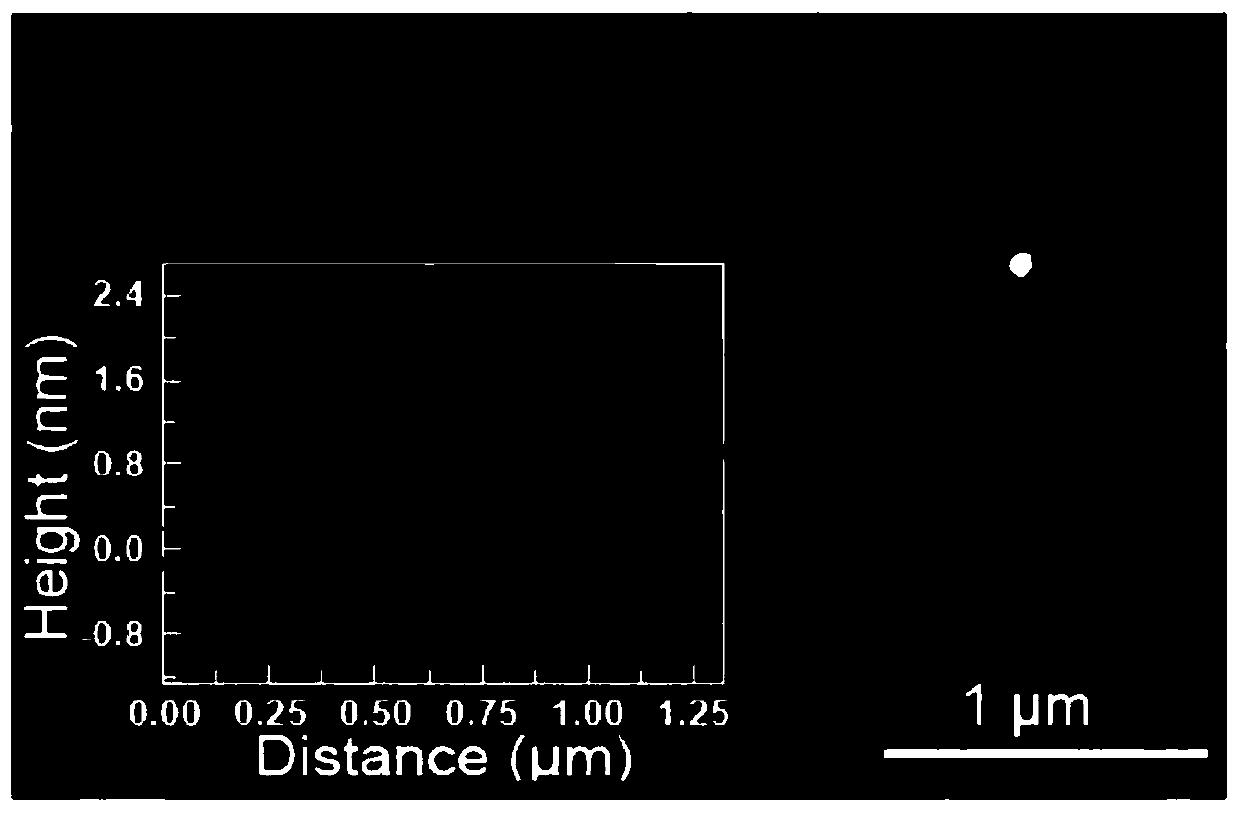

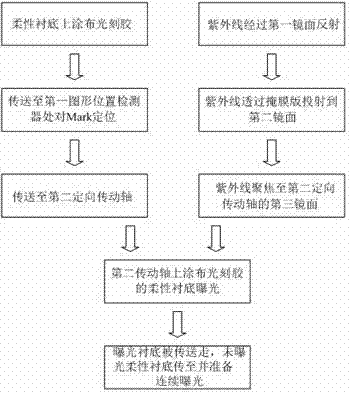

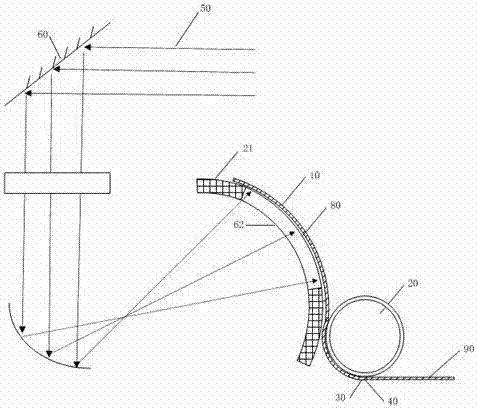

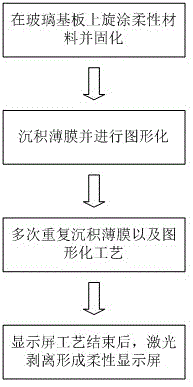

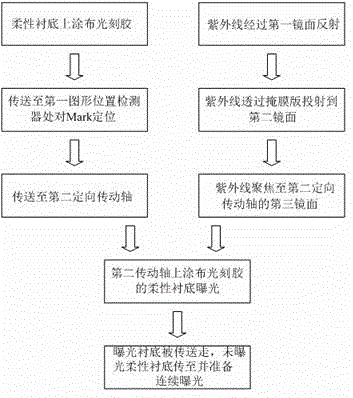

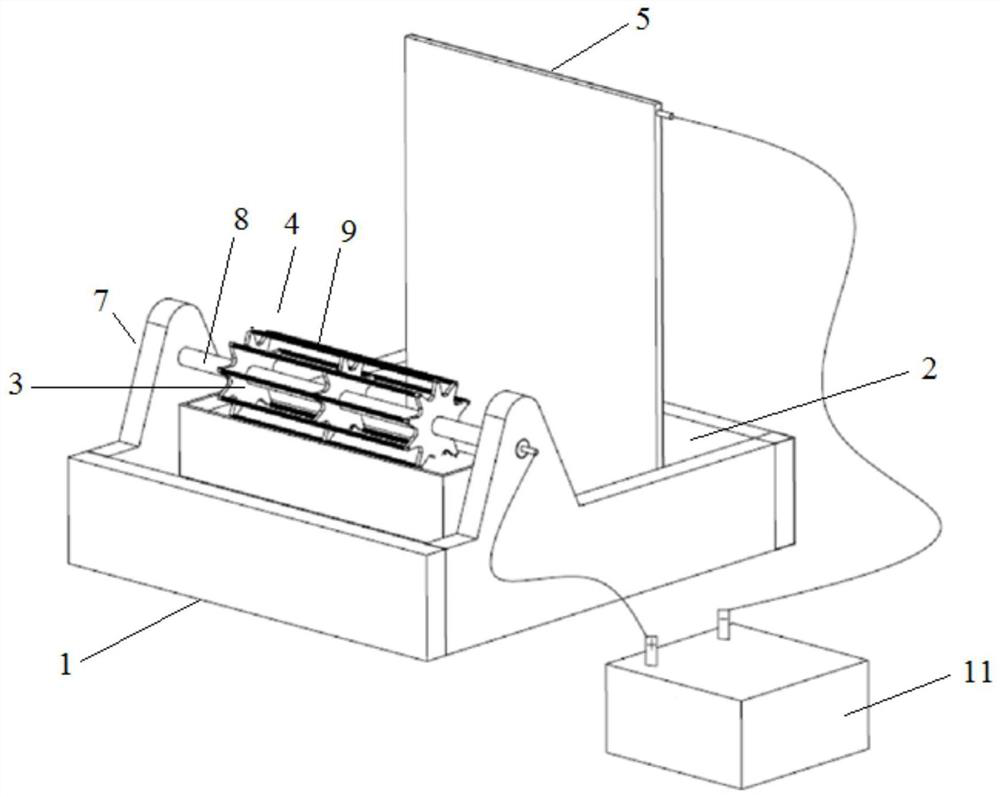

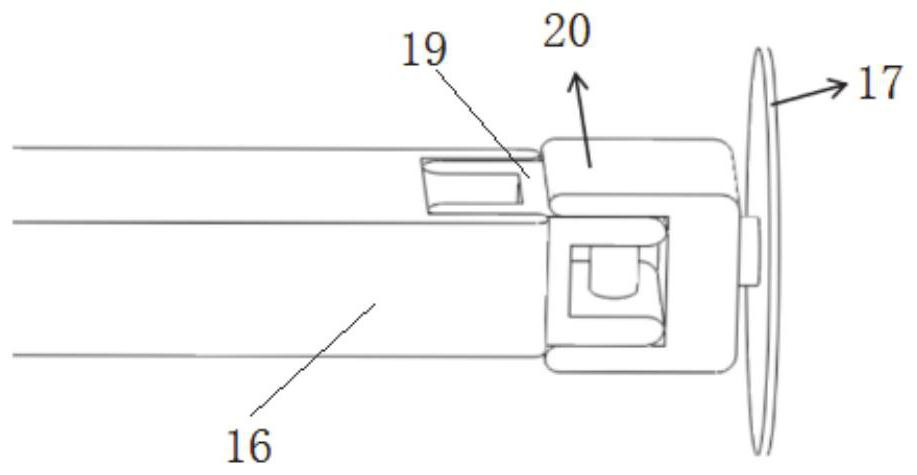

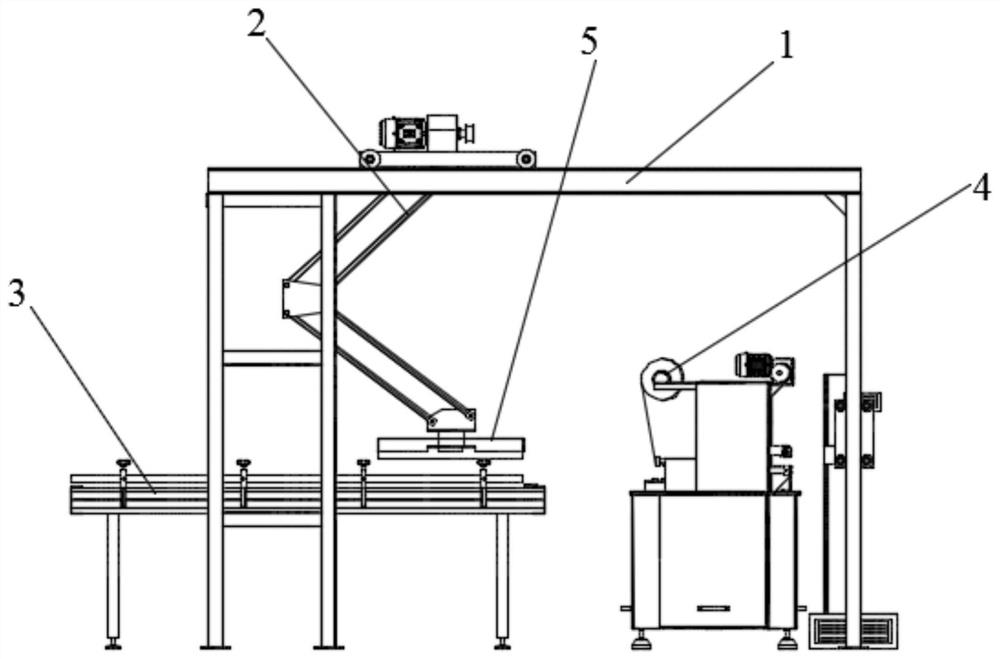

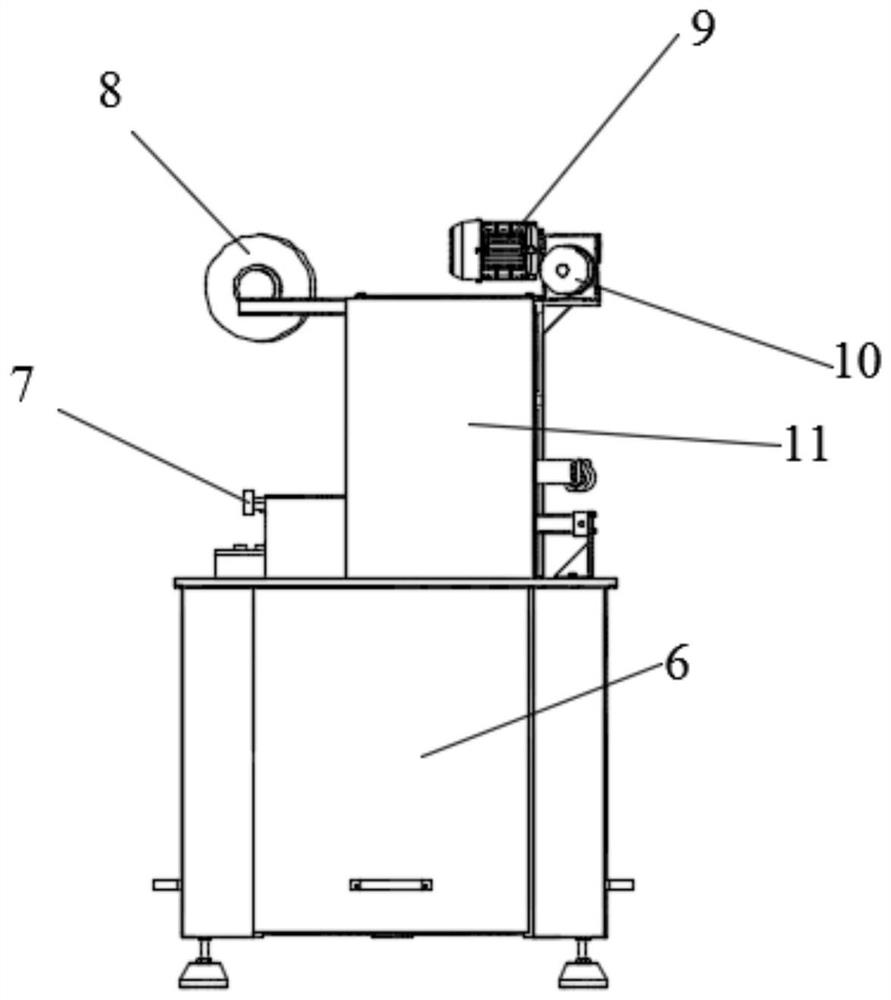

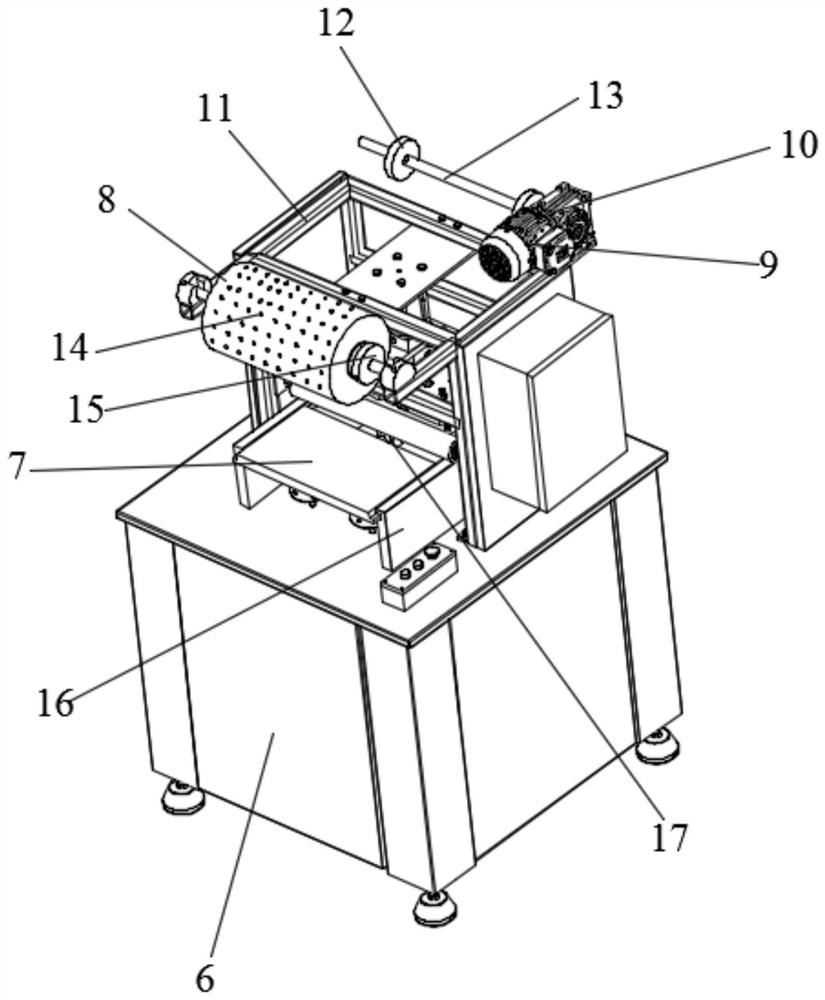

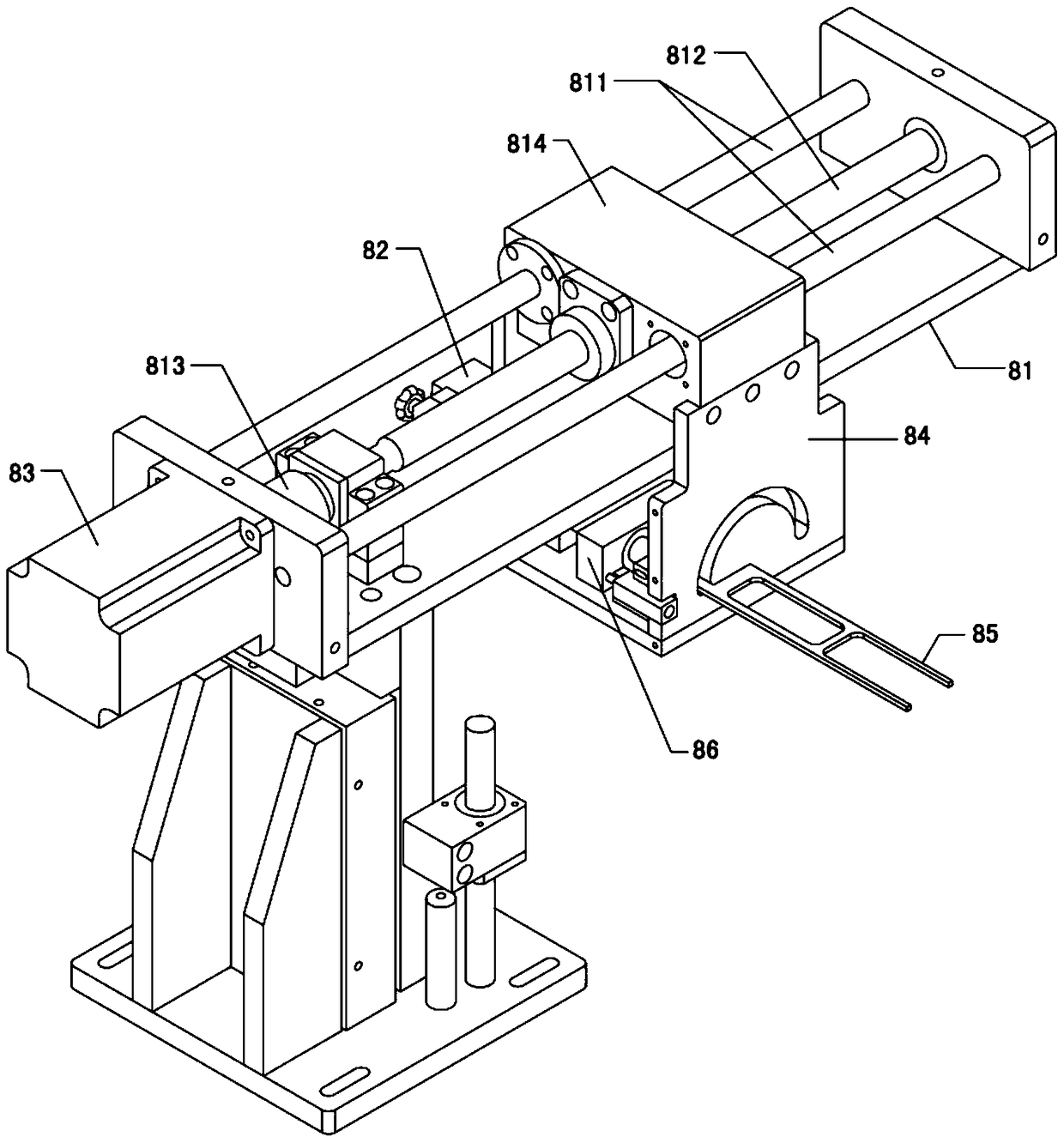

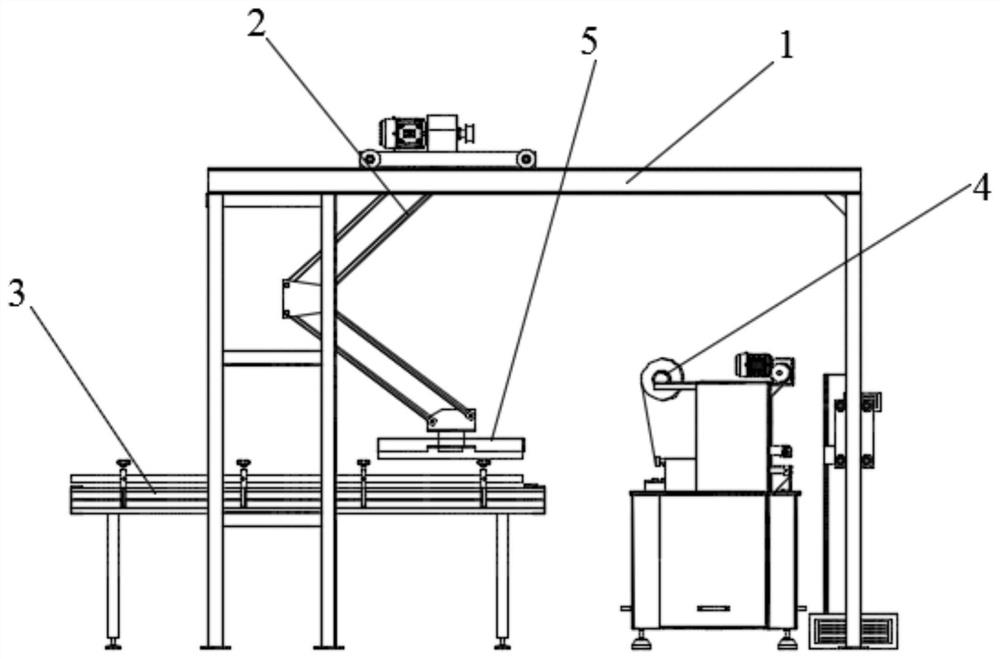

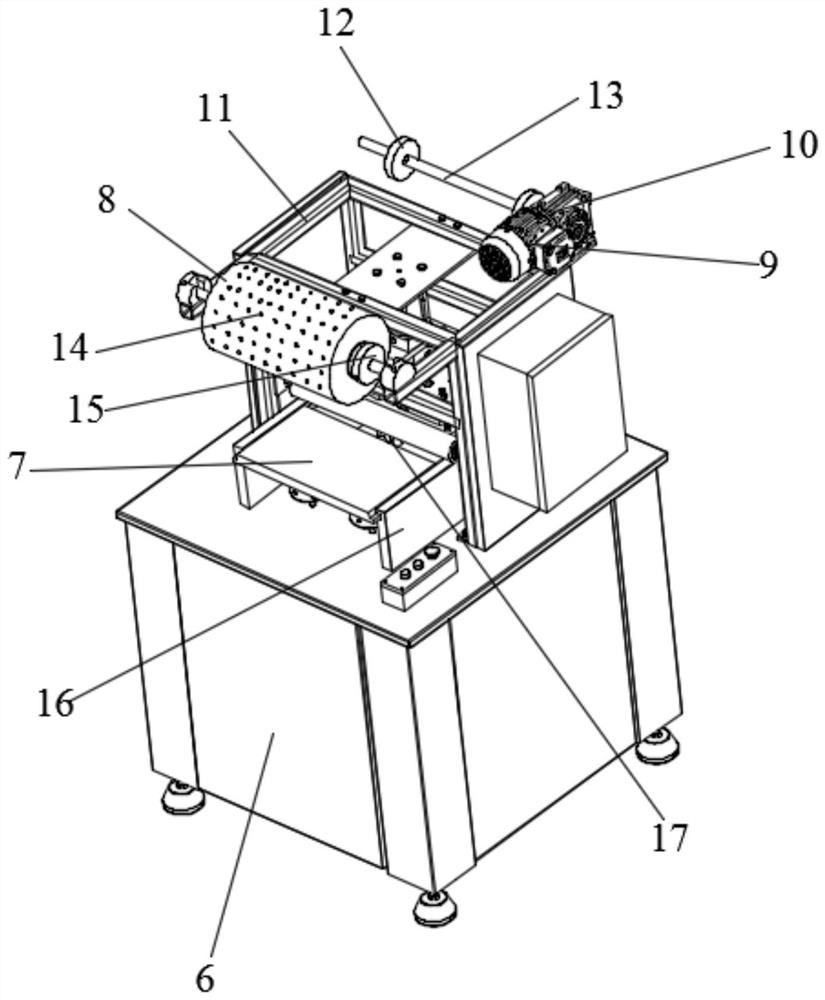

Roll-to-roll flexible substrate photolithography method and apparatus

ActiveCN105549340BHigh quality preparationFast and high quality manufacturingPhotomechanical exposure apparatusMicrolithography exposure apparatusProduction rateProcess equipment

The invention discloses a photoetching method and device of a roll to roll flexible substrate. By designing an exposure infrared transmission path and an exposure mode, photoetching of the flexible substrate is achieved, and process steps of attaching a traditional flexible substrate onto a glass substrate, final substrate stripping and the like are not needed; and on one hand, the process device cost is saved, and on the other hand, the production yield and the production rate are improved. The fabrication process is simple, the production rate can be effectively improved, and rapid and high-quality etching on the flexible substrate can be achieved on the condition of lower production cost. The device disclosed by the invention mainly comprises an infrared light source, a flexible substrate transfer system and a photoresist coating device. The device is simple in structure, and is convenient to use, maintain and fabricate.

Owner:SHANGHAI UNIV

Photoetching method and device of roll to roll flexible substrate

ActiveCN105549340AHigh quality preparationFast and high quality manufacturingPhotomechanical exposure apparatusMicrolithography exposure apparatusProduction rateProcess equipment

The invention discloses a photoetching method and device of a roll to roll flexible substrate. By designing an exposure infrared transmission path and an exposure mode, photoetching of the flexible substrate is achieved, and process steps of attaching a traditional flexible substrate onto a glass substrate, final substrate stripping and the like are not needed; and on one hand, the process device cost is saved, and on the other hand, the production yield and the production rate are improved. The fabrication process is simple, the production rate can be effectively improved, and rapid and high-quality etching on the flexible substrate can be achieved on the condition of lower production cost. The device disclosed by the invention mainly comprises an infrared light source, a flexible substrate transfer system and a photoresist coating device. The device is simple in structure, and is convenient to use, maintain and fabricate.

Owner:SHANGHAI UNIV

A kind of chemical vapor deposition preparation method of perovskite solar cell

ActiveCN104393109BEasy to operateImprove film qualityFinal product manufactureChemical vapor deposition coatingHeterojunctionSolar battery

The invention discloses a method for preparing a perovskite solar cell by chemical vapor deposition, which is characterized in that: a dense TiO2 film is deposited on the surface of the FTO film of FTO conductive glass as an electron transport layer; The perovskite light absorbing layer film is prepared by deposition method; the hole transport layer is prepared on the perovskite light absorbing layer film; the Ag electrode or Au electrode is evaporated on the hole transport layer as the top electrode, and the perovskite solar cell is obtained. . The preparation method of the present invention is simple, the cost is low, the film quality of the prepared perovskite light absorbing layer is high, the substrate coverage is good, the stability and repeatability are good, and the preliminary conversion of the prepared planar heterojunction perovskite solar cell The efficiency reaches 11%.

Owner:HEFEI UNIV OF TECH

Preparation method of guar gum nanofiber

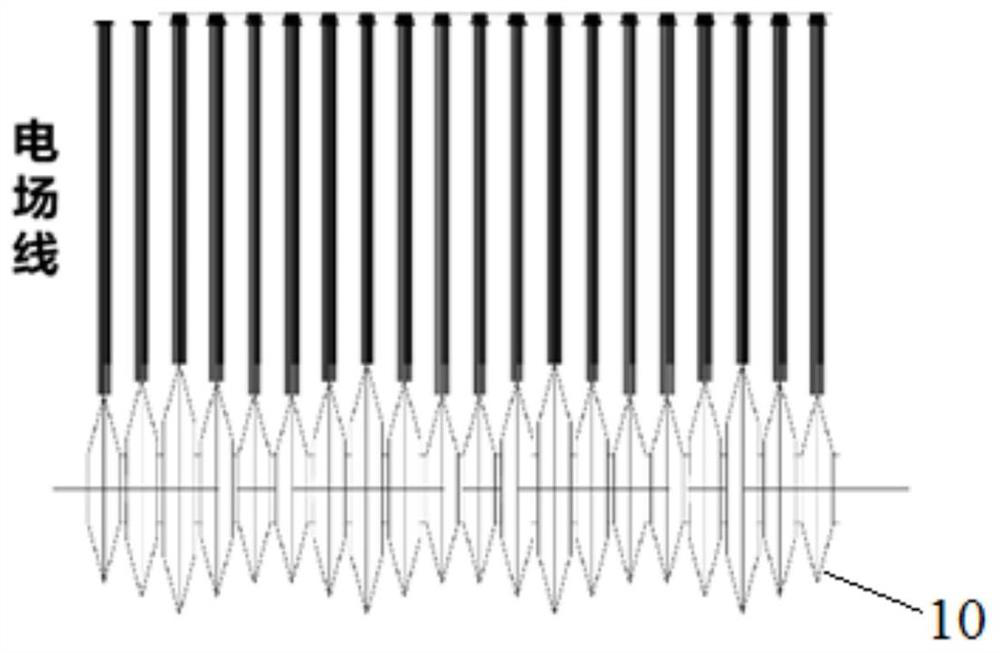

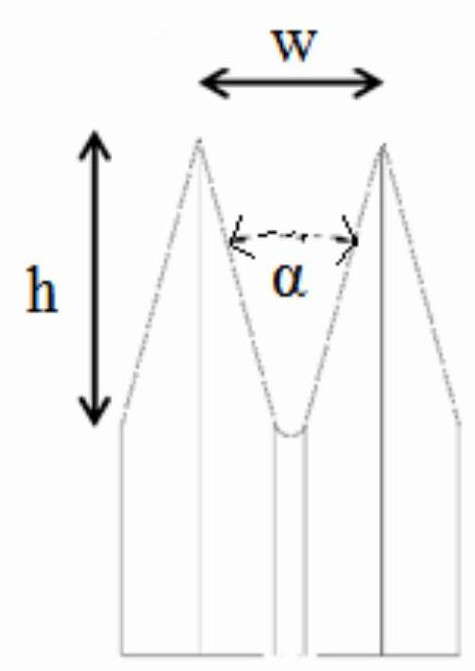

ActiveCN113061997ALarge specific surface areaBroad application spaceSpinning solution filteringFilament/thread formingPolymer scienceSpinning

The invention discloses a preparation method of guar gum nanofiber. The method comprises a step of spinning a guar gum spinning solution through electrostatic spinning, wherein the guar gum spinning solution is prepared by mixing a cationic surfactant, guar gum and water according to the weight ratio of (0.1-0.5): (0.5-4): (90-99). By adding a proper amount of the cationic surfactant into the guar gum solution, the surface tension of the guar gum solution is regulated and controlled, the chain entanglement degree of the guar gum solution is optimized, and the conformation of the guar gum solution is improved, so that the spinnability of guar gum electrostatic spinning is improved. The invention further provides an improved needleless electrostatic spinning device. By means of the device, the spinning efficiency and spinning quality of the guar gum spinning solution can be improved. The guar gum nanofiber prepared by the method has the diameter of 100 nm or below, relatively high dispersion and relatively high strength and rebound resilience.

Owner:DALIAN POLYTECHNIC UNIVERSITY

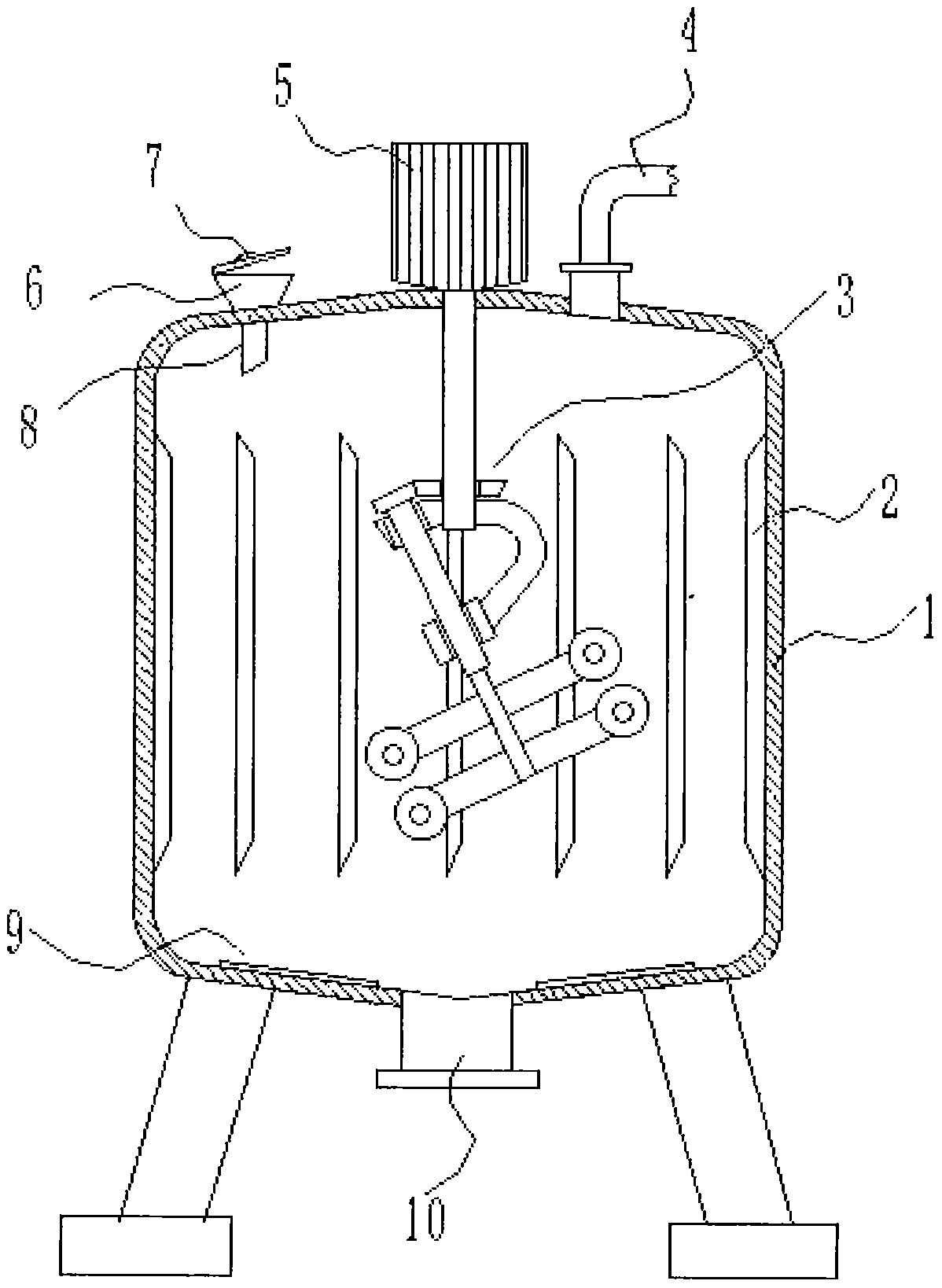

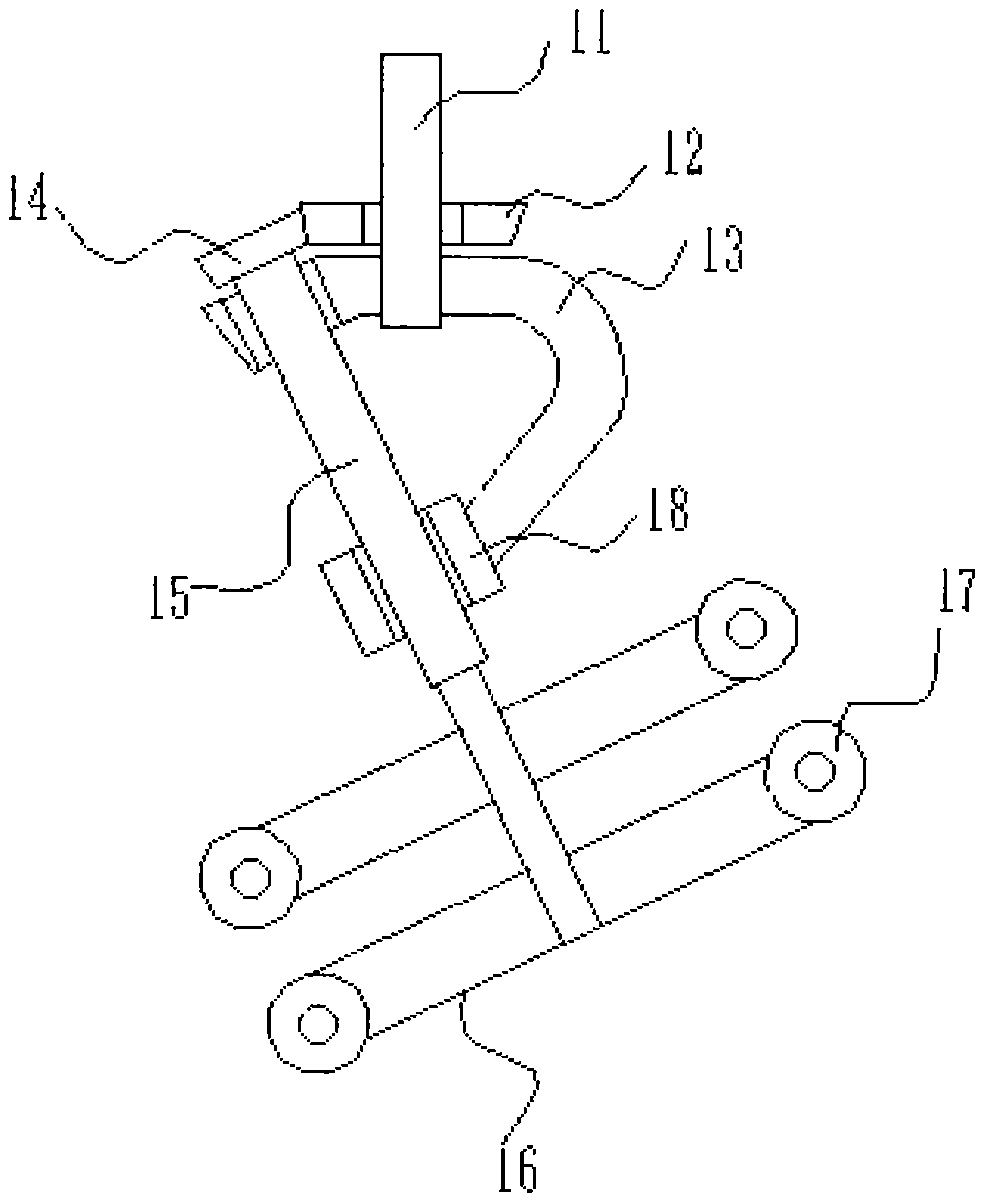

Energy-saving type garden nutrient solution mixing device

InactiveCN108404761AImprove solubilityHigh quality preparationShaking/oscillating/vibrating mixersRotary stirring mixersNutrient solutionRubbing

The invention discloses an energy-saving type garden nutrient solution mixing device which comprises a stirring tank. A stirring device for carrying out stirring is arranged inside the stirring tank,a liquid filling opening is formed in the top of the stirring tank, a hopper for adding solid raw materials is arranged on the top of the stirring tank, a discharge pipe is arranged at the bottom of the hopper, extends into the stirring tank and is used for conveying the solid raw materials into the stirring tank, a cover is mounted on the top of the hopper in a hinged manner, and a plurality of turbulent flow strips are further fixed onto the inner wall of the stirring tank; a liquid drain pipe for draining liquid is fixed to the bottom of the stirring tank, a valve is mounted on the liquid drain pipe, and a plurality of rubbing ridges are further fixed to the upper surface of the bottom of the stirring tank. The energy-saving type garden nutrient solution mixing device has the advantagesthat the solid raw materials can be effectively sufficiently dissolved, and accordingly nutrient solution can be prepared in a high-quality manner; extra solid raw material smashing mechanisms are omitted, accordingly, energy can be effectively saved, and the energy-saving type garden nutrient solution mixing device is light and simple in structure and can be widely used in nutrient solution preparation operation.

Owner:赵广海

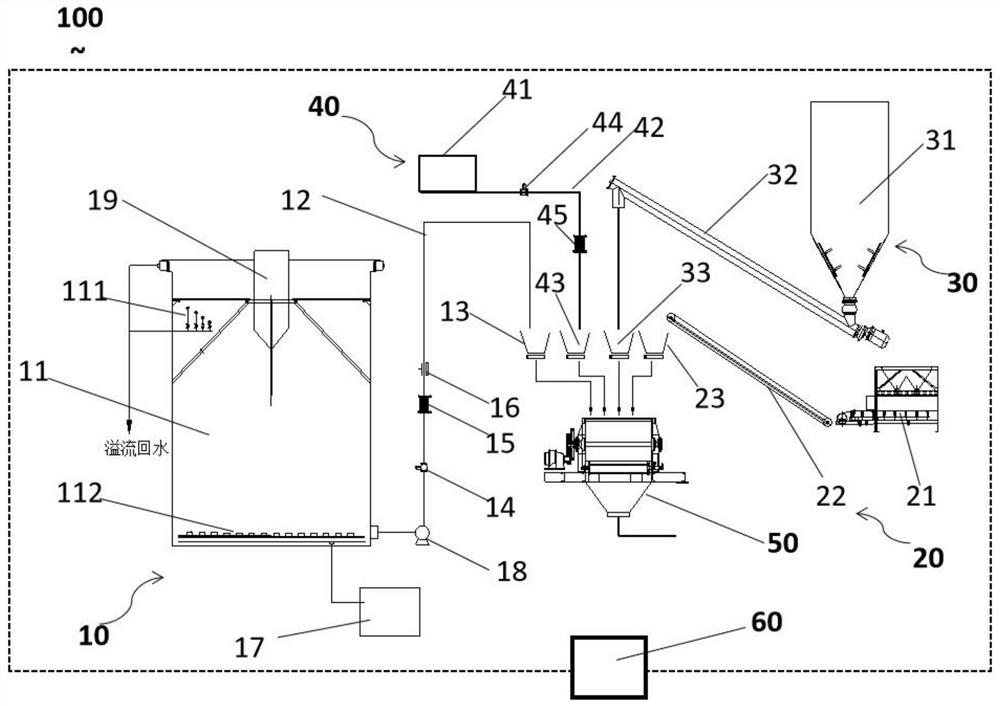

Precise preparation and filling system and method for coarse aggregate and tailing slurry

PendingCN113202551AMade preciselyPrecise preparation of filling methods, using static meteringSolid waste managementMaterial fill-upAutomatic controlControl system

The invention provides a precise preparation and filling system and method for coarse aggregate and tailing slurry. The precise preparation and filling system for the coarse aggregate and the tailing slurry comprises a tailing slurry dense storage and metering system, a coarse aggregate metering and feeding system, a cement metering and feeding system, a concentrated water metering and feeding system, a filling slurry preparation system and an automatic control system, wherein the filling slurry preparation system and the automatic control system are correspondingly connected with all the systems. According to the precise preparation and filling method for the coarse aggregate and the tailing slurry, a static metering-periodic preparation circulating process is adopted, so that each filling material can be accurately metered; the stirring time of a stirrer can be set at will, full stirring of the filling materials is guaranteed, and high-quality preparation of filling slurry is guaranteed; the technical defects of poor filling slurry preparation quality, poor slurry pipeline conveying reliability, high filling cost and the like caused by low filling material metering precision, large errors, large sand discharging concentration fluctuation of tailing thickening equipment and the like in the conventional coarse aggregate cemented filling process in the prior art are effectively overcome.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

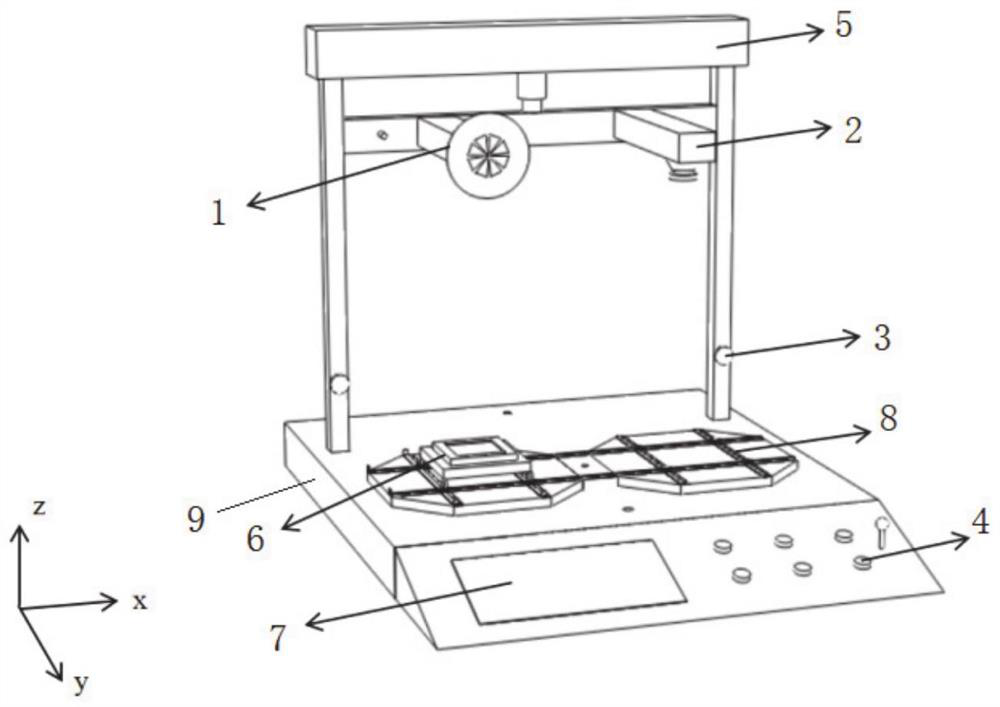

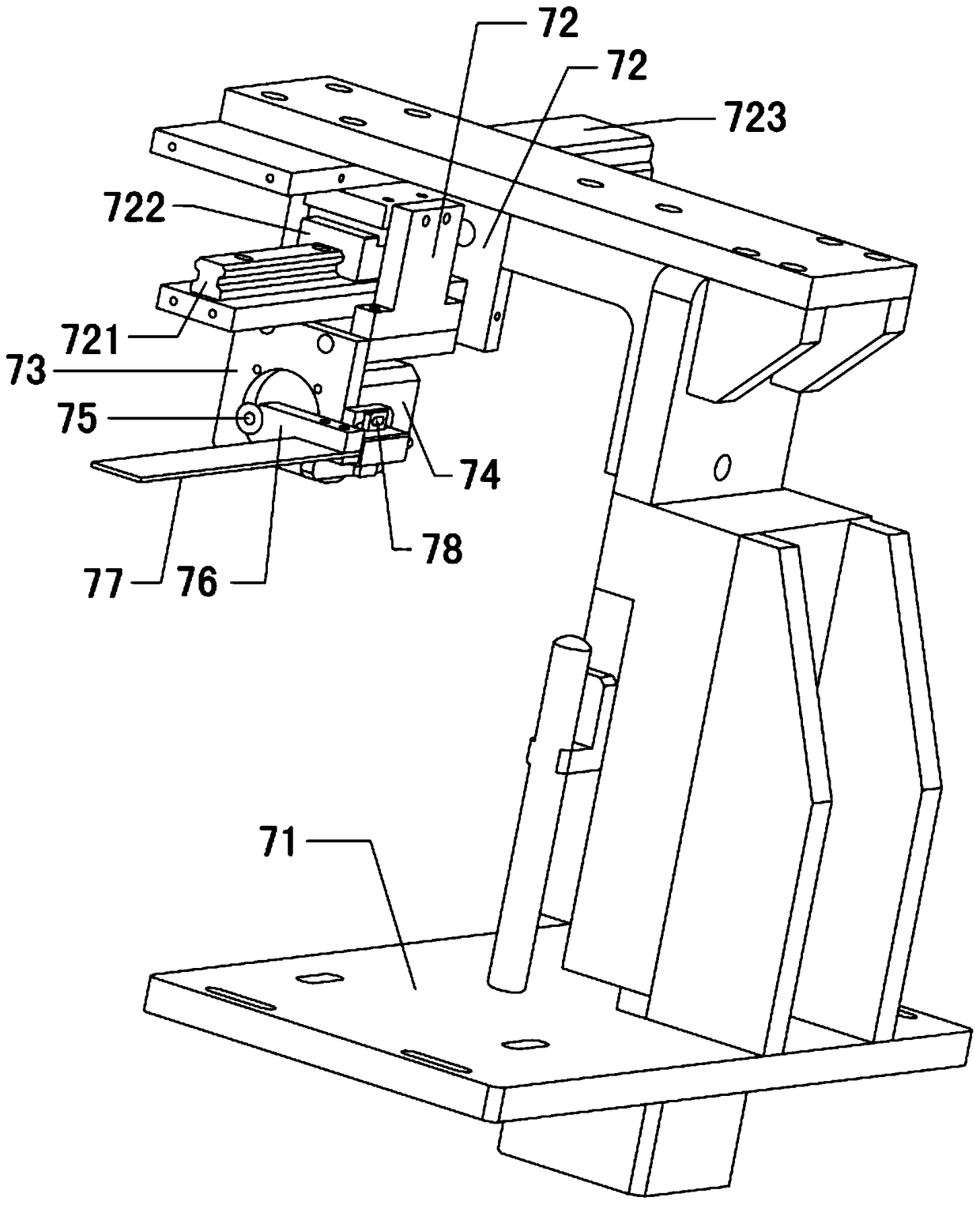

A device and method for preparing cement stone microscopic samples and testing bending and tensile strength

ActiveCN112014237BGuaranteed production quantityHigh precisionPreparing sample for investigationMaterial strength using steady bending forcesProcess engineeringUltimate tensile strength

The invention discloses a device and method for preparing microscopic samples of cement stone and testing the bending and tensile strength, including a workbench, a support frame and a chute track are fixedly arranged on the workbench; a grinding and cutting assembly is fixedly arranged on the support frame for Grinding and cutting the sample to form a sample, and the support frame is also fixedly equipped with a test component to test the bending and tensile strength of the sample; the grinding and cutting component and the test component are both located above the chute track, and are used to fix the sample or the operating table of the sample It is set on the chute track and can move along the chute track.

Owner:SHANDONG UNIV +1

A Multi-Channel Tunable Tamm Plasma Perfect Absorber

ActiveCN105576384BHigh quality preparationCompact structureAntennasSurface plasmonStealth technology

The invention discloses a multi-channel tunable Tamm plasma perfect absorber, comprising: MIM waveguide and metal-DBR-metal intercalation-DBR-metal structure in the waveguide, wherein metal-DBR-metal intercalation-DBR-metal The thickness of the metal on both sides of the structure is different, with the metal intercalation as the center, the period numbers of the DBRs on both sides are N1 and N2 respectively. The invention is a novel multi-channel tunable Tamm plasmon perfect absorber, TM polarized light is incident from the left side, through the MIM structure, the Gap-SPPs can be efficiently excited in the waveguide, and the metal-DBR in the waveguide ‑Metal intercalation‑DBR‑metal structure can excite multiple optical Tamm states, and couple with each other to form multiple split absorption peaks, realizing multi-channel narrow-band perfect absorption. The surface plasmon absorber of the invention has a compact structure, is easy to process and has high-quality preparation, and has good application prospects in the fields of dangerous substance detection, hyperspectral multi-frequency imaging, coherent thermal radiation and stealth technology.

Owner:NANJING UNIV OF POSTS & TELECOMM

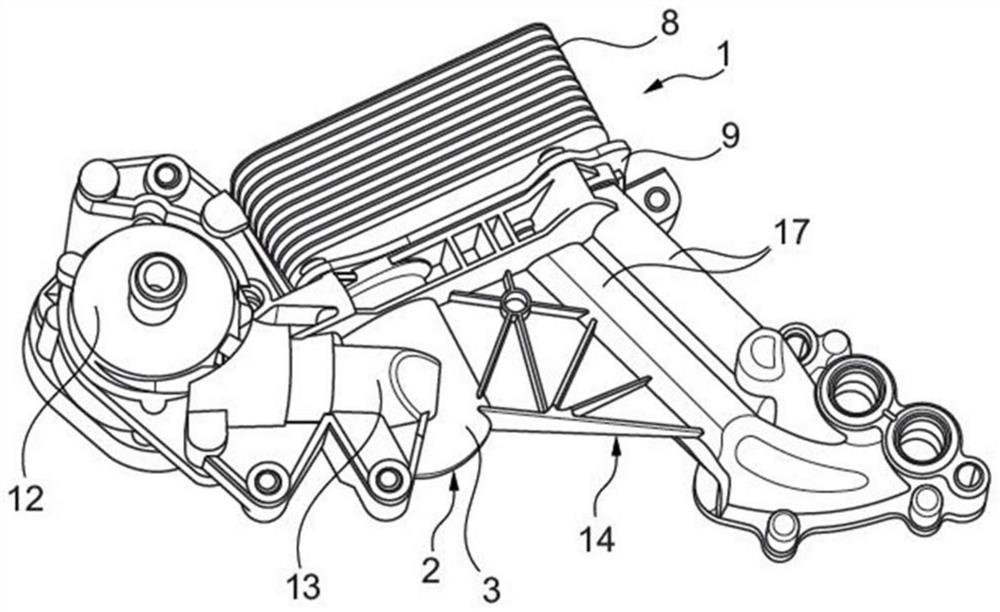

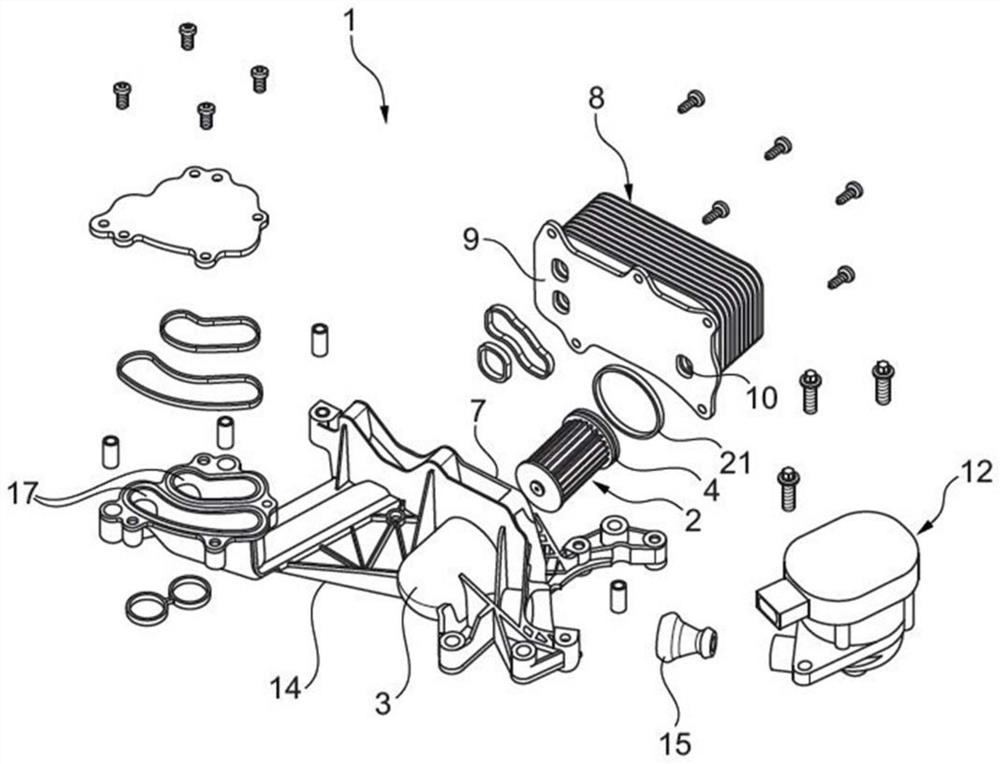

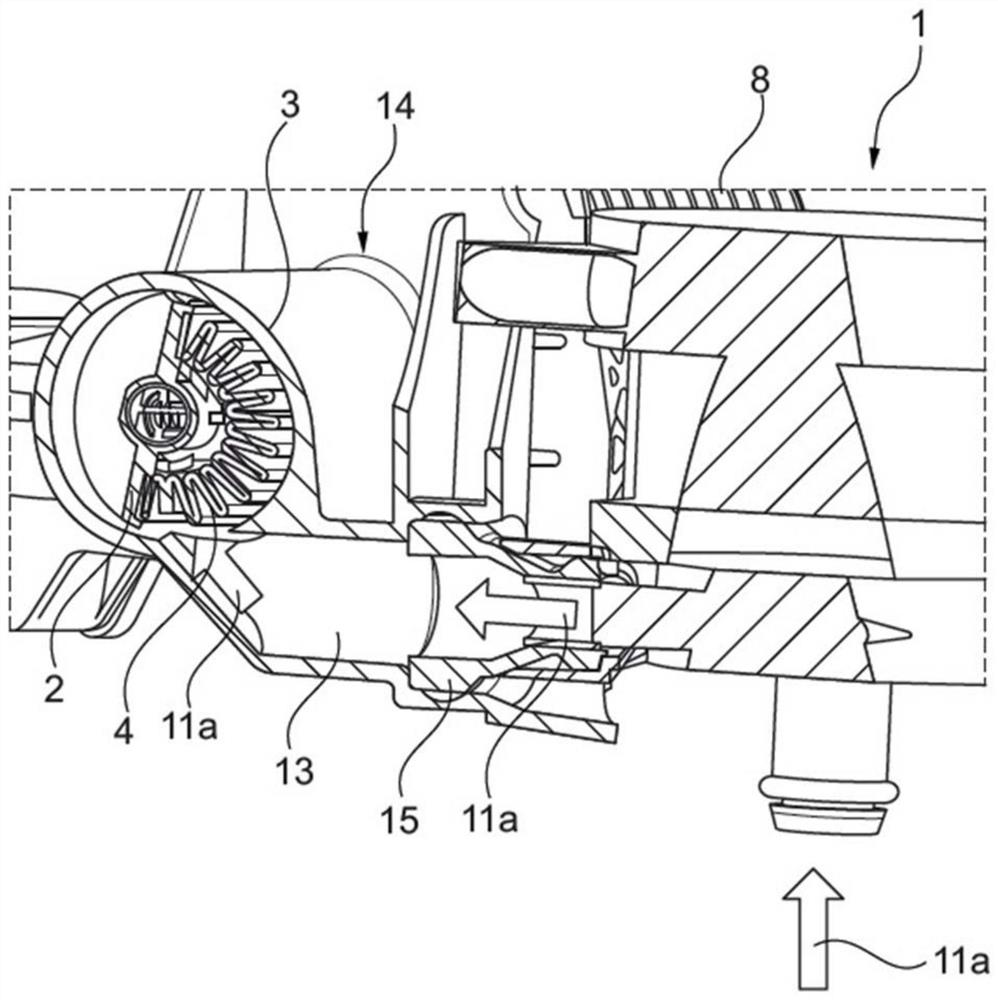

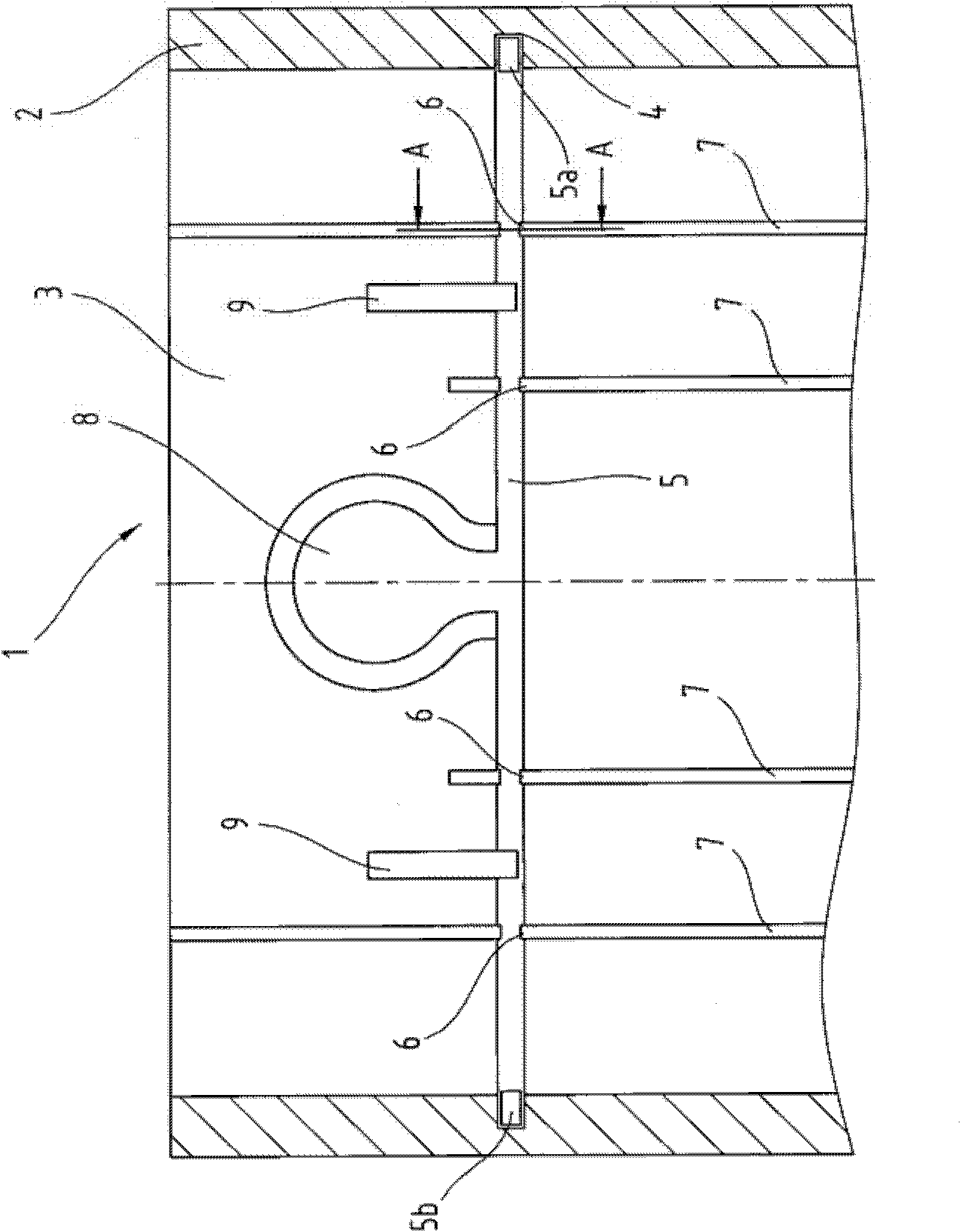

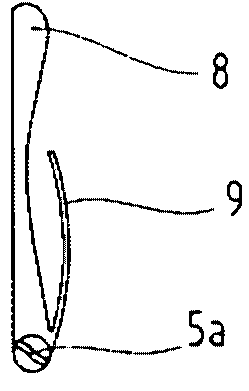

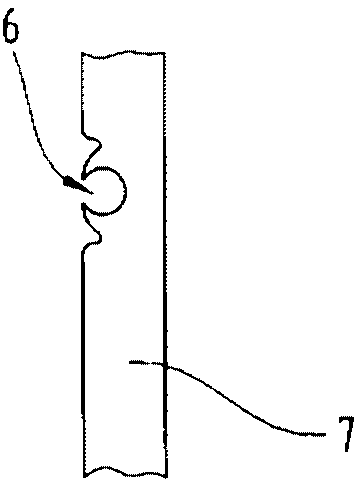

Oil cooler module

PendingCN112709808AQuality improvementRealize the interfaceGear lubrication/coolingMembrane filtersTemperature controlEngineering

The invention relates to an oil cooler module (1), comprising: a filter device (2) having a filter housing cavity (3) in which an annular filter element (4), which separates an unprocessed side (5) from a cleaned side (6), is arranged, wherein the filter housing cavity (3) comprises an opening (7) for inserting the annular filter element (4); and a heat exchanger (8) for controlling the temperature of oil (11) comprises a base plate (9). It is important for the invention that the filter device (2) is connected directly and tightly to the base plate (9) of the heat exchanger (8) via the filter housing cavity (3) of the the filter device (2) , such that the base plate (9) closes the opening (7) of the filter housing cavity (3). As a result, a previously required filter housing cover can be discarded, and pressure losses can be reduced.

Owner:MAHLE INT GMBH

Folding box

ActiveCN102348607BAvoid accidental foldingQuality improvementRigid containersEngineeringMechanical engineering

Owner:莱施咨询和投资有限公司

A large-area preparation method for perovskite thin films suitable for various substrate shapes

ActiveCN105655447BQuality improvementReduce stepsFinal product manufactureSemiconductor devicesThioureaLead nitrate

The invention discloses a large-area preparation method of perovskite films suitable for various substrate shapes. The method is characterized by comprising steps as follows: lead nitrate is used as a lead source, thiourea is used as a sulfur source, ammonia water is used as a complexing agent, the reaction speed and temperature are controlled, and lead sulfide films are produced on substrates in any shapes through chemical baths; then the lead sulfide films are converted into perovskite light absorption layer film materials with a solution immersion method or a chemical vapor deposition method. Perovskite light absorption layers are prepared through the chemical baths in combination with the solution immersion method or the chemical vapor deposition method, the method has the advantages of low cost, simplicity in operation, capability of realizing large-area amplification and the like, meanwhile, the prepared films are not affected by the substrate shapes and materials, and the high-quality perovskite films can be prepared on rigid or flexible substrates in various complex shapes such as curved surfaces, spherical surfaces and the like.

Owner:HEFEI UNIV OF TECH

A device for making fabric or wallpaper integrated wall panels

ActiveCN111890777BIncrease supplyExtended service lifeLamination ancillary operationsCovering/liningsMechanical engineeringWall plate

The invention discloses a production device for fabric or wallpaper integrated wall panels. The prepared wall panels are provided with the frame around the periphery of the slab, and the fabric or wallpaper is clamped on the frame and the frame. between the slabs, in this way, the service life of the wallboard can be effectively improved, the problems such as cracking at the edge of the fabric or wallpaper and the slab can be prevented, and the performance and life of the wallboard can be improved. , fabric or wallpaper supply mechanism, frame grabbing and clamping manipulator mechanism, flattening and rolling mechanism, operation conveying mechanism and glue spraying mechanism, which can realize the automatic production of wall panels and improve the production capacity and efficiency. When setting the frame, the pressing scraper is used and the sliding of the pressing scraper is used to realize the flattening and rolling of the fabric or wallpaper, so as to achieve high-quality production.

Owner:ZHENGZHOU UNIV OF IND TECH

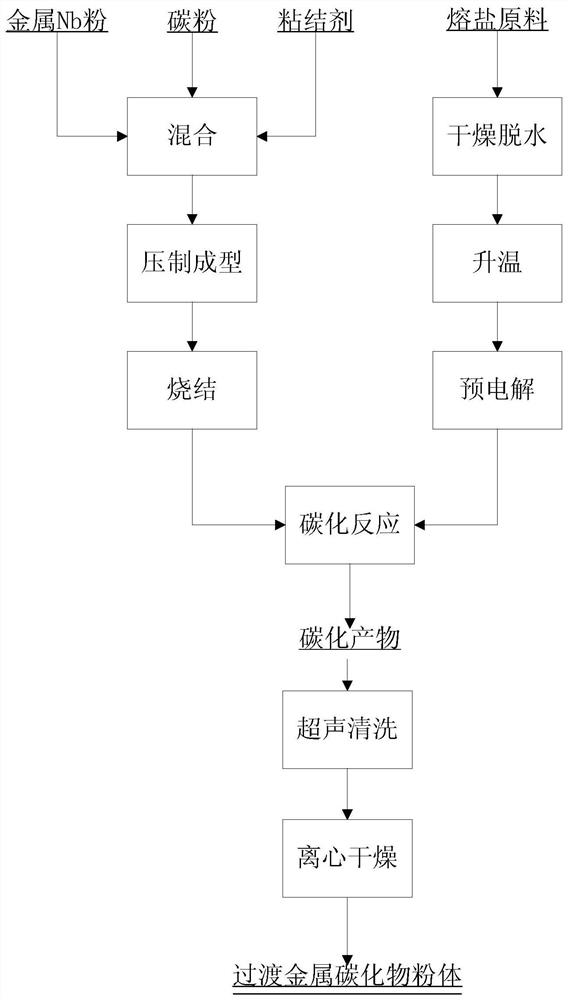

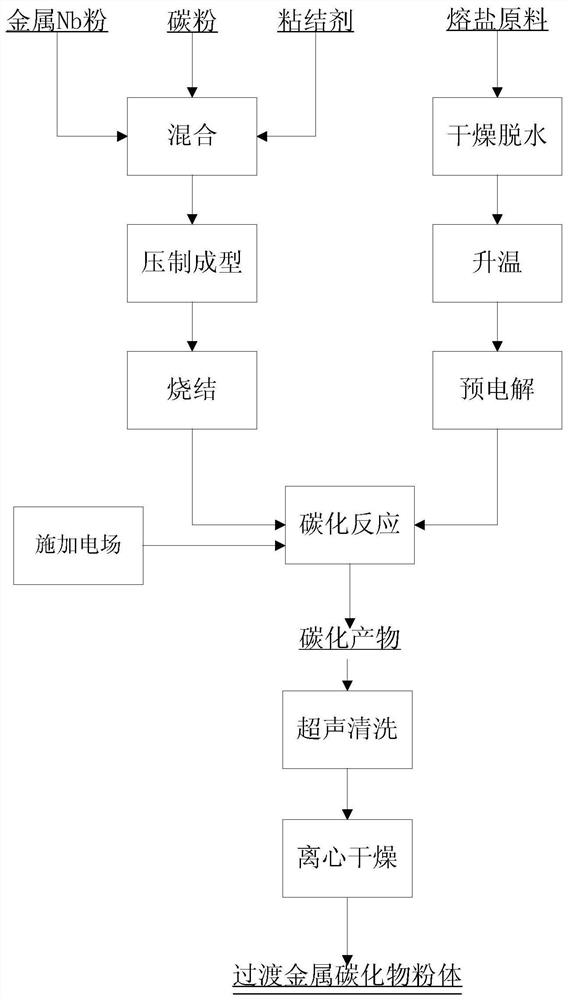

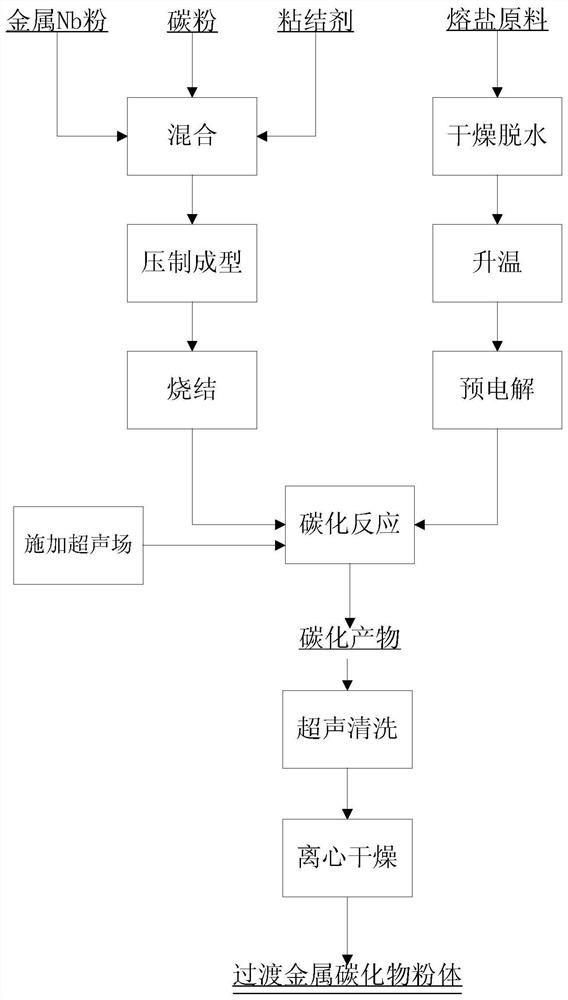

Method for preparing transition metal carbide powder strengthened by electric field and/or ultrasonic field

ActiveCN109881210BEfficient mass preparationEasy to operateElectrolysis componentsTransition metal carbidesElectrolysis

A method for preparing transition metal carbide powder by intensifying electric field and / or ultrasonic field, belonging to the field of transition metal ceramic powder smelting. The method is as follows: mix high melting point transition metal powder and carbon powder according to the proportion, then add a binder, mix, press and roast to obtain a sintered sheet; dehydrate the molten salt, perform pre-electrolysis, and immerse the sintered sheet into the dehydrated molten metal. In the salt, electric field and / or ultrasonic field are applied to strengthen the carbonization reaction, and after cleaning and drying, transition metal carbide powder is obtained. This method uses transition metals as raw materials, uses a molten salt medium environment, and uses electric field and / or ultrasonic field strengthening methods to prepare carbide powder, which can effectively solve the problems of incomplete oxygen removal in oxides and low product quality. It can achieve efficient and high-quality preparation of transition metal carbide powder at lower temperatures, and the equipment used is simple to operate.

Owner:NORTHEASTERN UNIV LIAONING

A fully automatic phoenix rolling machine

InactiveCN105212098BReduce in quantityReduce waiting timeDough sheet coiling machinesFood coatingElectricityWinding machine

The invention provides a full-automatic phoenix roll machine, which structurally comprises a fixed base; the fixed base is provided with a fixed stand and a stand assembly; a plurality of baking ovens electrically connected with the stand assembly are evenly arranged on the surface of the fixed stand and along the periphery of the stand assembly; a sea sedge suction device, a flip support, a turnover device and a rolling device are also arranged at the periphery of the edge of the fixed stand on the fixed base; a charging device is also arranged beside the sea sedge suction device; the top part of the turnover device is also provided with an accessory device. According to the full-automatic phoenix roll machine provided by the invention, multiple making process devices for phoenix rolls are gathered together innovatively; the fixed stand directionally rotates at a fixed angle along with the stand assembly under the action of a rotating shaft; each baking oven rotates to a position below the corresponding device, so not only is waiting time during processing saved, is the efficiency improved, is safety high and is energy saved but also the number of workers required by manual operation is reduced, and the labor strength is reduced; the charging to rolling of the phoenix rolls are finished in one step; the full-automatic phoenix roll machine runs automatically in the whole process, and is efficient and fast.

Owner:刘红旗

A mild discharge preparation method and device for fluorinated graphene

Owner:GUANGDONG UNIV OF TECH

A method for preparing amorphous coatings by ultrasonic shock-assisted ultra-high-speed laser cladding

ActiveCN111286733BLow dilution rateHigh content of amorphous phaseMetallic material coating processesUltra high speedMetallurgy

The invention discloses a method for preparing an amorphous coating by ultrasonic impact assisted ultra-high-speed laser cladding, which integrates ultra-high-speed laser cladding technology and ultrasonic impact micro-forging technology for composite use, degreasing and rust-removing workpieces, installation and positioning; amorphous metal Dry the powder and load it into the powder feeder; set the laser power, spot diameter, walking speed, and powder feeding rate, and turn on the ultra-high laser cladding equipment; set the ultrasonic power, ultrasonic frequency, turn on the ultrasonic impact equipment, and the ultrasonic impact head It acts on a specific area of the solidified coating; after the cladding process is completed, the amorphous coating is naturally cooled to room temperature; the amorphous coating is cleaned with absolute ethanol, and dried after cleaning; the invention makes full use of the ultra-high-speed laser cladding technology The principles of "rapid solidification" and "controlled solidification", "stress relief" and "microscopic defect elimination" of ultrasonic impact micro forging technology realize high-efficiency and high-quality manufacturing of amorphous coatings.

Owner:HARBIN ENG UNIV

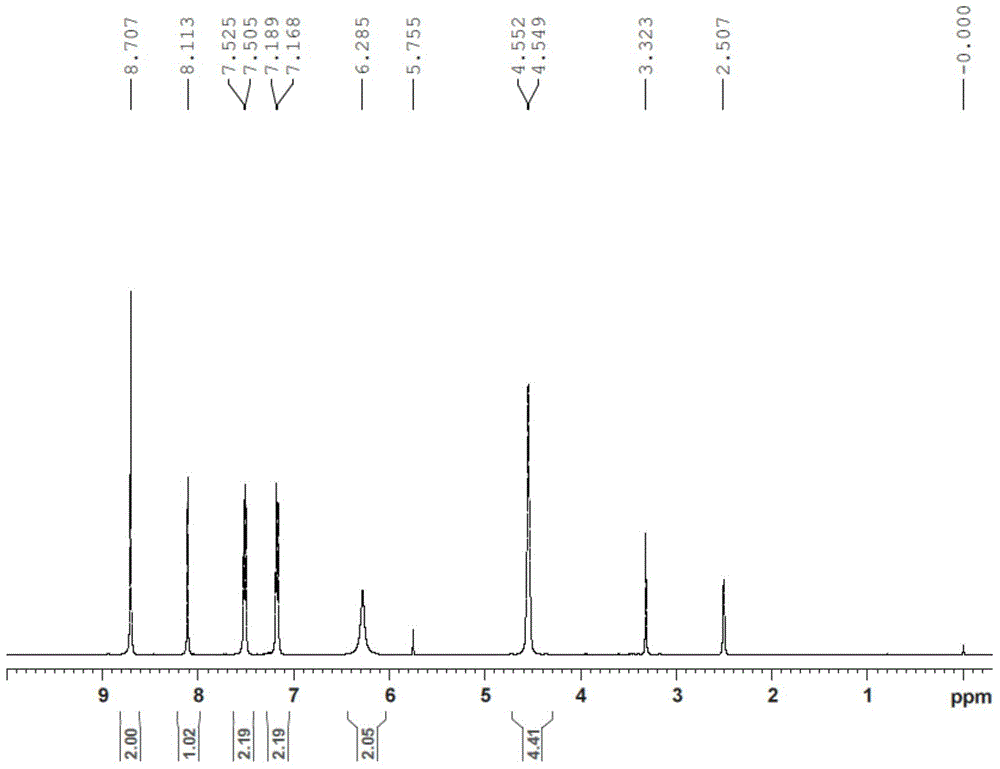

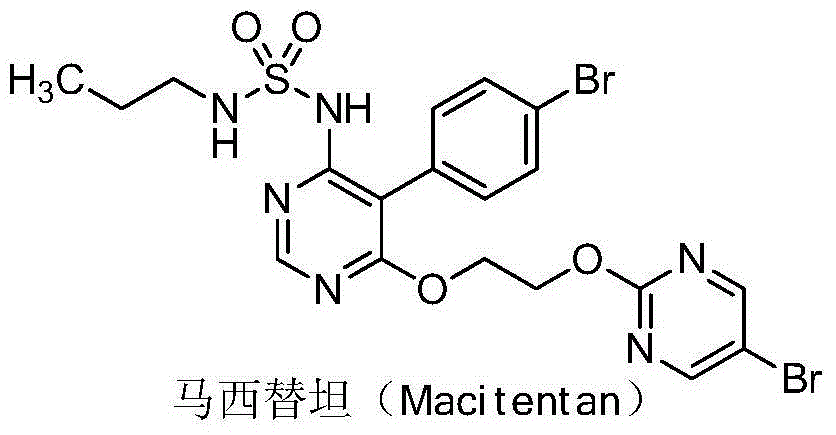

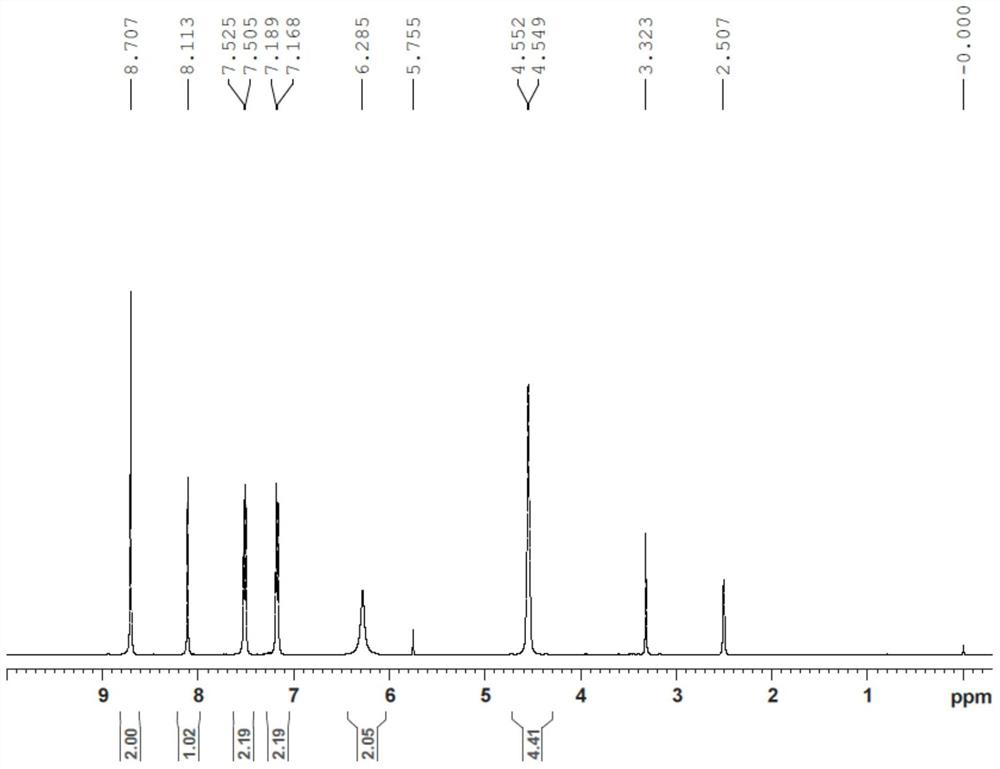

Method for preparing macitentan related substance

The invention discloses a method for preparing a macitentan related substance. Specifically, the invention relates to a method for preparing a metabolic product (a compound of a formula I) of a pulmonary hypertension-resistant drug macitentan (N-[5-(4-bromophenyl)-6-[2-[(5-bromo-2-pyrimidyl)oxo] ethyoxyl]-4-pyrimidyl]-N'-propanesulfonamide). The method comprises the following steps: carrying out a heating reaction on macitentan, and obtaining a target compound. According to the method, the target product can be efficiently prepared at high purity. The structural formula is as shown in the specification.

Owner:JIANGSU HANSOH PHARMA CO LTD

Preparation method of macitentan related substances

ActiveCN106279043BEfficient preparationHigh quality preparationOrganic chemistryPharmaceutical SubstancesBiology

The invention discloses a method for preparing a macitentan related substance. Specifically, the invention relates to a method for preparing a metabolic product (a compound of a formula I) of a pulmonary hypertension-resistant drug macitentan (N-[5-(4-bromophenyl)-6-[2-[(5-bromo-2-pyrimidyl)oxo] ethyoxyl]-4-pyrimidyl]-N'-propanesulfonamide). The method comprises the following steps: carrying out a heating reaction on macitentan, and obtaining a target compound. According to the method, the target product can be efficiently prepared at high purity. The structural formula is as shown in the specification.

Owner:JIANGSU HANSOH PHARMA CO LTD

Preparation process of dolomite sand

The invention provides a preparation technology of dolomite sand, which comprises the following steps: (1) dolomite with the particle size of 10-80 mm is selected, wherein the dolomite comprises the following chemical components in parts by weight: larger than or equal to 0.29 part of SiO2, larger than or equal to 0.1 part of Fe2O3, larger than or equal to 0.15 part of Al2O3, larger than or equal to 30.06 parts of CaO, and larger than or equal to 22.7 parts of MgO, in addition, the dolomite is cut down for 40-50 according to the circumference, (2) low-ash hard coal is adopted as fuels to be calcinated in a high temperature shaft kiln, wherein the calcinating temperature is 1,750-1,850 DEG C; an intermittent oxygen-enriched calcination way is adopted, wherein one-time drawing out of the kiln is carried out in calcinating for 4-6 hours, and the times of entering in and drawing out of the kiln is 4-6; (3) the calcinated dolomite sand comprises the chemical components in parts by weight: 1.11-1.18 parts of SiO2, 0.56-0.6 part of Fe2O3, 0.45-0.64 part of Al2O3, 56.94-57.67 parts of CaO, and 39.93-40.21 parts of MgO, in addition, the calcinated dolomite sand is cut down for 0.28-0.43 according to the circumference, and has volume density of higher than or equal to 3.2. The dolomite sand is manufactured by one-step calcinating, and on one hand, the consumption of raw materials and fuels are enabled to be remarkably reduced, on the other hand, the preparation technology is greatly simplified, therefore, the production cost is lowered greatly.

Owner:大石桥市大岭天成耐火材料有限公司 +1

Manufacturing device of cloth or wallpaper integrated wallboard

ActiveCN111890777AIncrease supplyExtended service lifeLamination ancillary operationsCovering/liningsMechanical engineeringIndustrial engineering

The invention discloses a manufacturing device of a cloth or wallpaper integrated wallboard, and the wallboard prepared from same; a frame is clamped around the periphery of a board blank; cloth or wallpaper is clamped between the frame and the board blank; therefore, the service life of the wallboard can be effectively prolonged, the problems of cracking and the like of the edges of the cloth orwallpaper and the board blank are prevented, wallboard performance is enhanced and the wallboard lifetime is prolonged. A board blank conveying mechanism, a supporting mechanism, a cloth or wallpapersupply mechanism, a frame grabbing and clamping manipulator mechanism, a flattening and rolling mechanism, an operation conveying mechanism and a glue spraying mechanism can be utilized, automatic manufacturing of the wallboard can be achieved, the manufacturing capacity and efficiency are improved, when the frame is mounted, flattening and grinding of the cloth or wallpaper are achieved by a pressing scraping piece through sliding of the pressing scraping piece, and high-quality manufacturing is achieved.

Owner:ZHENGZHOU UNIV OF IND TECH

hook commutator

ActiveCN106451001BAvoid enteringEasy to completeRotary current collectorDynamoelectric machine connectorsPunchingMilling cutter

The invention discloses a hook-shaped commutator composed of a bakelite powder base and commutating copper sheets. The hook-shaped commutator is characterized in that insulation between the commutating copper sheets is carried out by milling insulating grooves with a circular milling cutter between, the tops of the insulating grooves is subjected to arc transition so as to be prevented from being pierced; the commutating copper sheets are elongated bodies before the insulating grooves are milled and hooks are formed; the outer side of each elongated body is an arc surface, the height of the top, where a hook is to be formed, of the elongated body is H; the middle positions of the left and right sides of the elongated body are provided with connected upper and lower punching notches respectively, the distance between the top of the upper punching notch and the top of the elongated body is less than H; the width of the lower punching notch is narrow; the width of the upper punching notch is wide; the upper punching notch has a punching slope in the radial direction, the punching slopes of adjacent elongated bodies define a tapered mouth with an inward large end. The hook-shaped commutator prevents glue from entering the insulating grooves, enables high-quality production and high mechanical strength, and facilitates automatic insertion and mass production.

Owner:ZHEJIANG SONGPU COMMUTATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com