A fully automatic phoenix rolling machine

A fully automatic, phoenix technology, applied in the directions of rolling dough sheet machines, dough processing, baking, etc., to achieve the effect of reducing operating intensity, increasing speed, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

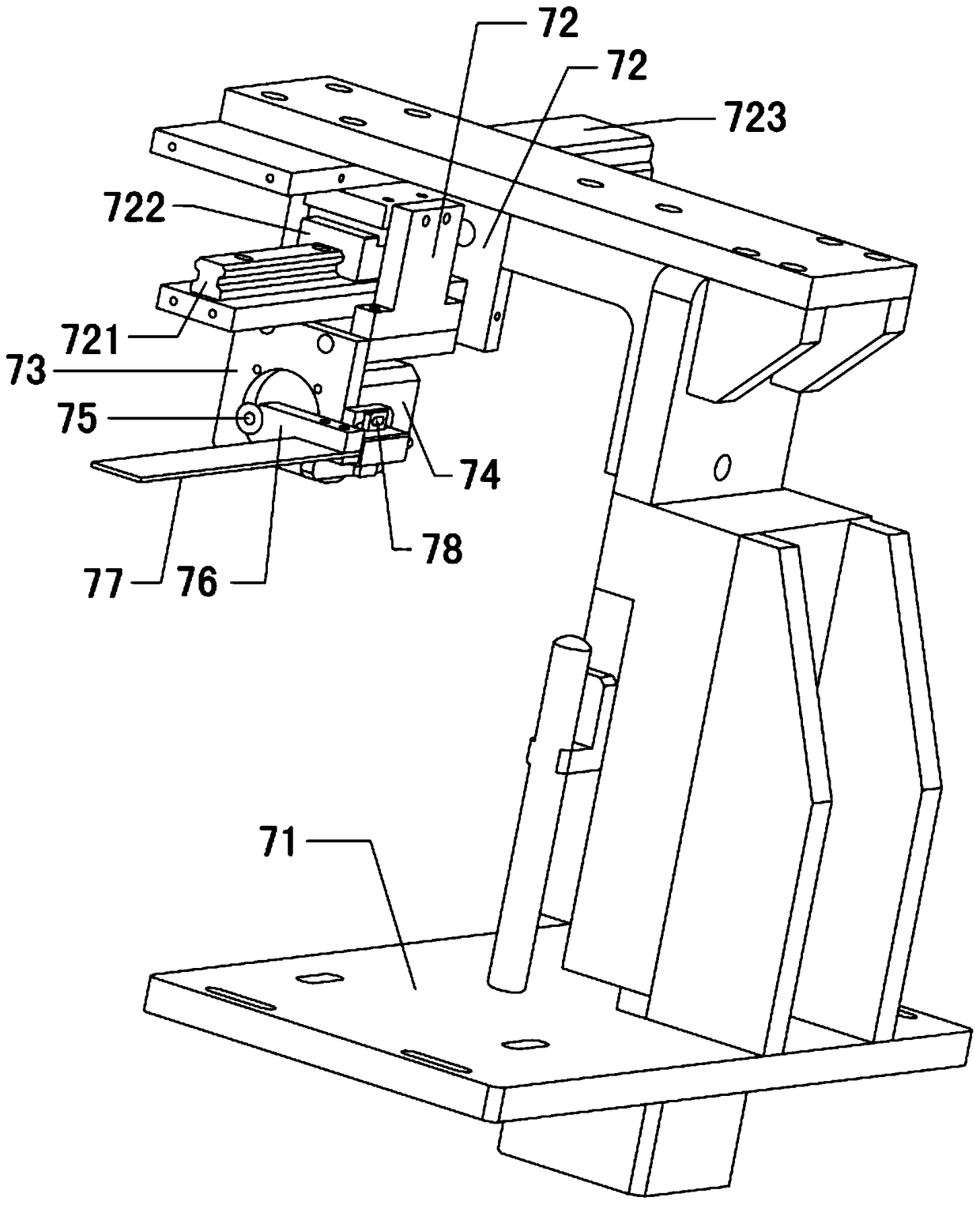

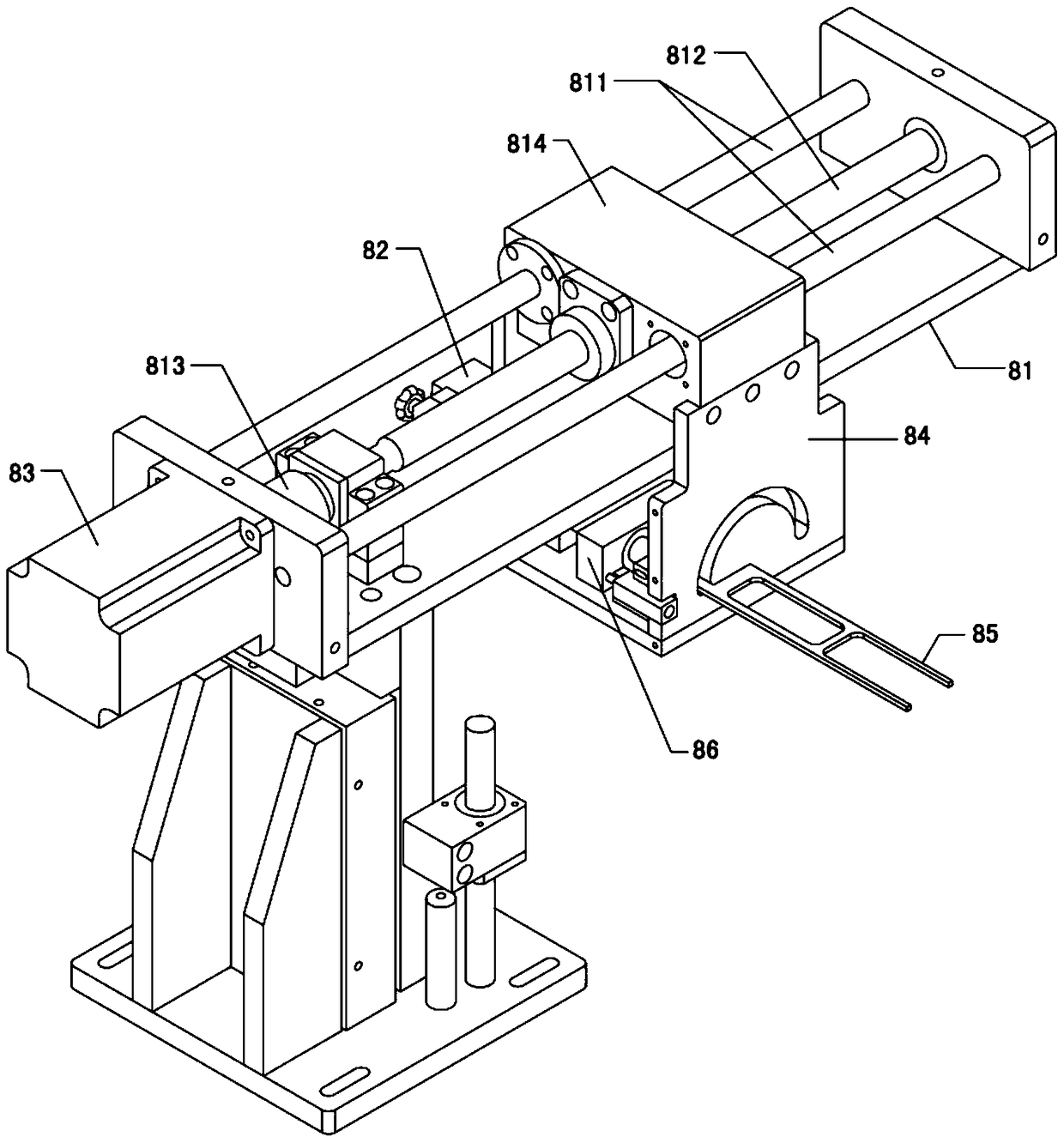

[0026] combine Figure 1 to Figure 5 As shown, the structure of the present invention includes a fixed base 1 and a fixed stand 2 installed on the fixed base 1 , and a stand assembly 3 is installed at the center of the fixed stand 2 . The surface of the fixed platform 2 is evenly arranged with several ovens 4 along the periphery of the platform assembly 3, and the described ovens 4 are electrically connected with the platform assembly 3; The periphery of the edge of frame 2 is also equipped with sucking seaweed device 5, flip support 6, material turning device 7 and coiling device 8, and described sucking seaweed device 5 is also provided with feeding device 9 on the side, and described turning over material The device 7 is also provided with an auxiliary material device 10 at the top.

[0027] The platform assembly 3 is fastened to the fixed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com