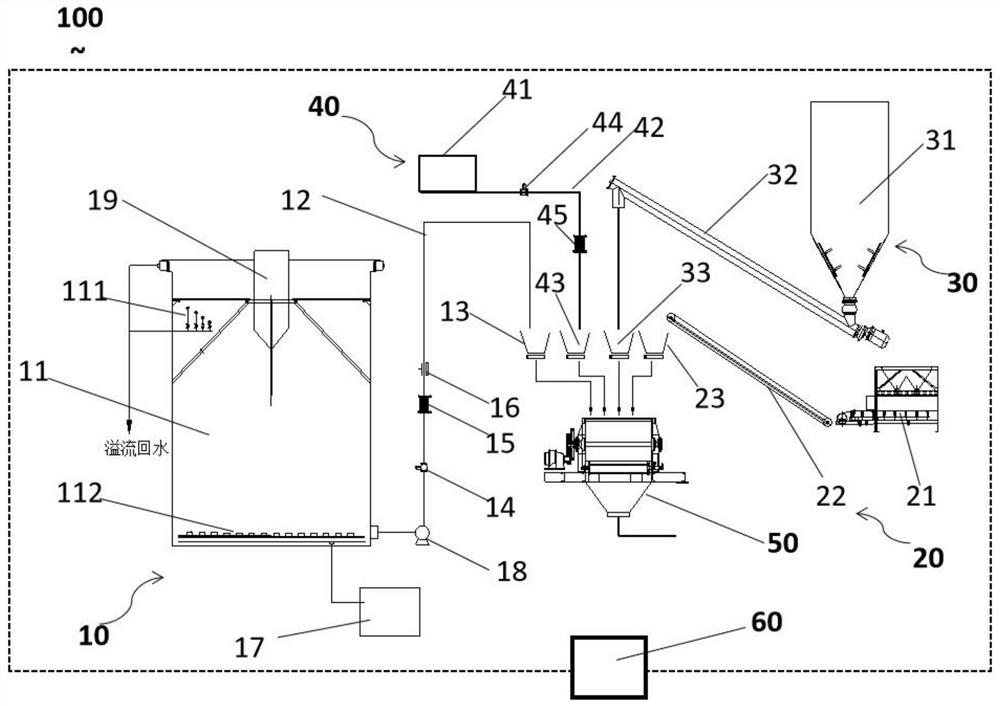

Precise preparation and filling system and method for coarse aggregate and tailing slurry

A technology of coarse aggregate and feeding system, which is applied in the field of precise preparation and filling system of coarse aggregate and tailings mortar, can solve the problems of difficult maintenance and inspection, inability to perform accurate measurement of filling system, poor measurement accuracy, etc., so as to solve the problem of safe mining. Problems, metering and buffer feeding process efficient and accurate, ensuring the effect of metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The invention provides a filling method for preparing filling slurry, which is prepared by using the above-mentioned coarse aggregate and tailing mortar precision preparation filling system, and adopts a cycle process of static metering-period preparation, including the following steps:

[0052] S1, preparation of tailings mortar: adopt tailings mortar dense storage and metering system 10, after the tailings are settled by self-diluted flocculation and sedimentation feeding barrel 19, the tailings are transported to the paste storage thickener 11 after being concentrated, and the air compressor 17 is turned on before filling Slurry is carried out in the whole warehouse to ensure that the filling slurry in the warehouse is homogeneous and the concentration remains unchanged when sand is released. When filling is required, under the action of the slurry pump 18, the underflow is lifted through the underflow conveying pipeline 12 to the underflow metering buffer bucket 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com