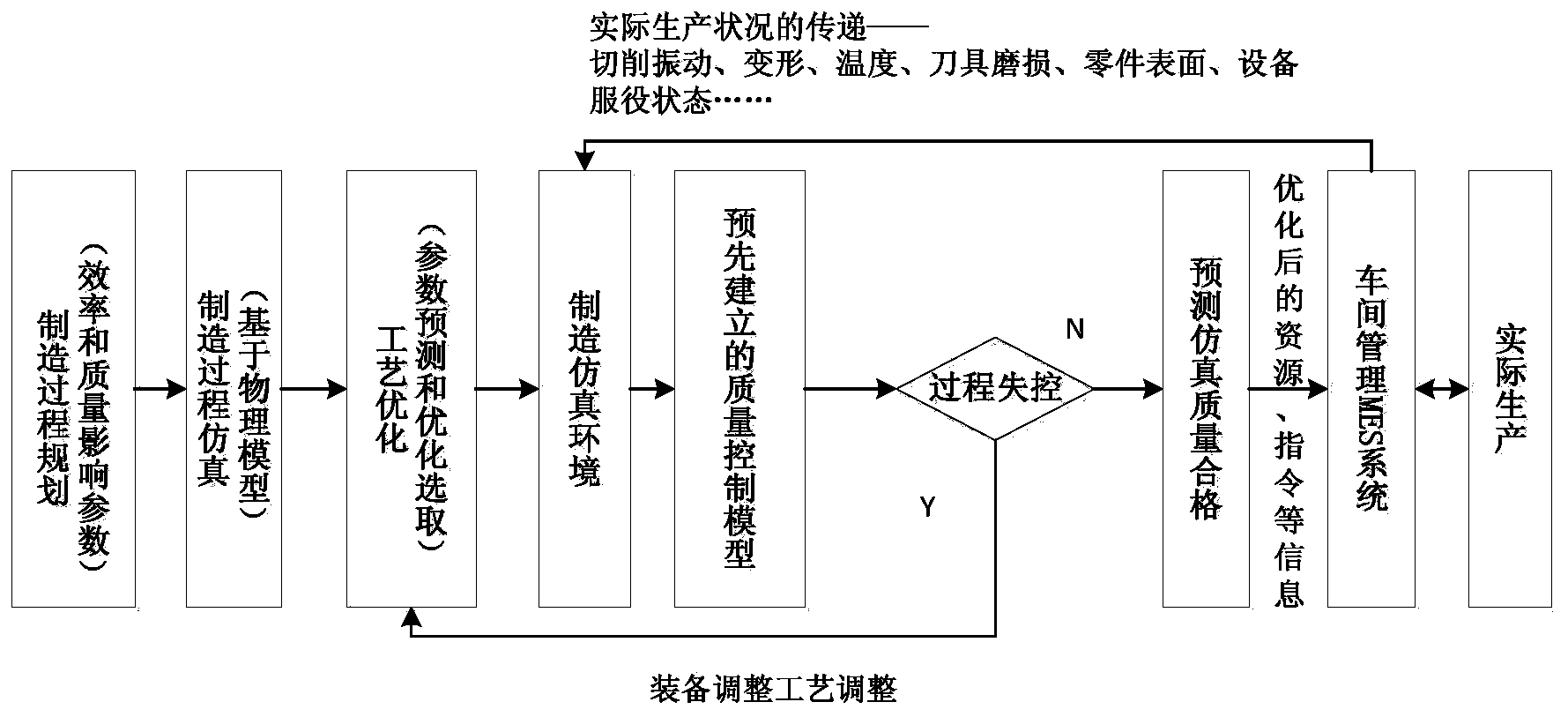

Closed-loop quality control simulation method with simulation prediction and actual production integrated

A simulation prediction, closed-loop quality technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult to achieve process adjustment, inaccurate quality monitoring and analysis, and linkages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

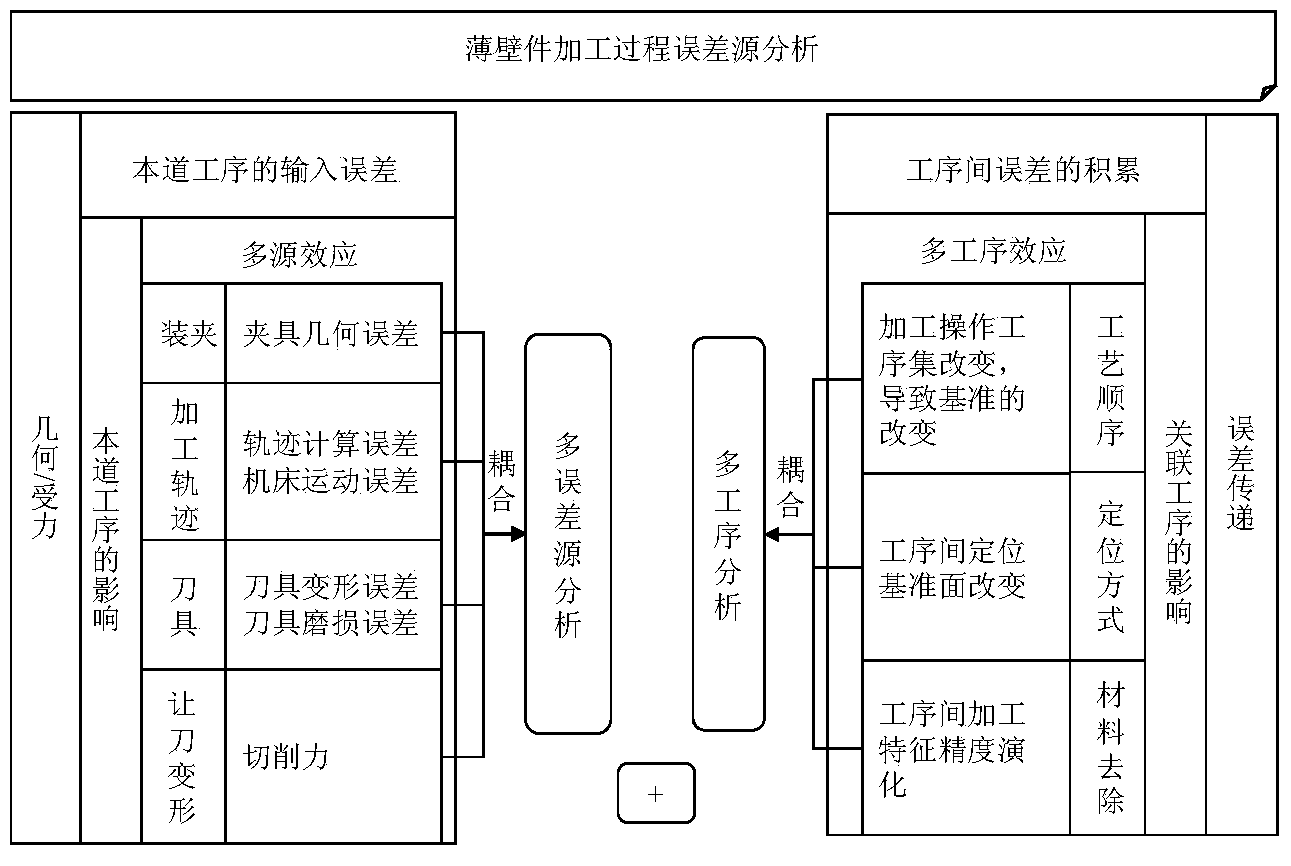

[0135] To demonstrate the effectiveness of the proposed method in error modeling, consider the following Image 6 The thin plate parts shown, where ps 1 to ps 4 For the micro yuan. Considering several possible error sources, it is assumed that the process consists of two processes, the first process processes part 1, and the second process processes part 2, and the processing characteristics of the first process are the processing benchmarks of the second process .

[0136] (1) Error prediction of the first process

[0137] If the noise is set to 0, the microelement ps can be obtained through the formula of the dynamic SoV prediction model 1 The prediction error value for is:

[0138] [-0.0035, -0.0334, 0.00126, 0.0006, 0.0000, 0.0003] T

[0139] (2) Second process error prediction

[0140] The second process benchmark ps can be known from the first process 1 The resulting micro-element deviation in the micro-element coordinate system is:

[0141] [-0.0035, -0.0334, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com