Fully automatic wall surface and shed surface spray coating grinding device

A fully automatic, shed surface technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of cumbersome and inflexible operation and increase the work intensity of operators, so as to avoid cumbersome construction and solve the problem of Labor intensity and dust pollution, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

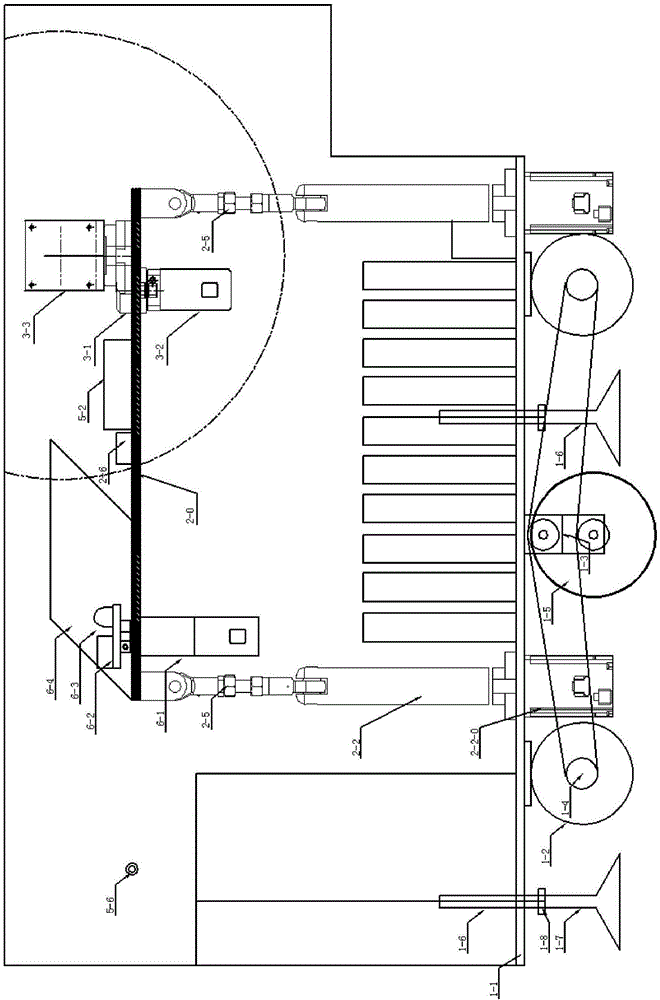

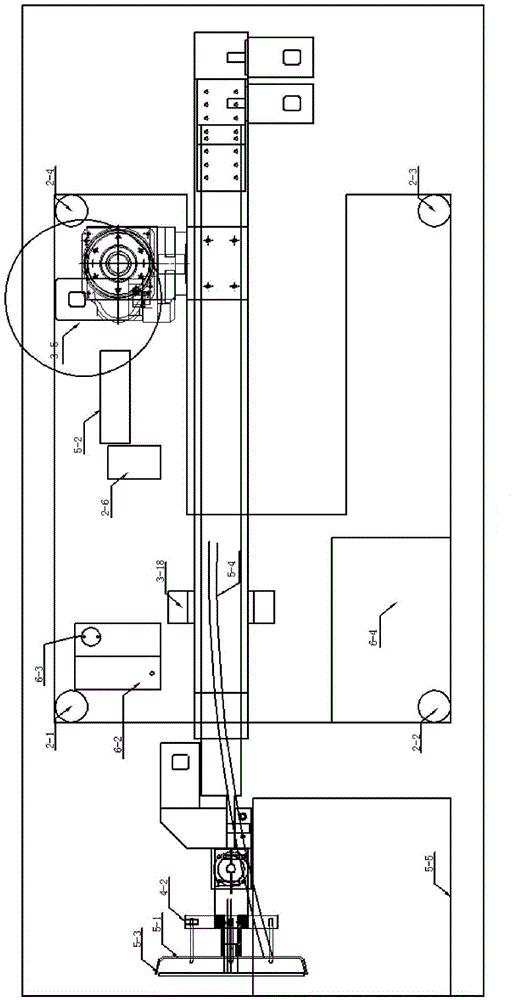

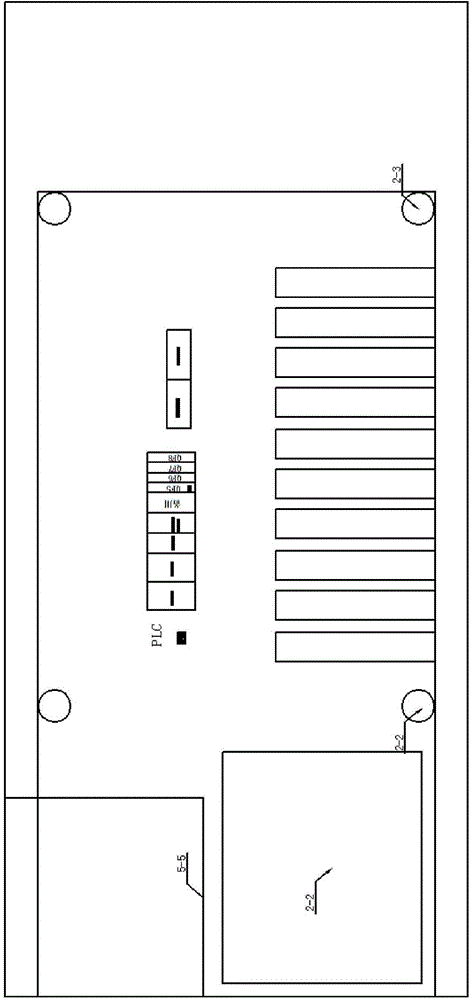

[0052] As shown in the accompanying drawings, the fully automatic wall shed surface spraying, smoothing and polishing device of the present invention includes: a moving mechanism, a load-bearing installation platform 2 and an automatic moving arm 3; it is characterized in that: the moving mechanism adopts a manual moving mechanism or Automatic moving mechanism 1, manual moving mechanism is the technology that ordinary technicians can realize, the present invention preferably automatic moving mechanism 1, the fixed plate 2-0 of bearing installation platform 2 is installed on the adjustment bearing 2-5 or ball head of automatic moving mechanism 1 above; the adjusting bearing or ball head is connected to the adjusting foot driven by the electric cylinder; the electric cylinder is connected to the bottom plate 1-1, and the bottom plate 1-1 is movable; the automatic moving arm 3 is installed on the load-bearing installation platform 2. The front end of the moving arm 3 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com