Nickel-platinum alloy target and preparation method thereof

A technology of nickel-platinum alloy and target material, which is applied in the field of nickel-platinum alloy target material and its preparation, can solve the problems of increased film impedance and achieve the effect of uniform thickness and less particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

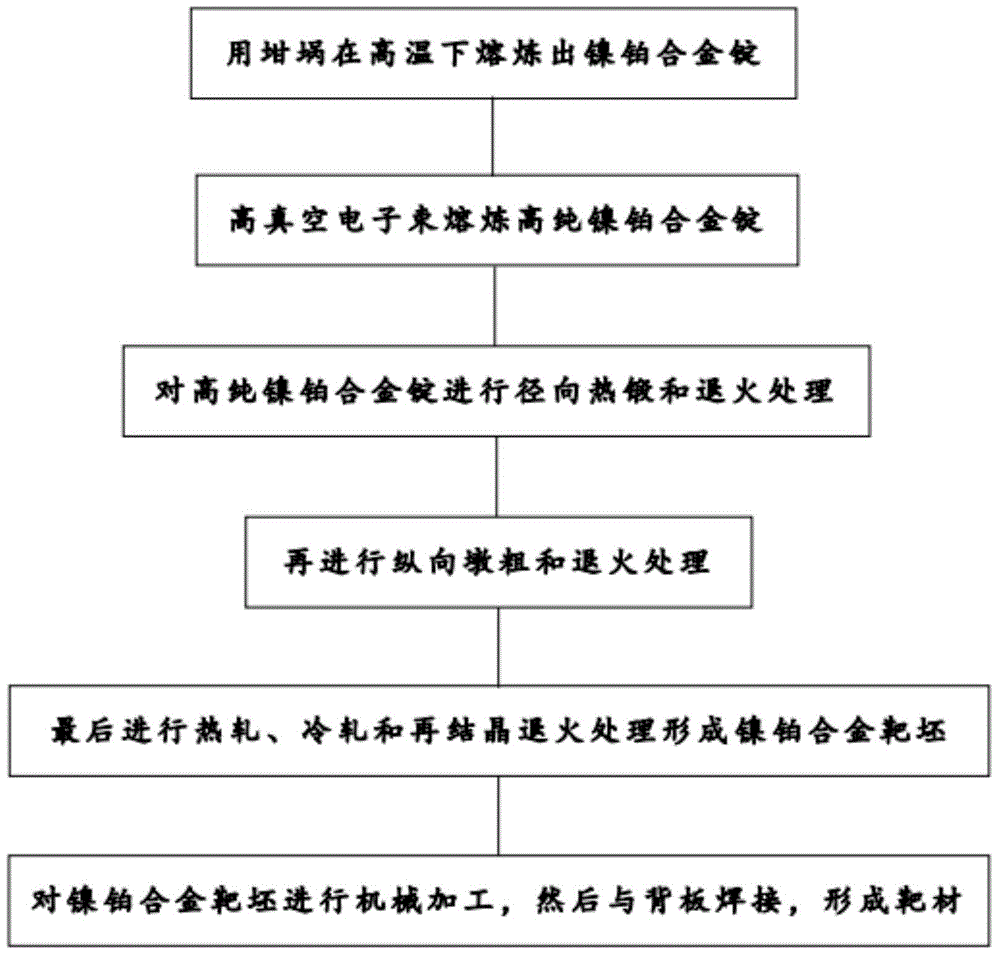

[0029] The inventor concentrated on research and practiced many times to improve the optimal method for making nickel-platinum alloy targets. The process flow is as follows figure 1 As shown, it mainly includes the following steps:

[0030] Step (1): Weigh electrolytic nickel with a purity of 99.99% and platinum powder with a purity of 99.95% according to the platinum content of the raw material at 5 at.%, disperse the electrolytic nickel and platinum powder into a graphite crucible, and adopt the method of vacuum induction melting Smelt nickel-platinum alloy ingots.

[0031] Step (2), under the condition of a vacuum degree of 4Pa, use a vacuum electron beam to drip melt the nickel-platinum alloy ingot into a high-purity Ni-5at.%Pt alloy ingot with a diameter of 300mm; high-purity Ni-5at. The purity of the %Pt alloy ingot is greater than 99.995%, and the oxygen content is less than 50ppm.

[0032] Step (3), before radial hot forging, preheat the Ni-5at.%Pt alloy ing...

Embodiment 2

[0038] A method for preparing a nickel-platinum alloy target, comprising the following steps:

[0039] Step (1): Weigh electrolytic nickel with a purity of 99.99% and platinum powder with a purity of 99.95% according to the platinum content in the raw material of 10 at.%, disperse the electrolytic nickel and platinum powder into a graphite crucible, and adopt the method of vacuum induction melting Smelting Ni-10at.%Pt alloy ingots.

[0040] Step (2), under the condition of vacuum degree of 4Pa, use vacuum electron beam to drip melt the Ni-10at.%Pt alloy ingot into a high-purity nickel-platinum alloy ingot with a diameter of 300mm; high-purity Ni-10at.%Pt The purity of the alloy ingot is greater than 99.995%, and the oxygen content is less than 50ppm.

[0041] Step (3), before radial hot forging, preheat the high-purity Ni-10at.%Pt alloy ingot by heating the high-purity Ni-10at.%Pt alloy ingot to 1000°C; then At 1000°C, the air hammer is used to hit the high-purity Ni...

Embodiment 3

[0046] A method for preparing a nickel-platinum alloy target, comprising the following steps:

[0047] Step (1): Weigh electrolytic nickel with a purity of 99.99% and platinum powder with a purity of 99.95% according to a platinum content of 20 at.% in the raw material, disperse the electrolytic nickel and platinum powder into a graphite crucible, and use vacuum induction melting Methods Ni-20 at.%Pt alloy ingots were smelted.

[0048] Step (2), under the condition of vacuum degree of 3Pa, the Ni-20 at.%Pt alloy ingot is drip melted by vacuum electron beam (drip melting) into a high-purity Ni-20 at.%Pt alloy ingot with a diameter of 300mm; The purity of the high-purity Ni-20 at.%Pt alloy ingot is greater than 99.995%, and the oxygen content is less than 50ppm.

[0049] Step (3), before radial hot forging, preheat the high-purity Ni-20 at.%Pt alloy ingot. The preheating method is to heat the high-purity Ni-20 at.%Pt alloy ingot to 1150°C ; Then use an air hammer to hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com