Graphite fiber and preparation method thereof

A graphite fiber and fiber technology, applied in the field of graphite fiber and its preparation, can solve the problems of unsuitability, graphite lattice integrity, low graphitization, and non-individualization, etc., and achieve the effect of improved purity and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

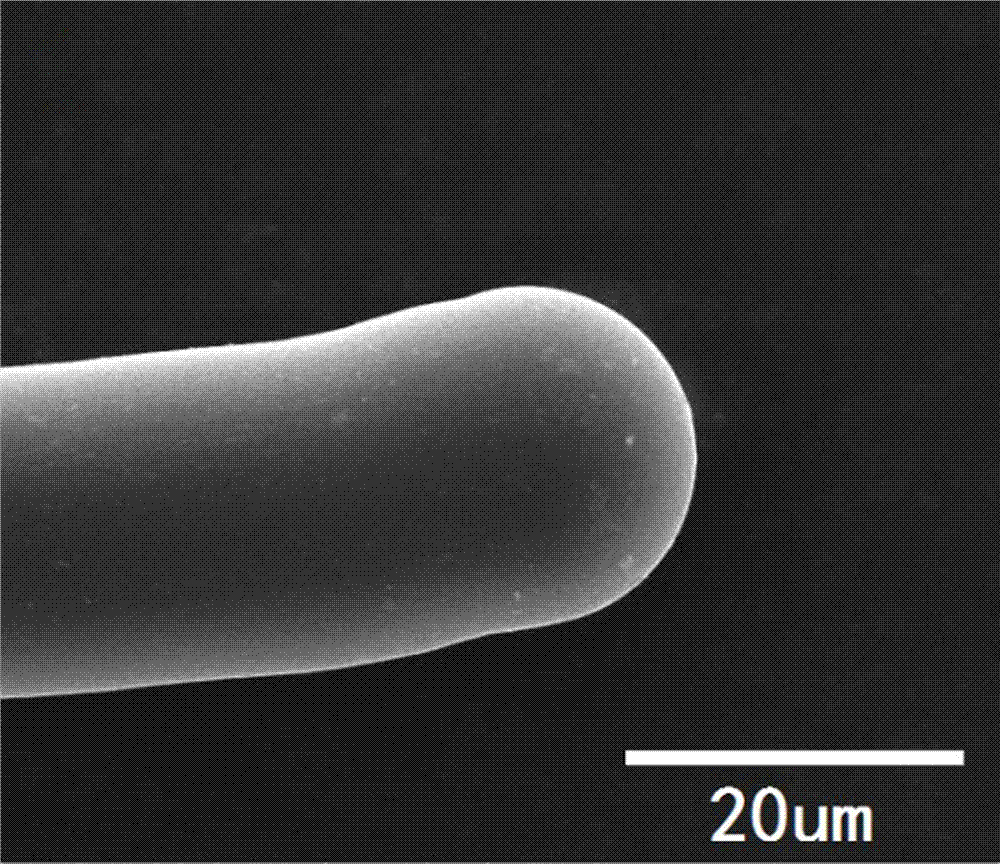

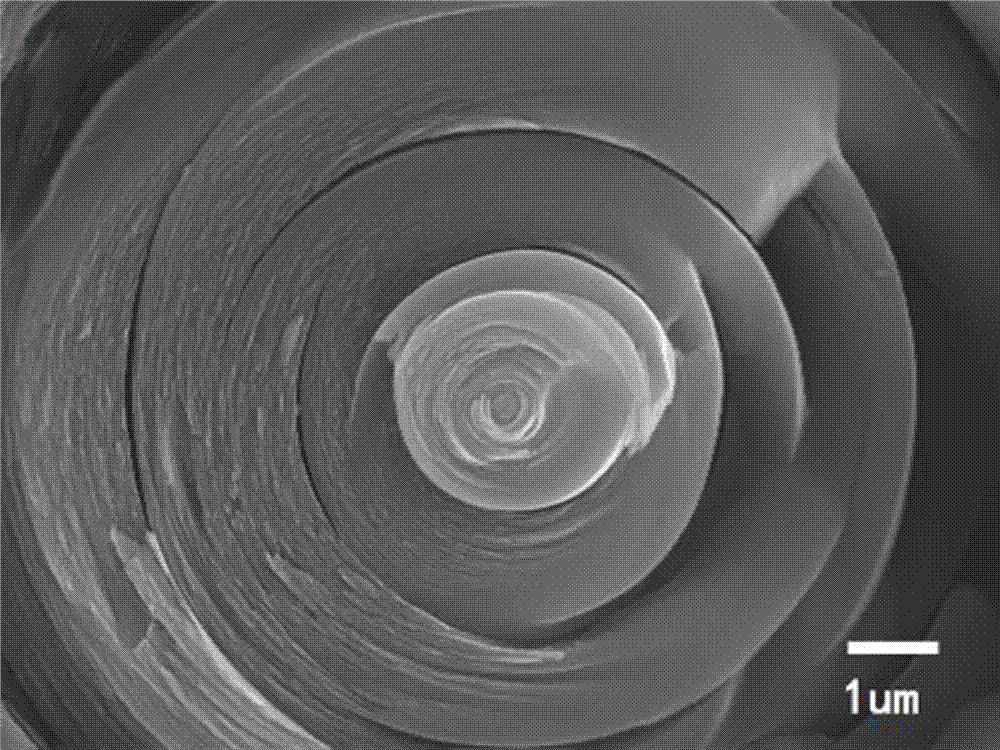

Image

Examples

preparation example Construction

[0036] A kind of preparation method of graphite fiber is characterized in that, concrete steps are as follows:

[0037] Step 1. Substrate cleaning: clean the substrate according to the standard cleaning procedure and then dry it for use;

[0038] Step 2. Furnace loading: put the cleaned substrate into the designated position in the growth furnace, and check the working status of the equipment and the sealing of the gas path at the same time;

[0039]Step 3. Growth: Heat the working area in the growth furnace at a certain heating rate, and when the temperature rises to 150-250°C, argon gas is introduced; when the temperature rises to 550-650°C, the flow of argon gas is maintained, and Hydrogen: When the temperature rises to 950-1050°C, the temperature is kept constant, and after 10-60 minutes of constant temperature, methane gas is introduced to officially start the growth stage. The growth time is expressed by the time of methane gas ventilation, and the time is 60-120 minutes...

Embodiment 1

[0046] Graphite fibers are prepared by gas phase deposition under catalyst-free conditions, and the specific steps are as follows:

[0047] 1. Substrate cleaning. The catalyst-free quartz slices were cleaned according to standard cleaning procedures and then dried for use. The cleaning procedure is: first put the quartz substrate into a proper amount of absolute alcohol and acetone 1:1 mixture and ultrasonically clean it for more than 15 minutes, then take it out and ultrasonically clean it in deionized water for 5 minutes, then take it out and put it into concentrated sulfuric acid and hydrogen peroxide In the 5:1 mixed system, pickle for 15 minutes while heating to boiling state, then take it out and wash it with deionized water, then dry it or blow it dry with high-purity gas.

[0048] 2. Load the furnace. Load the clean substrate into the middle area of the constant temperature zone of the tube furnace, and the outer diameter of the quartz tube is 8 cm.

[0049] 3. Gr...

Embodiment 2

[0053] Graphite fibers are prepared by gas phase deposition under catalyst-free conditions, and the specific steps are as follows:

[0054] 1. Substrate cleaning. The catalyst-free quartz slices were cleaned according to standard cleaning procedures and then dried for use. The cleaning procedure is: put the quartz substrate into a proper amount of absolute alcohol and acetone 1:1 mixture and ultrasonically clean it for 60 minutes. In the 5:1 mixed system, pickle for 60 minutes under heating to boiling state, then take it out and wash it with deionized water, then dry it or blow it dry with high-purity gas.

[0055] 2. Load the furnace. Put the clean substrate into the middle area of the constant temperature zone of the chemical vapor deposition equipment, and the outer diameter of the quartz tube is 8 cm.

[0056] 3. Growth. Check the working status of the equipment, especially whether there is any leakage in the gas path; heat the working area of the chemical vapor de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com