Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

521 results about "Chalcogenide glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

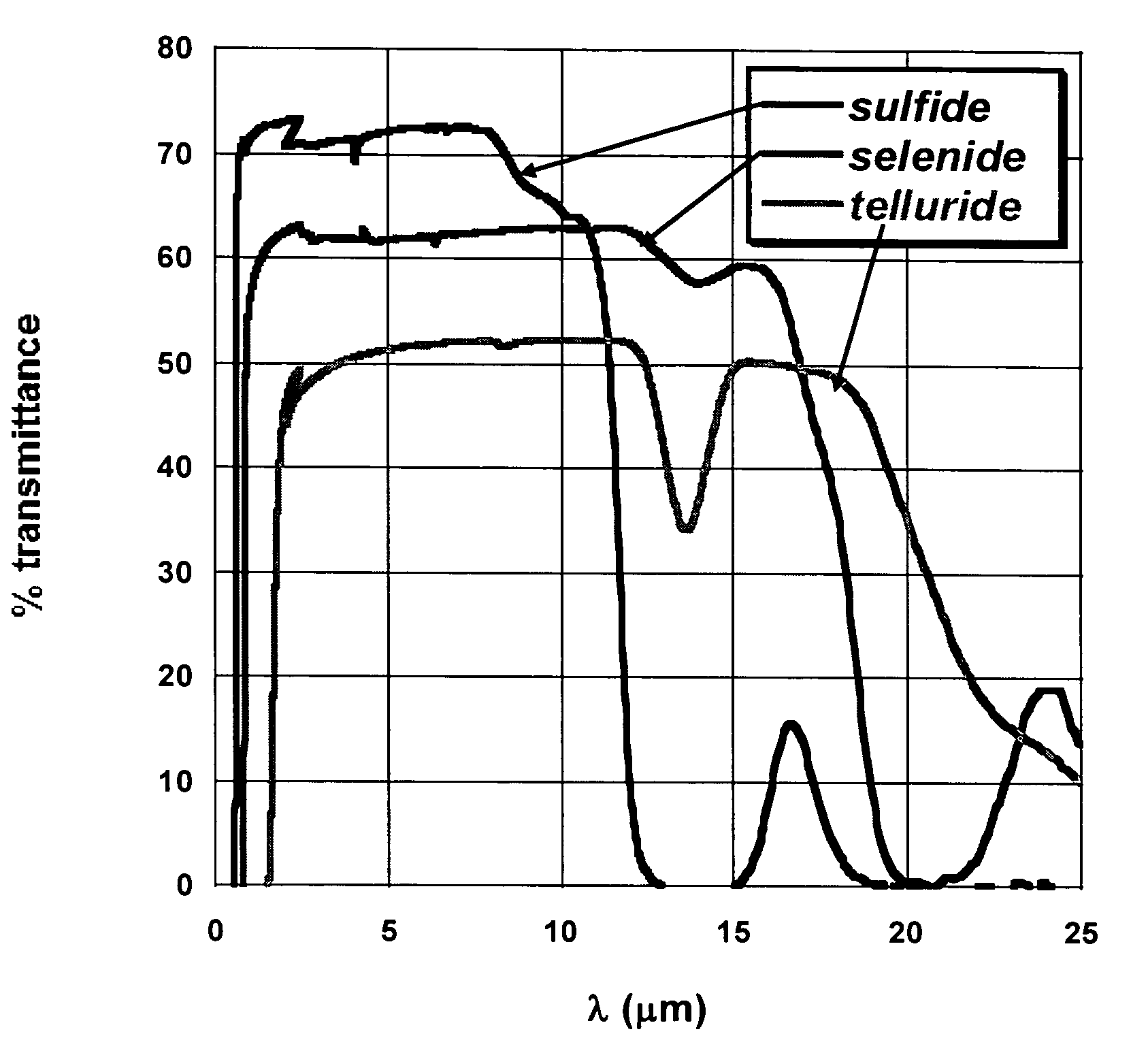

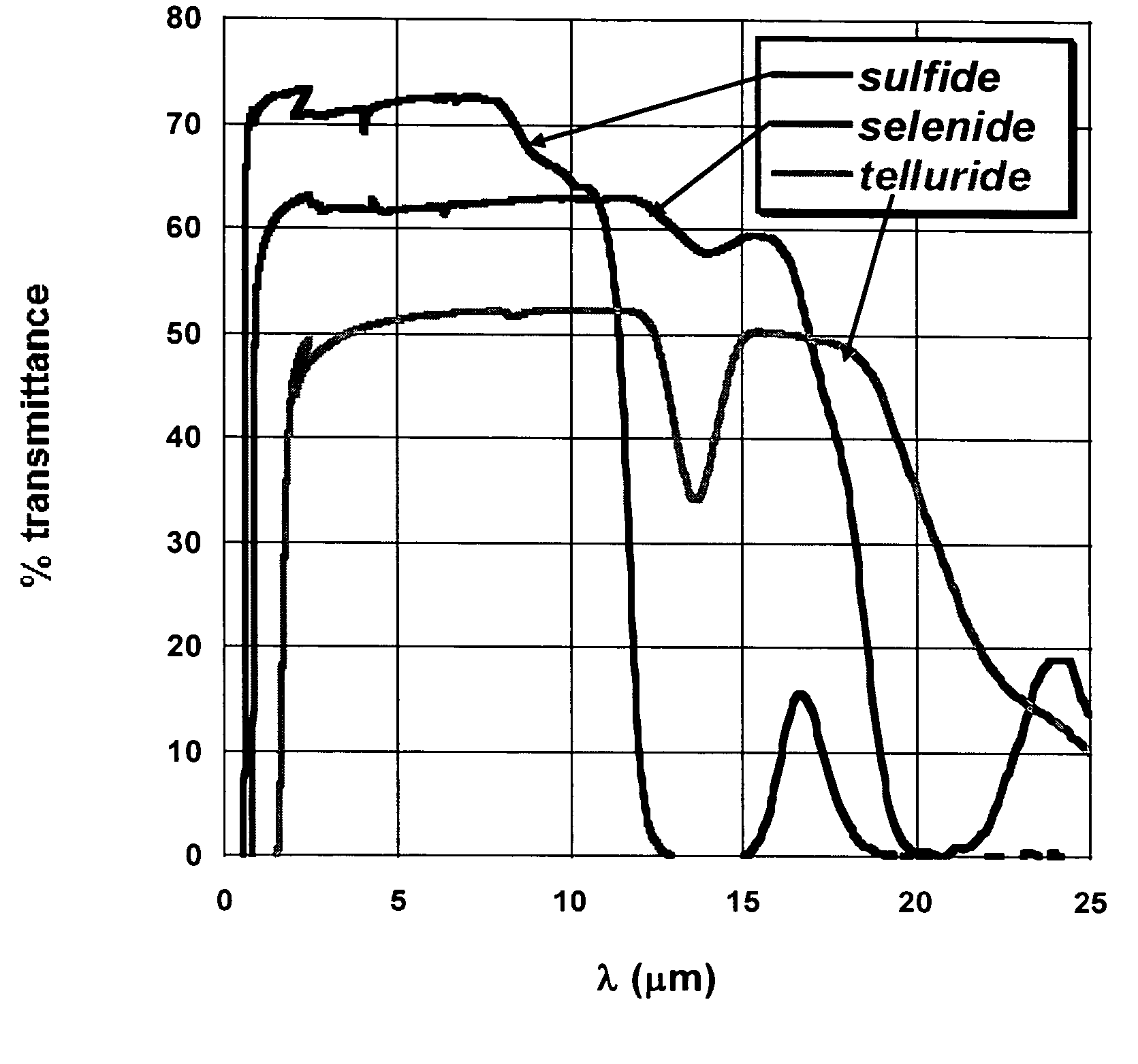

Chalcogenide glass (pronounced hard ch as in chemistry) is a glass containing one or more chalcogens (sulfur, selenium and tellurium, but excluding oxygen). Such glasses are covalently bonded materials and may be classified as covalent network solids. Polonium is also a chalcogen but is not used because of its strong radioactivity. Chalcogenide materials behave rather differently from oxides, in particular their lower band gaps contribute to very dissimilar optical and electrical properties.

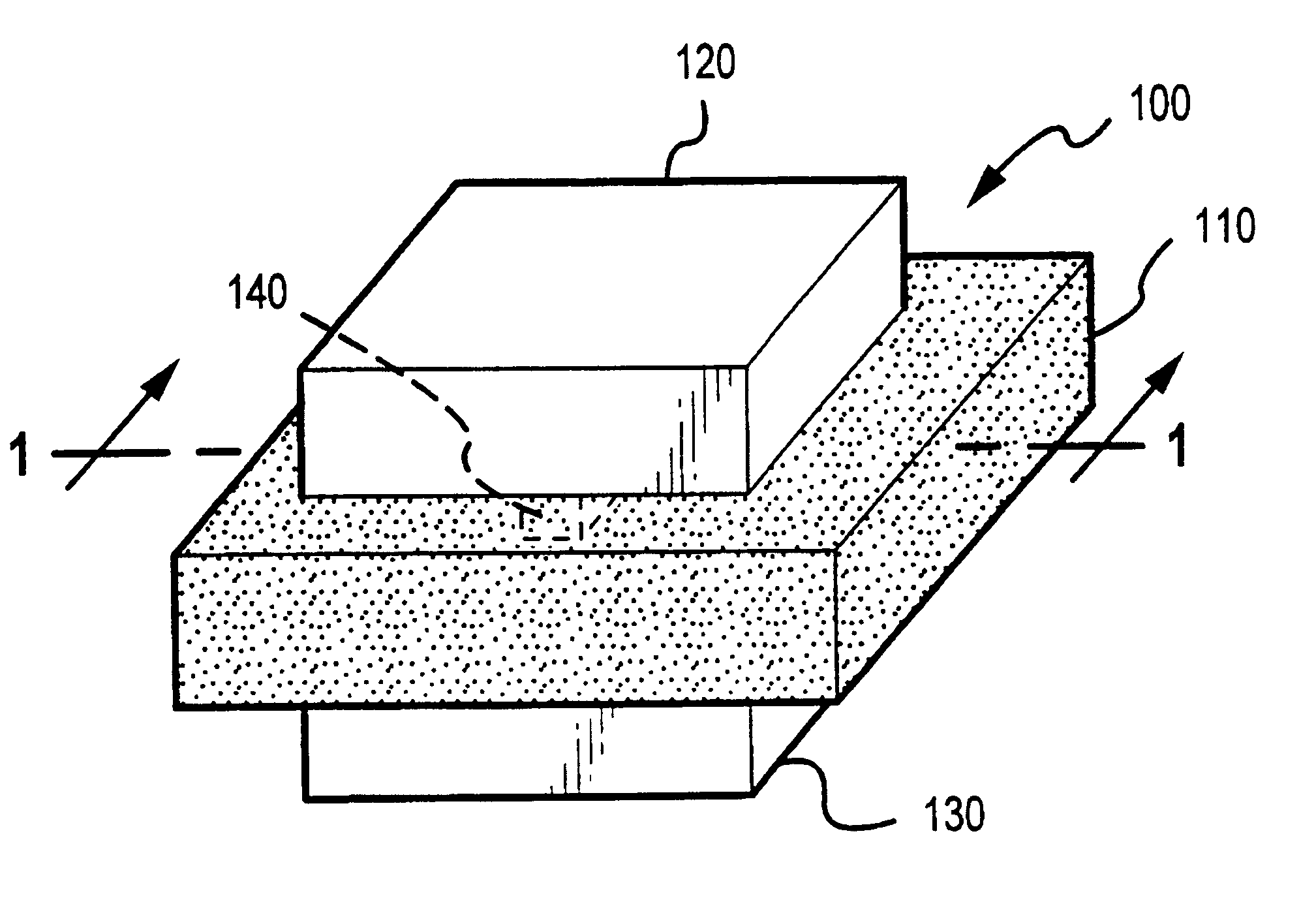

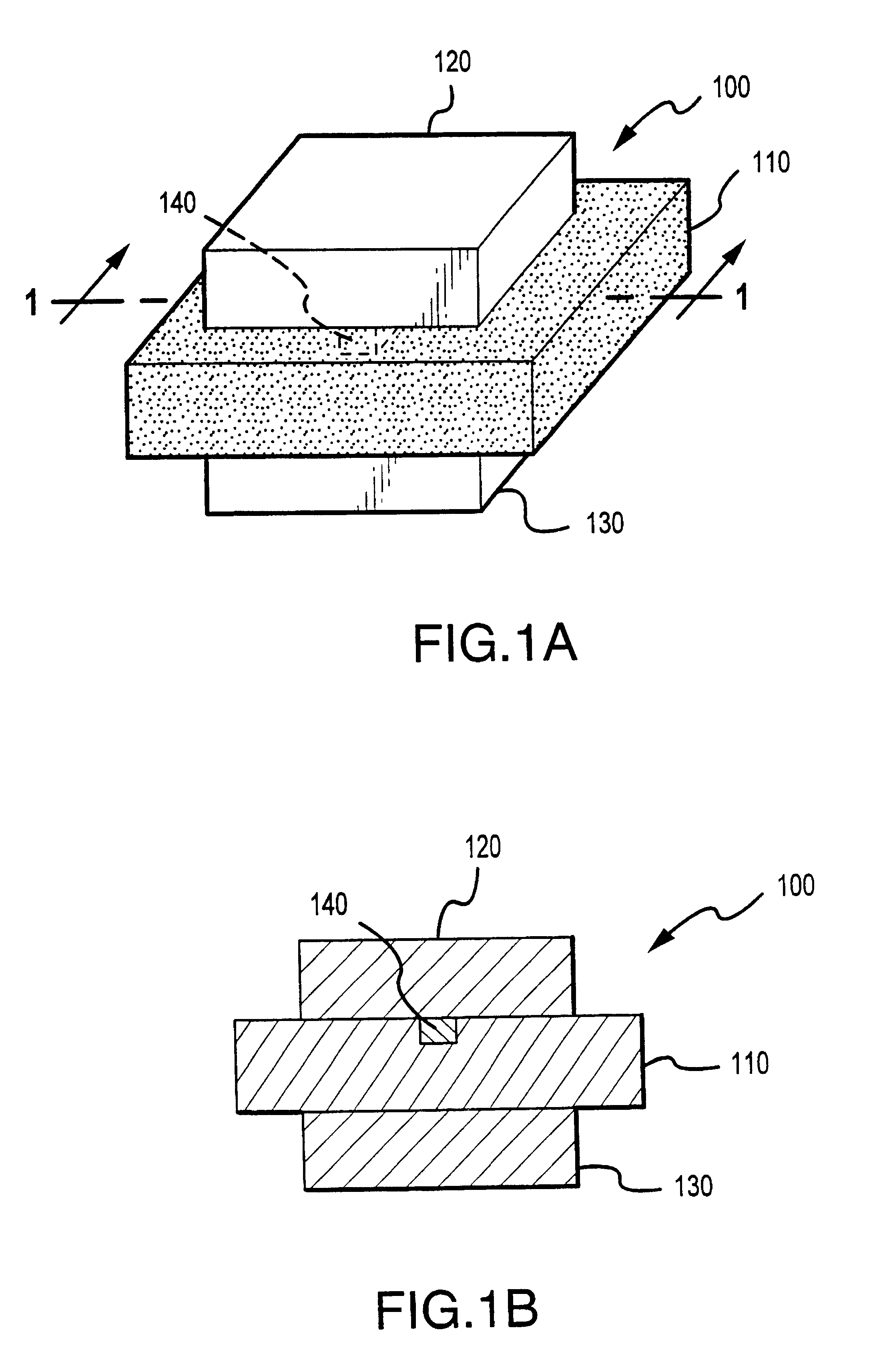

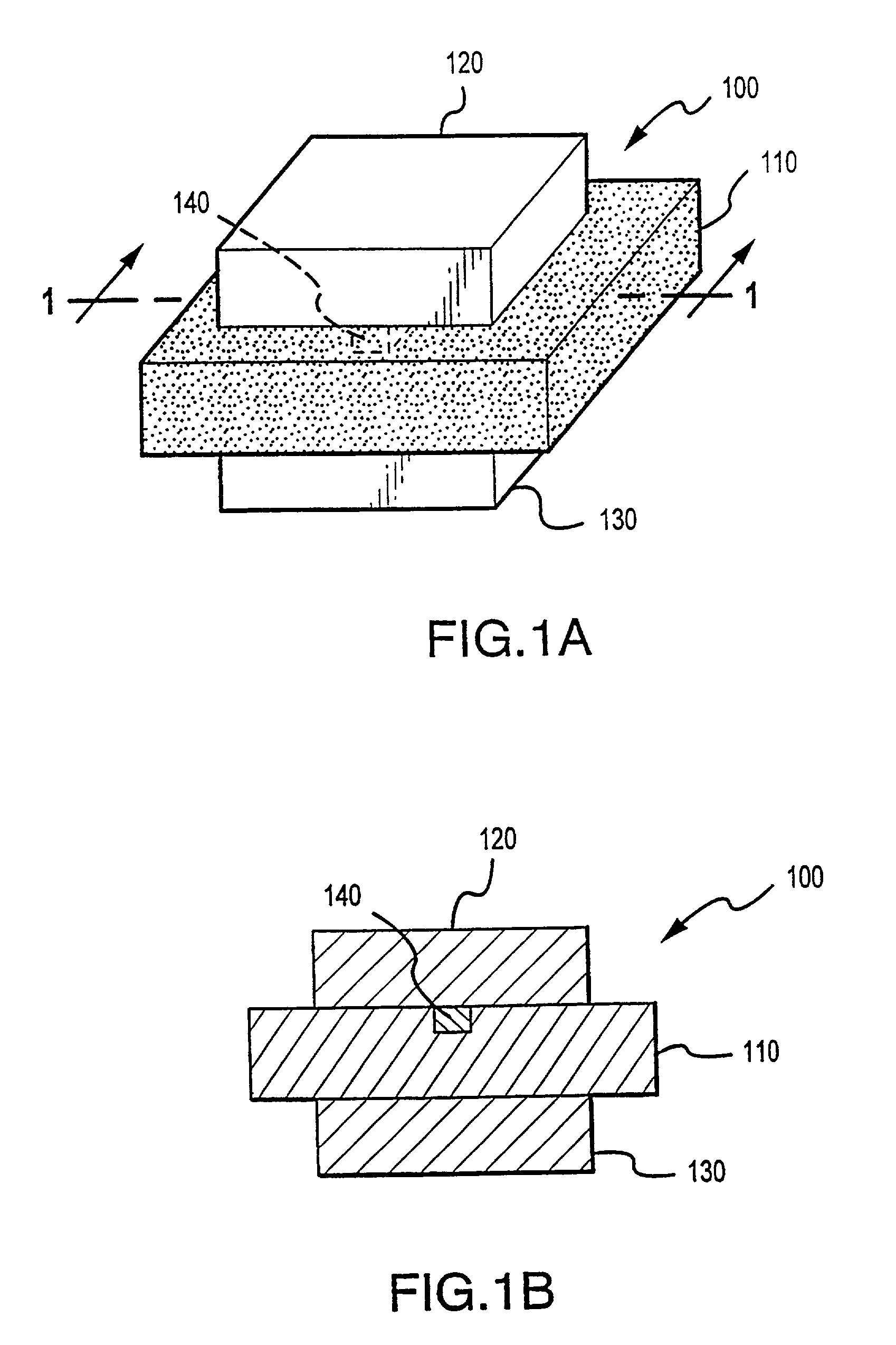

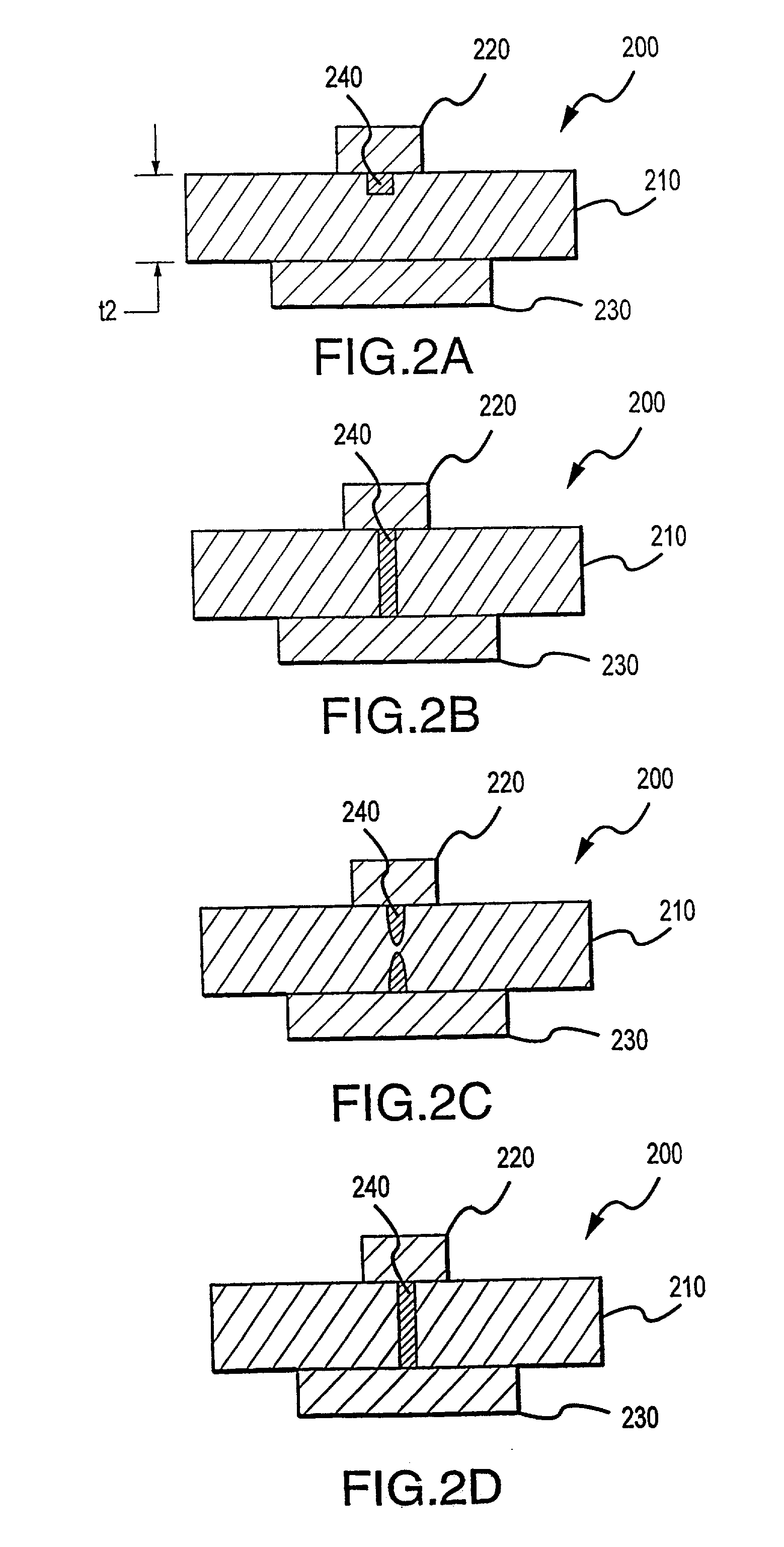

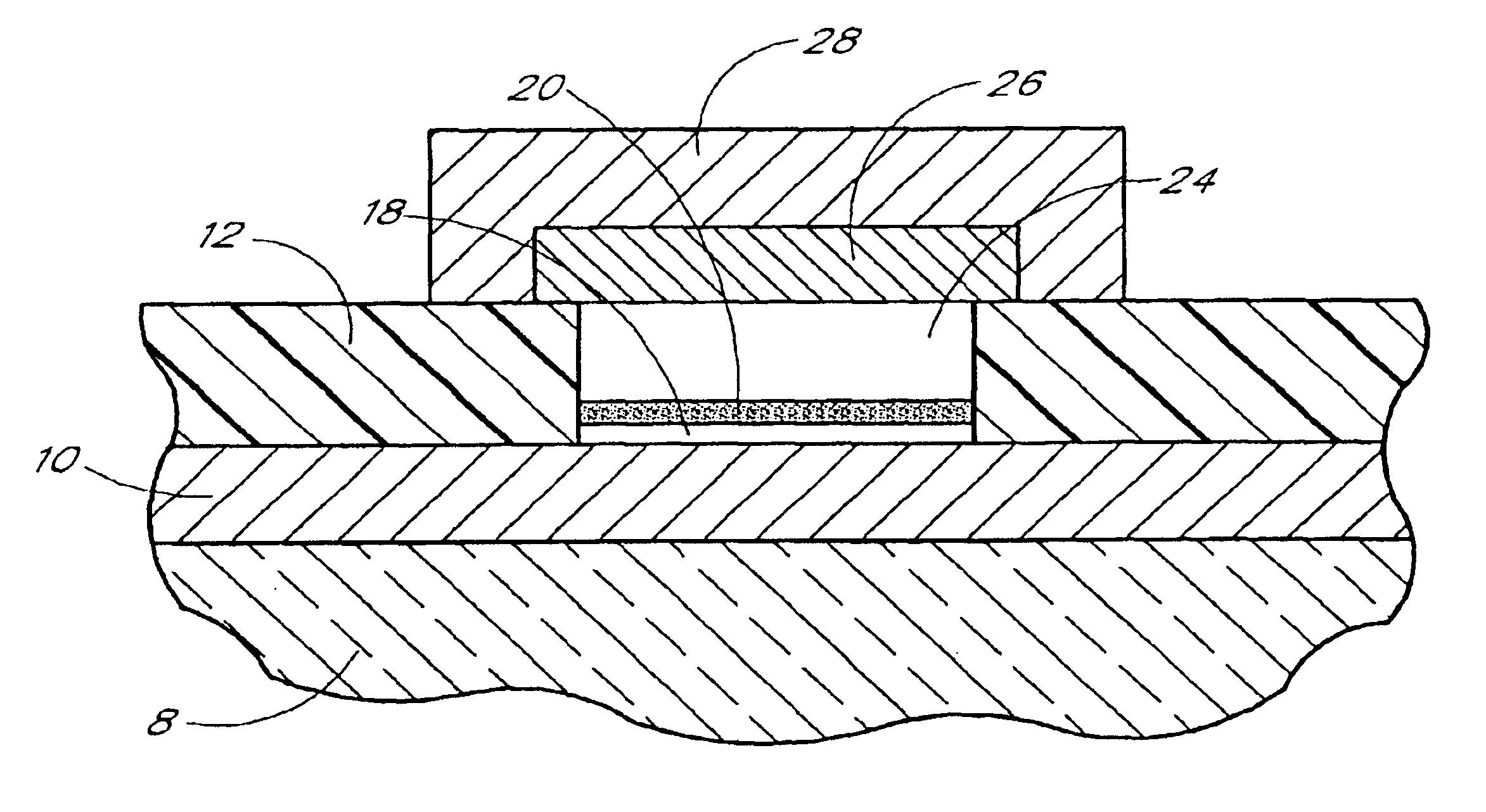

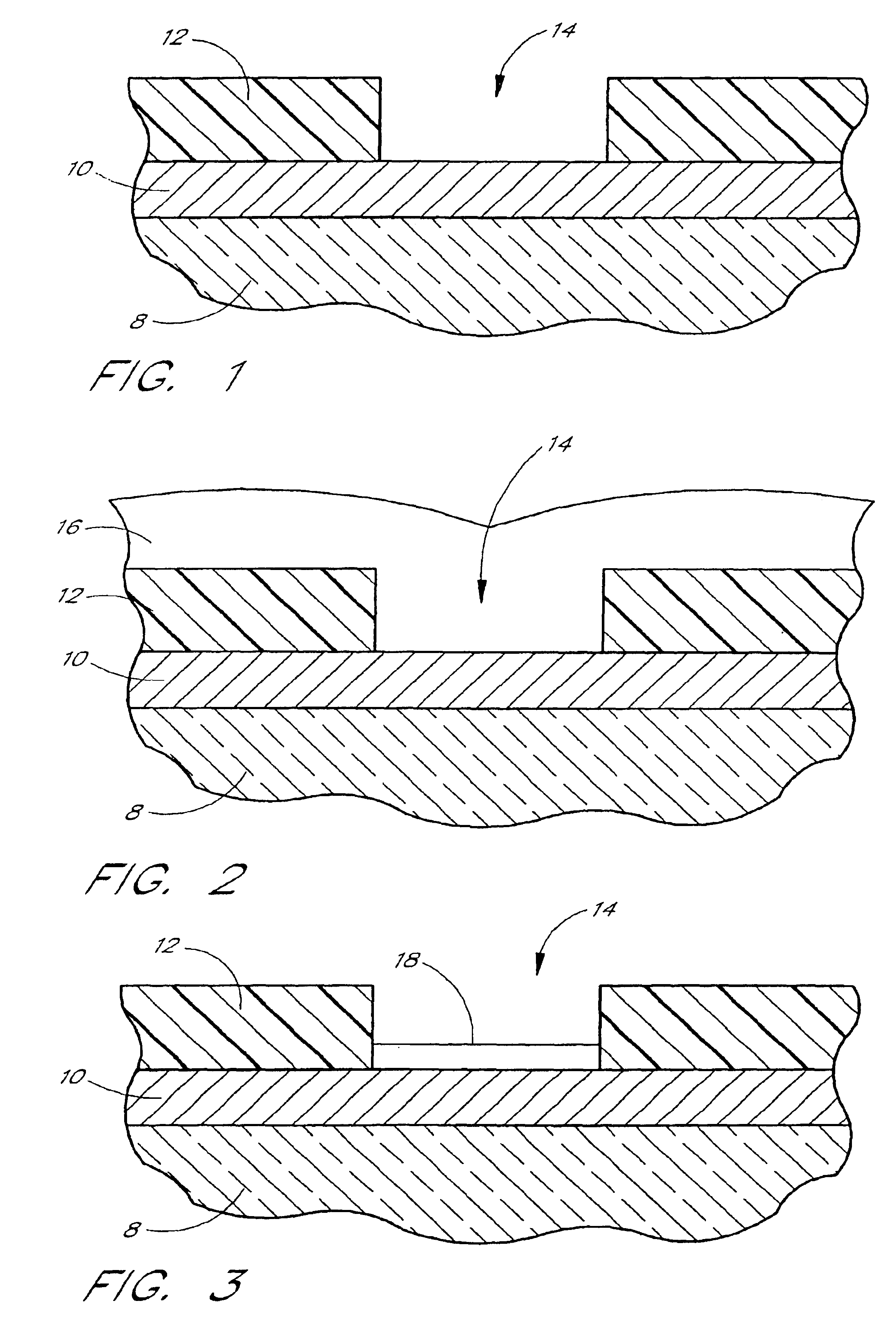

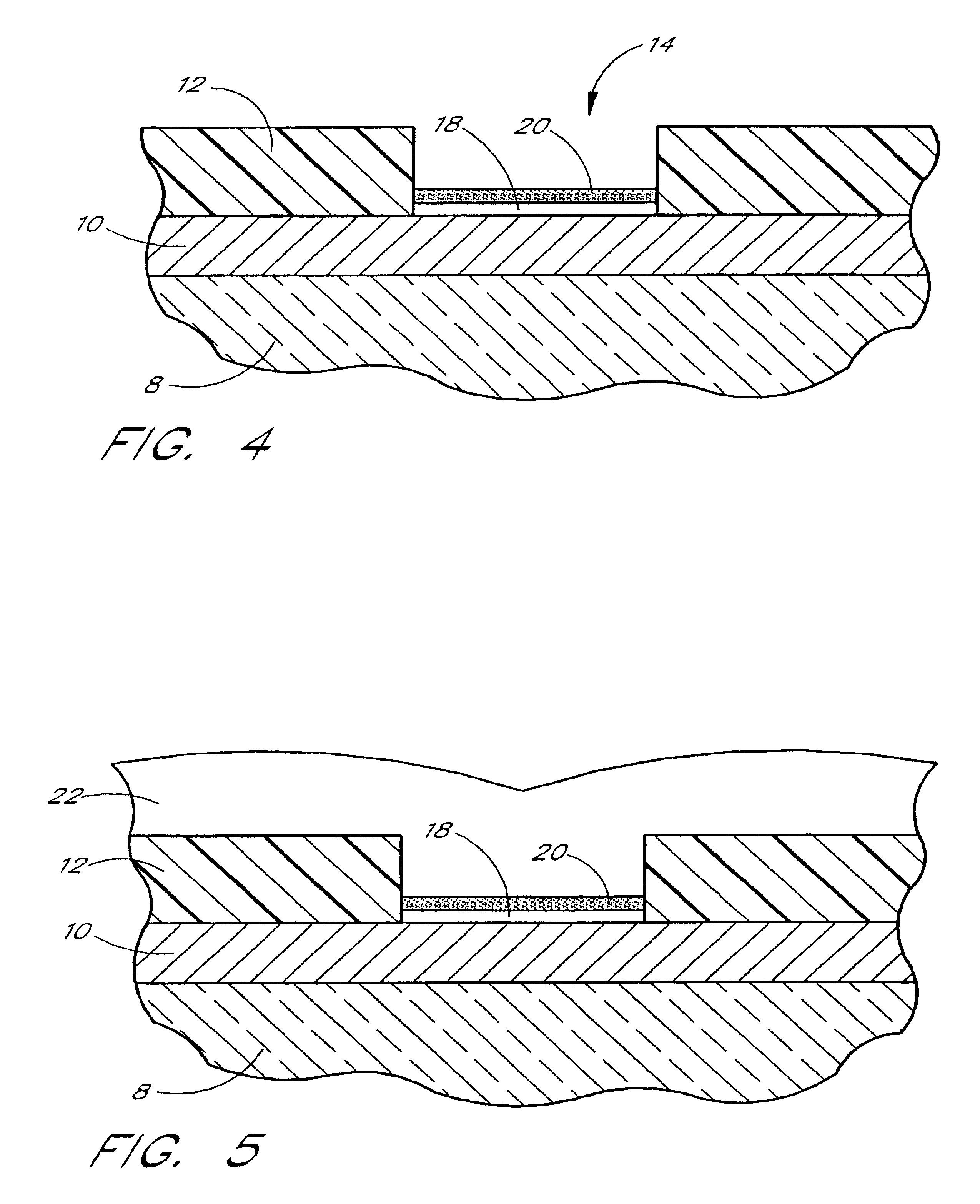

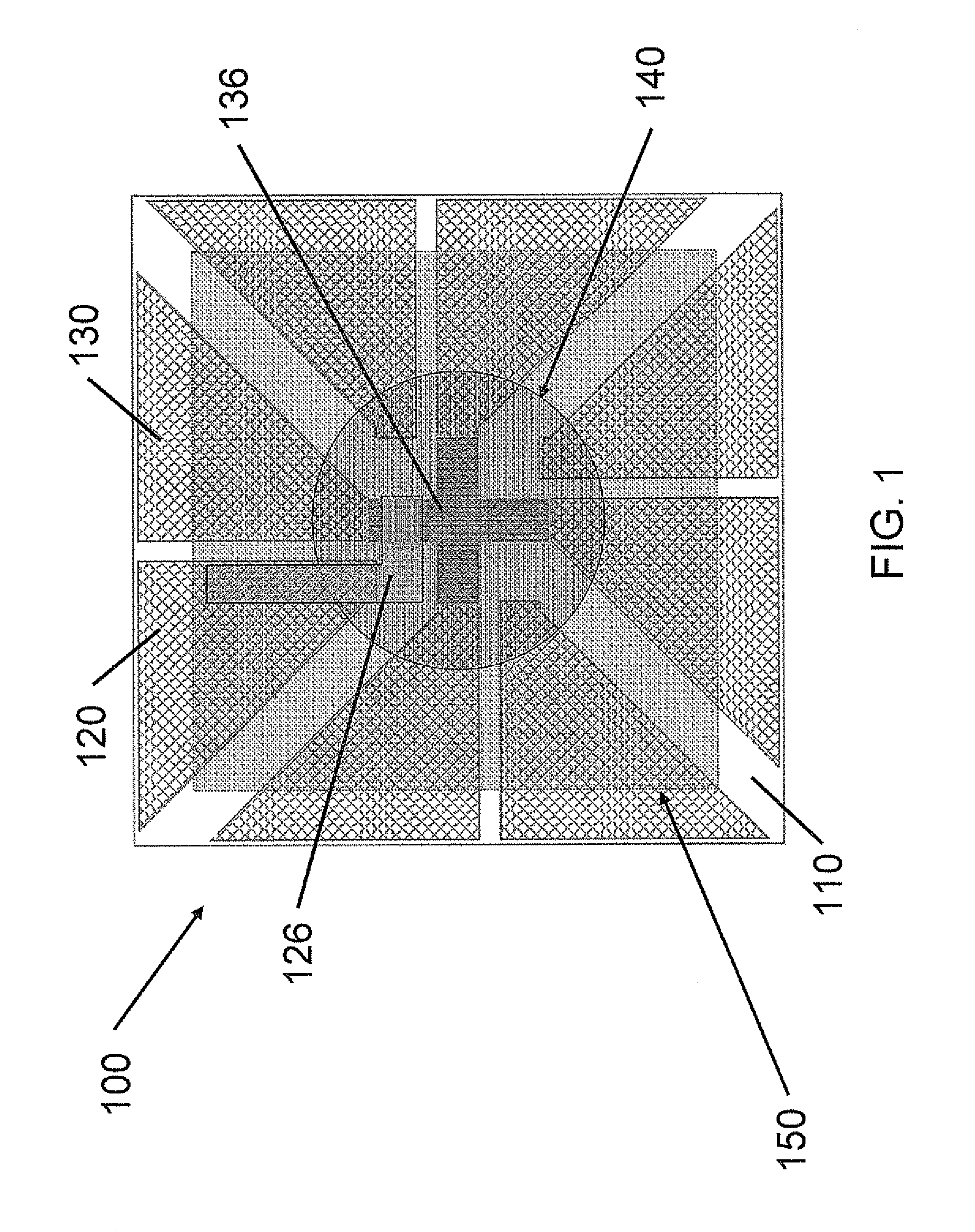

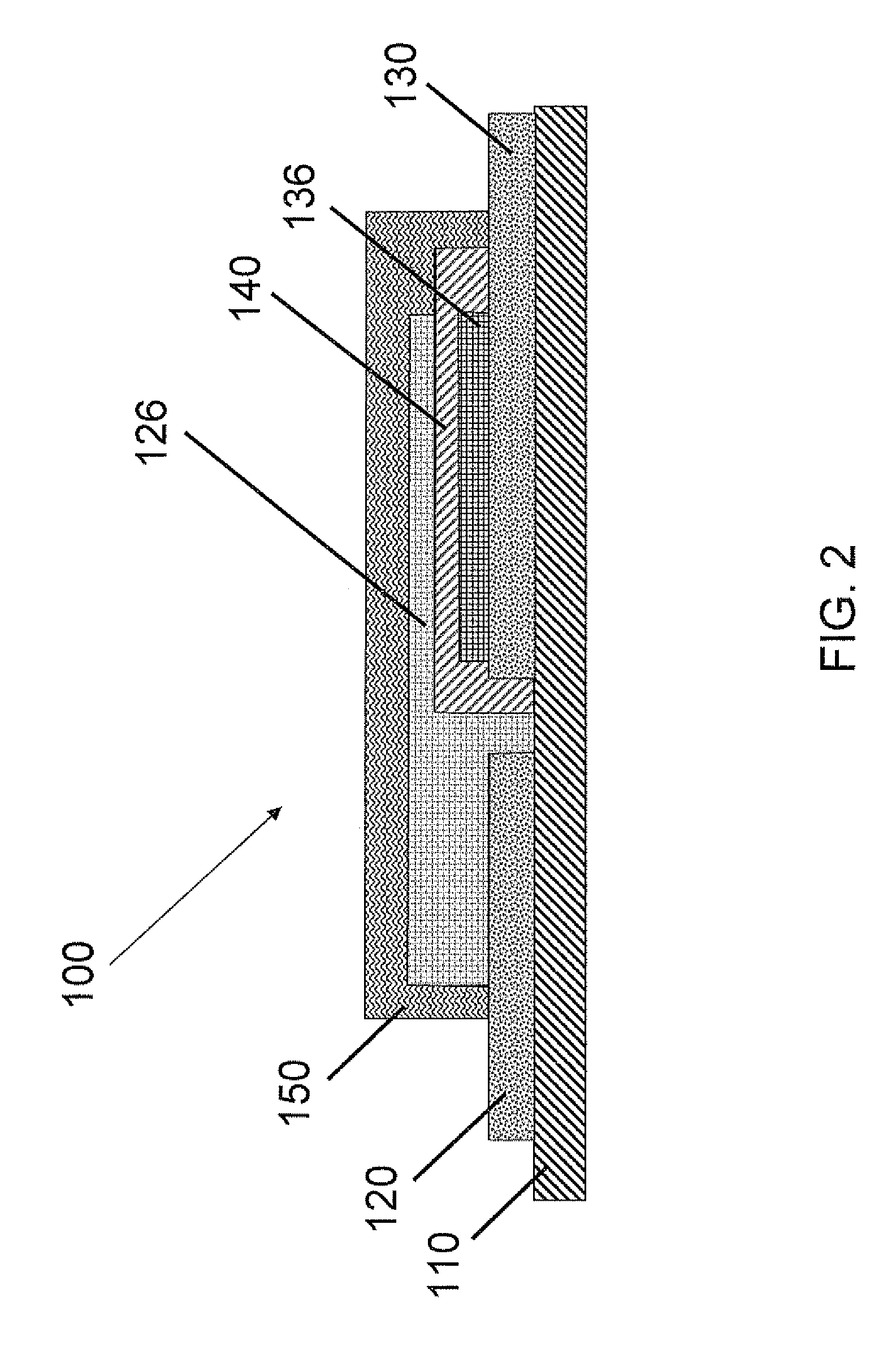

Programmable sub-surface aggregating metallization structure and method of making same

InactiveUS6418049B1Low costHighly manufacturableNanoinformaticsSolid-state devicesCapacitanceElectrical conductor

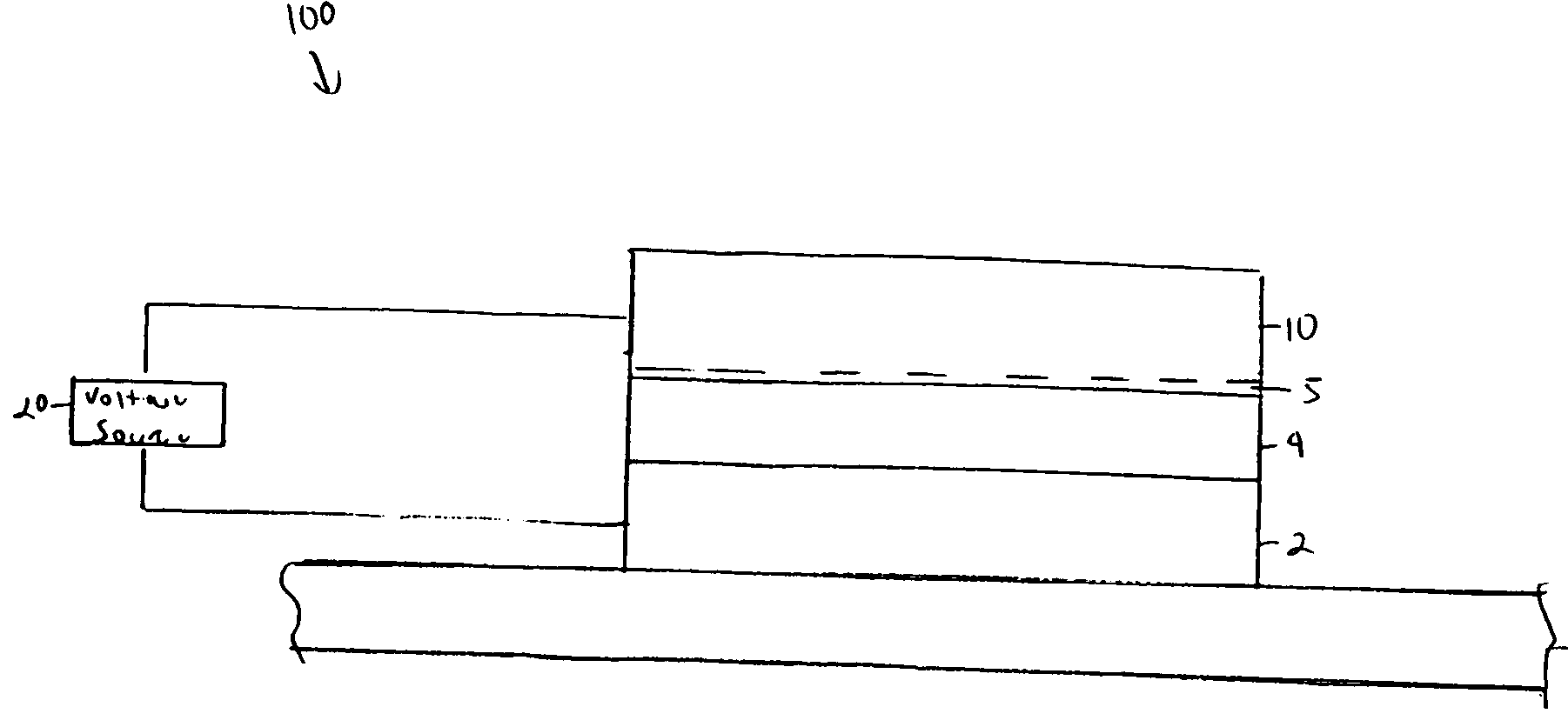

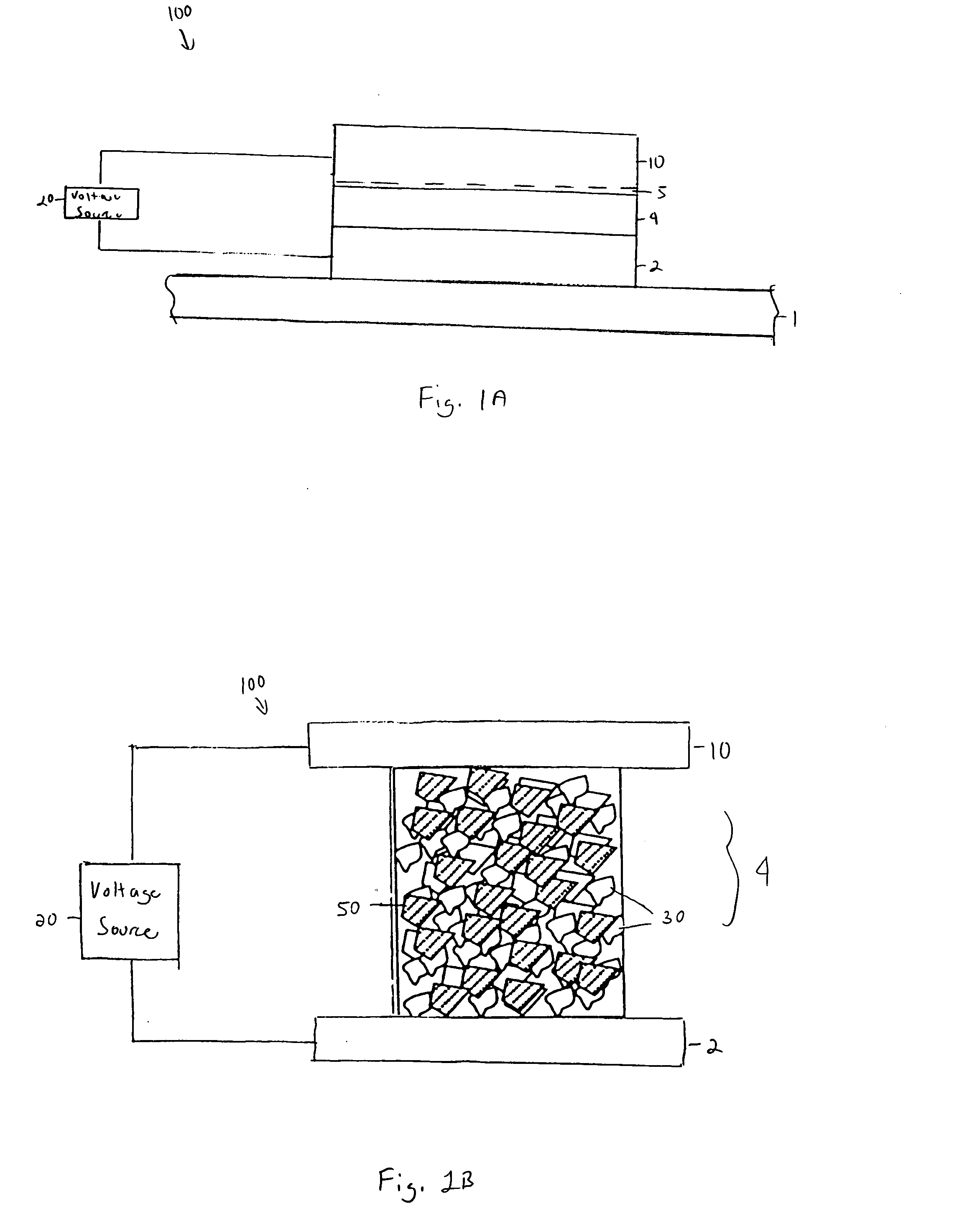

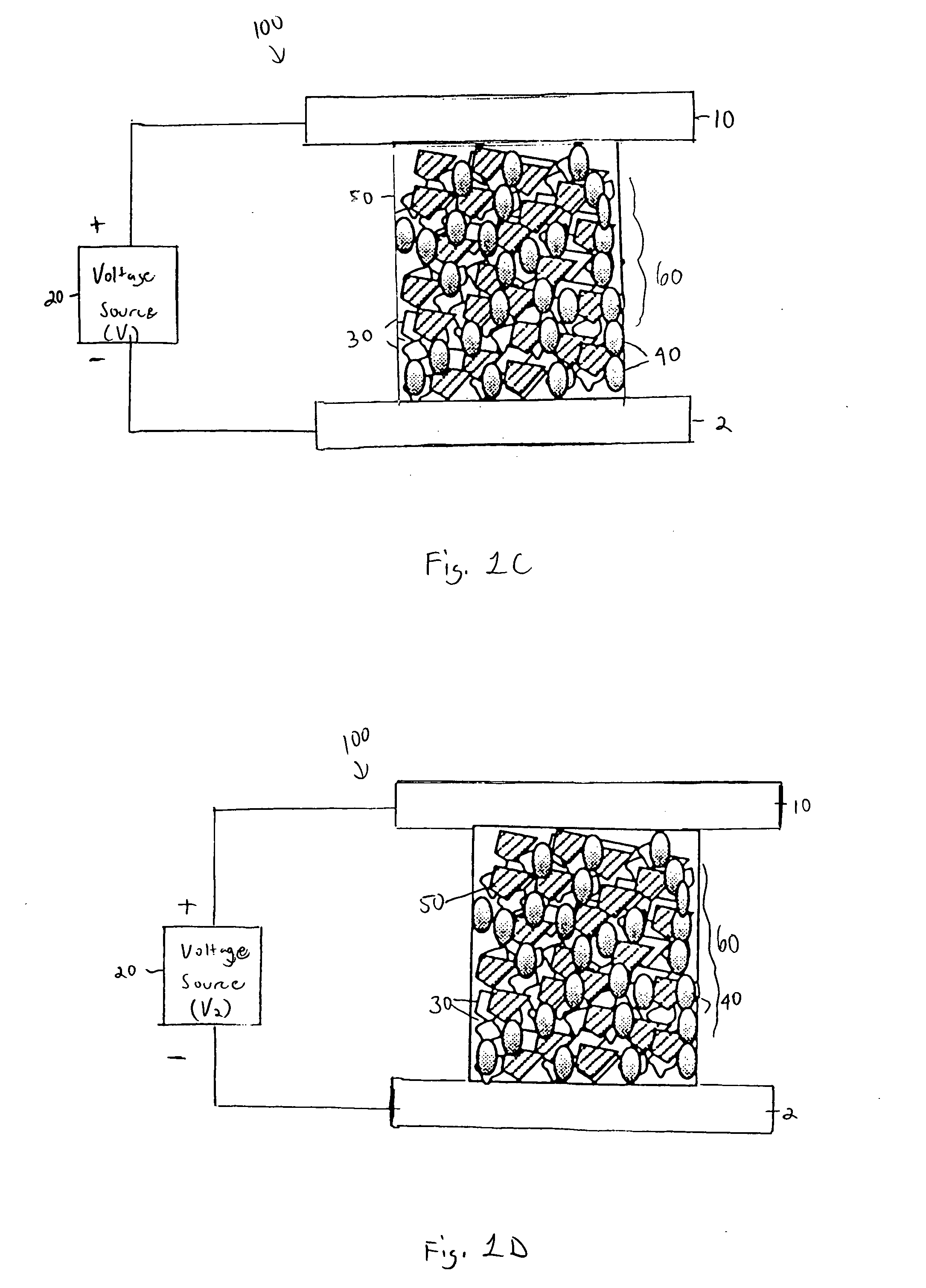

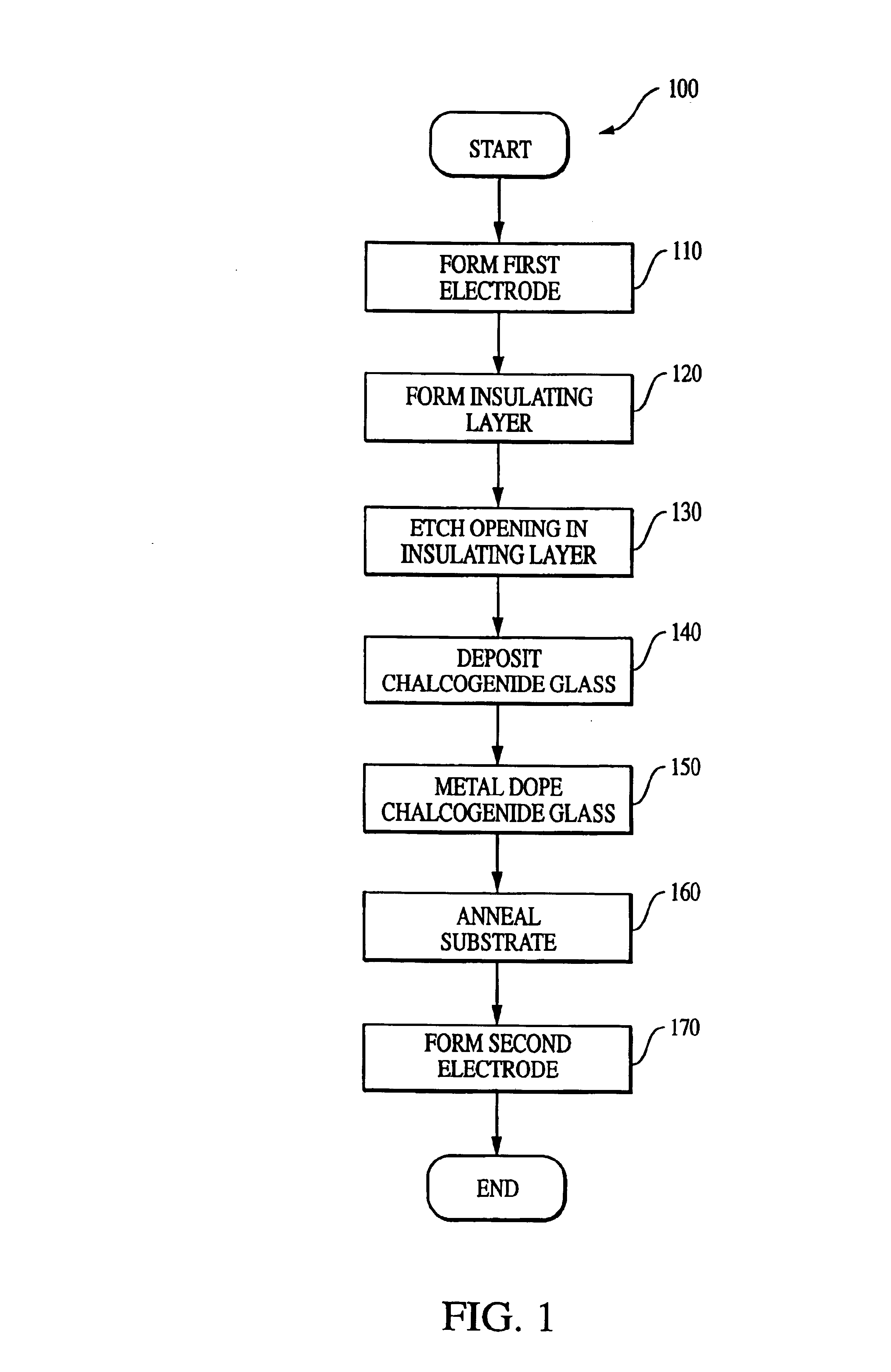

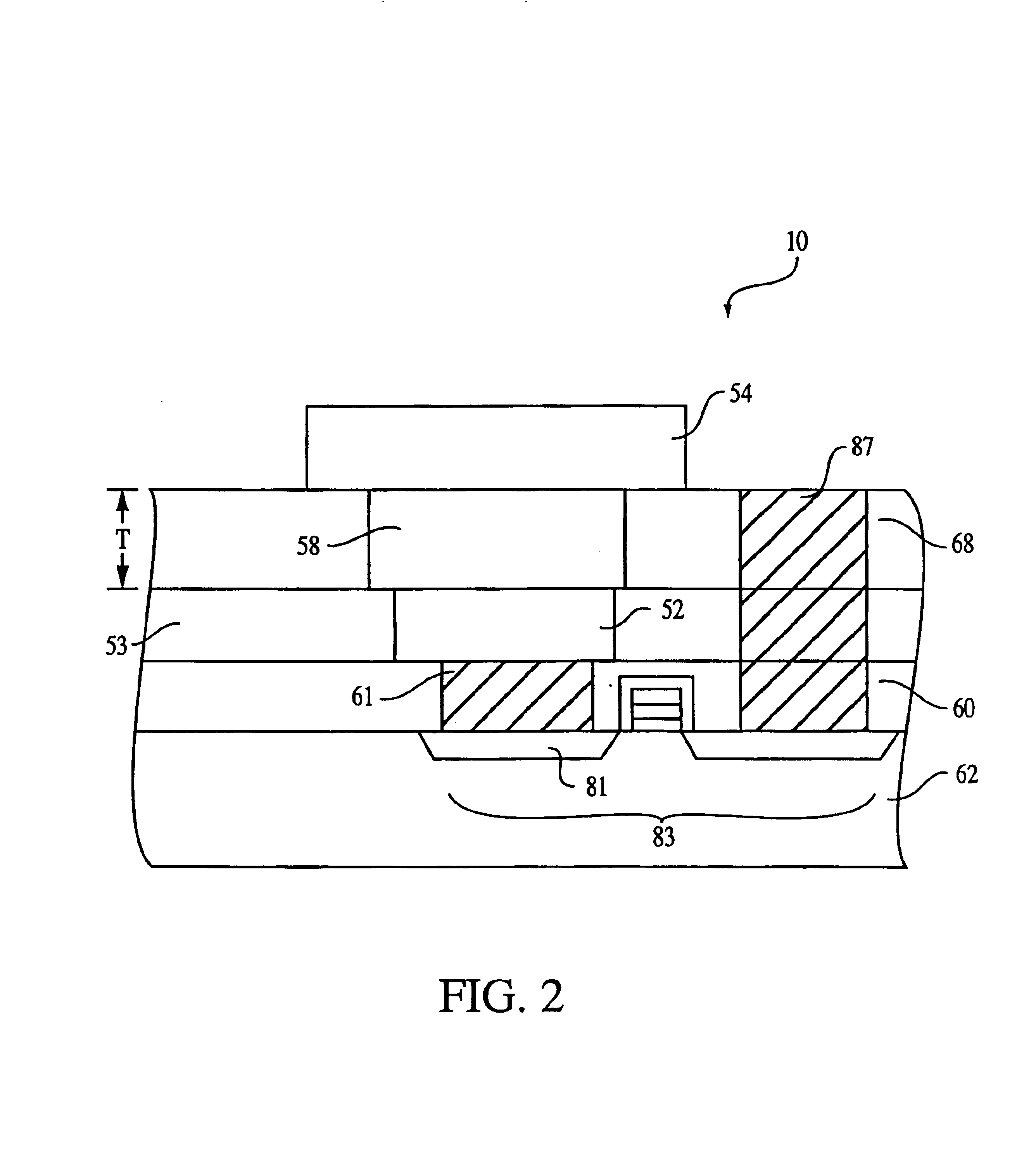

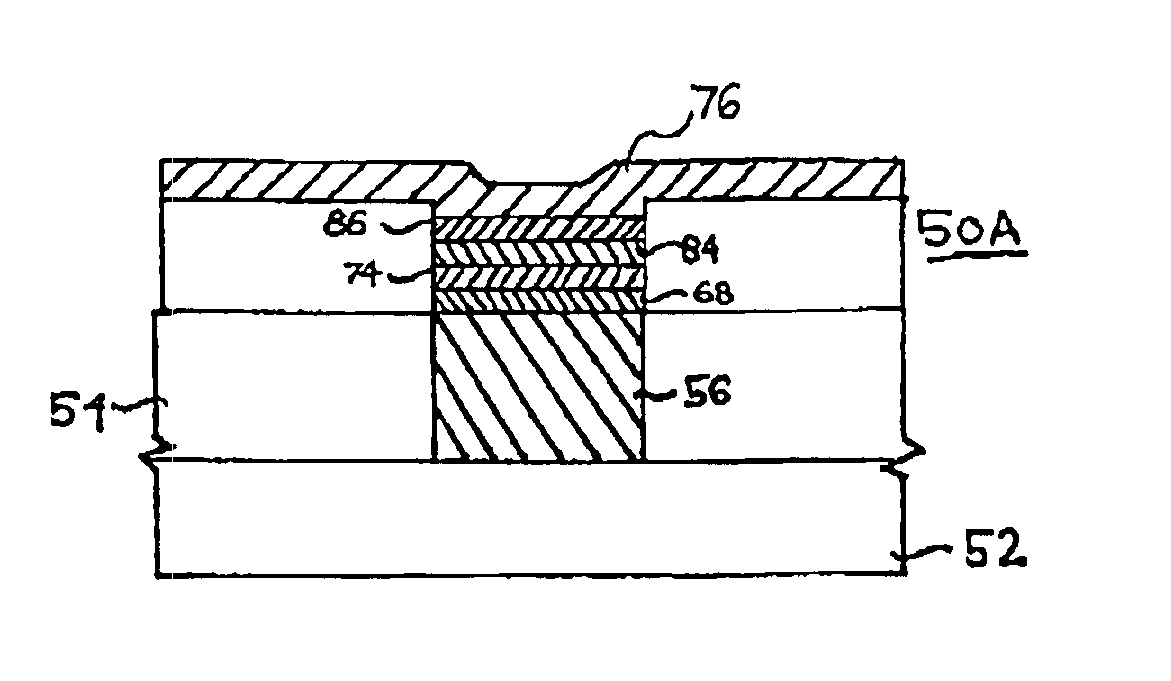

A programmable sub-surface aggregating metallization sructure ("PSAM") includes an ion conductor such as a chalcogenide-glass which includes metal ions and at least two electrodes disposed at opposing surfaces of the ion conductor. Preferably, the ion conductor includes a chalcogenide material with Group IB or Group IIB metals. One of the two electrodes is preferably configured as a cathode and the other as an anode. When a voltage is applied between the anode and cathode, a metal dendrite grows from the cathode through the ion conductor towards the anode. The growth rate of the dendrite may be stopped by removing the voltage or the dendrite may be retracted back towards the cathode by reversing the voltage polarity at the anode and cathode. When a voltage is applied for a sufficient length of time, a continuous metal dendrite grows through the ion conductor and connects the electrodes, thereby shorting the device. The continuous metal dendrite then can be broken by applying another voltage. The break in the metal dendrite can be reclosed by applying yet another voltage. Changes in the length of the dendrite or the presence of a break in the dendrite affect the resistance, capacitance, and impedance of the PSAM.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA +1

Programmable sub-surface aggregating metallization structure and method of making same

InactiveUS20020190350A1Low costHighly manufacturableNanoinformaticsSolid-state devicesCapacitanceElectrical conductor

A programmable sub-surface aggregating metallization structure ("PSAM") includes an ion conductor, such as a chalcogenide-glass which includes metal ions and at least two electrodes disposed at opposing surfaces of the ion conductor. Preferably, the ion conductor includes a chalcogenide material with, Group IB or Group IIB metal. One of two electrodes is preferably configured as a cathode and the other as an anode. When a voltage is applied between the anode and cathode a metal dendrite grows from the cathode through the ion conductor towards the anode. The growth rate of the dendrite may be stopped by removing the voltage or the dendrite may be retracted back towards the cathode by reversing the voltage polarity at the anode and cathode. When a voltage is applied for a sufficient length of time, a continuous metal dendrite grows through the ion conductor and connects the electrodes, thereby shorting the device. The continuous metal dendrite then can be broken by applying another voltage. The break in the metal dendrite can be reclosed by applying yet another voltage. Changes in the length of the dendrite or the presence of a break in the dendrite affect the resistance, capacitance and impedance of the PSAM.

Owner:AXON TECH

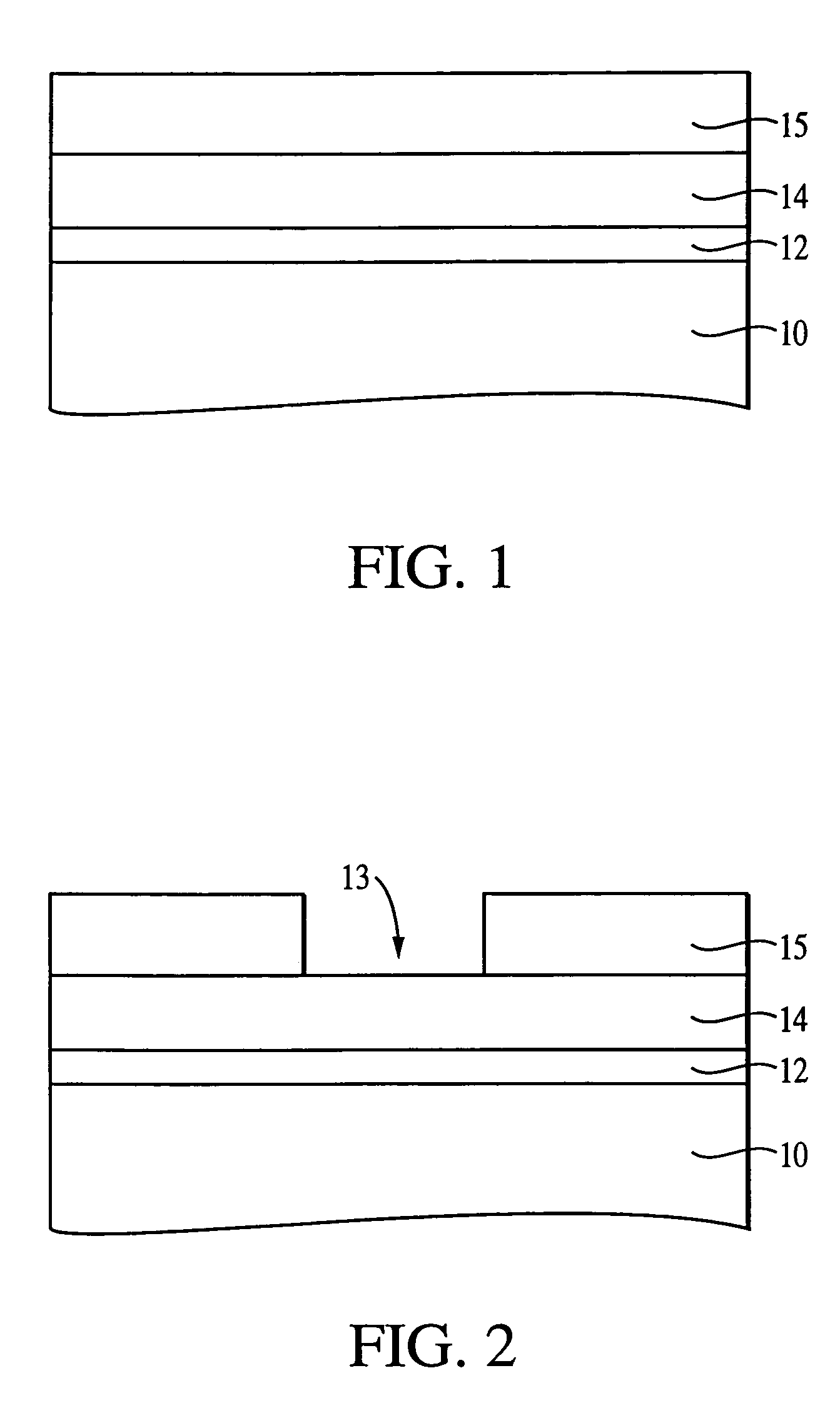

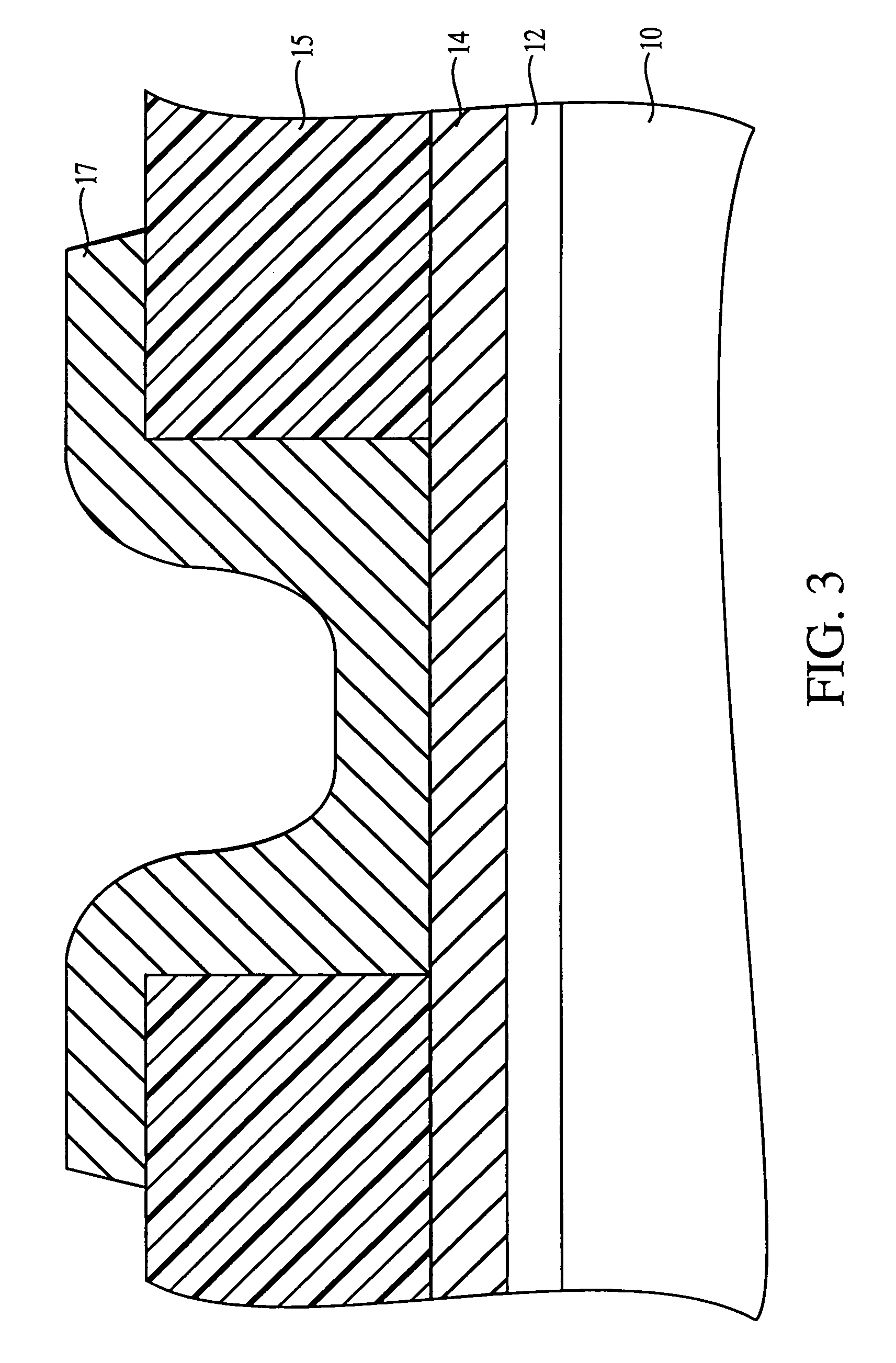

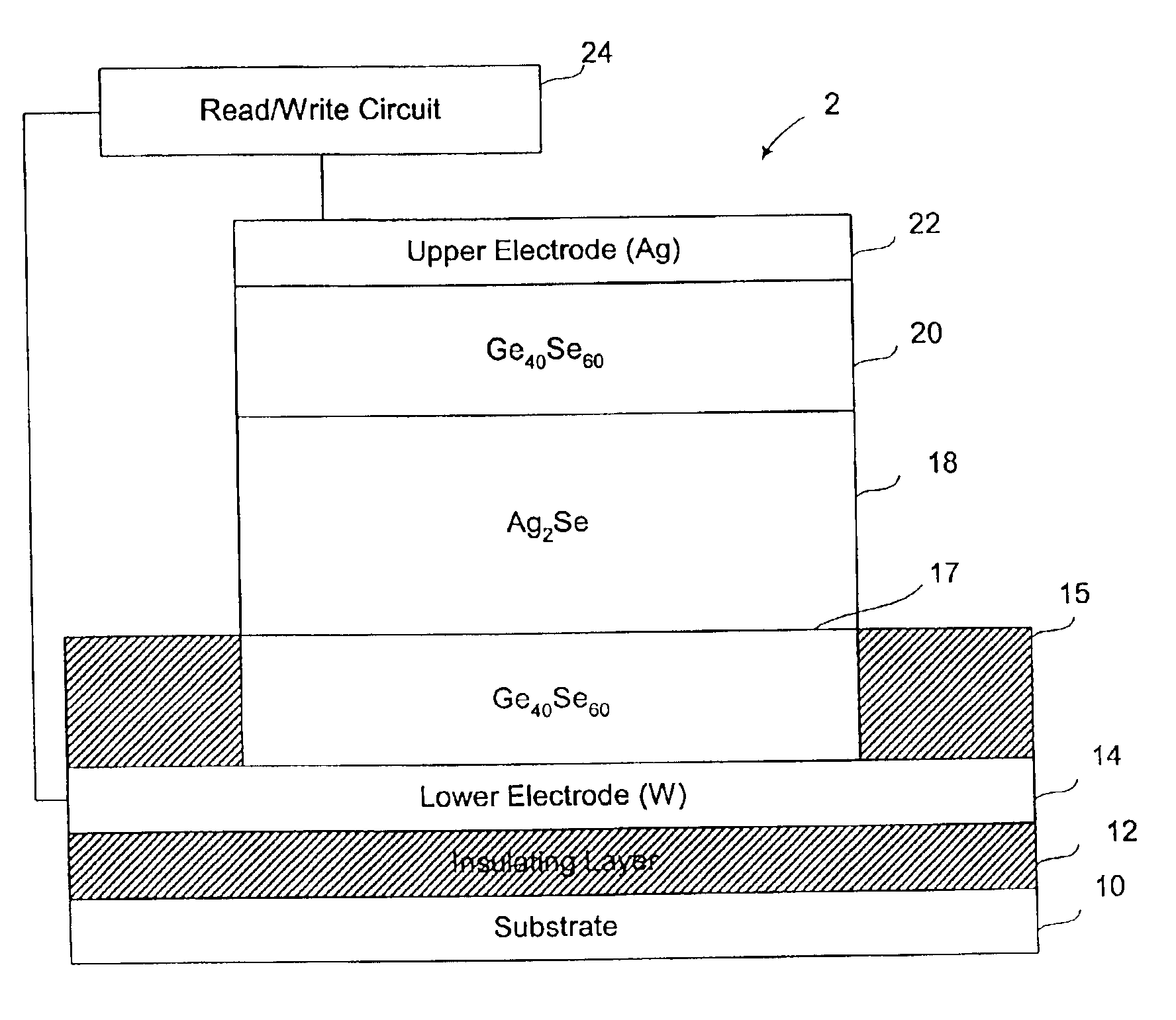

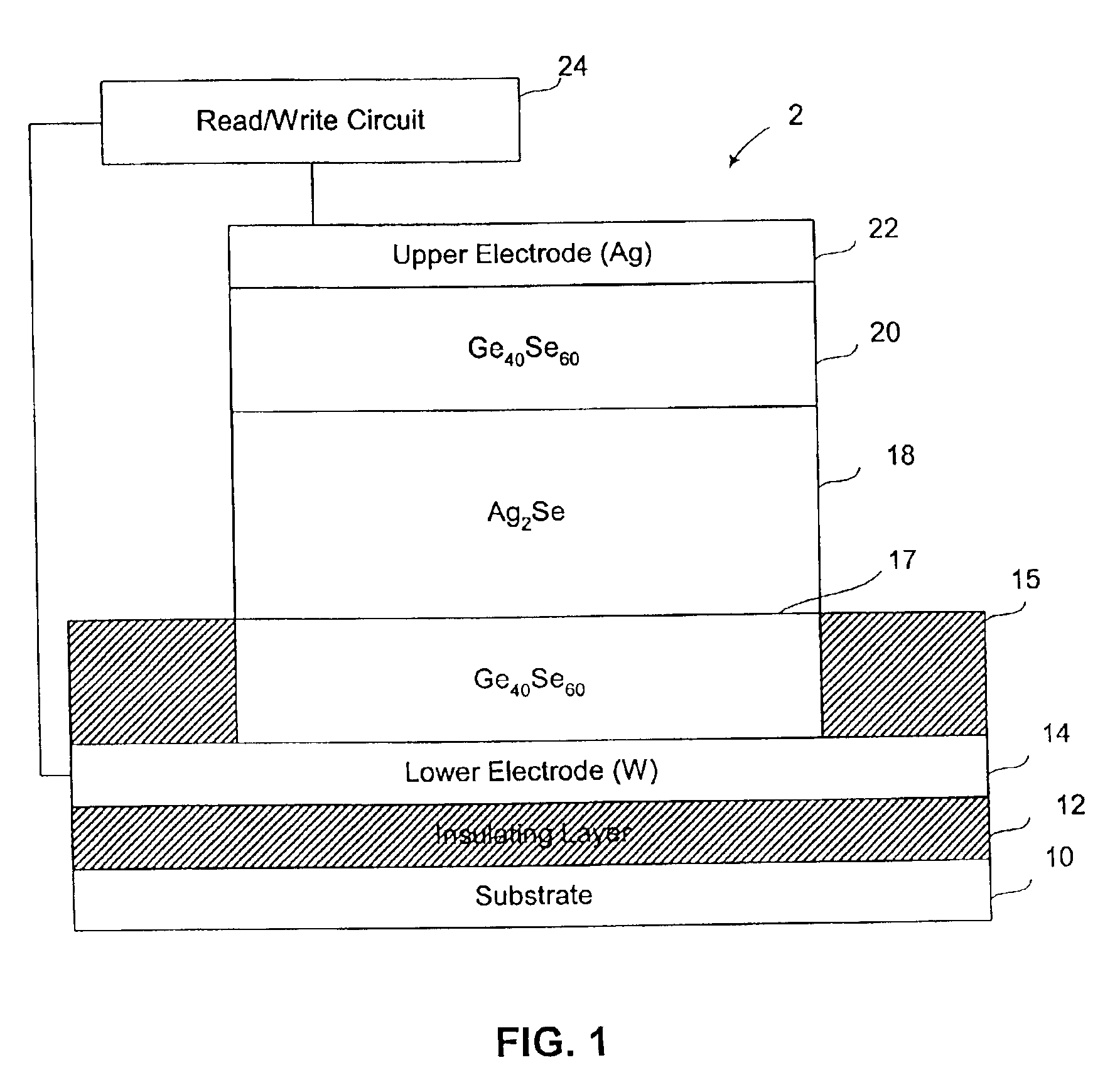

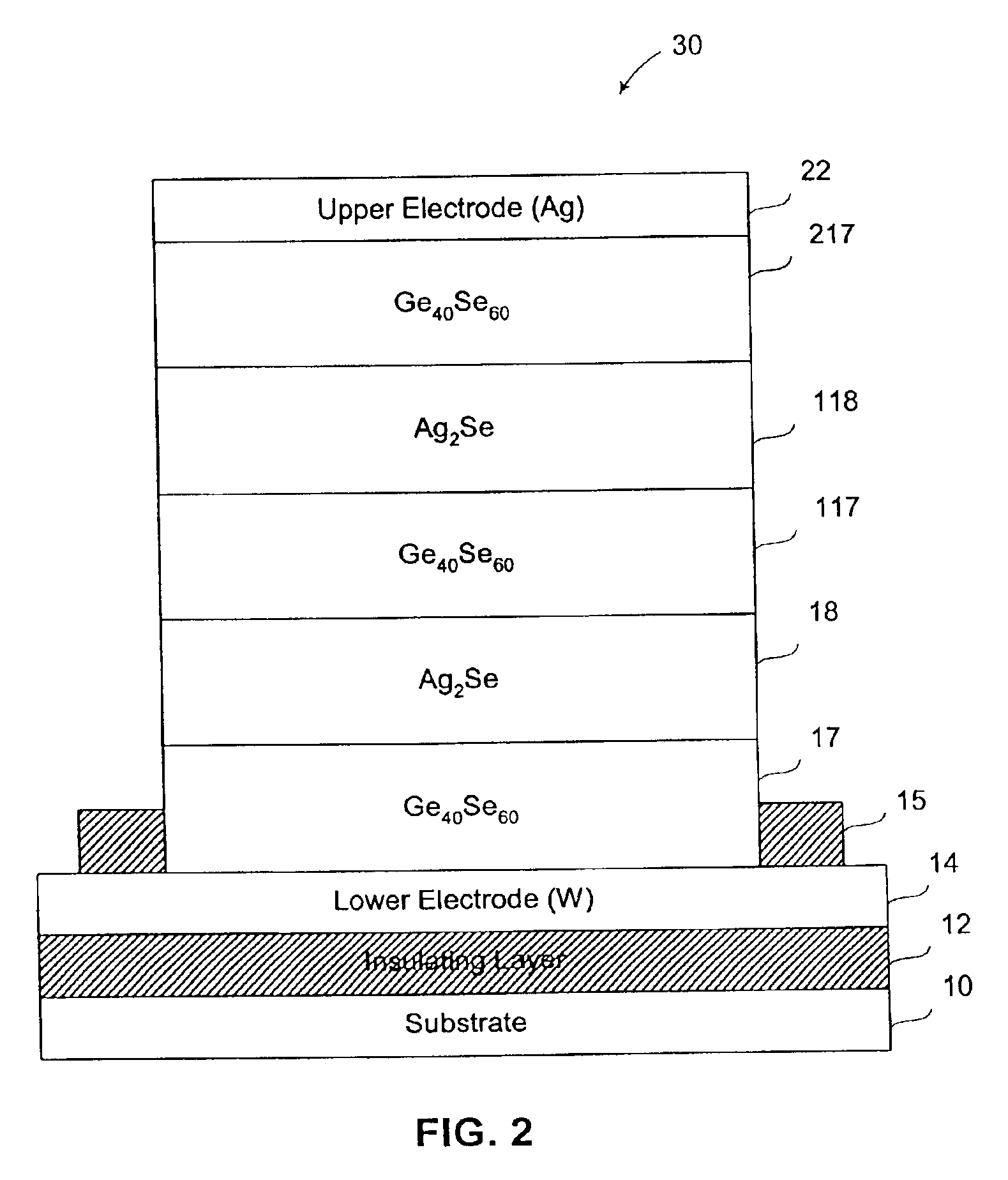

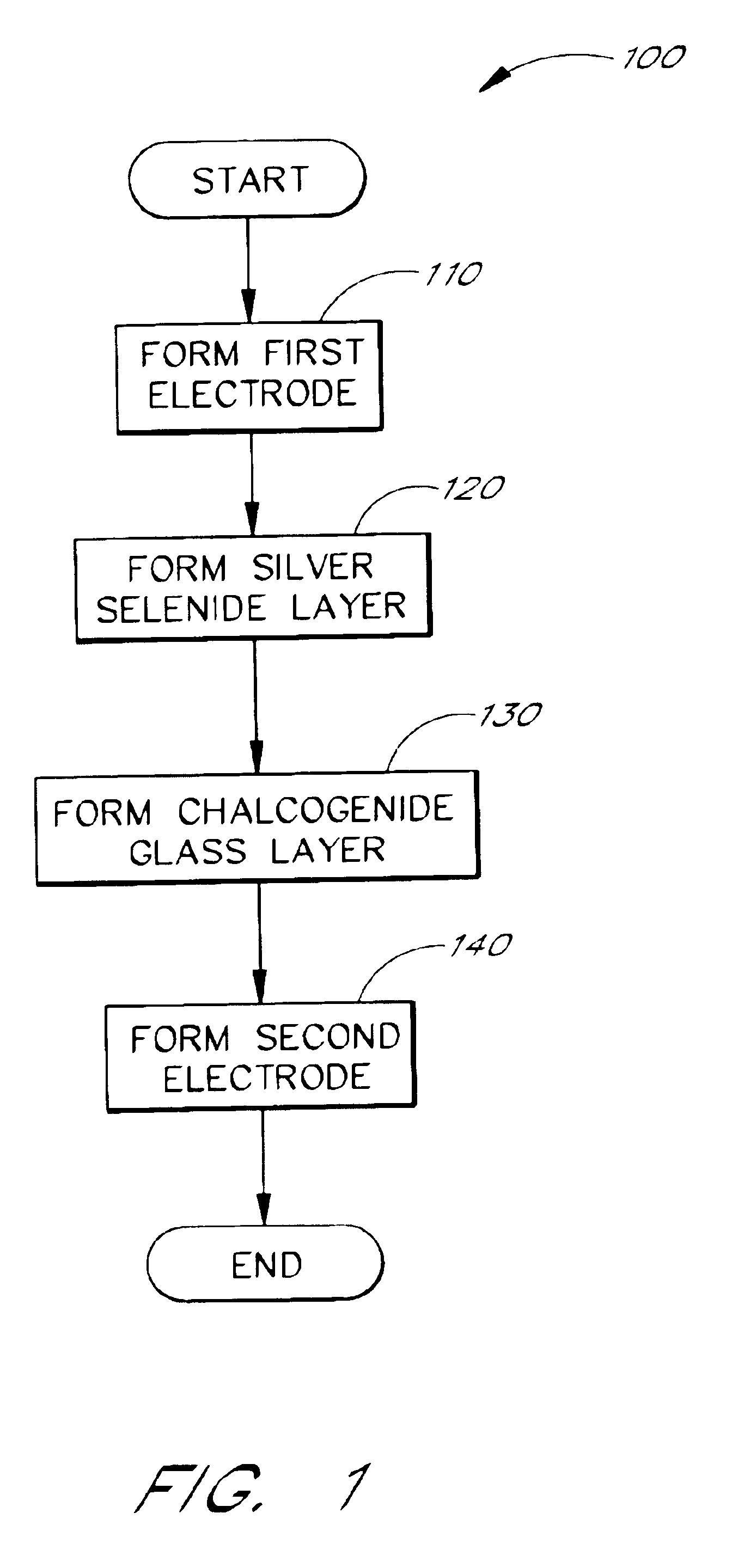

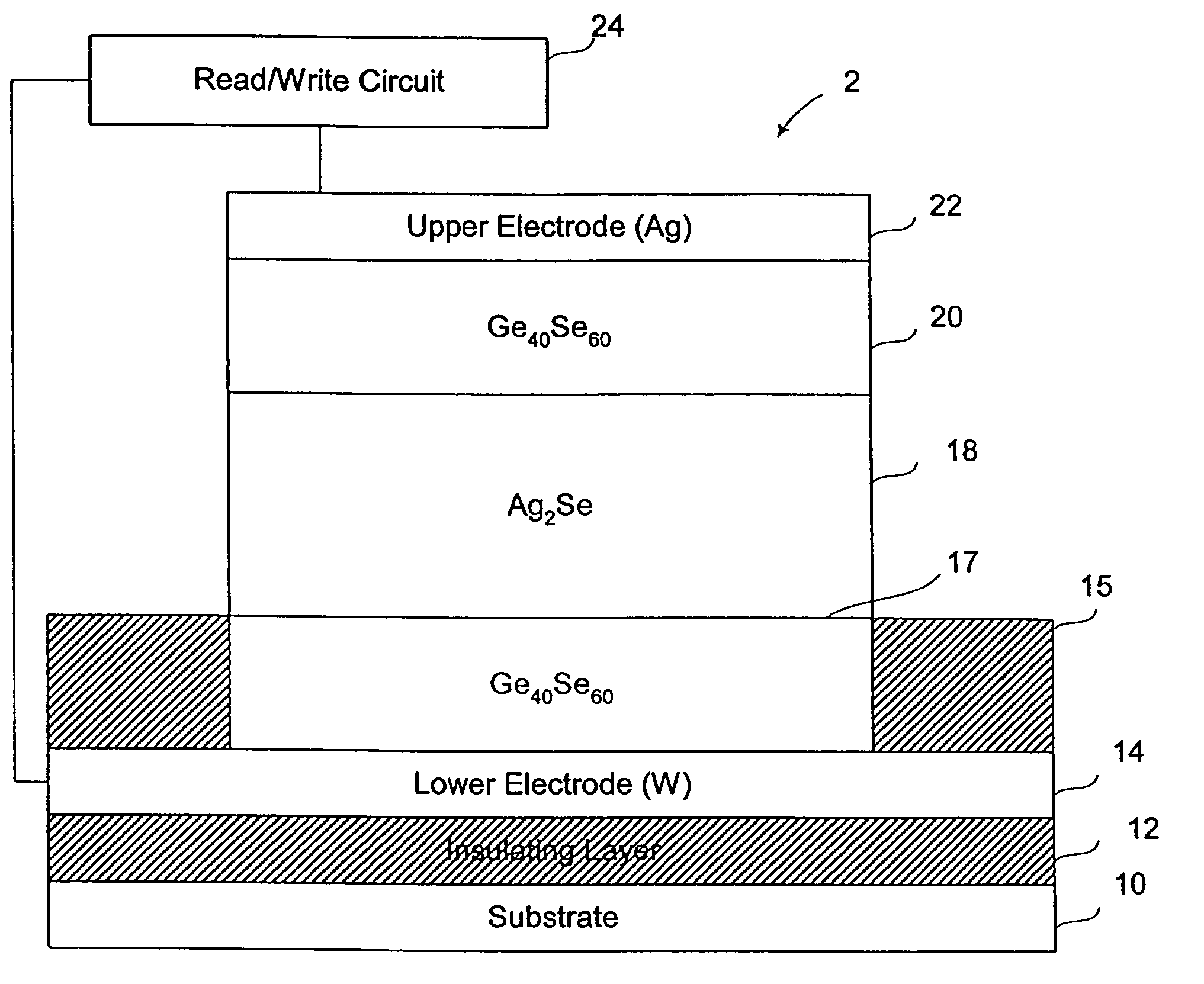

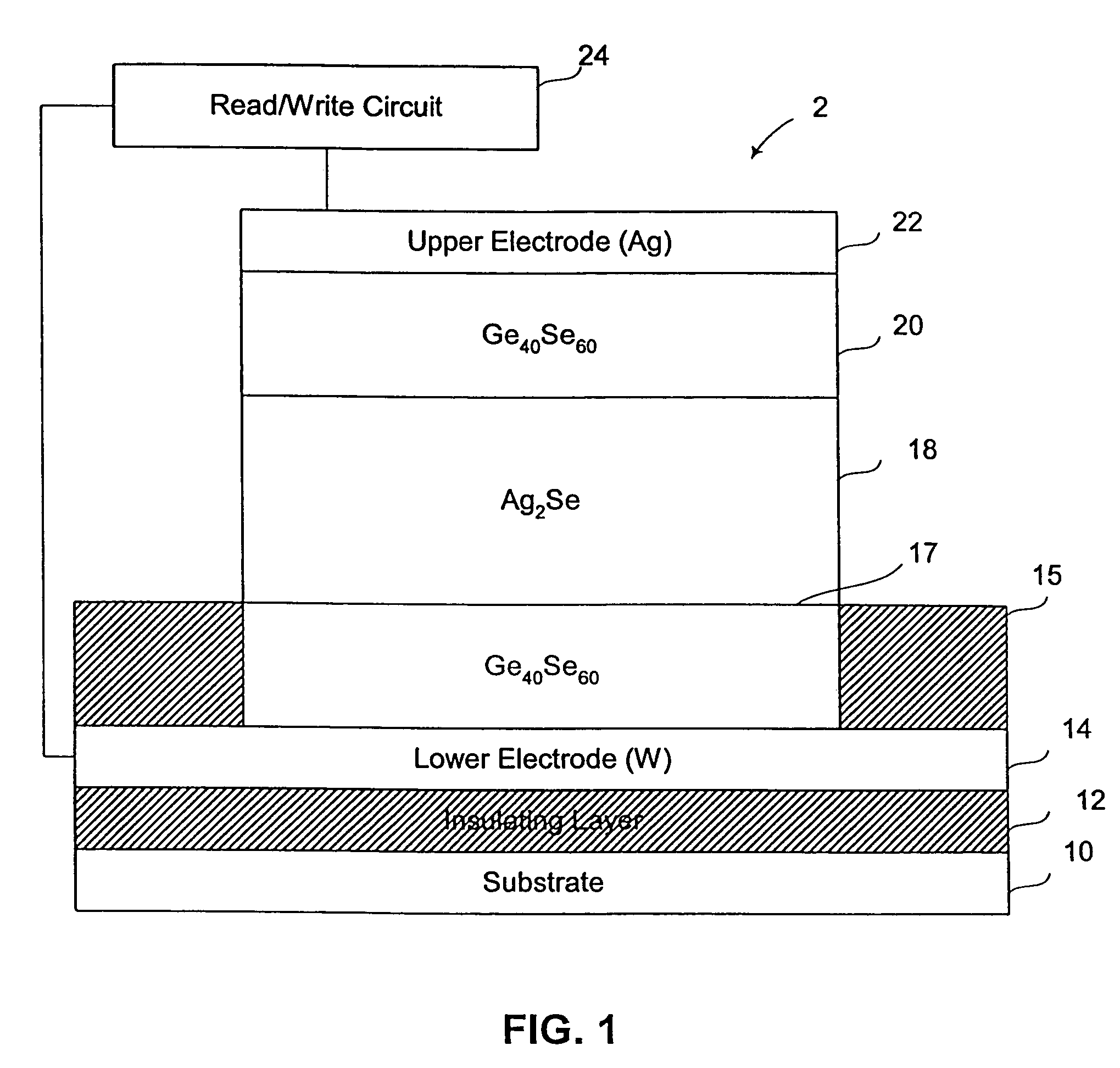

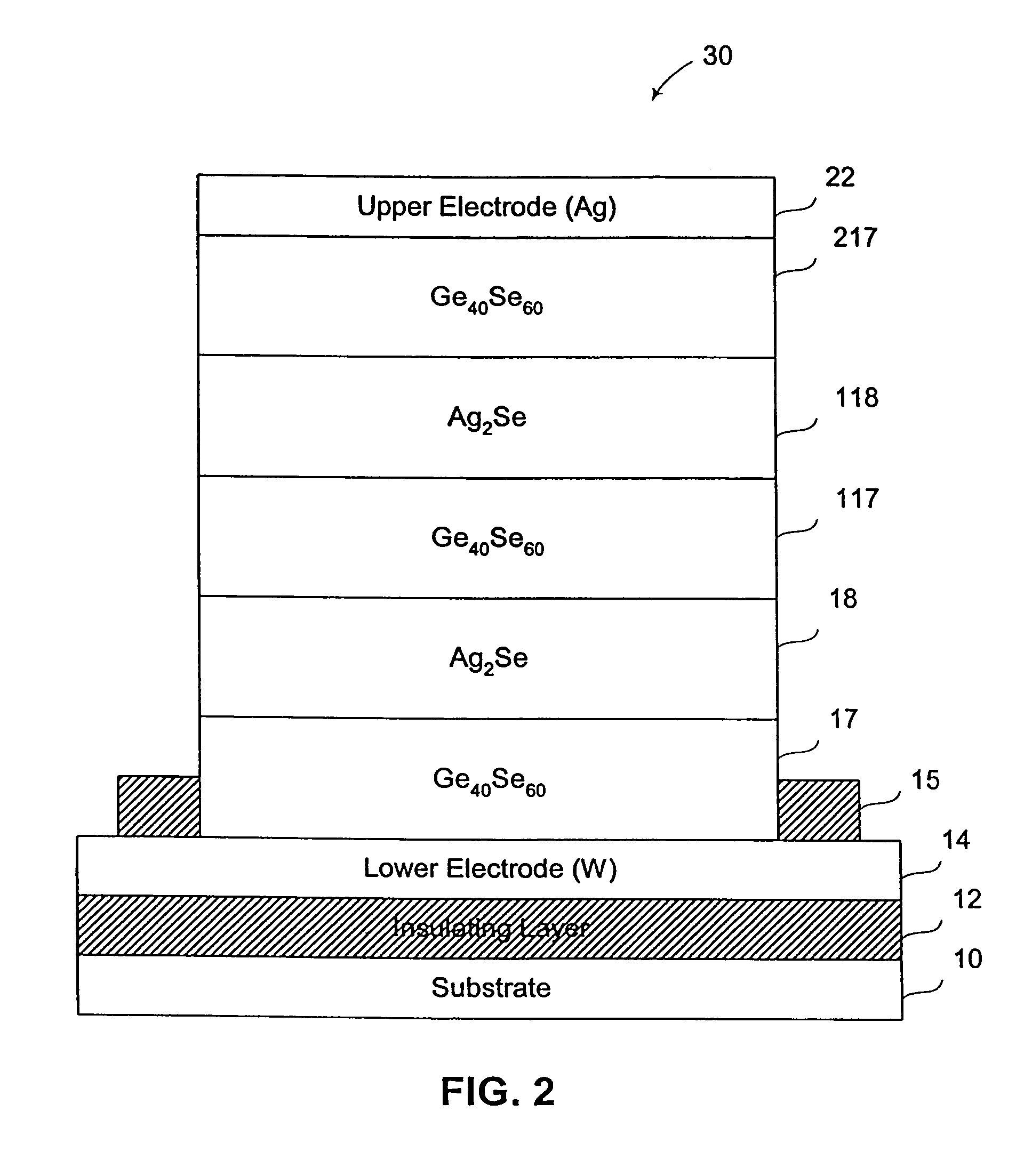

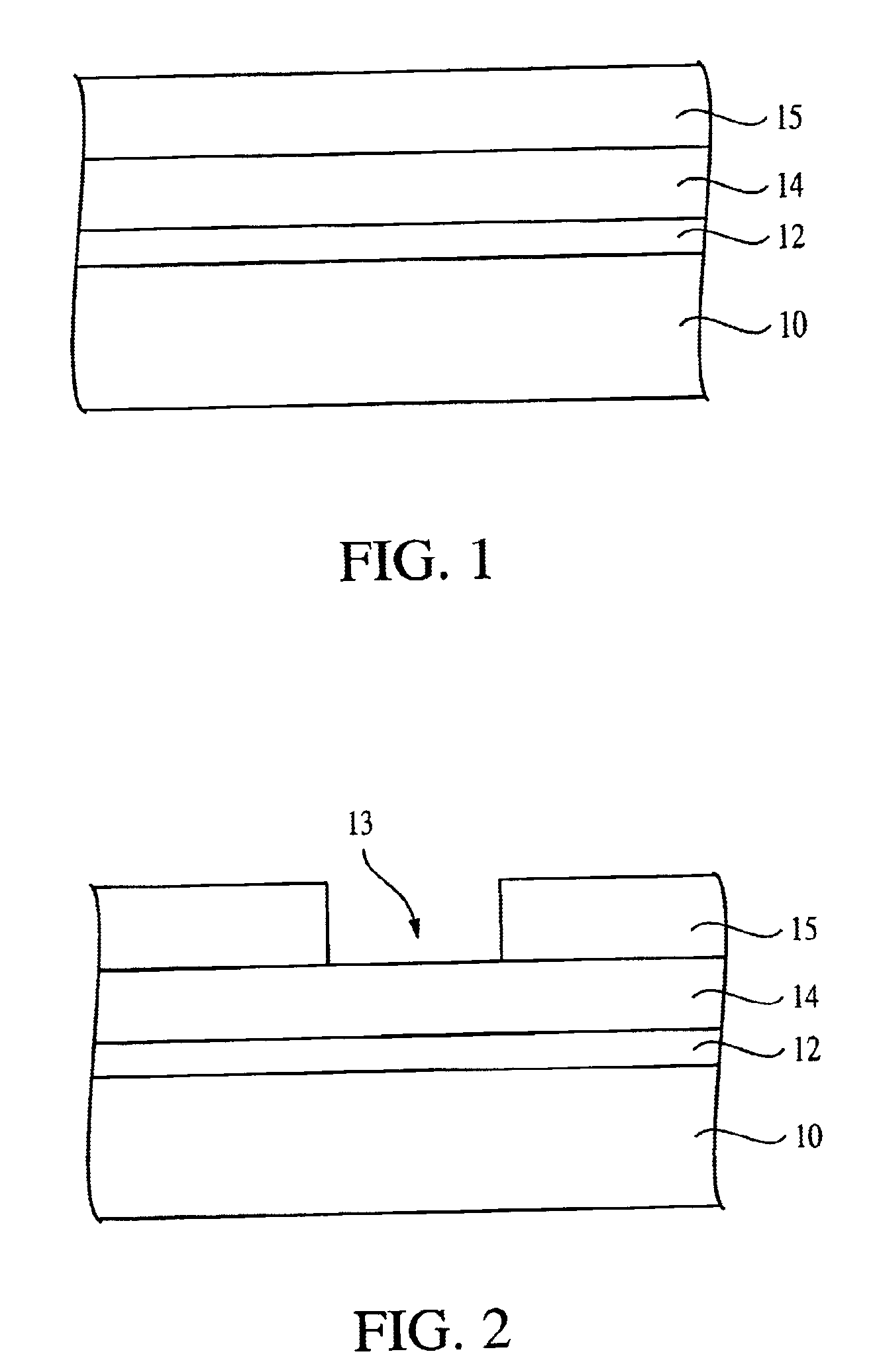

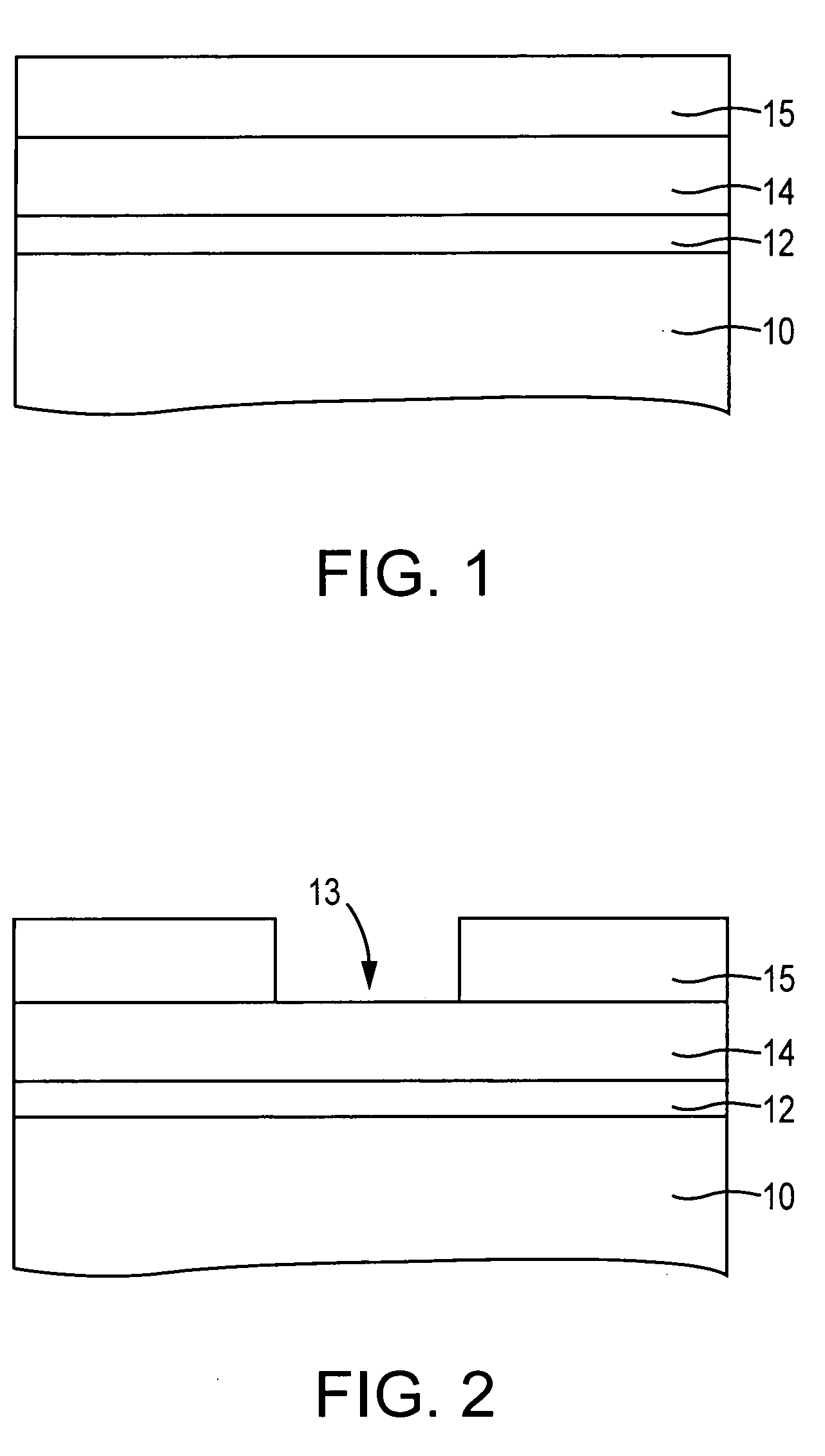

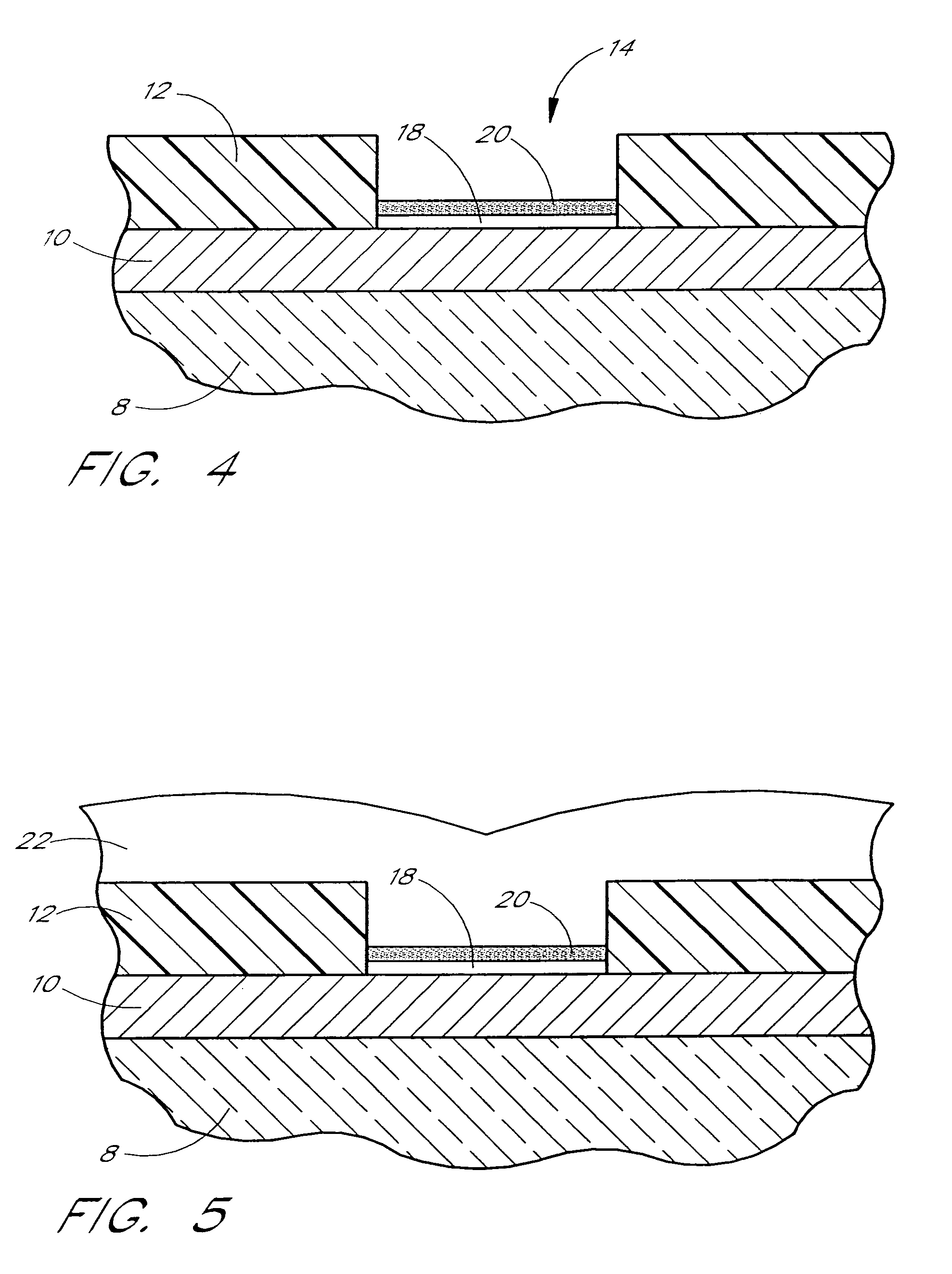

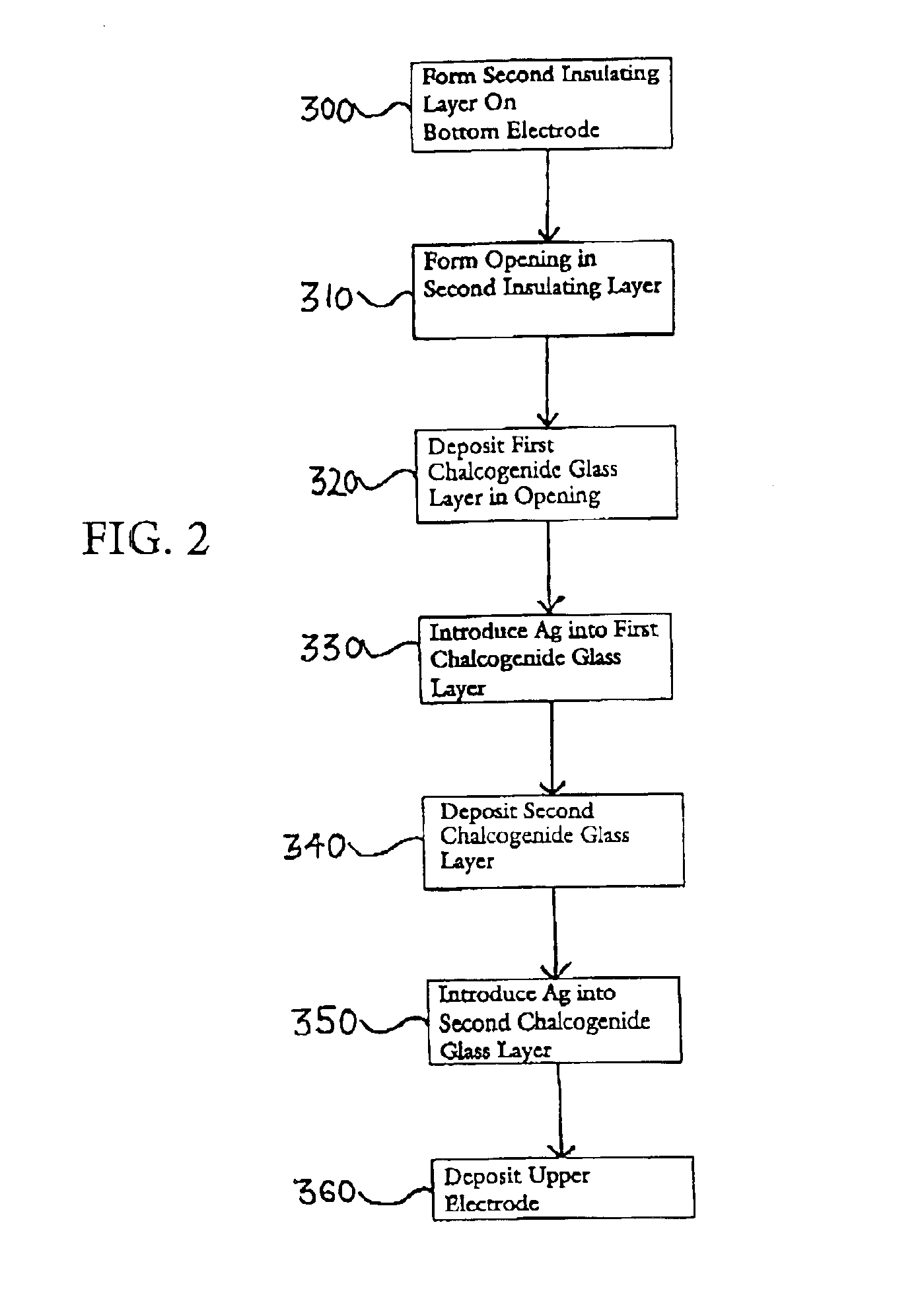

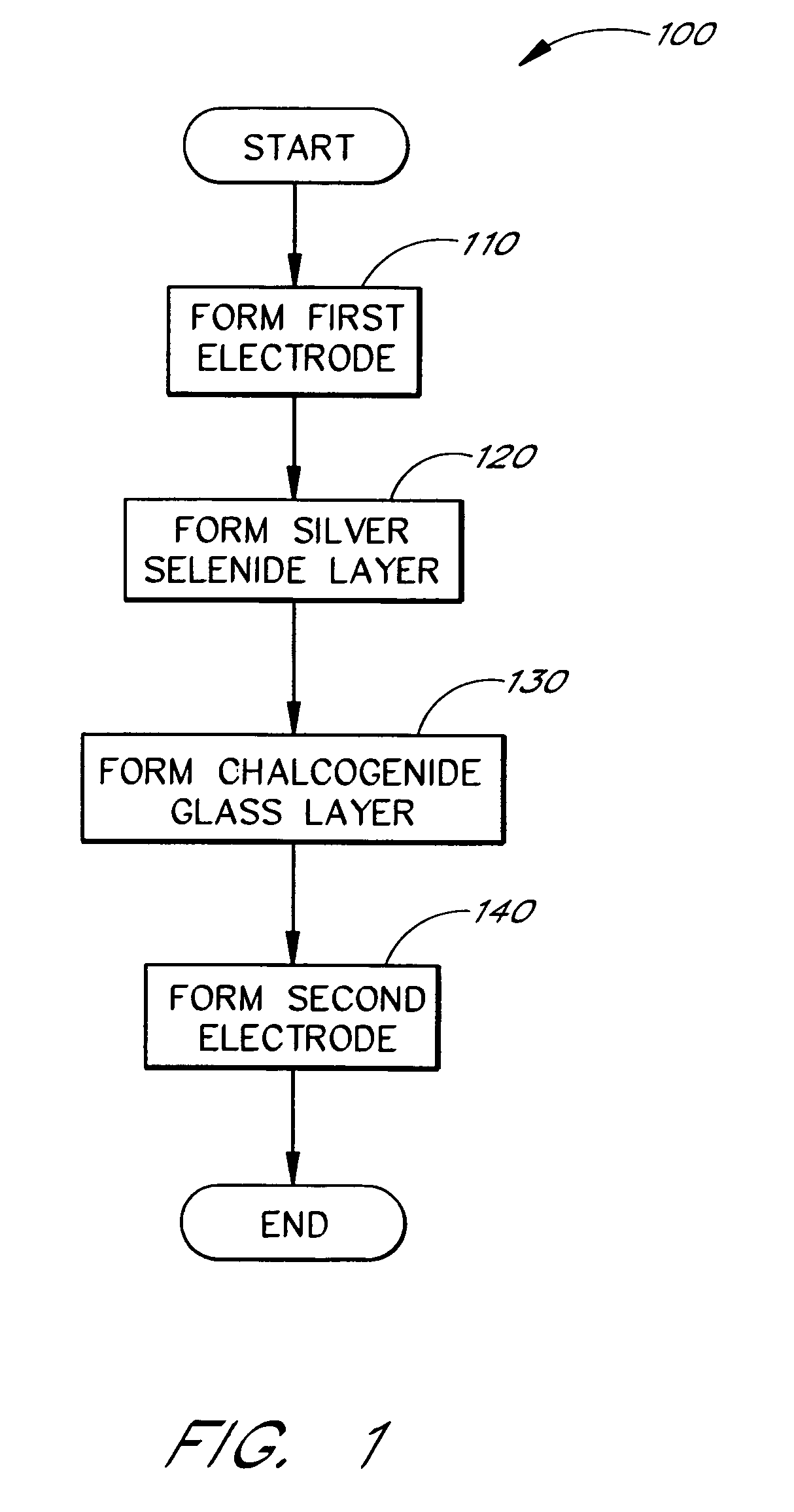

Silver-selenide/chalcogenide glass stack for resistance variable memory

InactiveUS7151273B2Solid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareSulfur

The invention is related to methods and apparatus for providing a resistance variable memory element with improved data retention and switching characteristics. According to an embodiment of the invention a resistance variable memory element is provided having at least one silver-selenide layer in between glass layers, wherein at least one of the glass layers is a chalcogenide glass, preferably having a GexSe100−x composition.

Owner:MICRON TECH INC

Single-polarity programmable resistance-variable memory element

A resistance variable memory element with improved data retention and switching characteristics switched between resistance memory states upon the application of write pulses having the same polarity. The resistance variable memory element can be provided having at least one silver-selenide layer in between glass layers, the glass layers are a chalcogenide glass having a GexSe100−x composition.

Owner:OVONYX MEMORY TECH LLC

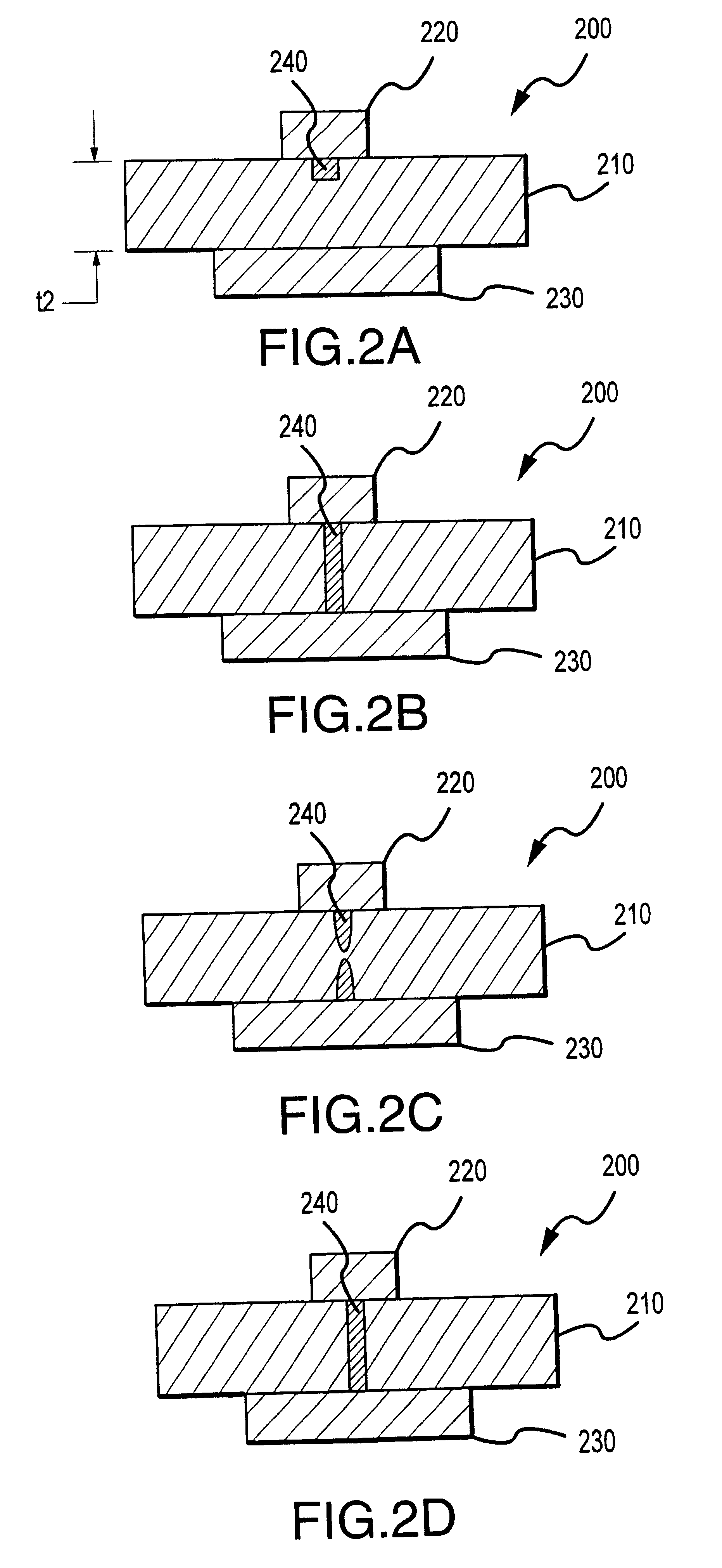

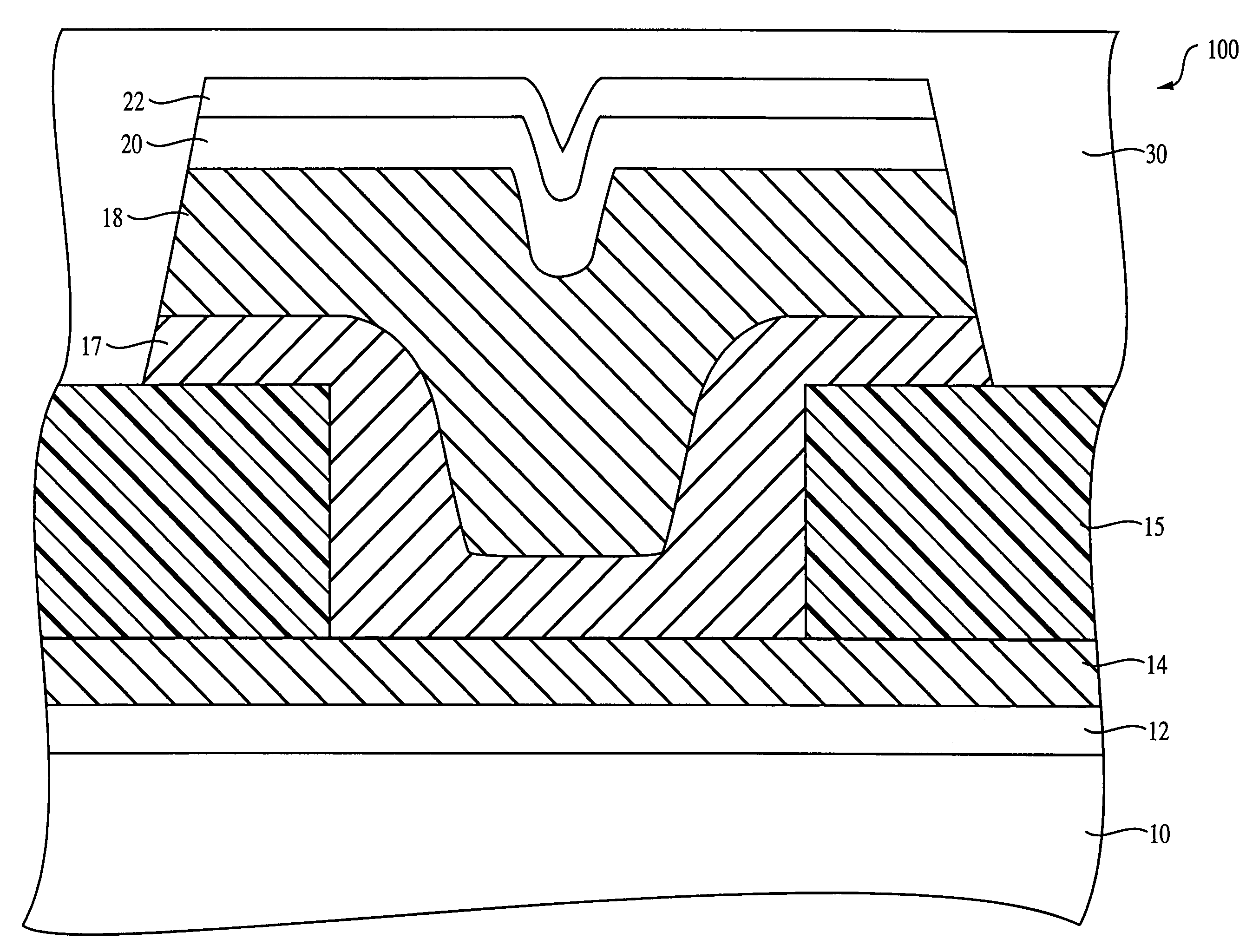

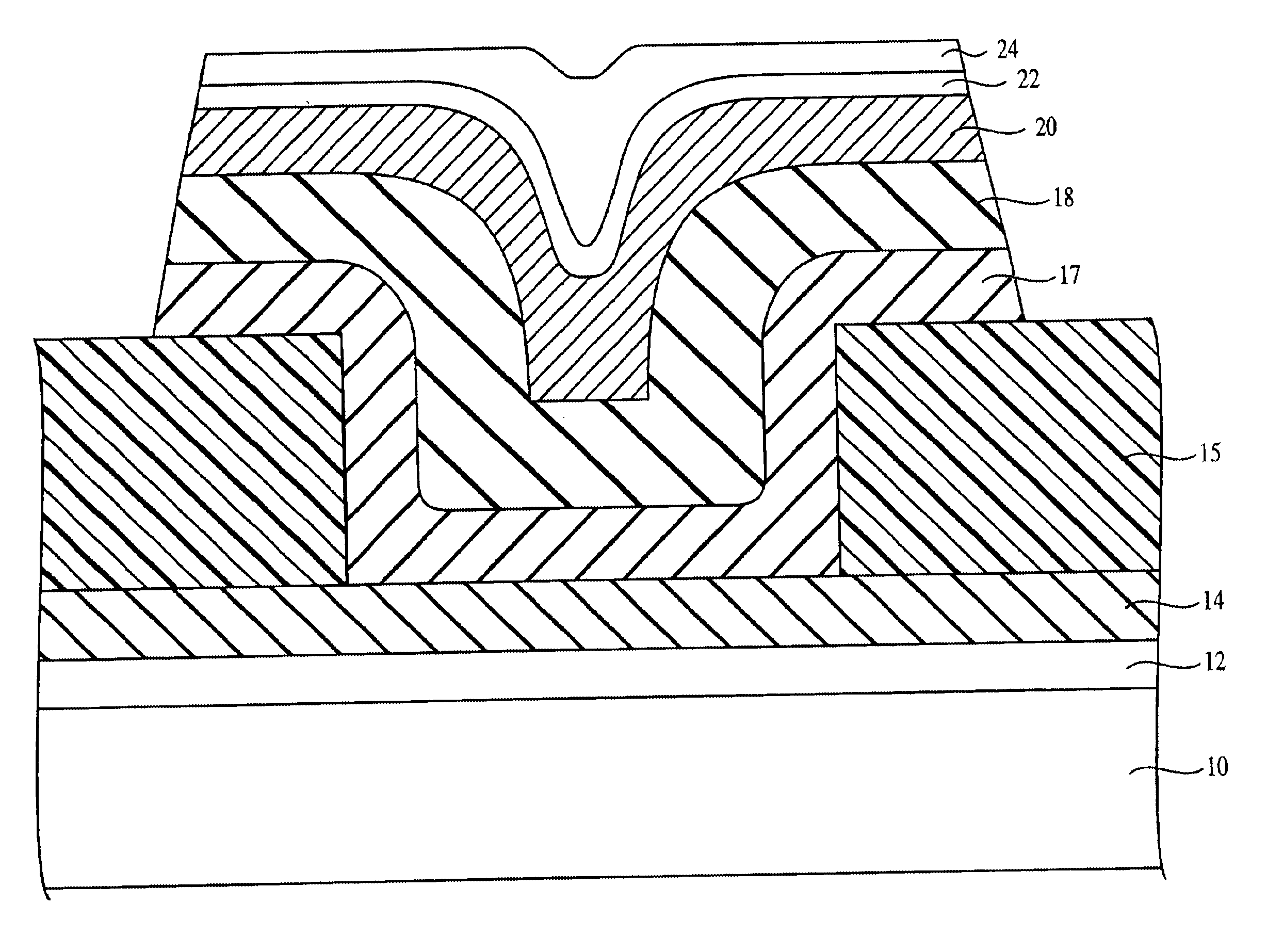

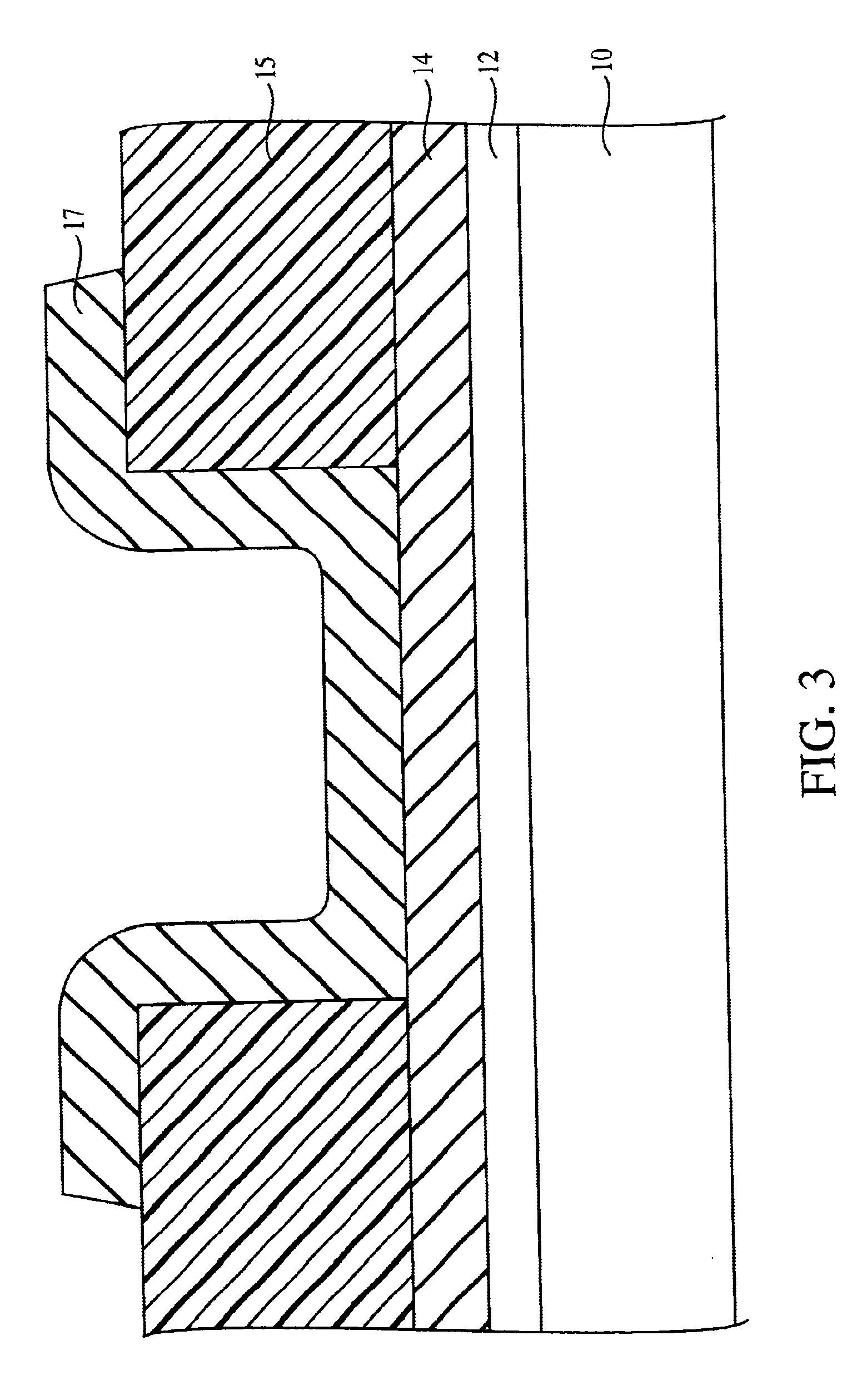

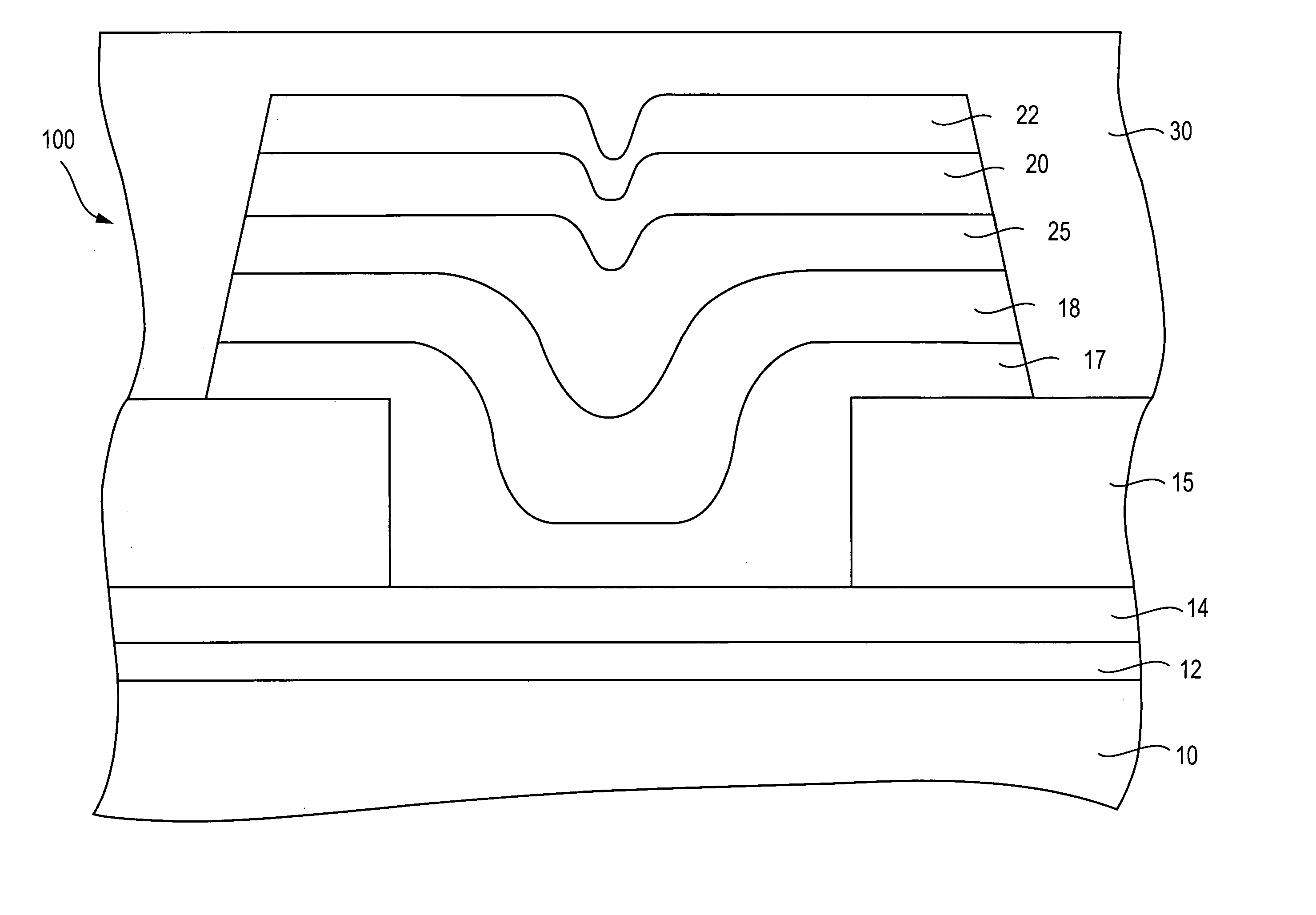

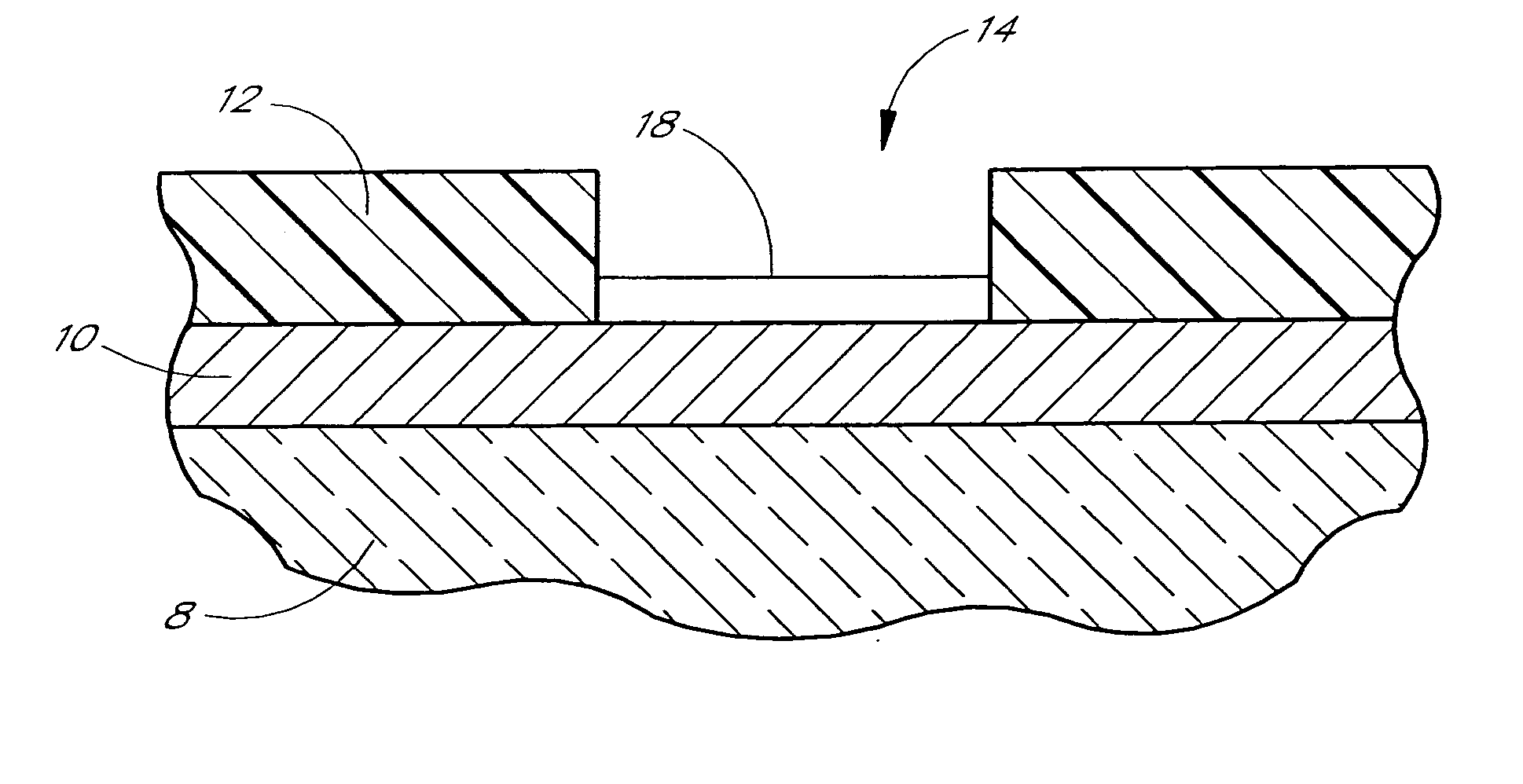

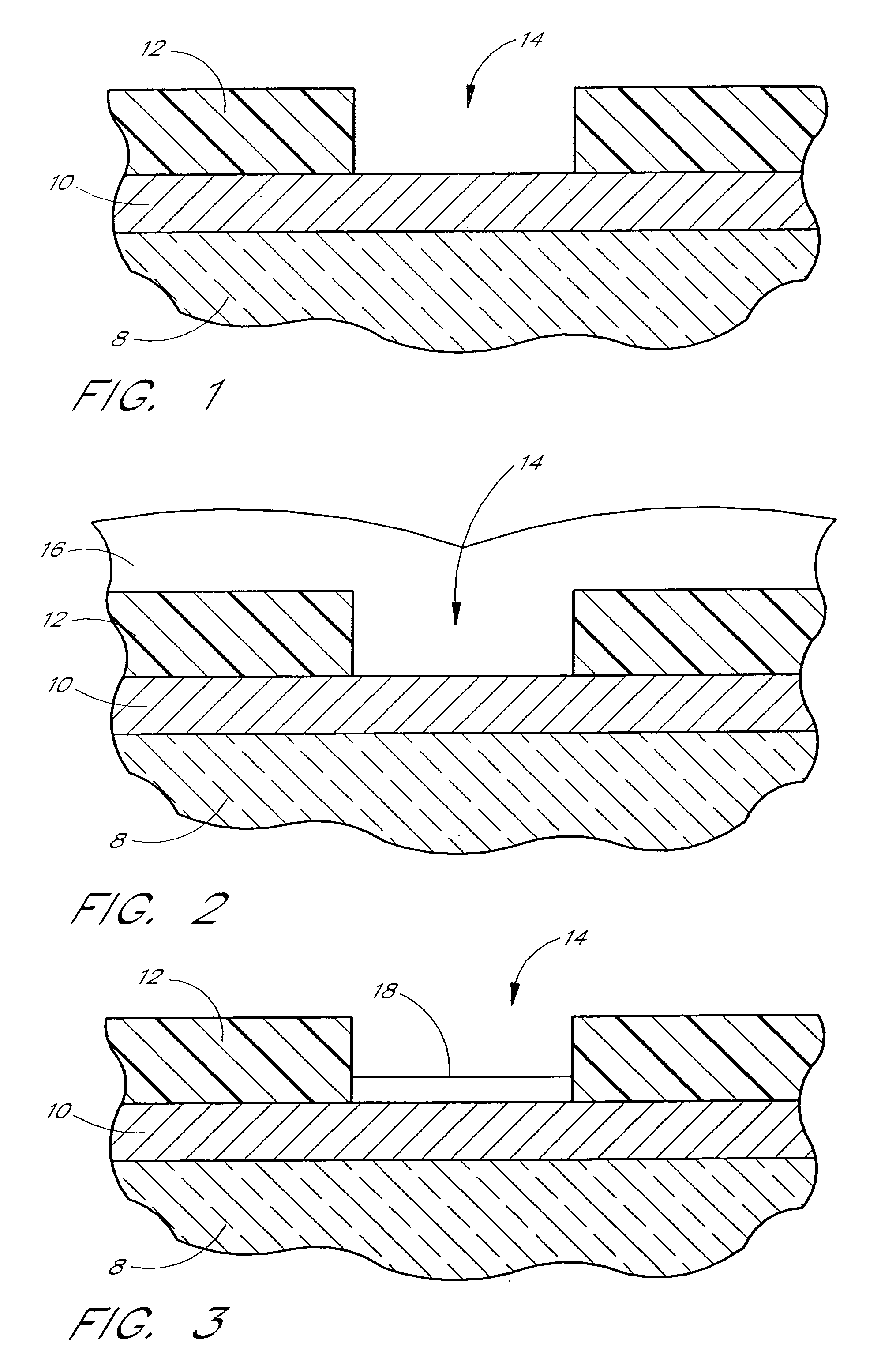

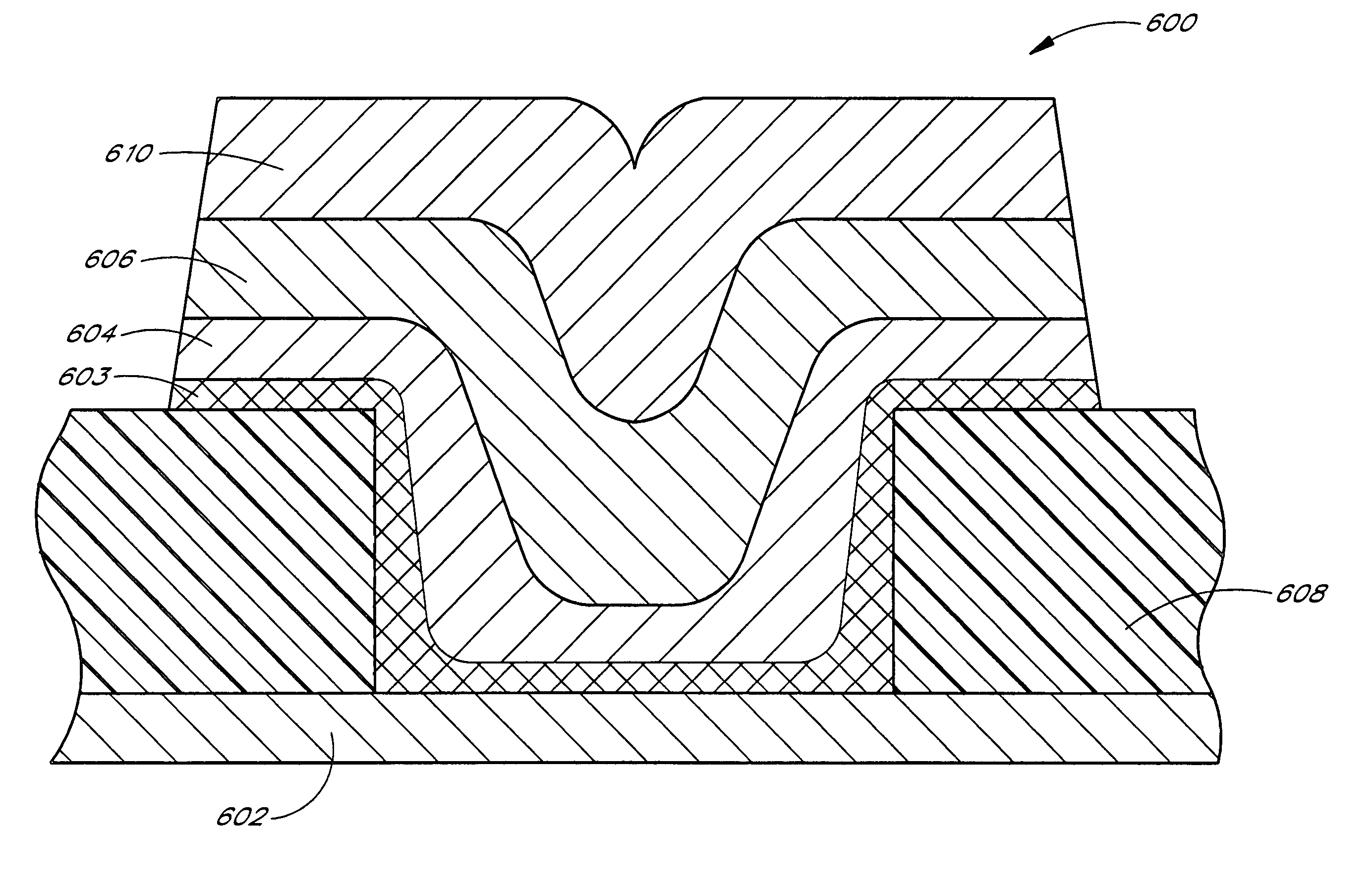

Thin film diode integrated with chalcogenide memory cell

InactiveUS6855975B2TransistorSemiconductor/solid-state device detailsThin-film diodeChalcogenide glass

An integrated programmable conductor memory cell and diode device in an integrated circuit comprises a diode and a glass electrolyte element, the glass electrolyte element having metal ions mixed or dissolved therein and being able to selectively form a conductive pathway under the influence of an applied voltage. In one embodiment, both the diode and the memory cell comprise a chalcogenide glass, such as germanium selenide (e.g., Ge2Se8 or Ge25Se75). The first diode element comprises a chalcogenide glass layer having a first conductivity type, the second diode element comprises a chalcogenide glass layer doped with an element such as bismuth and having a second conductivity type opposite to the first conductivity type and the memory cell comprises a chalcogenide glass element with silver ions therein. In another embodiment, the diode comprises silicon and there is a diffusion barrier layer between the diode and the chalcogenide glass memory element. Methods of fabricating integrated programmable conductor memory cell and diode devices are also disclosed.

Owner:OVONYX MEMORY TECH LLC

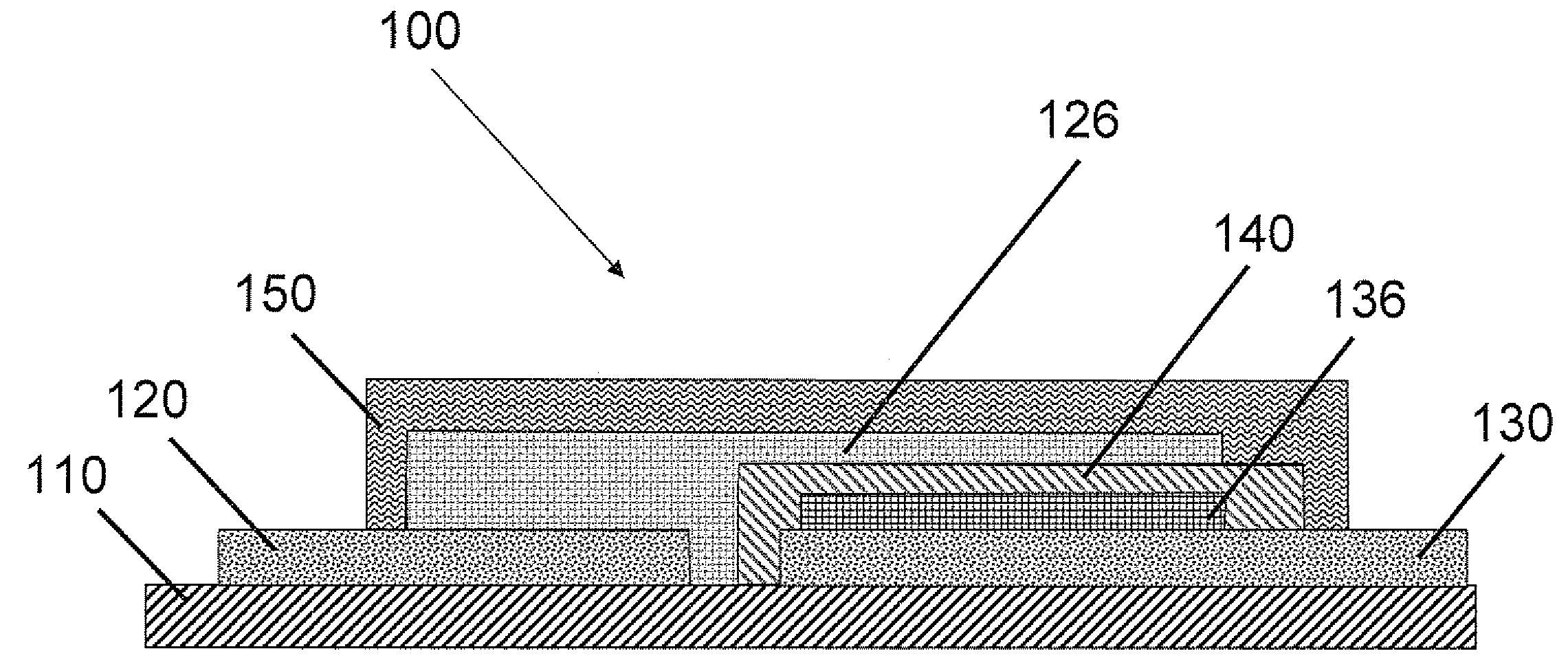

Barrier layer for thin film battery

InactiveUS20100190051A1Improve efficiencyExtend lifetime of battery packFinal product manufactureElectrode carriers/collectorsPhosphateChalcogenide glass

A thin film battery comprises a substrate, anode and cathode current collector layers formed over the substrate, anode and cathode layers formed over and in electrical contact with respective ones of the current collector layers, and an electrolyte layer formed between the anode and cathode layers. The thin film battery further comprises a barrier layer formed from a material such as tin oxide, tin phosphate, tin fluorophosphate, chalcogenide glass, tellurite glass or borate glass. The barrier layer is configured to encapsulate the thin film battery layers and substantially inhibit or prevent exposure of the thin film battery layers to air or moisture.

Owner:CORNING INC

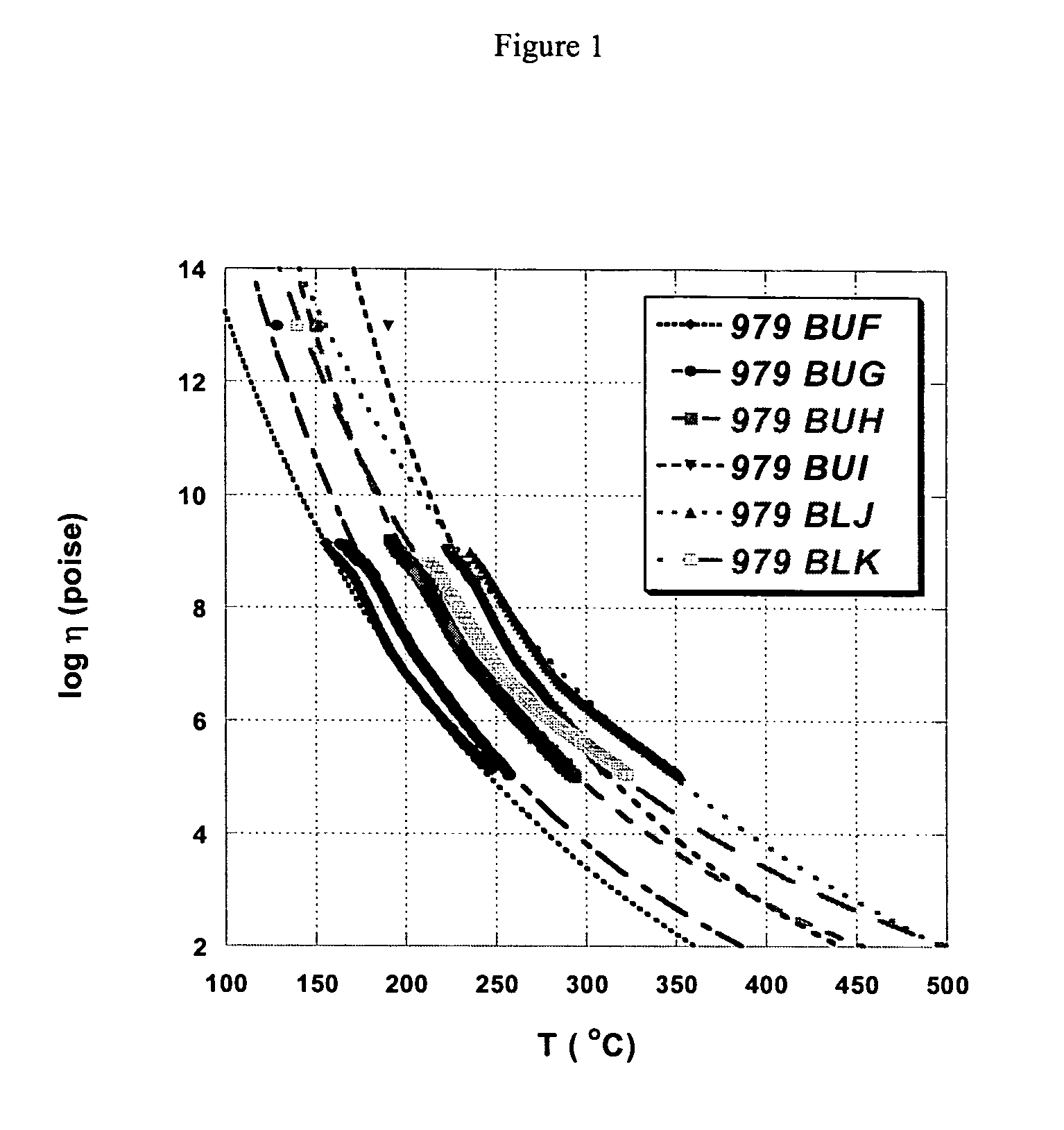

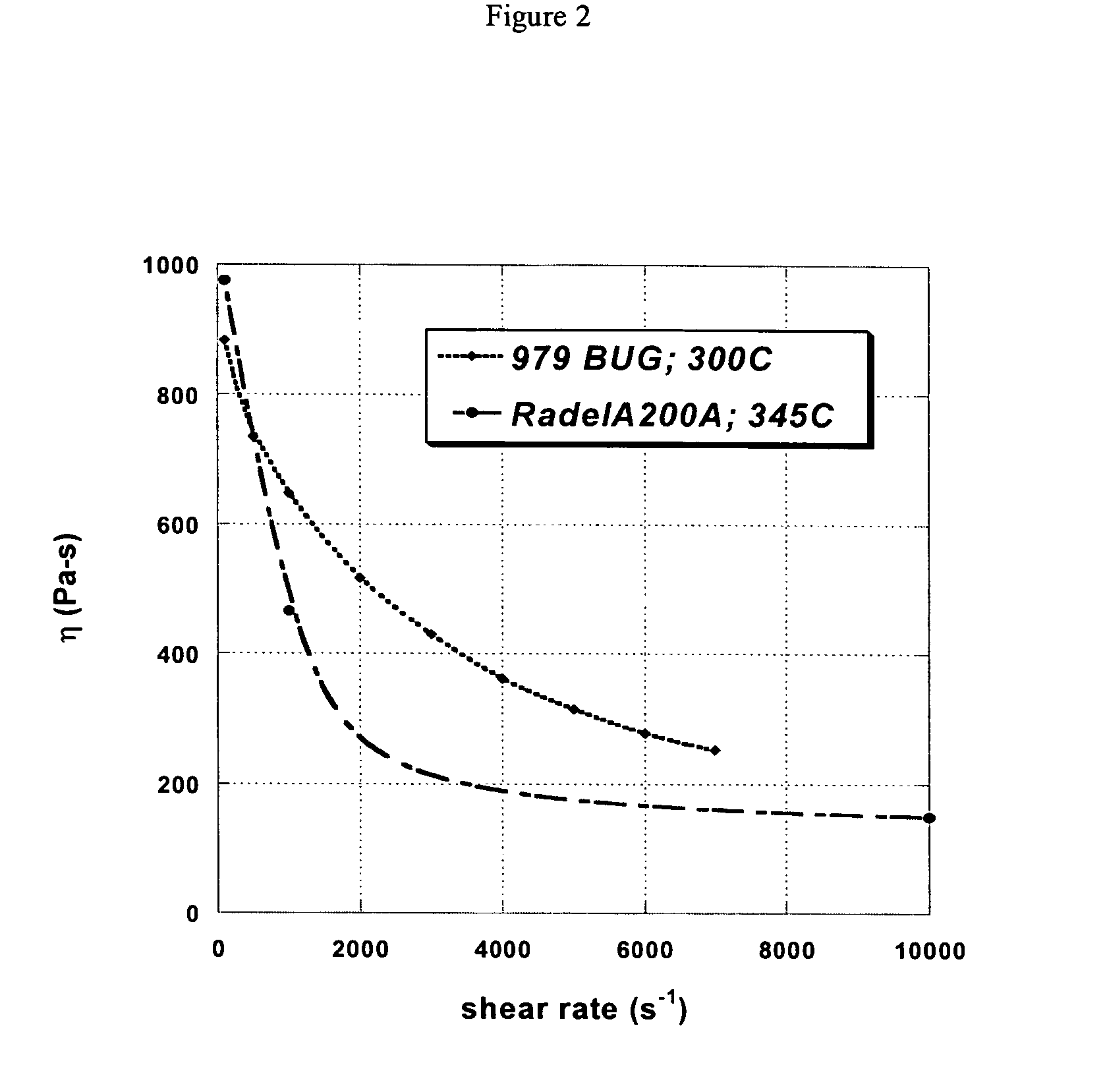

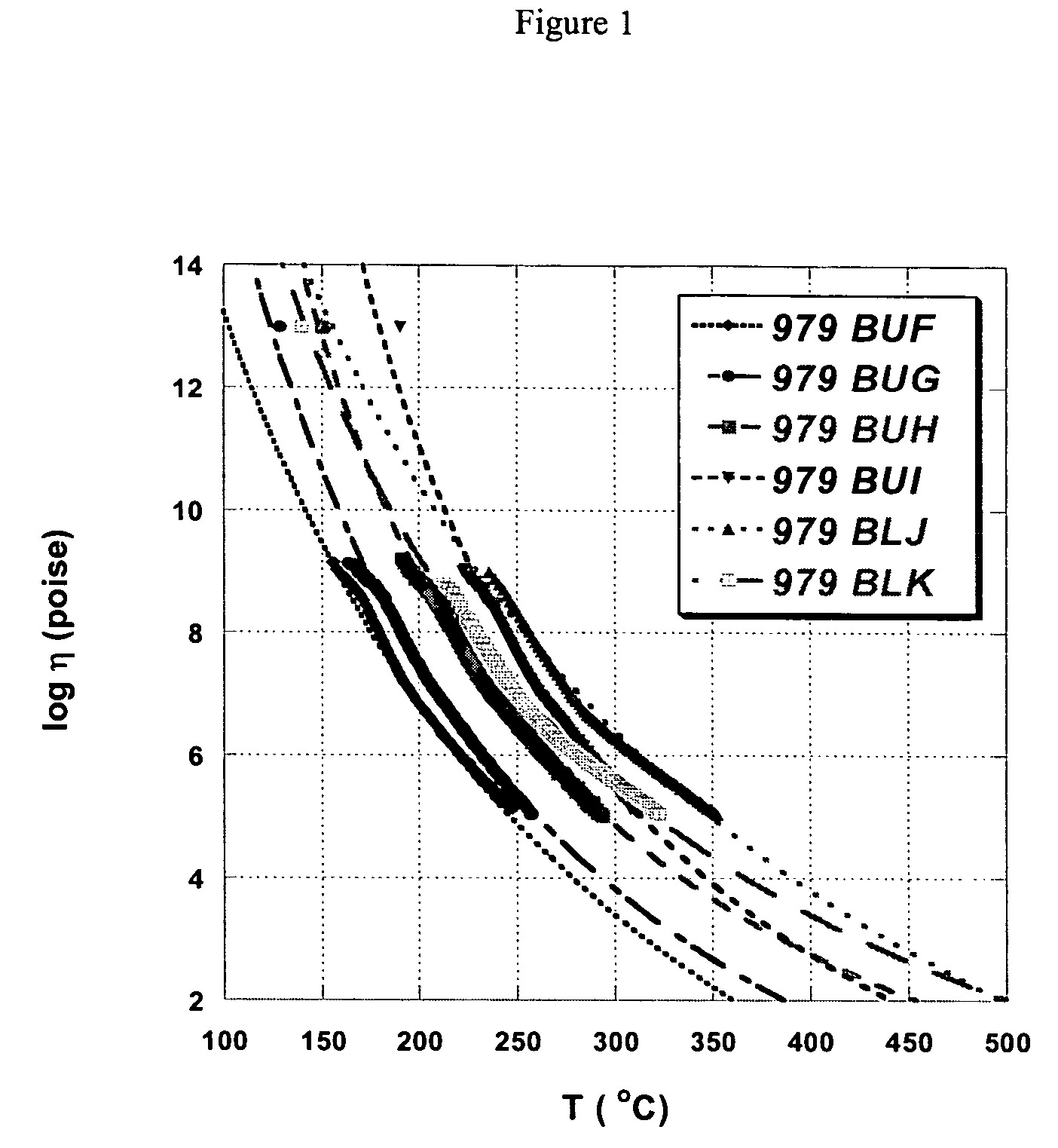

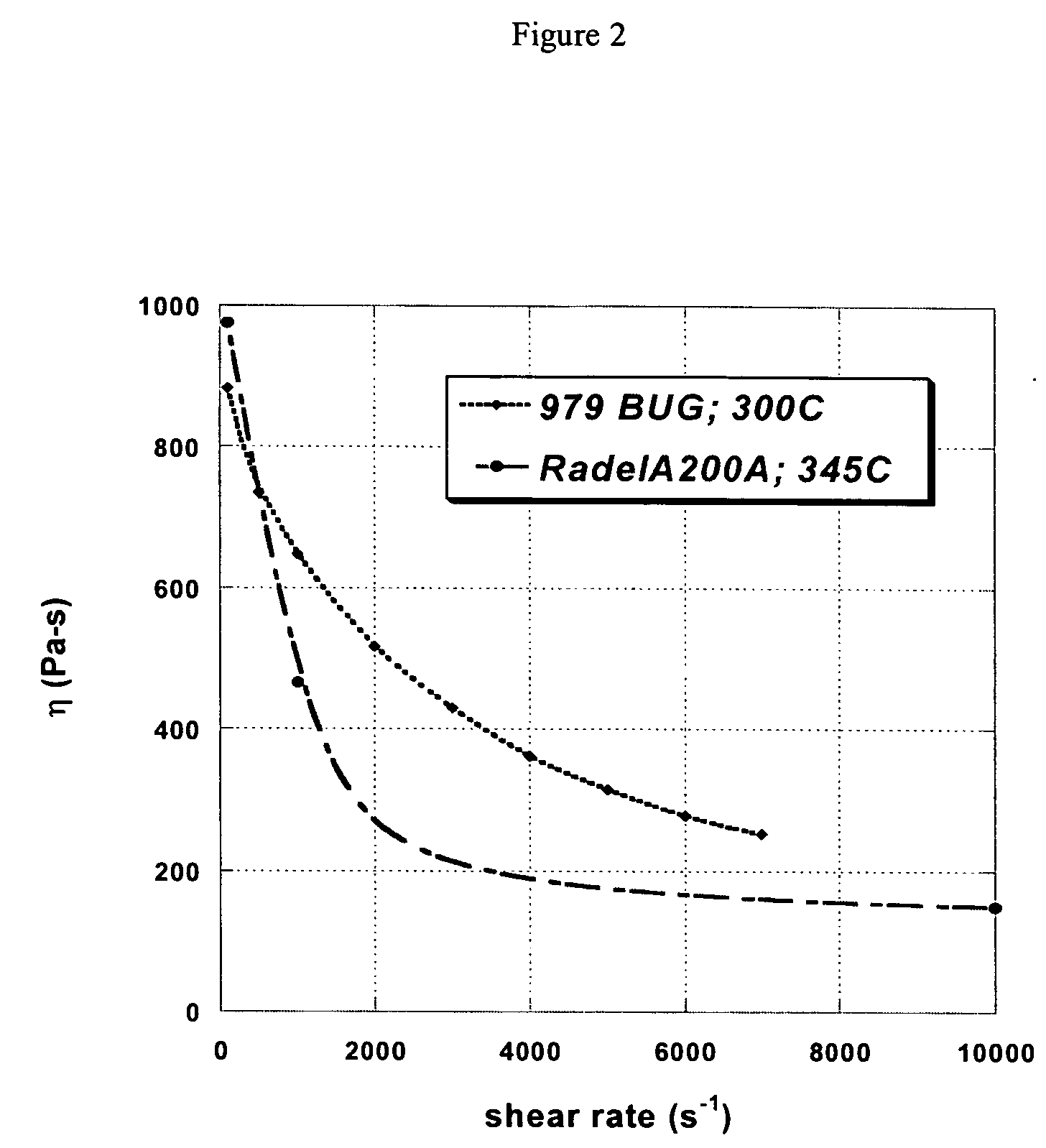

Chalcogenide glass for low viscosity extrusion and injection molding

The invention is directed to chalcogenide glasses suitable for use in plastics forming processes. The glasses have the general formula YZ, where Y is Ge, As, Sb or a mixture of two or more of the same; Z is S, Se, Te, or a mixture of two or more of the same; and Y and Z are present in amounts (in atomic / element percent) in the range of Y=15–70% and Z=30–85%. The chalcogenide glasses of the invention have a 10,000 poise temperature of 400° C. and are resistant to crystallization when processed at high shear rates at their 10,000 poise temperature. The glasses can be used to make, among other items, molded telecommunication elements, lenses and infrared sensing devices.

Owner:CORNING INC

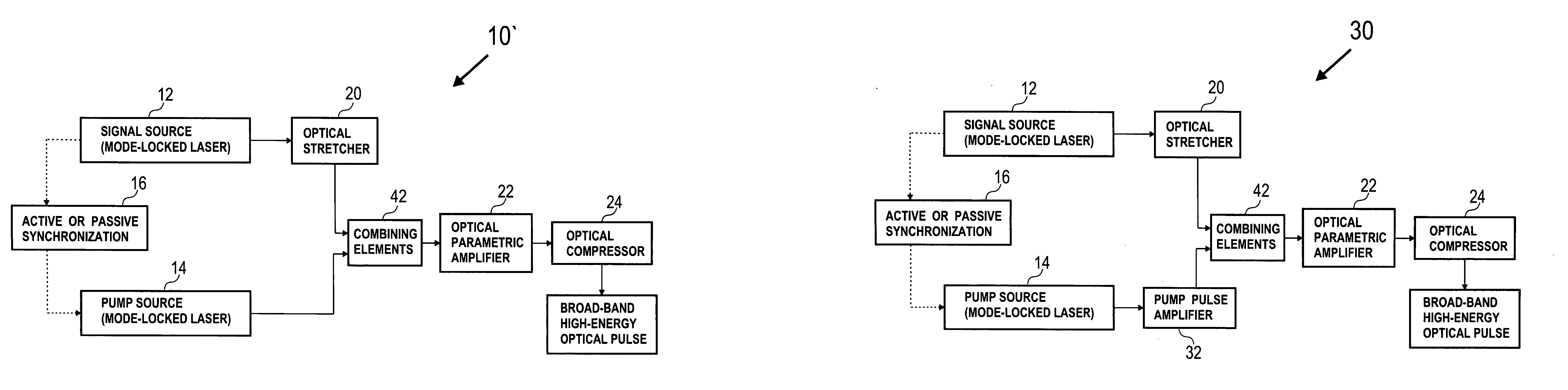

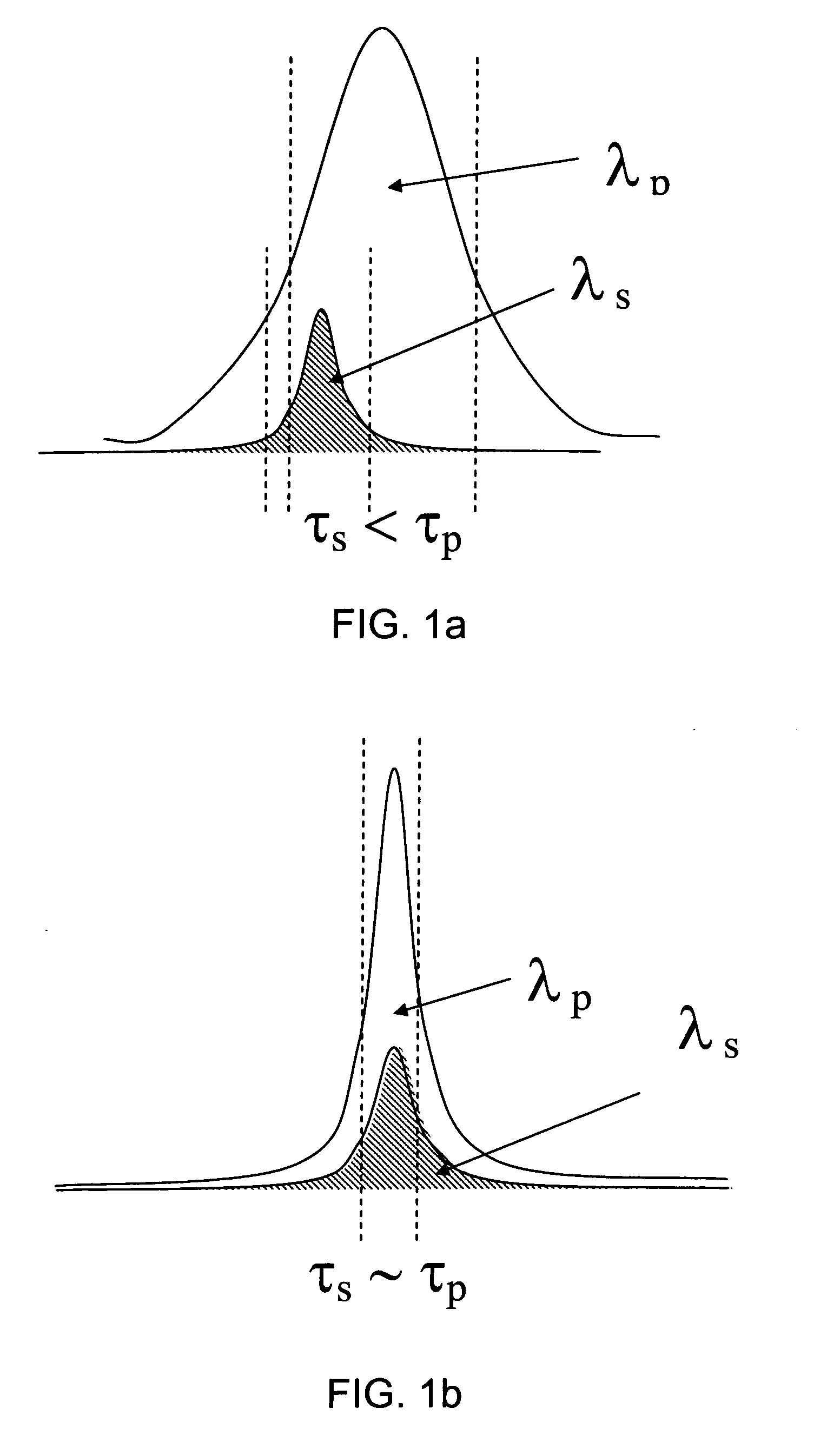

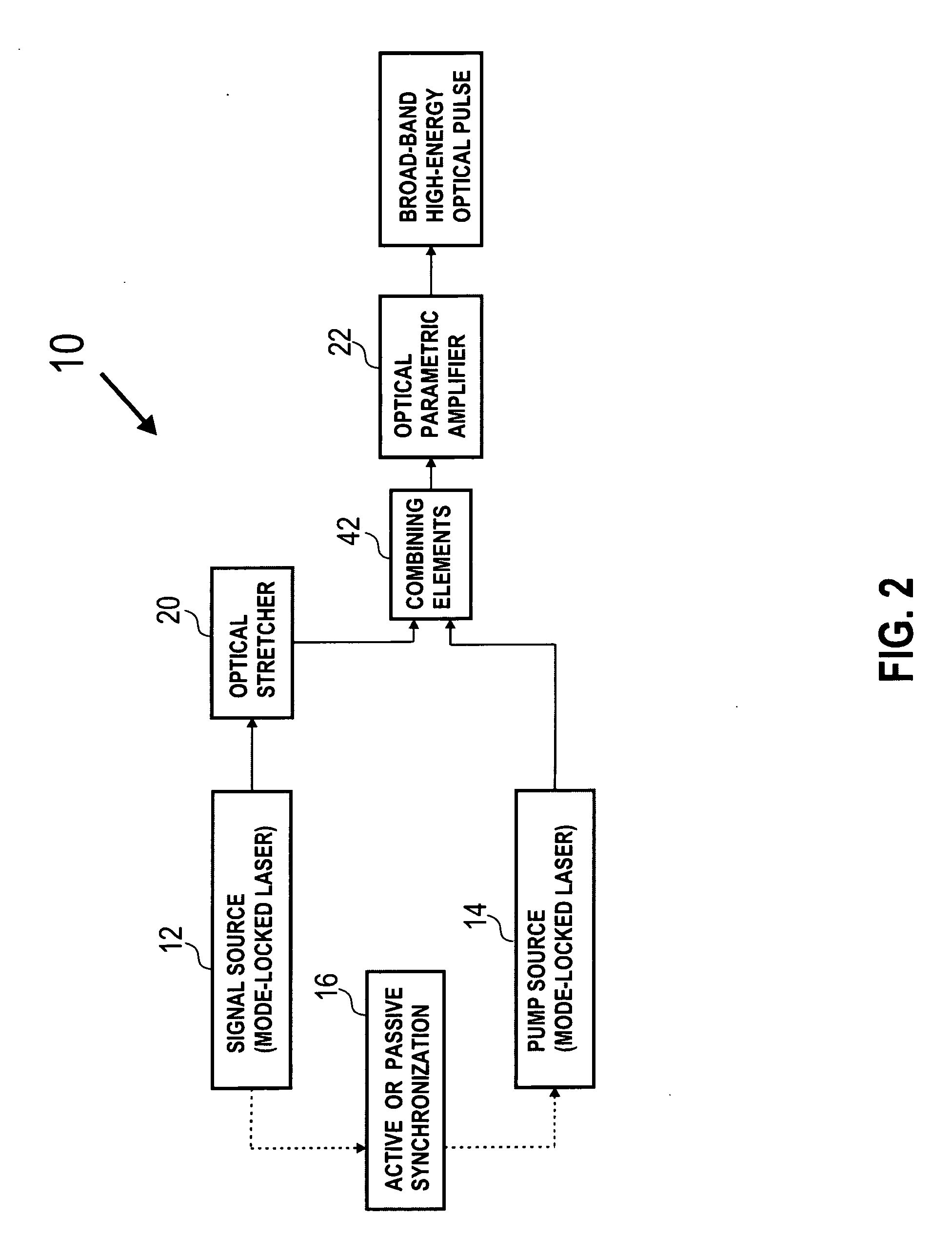

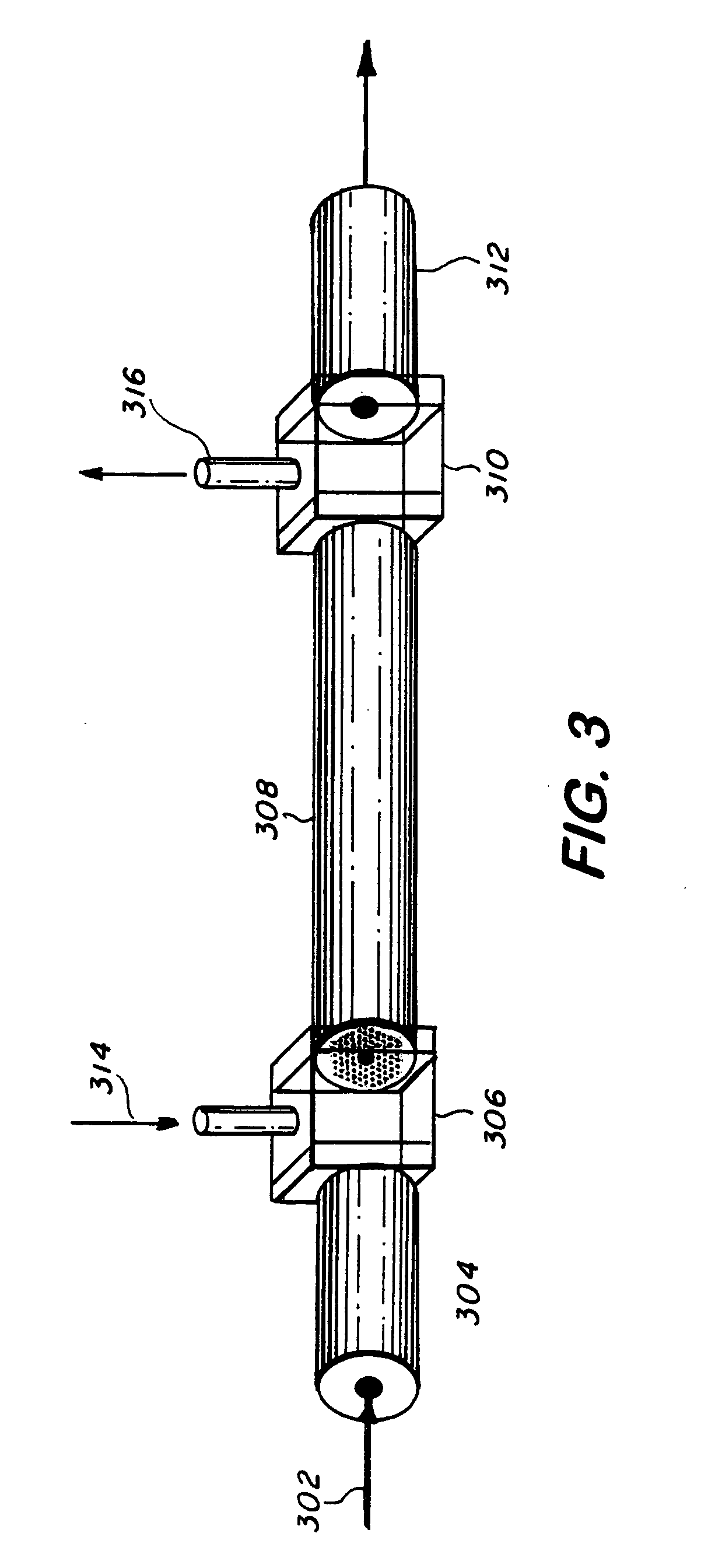

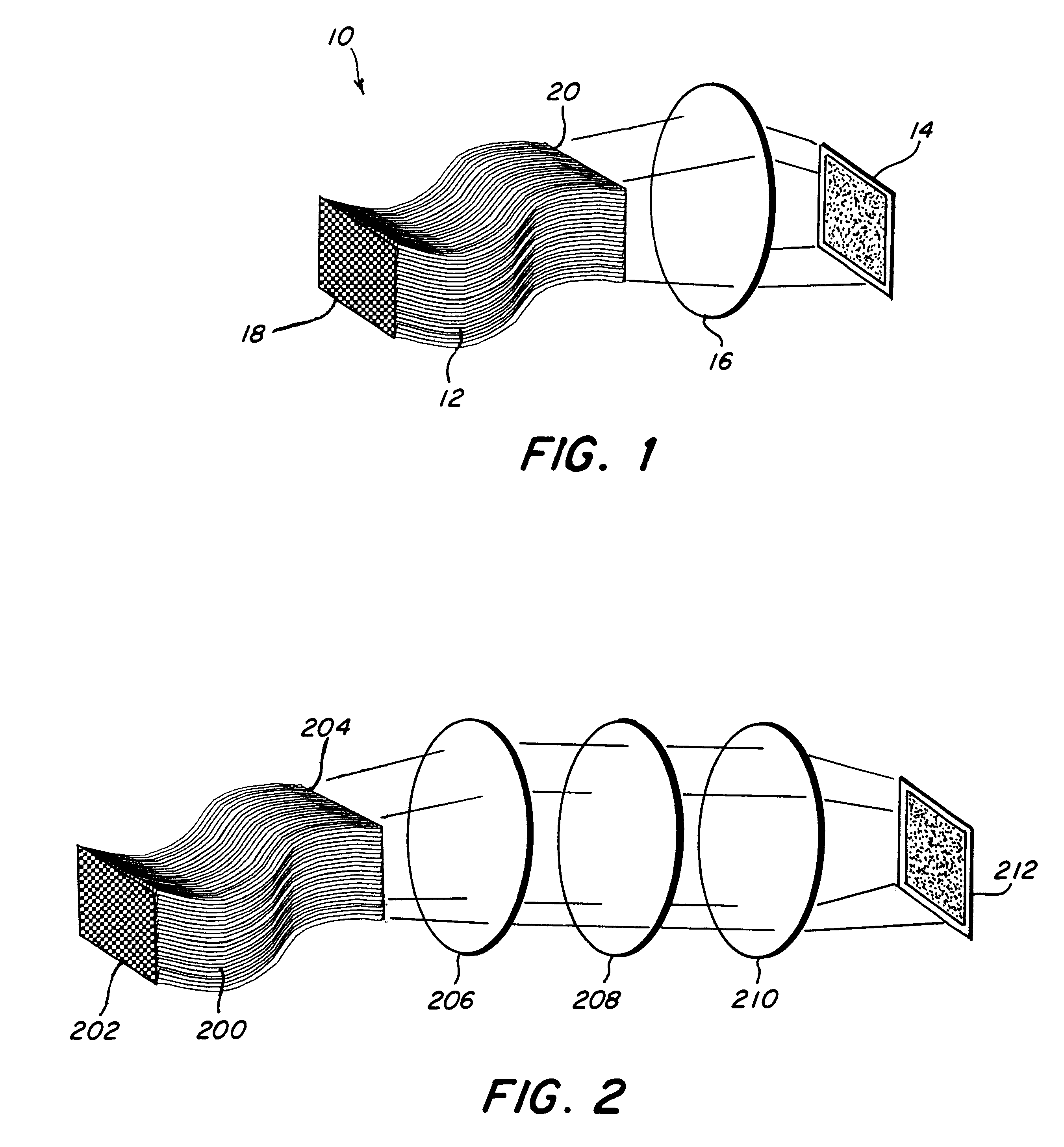

Method and apparatus for high power optical amplification in the infrared wavelength range (0.7-20 mum)

InactiveUS20050271094A1Laser detailsNon-linear opticsAcousto-optic programmable dispersive filterAdemetionine

A novel method for high power optical amplification of ultrashort pulses in IR wavelength range (0.7-20 Ãm) is disclosed. The method is based on the optical parametric chirp pulse amplification (OPCPA) technique where a picosecond or nanosecond mode locked laser system synchronized to a signal laser oscillator is used as a pump source or alternatively the pump pulse is created from the signal pulse by using certain types of optical nonlinear processes described later in the document. This significantly increases stability, extraction efficiency and bandwidth of the amplified signal pulse. Further, we disclose five new practical methods of shaping the temporal and spatial profiles of the signal and pump pulses in the OPCPA interaction which significantly increases its efficiency. In the first, passive preshaping of the pump pulses has been made by a three wave mixing process separate from the one occurring in the OPCPA. In the second, passive pre-shaping of the pump pulses has been made by spectral filtering in the pump mode-locked laser or in its amplifier. In the third, the temporal shape of the signal pulse optimized for OPCPA interaction has been actively processed by using an acousto-optic programmable dispersive filter (Dazzler) or liquid crystal light modulators. In the fourth alternative method, the signal pulse intensity envelope is optimized by using passive spectral filtering. Finally, we disclose a method of using pump pulses which interact with the seed pulses with different time delays and different angular orientations allowing the amplification bandwidth to be increased. In addition we describe a new technique for high power IR optical beam delivery systems based on the microstructure fibres made of silica, fluoride or chalcogenide glasses as well as ceramics. Also we disclose a new optical system for achieving phase matching geometries in the optical parametric interactions based on diffractive optics. All novel methods of the ultrashort optical pulse amplification described in this disclosure can be easily generalized to other wavelength ranges.

Owner:MILLER ROBERT JOHN DWAYNE +3

Chalcogenide glass for low viscosity extrusion and injection molding

ActiveUS20060233512A1Low cost manufacturingGlass making apparatusCladded optical fibreSulfurChalcogenide glass

Owner:CORNING INC

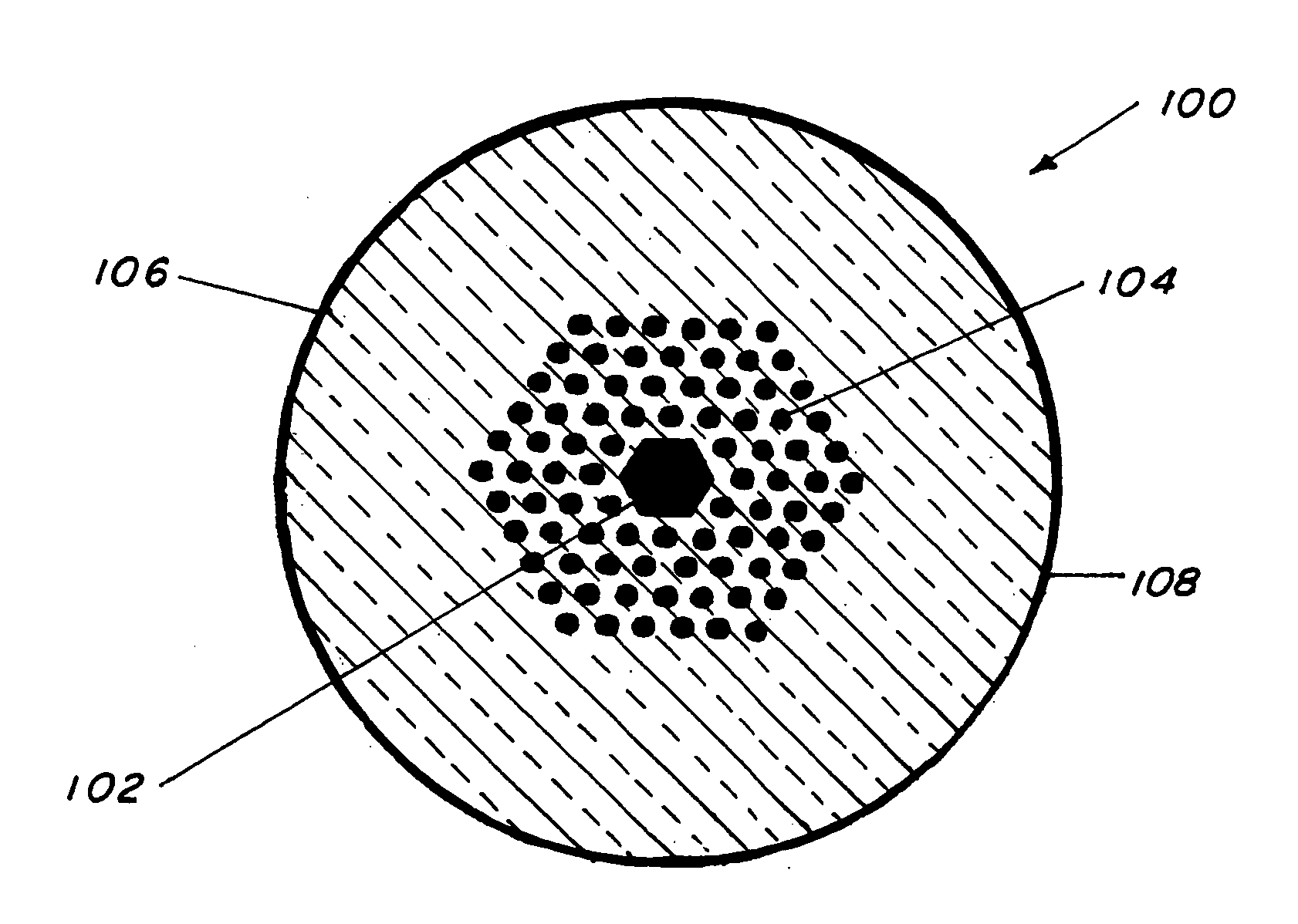

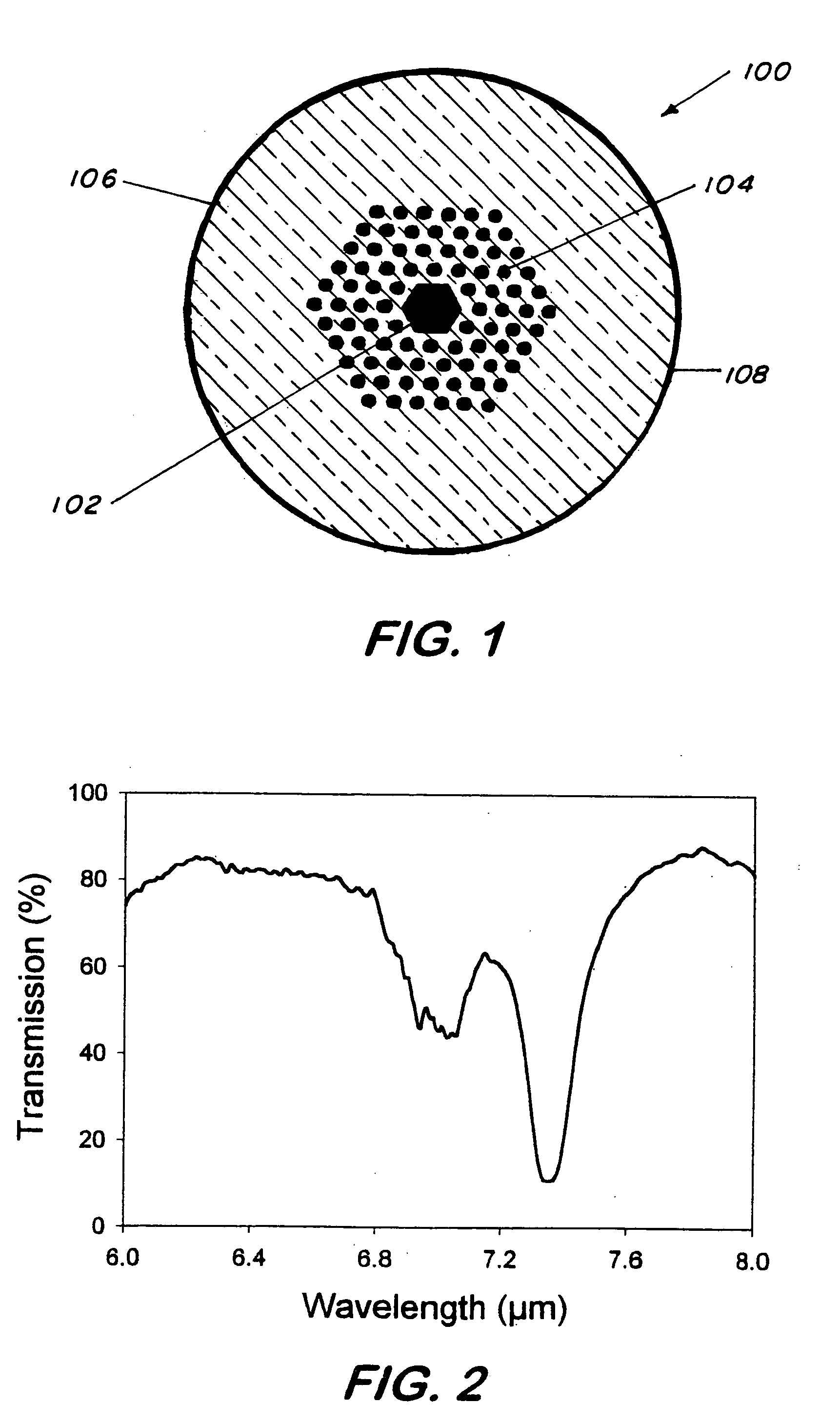

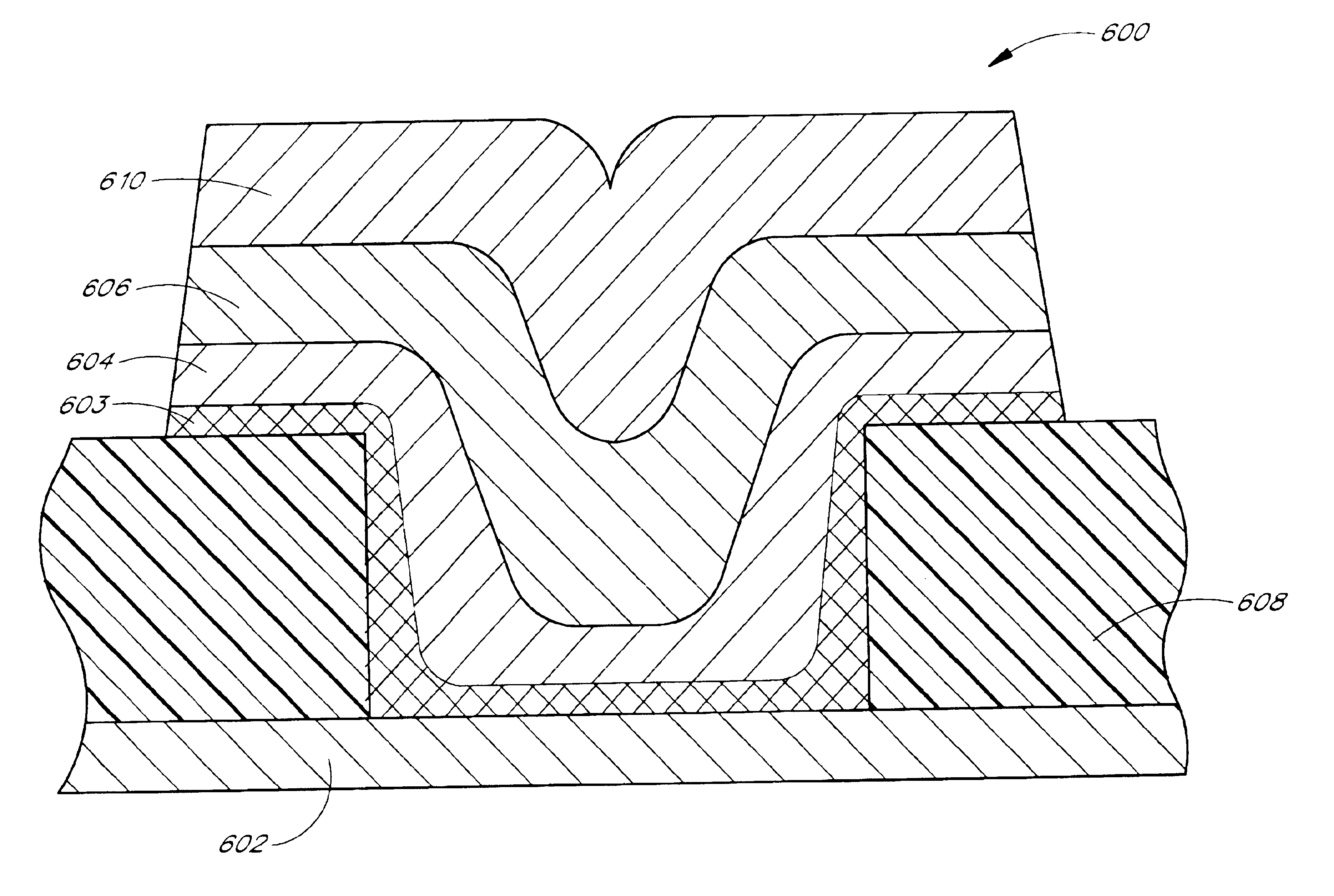

Hollow core photonic band gap infrared fibers

This invention pertains to a hollow core photonic band gap chalcogenide optical glass fiber and to a fabrication method for making the fiber. The fiber, which is 80-1000 microns in outside diameter, is characterized by a solid glass circumferential region and a structured region disposed centrally within the solid region, the structured region includes a hollow core of 1 micron to several hundreds of microns in diameter surrounded by a plurality of parallel hollow capillaries extending parallel to the core, the core being centrally and longitudinally located within the fiber. Ratio of open space to glass in the structured region is 30-99%. The fabrication method includes the steps of providing a mold, placing chalcogenide micro-tubes around the mold, stacking chalcogenide micro-canes around the stacked micro-tubes, fusing the micro-tubes and the micro-canes to form a preform, removing the mold and drawing the preform to obtain the fiber. In an alternative fabrication method, the fiber is made by extruding flowing chalcogenide glass through suitably made plate to form a preform and then drawing the preform to form the fiber.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

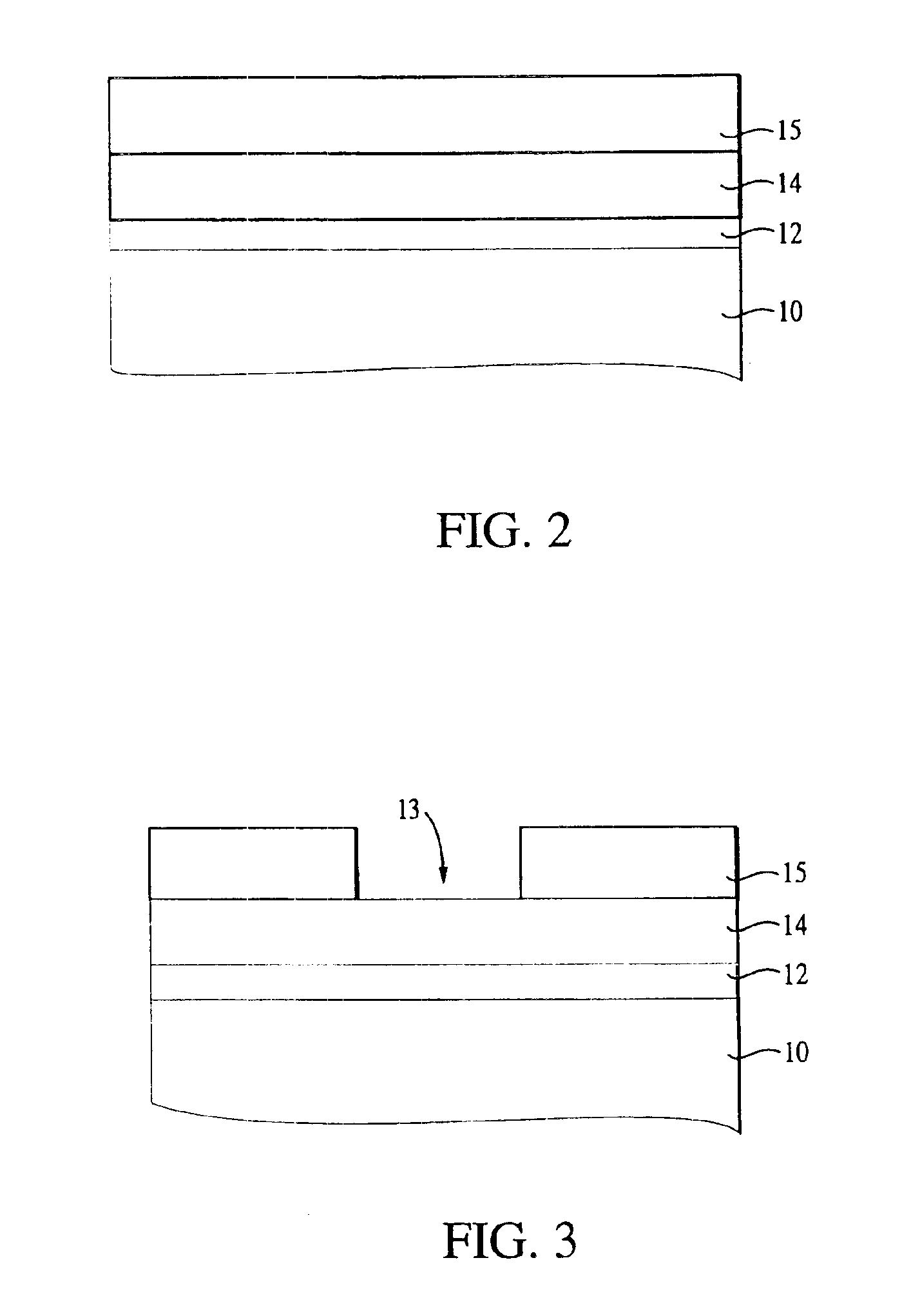

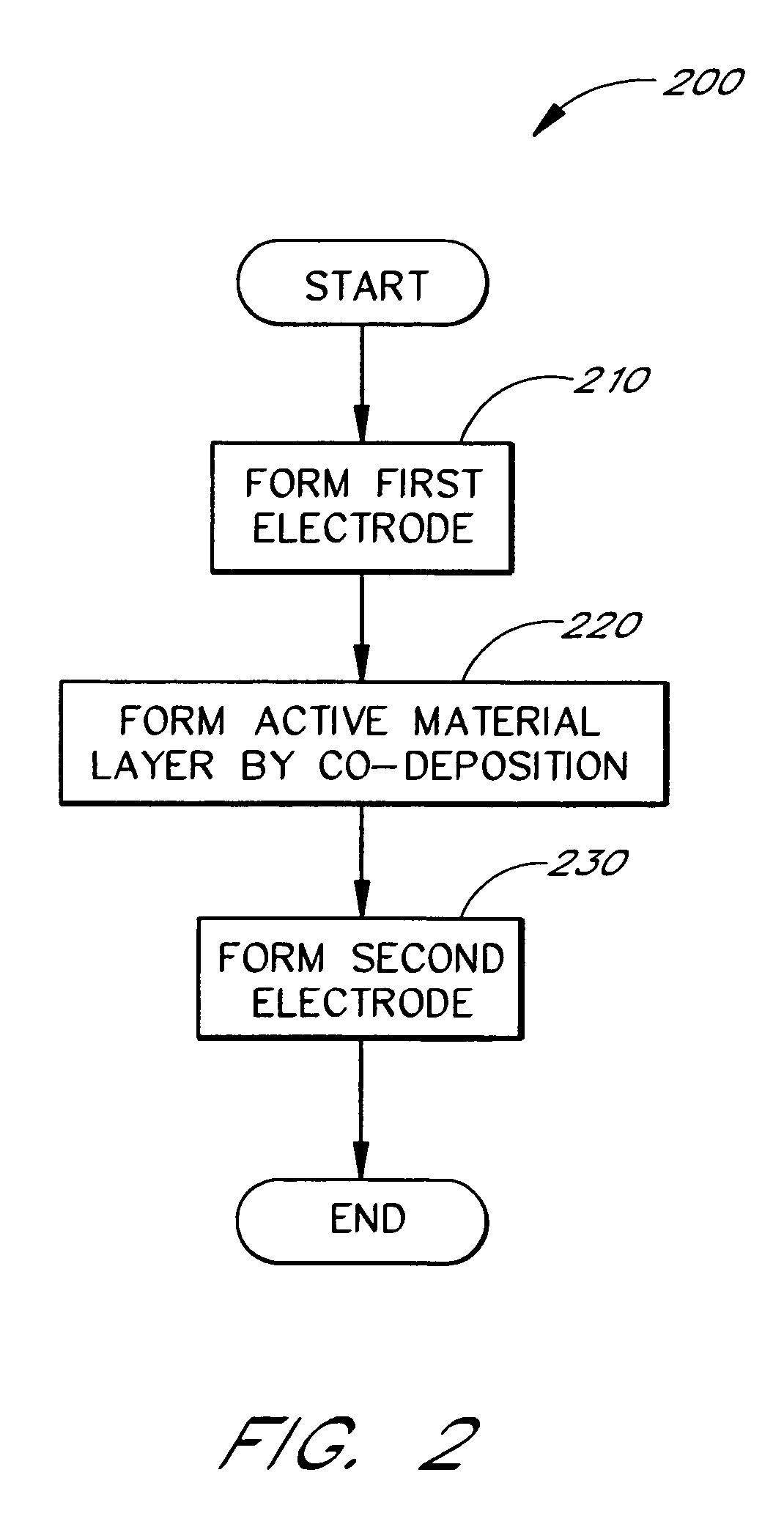

Methods and apparatus for resistance variable material cells

InactiveUS6849868B2Increase chanceFast switching speedSolid-state devicesPhotomechanical apparatusElectrical resistance and conductanceSulfur

The present invention is related to methods and apparatus to produce a memory cell or resistance variable material with improved data retention characteristics and higher switching speeds. In a memory cell according to an embodiment of the present invention, silver selenide and a chalcogenide glass, such as germanium selenide (GexSe(1−x)) are combined in an active layer, which supports the formation of conductive pathways in the presence of an electric potential applied between electrodes. Advantageously, embodiments of the present invention can be fabricated with relatively wide ranges for the thicknesses of the silver selenide and glass layers.

Owner:OVONYX MEMORY TECH LLC

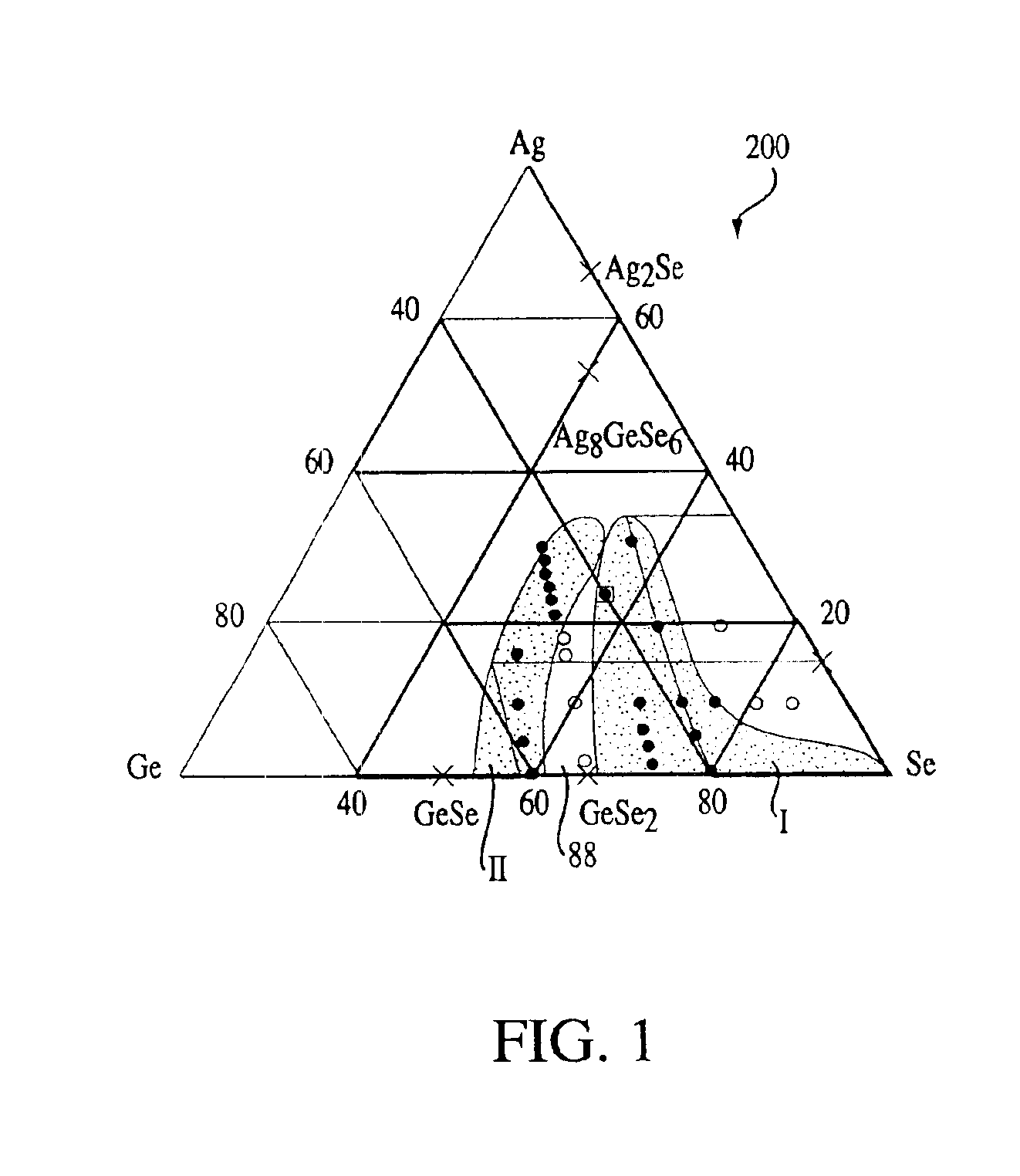

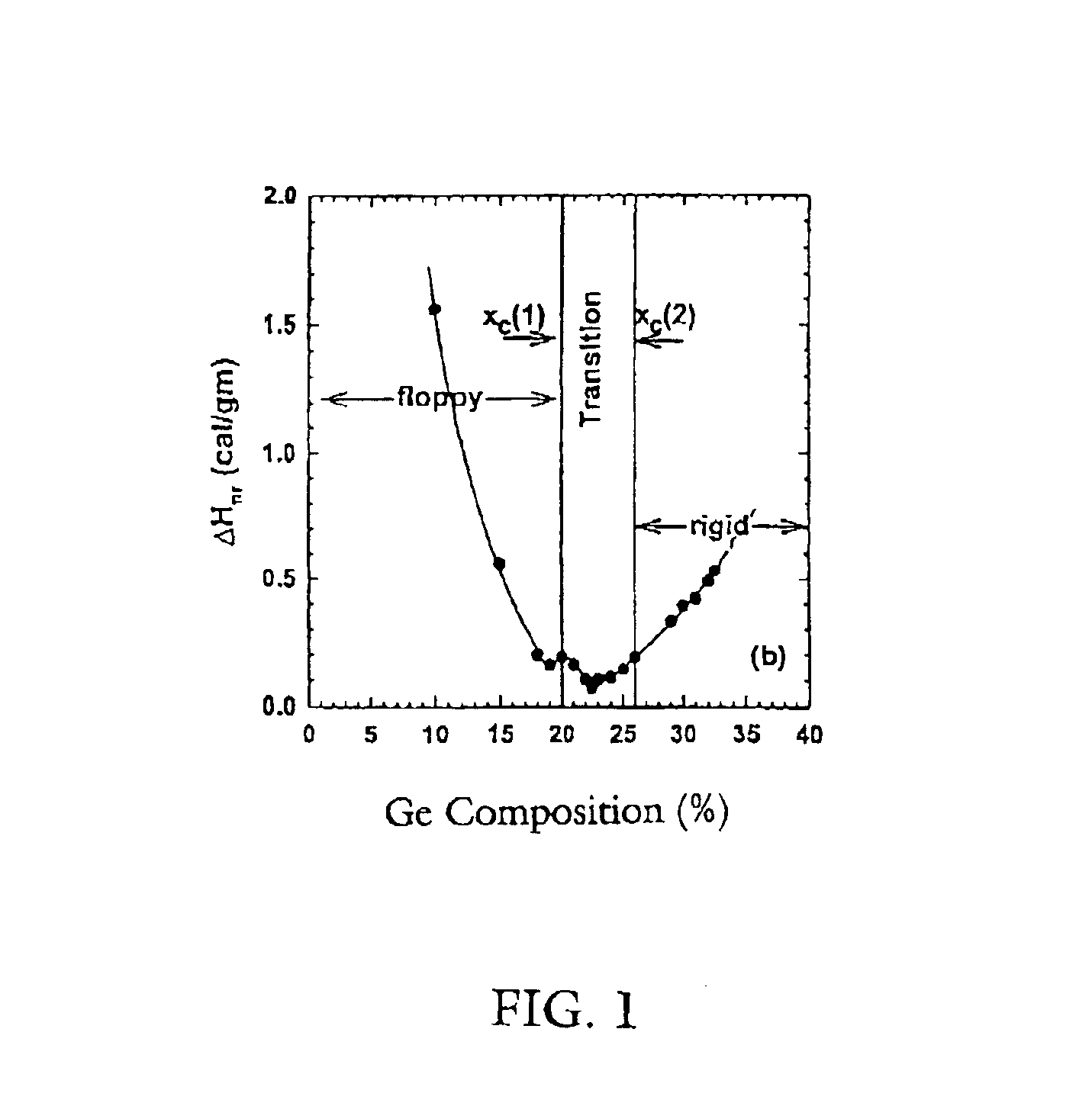

Stoichiometry for chalcogenide glasses useful for memory devices and method of formation

InactiveUS6888155B2High glass transition temperatureRead-only memoriesSemiconductor/solid-state device manufacturingVitrificationChalcogenide glass

A method of forming resistance changing elements with improved operational characteristics for use in memory devices and the resulting structures are disclosed. A chalcogenide glass having the formula (Gex1Se1-x1)1-y1Agy1, wherein 18≦x1≦28, or the formula (Gex2Se1-x2)1-y2Agy2, wherein 39≦x2≦42, and wherein in both the silver is in a concentration which maintains the germanium selenide glass in the glass forming region is used in a memory cell. The glass may also have a glass transition temperature (Tg) near or higher than typical temperatures used for fabricating and packaging memory devices containing the memory cell.

Owner:MICRON TECH INC

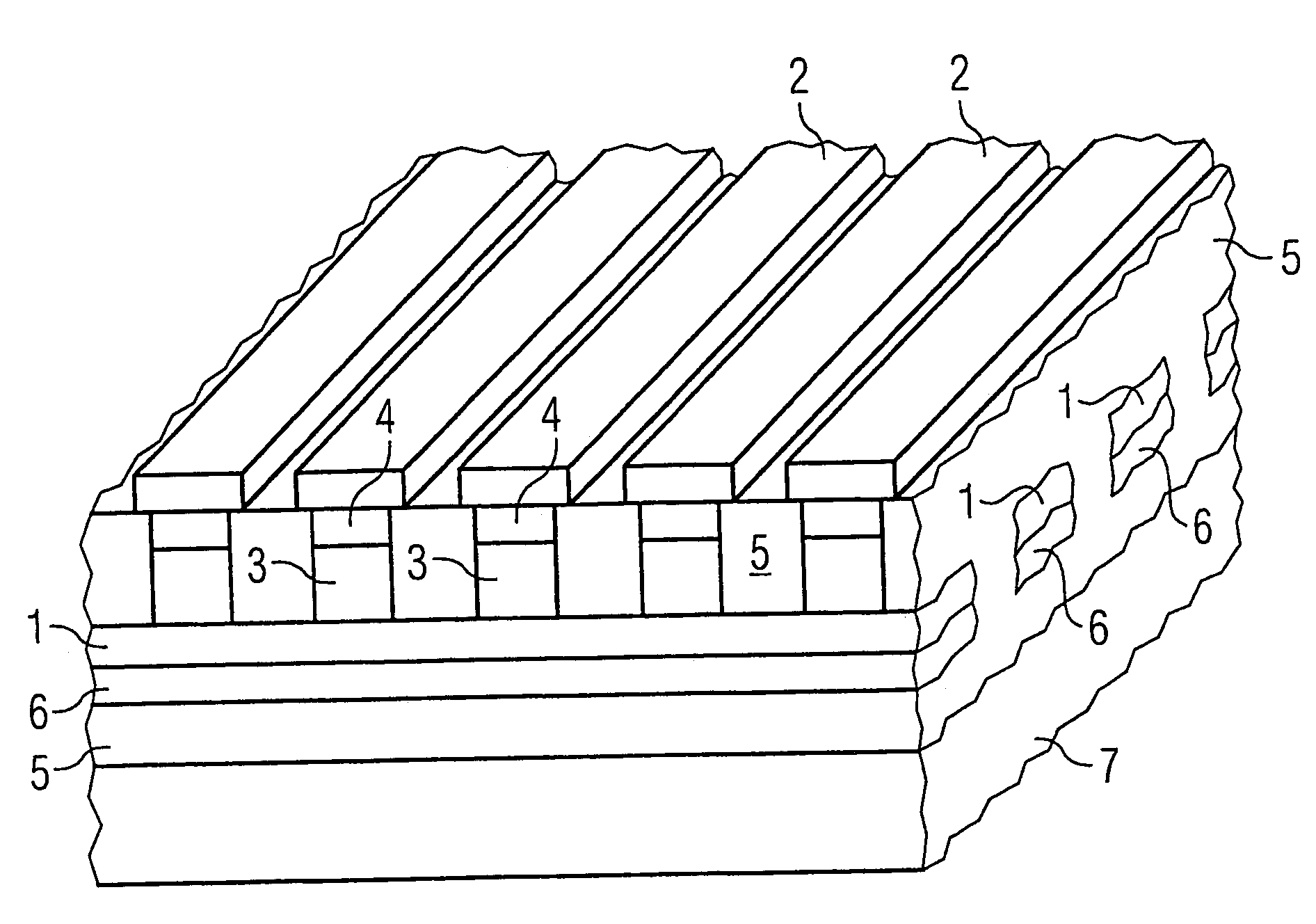

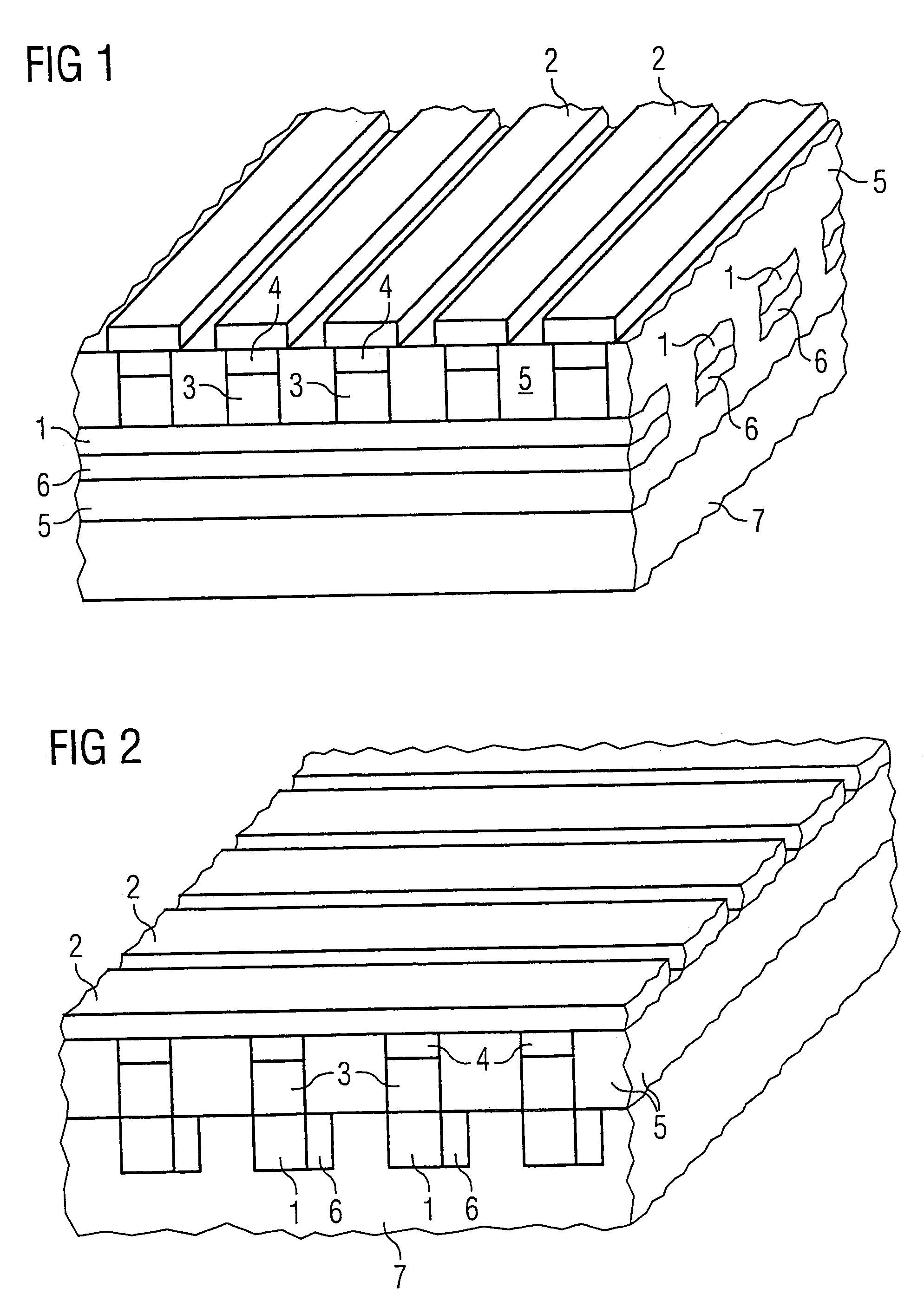

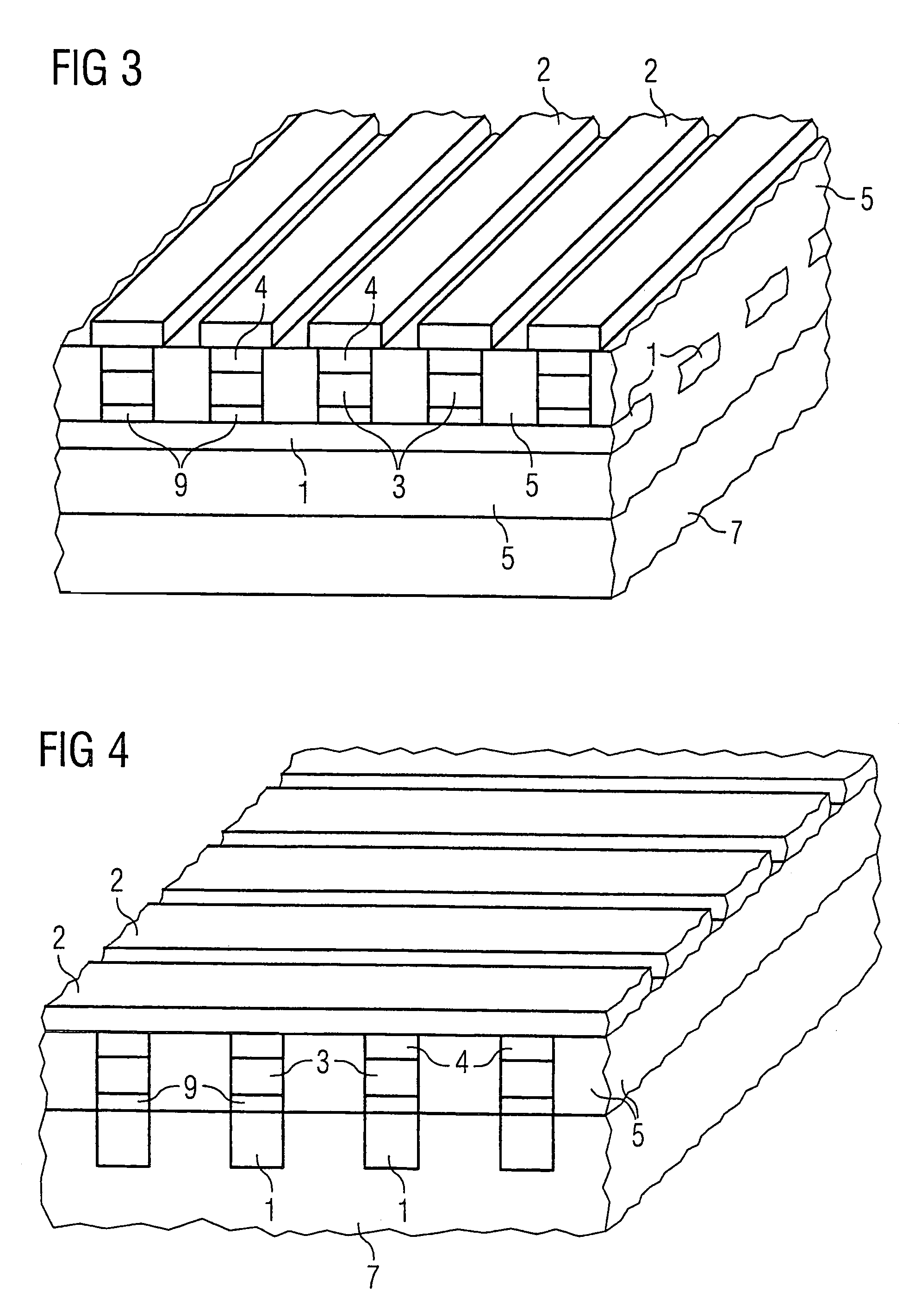

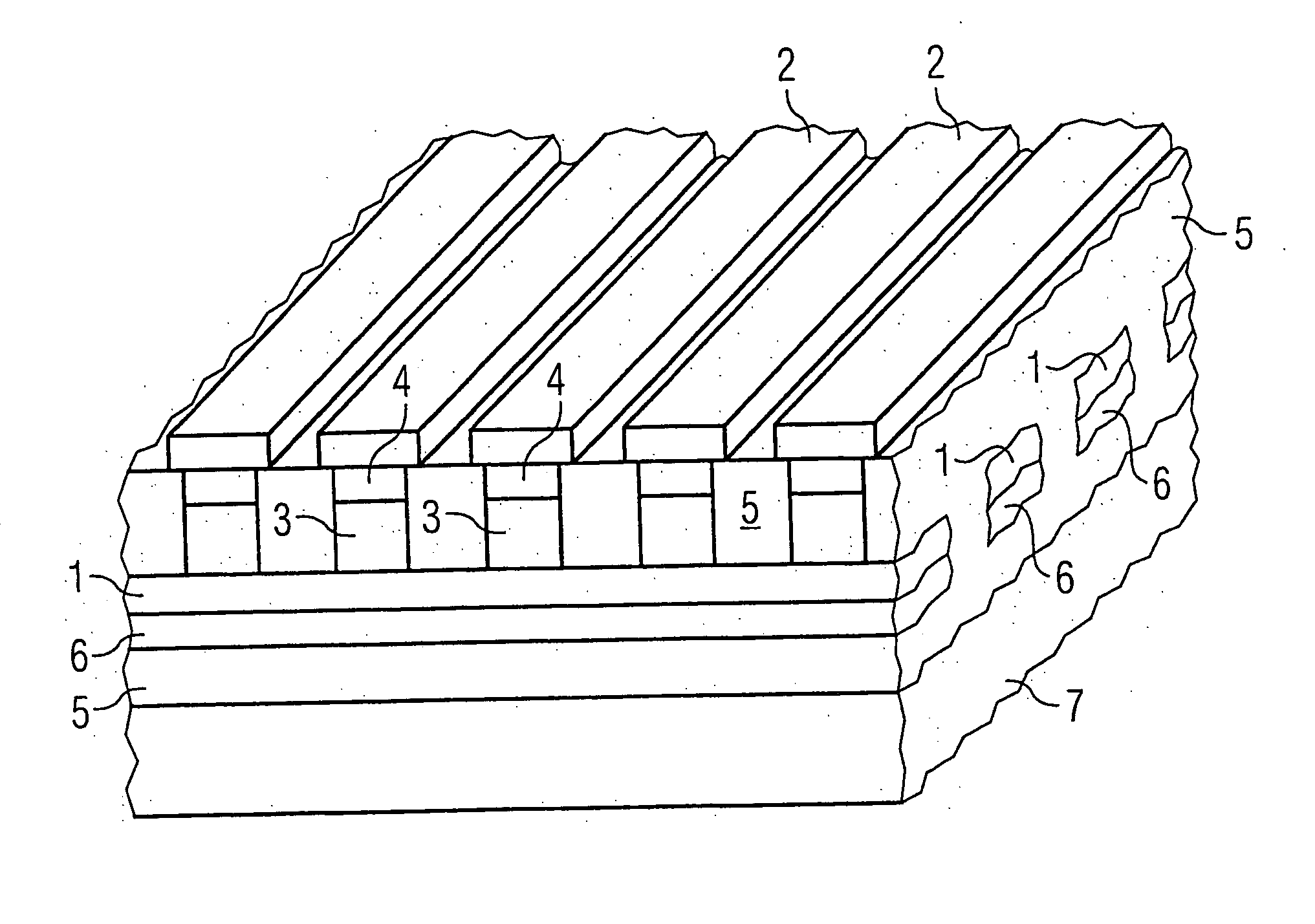

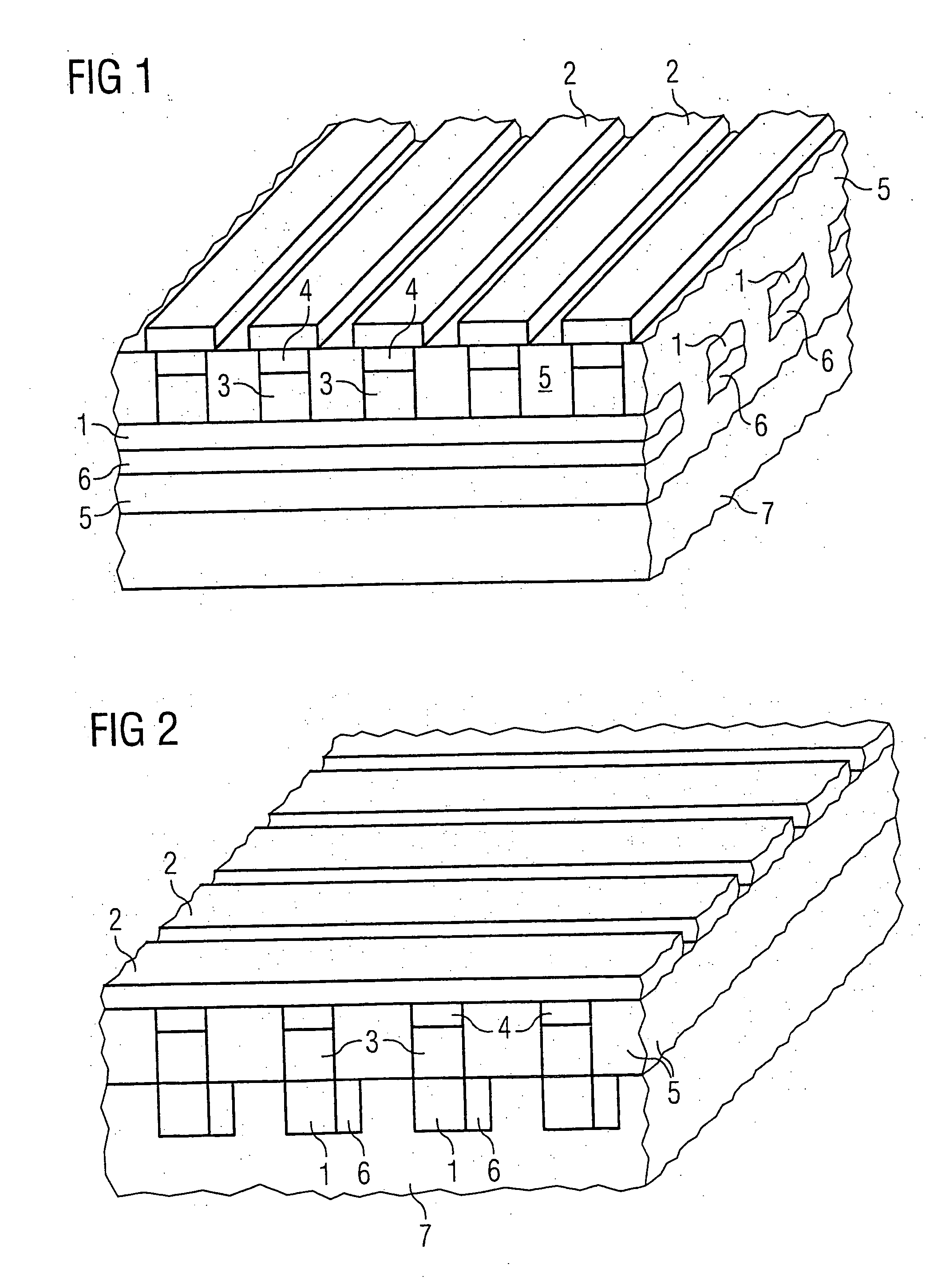

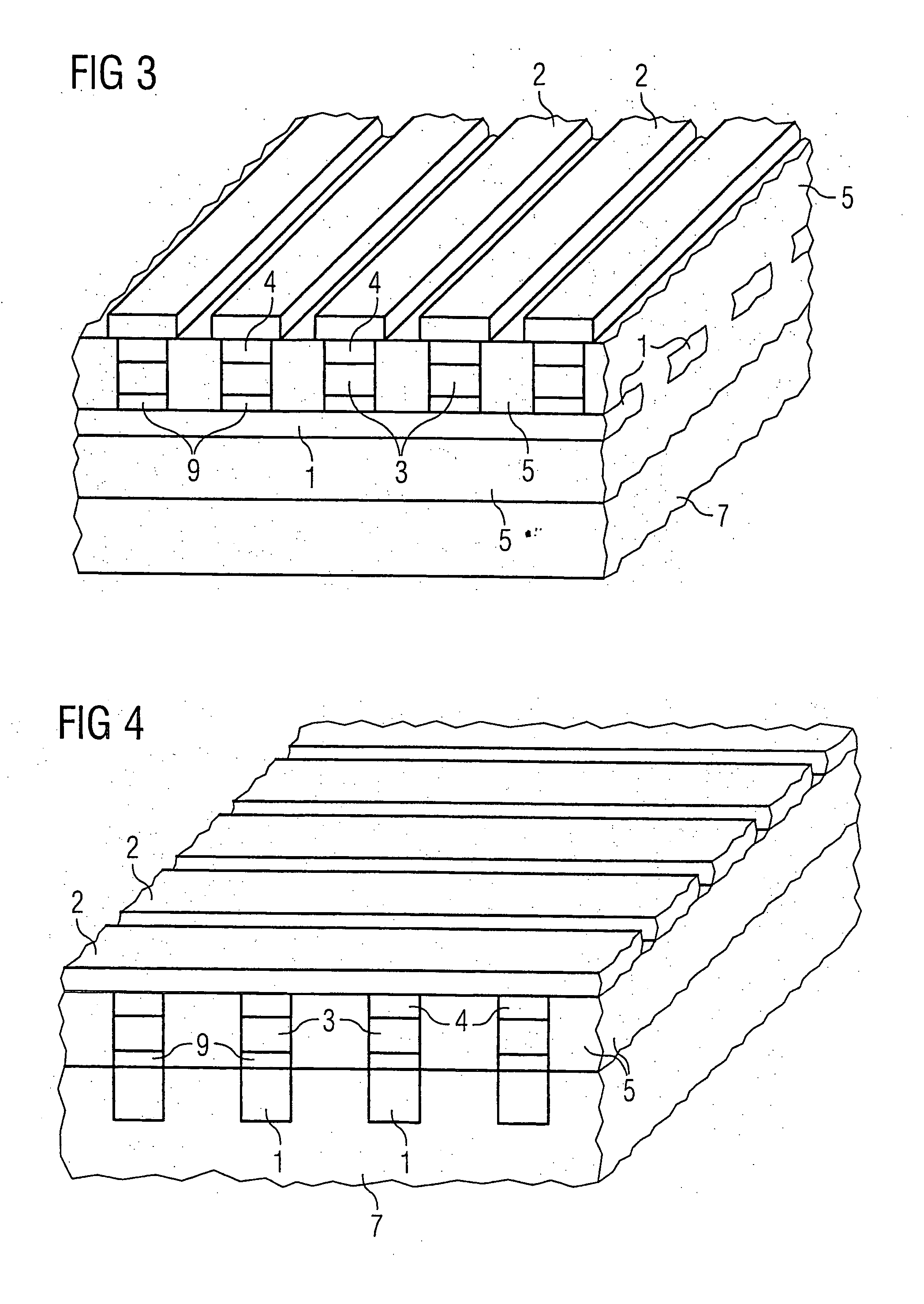

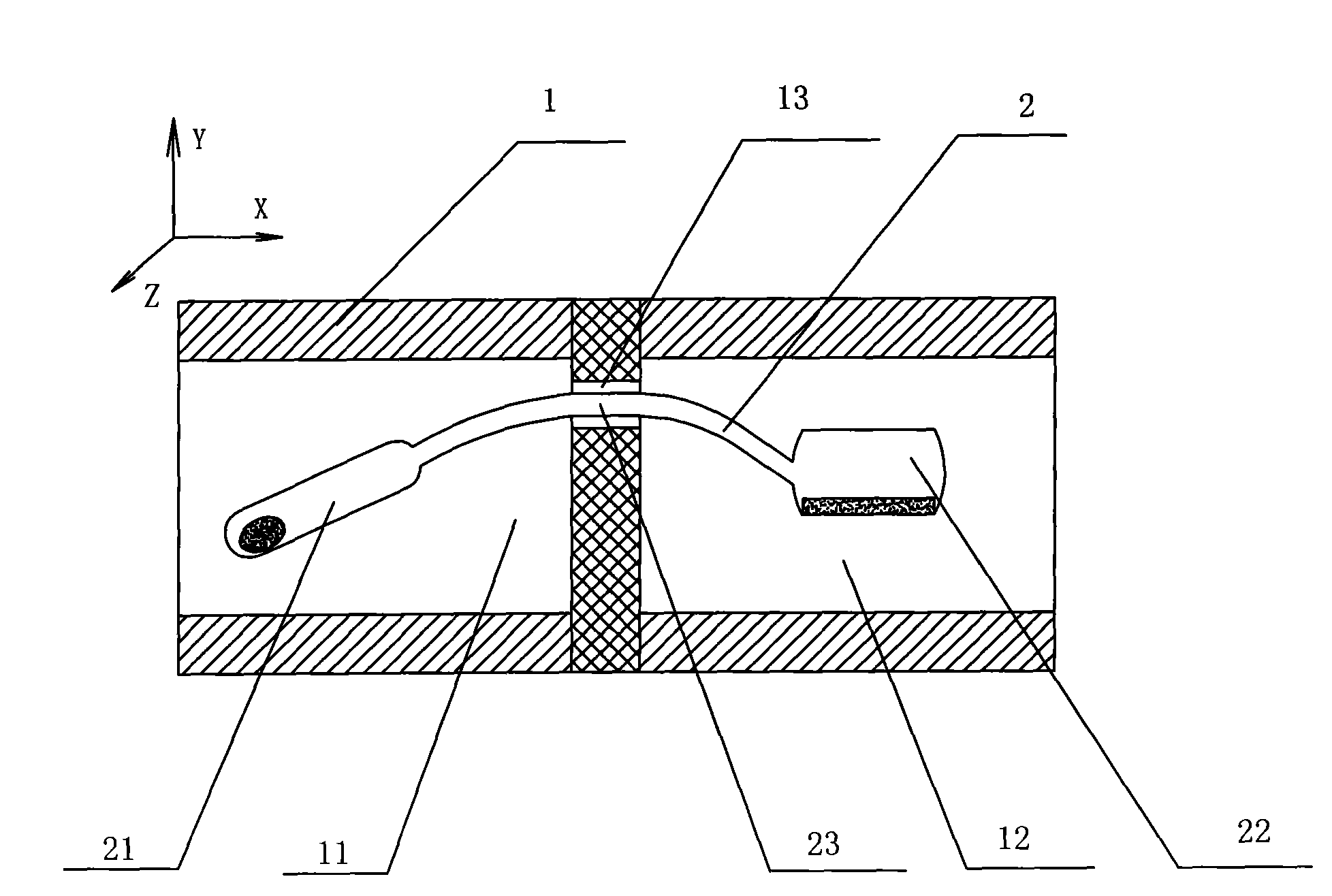

Semiconductor memory component in cross-point architecture

Owner:ADESTO TECH

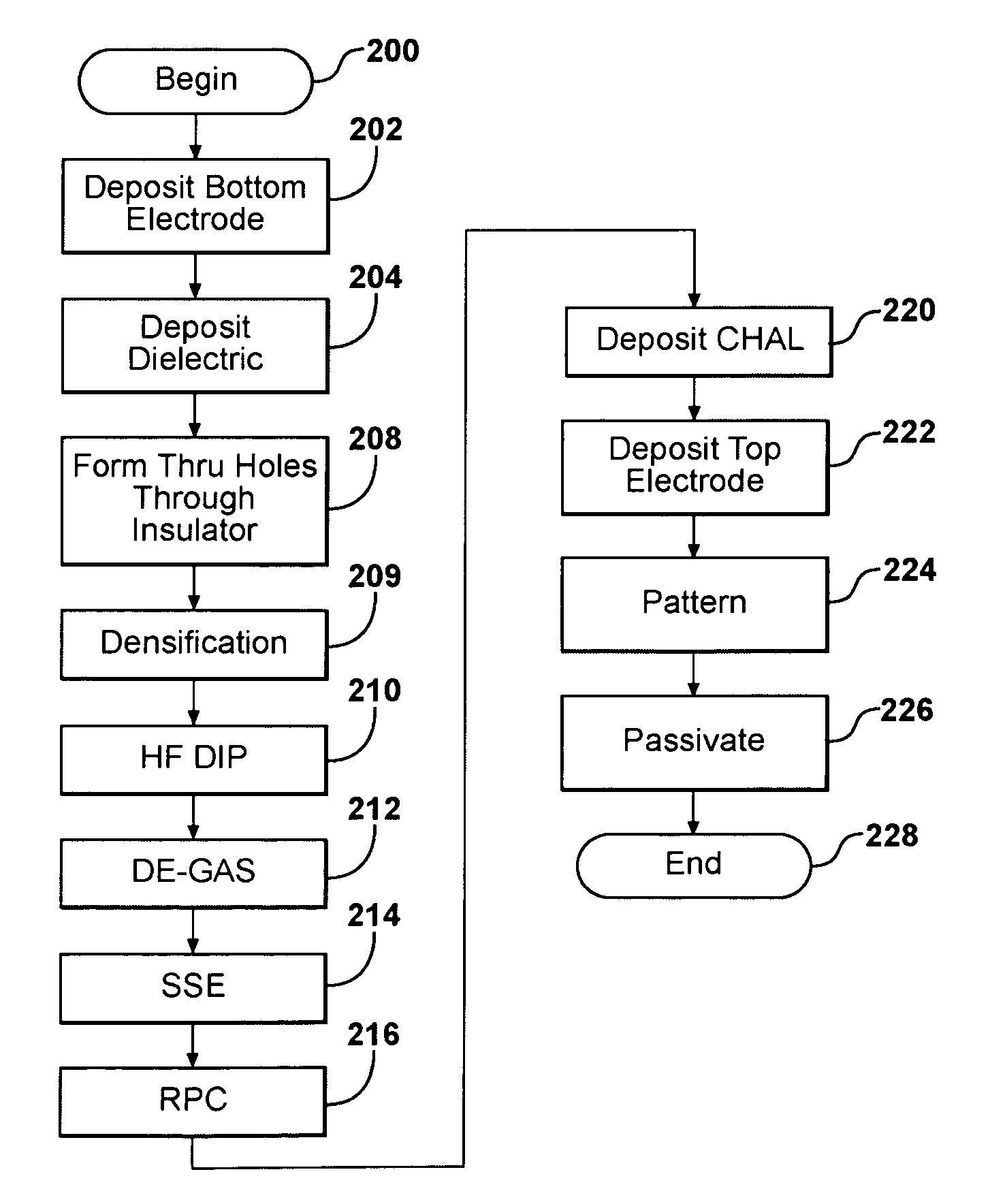

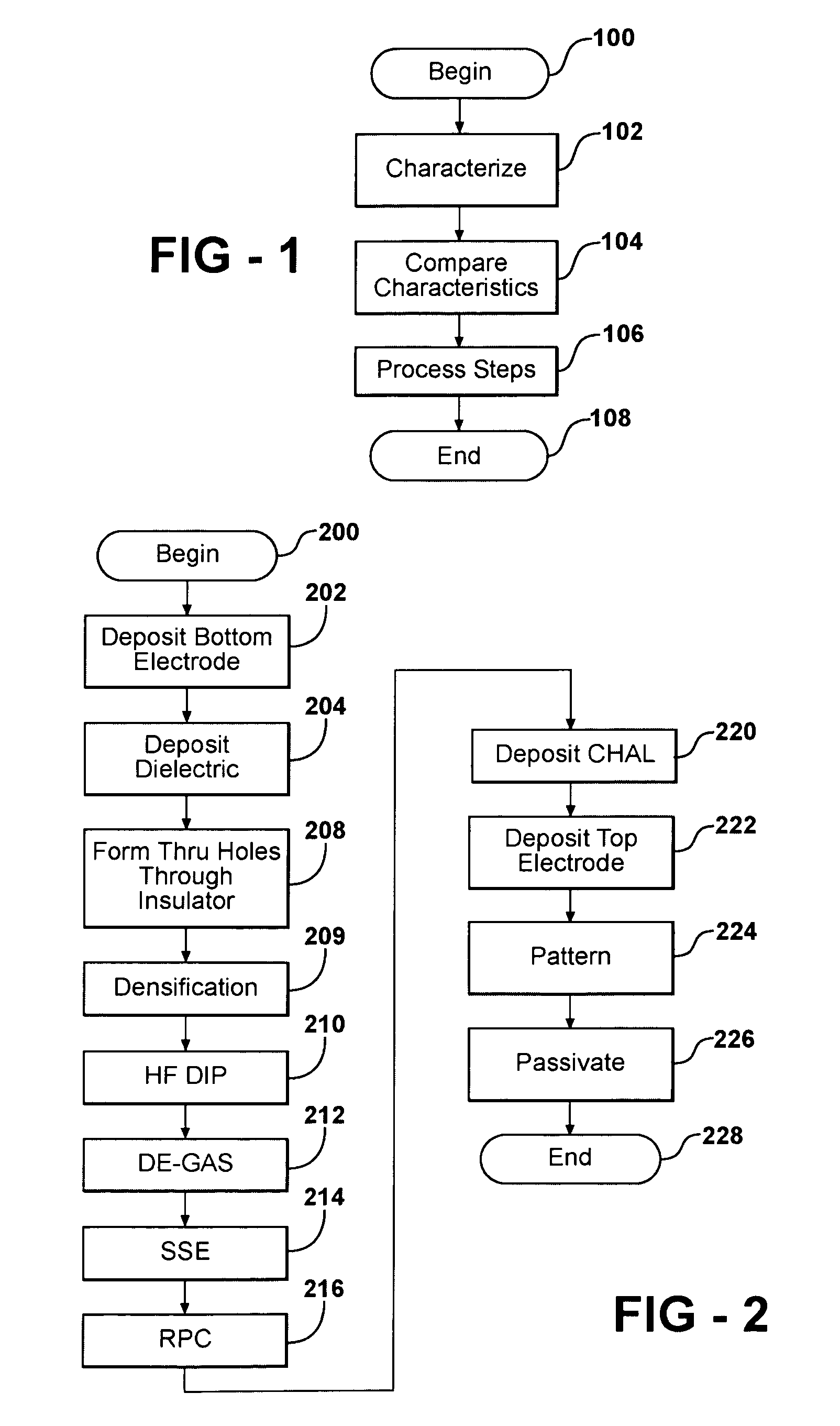

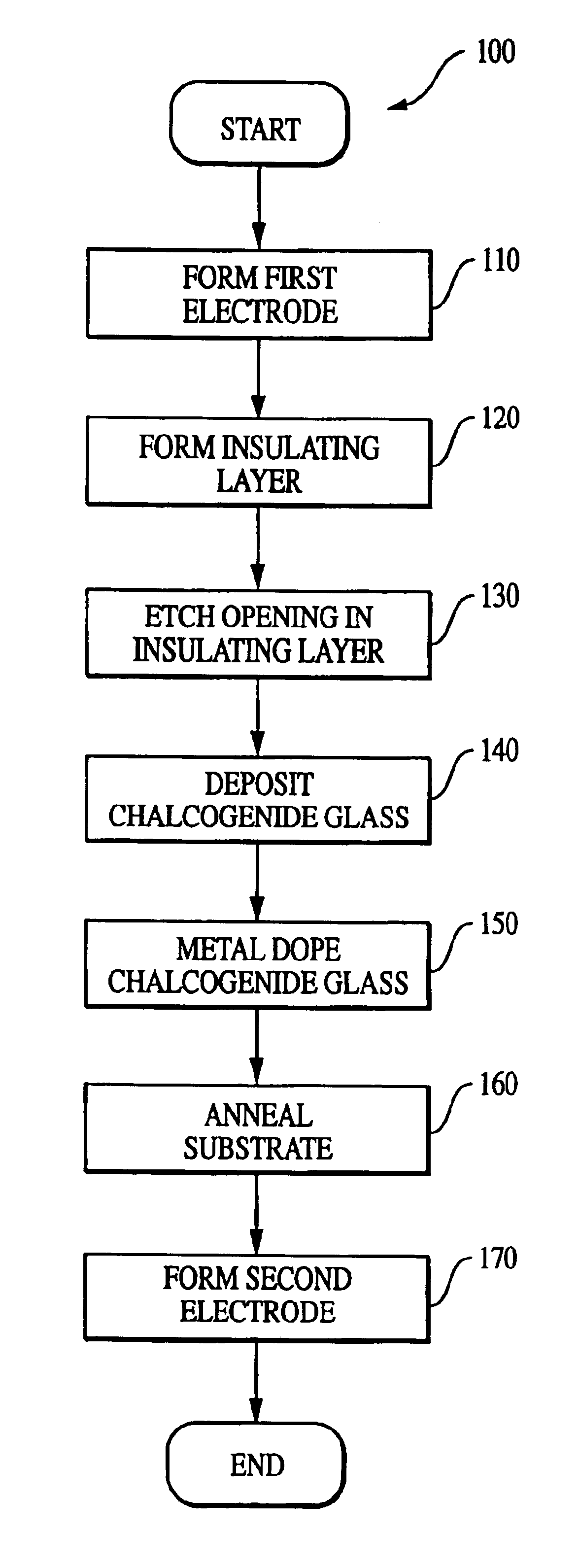

Method for manufacturing Chalcogenide devices

InactiveUS20090298222A1Reduces eliminatesImprove adhesionSemiconductor/solid-state device manufacturingChalcogenide glassAmount of substance

A method of chalcogenide device formation includes treatment of the surface upon which the chalcogenide material is deposited. The treatment reduces or eliminates native oxides and other contaminants from the surface, thereby increasing the adhesion of the chalcogenide layer to the treated surface, eliminating voids between the chalcogenide layer and deposition surface and reducing the degradation of chalcogenide material due to the migration of contaminants into the chalcogenide.

Owner:OVONYX

Fabrication of single polarity programmable resistance structure

InactiveUS7087454B2Read-only memoriesSemiconductor/solid-state device manufacturingChalcogenide glassData retention

Owner:OVONYX MEMORY TECH LLC

Semiconductor memory component in cross-point architecture

InactiveUS20050254291A1Improve conductivitySolid-state devicesRead-only memoriesBit lineChalcogenide glass

A programmable metallization memory cell with a storage region (3) formed from a chalcogenide glass and an electrode (4) which is preferably silver is located at the crossing point of a respective bit line (1) and a respective word line (2). There is a pn junction between the bit lines (1) and the chalcogenide glass.

Owner:ADESTO TECH

Method to control silver concentration in a resistance variable memory element

A method for controlling silver doping of a chalcogenide glass in a resistance variable memory element is disclosed herein. The method includes forming a thin metal containing layer having a thickness of less than about 250 Angstroms over a second chalcogenide glass layer, formed over a first metal containing layer, formed over a first chalcogenide glass layer. The thin metal containing layer preferably is a silver layer. An electrode may be formed over the thin silver layer. The electrode preferably does not contain silver.

Owner:OVONYX MEMORY TECH LLC

Performance PCRAM cell

InactiveUS20050017233A1Bulk negative resistance effect devicesSemiconductor devicesChalcogenide glassMaterials science

A method and apparatus for providing a resistance variable memory element with improved data retention and switching characteristics have at least one metal-containing layer and a silver layer disposed between glass layers. At least one of the glass layers is a chalcogenide glass, preferably having a GexSe100-x composition.

Owner:MICRON TECH INC

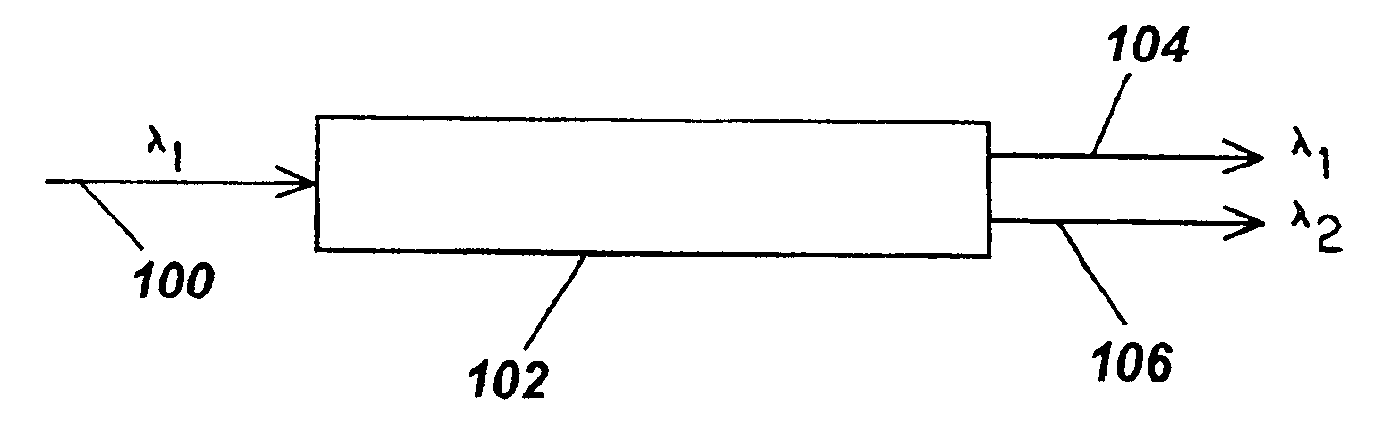

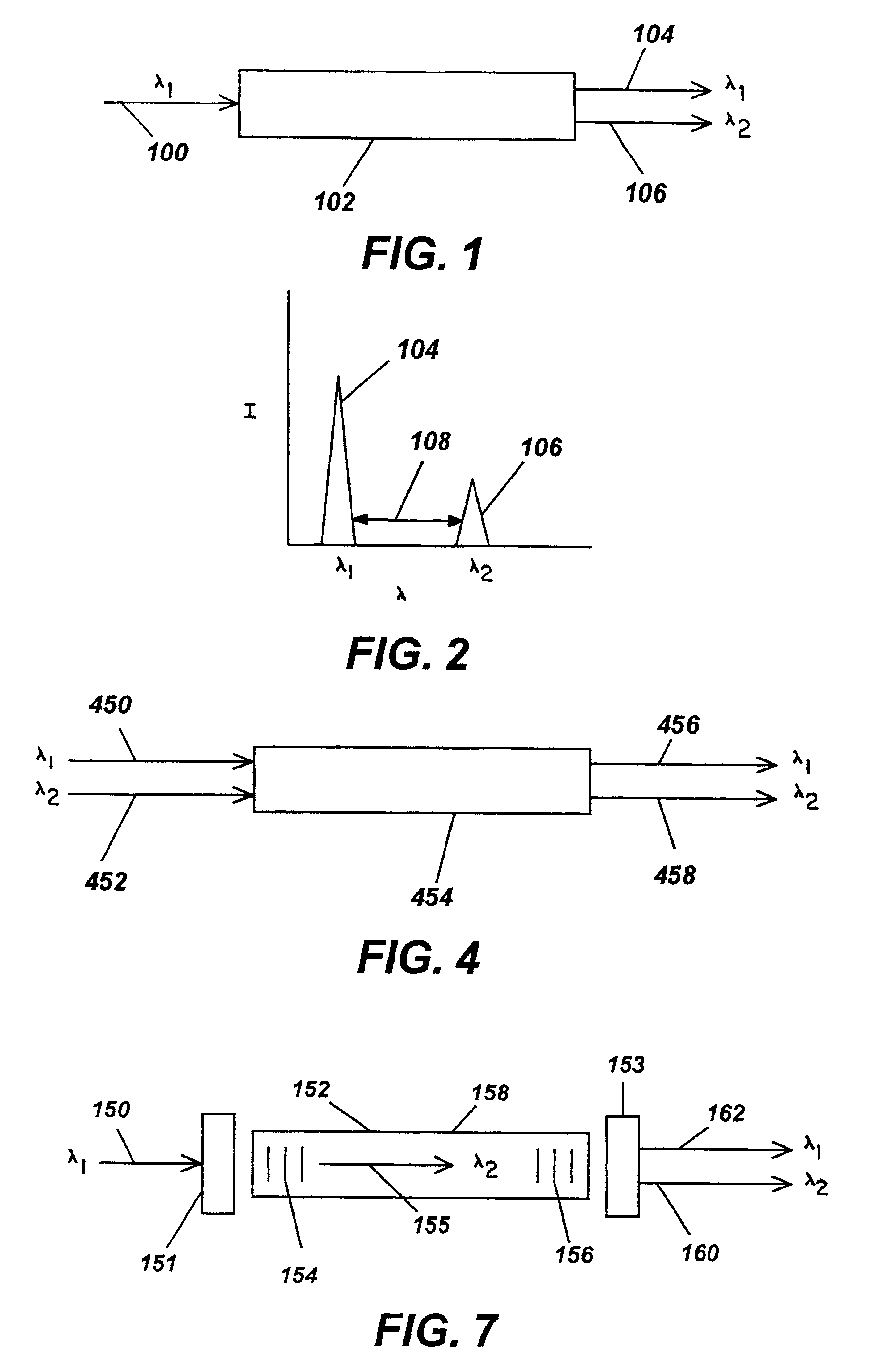

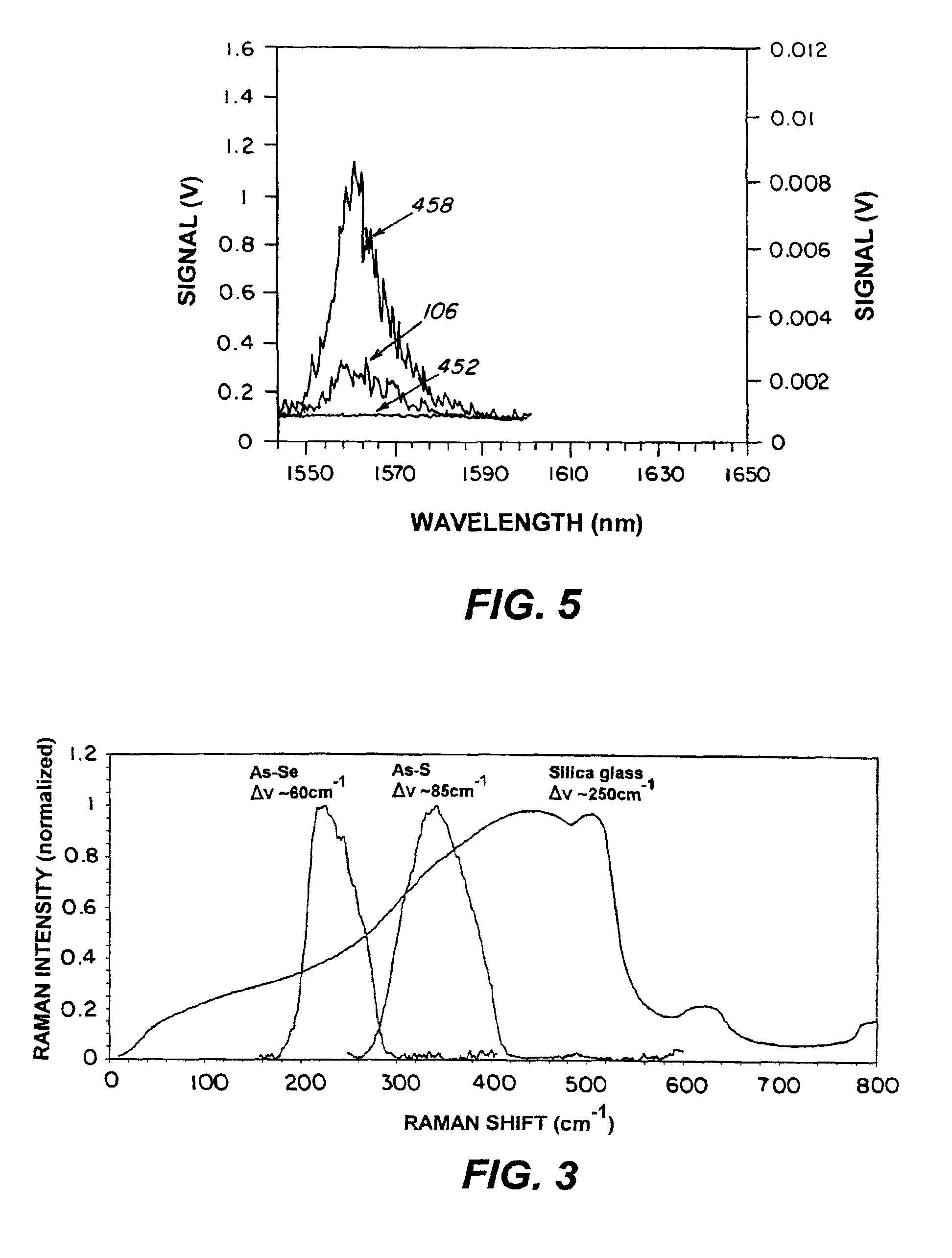

Amplification with chalcogenide glass fiber

InactiveUS6928227B2High enough Raman gainLow enough lossLaser using scattering effectsActive medium materialGlass fiberFiber

This invention pertains to an optical device and method for using a chalcogenide glass waveguide to amplify a pump light beam by means of stimulated Raman scattering and obtaining a depleted pump light beam and an amplified beam at a wavelength higher than the wavelength of the depleted pump light beam.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

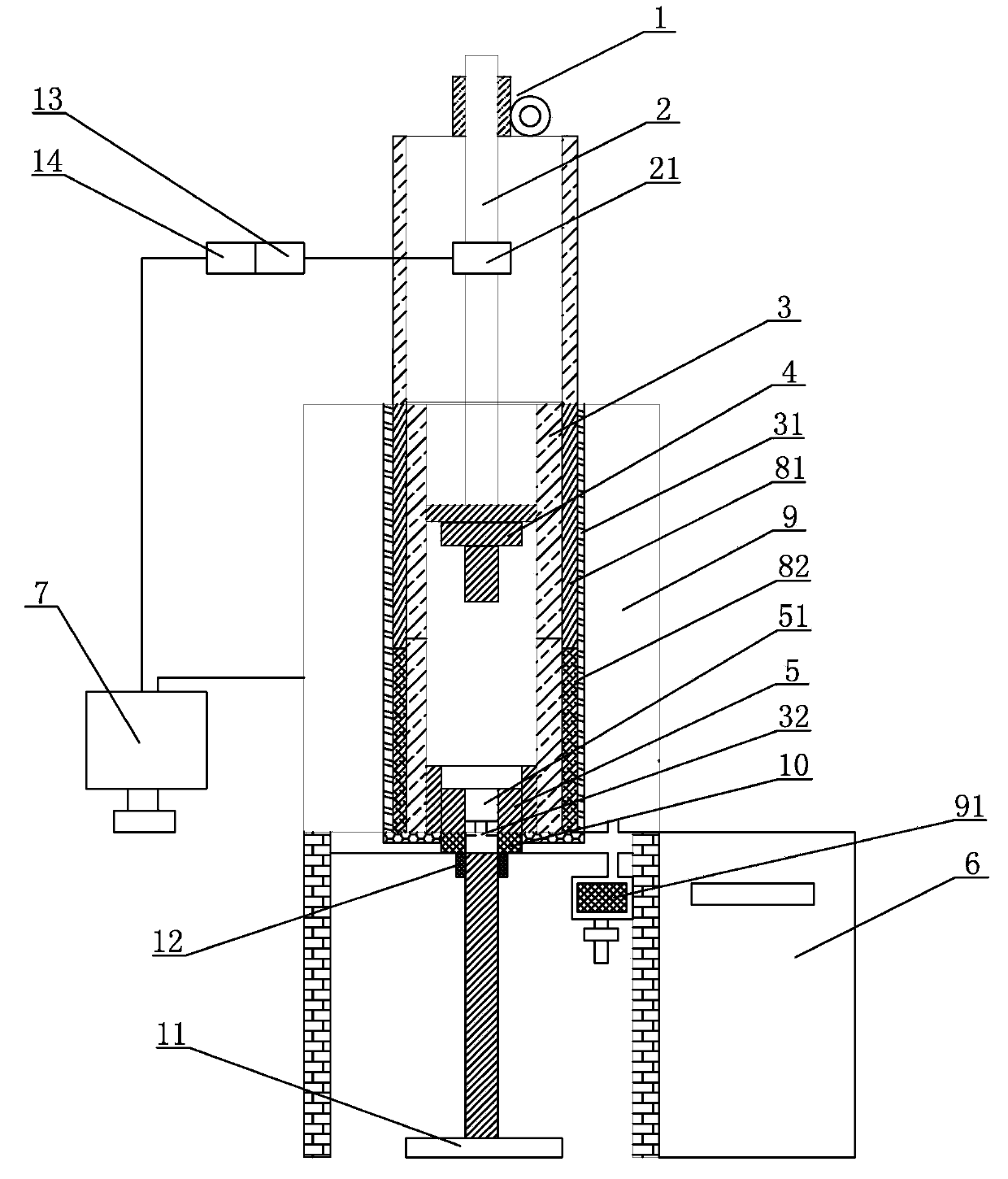

Extrusion device and method for extruding chalcogenide glass optical fiber perform with superposition method

ActiveCN103466933AUniform structureSmooth inside and outsideGlass making apparatusGlass productionSurface layerChalcogenide glass

The invention discloses an extrusion device and method for extruding a chalcogenide glass optical fiber perform with a superposition method. A pushing mechanism of the extrusion device is arranged above an extrusion container, and an extrusion rod is fixedly connected with the pushing mechanism; a heating furnace set used for heating the extrusion container is arranged outside the extrusion container, and a vacuum chamber is arranged outside the heating furnace set and is connected with a vacuum pump; an extrusion pad is arranged in the extrusion container, and an extrusion outlet is formed in the lower end of the extrusion container; a mould is arranged at the bottom of the extrusion container, and a mould hole of the mould is communicated with the extrusion outlet; a heat reducing furnace used for annealing the extruded optical fiber perform is arranged at the bottom of the extrusion container, and a traction device is arranged at the lower part of the heat reducing furnace. The extrusion device and the method have the characteristics of good controllability and high production efficiency.; the superposition method is adopted to extrude chalcogenide glass, and the obtained optical fiber perform has uniform structural composition, smooth inner and outer surfaces and a perfect interface; a surface layer is provide with a protective layer composed of high-molecular polymers, so that a performance test after drawing optical fibers is facilitated.

Owner:NINGBO UNIV

Resistance variable memory elements based on polarized silver-selenide network growth

The invention relates to a resistance variable memory element including polarizable metal-chalcogen regions within a doped chalcogenide glass. A method for physically aligning the polarizable metal-chalcogen regions to form a conducting channel is provided. The invention also relates to a resistance variable memory element including metal-chalcogen regions within a chalcogenide glass backbone. The metal-chalcogen regions and glass regions bond to form a conducting channel. In addition, a method of operating such memory elements is provided in which metal ions move in and out of the conducting channels in response to applied voltages, thereby affecting the resistance of the memory elements.

Owner:ROUND ROCK RES LLC

Method to alter chalcogenide glass for improved switching characteristics

InactiveUS6867064B2Tighter more rigid glass matrixImprove switching characteristicsTransistorSolid-state devicesElectrical resistance and conductanceSulfur

The present invention is related to methods of fabricating a resistance variable memory element and a device formed therefrom having improved switching characteristics. According to an embodiment of the present invention a resistance variable material memory element is annealed to remove stoichiometric amounts of a component of the resistance variable material. According to another embodiment of the present invention a silver-germanium-selenide glass is annealed for a duration of about 10 minutes in the presence of oxygen to drive off selenium and increase the rigidity of the glass.

Owner:ROUND ROCK RES LLC

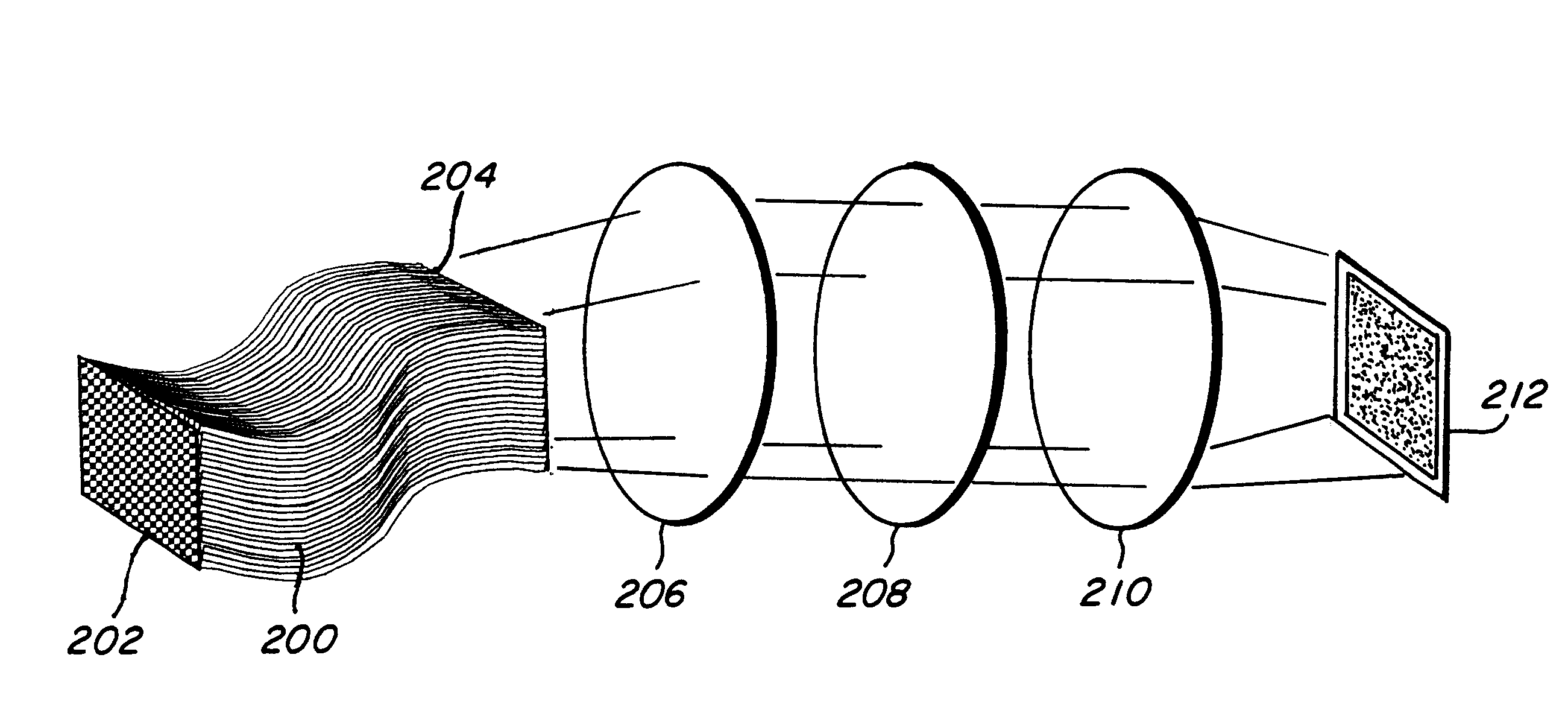

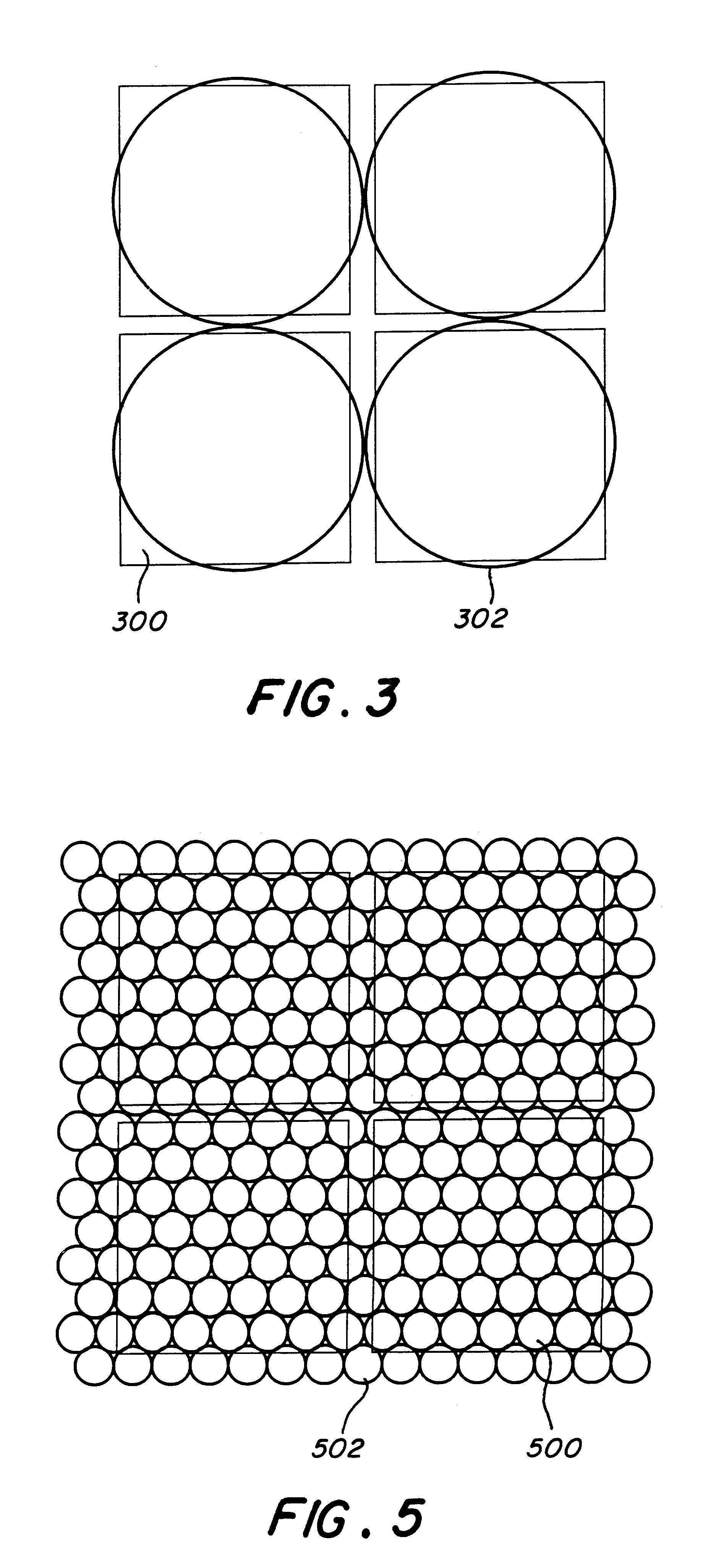

Infrared fiber imager

An apparatus for performing spatial and spectral analysis comprising a bundle of a plurality of chalcogenide glass fiber, an optical system for transmitting light received from the bundle, and a detector for receiving the light signal from the optical system for providing spatial and spectral analysis of the bundle image; maximum diameter of the fibers is about the size of the pixels on the detector.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Thin film diode integrated with chalcogenide memory cell

InactiveUS20050101084A1Solid-state devicesSemiconductor/solid-state device manufacturingThin-film diodeChalcogenide glass

An integrated programmable conductor memory cell and diode device in an integrated circuit comprises a diode and a glass electrolyte element, the glass electrolyte element having metal ions mixed or dissolved therein and being able to selectively form a conductive pathway under the influence of an applied voltage. In one embodiment, both the diode and the memory cell comprise a chalcogenide glass, such as germanium selenide (e.g., Ge2Se8 or Ge25Se75). The first diode element comprises a chalcogenide glass layer having a first conductivity type, the second diode element comprises a chalcogenide glass layer doped with an element such as bismuth and having a second conductivity type opposite to the first conductivity type and the memory cell comprises a chalcogenide glass element with silver ions therein. In another embodiment, the diode comprises silicon and there is a diffusion barrier layer between the diode and the chalcogenide glass memory element. Methods of fabricating integrated programmable conductor memory cell and diode devices are also disclosed.

Owner:OVONYX MEMORY TECH LLC

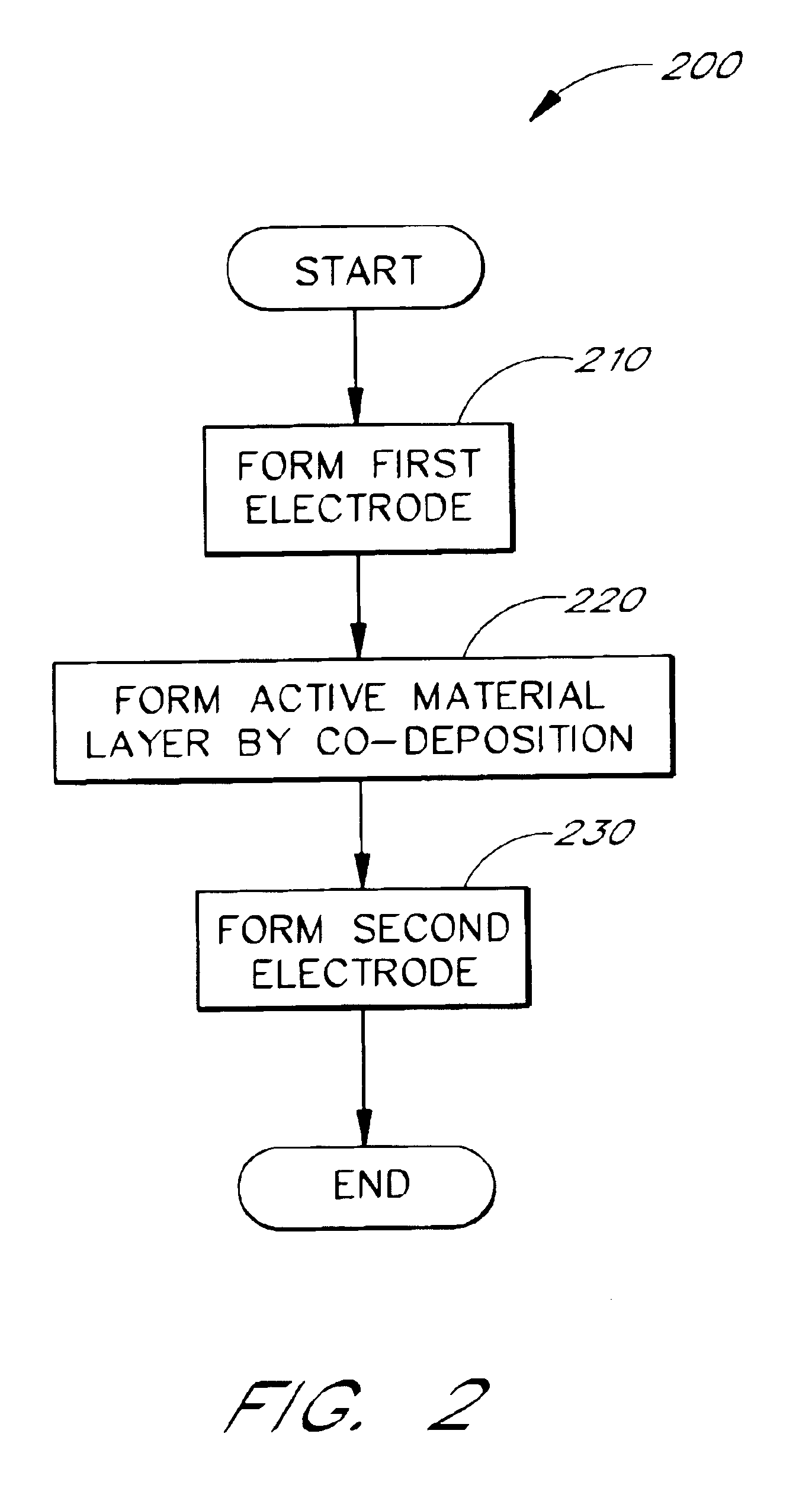

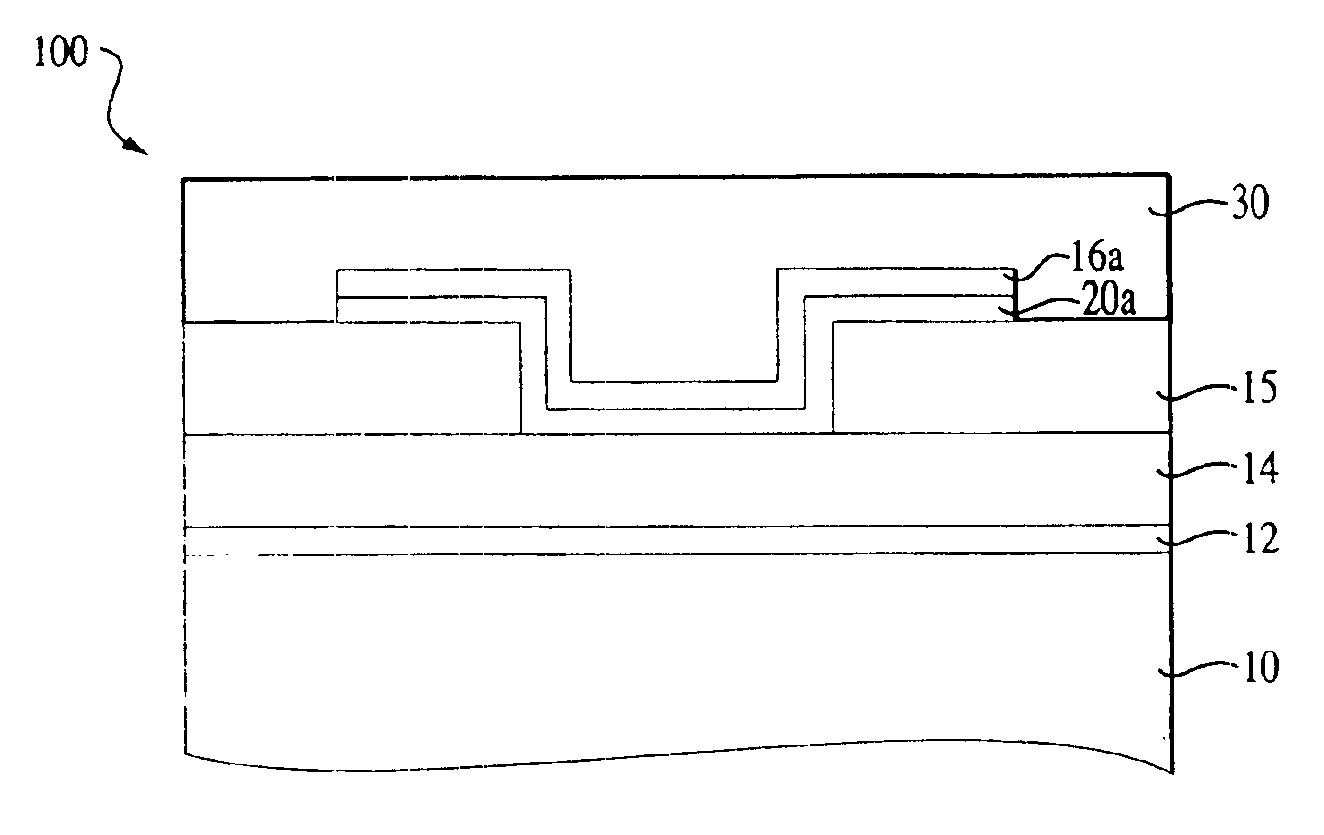

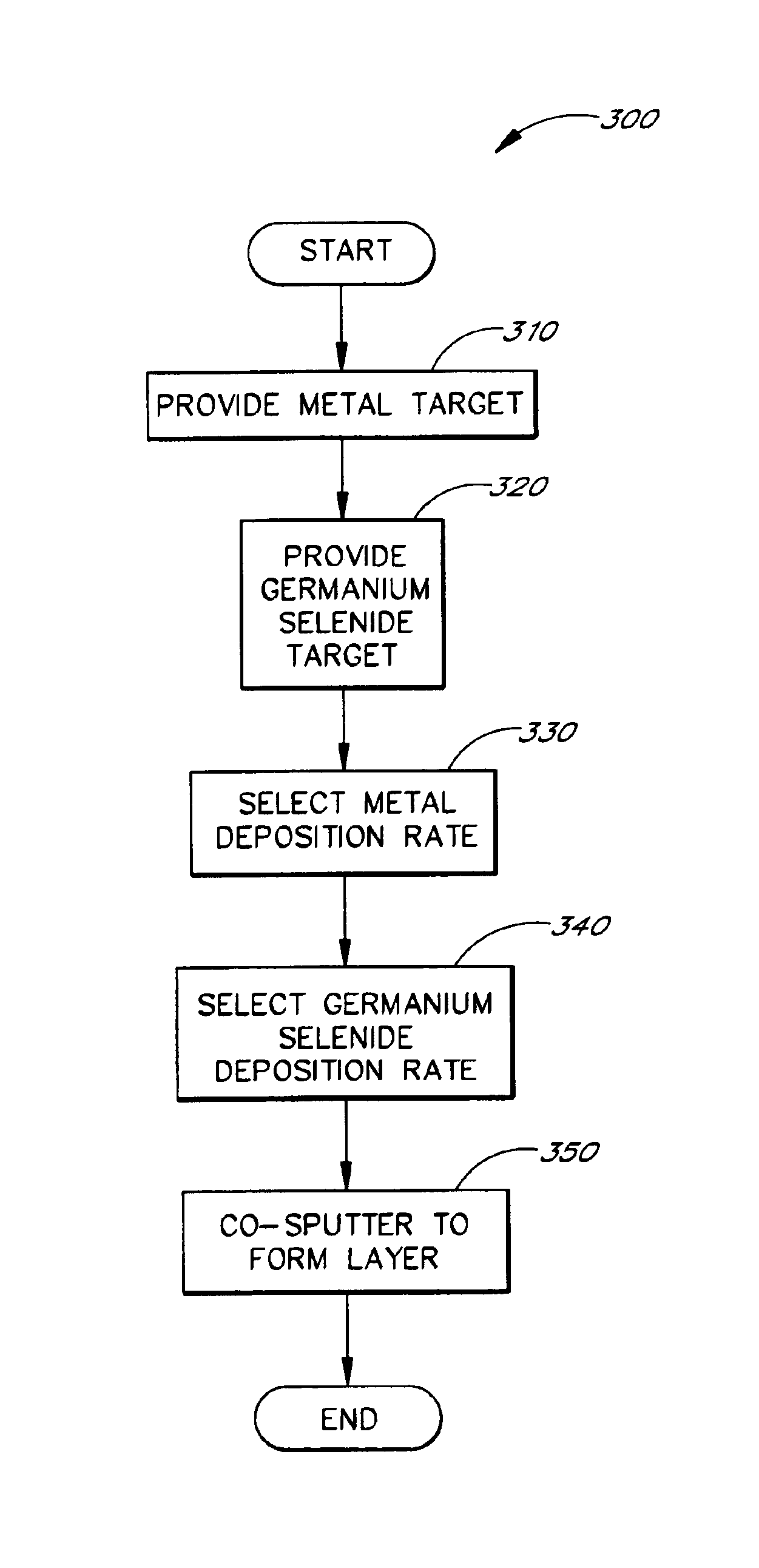

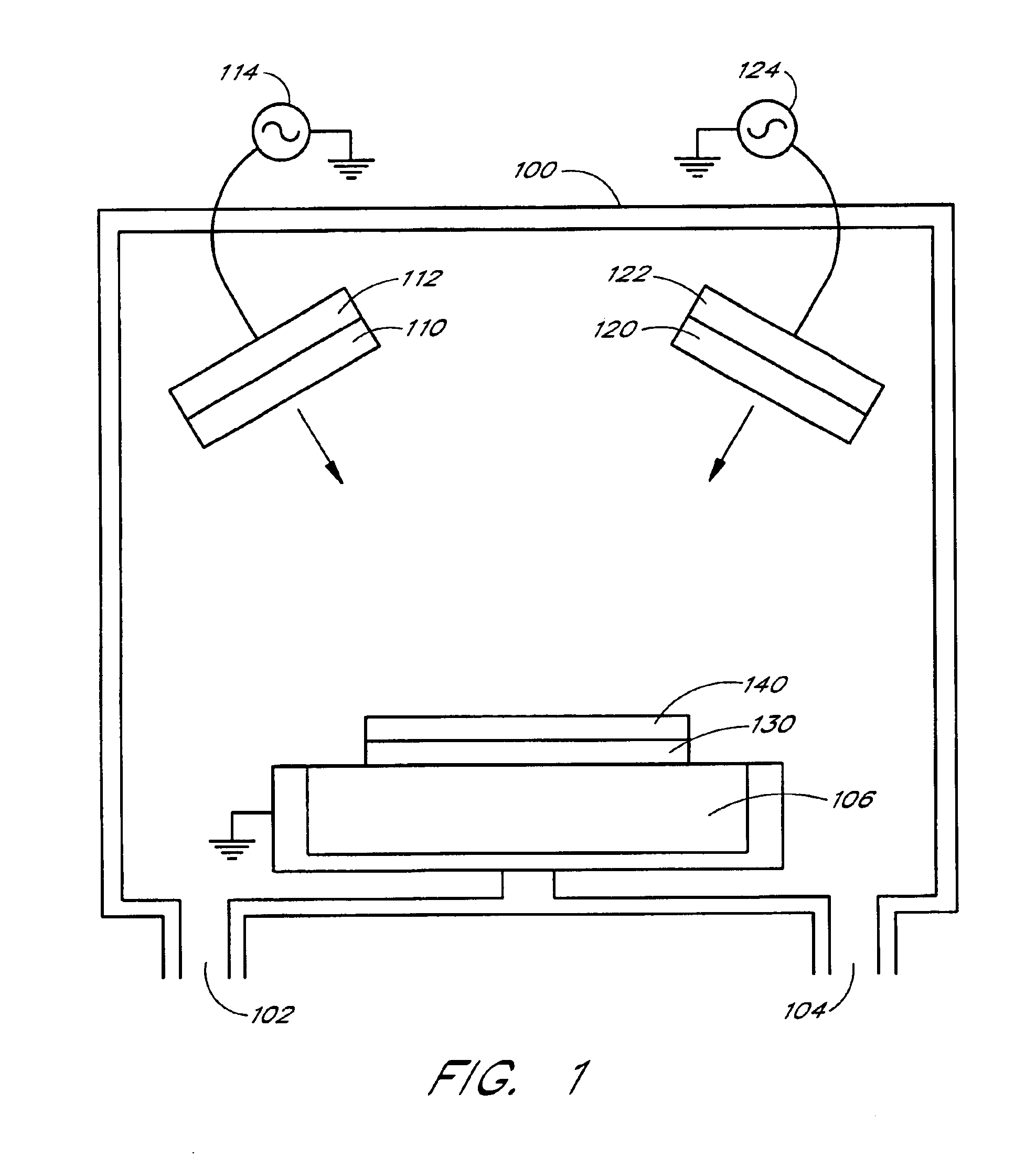

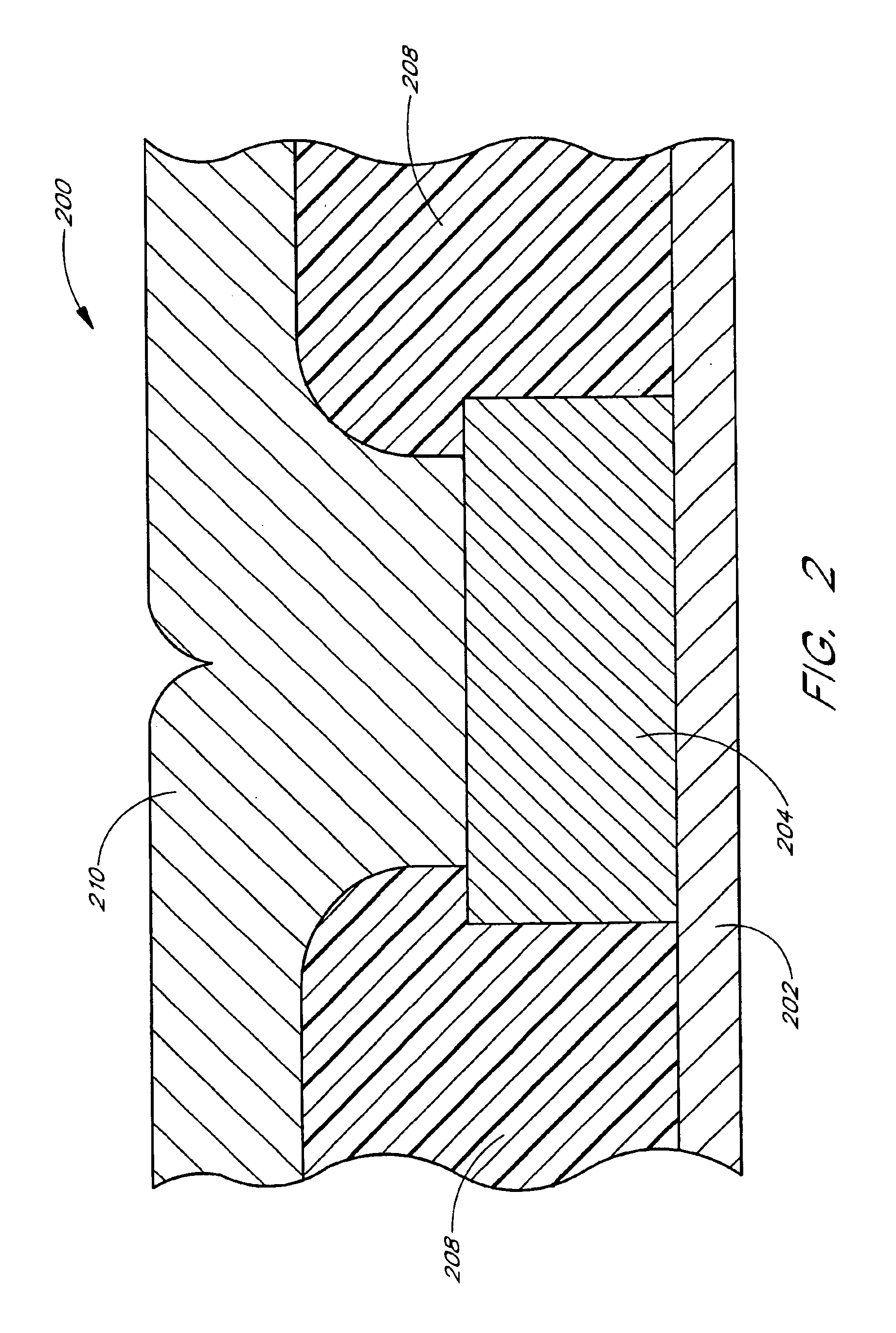

Co-sputter deposition of metal-doped chalcogenides

InactiveUS6890790B2Precise and Efficient ControlHigh degreeVacuum evaporation coatingSputtering coatingControl mannerSulfur

The present invention is related to methods and apparatus that allow a chalcogenide glass such as germanium selenide (GexSe1-x) to be doped with a metal such as silver, copper, or zinc without utilizing an ultraviolet (UV) photodoping step to dope the chalcogenide glass with the metal. The chalcogenide glass doped with the metal can be used to store data in a memory device. Advantageously, the systems and methods co-sputter the metal and the chalcogenide glass and allow for relatively precise and efficient control of a constituent ratio between the doping metal and the chalcogenide glass. Further advantageously, the systems and methods enable the doping of the chalcogenide glass with a relatively high degree of uniformity over the depth of the formed layer of chalcogenide glass and the metal. Also, the systems and methods allow a metal concentration to be varied in a controlled manner along the thin film depth.

Owner:ROUND ROCK RES LLC

Methods for forming chalcogenide glass-based memory elements

InactiveUS6953720B2Solid-state devicesSemiconductor/solid-state device manufacturingChalcogenide glassComputer science

Owner:MICRON TECH INC

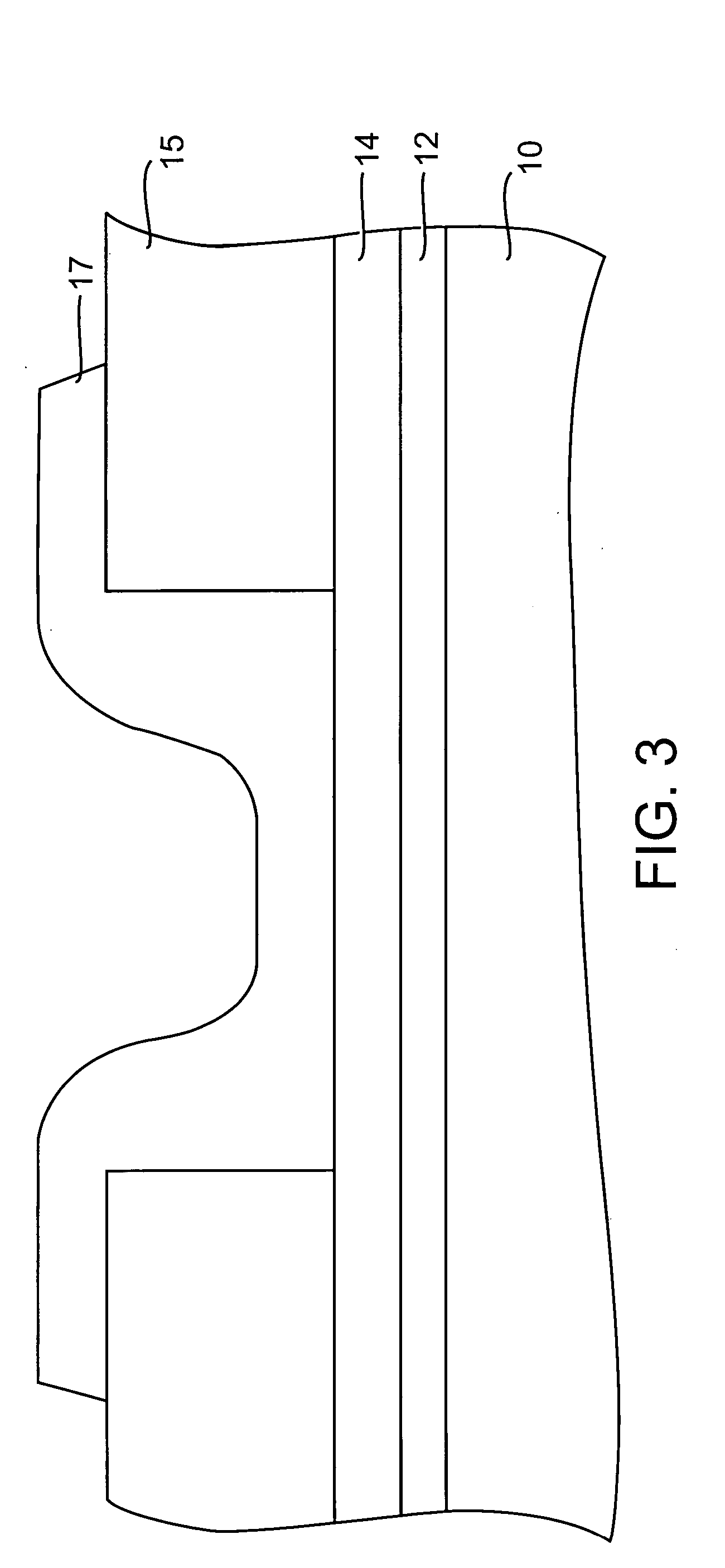

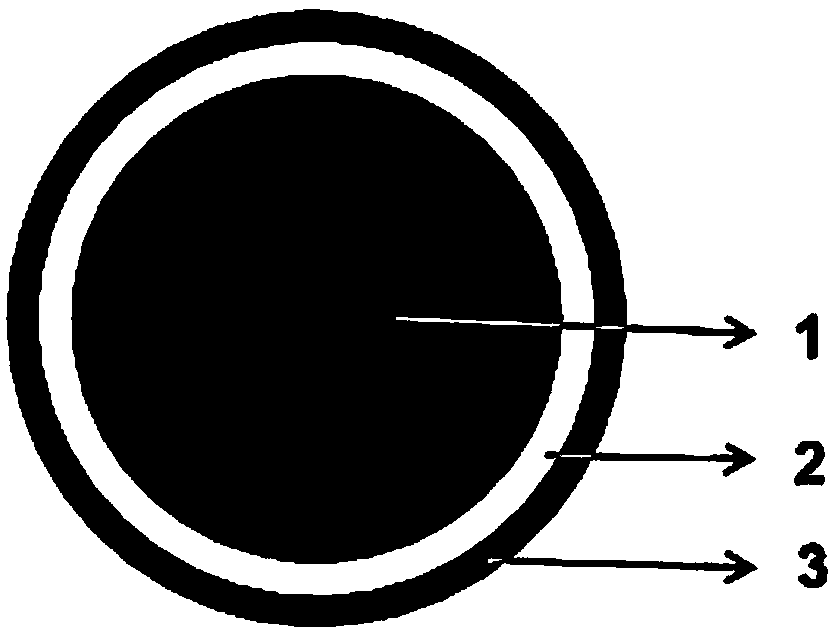

Chalcogenide glass fiber

Chalcogenide glass fibers having a glass core with two cladding glass layers, the second cladding glass layer having a refractive index lower than that of the core glass and higher than that of the first cladding glass. The core glass does not contain germanium. Glass fiber having this core-cladding structure is mechanically strong and exhibits only small transmission loss of infrared light passing through the fiber.

Owner:HOYA CORP +1

Method and apparatus for resistance variable material cells

InactiveUS7030405B2Increase chanceFast switching speedSolid-state devicesSemiconductor/solid-state device manufacturingSulfurChalcogenide glass

The present invention is related to methods and apparatus to produce a memory cell or resistance variable material with improved data retention characteristics and higher switching speeds. In a memory cell according to an embodiment of the present invention, silver selenide and a chalcogenide glass, such as germanium selenide (GexSe(1−x)) are combined in an active layer, which supports the formation of conductive pathways in the presence of an electric potential applied between electrodes. Advantageously, embodiments of the present invention can be fabricated with relatively wide ranges for the thicknesses of the silver selenide and glass layers.

Owner:MICRON TECH INC

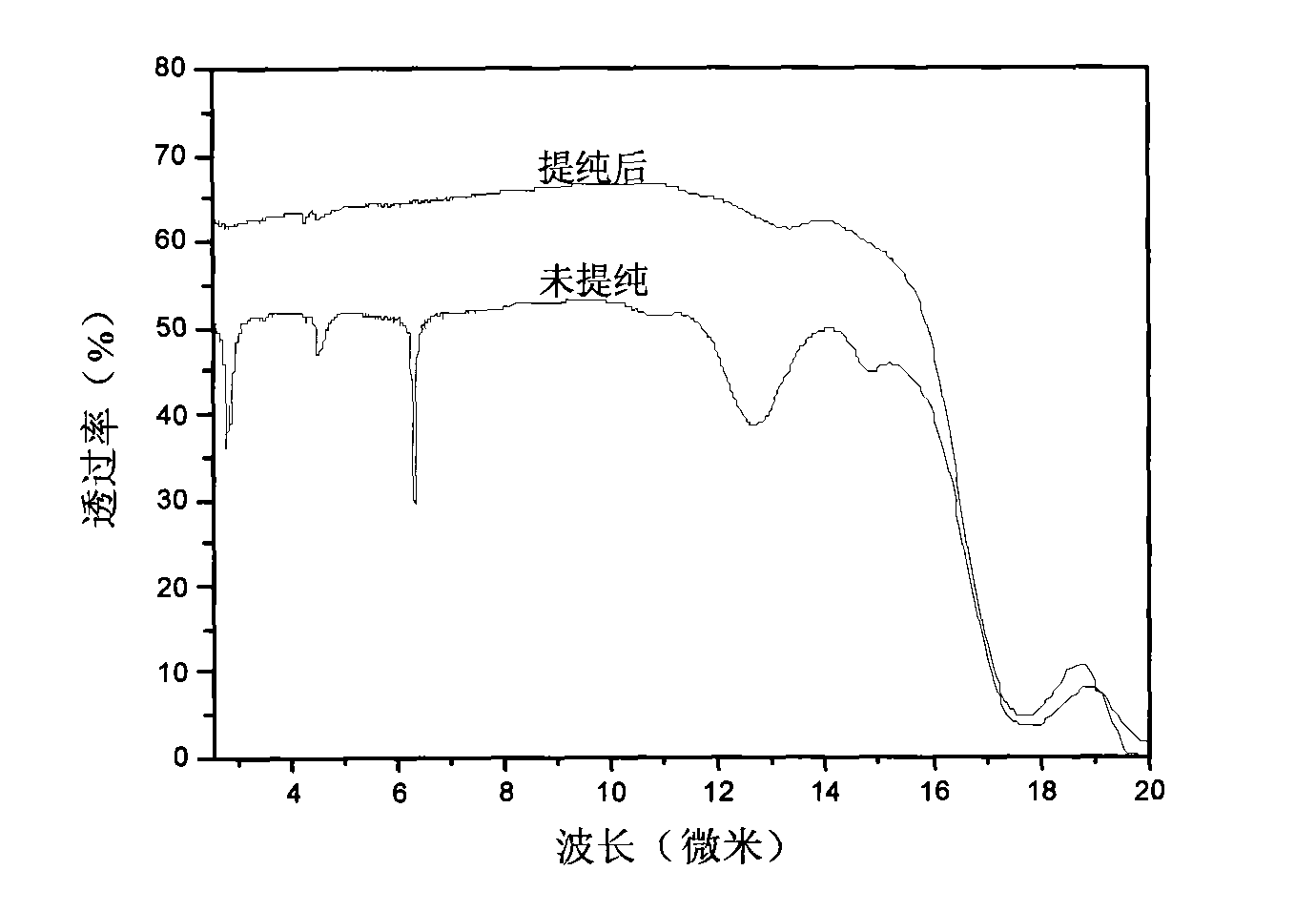

Apparatus and method for producing high-purity sulphur glass

ActiveCN101492235AUniform optical qualityGood infrared transmittancePot furnacesGlass furnace apparatusTemperature controlChalcogenide glass

The invention discloses a device for preparing high-purity chalcogenide glass, which is characterized by comprising a swaying furnace body with the function of swaying backwards and forwards and a quartz ampoule, wherein the swaying furnace body is provided with a first hearth and a second hearth which are provided with an independent temperature control and heating system respectively and are communicated with each other through a transition area; the quartz ampoule comprises a glass raw material tube and a purification glass tube which are communicated with each other through a connecting tube; the glass raw material tube is arranged in the first hearth; the purification glass tube is arranged in the second hearth; and the connecting tube is positioned in the transition area. The device has the advantages that one quartz ampoule provided with the glass raw material tube and the purification glass tube is arranged on the device, the glass raw material tube and the purification glass tube are placed in two hearths with different temperatures respectively, the temperature difference between the two hearths is controlled to realize the purification of glass so that the high-purity chalcogenide glass with even optical quality and good infrared light transmittance can be obtained.

Owner:NINGBO UNIV +1

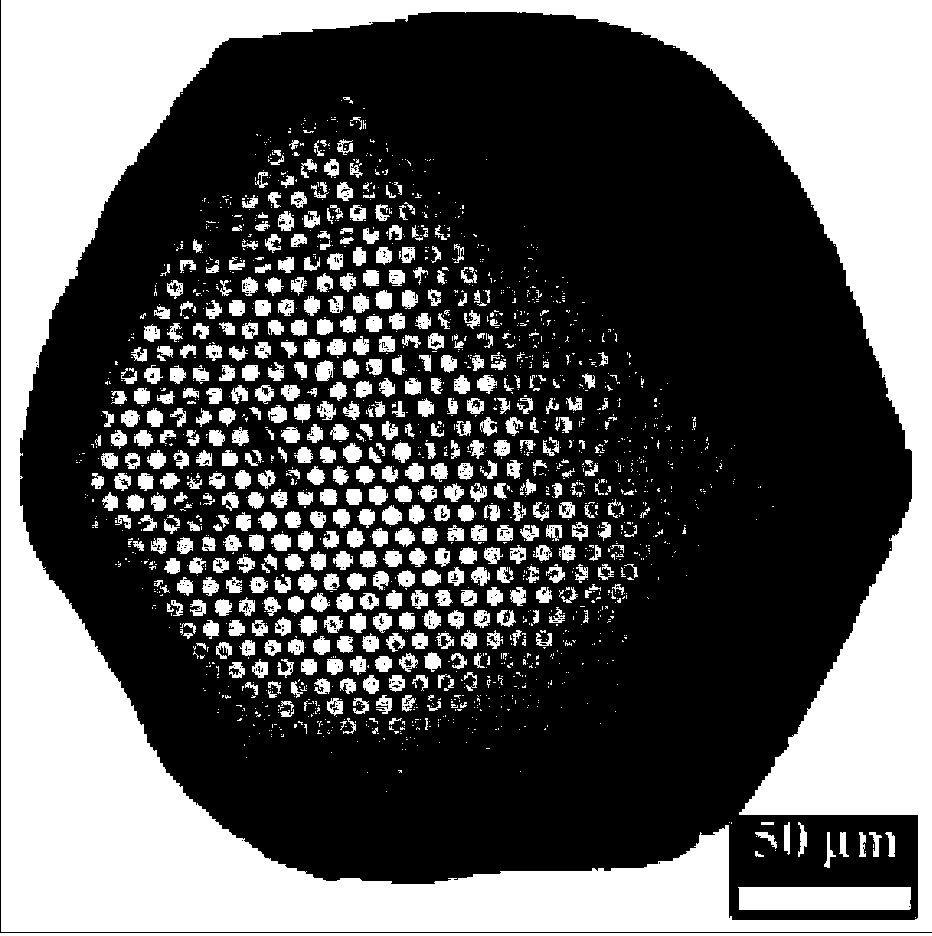

Flexible high-resolution infrared chalcogenide glass optical fiber image transmission bundle and manufacturing method

ActiveCN104181636AHigh mechanical strengthIncreased mechanical toughnessGlass making apparatusBundled fibre light guideFiberImage resolution

The invention discloses a flexible high-resolution infrared chalcogenide glass optical fiber image transmission bundle and a manufacturing method. The optical fiber image transmission bundle is formed by closely stacking optical fiber multifilaments, the optical fiber multifilaments are formed by drawing optical fiber monofilament bundles, the optical fiber monofilament bundles are formed by closely stacking optical fiber monofilaments, the optical fiber monofilaments sequentially comprise chalcogenide glass fiber cores, chalcogenide glass inner coating layers and thermoplastics polymer outer coating layers from inside to outside, and the relation among the refractive index n1 of the chalcogenide glass fiber cores, the refractive index n2 of the chalcogenide glass inner coating layers and the refractive index n3 of the thermoplastics polymer outer coating layers is n1>n2>n3. The manufacturing process is simple and easy to control, the wire breakage rate of the optical fiber bundles is low, and the large-section high-resolution flexible infrared optical fiber image transmission bundle can be manufactured easily.

Owner:XUZHOU NORMAL UNIVERSITY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com