Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Smooth inside and outside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion device and method for extruding chalcogenide glass optical fiber perform with superposition method

ActiveCN103466933AUniform structureSmooth inside and outsideGlass making apparatusGlass productionSurface layerChalcogenide glass

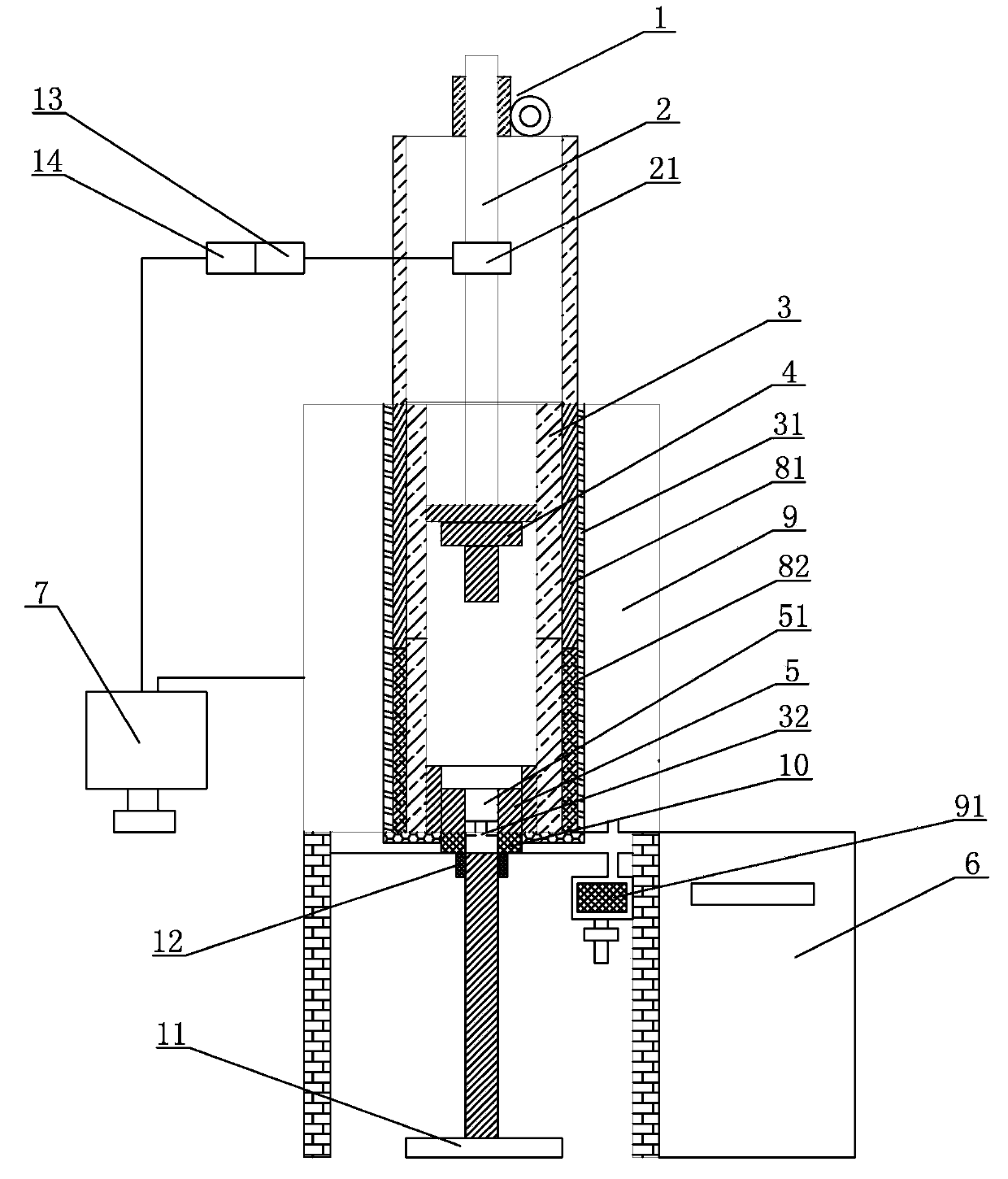

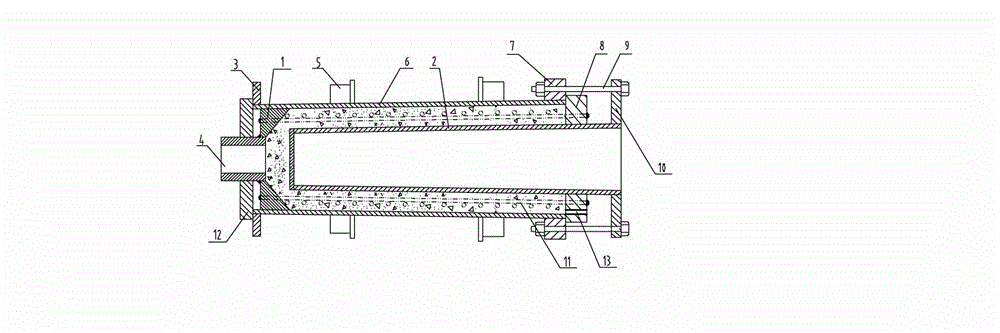

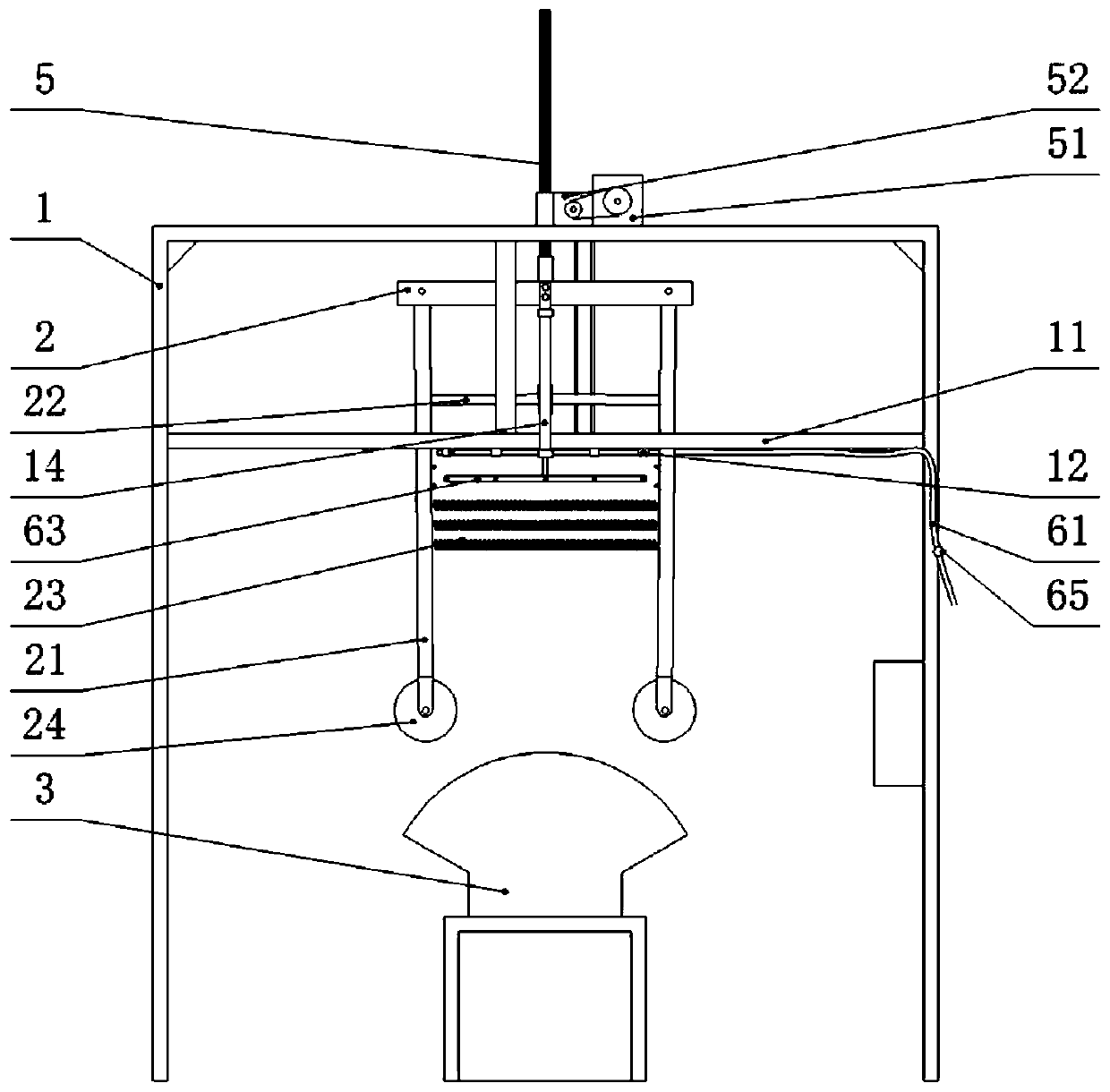

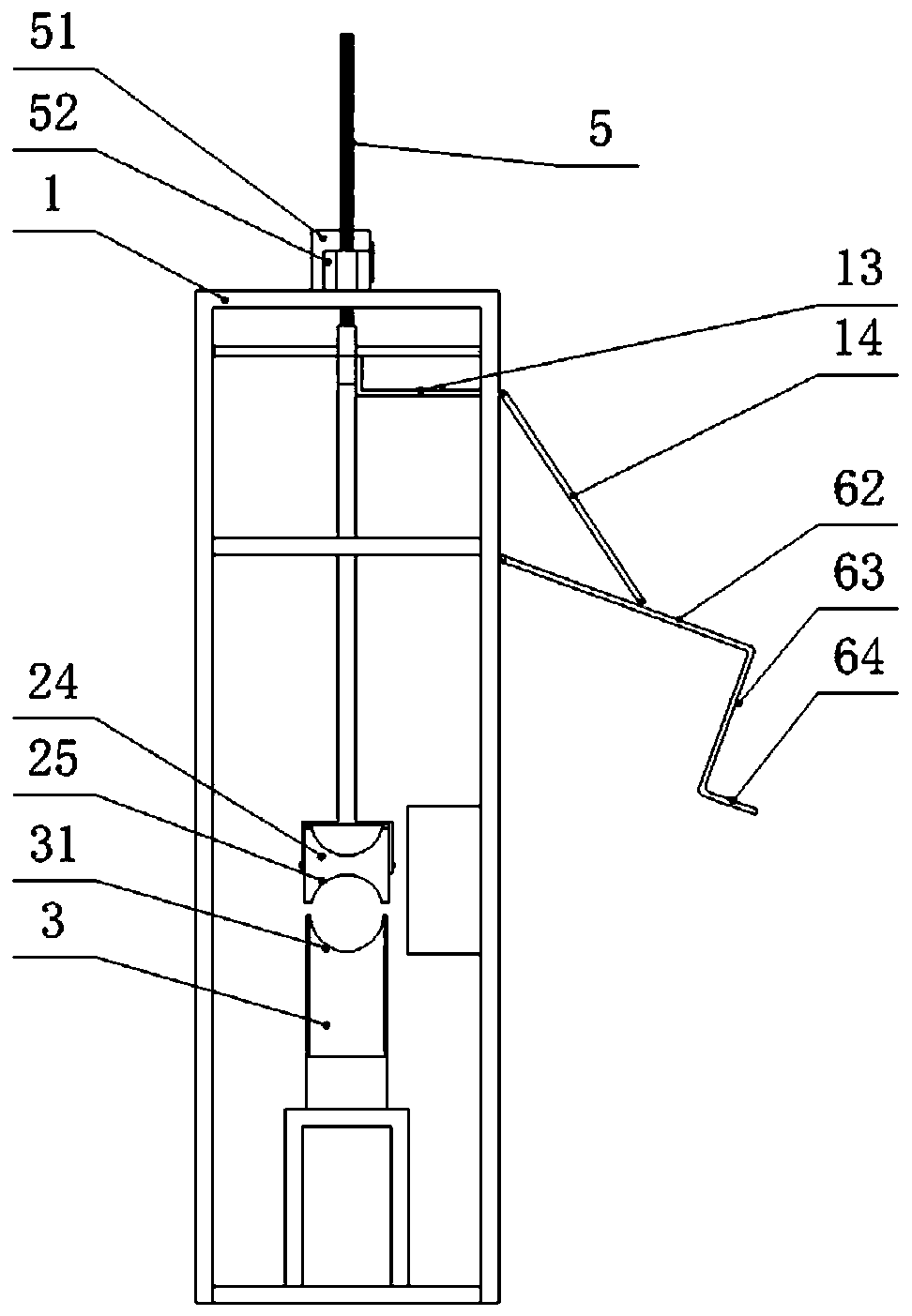

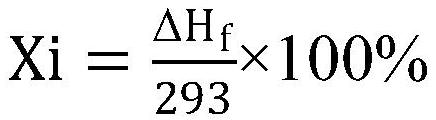

The invention discloses an extrusion device and method for extruding a chalcogenide glass optical fiber perform with a superposition method. A pushing mechanism of the extrusion device is arranged above an extrusion container, and an extrusion rod is fixedly connected with the pushing mechanism; a heating furnace set used for heating the extrusion container is arranged outside the extrusion container, and a vacuum chamber is arranged outside the heating furnace set and is connected with a vacuum pump; an extrusion pad is arranged in the extrusion container, and an extrusion outlet is formed in the lower end of the extrusion container; a mould is arranged at the bottom of the extrusion container, and a mould hole of the mould is communicated with the extrusion outlet; a heat reducing furnace used for annealing the extruded optical fiber perform is arranged at the bottom of the extrusion container, and a traction device is arranged at the lower part of the heat reducing furnace. The extrusion device and the method have the characteristics of good controllability and high production efficiency.; the superposition method is adopted to extrude chalcogenide glass, and the obtained optical fiber perform has uniform structural composition, smooth inner and outer surfaces and a perfect interface; a surface layer is provide with a protective layer composed of high-molecular polymers, so that a performance test after drawing optical fibers is facilitated.

Owner:NINGBO UNIV

Centrifugal forming die and construction method for high-strength conical cement pole

ActiveCN102941622AImprove internal structural strengthSmooth inside and outsideMouldsPre stressWorking environment

The inventions belongs to the technical fields of manufacture of conical cement electric poles, cements communication poles and cement lamp poles and particularly relates to a centrifugal forming die and a construction method for a high-strength conical cement pole. The centrifugal forming die comprises a conical outer die, a conical inner die, an inner die large-end flange plate, a large-end prestress tensioning ring, an outer-die large-end flange plate, an outer-die small-end flange plate, a die cavity small-end closing plate, one group of running wheels, one group of bolt assemblies, a prestress locking nut, a mortar injecting port and an exhaust port, wherein the conical outer die, the conical inner die, the large-end prestress tensioning ring and the die cavity small-end closing plate form a closed annular die cavity; one group of large-end longitudinal rib inserting holes are formed in the large-end prestress tensioning ring; and one group of small-end longitudinal rib inserting holes are formed in the die cavity small-end closing plate. According to the centrifugal forming die and the construction method disclosed by the invention, the conical cement poles with the advantages of smooth inner and outer surfaces, high internal structural strength and uniformity in wall thickness can be produced. In addition, the wall thickness of the cement poles can be accurately controlled, so that the materials can be saved, the service strength of the pole bodies is ensured and the work environment of the field is improved.

Owner:元工能源科技集团有限公司

Cross-linked polyolefin composition for rotational molding and preparation method thereof

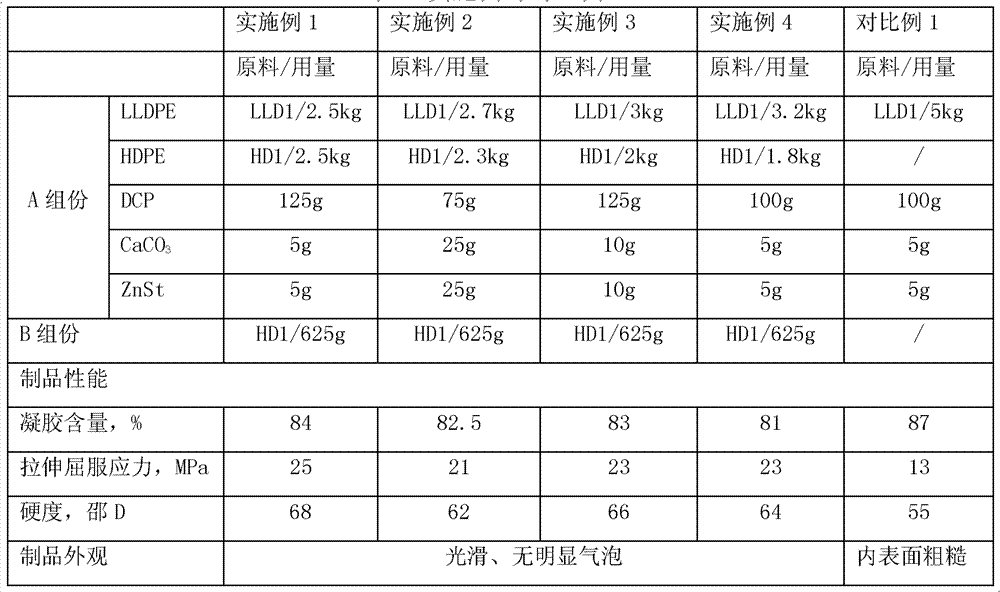

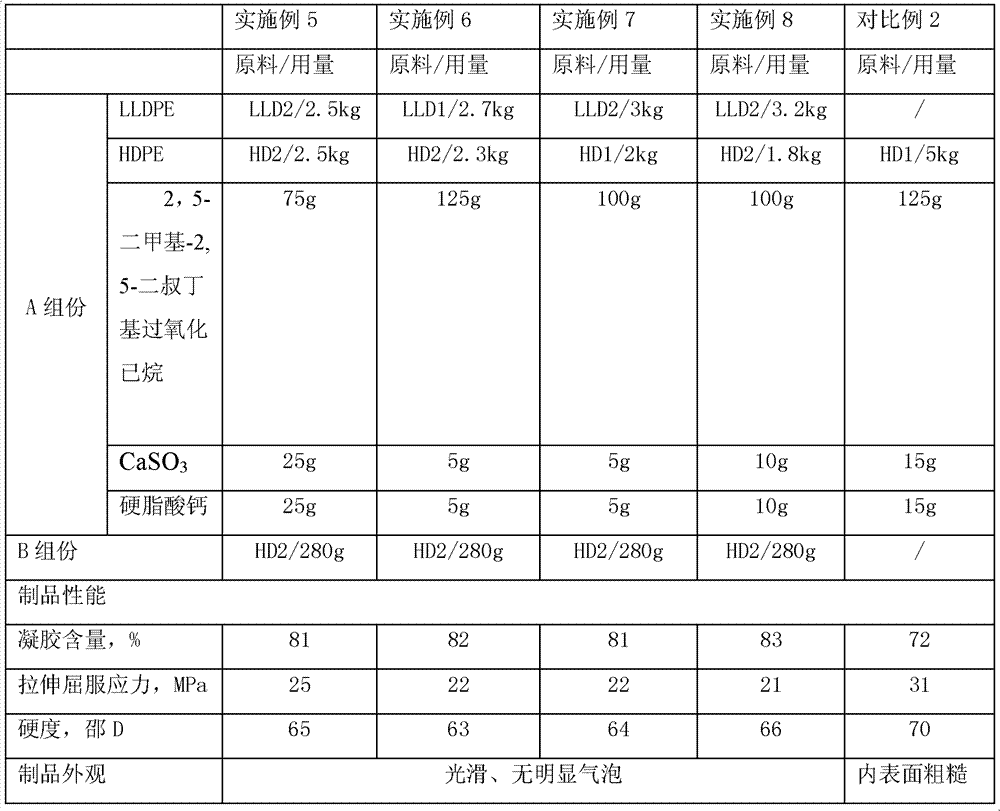

The invention relates to a cross-linked polyolefin composition for rotational molding and a preparation method thereof, belonging to the field of cross-linked polyolefin composition for rotational molding. The cross-linked polyolefin composition comprises a component A and a component B, wherein the component A comprises 100 weight parts of linear low density polyethylene (LLDPE), 50-100 weight parts of high density polyethylene (HDPE), 2-5 weight parts of cross-linking agent, 0.2-1.0 weight parts of nucleating agent, and 0.2-1.0 weight parts of lubricant; and the component B is high density polyethylene, and the ratio of the component A to the component B is 90:10-95:5. According to the invention, optimum crosslinking degree is achieved and high hardness and difficulty in warpage are guaranteed by selecting the basic resin, and the addition of the nucleating agent is beneficial for reducing product bubbles; products produced by using the composition of the invention has smooth internal and external surface, easiness in mold stripping, high crosslinking degree, and good comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP

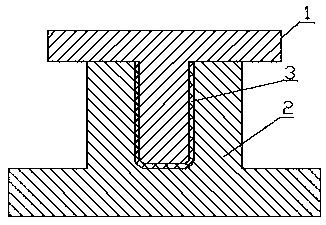

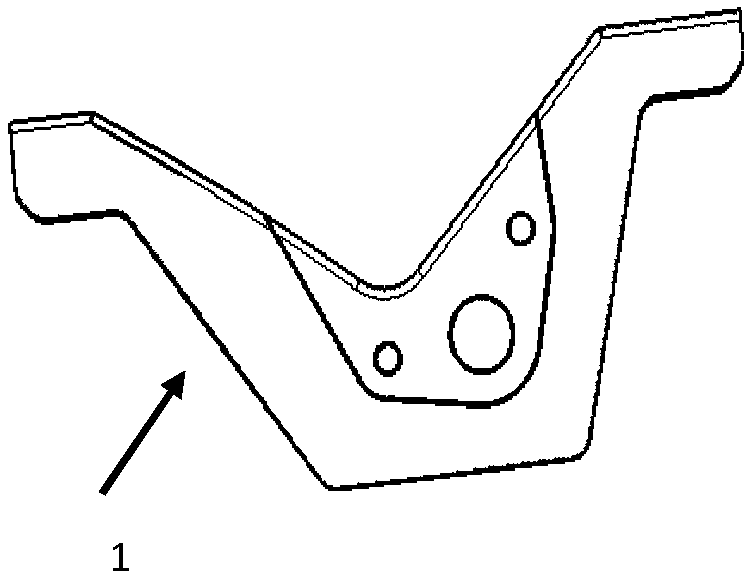

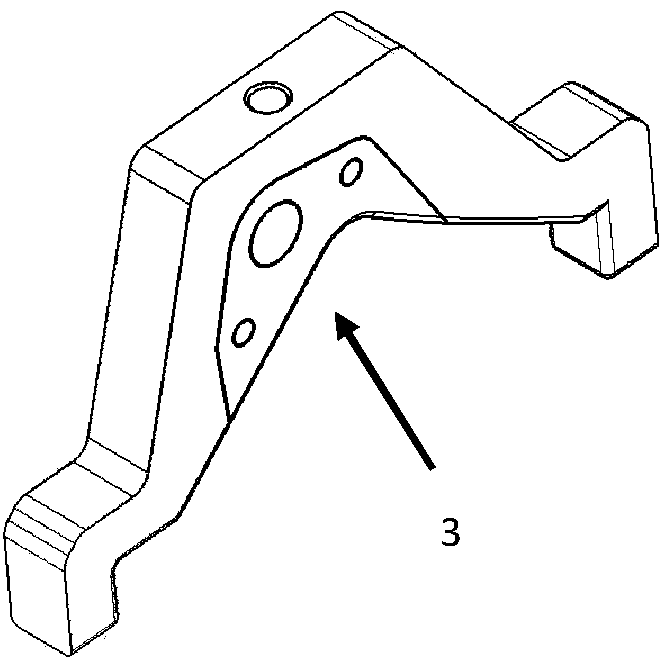

A manufacturing process of a carbon-fibre composite material U-shaped part

ActiveCN104162996AThe degree of difficulty of the link is reducedImproved condition of the bridgeCarbon fiber compositeFlat panel

A manufacturing process of a carbon-fibre composite material U-shaped part is provided. A U-shaped part product is obtained by steps of: paving a prepreg on a flat plate, tightly covering a convex mould with the paved prepreg, inserting the shaped prepreg and the convex mould as a whole into a concave mould, performing pre-compaction, taking the convex mould out, covering the pre-form with an auxiliary material, heating under a certain pressure, curing and moulding. The process overcomes the problem that U-shaped parts with small opening widths are not liable to pave, reduces the degree of difficulty of each step, guarantees the flatness of the internal and external surfaces, overcomes the problem that defects caused are liable to generate in corner zones in traditional paving processes, and opens up a new window for manufacturing of carbon-fibre composite material structural parts.

Owner:HENGSHEN

Rotomolded polyolefin composition and preparation method thereof

The invention relates to a polyolefin composition, in particular to a rotomolded polyolefin composition and a preparation method thereof. The rotomolded polyolefin composition comprises polyethylene,hyperbranched polyethylene, a nucleating agent, an acid absorbent, an ultraviolet absorbent, and an antioxidant, wherein the hyperbranched polyethylene, the nucleating agent, the antioxidant and the acid absorbent are pretreated; to be specific, the hyperbranched polyethylene, the nucleating agent, the antioxidant and the acid absorbent are mixed, n-hexane is added, a solvent is removed after heating and reflowing, and drying is performed. The rotomolded polyolefin composition and the preparation method thereof have the advantages that mechanical properties of rotomolding materials can be significantly improved, melt viscosity (low zero-cut viscosity) is reduced, the produced rotomolded product has smooth inner and outer surfaces and good plasticity, the section of the product has no evident bubbles, heating time is short, demolding is facilitated, and the product has long-term ultraviolet ageing resistance. The invention also provides the preparation method of the rotomolded polyolefin composition.

Owner:CHINA PETROLEUM & CHEM CORP

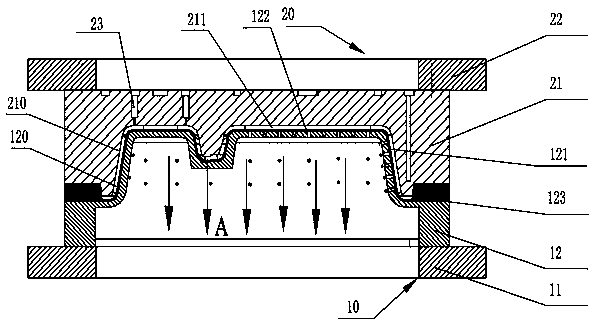

Production system for paper pulp moulded products and production method utilizing production system

InactiveCN103388290ASmooth inside and outsideImprove dehydration effectTextiles and paperShell moldingPulp and paper industry

The invention relates to a production system for paper pulp moulded products. The production system comprises a molding device for molding, a drying device for drying, and a transferring device for transferring the molded paper pulp moulded product blanks to the drying device from the molding device; the molding device comprises a molding water die; the molding face of a die core of the molding water die is smooth and is drilled with a dehydration hole with a certain diameter and aperture; a layer of molding net is attached to the die core for molding the paper pulp moulded product blanks; a hot press die comprises a hot press upper die and a hot press lower die, of which the die cores are adaptive to each other; the hot press upper and lower dies are used for clamping the paper pulp moulded product blanks therebetween; multiple dehydration gas holes are drilled in the die cores of the hot press upper and lower dies respectively for vacuumizing and dehydrating the paper pulp moulded product blanks; and the hot press die also comprises a hot press upper template and a hot press lower template for providing heat to dry, and a pressure applying device for applying pressure onto the hot press upper and lower dies. The invention also relates to a production method utilizing the production system.

Owner:HGHY PULP MOLD

Skid and scrub resistant rotationally molded product and preparation method thereof

ActiveCN103772798AImproves surface slip resistanceExtended service lifeCoatingsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a skid and scrub resistant rotationally molded product and a preparation method thereof, and belongs to the technical field of rotationally molded materials. The skid and scrub resistant rotationally molded product comprises a low-density polyethylene base and a skid and scrub resistant layer added on the base, and the skid and scrub resistant layer is composed of linear low-density polyethylene, an inorganic wear-resisting agent, a high molecular reinforcing agent and an auxiliary agent. The rotationally molded product is prepared through three steps: processing of the inorganic superfine wear-resisting agent, preparation of a rotational molding composition for the skid and scrub resistant layer, and preparation of the rotationally molded product. The skid and scrub resistant rotationally molded product has smooth inner surface and outer surface, is good in layer combination, and has no warping, no deformation, no foams and no recesses, the scrub-wear volume loss of the product is reduced by 50% or more, and the preparation method of the skid and scrub resistant rotationally molded product is simple, safe and obvious in effect.

Owner:CHINA PETROLEUM & CHEM CORP

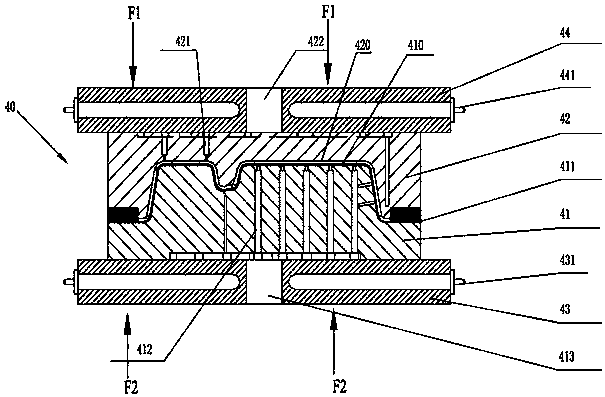

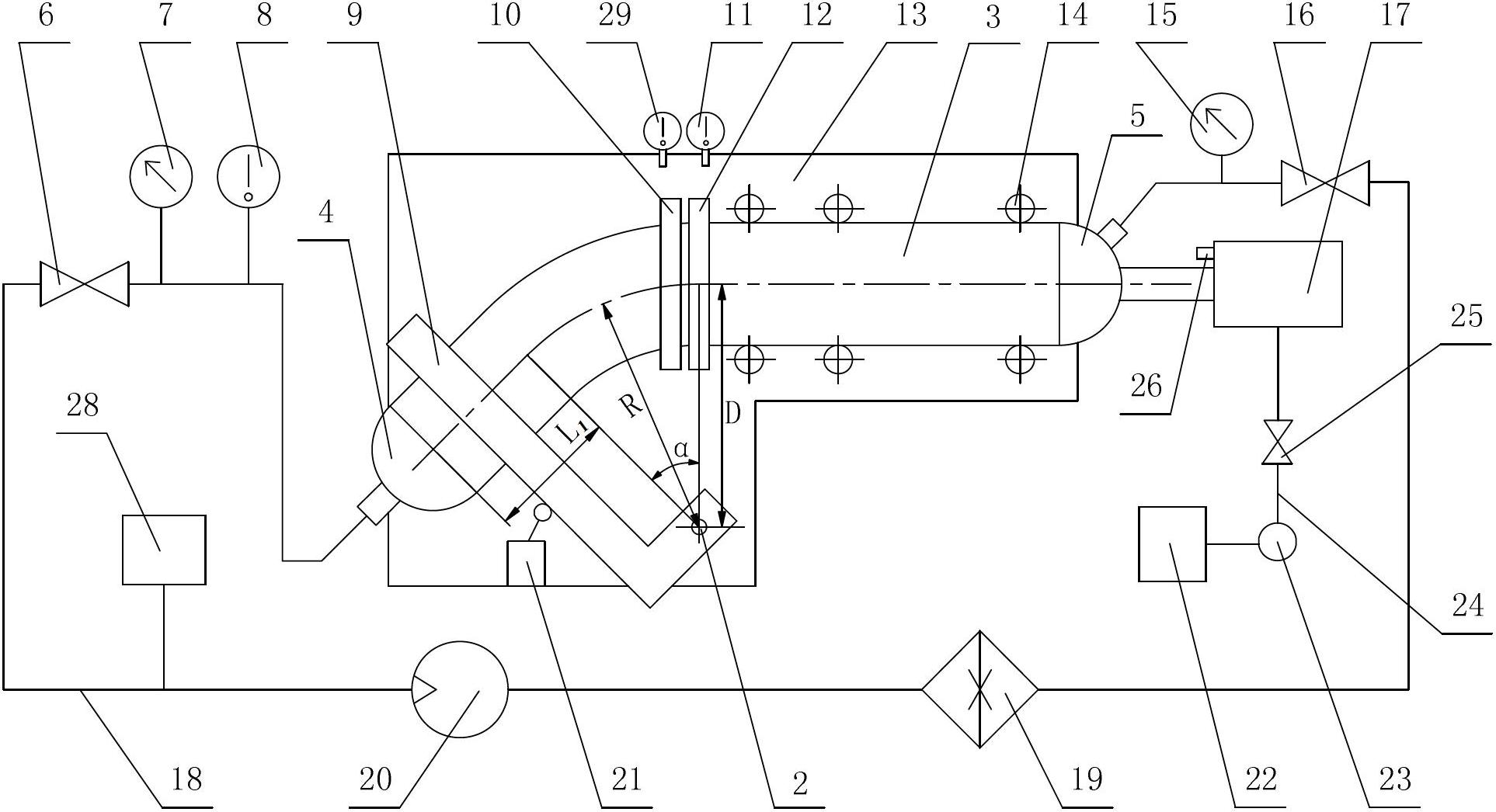

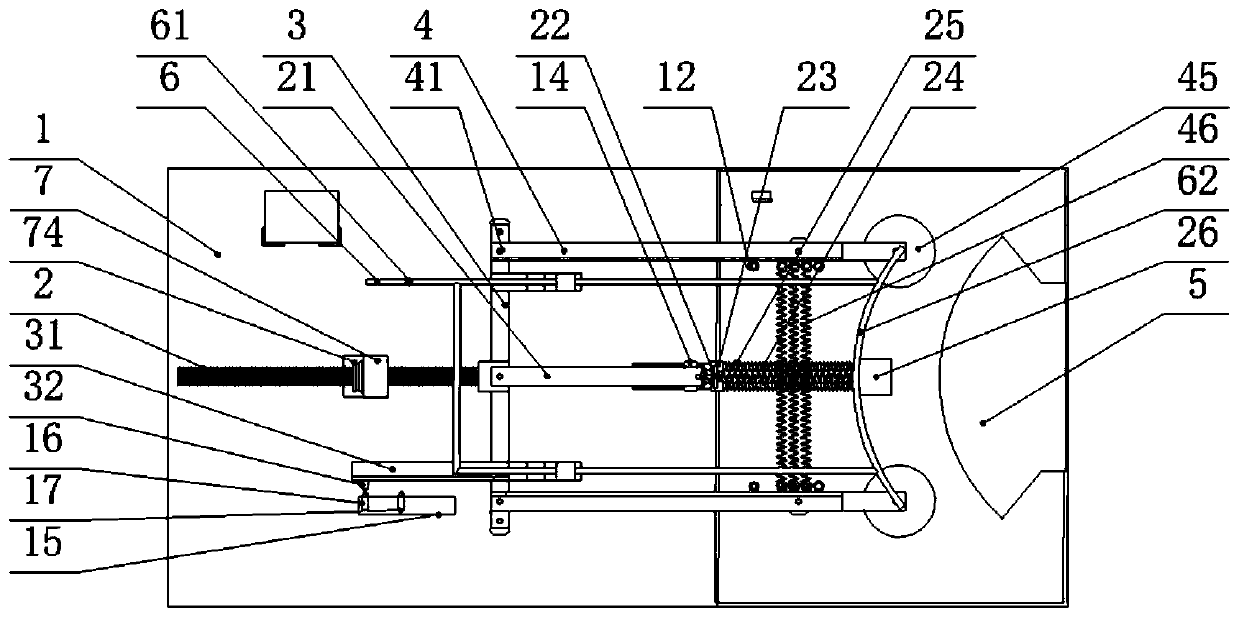

Manufacturing device and method for bimetal composite hot bend

The invention discloses a manufacturing device and a method for a bimetal composite hot bend. The device comprises a thermal induction bend mechanism, an inert gas protecting system and an automatic control system, wherein the thermal induction bend mechanism comprises a rack, a hydraulic cylinder and a hydraulic control system, a rolling wheel, a heating inductor, a limiting stopper, a rotating clamp and a first cooler are arranged on the rack, the inert gas protecting system comprises a gas inlet end socket, an exhausting end socket and a gas circulating pipeline, and a gas inlet end valve, an exhausting end valve, a gas concentration tester, a gas motor and a second cooler are mounted on the gas circulating pipeline. The method includes the steps of intercepting a required bimetal composite pipe, sealing the bimetal composite pipe, installing the bimetal composite pipe on the thermal induction bend mechanism, connecting the inert gas protecting system and roasting and bending. The manufacturing device and the method for the bimetal composite hot bend are reasonable in design, high in intelligent degree, applicability, rate of finished products, product qualities and practicability, and convenient to popularize and apply.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Polyethylene composite material for rotationally-molded buried product

ActiveCN105713278AHigh strengthSmooth inside and outsideSievingScreeningGlass fiberLinear low-density polyethylene

The invention discloses a polyethylene composite material for a rotationally-molded buried product. The polyethylene composite material is prepared by mixing, by mass, 10-30% of linear low density polyethylene fine powder, 40-80% of glass fiber reinforced high density polyethylene powder and 10-30% of linear low density polyethylene coarse powder. The product machined from the material through the rotational molding technology has the advantages of being high in strength and easy to demold and having smooth inner and outer surfaces.

Owner:ZHEJIANG ROTOUN PLASTIC TECH

Rotational molding product and preparation method thereof

InactiveCN106700213AImproves surface slip resistanceExtended service lifeLow-density polyethyleneLinear low-density polyethylene

The invention discloses a rotational molding product and a preparation method thereof and belongs to the technical field of rotational molding materials. The rotational molding product comprises a linear low-density polyethylene substrate; a slipping and abrasion resisting layer is additionally arranged on the substrate; and the slipping and abrasion resisting layer is composed of linear low-density polyethylene, an inorganic abrasion-resisting agent, a macromolecular enhancing agent and an auxiliary agent. The rotational molding product is prepared through three steps of treating an inorganic ultrafine abrasion-resisting agent, preparing a rotational molding composition of the slipping and abrasion resisting layer, and preparing the slipping and abrasion resisting rotational molding product. The slipping and abrasion resisting rotational molding product has smooth inner and outer surfaces; the combination between layers is good; the rotational molding product has no warping, deformation, air bubbles and concave parts; the scraping abrasion loss volume of the product is reduced by 50% or more; the preparation method of the slipping and abrasion resisting rotational molding product is simple and safe and has an obvious effect.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Production process of specially-shaped pipe

The invention discloses a production process of a specially-shaped pipe. The production process of the specially-shaped pipe comprises the following steps: selecting a pipe, grinding ends of the pipe, annealing for a first time, pickling with acid for a first time, washing for a first time, phosphatizing for a first time, washing for a second time, saponifying for a first time, cold drawing for a first time, annealing for a second time, pickling with acid for a second time, washing for a third time, phosphatizing for a second time, washing for a fourth time, saponifying for a second time, cold drawing for a second time, straightening and carrying out antirust treatment. The production process of the specially-shaped pipe is characterized by firstly cold drawing a billet pipe in inner and outer circular dies so as to reduce the outer diameter of the wall thickness of the billet pipe, so that the inner and outer surfaces of the billet pipe are more smooth; the quality during cold drawing for the second time is improved; grains in the billet pipe subjected to cold drawing for the first time are unevenly distributed in the presence of stress; through annealing, the grains in the billet pipe are evenly distributed and the stress is removed, so that the breakage of the billet pipe when the billet pipe is subjected to cold drawing for the second time is avoided.

Owner:ZHEJIANG JIUDING MACHINERY CO LTD

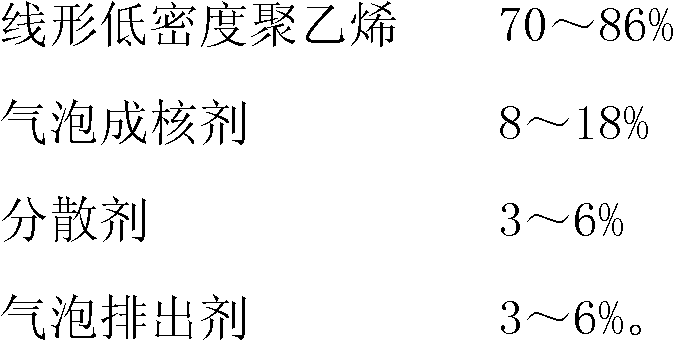

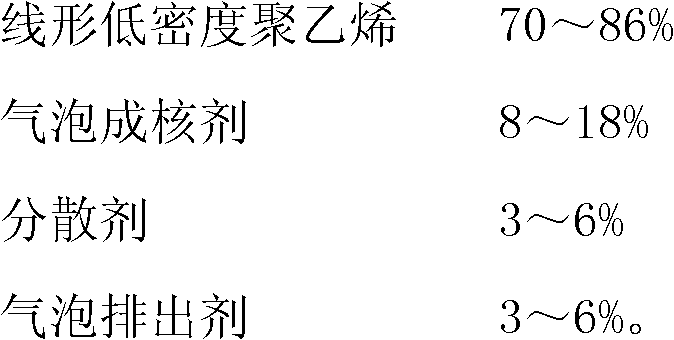

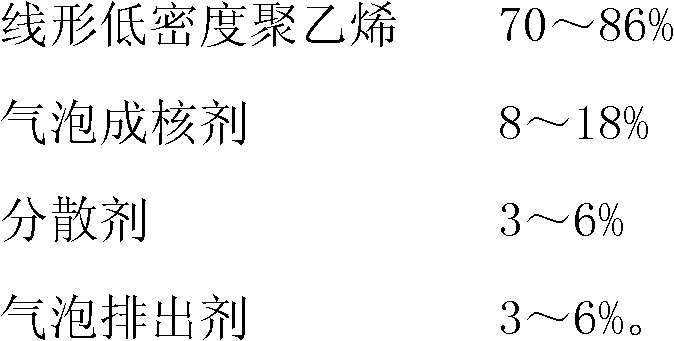

Defoaming master batch for rotational molding and preparation method thereof

ActiveCN102952322AIncrease surface tensionEnhanced interactionLinear low-density polyethyleneExtrusion Granulation

The invention relates to a defoaming master batch for rotational molding and a preparation method thereof, belonging to the technical field of plastic processing. The defoaming master batch is prepared by mixing and stirring raw materials in a certain ratio and then extruding and granulating. The defoaming master batch is characterized by containing the following raw materials in percentage by mass: 70-86% of linear low-density polyethylene, 8-18% of bubble nucleating agent, 3-6% of dispersing agent and 3-6% of bubble eliminant. The invention aims to provide a defoaming master batch for rotational molding and a preparation method thereof. The defoaming master batch is low in cost and can solve the problem on bubbles of a rotational molding product; the rotational molding product prepared from the defoaming master batch is free of bubbles and has favorable processability, good plasticization performance, high production efficiency and high product performance; and the preparation method is scientific and reasonable, and is simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

Bending device for plastic pipe bending equipment

The invention relates to the technical field of profile processing, and discloses a bending device for plastic pipe bending equipment. The bending device comprises a frame platform and a screw rod drive mechanism. The screw rod tail end of the screw rod drive mechanism is connected with a fixing frame. A left push rod and a right push rod are correspondingly hinged to the left end and the right end of the fixing frame. The left push rod and the right push rod are connected with support rods. Wheels are connected to the lower ends of the support rods. The wheels are positioned on the frame platform. The tail ends of the left push rod and the right push rod are connected with U-shaped wheels. Pillars with rolling wheels are correspondingly fixed to the portions, under the left push rod and the right push rod, of the frame platform. The rolling wheels are positioned on the inner sides of the push rods. The rolling wheel faces are attached to the push rods, and springs are arranged between the left push rod and the right push rod. The tail end of a screw rod is connected with a flat plate. The flat plate is located in the middle between the left push rod and the right push rod. An ejector plate is connected to the tail end of the flat plate. A U-shaped block is connected to the tail end of an ejector rod. The ejector rod is sleeved with a compression spring. The compression spring is arranged between a shaft sleeve and the U-shaped block. An abutting pressing die is arranged on the portion, corresponding to the U-shaped block, of the frame platform. By the adoption of the bending device, mass production of the pipe bending processing of large-sized and long-length plastic pipes can be realized.

Owner:浙江甬源塑业有限公司

Special polyolefin resin modified composition for rotational molded products and preparation method thereof

The invention relates to a special polyolefin resin modified composition for rotational molded products and a preparation method thereof, belonging to compositions of polyolefin homopolymers or copolymers. The special polyolefin resin modified composition is characterized by being prepared from the following raw materials in parts by weight: 50-80 parts of carrier resin, 10-45 parts of heterogeneous nucleating agent, 0.5-2 parts of master antioxidant, 0.5-2 parts of secondary antioxidant, 0.5-2 parts of anti-ultraviolet agent, 0.5-2 parts of surface treating agent and 0.5-3 parts of dispersing agent. The special polyolefin resin modified composition for rotational molded products and the preparation and use methods thereof, provided by the invention, have the advantages that the crystallization rate of a rotational molded product preparation process can be controlled and adjusted, the dimensional stability of the products is improved, and the products are smooth in inside / outside surface, uniform in wall thickness, long in service life and excellent in comprehensive performance and are free from the defects of obvious distortions, pits and bubbles; the deformation of the products can be decreased by 50%, the production time is shortened by over 30%, and the dimensional stability is improved by more than 1 times.

Owner:CHINA PETROLEUM & CHEM CORP

Production method of bimetal composite hob ring

The invention relates to a production method of a bimetal composite hob ring. Firstly, a high-wear-resistance alloy tool steel and a high-toughness alloy structure steel material are adopted to be smelted into two kinds of metal liquid separately through a refining furnace; after the smelting is completed, the refining furnace is moved to the position of a centrifugal machine, and a blade materialis poured into a centrifugal machine mould so as to prepare a high-wear-resistance blade part; then pouring smelted high-toughness alloy structural steel material into the centrifugal machine mould in 10-60 seconds after the high-wear-resistance blade part is centrifuged, and centrifugal forming is carried out to obtain a double-metal composite hob ring rough blank; after the centrifugal machineis shut down, a product is taken out for heat preservation; and finally, cleaning, annealing, rough machining, quality inspection analysis, heat treatment and finish machining is performed to obtain the bimetal composite hob ring. According to the method, the service performance of the hob ring is improved, a lot of resources are saved, the time for repeated installation or maintenance of the hobring due to scrap is reduced, the production efficiency is improved, and the hob ring has great economic and social significances.

Owner:山东天物成型科技有限公司

Forming method for different-plane pi-type carbon fiber composite joint

InactiveCN107553933ASolve the problem that artificial layering cannot be performedThe degree of difficulty of the link is reducedInverted tTemperature and pressure

The invention provides a forming method for a different-plane pi-type carbon fiber composite joint. According to the forming method, four core blocks are laid and attached according to the lay-up design in the form of two kinds of L type, one U type and one inverted-T type; the four core blocks are subjected to heat pre-pressing; and after integrated assembly and pre-pressing, an auxiliary material is laid, curing forming is conducted under a certain temperature and pressure, and a pi-type product is formed. By the adoption of the process, the problem that lay-up of pi-type products with smallopening widths cannot be achieved is solved, the problem about manufacturing of complex pi-type products by the carbon fiber composite is solved, the coefficient of the difficulty of all the links islowered, and the flatness of the inner surface and the outer surface of the composite product is guaranteed. The forming method provides a new idea for manufacturing of the pi-type carbon fiber composite structural piece.

Owner:HENGSHEN

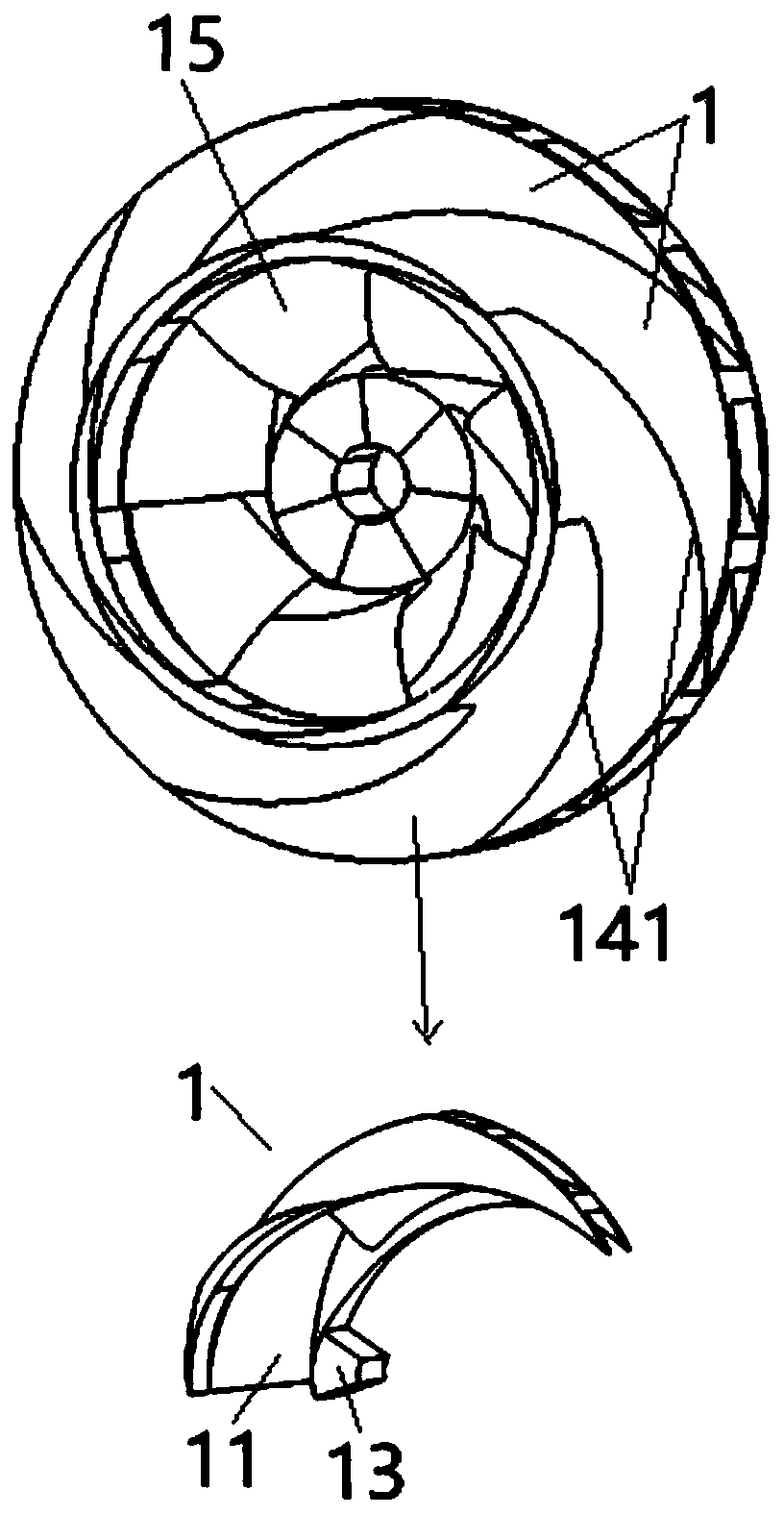

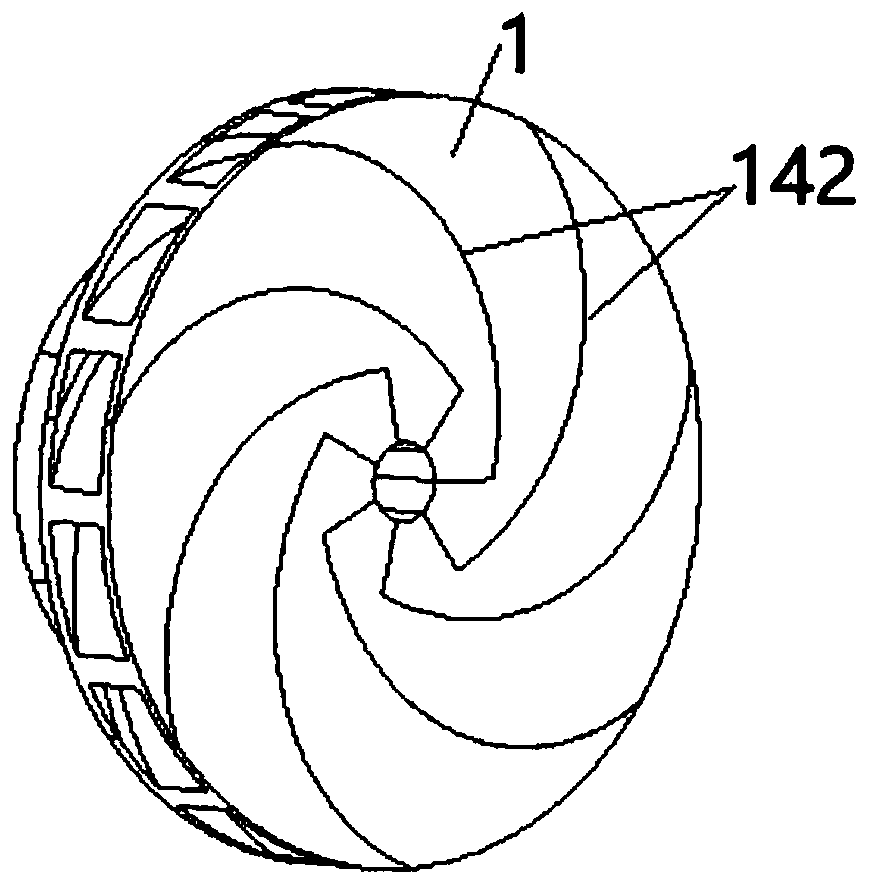

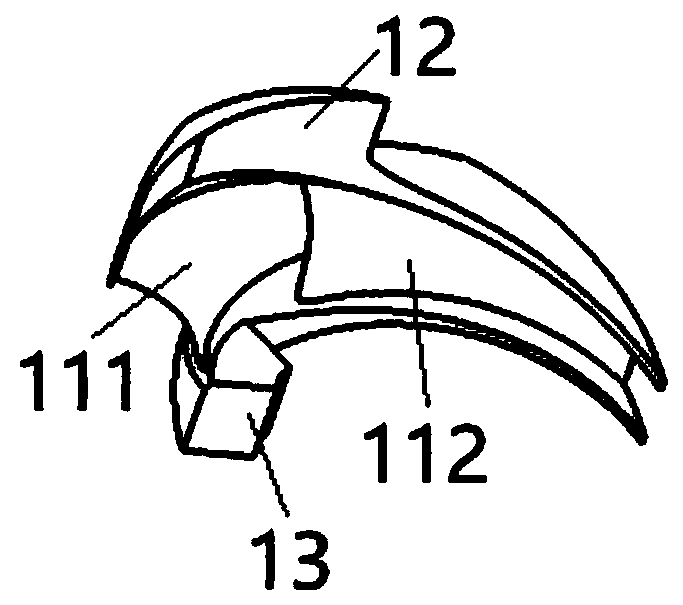

Closed impeller provided with twisted blades and applicable to water pump and machining technology of closed impeller

InactiveCN109909692ABig space warpSolve unprocessable problemsPump componentsPumpsStructural reliabilityImpeller

The invention discloses a closed impeller provided with twisted blades and applicable to a water pump and a machining technology of the closed impeller. The impeller comprises single twisted blades; aplurality of single twisted blades are assembled sequentially to form the closed impeller; each single twisted blade is formed through overall milling by the aid of a five-axis CNC machine tool; assembled positions of every two adjacent single twisted blades are connected through welding and form welding lines; and the number of the welding lines is equal to that of the single twisted blades of the closed impeller. According to the impeller and the technology, the manufacturing accuracy, the surface smoothness and the weight uniformity of the closed impeller are substantially improved, the manufacturing cycle of the closed impeller is substantially shortened, the problems of large machining difficulty and the like of the overall large-distortion and multi-blade milling technology are solved, meanwhile, the structural reliability and the hydraulic performance of the closed impeller are improved, and vibration of the closed impeller is reduced.

Owner:SHANGHAI MICROPOWERS

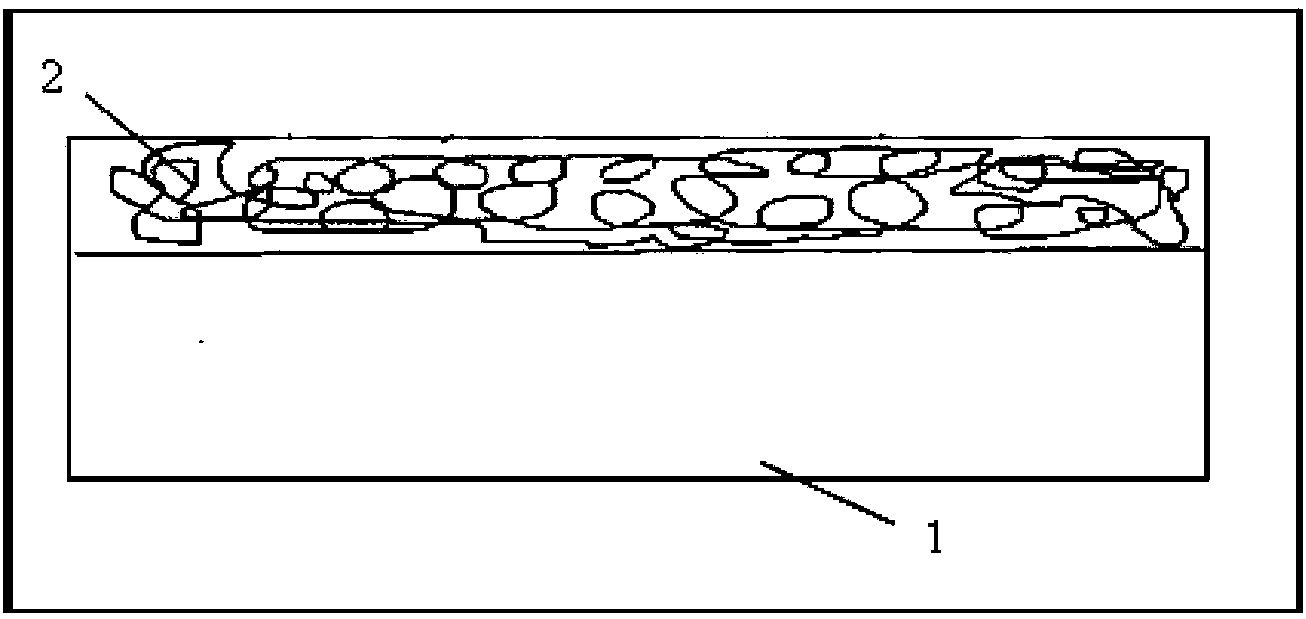

Making process of light environment-protecting board as building material

The present invention relates to the production process of one kind of light environment-protecting board as building material. Of the board, the main material includes the mixture of wheat straw and one of rice straw, bagasse and saw dust, waste phosphate rock powder, magnesia and anhydrous magnesium sulfate; and the supplementary material includes bentonite, copper naphthenate, white carbon black, calgon and copper sulfite.

Owner:蒋启良

Method for preparing calendered film of polyvinyl chloride for blood transfusion appliance

The method for preparing PVC calendered film which can be used for making blood bag for blood transfusion includes the following steps: adding granular or powdered PVC material into a high-speed mixing machine, high-speed kneading, then feeding the above-mentioned into an extruding machine to make plastication, uniformly extruding out, refining extruded material, filtering, calendaring and forming by means of calendaring machine to obtain film, double-face embossing, cooling, eliminating static electricity, removing dust and cleaning treatment so as to obtain the invented film product.

Owner:上海爱平塑胶有限公司

Defoaming master batch for rotational molding and preparation method thereof

ActiveCN102952322BIncrease surface tensionEnhanced interactionLinear low-density polyethyleneRotational molding

The invention relates to a defoaming master batch for rotational molding and a preparation method thereof, belonging to the technical field of plastic processing. The defoaming master batch is prepared by mixing and stirring raw materials in a certain ratio and then extruding and granulating. The defoaming master batch is characterized by containing the following raw materials in percentage by mass: 70-86% of linear low-density polyethylene, 8-18% of bubble nucleating agent, 3-6% of dispersing agent and 3-6% of bubble eliminant. The invention aims to provide a defoaming master batch for rotational molding and a preparation method thereof. The defoaming master batch is low in cost and can solve the problem on bubbles of a rotational molding product; the rotational molding product prepared from the defoaming master batch is free of bubbles and has favorable processability, good plasticization performance, high production efficiency and high product performance; and the preparation method is scientific and reasonable, and is simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

Oil and gas recovery oil filling gun with non-pressure self-sealing function and oil filling method thereof

InactiveCN104743492ANice appearanceGood installation compatibilityLiquid transferring devicesFuel oilRecovery stage

The invention relates to an oil and gas recovery oil filling gun with a non-pressure self-sealing function and an oil filling method thereof. The oil and gas recovery oil filling gun comprises a connecting thread, a gas path connector, a gun body, an oil and gas separator, a handle sleeve, a valve, a trigger, a roller pin, a diaphragm, a gas adjusting device, a non-pressure self-sealing device, a one-way valve and an oil outlet pipe. According to the technical scheme, the oil and gas recovery oil filling gun can be applied to the secondary oil and gas recovery stage, has the non-pressure self-sealing function and is suitable for a self-help oil filling machine; the oil filling gun can seal an oil path automatically after the oil filling machine is completely stopped, and therefore the situation that because the oil filling gun is not self-sealed after the last time of oil filling, fuel oil leaks in the process of secondary oil filling and danger is caused will not occur; the one-way valve arranged in the oil filling gun can be synchronously opened in the process of oil filling and can be completely closed after the oil filling gun is self-sealed, and therefore oil dripping occurring after the oil filling gun is self-sealed can be effectively prevented.

Owner:LUOYANG PRIMEMAN AUTOMATIC CONTROL TECH

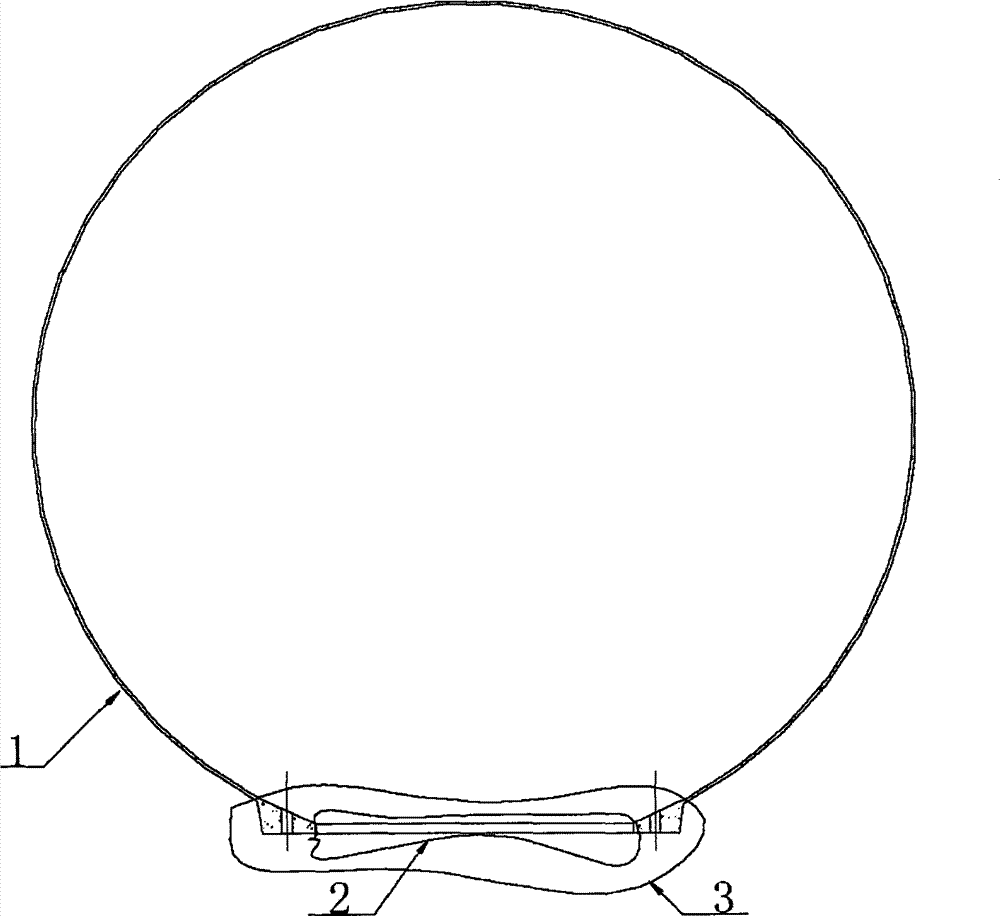

Method for manufacturing seamless spherical screen by using ball bladder

The invention relates to a method for manufacturing a seamless spherical screen by using a ball bladder. The method comprises the steps of: (1) manufacturing the ball bladder in the shape of an entire ball and waxing on all the outer surface of the ball bladder to form a wax layer; (2) spraying a resin mixture to the surface of the wax layer on the ball bladder to manufacture a seamless spherical shell; (3) casing a flange on the ball mouth of the seamless spherical shell and then separating the seamless spherical shell from the ball bladder; and (4) spraying an imaging layer on the surface of the seamless spherical shell to form the seamless spherical screen. The method is used for manufacturing the seamless spherical screens of various sizes.

Owner:佘广为

Vertical plastic pipe bending device

The invention relates to the technical field of profile processing, and discloses a vertical plastic pipe bending device. The vertical plastic pipe bending device comprises a rack and a driving device. An abutting pressing assembly and a U-shaped mold are sequentially arranged below the rack; the abutting pressing assembly comprises a cross beam on the upper portion, and the two sides of the cross beam are movably connected with left and right push rods correspondingly; ejecting rods are correspondingly connected to the left and right push rods, and the other ends of the left and right ejecting rods are abutted together in an ejecting manner on the middle portions of the left and right push rods; a spring is arranged between the left and right push rods; the lower ends of the left and right push rods are movably connected with U-shaped rolling wheels correspondingly; the left and right U-shaped rolling wheels correspond to pipe bending grooves of the U-shaped mold, and are correspondingly located on the left and right sides of the U-shaped mold; and the shapes of the pipe bending grooves of the U-shaped mold are matched with the shapes of machined plastic pipe workpieces. The vertical plastic pipe bending device can be used for performing batch production of pipe bending machining on large specification and large-length plastic pipes.

Owner:浙江甬源塑业有限公司

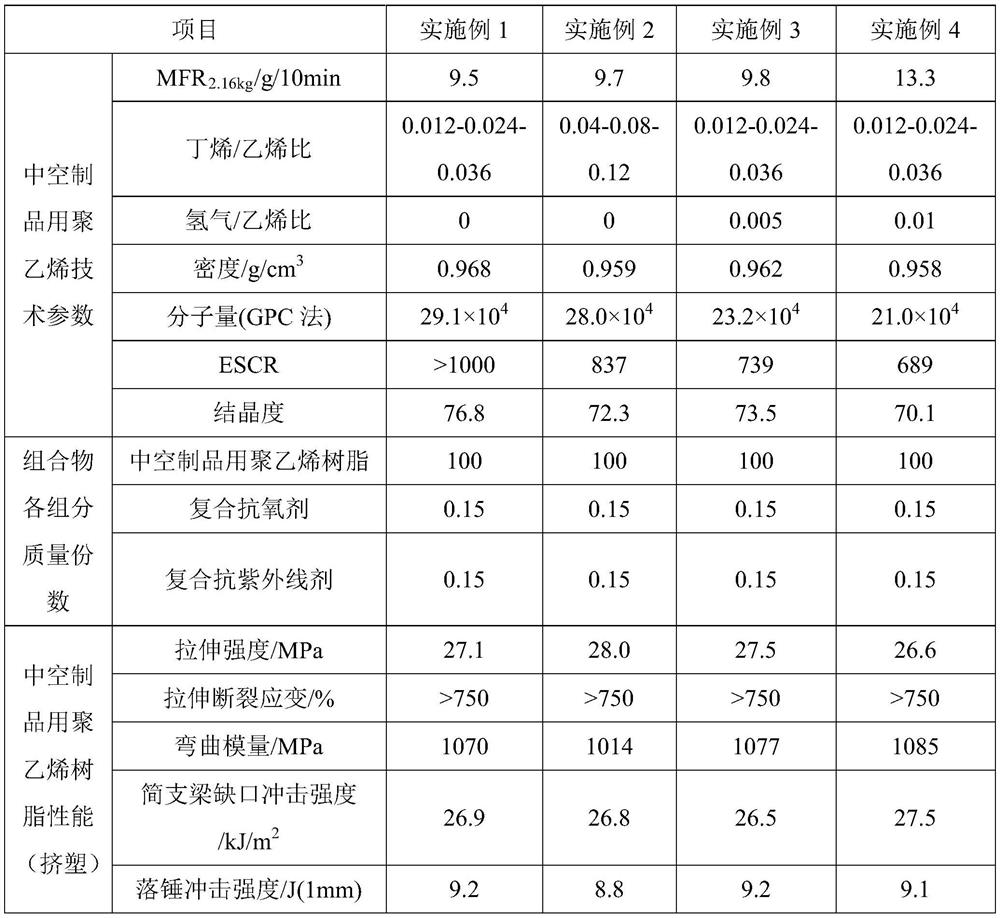

Polyethylene resin for hollow product, and composition and preparation method thereof

ActiveCN112679641AGuaranteed DensityGuaranteed crystallinityBulk chemical productionButenePolymer science

The invention relates to the technical field of polyethylene resin, in particular to polyethylene resin for hollow products as well as a composition and a preparation method of the polyethylene resin. The weight-average molecular weight of the polyethylene resin for the hollow product is 180000-320000, the density is 0.950-0.970 g / cm < 3 >, the melt mass flow rate under the load of 21.6 kg is 8-18 g / 10 min, the crystallinity is 65-90%, the ESCR is not less than 600 h, and the tensile strength is 24-28 MPa; according to the preparation method, under the action of a chromium-containing catalyst, ethylene is taken as a polymerization monomer, 1-butene is taken as a comonomer, and polymerization is carried out so as to obtain the product. According to the polyethylene resin for the hollow product, the content of short branched chains is increased, the environmental stress cracking resistance is greatly improved, and meanwhile, the density and rigidity of the material are guaranteed; the invention also provides a composition of the composition, which has high environmental stress cracking resistance and maintains high rigidity and toughness. The invention also provides a preparation method thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Seamless patch pocket and sewing method thereof

The invention discloses a seamless patch pocket structure, comprising main fabric and a decorative patch pocket attached to the main fabric; the decorative patch pocket comprises pocket fabric and a pocket bottom; the upper end of the decorative patch pocket is also provided with a pocket flap; the pocket flap and the main fabric are integrated; expect for the pocket flap part, decorative glue is attached to the periphery of the pocket fabric to cover the pocket fabric edge; two sides of the upper end of the pocket flap are symmetrically provided with two cuts, and the length of the cuts is half the width of the decorative glue; the decorative glue runs through the cuts and compresses two sides of the upper end of the pocket flap. The seamless patch pocket structure processed by using a sewing method of the invention is simple in structure and unique and attractive in appearance, has smooth front and back that are non-abrasive to skin and is highly comfortable to wear, laser cutting technology and cold and hot pressing seamless double-side bonding process are mainly used, operating is simple, processing efficiency is high, and the yield is high.

Owner:FAR EAST CLOTHES SUZHOU CO LTD

SF6 current transformer

PendingCN105655117AImprove sealingLow costTransformersTransformers/inductances coils/windings/connectionsInstrument transformerElectric power

The invention relates to an SF6 current transformer for the power industry. The SF6 current transformer includes a primary conductive part, a housing, a top plate, an electrode, a secondary wiring tube, a sleeve, and a base; the primary conductive part is arranged in the housing; the top plate and the sleeve are arranged under the housing, wherein the sleeve is connected to the housing; the lower end of the sleeve is connected to the base; the secondary wiring tube passes through the electrode and the sleeve and then is connected to a secondary terminal on the base; and the electrode is of a mouse cage structure. The electrode adopts the mouse cage structure made of an aluminium alloy material, and the service life of the SF6 current transformer can be prolonged; Through ring connection adopted by the electrode, the diameters of all the rings can be designed to be identical or unequal according to an electric field distribution condition and an accuracy requirement, electric field distribution is more even, and the accuracy of the SF6 current transformer can be improved; and the sleeve and the base form a whole structure, such that the SF6 current transformer is easy to process, is convenient to install, and is excellent in sealing performance, and the cost is saved.

Owner:JIANGSU SIYUAN HERTZ TRANSFORMER

Adhesive resin for composite hose, and preparation method of adhesive resin

InactiveCN106905890AImprove adhesionImprove barrier propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolyolefin

The invention provides an adhesive resin for a composite hose. The adhesive resin comprises the following components in parts by mass: 35-45 parts of maleic anhydride and acetamide grafted polypropylene granule, 60-80 parts of high-density polyethylene, 20-30 parts of polyolefin elastomer, 0.2-1 part of processing agent, 0.2-0.5 part of antioxidant, 1-10 parts of plasticizer, and 3-9 parts of heat stabilizer. The invention further provides a preparation method of the adhesive resin for a composite hose. According to the adhesive resin for the composite hose and the preparation method of the adhesive resin, the prepared adhesive resin for the composite hose is transparent in inherent color, stable in performances, fewer in fisheyes, and high in adhesion power, the composite hose prepared from the adhesive resin has good adhesion property, strong barrier property and smooth internal and external surface, as well as the advantages of being good in thermal stability, and the like.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

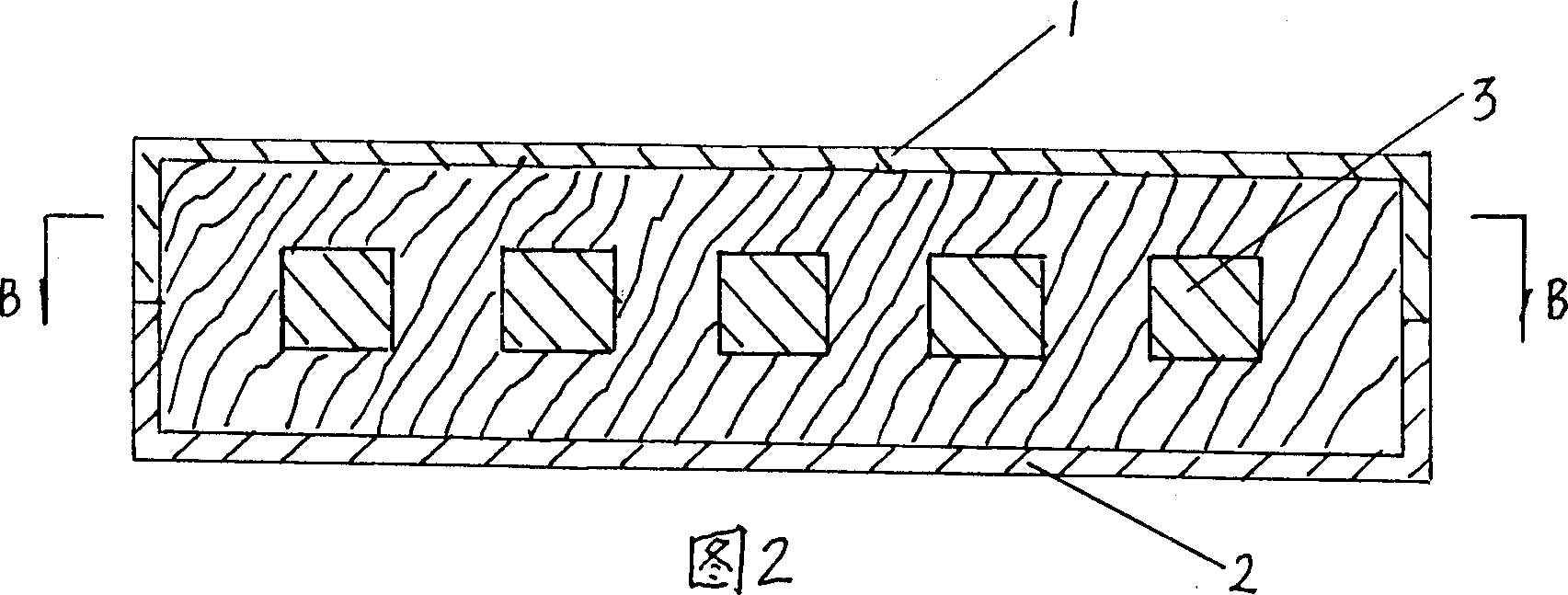

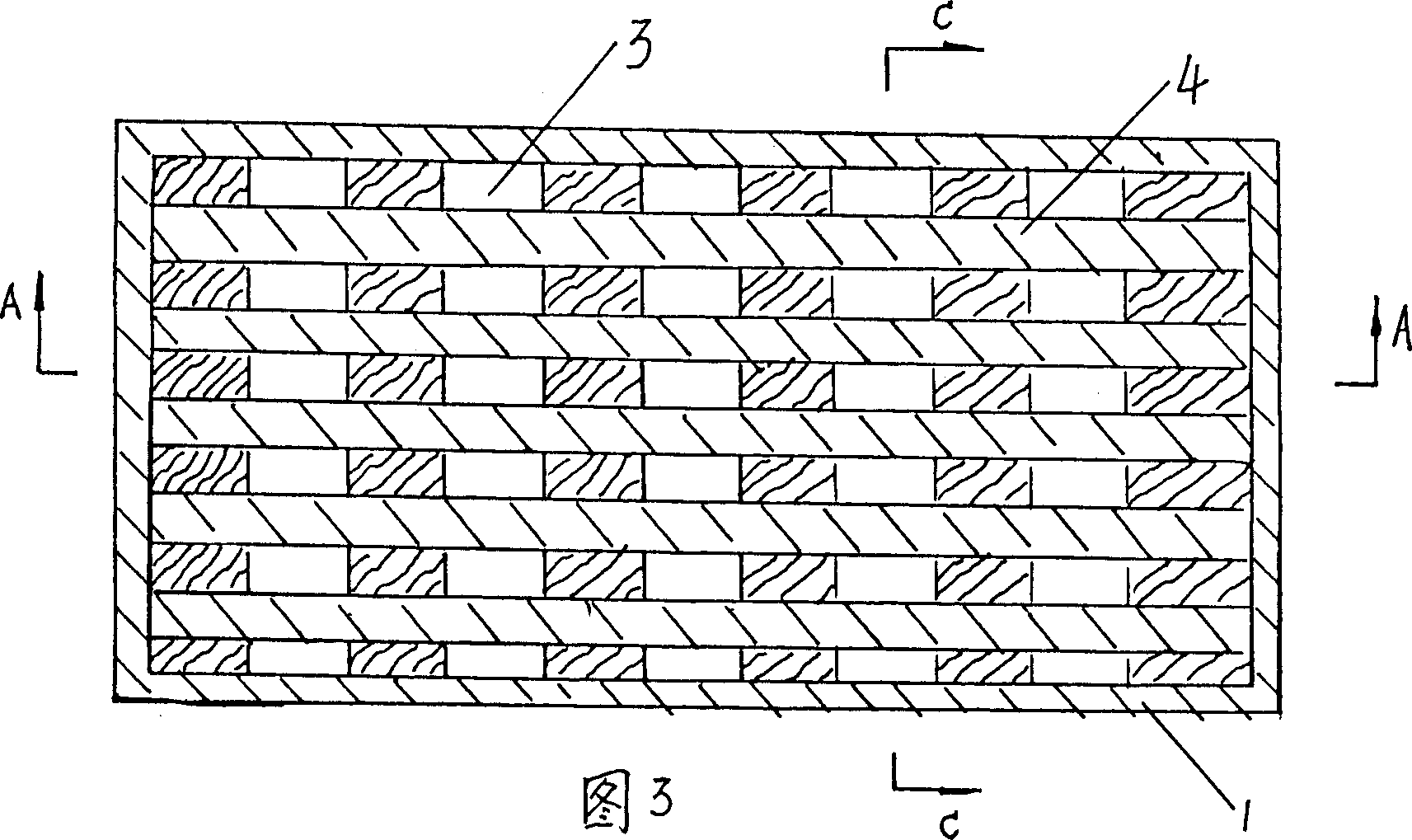

Three-layer co-extrusion sandwiched honeycomb pipe and production technology thereof

InactiveCN106195462AOutstanding and Beneficial Technical EffectsHigh radial ring stiffnessRigid pipesTubular articlesSolid structurePlastic materials

The invention belongs to the technical field of plastic pipes, and relates to a three-layer co-extrusion sandwiched honeycomb pipe and a production technology thereof. An inner-layer pipe, a sandwiched layer and an outer-layer pipe of the three-layer co-extrusion sandwiched honeycomb pipe are of an integrated structure which is formed through one-time extrusion of plastic materials. The pipe wall of the inner-layer pipe and the pipe wall of the outer-layer pipe are of a solid structure, and the sandwiched layer is a honeycomb structure layer. According to the production technology, the plastic in a fusion state is subjected to one-time extrusion to form the sandwiched pipe with the inner-layer pipe, the sandwiched layer and the outer-layer pipe through three extrusion die runners of one injection molding extruder; and the pipe wall of the inner-layer pipe and the pipe wall of the outer-layer pipe are of the solid structure, and the sandwiched layer is the honeycomb structure layer. The three-layer co-extrusion sandwiched honeycomb pipe and the production technology thereof have the beneficial effects that the honeycomb structure layer is adopted as the sandwiched layer, the inner surface and the outer surface of the honeycomb structure layer, the outer surface of the inner-layer pipe and the inner surface of the outer-layer pipe are fused into the integrated structure through the temperature and stickiness during injection molding extrusion, and bonding or welding is not needed; and the overall weight is small, the inner surface and the outer surface are smooth, the overall performance is high, and the three-layer co-extrusion sandwiched honeycomb pipe and the production technology thereof are suitable for pipelines or guide pipes with the high performance requirement.

Owner:徐胜

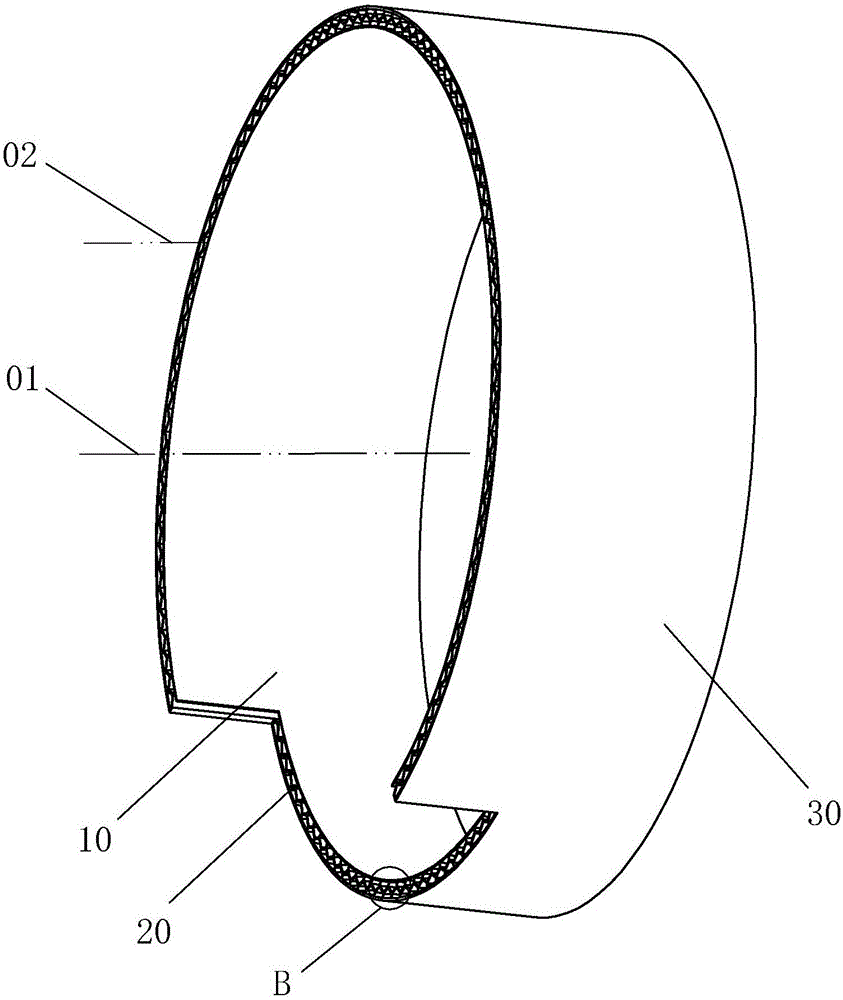

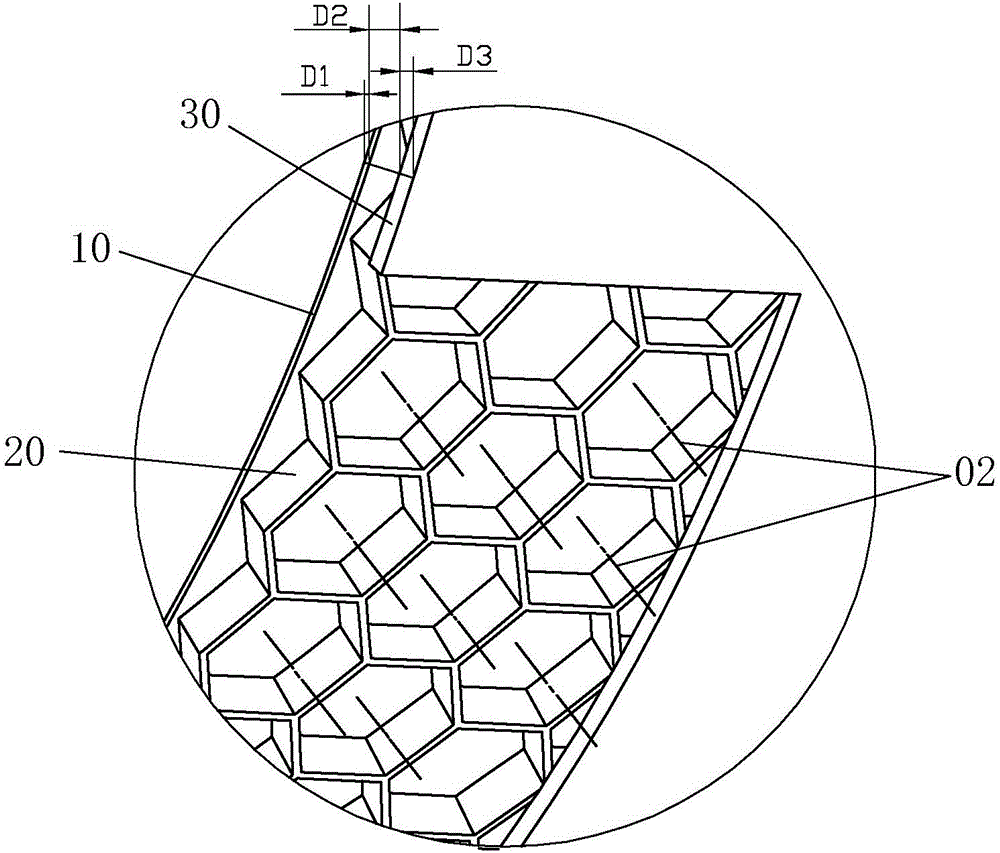

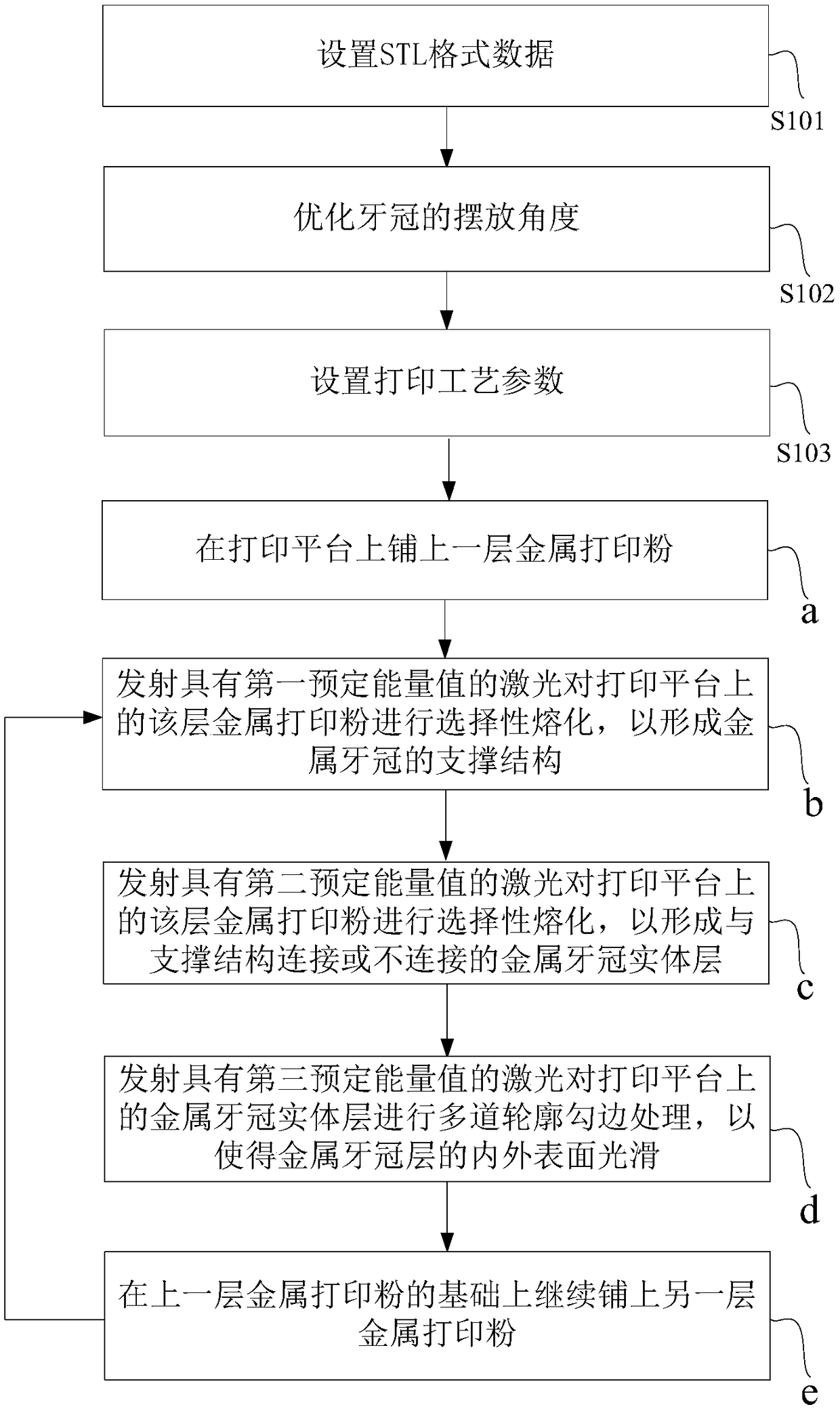

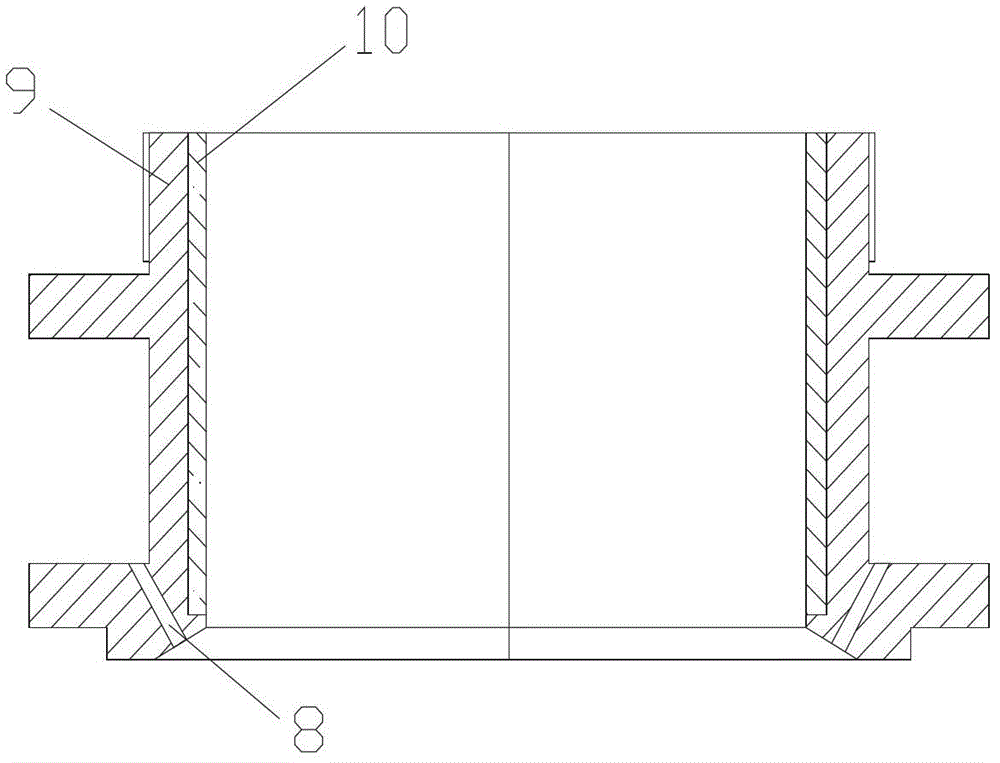

3D printing method of metal dental crown

ActiveCN108971491ASmooth inside and outsideWon't wear outAdditive manufacturing apparatusIncreasing energy efficiencyMetal3D printing

The invention discloses a 3D printing method of a metal dental crown. The method comprises the steps that a, a layer of metal printing powder is laid on a printing platform; b, laser with first reserved energy value is emitted to carry out selective melting on the metal printing powder on the printing platform, and a supporting structure is formed; c, laser with second reversed energy value is emitted to carry out selective melting on the metal printing powder on the printing platform, and a metal dental crown solid layer is formed; d, laser with third reserved energy value is emitted to carryout multiple of outline crispening treatment on the metal dental crown solid layer; e, the other layer of metal printing powder is laid on the basis of the previous layer of metal printing powder, and the step b is continuously executed. Through the above manner, when the metal dental crown is printed, each metal dental crown layer is subject to crispening treatment, the inner surface and the outer surface of the metal dental crown layer are smooth, the metal dental crown cannot wear tooth flesh, and the user experience is greatly improved.

Owner:广州瑞通增材科技有限公司

Short crystallizer for casting hollow aluminum ingots

The invention discloses a short crystallizer for casting hollow aluminum ingots. The short crystallizer comprises a crystallizer housing, wherein a triangular support is clamped inside an annular groove of the housing and can rotate on the housing; an internal sleeve and an liner are fixedly arranged inside the housing; a core is placed inside the liner; a water inlet is formed above the core, is connected with a core water inlet pipe and is arranged on the triangular support; a water outlet and a water outlet hole are formed below the core; and an aluminum liquid inlet is formed between the core and the liner. The short crystallizer is characterized in that the core (4) is internally hollow and conical, and the height of the core is 80mm-120mm; the height of the upper part of the core (4) is 65%-70% of that of the core, and the conical degree of the upper part of the core (4) is 1: (30-50); the height of the lower part of the core (4) is 30%-35% of that of the core, and the conical degree of the lower part of the core (4) is 1: (15-17); the internal sleeve is made of aluminum alloy; and the liner is made of copper and can be pulled out from the internal sleeve to be and replaced. By shortening the length of the crystallizer, the crystal grains of the hollow ingots are relatively thin, and the surface quality of finished tubes is good; and through the improvement that the upper and lower parts of the core of the crystallizer have two different conical degrees, the remelting and cracking of crystal membranes are avoided.

Owner:ANLU PHOENIX ALUMINUM LIMITED LIABILITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com