A manufacturing process of a carbon-fibre composite material U-shaped part

A technology of composite material and manufacturing process, which is applied in the field of manufacturing process of carbon fiber composite U-shaped parts, can solve problems affecting reliability and precision, rich resin and delamination, uneven pressure, etc., and achieve improved bridging conditions, inner and outer surfaces Effect of flattening and improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

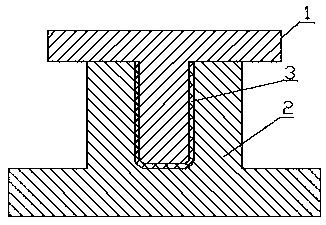

[0022] A manufacturing process for carbon fiber composite material U-shaped parts, laying carbon fiber prepreg on a smooth flat plate, such as glass, steel plate plane, etc. The preform 3 laid on the flat plate is pasted on the convex mold 1 in the figure, as figure 1 , figure 2 As shown, the convex mold 1 is smaller than the concave mold 2, and then the convex mold 1 is put into the concave mold 2 for pre-compaction. Then the convex mold 1 is lifted out, and the preform 3 is prepared by laying up the U-shaped parts.

[0023] On the concave mold 2, the auxiliary materials such as the preform 3, the release cloth 4, the isolation film 5, the air felt 6, and the vacuum bag 7 are placed in sequence, such as image 3 As shown, the external vacuum bag 7 is used for vacuuming, while applying a pressure of 3bar-6bar, heating at 120°C-150°C for curing and molding to obtain a carbon fiber composite U-shaped product.

[0024] The inner concave surface of the preform 3 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com