Forming method for different-plane pi-type carbon fiber composite joint

A composite material and molding method technology, which is applied in the field of manufacturing process of dissimilar π-type carbon fiber composite material joints, can solve the problems of voids, uneven pressure, influence on performance and accuracy, etc. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

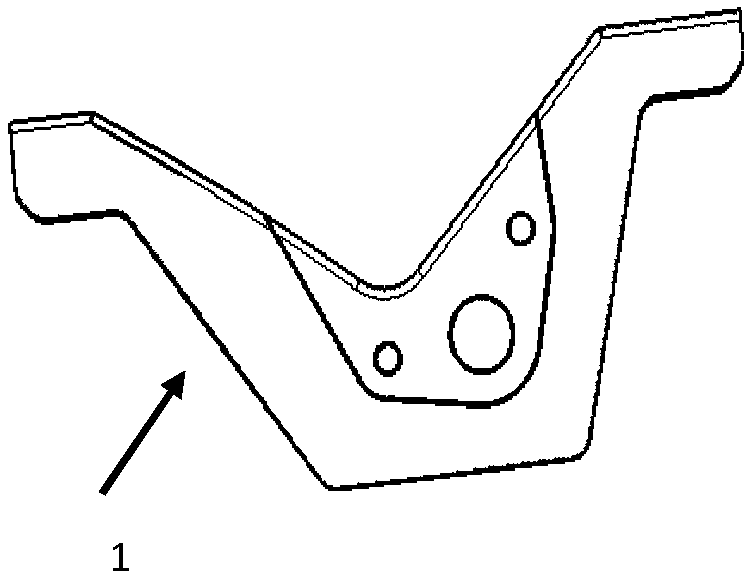

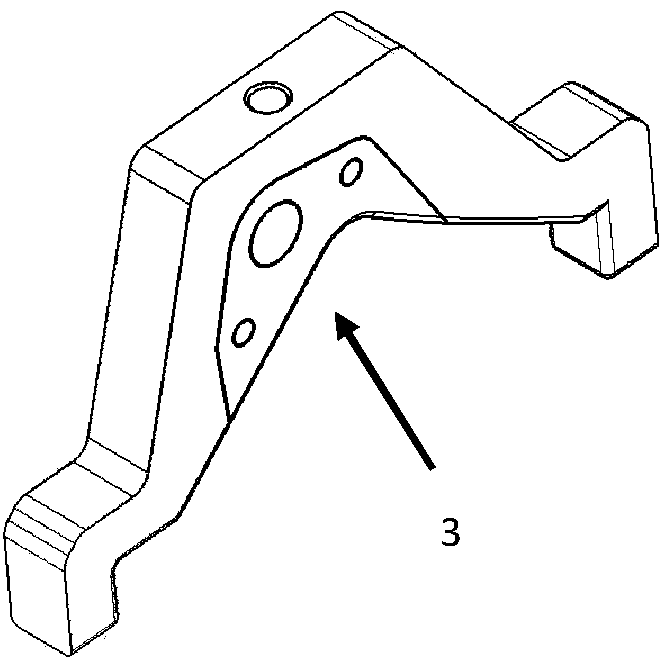

[0020] Figure 1, figure 2 As shown, this embodiment provides a manufacturing process for different-plane π-shaped carbon fiber composite joints, laying carbon fiber prepregs on L-shaped, U-shaped and convex molds; Heat pre-compacting separately with the convex shape; assemble the shaped L-shaped and U-shaped prepregs with the convex mold; after pre-compacting, lay auxiliary materials.

[0021] Such as Figure 4 As shown, on the composite mold 101, the lay-up layer 107, the release cloth 103, the isolation film 106, the air felt 104, and the auxiliary materials of the vacuum bag 105 are sequentially placed, and a sealing strip 102 is arranged between the vacuum bag and the mould. Vacuumize the vacuum bag, heat at 180°C, and apply 6bar pressure to cure and form to obtain a different-plane π-shaped carbon fiber composite joint.

[0022] A di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com